power steering fluid FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 29 of 1226

100-00-1 3 General Information 100-00-1 3

DESCRIPTION AND OPERATION

Do not use damaged or defective tools or

equipment, particularly high-speed equipment such

i as grinding wheels. A damaged grinding wheel can

disintegrate without warning and cause serious

injury.

Wear suitable eye protection when using grinding,

chiseling or sand blasting equipment.

Wear a suitable breathing mask when using

abrasive blasting equipment, working with

asbestos-based materials or using spraying

equipment.

Make sure there is adequate ventilation to control

dusts, mists and fumes.

High Pressure Air, Lubrication and Oil

Test Equipment

See also Lubricants and Greases.

Always keep high-pressure equipment in good

condition, and regularly maintained, particularly at

joints and unions.

Never direct a high-pressure nozzle, for example

diesel injector, at the skin as the fluid may

, penetrate to the underlying tissue, and cause

serious injury.

Halon

See CFCs.

Legal Aspects

There are many laws and regulations relating to

health and safety in the use and disposal of

materials and equipment in a workshop.

For a safe working environment and to avoid

environmental pollution, workshops should be

familiar, in detail, with the many health and safety

laws and regulations within their country, published

by both national and local authorities.

Lubricants and Greases

Avoid all prolonged and repeated contact with

mineral oils. All lubricants and greases may be

irritating to the eyes and skin.

'

Transmission Fluids

Safety instructions

Certain Transmission and Power Steering fluids

supplied to Ford may contain additives which have

the potential to cause skin disease (dermatitis) to

exposed persons. The dermatitis may be irritant

or allergic in nature. Risks are higher where

prolonged or repeated skin contact with a fluid may

occur. These fluids are used for vehicle initial

fill

and service purposes. This sub-section is to:

Inform Service personnel who may come into

contact with these vehicle fluids (hazard

communication).

Summarise appropriate workplace control

measures and personal protective equipment

requirements.

Draw attention to the existence of Material

Safety Datasheets (MSDS's) for the fluids

(available from Ford Customer Service Division).

These MSDS's contain detailed information on

hazards and appropriate controls.

Control measures

Workplace risk assessments made under national

chemical control regulations should identify

operations involving the fluids as potentially

hazardous and specify workplace control and

worker awareness measures. In such

circumstances, the relevant Material Safety

Datasheet (see the details specified below) which

specifies hazards and control measures in detail

should be made available for guidance.

Avoid unprotected skin contact with the fluids, and

in particular, avoid prolonged or repeated skin

contact. Work practices should be organised so as

to minimise the potential for skin contact. This may

include the use of drip trays, absorbents, correct

fluid handling equipment (funnels etc), and

workplace housekeeping measures such as the

cleaning of contaminated surfaces.

Personnel engaged in operations where skin

contact could occur (such as fluid draining or filling)

should wear impervious gloves made from

nitrile

rubber, certified to a chemical protection standard,

e.g. Europe Standard EN374. This glove type is

widely available from reputable suppliers of gloves

for chemical protection [including the manufacturers

Ansell-Admont

(Solvex Range), North Safety

products (North

Nitrile Latex Gloves range), and

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 39 of 1226

100-00-23 General Information 100-00-23

DESCRIPTION AND OPERATION

RoadIRoller Testing

I Road or roller testing may be carried out for various

reasons and a procedure detailing pre-test checks,

engine starting and stopping, pre-driving checks,

on-test checks and final checks to be completed

on completion of the test is given below.

Unless complete vehicle performance is being

checked, the full road test procedure need not be

carried out. Instead, those items particularly

relevant to the

system(s) being checked can be

extracted.

Pre-Test Checks

A WARNING:lf the brake system hydraulic

fluid level is low, pedal travel is excessive

or a hydraulic leak is found, do not attempt

to road test the vehicle until the reason for

the low fluid level, excessive pedal travel

or hydraulic leak is found and rectified.

It is suggested that pre-test checks and functional

tests of those systems and circuits which affect the

safe and legal operations of the vehicle, such as

( , brakes, lights and steering, should always be

carried out before the road or roller test.

With the ignition switched off, check:

- the engine oil level.

- the engine coolant level.

- the tires, for correct pressure, compatible types

and tread patterns, and wear within limits.

- that there is sufficient fuel in the tank to

complete the test.

- all around the engine, transmission and under

the vehicle for oil, coolant, hydraulic and fuel

leaks. Make a note of any apparent leaks and

wipe off the surrounding areas to make it easier

to identify the extent of the leak on completion

of the test.

Starting the Engine

N0TE:On initial drive away from cold and within

the first 1.5 km (1 mile), do not depress the

accelerator pedal beyond half travel until the

vehicle has attained a minimum speed of

25 kmlh

(15 mileslh). Never operate at high engine speed

or with the accelerator pedal at full travel whilst the

engine is cold.

With the ignition switched off, check:

- that the parking brake is applied.

- that the gear lever is in the neutral position.

- that all instrument gauges (except fuel gauge)

read zero.

With the ignition switched on, check:

- that the ignition controlled warning lamps are

illuminated.

- that the engine temperature gauge registers a reading compatible with the engine temperature.

- that the fuel gauge registers a reading

appropriate to the fuel level in the tank.

- the operation of the parking brake warning lamp

and fluid level warning indicator.

