water pump FORD FIESTA 2007 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 763 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V (Sigma)ll.4L

303-03A-21 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-03A-21

REMOVAL AND INSTALLATION

Water Pump - 1.25L Duratec-1 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V (Sigma)(24 404 0)

Removal

Vehicles built up to 0412005

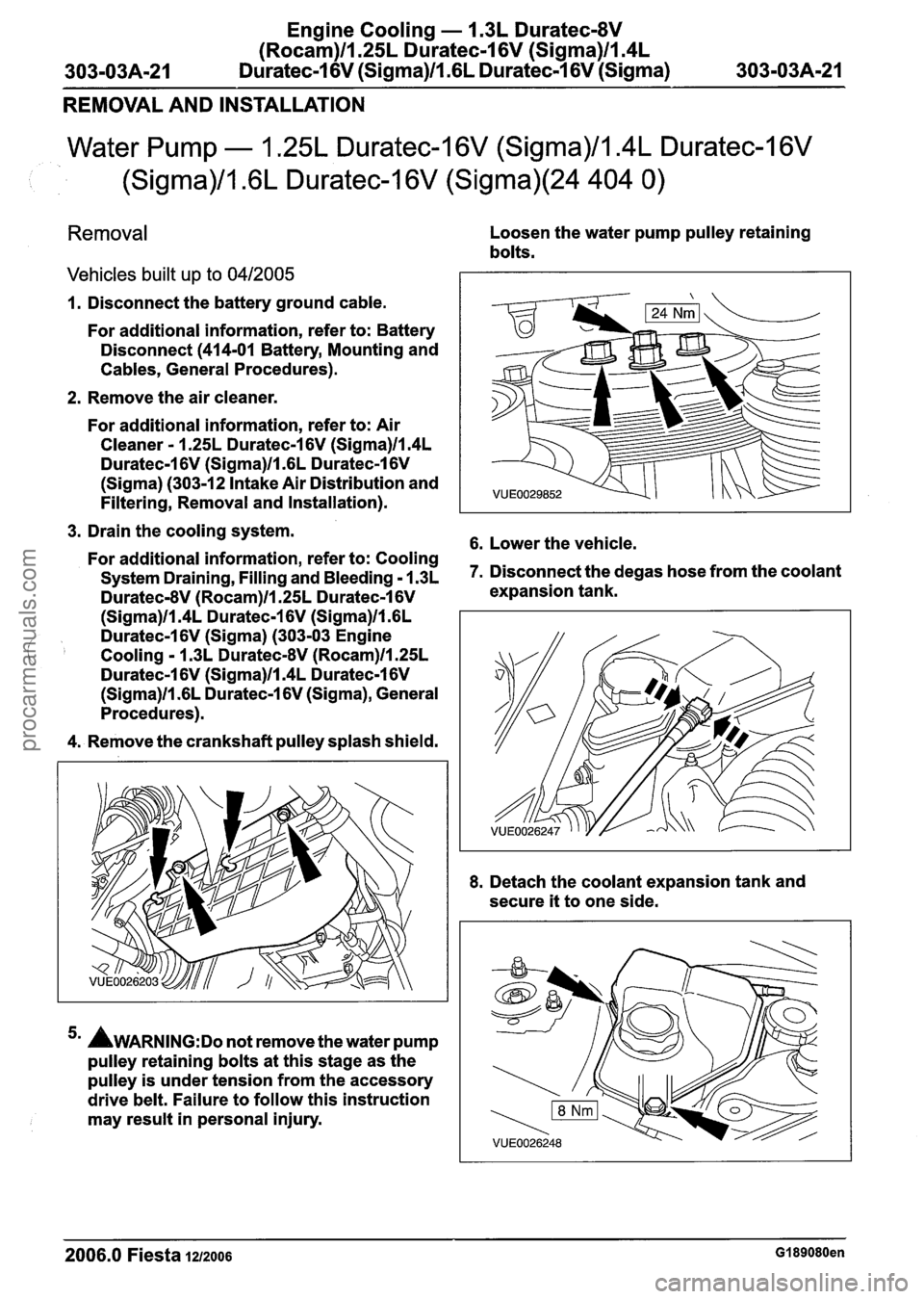

Loosen the water pump pulley retaining

bolts.

1. Disconnect the battery ground cable.

For additional information, refer to: Battery

Disconnect

(414-01 Battery, Mounting and

Cables, General Procedures).

2. Remove the air

cleaner.

For additional information, refer to: Air

Cleaner - 1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma) (303-12 Intake Air Distribution and

Filtering, Removal and Installation).

3. Drain the cooling system.

6. Lower the vehicle. For additional information, refer to: Cooling

System Draining, Filling and Bleeding - 1.3~ 7. Disconnect the degas hose from the coolant

Duratec-8V (Rocam)ll.25L Duratec-1 6V expansion tank.

(Sigma)ll.4L Duratec-1 6V (Sigma)ll .6L

Duratec-1 6V (Sigma) (303-03 Engine

Cooling - 1.3L DuratecdV (Rocam)ll.25L

Duratec-1 6V (Sigma)ll.4L Duratec-1 6V

(Sigma)ll .6L Duratec-1 6V (Sigma), General

Procedures).

4. Remove the crankshaft

pulley splash shield.

5m AWARNING:D~ not remove the water pump

pulley retaining bolts at this stage as the

pulley is under tension from the accessory

drive

belt. Failure to follow this instruction

may

result in personal injury. 8.

Detach the

coolant expansion tank and

secure

it to one side.

