tyre pressure FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 4 of 296

Ignition system

Firing order:HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 1-2-4-3 (No 1 cylinder at timing chain end of engine)

All other engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 1-3-4-2 (No 1 cylinder at timing belt end of engine)

Spark plugs*:

HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . Champion RS9YCC or RS9YC

1.4 and 1.6 litre CVH (carburettor) engines . . . . . . . . . . . . . . . . . . . . Champion RC7YCC or RC7YC

1.6 litre CVH (EFi fuel injection) and PTE engines Non-turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . Champion RC7YCC4 or RC7YC4

Turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . Champion C61YC

1.6 and 1.8 litre Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion RE7YCC

Electrode gap*:

HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 1.0 mm

1.4 litre CVH (carburettor) engines . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 mm

1.4 litre CVH (CFi fuel injection) and PTE engine . . . . . . . . . . . . . . . . 1.0 mm

1.6 litre CVH (carburettor) engines: With Champion RC7YCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 mmWith Champion RC7YC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.7 mm

1.6 litre CVH (EFi fuel injection) engines: Non-turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 1.0 mm

Turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 0.7 mm

1.6 and 1.8 litre Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3 mm

Spark plug (HT) leads: HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . Champion LS-28

1.4 and 1.6 litre CVH (carburettor) engines . . . . . . . . . . . . . . . . . . . . Champion LS-14

1.4 litre CVH (CFi fuel injection) and PTE engines . . . . . . . . . . . . . . . Champion LS-14

1.6 litre CVH (EFi fuel injection) engines . . . . . . . . . . . . . . . . . . . . . . . Champion LS-26

1.6 and 1.8 litre Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion type not available

Maximum resistance per lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 000 ohms * Information on spark plug types and electrode gaps is as recommended b\

y Champion Spark Plug. Where alternative types are used, refer to their

manufacturer’s recommendations.

Braking system

Minimum front brake pad lining thickness . . . . . . . . . . . . . . . . . . . . . . . 1.5 mm

Minimum rear brake shoe lining thickness . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm

Tyres

Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . See “Weekly Checks”

Wiper blades

Windscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . Champion X-4803Tailgate/rear window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . Champion X-4103

Torque wrench settingsNm lbf ft

Auxiliary drivebelt cover fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Auxiliary drivebelt adjustment: Adjusting bolt (sliding arm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2216

Central (locking) bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 2216

Pinion (adjuster) nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 129

Alternator mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2418

Tensioner pulley centre bolt (HCS engines) . . . . . . . . . . . . . . . . . . . . 2015

Engine oil drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . 2418

Manual transmission filler/level plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2015

Spark plugs: HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 1813

CVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

2418

Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 1511

Roadwheel nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 71 to 100 52 to 74

Servicing Specifications1•3

1

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 11 of 296

filter; if the additional working clearance is

required, remove also the auxiliary drivebelt

cover.

7Being careful not to touch the hot exhaust

components, place the drain pan under the

drain plug, and unscrew the plug (see

illustrations) . If possible, try to keep the plug

pressed into the sump while unscrewing it by

hand the last couple of turns.

8 Allow some time for the old oil to drain,

noting that it may be necessary to reposition

the pan as the oil flow slows to a trickle.

Check the condition of the plug’s sealing

washer and renew it if worn or damaged.

When the oil has completely drained, wipe

clean the drain plug and its threads in the

sump and refit the plug, tightening it to the

specified torque wrench setting.

9 Reposition the drain pan under the oil filter

then, using a suitable filter removal tool, unscrew the oil filter from the cylinder block,

oil pump or oil filter adaptor, as applicable; be

prepared for some oil spillage

(see

illustration) . Check the old filter to make sure

that the rubber sealing ring hasn’t stuck to the

engine; if it has, carefully remove it. Withdraw

the filter through the wheel arch, taking care

to spill as little oil as possible.

10 Using a clean, lint-free rag, wipe clean the

cylinder block around the filter mounting. If

there are no specific instructions supplied

with it, fit a new oil filter as follows. Apply a

light coating of clean engine oil to the filter’s

sealing ring (see illustration) . Screw the filter

into position until it seats, then tighten it

through a further half- to three-quarters of a

turn only (see illustration) . Tighten the filter

by hand only - do not use any tools.

11 Remove the old oil and all tools from

under the vehicle, refit the roadwheel, and

lower the vehicle to the ground.

12 Refill the engine with oil, using the correct

grade and type of oil, as given in “Lubricants,

fluids and tyre pressures” . Pour in half the

specified quantity of oil first, then wait a few

minutes for the oil to run to the sump.

Continue adding oil a small quantity at a time,

until the level is up to the lower notch on the dipstick. Adding approximately 0.5 to 1.0 litre

(depending on model) will raise the level to the

dipstick’s upper notch.

13

Start the engine. The oil pressure warning

light will take a few seconds to go out while

the new filter fills with oil; do not race the

engine while the light is on. Run the engine for

a few minutes, while checking for leaks

around the oil filter seal and the drain plug.

14 Switch off the engine, and wait a few

minutes for the oil to settle in the sump once

more. With the new oil circulated and the filter

now completely full, recheck the level on the

dipstick, and add more oil as necessary.

15 Dispose of the used engine oil safely, with

reference to “General repair procedures” in

the Reference Sections of this manual.

1•10Every 5000 miles or 6 months

3.10b Fitting the new oil filter on the Zetec engine 3.10a Lubricate the filter’s sealing ring with clean engine oil before installing the filter on the engine

3.9 Removing the oil filter on the CVHengine using a strap wrench3.7b Removing the engine oil drain plug on the Zetec engine3.7a Engine oil drain plug location in thesump on HCS, CVH and PTE engines

1595Ford Fiesta Remake

Note: It is

antisocial and

illegal to dump oil

down the drain.

To find the

location of your

local oil recycling

bank, call this

number free.