Road or Roller Testing

A CAUTI0N:lf road testing, check the brake

operation while still traveling at low speed

before continuing with the test. If the

brakes pull to one side, or appear to be

otherwise faulty, do not continue with the

road test until the fault has been found and

rectified.

During the road or roller test, check:

- that the clutch pedal operation is not stiff or

heavy.

- that the initial gear engagement is smooth and

there is no evidence of clutch drag.

- that the parking brake control operates smoothly

and releases quickly and completely.

- that the clutch takes up the drive smoothly,

without slip or judder.

- that gear changing is smooth with no abnormal

noises or vibrations from the transmission.

- the engine power output is satisfactory, full

power is achieved, acceleration is smooth and

pedal operation is not stiff or heavy, and engine

speed returns to idle correctly.

- there is no excessive or abnormally colored

smoke from the engine under normal driving,

heavy load or overrun conditions.

- that steering operation, including power steering

(if equipped), is smooth, accurate, not

excessively heavy or with excessive free play

or vibration.

- that the steering does not pull to one side and

self centers smoothly after cornering.

2006.0 Fiesta 1212006 GI 7375en

procarmanuals.com

Page 65 of 1226

100-04-9 Noise, Vibration and Harshness 1 00-04-9

DIAGNOSIS AND TESTING

Step 3: According to each identified operating

condition (Column A, B,

C, D, E, F), check each

possible Steering System

NVH concern with the

detail symptom charts below.

Before conducting a vehicle test to identify a

NVH

concern carry out the following checks.

1. Check the tire pressures and adjust to

specification, as necessary.

2. Make sure the steering system fluid is correct,

the system is free of leaks and is operating

correctly.

3. Make sure the vehicle steering system

temperature is the same as described at the

customer interview.

4. All evaluations must take place in a relatively

quiet location.

5. The heating

- air conditioning (AIC) fan and

radio must be turned off during evaluations and

the windows closed.

Symptom Chart

Power Steering Moan Noise

Test Condition

Listen for steering moan noise with the vehicle

parked, transmission in neutral and all windows

closed in the following test conditions.

1. Engine speed at idle with no steering action.

2. Engine speed at idle with slow 90 degrees per

second turning of the steering wheel.

3. Engine speed at 1250 +I- 50 rpm with no

steering action.

4. Engine speed at 1250 +I- 50 rpm with slow 90

degrees per second turning of the steering

wheel.

2006.0 Fiesta 12/2006 G37349en

procarmanuals.com

Page 66 of 1226

100-04-1 0 Noise, Vibration and Harshness 100-04-10

DIAGNOSIS AND TESTING

Power Steering Whine Noise 2. Engine speed at 1800 +/- 50 rpm with slow 90

degrees turning of the steering wheel.

Test Condition 3. Engine speed at 3000 +I- 50 rpm with no

Listen for steering whine noise with the vehicle steering action.

parked, transmission in neutral and all windows

4. Engine speed at 3000

+I- 50 rpm with slow 90

closed in the following test conditions. degrees turning of the steering wheel.