2006.0 Fiesta 1212006 GI 89080en

procarmanuals.com

Page 764 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V (Sigma)llI4L

303-03A-22 Duratec-1 6V (Sigma)lIl6L Duratec-1 6V (Sigma) 303-03A-22

REMOVAL AND INSTALLATION

9. Remove the generator.

For

additional information, refer to:

Generator

- 1.25L Duratec-1 6V (Sigma)/l.4L

Duratec-I 6V (Sigma)/l .6L Duratec-I 6V

(Sigma)

(414-02 Generator and Regulator,

Removal and Installation).

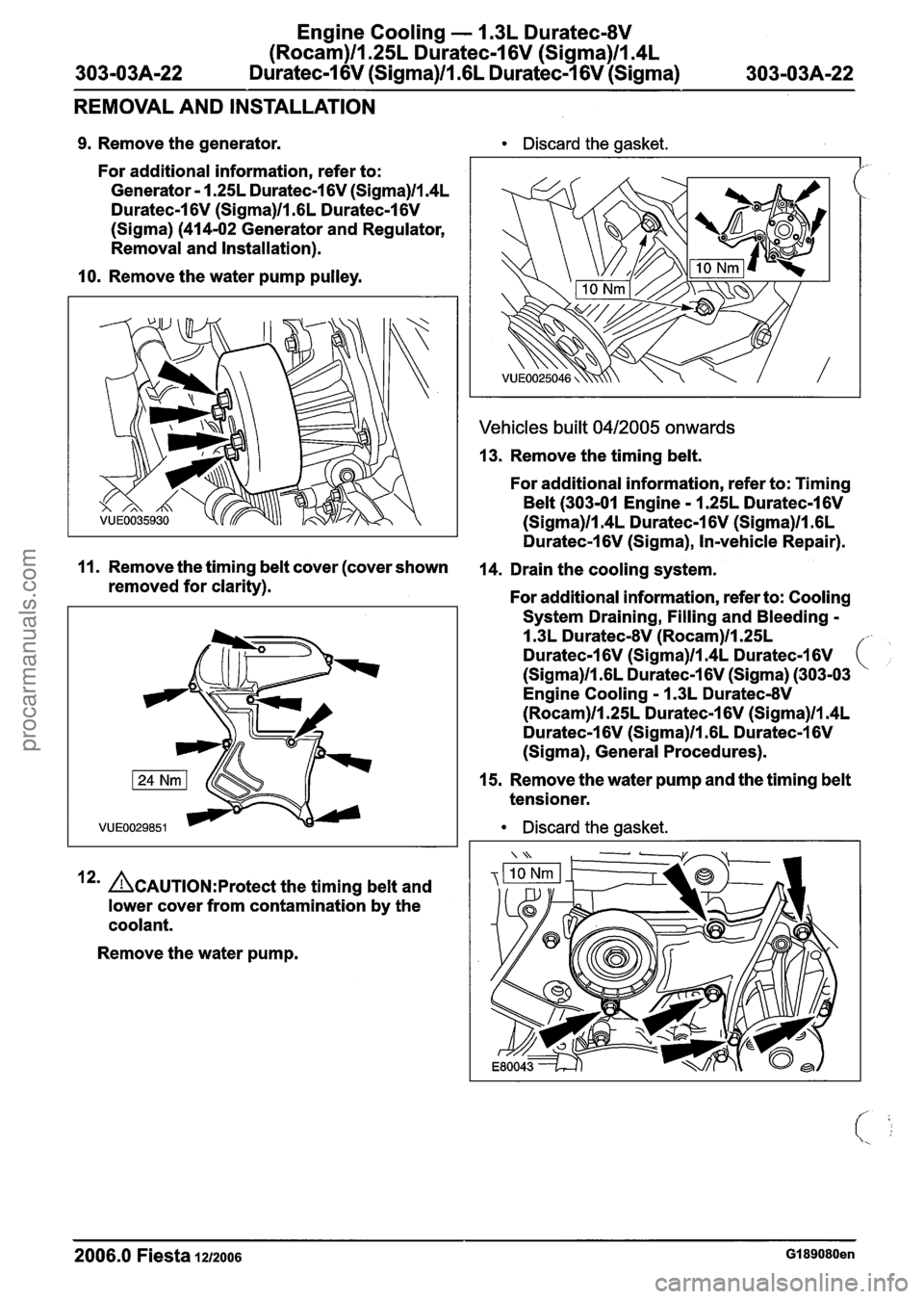

10. Remove the water pump pulley.

Discard the gasket.

Vehicles built 0412005 onwards

13. Remove the timing belt.

For additional information, refer to: Timing

Belt (303-01 Engine - 1.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V (Sigma)ll .6L

Duratec-1 6V (Sigma), ln-vehicle Repair).

11. Remove the timing belt cover (cover shown 14. Drain the cooling system,

removed for clarity). For additional information, refer to: Cooling

12' &AUTION:P~~~~~~ the timing belt and

lower cover from contamination by the

coolant.

Remove the water pump. System

Draining,

Filling and Bleeding -

1.3L Duratec-8V (Rocam)ll.25L

Duratec-1 6V (Sigma)ll.4L Duratec-1 6V (,

(Sigma)ll .6L Duratec-1 6V (Sigma) (303-03

Engine

Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-I 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma), General Procedures).

15. Remove the water pump and the timing

belt

tensioner.

Discard the gasket.