As the drain plug releases

from the threads, move it

away sharply, so the stream

of oil issuing from the sump

runs into the pan, not up

your sleeve!

procarmanuals.com

http://vnx.su

Page 17 of 296

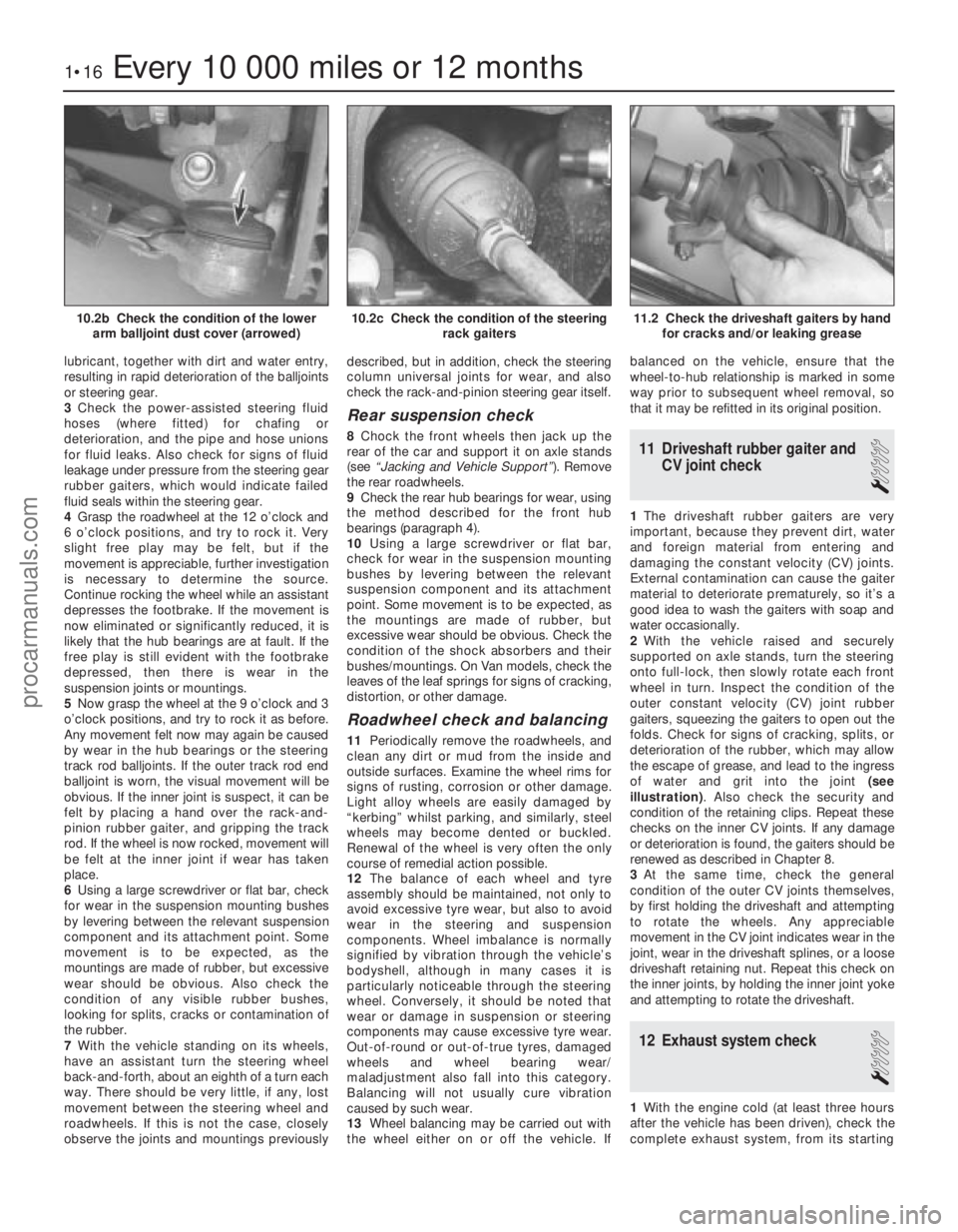

lubricant, together with dirt and water entry,

resulting in rapid deterioration of the balljoints

or steering gear.

3Check the power-assisted steering fluid

hoses (where fitted) for chafing or

deterioration, and the pipe and hose unions

for fluid leaks. Also check for signs of fluid

leakage under pressure from the steering gear

rubber gaiters, which would indicate failed

fluid seals within the steering gear.

4 Grasp the roadwheel at the 12 o’clock and

6 o’clock positions, and try to rock it. Very

slight free play may be felt, but if the

movement is appreciable, further investigation

is necessary to determine the source.

Continue rocking the wheel while an assistant

depresses the footbrake. If the movement is

now eliminated or significantly reduced, it is

likely that the hub bearings are at fault. If the

free play is still evident with the footbrake

depressed, then there is wear in the

suspension joints or mountings.

5 Now grasp the wheel at the 9 o’clock and 3

o’clock positions, and try to rock it as before.

Any movement felt now may again be caused

by wear in the hub bearings or the steering

track rod balljoints. If the outer track rod end

balljoint is worn, the visual movement will be

obvious. If the inner joint is suspect, it can be

felt by placing a hand over the rack-and-

pinion rubber gaiter, and gripping the track

rod. If the wheel is now rocked, movement will

be felt at the inner joint if wear has taken

place.

6 Using a large screwdriver or flat bar, check

for wear in the suspension mounting bushes

by levering between the relevant suspension

component and its attachment point. Some

movement is to be expected, as the

mountings are made of rubber, but excessive

wear should be obvious. Also check the

condition of any visible rubber bushes,

looking for splits, cracks or contamination of

the rubber.

7 With the vehicle standing on its wheels,

have an assistant turn the steering wheel

back-and-forth, about an eighth of a turn each

way. There should be very little, if any, lost

movement between the steering wheel and

roadwheels. If this is not the case, closely

observe the joints and mountings previously described, but in addition, check the steering

column universal joints for wear, and also

check the rack-and-pinion steering gear itself.

Rear suspension check

8

Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the rear roadwheels.

9 Check the rear hub bearings for wear, using

the method described for the front hub

bearings (paragraph 4).

10 Using a large screwdriver or flat bar,

check for wear in the suspension mounting

bushes by levering between the relevant

suspension component and its attachment

point. Some movement is to be expected, as

the mountings are made of rubber, but

excessive wear should be obvious. Check the

condition of the shock absorbers and their

bushes/mountings. On Van models, check the

leaves of the leaf springs for signs of cracking,

distortion, or other damage.

Roadwheel check and balancing

11 Periodically remove the roadwheels, and

clean any dirt or mud from the inside and

outside surfaces. Examine the wheel rims for

signs of rusting, corrosion or other damage.

Light alloy wheels are easily damaged by

“kerbing” whilst parking, and similarly, steel

wheels may become dented or buckled.

Renewal of the wheel is very often the only

course of remedial action possible.

12 The balance of each wheel and tyre

assembly should be maintained, not only to

avoid excessive tyre wear, but also to avoid

wear in the steering and suspension

components. Wheel imbalance is normally

signified by vibration through the vehicle’s

bodyshell, although in many cases it is

particularly noticeable through the steering

wheel. Conversely, it should be noted that

wear or damage in suspension or steering

components may cause excessive tyre wear.

Out-of-round or out-of-true tyres, damaged

wheels and wheel bearing wear/

maladjustment also fall into this category.

Balancing will not usually cure vibration

caused by such wear.

13 Wheel balancing may be carried out with

the wheel either on or off the vehicle. If balanced on the vehicle, ensure that the

wheel-to-hub relationship is marked in some

way prior to subsequent wheel removal, so

that it may be refitted in its original position.

11 Driveshaft rubber gaiter and

CV joint check

1

1The driveshaft rubber gaiters are very

important, because they prevent dirt, water

and foreign material from entering and

damaging the constant velocity (CV) joints.