1. Engine speed at 1800

+I- 50 rpm with no

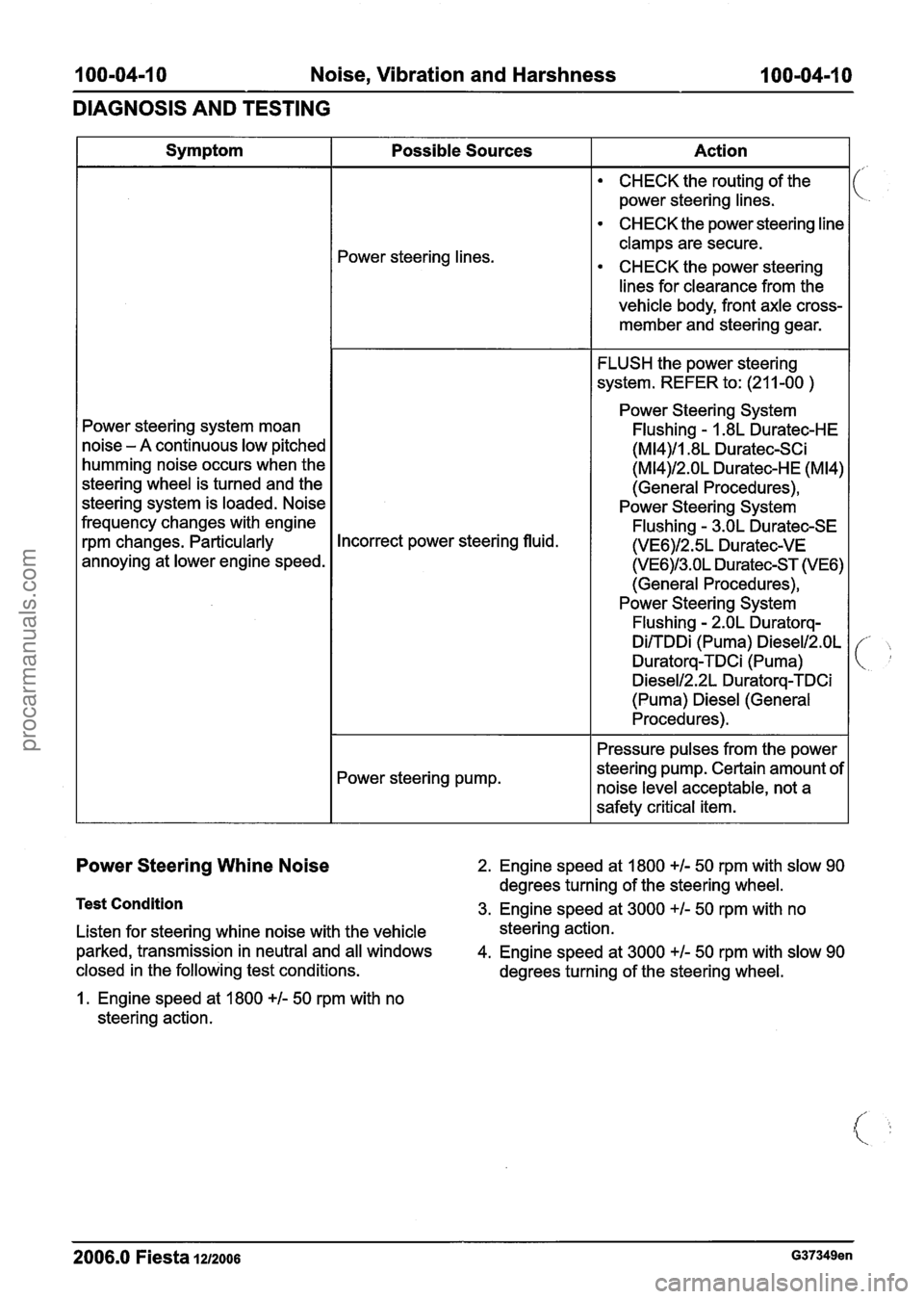

steering action. Symptom

Power steering system moan

noise

- A continuous low pitched

humming noise occurs when the

steering wheel is turned and the

steering system is loaded. Noise

frequency changes with engine

rpm changes. Particularly

annoying at lower engine speed.

2006.0 Fiesta 1212006 G37349en

Possible Sources

Power steering lines.

Incorrect power steering fluid.

Power steering pump. Action

CHECK

the routing of the

power steering lines.

CHECK the power steering line

clamps are secure.

CHECK the power steering

lines for clearance from the

vehicle body, front axle cross-

member and steering gear.

FLUSH the power steering

system. REFER to: (21 1-00

)

Power Steering System

Flushing

- I .8L Duratec-HE

(M14)/1.8L Duratec-SCi

(M14)/2.OL Duratec-HE (M14)

(General Procedures),

Power Steering System

Flushing

- 3.OL Duratec-SE

(VE6)/2.5L Duratec-VE

(VE6)/3.OL Duratec-ST (VE6)

(General Procedures),

Power Steering System

Flushing

- 2.OL Duratorq-

DirrDDi (Puma) Diesel12.0L

Duratorq-TDCi (Puma)

Diesell2.2L Duratorq-TDCi

(Puma) Diesel (General

Procedures).

Pressure pulses from the power

steering pump. Certain amount of

noise level acceptable, not a

safety critical item.