2006.0 Fiesta 1212006 GI 89080en

procarmanuals.com

Page 765 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V (Sigma)ll.4L

303-03A-23 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-0349-23

REMOVAL AND INSTALLATION

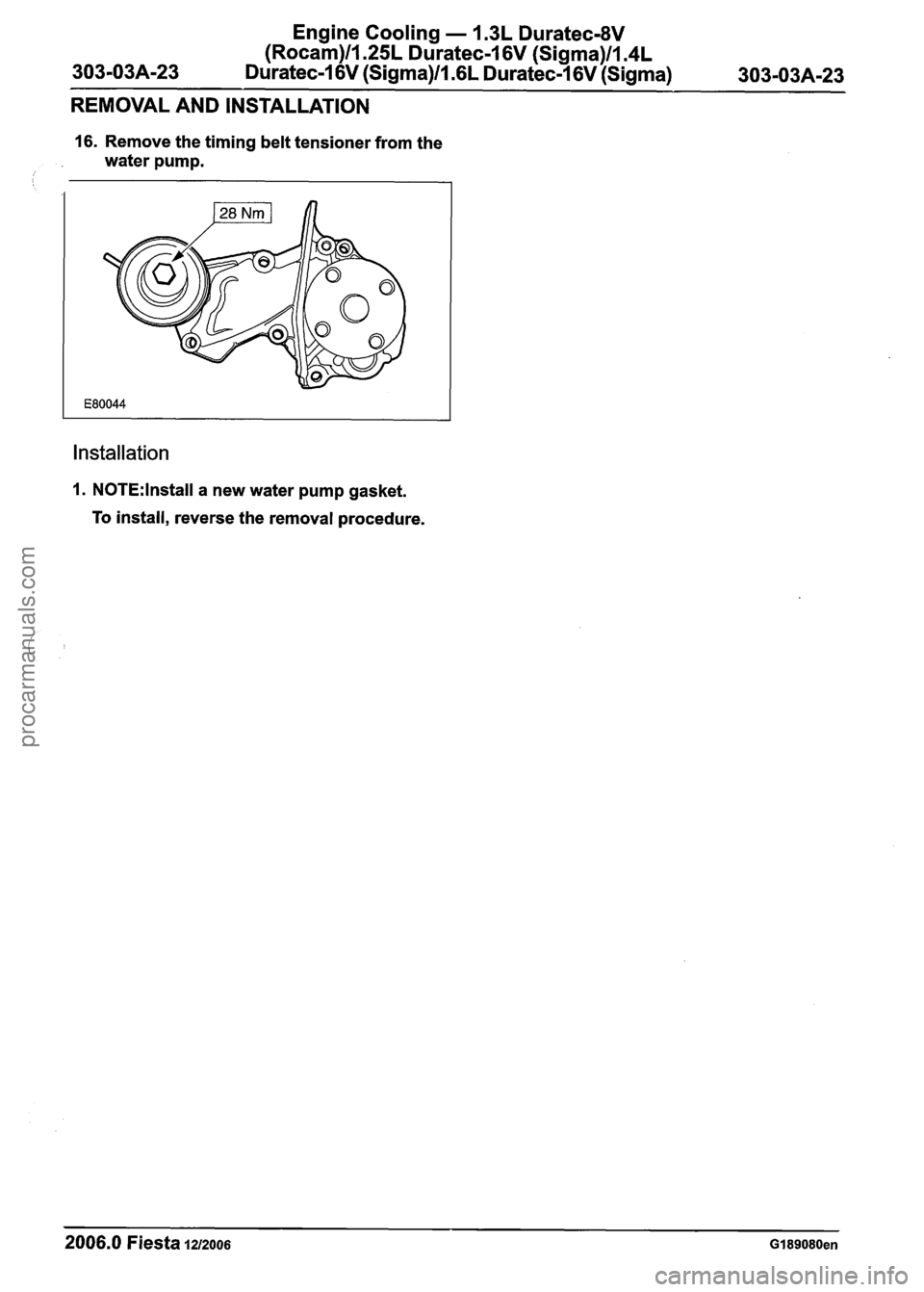

16. Remove the timing belt tensioner from the

water pump.

Installation

1. N0TE:lnstall a new water pump gasket.

To install, reverse the removal procedure.