External contamination can cause the gaiter

material to deteriorate prematurely, so it’s a

good idea to wash the gaiters with soap and

water occasionally.

2 With the vehicle raised and securely

supported on axle stands, turn the steering

onto full-lock, then slowly rotate each front

wheel in turn. Inspect the condition of the

outer constant velocity (CV) joint rubber

gaiters, squeezing the gaiters to open out the

folds. Check for signs of cracking, splits, or

deterioration of the rubber, which may allow

the escape of grease, and lead to the ingress

of water and grit into the joint (see

illustration) . Also check the security and

condition of the retaining clips. Repeat these

checks on the inner CV joints. If any damage

or deterioration is found, the gaiters should be

renewed as described in Chapter 8.

3 At the same time, check the general

condition of the outer CV joints themselves,

by first holding the driveshaft and attempting

to rotate the wheels. Any appreciable

movement in the CV joint indicates wear in the

joint, wear in the driveshaft splines, or a loose

driveshaft retaining nut. Repeat this check on

the inner joints, by holding the inner joint yoke

and attempting to rotate the driveshaft.

12 Exhaust system check

1

1 With the engine cold (at least three hours

after the vehicle has been driven), check the

complete exhaust system, from its starting

1•16Every 10 000 miles or 12 months

11.2 Check the driveshaft gaiters by hand for cracks and/or leaking grease10.2c Check the condition of the steering rack gaiters10.2b Check the condition of the lowerarm balljoint dust cover (arrowed)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 26 of 296

the specified type of fluid. It is essential that

no dirt is introduced into the transmission

during this operation.

7Depending on the extent to which the fluid

was allowed to drain, it is possible that the

amount of fluid required when filling the

transmission may be more than the specified

amount (see “Lubricants, fluids and tyre

pressures” ). However, due to fluid remaining in

the system, it is more likely that less than the

specified amount will be required. Add about

half the specified amount, then run the engine

up to its normal operating temperature and

check the level on the dipstick. When the level

approaches the maximum mark, proceed as

detailed in Section 20 to check the level and

complete the final topping-up as described.

27 Handbrake adjustment

3

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Fully

release the handbrake.

2 Check that the handbrake cables are

correctly routed and secured by the retaining

clips at the appropriate points under the vehicle.

3 The handbrake is checked for adjustment

by measuring the amount of movement

possible in the handbrake adjuster plungers.

These are located on the inside face of each

rear brake backplate (see illustration) . Thetotal movement of the two plungers combined

should be between 0.5 and 2.0 mm. If the

movement measured is outside of this

tolerance, the handbrake is in need of

adjustment. Adjustment is made altering the

position of the in-line cable adjuster sleeve.

4

When adjustment to the handbrake is

necessary, a new adjustment sleeve locking

pin will be required, and this must therefore

be obtained before making the adjustment.

5 To adjust the handbrake, first ensure that it

is fully released, then firmly apply the

footbrake a few times to ensure that the rear

brake adjustment is taken up by the automatic

adjusters. Extract the locking pin from

the adjuster sleeve (see illustration), then

turn the sleeve to set the combined move-

ment of the plungers within the tolerance range specified (0.5 to 2.0 mm). Turn the

locking nut by hand as tight as is possible

(two clicks) against the adjustment sleeve.

Now grip the locknut with a suitable wrench,

and turn it a further two clicks (maximum).

6

Secure the adjustment by inserting the new

lock pin.

7 Check that the operation of the handbrake

is satisfactory, then lower the vehicle to the

ground, apply the handbrake and remove the

chocks from the front wheels.

28 Front wheel alignment check

4

Refer to Chapter 10, Section 29.

Every 30 000 miles or three years1•25

27.5 Handbrake cable adjuster locking

pin (A), locknut (B) and adjuster sleeve (C)27.3 Handbrake adjustment plunger

located on the inside face of each rear brake backplate

1

1595Ford Fiesta Remake

Every 40 000 miles

29 Timing belt renewal

4

Refer to Chapter 2, Part B or C as

applicable.

Every 60 000 miles

30 Fuel filter renewal

1

Warning: Petrol is extremely

flammable, so extra precautions

must be taken when working on

any part of the fuel system. Do

not smoke, or allow open flames or bare

light bulbs, near the work area. Also, do

not work in a garage if a natural gas-type appliance with a pilot light is present.

While performing any work on the fuel system, wear safety glasses, and have a

suitable (Class B) fire extinguisher on

hand. If you spill any fuel on your skin,

rinse it off immediately with soap and

water.

1

On fuel injection engines, an in-line fuel

filter is provided in the fuel pump outlet line.

The filter is located in the engine compartment

either below and behind the battery, or on the

left-hand side of the engine compartment

bulkhead. The renewal procedure is the same

for both locations. The filter performs a vital

role in keeping dirt and other foreign matter

out of the fuel system, and so must be renewed at regular intervals, or whenever you

have reason to suspect that it may be

clogged. It is always unpleasant working

under a vehicle - pressure-washing or hosing

clean the underbody in the filter’s vicinity will

make working conditions more tolerable, and

will reduce the risk of getting dirt into the fuel

system.

2

Depressurise the fuel system as described

in the relevant Part of Chapter 4.

3 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1), then position

a suitable container beneath the fuel filter to

catch escaping fuel. Have a rag handy to soak

procarmanuals.com

http://vnx.su

Page 29 of 296

Lubrication

Engine oil type/specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See “Lubricants, fluids and tyre pressures”

Engine oil capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . See “Lubricants, fluids and tyre pressures”

Oil pressure: At idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 0.60 barsAt 2000 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 1.50 bars

Oil pump clearances: Outer rotor-to-body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 0.14 to 0.26 mm

Inner rotor-to-outer rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.051 to 0.127 mm

Rotor endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 0.025 to 0.06 mm

Torque wrench settingsNm lbf ft

Camshaft thrust plate bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 4

Camshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. 1813

Crankshaft pulley bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . 115 85

Rocker shaft pedestal bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4332

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . 6749

Sump: Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 7 5

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 9 7

Stage 3 (with engine warm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Oil pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 1410

Cylinder head bolts (may be re-used once only): Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 3022

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . Angle-tighten a further 90º

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . Angle-tighten a further 90º

Timing chain tensioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 8 6

Timing chain cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 9 7

Crankshaft rear oil seal housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1813

Rocker cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 5 4

Oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . 1813

Oil pump cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 9 7

Engine mountings: Engine mounting (right-hand):Bolt to body (in wheel arch) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 to 58 30 to 43

Nut to body (by suspension strut) . . . . . . . . . . . . . . . . . . . . . . . . . . 41 to 58 30 to 43

Bracket to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 to 72 40 to 53

Rubber insulator to bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 to 95 52 to 70

Transmission mounting fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refer to Chapter 7A or 7B

Note: Refer to Part D of this Chapter for remaining torque wrench settings.