procarmanuals.com

Page 67 of 1226

100-04-1 1 Noise, Vibration and Harshness 100=04=1 I

DIAGNOSIS AND TESTING

2006.0 Fiesta 1212006 G37349en

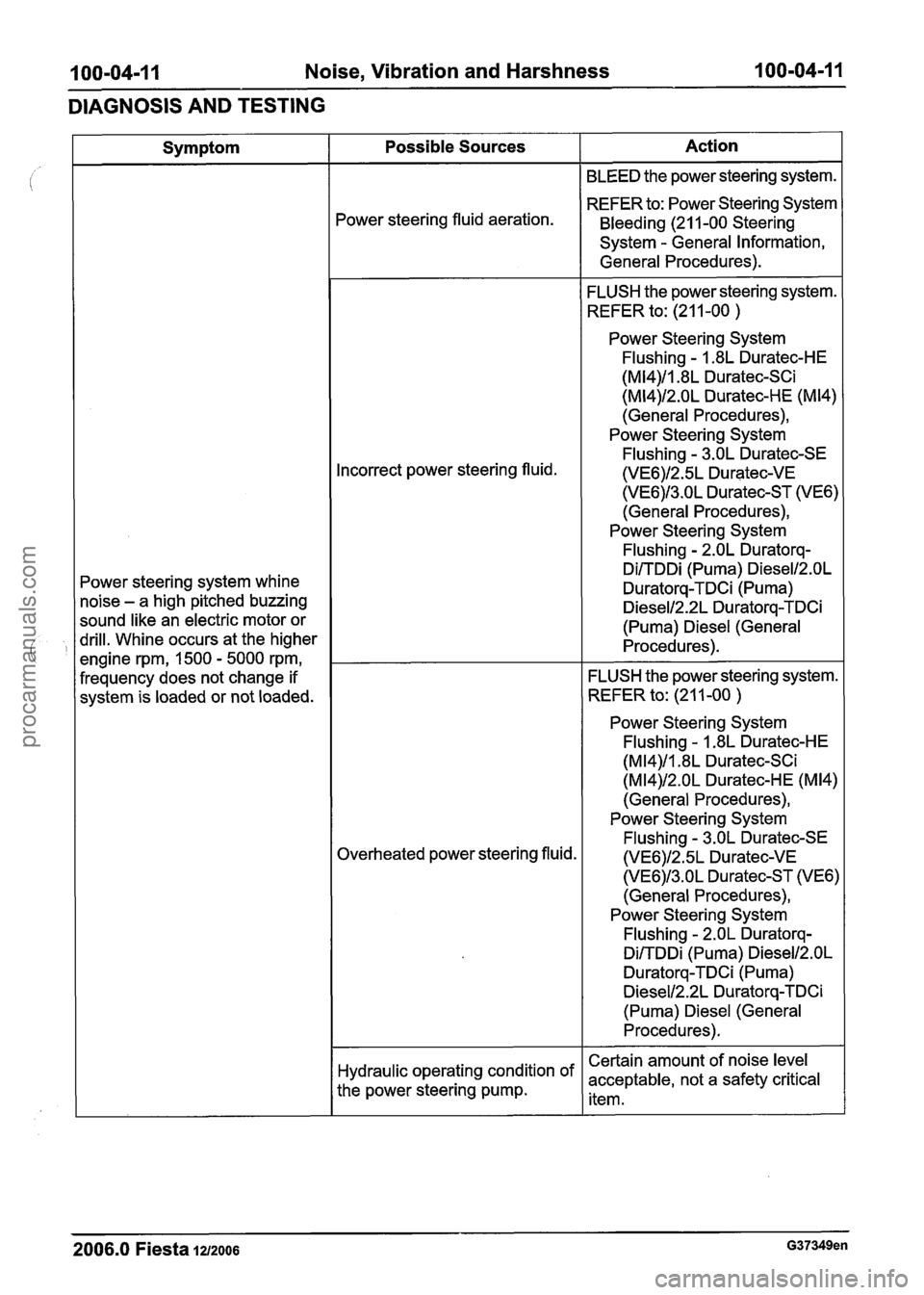

Symptom

Power steering system whine

noise

- a high pitched buzzing

sound like an electric motor or

drill. Whine occurs at the higher

engine rpm, 1500

- 5000 rpm,

frequency does not change if

system is loaded or not loaded.

Possible Sources

Power steering fluid aeration.

l ncorrect power steering fluid.

Overheated power steering fluid.

'perating condition of

the power steering pump.

Action

BLEED the power steering system.

REFER to: Power Steering System

Bleeding (21 1-00 Steering

System

- General Information,

General Procedures).

FLUSH the power steering system.

REFER

to: (21 1-00 )

Power Steering System

Flushing

- 1.8L Duratec-HE

(M14)/1.8L Duratec-SCi

(M14)/2.OL Duratec-HE (M14)

(General Procedures),

Power Steering System Flushing

- 3.OL Duratec-SE

(VE6)/2.5L Duratec-VE

(VE6)/3.OL Duratec-ST (VE6)

(General Procedures),

Power Steering System Flushing

- 2.OL Duratorq-

DilTDDi (Puma) Diesel12.0L

Duratorq-TDCi (Puma)

DieselI2.2L Duratorq-TDCi

(Puma) Diesel (General Procedures).

FLUSH the power steering system.

REFER to: (21 1-00

)

Power Steering System

Flushing

- 1.8L Duratec-HE

(M14)/1.8L Duratec-SCi

(M14)/2.OL Duratec-HE (M14)

(General Procedures),

Power Steering System Flushing

- 3.OL Duratec-SE

(VE6)/2.5L Duratec-VE

(VE6)/3.OL Duratec-ST (VE6)

(General Procedures),

Power Steering System Flushing

- 2.OL Duratorq-

DilTDDi (Puma) Diesel12.0L

Duratorq-TDCi (Puma)

Diesel12.2L Du ratorq-TDCi

(Puma) Diesel (General

Procedures).

Certain amount of noise level

acceptable, not a safety critical

item.

procarmanuals.com

Page 71 of 1226

100-04-15 Noise, Vibration and Harshness 100-04-15

DIAGNOSIS AND TESTING

Power Steering Grinding Noise 1. Slowly turn the steering wheel from lock to lock.

Test Condition

Action

Certain amount of noise level

acceptable, not a safety critical

item.