2006.0 Fiesta 1212006 GI 89080en

procarmanuals.com

Page 774 of 1226

303-03B-4 Engine Cooling - 2.OL Duratec-HE (M14) 303-03B-4

DESCRIPTION AND OPERATION

Components

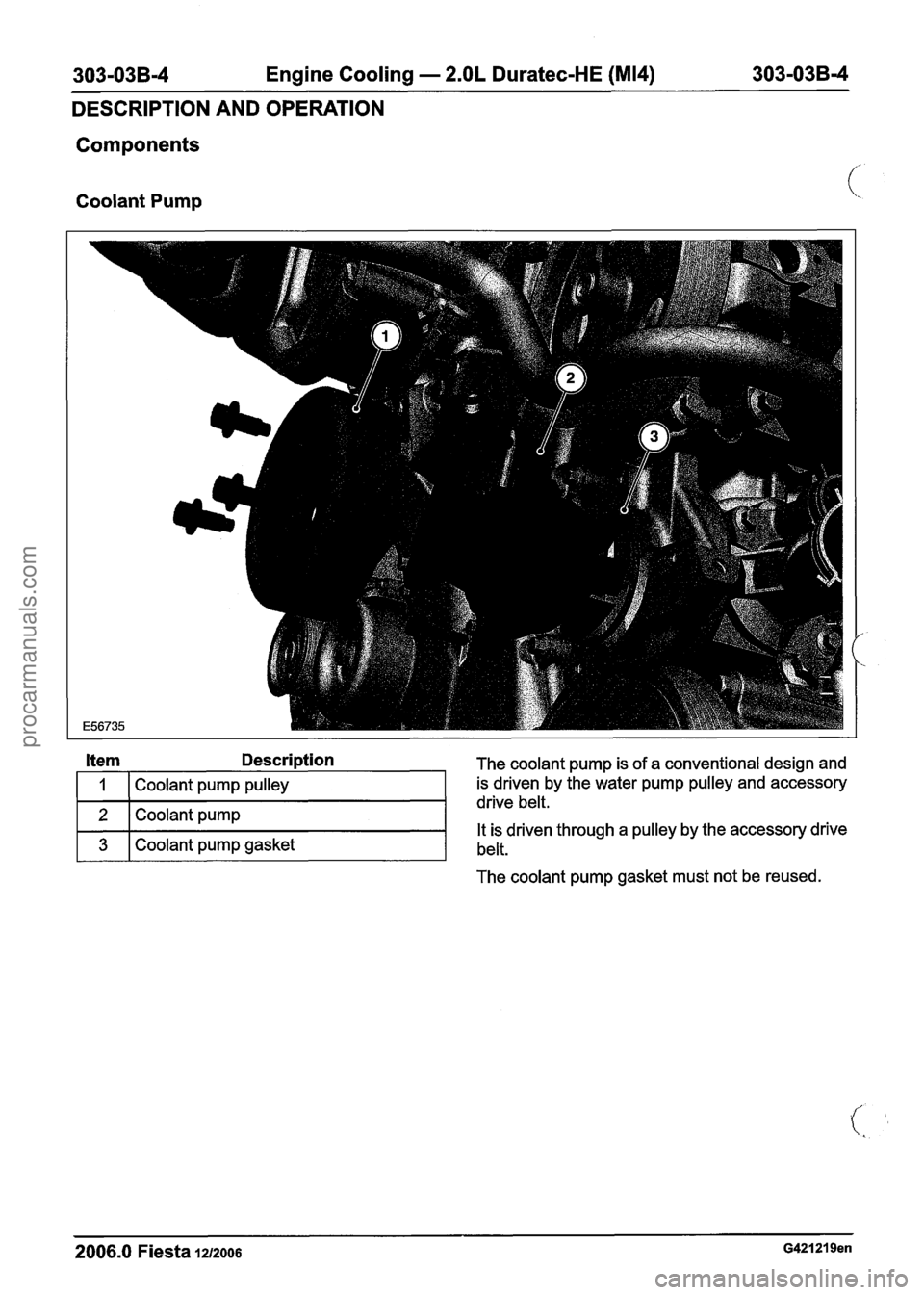

Coolant Pump (.

Description The coolant pump is of a conventional design and

is driven by the water pump pulley and accessory

drive belt.

It is driven through a pulley by the accessory drive

belt.

The coolant pump gasket must not be reused.

2006.0 Fiesta 1212006 G421219en

procarmanuals.com

Page 784 of 1226

303-03B-14 Engine Cooling - 2.OL Duratec-HE (M14) 303-03B-14

DIAGNOSIS AND TESTING

4. Observe the cooling system pressure tester make sure the pressure test reading

is

gauge reading for approximately two minutes. repeatable

and within acceptable gauge reading

The pressure should not drop during this time. limits of

the coolant expansion tank cap.

( If the system holds Pressure, proceed to Step 5. If the pressure test gauge readings are not 7. If the system does not hold pressure, check

within the acceptable gauge reading limits,

it thoroughly for coolant leaks.

INSTALL a new coolant expansion tank cap.

5. Check the engine for coolant leaks. Drain the

cooling system, repair any coolant leaks found

and fill and bleed the cooling system as

Thermostat Test

necessaw.

REFER to: Cooling System Draining, Filling and

Bleeding (303-03 Engine Cooling

- 2.OL

Duratec-HE (M14), General Procedures).

.Recheck the system by repeating Steps 3 and

4 at least twice.

Radiator Leak Test, Removed From Vehicle

CAUTI0N:Radiator internal pressure must

not exceed

130 kpa (20 psi) or damage may

result.

Clean the radiator thoroughly before leak testing

it, to prevent contamination of the water in the test

tank. Leak test the radiator in clean water with 138

kpa (20 psi) air pressure. Check it thoroughly for

air leaks. INSTALL a new radiator if necessary.

REFER to: Radiator (303-03 Engine Cooling

- 2.OL

Duratec-HE (M14), Removal and Installation).

Coolant Expansion Tank Cap Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2. Use water to clean the area of the rubber seal

and pressure relief valve. Install the pressure

tester and adapter and immerse the coolant

-

expansion tank cap in water.

N0TE:lf the plunger of the pump is depressed too

quickly, an erroneous pressure reading will result.

3. Slowly depress the plunger of the pressure test

pump until the pressure gauge reading stops

increasing, and note the highest pressure

reading obtained.

4. Release pressure by turning the pressure relief

screw counterclockwise. Tighten the pressure

relief screw and repeat step 3 at least twice to

I. Connect the WDS to the data link connector

(DLC).

2. Using the WDS datalogger function, SELECT

the following sensors (as applicable to the

application):

IAT

- intake air temperature (IAT) sensor

ECT

- engine coolant temperature (ECT) sensor

CHT

- cylinder head temperature (CHT) sensor

LOAD

- engine load

VSS

- vehicle speed sensor (VSS)

RPM

- engine speed

DSRPM

- desired engine speed

The IAT sensor output is useful if the engine being

tested is cold or after an over-night cold soak. The

ECT sensor or CHT sensor and the IAT sensor

(

should either indicate the same value or be within

1 to 2 degrees Celsius of each other.

The ECT sensor output is important to display as

it indicates the engine warm-up and opening

temperature for the thermostat. It will initially

indicate a slightly higher reading just before the

thermostat opens and then drops back before

settling to a near flat line output (see graphic

below).

Item Description 1'. .