2A•2 HCS engine in-car repair procedures

1595Ford Fiesta Remake

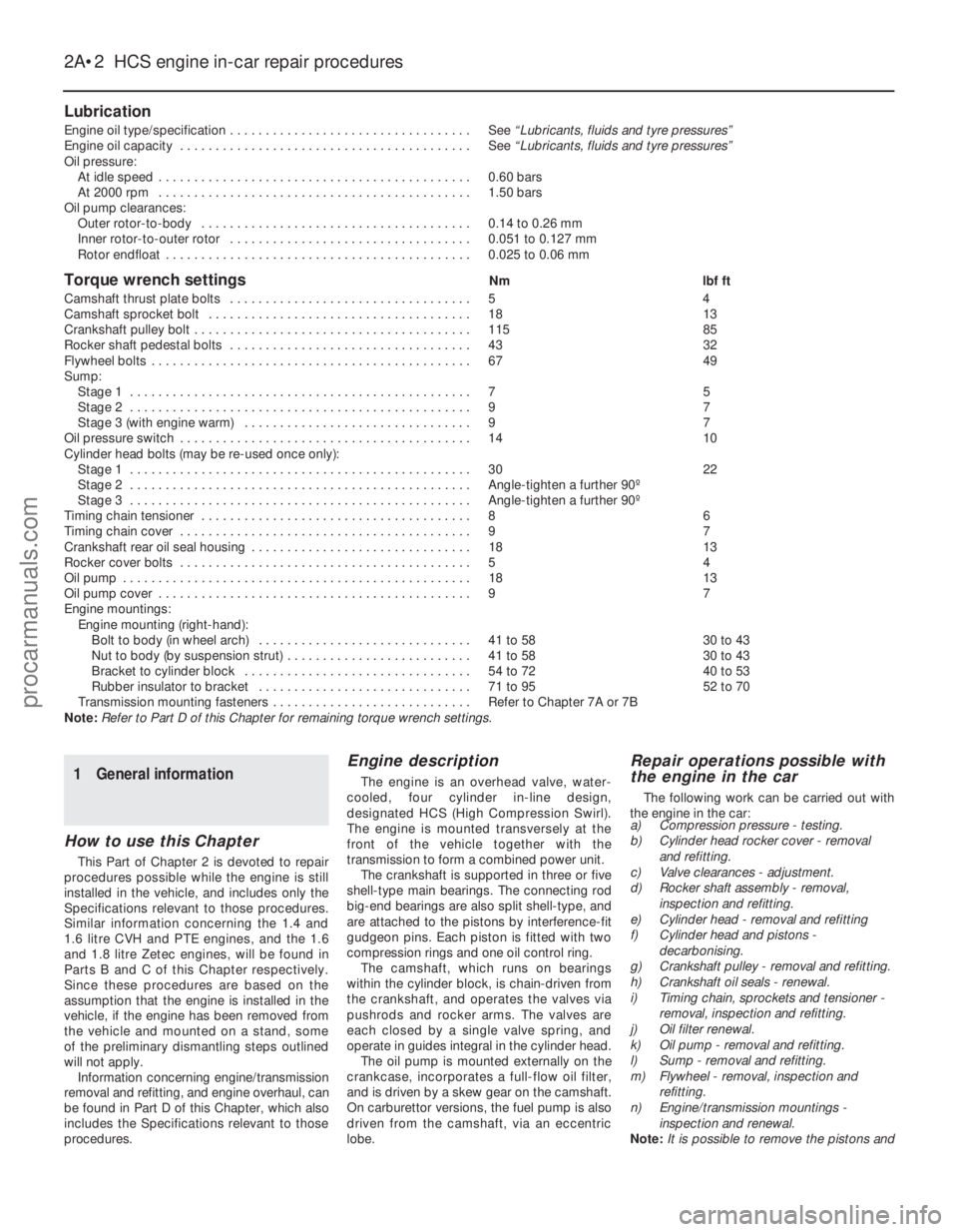

1 General information

How to use this Chapter

This Part of Chapter 2 is devoted to repair

procedures possible while the engine is still

installed in the vehicle, and includes only the

Specifications relevant to those procedures.

Similar information concerning the 1.4 and

1.6 litre CVH and PTE engines, and the 1.6

and 1.8 litre Zetec engines, will be found in

Parts B and C of this Chapter respectively.

Since these procedures are based on the

assumption that the engine is installed in the

vehicle, if the engine has been removed from

the vehicle and mounted on a stand, some

of the preliminary dismantling steps outlined

will not apply. Information concerning engine/transmission

removal and refitting, and engine overhaul, can

be found in Part D of this Chapter, which also

includes the Specifications relevant to those

procedures.

Engine description

The engine is an overhead valve, water-

cooled, four cylinder in-line design,

designated HCS (High Compression Swirl).

The engine is mounted transversely at the

front of the vehicle together with the

transmission to form a combined power unit. The crankshaft is supported in three or five

shell-type main bearings. The connecting rod

big-end bearings are also split shell-type, and

are attached to the pistons by interference-fit

gudgeon pins. Each piston is fitted with two

compression rings and one oil control ring. The camshaft, which runs on bearings

within the cylinder block, is chain-driven from

the crankshaft, and operates the valves via

pushrods and rocker arms. The valves are

each closed by a single valve spring, and

operate in guides integral in the cylinder head. The oil pump is mounted externally on the

crankcase, incorporates a full-flow oil filter,

and is driven by a skew gear on the camshaft.

On carburettor versions, the fuel pump is also

driven from the camshaft, via an eccentric

lobe.

Repair operations possible with

the engine in the car

The following work can be carried out with

the engine in the car:

a) Compression pressure - testing.

b) Cylinder head rocker cover - removal

and refitting.

c) Valve clearances - adjustment.

d) Rocker shaft assembly - removal,

inspection and refitting.

e) Cylinder head - removal and refitting

f) Cylinder head and pistons - decarbonising.

g) Crankshaft pulley - removal and refitting.

h) Crankshaft oil seals - renewal.

i) Timing chain, sprockets and tensioner -

removal, inspection and refitting.

j) Oil filter renewal.

k) Oil pump - removal and refitting.

l) Sump - removal and refitting.

m) Flywheel - removal, inspection and

refitting.

n) Engine/transmission mountings -

inspection and renewal.