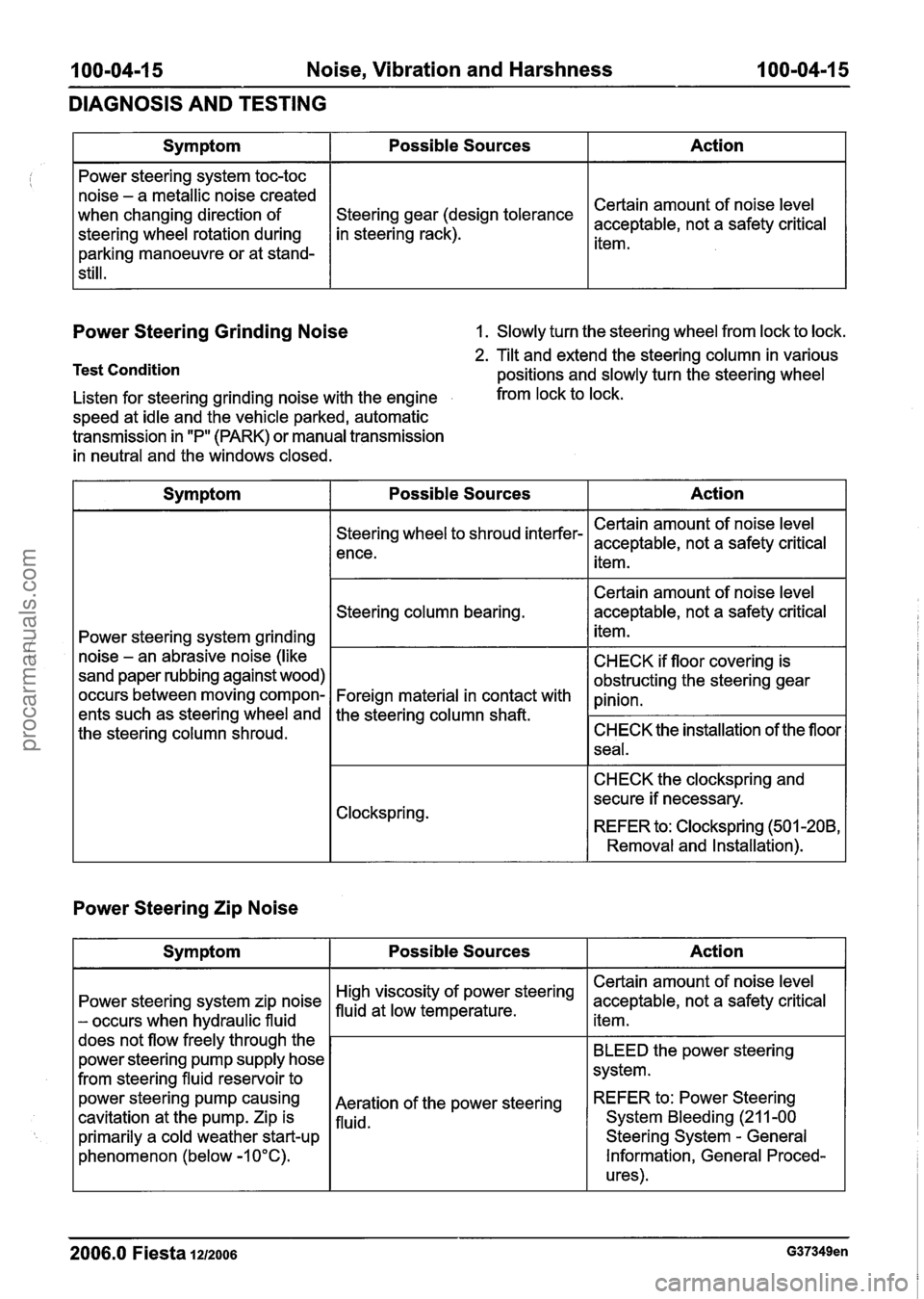

Symptom

Power steering system toc-toc

noise - a metallic noise created

when changing direction of

steering wheel rotation during

parking manoeuvre or at stand-

still.

2. Tilt and extend the steering column in various

positions and slowly turn the steering wheel

Possible Sources

gear (design tolerance

in steering rack).

Listen for steering grinding noise with the engine from lock to lock.

speed at idle and the vehicle parked, automatic

transmission in "P" (PARK) or manual transmission

in neutral and the windows closed.

Power Steering Zip Noise

Symptom Possible Sources Action

Power steering system grinding

noise

- an abrasive noise (like

sand paper rubbing against wood)

occurs between moving compon-

ents such as steering wheel and

the steering column shroud.

2006.0 Fiesta 1212006 G37349en

Steering wheel to shroud interfer-

ence.

Steering column bearing.

Foreign material in contact with

the steering column

shaft.

Clockspring.

Action

Certain amount of noise level

acceptable, not a safety critical item.

BLEED the power steering

system.

REFER

to: Power Steering

System Bleeding

(21 1-00

Steering System

- General

Information, General Proced-

ures).

Symptom

Power steering system zip noise

- occurs when hydraulic fluid

does not flow freely through the

power steering pump supply hose

from steering fluid reservoir to

power steering

pump causing

cavitation

at the pump. Zip is

primarily a cold weather start-up

phenomenon (below -1 0°C). Certain amount

of noise level

acceptable, not a safety critical

item.

Certain amount of noise level

acceptable, not a safety critical

item.

CHECK if floor covering is

obstructing the steering gear

pinion.

CHECK the installation of the floor

seal.

CHECK the clockspring and

secure if necessary.

REFER to: Clockspring (501

-208,

Removal and Installation).

Possible Sources

steering

Aeration of the power steering

fluid.