) A 1 Thermostat opens I\

B Thermostat settles into a cyclic open and

I I closure pattern

2006.0 Fiesta 1212006 G426582en

procarmanuals.com

Page 813 of 1226

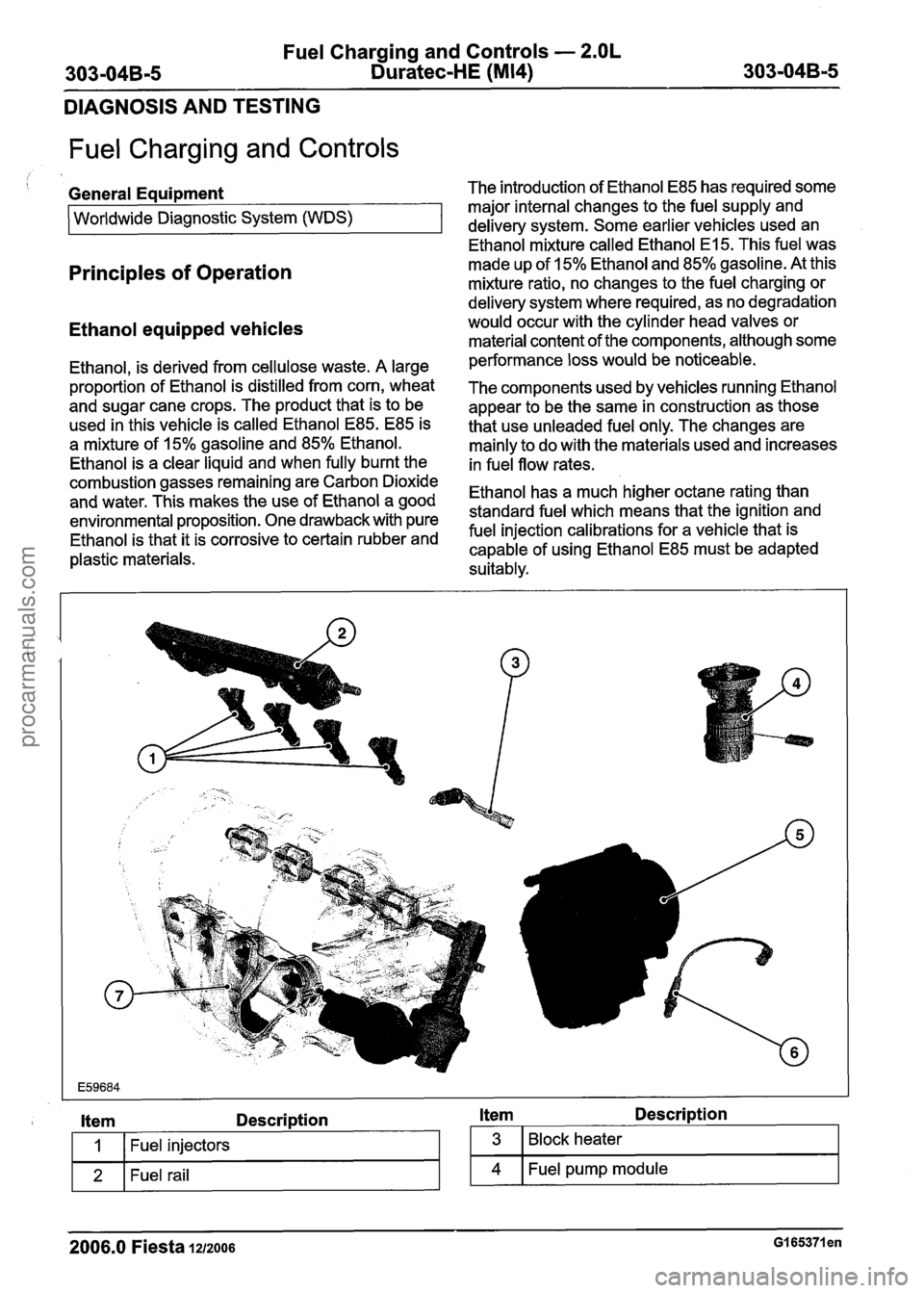

Fuel Charging and Controls - 2.OL

303-04B-5 Duratec-HE (M14) 303-04B-5

DIAGNOSIS AND TESTING

Fuel Charging and Controls

General Equipment

Wgnostic System (WDS) I

Principles of Operation

Ethanol equipped vehicles

Ethanol, is derived from cellulose waste. A large

proportion of Ethanol is distilled from corn, wheat

and sugar cane crops. The product that is to be

used in this vehicle is called Ethanol E85. E85 is

a mixture of 15% gasoline and 85% Ethanol.

Ethanol is a clear liquid and when fully burnt the

combustion gasses remaining are Carbon Dioxide

and water. This makes the use of Ethanol a good

environmental proposition. One drawback with pure

Ethanol is that it is corrosive to certain rubber and

plastic materials. The

introduction of Ethanol E85 has required some

major internal changes to the fuel supply and

delivery system. Some earlier vehicles used an

Ethanol mixture called Ethanol

El 5. This fuel was

made up of 15% Ethanol and 85% gasoline. At this

mixture ratio, no changes to the fuel charging or

delivery system where required, as no degradation

would occur with the cylinder head valves or

material content of the components, although some

performance loss would be noticeable.

The components used by vehicles running Ethanol

appear to be the same in construction as those

that use unleaded fuel only. The changes are

mainly to do with the materials used and increases

in fuel flow rates.

Ethanol has a much higher octane rating than

standard fuel which means that the ignition and

fuel injection calibrations for a vehicle that is

capable of using Ethanol E85 must be adapted

suitably.