Note: It is possible to remove the pistons and

procarmanuals.com

http://vnx.su

Page 41 of 296

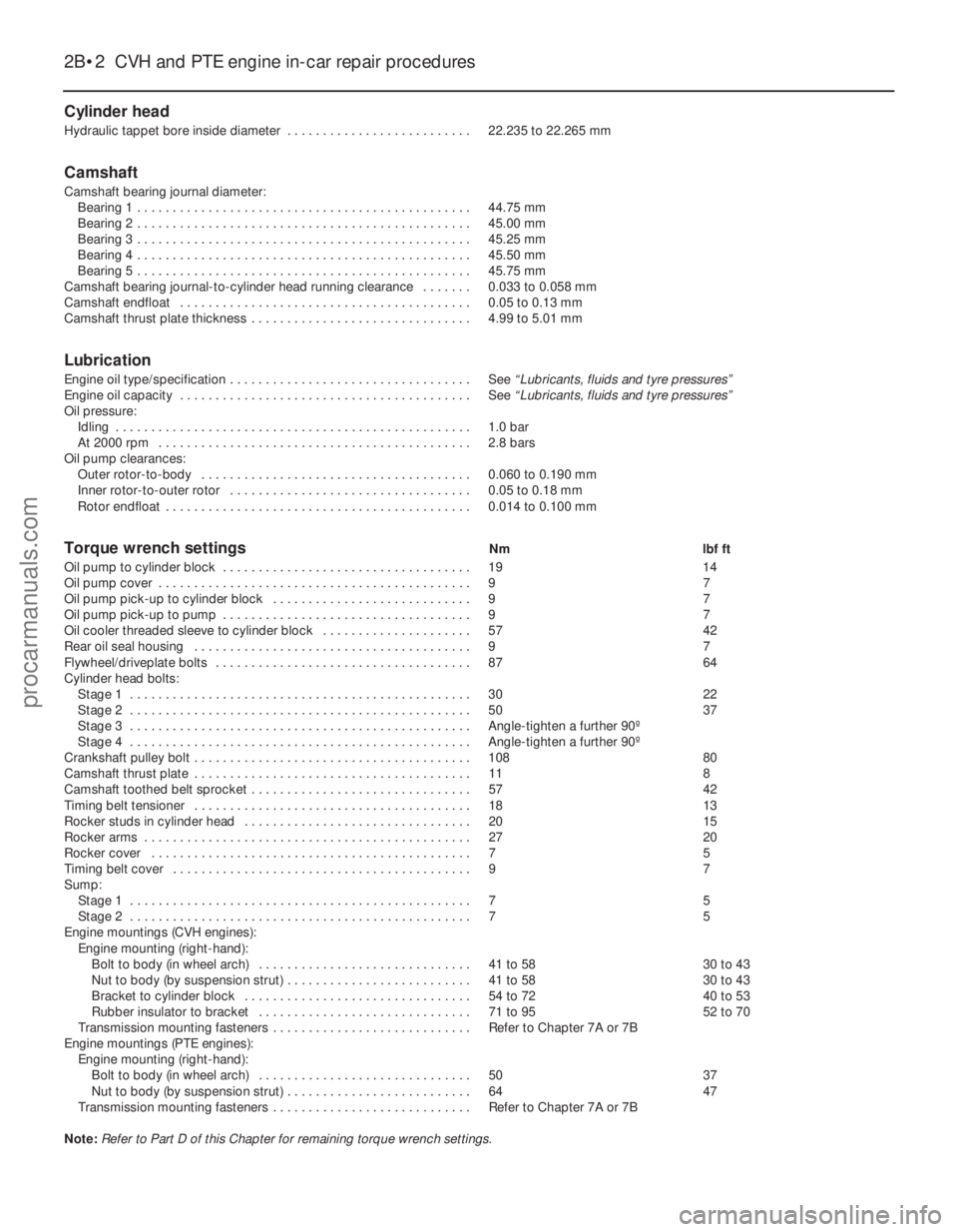

Cylinder head

Hydraulic tappet bore inside diameter . . . . . . . . . . . . . . . . . . . . . . . . . . 22.235 to 22.265 mm

Camshaft

Camshaft bearing journal diameter:Bearing 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . 44.75 mm

Bearing 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . 45.00 mm

Bearing 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . 45.25 mm

Bearing 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . 45.50 mm

Bearing 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . 45.75 mm

Camshaft bearing journal-to-cylinder head running clearance . . . . . . . 0.033 to 0.058 mm

Camshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 0.05 to 0.13 mm

Camshaft thrust plate thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.99 to 5.01 mm

Lubrication

Engine oil type/specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See “Lubricants, fluids and tyre pressures”

Engine oil capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . See “Lubricants, fluids and tyre pressures”

Oil pressure:

Idling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . 1.0 bar

At 2000 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 2.8 bars

Oil pump clearances: Outer rotor-to-body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 0.060 to 0.190 mm

Inner rotor-to-outer rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 to 0.18 mm

Rotor endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 0.014 to 0.100 mm

Torque wrench settingsNm lbf ft

Oil pump to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1914

Oil pump cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 9 7

Oil pump pick-up to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Oil pump pick-up to pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Oil cooler threaded sleeve to cylinder block . . . . . . . . . . . . . . . . . . . . . 5742

Rear oil seal housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . 9 7

Flywheel/driveplate bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

8764

Cylinder head bolts: Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 3022

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 5037

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . Angle-tighten a further 90º

Stage 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . Angle-tighten a further 90º

Crankshaft pulley bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . 108 80

Camshaft thrust plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . 118

Camshaft toothed belt sprocket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5742

Timing belt tensioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . 1813

Rocker studs in cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2015

Rocker arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . 2720

Rocker cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . 7 5

Timing belt cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 9 7

Sump: Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 7 5

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 7 5

Engine mountings (CVH engines):

Engine mounting (right-hand):Bolt to body (in wheel arch) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 to 58 30 to 43

Nut to body (by suspension strut) . . . . . . . . . . . . . . . . . . . . . . . . . . 41 to 58 30 to 43

Bracket to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 to 72 40 to 53

Rubber insulator to bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 to 95 52 to 70

Transmission mounting fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refer to Chapter 7A or 7B

Engine mountings (PTE engines):

Engine mounting (right-hand):Bolt to body (in wheel arch) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5037

Nut to body (by suspension strut) . . . . . . . . . . . . . . . . . . . . . . . . . . 6447

Transmission mounting fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refer to Chapter 7A or 7B

Note: Refer to Part D of this Chapter for remaining torque wrench settings.