procarmanuals.com

Page 158 of 1226

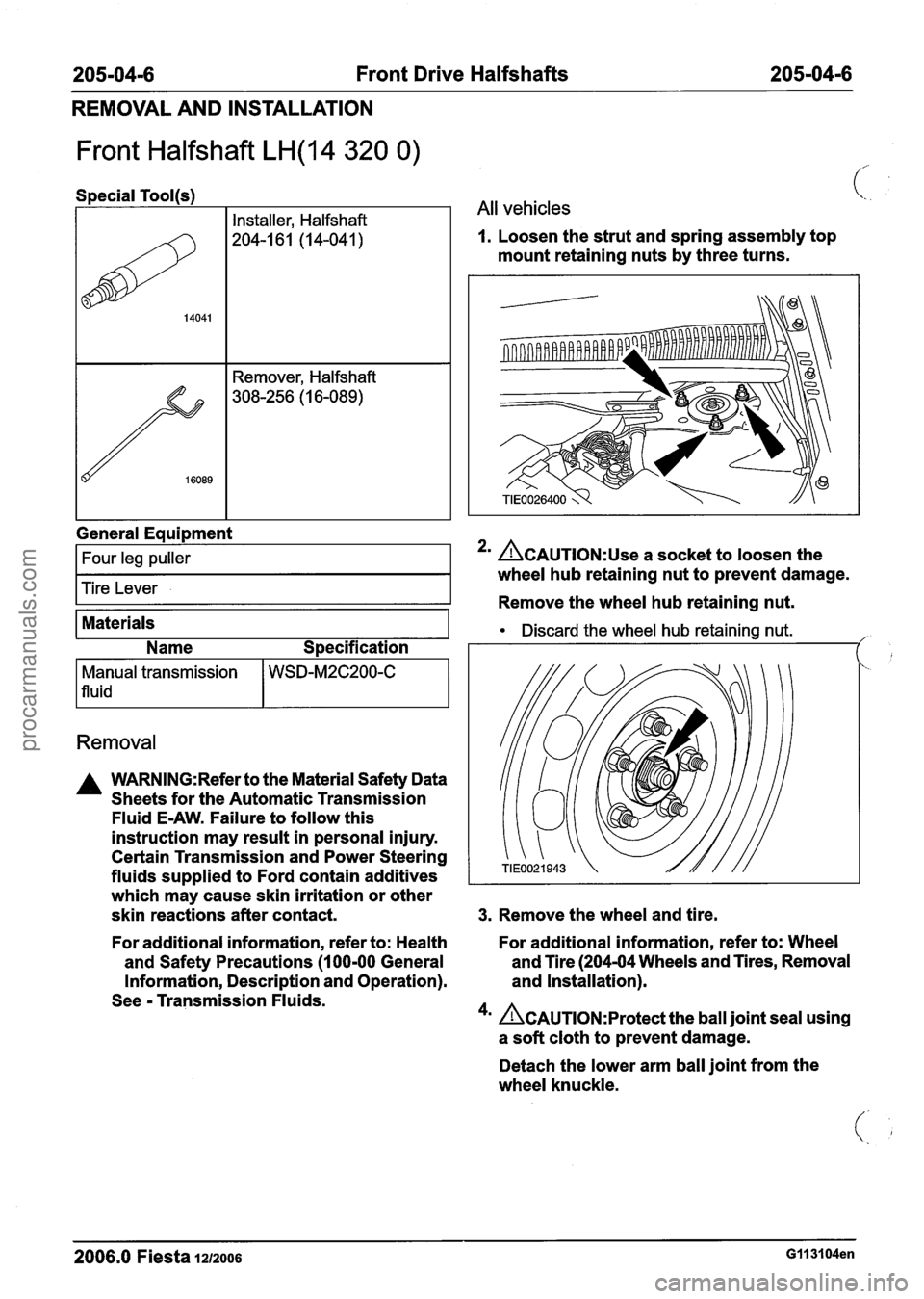

205-04-6 Front Drive Halfshafts 205-04-6

REMOVAL AND INSTALLATION

Front Halfshaft LH(14 320 0)

I I Installer, Halfshaft

(%. .

1 All vehicles

1. Loosen the strut and spring assembly top

mount retaining nuts by three turns.

General

Eaui~ment

I Four leg puller I

Tire Lever

Materials

Name Specification

Removal

Manual transmission

1 fluid

A WARNING:Refer to the Material Safety Data

Sheets for the Automatic Transmission

Fluid

E-AW. Failure to follow this

instruction may result in personal injury.

Certain Transmission and Power Steering

fluids supplied to Ford contain additives

which may cause skin irritation or other

skin reactions after contact.

WSD-M2C200-C

2' ACAUTION:~~~ a socket to loosen the

wheel hub retaining nut to prevent damage.

Remove the wheel hub retaining nut.

Discard the wheel hub retaining nut. ,'

3. Remove the wheel and tire.

For additional information, refer to: Health For

additional information, refer to: Wheel

and Safety Precautions

(1 00-00 General and

Tire (204-04 Wheels and Tires, Removal

Information, Description and Operation). and

Installation).

See

- Transmission Fluids.

4m Ac~u~10~:~rotect the ball joint seal using

a soft cloth to prevent damage.

Detach the lower arm ball joint from the

wheel knuckle.