I Item Description

I 1 I Fuel injectors

1ue1 rail I

2006.0 Fiesta 1212006 GI 65371 en

Item Description

3

4

Block heater

Fuel pump module

procarmanuals.com

Page 856 of 1226

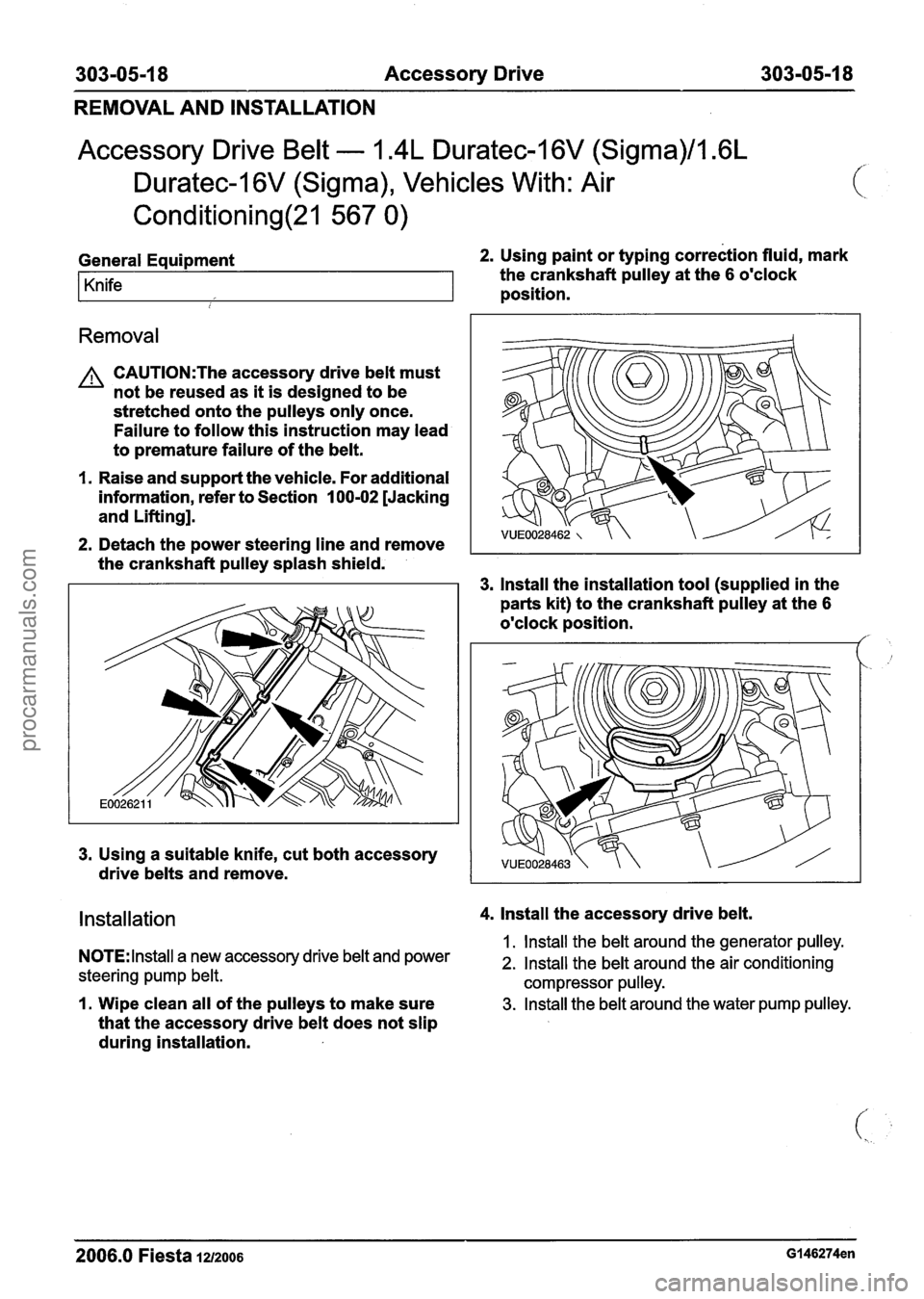

303-05-1 8 Accessory Drive 303-05-1 8

REMOVAL AND INSTALLATION

Accessory Drive Belt - 1.4L Duratec-1 6V (Sigma)/l .6L

Duratec-1

6V (Sigma), Vehicles With: Air

Conditioning(21 567 0)

General Equipment 2. Using paint or typing correction fluid, mark

Knife the crankshaft pulley at the 6 o'clock

position.

i

Removal

A CAUTI0N:The accessory drive belt must

not be reused as it is designed to be

stretched onto the pulleys only once.

Failure to follow this instruction may lead

to premature failure of the belt.

I. Raise and support the vehicle. For additional

information, refer to Section

100-02 [Jacking

and Lifting].

2. Detach the power steering line and remove

the crankshaft pulley splash shield.

3. lnstall the installation tool (supplied in the

parts kit) to the crankshaft pulley at the

6

o'clock position. /'

3. Using a suitable knife, cut both accessory

drive belts and remove.

Installation 4. lnstall the accessory drive belt.

1. lnstall the belt around the generator pulley. NOTE: Install a new accessory drive belt and power 2. Install the belt around the air conditioning

steering pump belt. compressor pulley.

I. Wipe clean all of the pulleys to make sure 3. Install the belt around the water pump pulley.

that the accessory drive belt does not slip

during installation.