2B•2 CVH and PTE engine in-car repair procedures

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 54 of 296

2C

1595Ford Fiesta Remake

General

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . Four-cylinder, in-line, double overhead camshafts

Engine code:1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . L1G

1.8 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . RDB or RQC

Capacity:

1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 1597 cc

1.8 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 1796 cc

Bore:

1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 76.0 mm

1.8 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 80.6 mm

Stroke - all models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 88.0 mm

Compression ratio: 1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 10.3:1

1.8 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 10.0:1

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . 1-3-4-2 (No 1 cylinder at timing belt end)

Direction of crankshaft rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise (seen from right-hand side of vehicle)

Cylinder head

Hydraulic tappet bore inside diameter . . . . . . . . . . . . . . . . . . . . . . . . . . 28.395 to 28.425 mm

Camshafts and hydraulic tappets

Camshaft bearing journal diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.960 to 25.980 mm

Camshaft bearing journal-to-cylinder head running clearance . . . . . . . 0.020 to 0.070 mm

Camshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 0.080 to 0.220 mm

Lubrication

Engine oil type/specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See “Lubricants, fluids and tyre pressures”

Engine oil capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . See “Lubricants, fluids and tyre pressures”

Oil pressure: Idling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . 1.3 to 2.5 bar

At 4000 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 3.7 to 5.5 bars

Oil pump clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . Not specified

Chapter 2 Part C:

Zetec engine in-car repair procedures

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . . .See Chapter 1

Camshaft oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Camshafts and hydraulic tappets - removal, inspection and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 11

Compression test - description and interpretation . . . . . . . . . . . . . . 2

Crankshaft oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Crankshaft pulley - removal and refitting . . . . . . . . . . . . . . . . . . . . . 6

Cylinder head - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 12

Cylinder head cover - removal and refitting . . . . . . . . . . . . . . . . . . . 4

Engine oil and filter renewal . . . . . . . . . . . . . . . . . . . . . . .See Chapter 1

Engine oil level check . . . . . . . . . . . . . . . . . . . . . . . . . “Weekly Checks”Engine/transmission mountings - inspection and renewal . . . . . . . . 16

Flywheel/driveplate - removal, inspection and refitting . . . . . . . . . . 17

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 1

Oil pump - removal, inspection and refitting . . . . . . . . . . . . . . . . . . . 14

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Timing belt - removal, refitting and adjustment . . . . . . . . . . . . . . . . 8

Timing belt covers - removal and refitting . . . . . . . . . . . . . . . . . . . . . 7

Timing belt tensioner and sprockets - removal, inspection

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 9

Top Dead Centre (TDC) for No 1 piston - locating . . . . . . . . . . . . . . 3

Valve clearances - general information . . . . . . . . . . . . . . . . . . . . . . . 5

2C•1

Specifications Contents

Easy, suitable for

novice with little

experience Fairly easy,

suitable

for beginner with

some experience Fairly difficult,

suitable for competent

DIY mechanic

Difficult,

suitable for

experienced DIY

mechanic Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

procarmanuals.com

http://vnx.su

Page 181 of 296

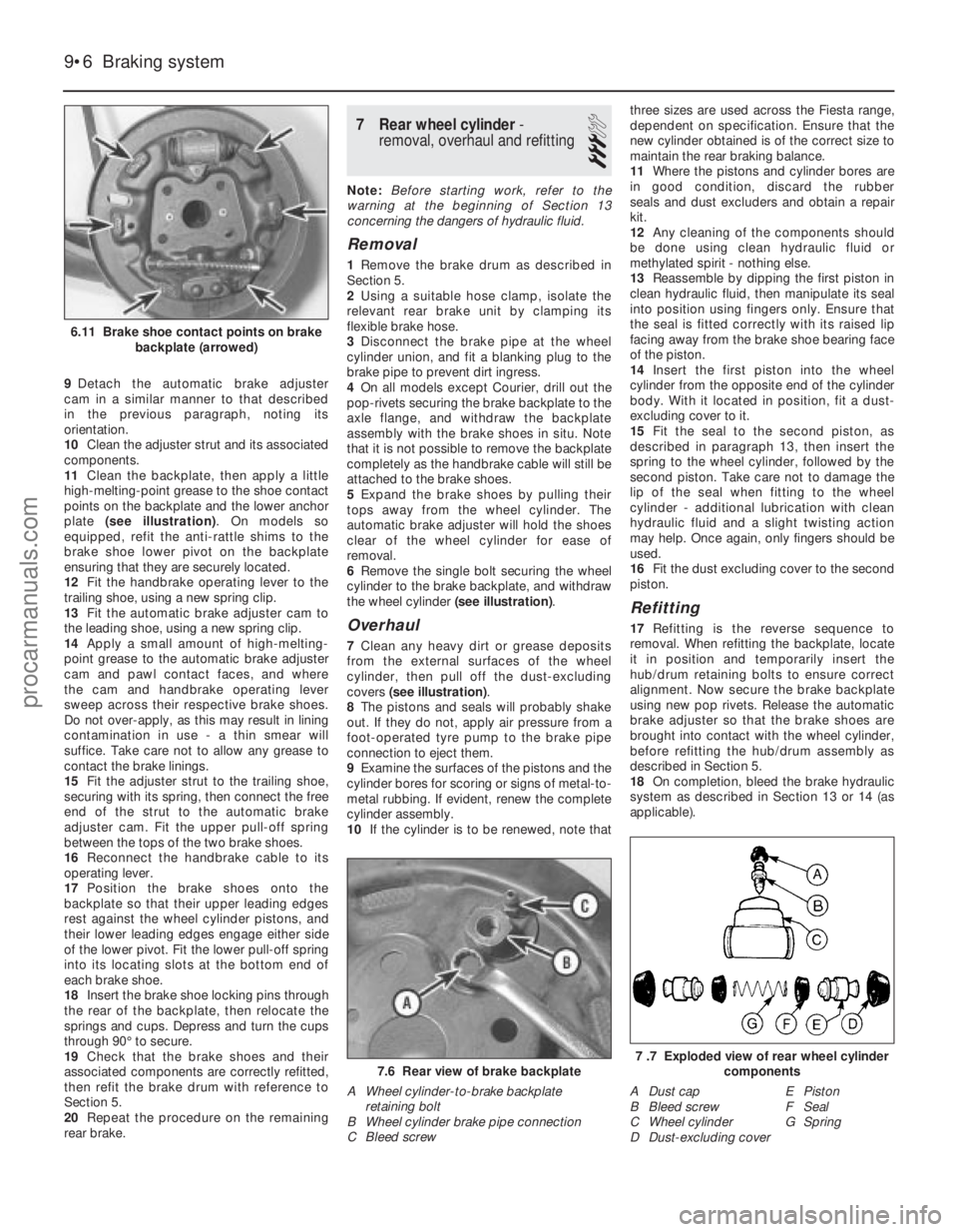

9Detach the automatic brake adjuster

cam in a similar manner to that described

in the previous paragraph, noting its

orientation.

10 Clean the adjuster strut and its associated

components.

11 Clean the backplate, then apply a little

high-melting-point grease to the shoe contact

points on the backplate and the lower anchor

plate (see illustration) . On models so

equipped, refit the anti-rattle shims to the

brake shoe lower pivot on the backplate

ensuring that they are securely located.

12 Fit the handbrake operating lever to the

trailing shoe, using a new spring clip.

13 Fit the automatic brake adjuster cam to

the leading shoe, using a new spring clip.

14 Apply a small amount of high-melting-

point grease to the automatic brake adjuster

cam and pawl contact faces, and where

the cam and handbrake operating lever

sweep across their respective brake shoes.