2006.0 Fiesta IZIZOO~ G113104en

procarmanuals.com

Page 165 of 1226

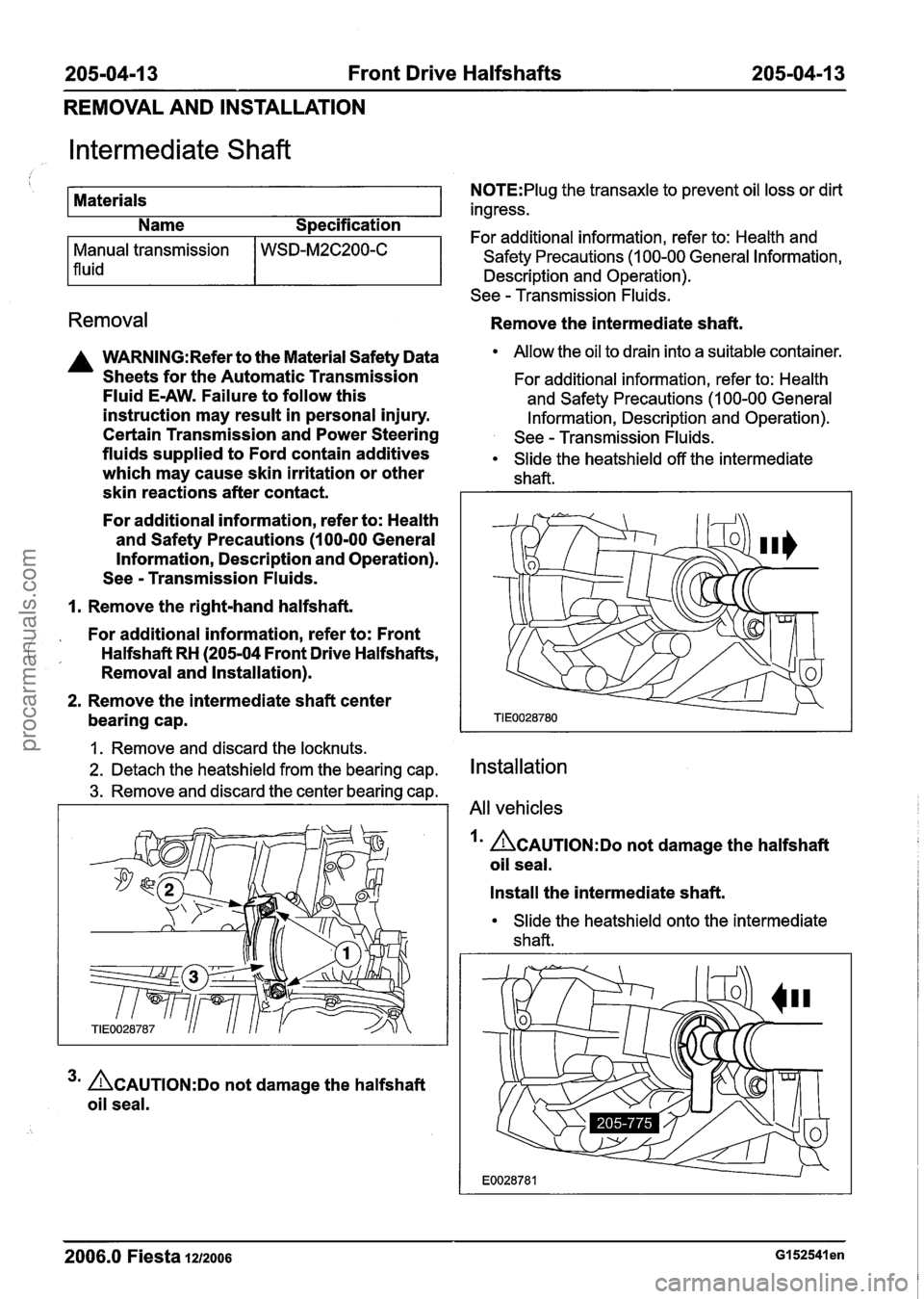

205-04-1 3 Front Drive Halfshafts 205-04-1 3

REMOVAL AND INSTALLATION

Intermediate Shaft

I

Materials

Name Specification

Removal

Manual transmission

1 fluid

A WARN1NG:Refer to the Material Safety Data

Sheets for the Automatic Transmission

Fluid E-AW. Failure to follow this

instruction may result in personal injury.

Certain Transmission and Power Steering

fluids supplied to Ford contain additives

which may cause skin irritation or other

skin reactions after contact.

WSD-M2C200-C

For additional information, refer to: Health

and Safety Precautions

(1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

I. Remove the right-hand halfshaft.

, For additional information, refer to: Front

i, Halfshaft RH (205-04 Front Drive Halfshafts,

Removal and Installation).

2. Remove the intermediate shaft center

bearing cap.

1. Remove and discard the locknuts.

2. Detach the heatshield from the bearing cap.

3. Remove and discard the center bearing cap.

3m ACAUTION:D~ not damage the halfshaft

oil seal.

N0TE:Plug the transaxle to prevent oil loss or dirt

ingress.

For additional information, refer to: Health and

Safety Precautions

(1 00-00 General Information,

Description and Operation).

See

- Transmission Fluids.

Remove the intermediate shaft.

Allow the oil to drain into a suitable container.

For additional information, refer to: Health

and Safety Precautions

(I 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

Slide the heatshield off the intermediate

shaft.

Installation

All vehicles

I' ACAUTION:D~ not damage the halfshaft

oil seal.

Install the intermediate shaft.

Slide the heatshield onto the intermediate

shaft.