2006.0 Fiesta 1212006 GI 46274en

procarmanuals.com

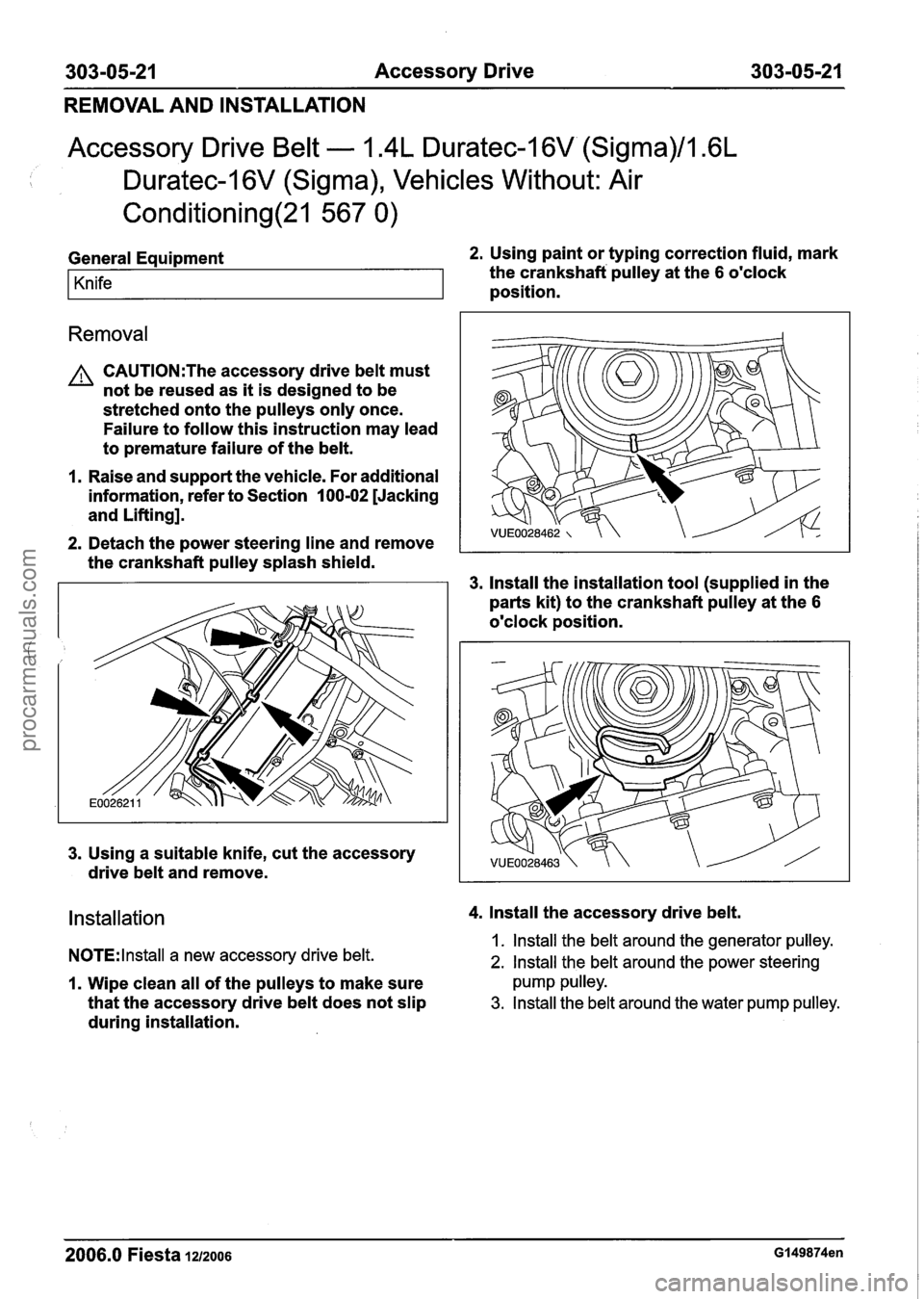

Page 859 of 1226

303-05-21 Accessory Drive 303-05-21

REMOVAL AND INSTALLATION

Accessory Drive Belt - 1.4L Duratec-I 6V (Sigma)/l .6L

Duratec-1 6V (Sigma), Vehicles Without: Air

Conditioning(21 567 0)

General Equipment 2. Using paint or typing correction fluid, mark

Knife the crankshaft pulley at the 6 o'clock

position.

Removal

A CAUTI0N:The accessory drive belt must

not be reused as it is designed to be

stretched onto the pulleys only once.

Failure to follow this instruction may lead

to premature failure of the belt.

1. Raise and support the vehicle. For additional

information, refer to Section

I 00-02 [Jacking

and Lifting].

2. Detach the power steering line and remove

the crankshaft pulley splash shield.

3. lnstall the installation tool (supplied in the

parts kit) to the crankshaft pulley at the

6

o'clock position.

3. Using a suitable knife, cut the accessory

drive belt and remove.

Installation 4. lnstall the accessory drive belt.

NOTE:

lnstall a new accessory drive belt. 1. lnstall the belt around the generator pulley.

2. lnstall the belt around the power steering

1. Wipe clean all of the pulleys to make sure pump pulley.

that the accessory drive belt does not slip 3. Install the belt around the water pump pulley.

during installation.