Do not over-apply, as this may result in lining

contamination in use - a thin smear will

suffice. Take care not to allow any grease to

contact the brake linings.

15 Fit the adjuster strut to the trailing shoe,

securing with its spring, then connect the free

end of the strut to the automatic brake

adjuster cam. Fit the upper pull-off spring

between the tops of the two brake shoes.

16 Reconnect the handbrake cable to its

operating lever.

17 Position the brake shoes onto the

backplate so that their upper leading edges

rest against the wheel cylinder pistons, and

their lower leading edges engage either side

of the lower pivot. Fit the lower pull-off spring

into its locating slots at the bottom end of

each brake shoe.

18 Insert the brake shoe locking pins through

the rear of the backplate, then relocate the

springs and cups. Depress and turn the cups

through 90° to secure.

19 Check that the brake shoes and their

associated components are correctly refitted,

then refit the brake drum with reference to

Section 5.

20 Repeat the procedure on the remaining

rear brake.

7 Rear wheel cylinder -

removal, overhaul and refitting

3

Note: Before starting work, refer to the

warning at the beginning of Section 13

concerning the dangers of hydraulic fluid.

Removal

1 Remove the brake drum as described in

Section 5.

2 Using a suitable hose clamp, isolate the

relevant rear brake unit by clamping its

flexible brake hose.

3 Disconnect the brake pipe at the wheel

cylinder union, and fit a blanking plug to the

brake pipe to prevent dirt ingress.

4 On all models except Courier, drill out the

pop-rivets securing the brake backplate to the

axle flange, and withdraw the backplate

assembly with the brake shoes in situ. Note

that it is not possible to remove the backplate

completely as the handbrake cable will still be

attached to the brake shoes.

5 Expand the brake shoes by pulling their

tops away from the wheel cylinder. The

automatic brake adjuster will hold the shoes

clear of the wheel cylinder for ease of

removal.

6 Remove the single bolt securing the wheel

cylinder to the brake backplate, and withdraw

the wheel cylinder (see illustration).

Overhaul

7Clean any heavy dirt or grease deposits

from the external surfaces of the wheel

cylinder, then pull off the dust-excluding

covers (see illustration) .

8 The pistons and seals will probably shake

out. If they do not, apply air pressure from a

foot-operated tyre pump to the brake pipe

connection to eject them.

9 Examine the surfaces of the pistons and the

cylinder bores for scoring or signs of metal-to-

metal rubbing. If evident, renew the complete

cylinder assembly.

10 If the cylinder is to be renewed, note that three sizes are used across the Fiesta range,

dependent on specification. Ensure that the

new cylinder obtained is of the correct size to

maintain the rear braking balance.

11

Where the pistons and cylinder bores are

in good condition, discard the rubber

seals and dust excluders and obtain a repair

kit.

12 Any cleaning of the components should

be done using clean hydraulic fluid or

methylated spirit - nothing else.

13 Reassemble by dipping the first piston in

clean hydraulic fluid, then manipulate its seal

into position using fingers only. Ensure that

the seal is fitted correctly with its raised lip

facing away from the brake shoe bearing face

of the piston.

14 Insert the first piston into the wheel

cylinder from the opposite end of the cylinder

body. With it located in position, fit a dust-

excluding cover to it.

15 Fit the seal to the second piston, as

described in paragraph 13, then insert the

spring to the wheel cylinder, followed by the

second piston. Take care not to damage the

lip of the seal when fitting to the wheel

cylinder - additional lubrication with clean

hydraulic fluid and a slight twisting action

may help. Once again, only fingers should be

used.

16 Fit the dust excluding cover to the second

piston.

Refitting

17 Refitting is the reverse sequence to

removal. When refitting the backplate, locate

it in position and temporarily insert the

hub/drum retaining bolts to ensure correct

alignment. Now secure the brake backplate

using new pop rivets. Release the automatic

brake adjuster so that the brake shoes are

brought into contact with the wheel cylinder,

before refitting the hub/drum assembly as

described in Section 5.

18 On completion, bleed the brake hydraulic

system as described in Section 13 or 14 (as

applicable).

9•6 Braking system

7 .7 Exploded view of rear wheel cylinder

components

A Dust cap E Piston

B Bleed screw F Seal

C Wheel cylinder G Spring

D Dust-excluding cover7.6 Rear view of brake backplate

A Wheel cylinder-to-brake backplate retaining bolt

B Wheel cylinder brake pipe connection

C Bleed screw

6.11 Brake shoe contact points on brake backplate (arrowed)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 186 of 296

Bleeding - using a pressure-

bleeding kit

24These kits are usually operated by the

reservoir of pressurised air contained in the

spare tyre. However, note that it will probably

be necessary to reduce the pressure to a

lower level than normal; refer to the

instructions supplied with the kit.

25 By connecting a pressurised, fluid-filled

container to the master cylinder reservoir,

bleeding can be carried out simply by opening

each screw in turn (in the specified sequence),

and allowing the fluid to flow out until no more

air bubbles can be seen in the expelled fluid.

26 This method has the advantage that the

large reservoir of fluid provides an additional

safeguard against air being drawn into the

system during bleeding.

27 Pressure-bleeding is particularly effective

when bleeding “difficult” systems, or when

bleeding the complete system at the time of

routine fluid renewal.

All methods

28 When bleeding is complete, and firm

pedal feel is restored, wash off any spilt fluid,

tighten the bleed screws securely, and refit

their dust caps.

29 Check the hydraulic fluid level in the

master cylinder reservoir, and top-up if

necessary.

30 Discard any hydraulic fluid that has been

bled from the system; it will not be fit for re-

use.

31 Check the feel of the brake pedal. If it

feels at all spongy, air must still be present in

the system, and further bleeding is required.

Failure to bleed satisfactorily after a

reasonable repetition of the bleeding

procedure may be due to worn master

cylinder seals.

14 Hydraulic system - bleeding

(anti-lock braking system)

3

Note: Before starting work, refer to the

warning at the beginning of Section 13

concerning the dangers of hydraulic fluid.

1 On vehicles equipped with the anti-lock braking system there are two bleed

procedures possible, depending on which

part of the brake hydraulic system has been

disturbed.

2

If any one of the following conditions are

present, bleed procedure A should be

adopted: a) A modulator has been removed.

b) A modulator return hose (between

modulator and brake fluid reservoir) has

been drained.

c) The rigid brake pipes have been disconnected from a modulator.

3 If any one of the following conditions are

present, bleed procedure B should be

adopted: a) Any condition where the master cylinder

has been removed or drained, providing

that the modulator return hoses have not

lost their head of fluid.

b) Removal or disconnection of any of the

basic braking system components ie,

brake caliper, flexible hose or rigid pipe,

wheel cylinder, or load-apportioning

valve.