2006.0 Fiesta 1212006 GI 52541 en

procarmanuals.com

Page 322 of 1226

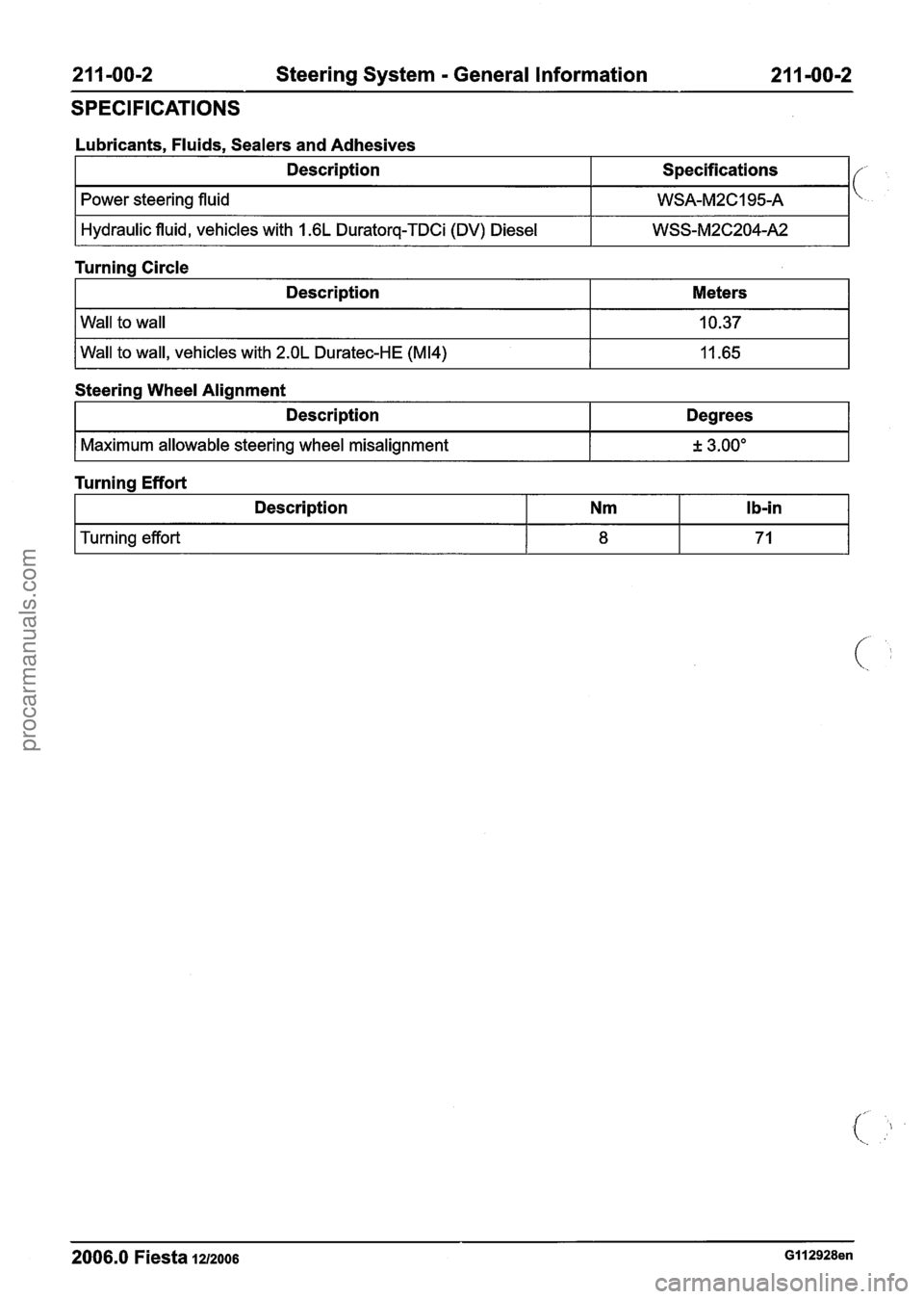

21 1-00-2 Steering System - General Information 21 1-00-2

SPECIFICATIONS

Lubricants, Fluids, Sealers and Adhesives

Turning Circle Description

Power

steering fluid

Hydraulic fluid, vehicles with

1.6L Duratorq-TDCi (DV) Diesel

I Description I Meters I

Specifications

WSA-M2C195-A

WSS-M2C204-A2

I Wall to wall, vehicles with 2.OL Duratec-HE (M14) I 11.65 I

I Maximum allowable steering wheel misalignment I k 3.00" I

Steering Wheel Alignment

Turning Effort Description

Description

Nm Ib-in

Turning effort

Degrees

2006.0 Fiesta 1212006 GI I 2928en

procarmanuals.com

Page 324 of 1226

21 1-00-4 Steering System - General Information 21 1-00-4

DESCRIPTION AND OPERATION

Item Descri~tion

A

RHD with Duratec 16V engine and Air

1 I Conditioning (NC)

I B I LHD with Duratec 16V engine and NC I

I C I RHD with Duratec 16V engine without AM: I

I D I LHD with Duratec 16V engine without NC I

I E ( RHD with 1.4L Duratorq TDCi engine I

I F I LHD with 1.4L Duratorq TDCi engine I

I I I Steering gear I

1 2 1 Additional cooling loop I

Independent of the equipment level, all vehicles

have conventional power-assisted rack and pinion

steering with an additional cooling loop.

The steering gear is supplied with hydraulic fluid

by a hydraulic pump.

The hydraulic pump is driven by the accessory

drive belt and has a separate reservoir.

Vehicles with petrol engines have a Power Steering

Pressure (PSP) switch in the pressure line, which

opens as the power steering load increases, thus

signalling to the Powertrain Control Module (PCM)

that it should increase the idle speed.

- - -- - -

2006.0 Fiesta 1212006 G202090en

procarmanuals.com