2006.0 Fiesta 1212006 Gl49874en

procarmanuals.com

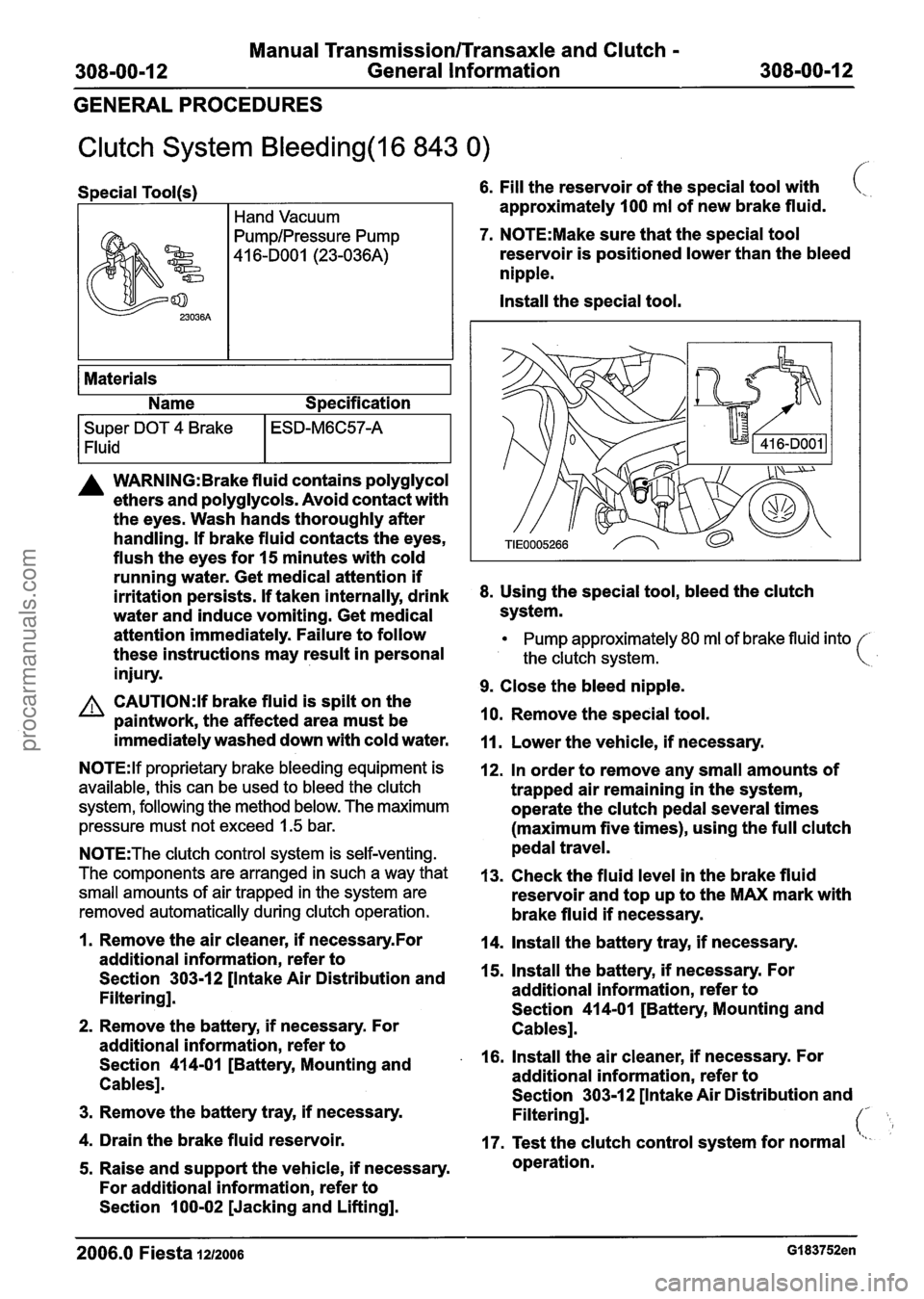

Page 1070 of 1226

Manual Transmission/Transaxle and Clutch -

308-00-1 2 General Information 308-00-1 2

GENERAL PROCEDURES

Clutch System Bleeding(l6 843 0)

Special Tool(s) 6. Fill the reservoir of the special tool with (,, .

I Hand Vacuum approximately 100 ml of new brake fluid.

7. N0TE:Make sure that the special tool

reservoir is positioned lower than the bleed

nipple.

Install the special tool.

Super DOT 4 Brake

1 Fluid

I

Materials

Name Specification

ESD-M6C57-A

A WARNING: Brake fluid contains polyglycol

ethers and polyglycols. Avoid contact with

the eyes. Wash hands thoroughly after

handling. If brake fluid contacts the eyes,

flush the eyes for 15 minutes with cold

running water. Get medical attention if

irritation persists. If taken internally, drink

8. Using the special tool, bleed the clutch

water and induce vomiting. Get medical system.

attention immediately. Failure to follow

Pump approximately 80 ml of brake fluid into

these instructions may result in personal the clutch svstem. (

injury. w

9. Close the bleed nipple. A CAUTI0N:Y brake fluid is spilt on the

paintwork, the affected area must be 10.

Remove the special tool.

immediately washed down with cold water.

11. Lower the vehicle, if necessary.

N0TE:lf proprietary brake bleeding equipment is

available, this can be used to bleed the clutch

system, following the method below. The maximum

pressure must not exceed

1.5 bar.

N0TE:The clutch control system is self-venting.

The components are arranged in such a way that

small amounts of air trapped in the system are

removed automatically during clutch operation.

12. In order to remove any small amounts of

trapped air remaining in the system,

operate the clutch pedal several times

(maximum five times), using the full clutch

pedal travel.

13. Check the fluid level in the brake fluid

reservoir and top up to the MAX mark with

brake fluid if necessary.

1. Remove the air cleaner, if necessaryfor 14. Install the battery tray, if necessary.

additional information, refer to

Section

303-12 [Intake Air Distribution and 15.

Install the battery, if necessary. For

Filtering]. additional

information, refer to

Section 414-01 [Battery, Mounting and

2. Remove the battery, if necessary. For

Cablesl.

additional information, refer to

Section

414-01 [Battery, Mounting and . 16. Install the air cleaner, if necessary. For

Cables]. additional

information, refer to

Section 303-1

2 [Intake Air Distribution and - 3. Remove the battery tray, if necessary.

Filtering]. (' L 4. Drain the brake fluid reservoir.

17. Test the clutch control system for normal "I-

5. Raise and support the vehicle, if necessary. operation.

For additional information, refer to

Section 100-02 [Jacking and Lifting].

2006.0 Fiesta 1212006 GI 83752en

procarmanuals.com