Bleed procedure A

4Raise the vehicle on ramps, or drive it over

an inspection pit, so that working clearance

may be obtained with the full weight of the

vehicle on its roadwheels. Remove the one-

piece undertray, as applicable, by turning its

bayonet-type fasteners and, on XR2i models,

remove the front suspension crossmember

(see Chapter 10).

5 Disconnect the wiring multi-plug from the

fluid level warning indicator in the master

cylinder reservoir filler cap, then remove the

filler cap. Note that the filler cap must not be

inverted. Top-up the brake fluid reservoir to

the MAX mark using fresh fluid of the

specified type (see “Weekly Checks”), and

keep it topped up throughout the bleeding

procedure.

6 Slacken the modulator bypass valve Torx

screw, located between the two rigid brake

pipe connections on the modulator body, and

unscrew it two full turns (see illustration).

7 Fully depress the auto-bleed plunger on the

modulator and hold it down so that the

plunger circlip contacts the modulator body

(see illustration) . With the plunger depressed, have an assistant steadily pump

the brake pedal at least twenty times whilst

you observe the fluid returning to the brake

fluid reservoir. Continue this operation until

the returning fluid is free from air bubbles.

8

Release the auto-bleed plunger, ensuring

that it returns to its normal operational

position - pull it out by hand if necessary.

9 Tighten the modulator bypass valve Torx

screw.

10 Repeat the operation on the other

modulator, if applicable, then refit the one-

piece undertray and the front suspension

crossmember if removed.

11 Now carry out bleed procedure B.

Bleed procedure B

12This procedure is the same as for

conventional braking systems, and reference

should be made to Section 13. Note,

however, that all the weight of the vehicle

must be on the roadwheels, otherwise the

load-apportioning valves will not bleed. If

problems are encountered whereby the rear

brakes will not bleed satisfactorily, ensure that

the load-apportioning valves are correctly

adjusted (see Section 25). As with the

conventional braking system, the brake fluid

level must be kept topped up during bleeding.

15 Vacuum servo unit - testing,

removal and refitting

3

Testing

1 To test the operation of the servo, depress

the footbrake four or five times to exhaust the

vacuum, then start the engine while keeping

the footbrake depressed. As the engine starts,

there should be a noticeable “give” in the

brake pedal as vacuum builds up. Allow the

engine to run for at least two minutes, and

then switch it off. If the brake pedal is

depressed again, it should be possible to

detect a hiss from the servo when the pedal is

depressed. After about four or five

applications, no further hissing will be heard,

and the pedal will feel considerably firmer.

2 Before assuming that a problem exists in

the servo itself, check the non-return valve as

described in the next Section.

Removal

3 Refer to Section 9 and remove the master

cylinder.

4 Disconnect the vacuum hose at the servo

non-return valve by pulling it free. If it is

reluctant to move, assist it by prising it free

using a screwdriver with its blade inserted

under the elbow flange.

5 Lift up the flap of sound insulation on the

bulkhead, in the passenger side footwell, to

expose the servo mounting bracket retaining

nuts (see illustration 11.6) . Remove the two

innermost nuts to free the inner section of the

servo mounting bracket from its bulkhead

Braking system 9•11

14.7 Modulator auto-bleed plunger (arrowed)14.6 Modulator bypass valve Torx screw (arrowed)

9

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 194 of 296

10

1595Ford Fiesta Remake

Wheel alignment and steering angles

Front wheel toe setting:Pre-1990 models: Tolerance allowed before resetting required . . . . . . . . . . . . . . . . . 3.0 mm toe-out to 3.0 mm toe-in (0°30’ toe-out to 0°30’ toe-in)

Adjustment setting (if required) . . . . . . . . . . . . . . . . . . . . . . . . . . . . Parallel ± 1.0 mm (0° ± 0°10’)

1990 models onward: All models except Turbo:

Tolerance allowed before resetting required . . . . . . . . . . . . . . \

. . 4.5 mm toe-out to 0.5 mm toe-in (0°45’ toe-out to 0°05’ toe-in)

Adjustment setting (if required) . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm toe-out ± 1.0 mm (0°20’ toe-out ± 0°10’)

Turbo models:

Tolerance allowed before resetting required . . . . . . . . . . . . . . \

. . 4.0 mm toe-out to parallel (0°40’ toe-out to 0°0’)

Adjustment setting (if required) . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm toe-out ± 1.0 mm (0°20’ toe-out ± 0°10’)

Chapter 10

Suspension and steering

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . . .See Chapter 1

Front hub bearings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front spindle carrier - removal and refitting . . . . . . . . . . . . . . . . . . . 2

Front suspension anti-roll bar - removal and refitting . . . . . . . . . . . . 6

Front suspension crossmember - removal and refitting . . . . . . . . . . 7

Front suspension lower arm - removal and refitting . . . . . . . . . . . . . 8

Front suspension strut - dismantling, examination and reassembly . . 5

Front suspension strut - removal and refitting . . . . . . . . . . . . . . . . . 4

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 1

Power steering fluid cooler - removal and refitting . . . . . . . . . . . . . . 26

Power steering fluid level check . . . . . . . . . . . . .See

“Weekly Checks”

Power steering hydraulic system - bleeding . . . . . . . . . . . . . . . . . . . 27

Power steering pump - removal and refitting . . . . . . . . . . . . . . . . . . 25

Rear axle (all models except Courier) - removal and refitting . . . . . . 12

Rear axle pivot bushes (all models except Courier) - renewal . . . . . 13

Rear hub bearings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rear shock absorber (Courier models) - removal, examination and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 16 Rear strut (all models except Courier) - dismantling, examination

and reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . 11

Rear strut (all models except Courier) - removal and refitting . . . . . 10

Rear suspension anti-roll bar (all models except Courier) - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Rear suspension assembly (Courier models) - removal and refitting . . 17

Rear suspension components (Courier models) - general . . . . . . . . 15

Rear suspension ride height (Courier models) - adjustment . . . . . . . 18

Steering column (manual steering) - removal and refitting . . . . . . . . 20

Steering column (power steering) - removal and refitting . . . . . . . . . 21

Steering gear (manual steering) - removal and refitting . . . . . . . . . . 23

Steering gear (power steering) - removal and refitting . . . . . . . . . . . 24

Steering gear rubber gaiters - renewal . . . . . . . . . . . . . . . . . . . . . . . 22

Steering wheel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 19

Suspension and steering check . . . . . . . . . . . . . . . . . . .See Chapter 1

Track rod end balljoint - removal and refitting . . . . . . . . . . . . . . . . . 28

Tyre condition and pressure checks . . . . . . . . . .See “Weekly Checks”

Wheel alignment and steering angles - general information . . . . . . . 29

10•1

Specifications Contents

Easy, suitable for

novice with little

experience Fairly easy,

suitable

for beginner with

some experience Fairly difficult,

suitable for competent

DIY mechanic

Difficult,

suitable for

experienced DIY

mechanic Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

procarmanuals.com

http://vnx.su