boot FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 24 of 1226

100=00=8 General Information 100=00=8

DESCRIPTION AND OPERATION

drowsiness. In extreme cases, loss of

consciousness may result. Long term exposure to

vapor concentrations may result in adverse health

effects.

Prolonged contact with the skin may have a

defatting effect which may lead to skin irritation

and in some cases, dermatitis.

Splashes entering the eye will cause discomfort

and possible damage.

Any spraying should preferably be carried out in

exhaust ventilated booths, removing vapors and

spray droplets from the breathing zone.

Wear appropriate gloves, eye and respiratory

protection. Asbestos dust

waste should be dampened, placed

in a sealed container and marked for safe disposal.

If any cutting or drilling is attempted on materials

(

containing asbestos the item should be dampened "

and only hand tools or low speed power tools used.

Battery Acids

See also Acids and Alkalis.

Gases released during charging are explosive.

Never use naked flames or allow sparks near

charging or recently charged batteries.

Make sure there is adequate ventilation.

Brake and Clutch Linings and Pads

Antifreeze

See Asbestos.

See also Fire, Solvents.

For example isopropanol, ethylene glycol,

methanol.

Highly flammable, flammable, combustible.

Used in vehicle coolant systems, brake air pressure

systems, screenwash solutions.

Vapors may be given off from coolant antifreeze

(glycol) when heated. Avoid breathing these

vapors.

Antifreeze may be absorbed through the skin in

toxic or harmful quantities. Antifreeze, if swallowed,

can be fatal and MEDICAL ATTENTION SHOULD

BE SOUGHT IMMEDIATELY.

These products must not be used in any cooling

or industrial water system that is connected or

linked to general, food preparation or drinking water

supplies.

Asbestos

See also Warning Symbols on Vehicles at the end

of this subsection.

Breathing asbestos dust may cause lung damage

or, in some cases, cancer.

Used in brake and clutch linings, transmission

brake bands and gaskets.

The use of drum cleaning units, vacuum cleaning

or damp wiping is preferred.

Brake Fluids (Polyal kylene Glycols)

See also Fire.

Splashes to the skin and eyes are slightly irritating.

Avoid skin and

eye'contact as far as possible.

Inhalation vapor hazards do not arise at ambient

temperatures because of the very low vapor

pressure.

Brazing

See Welding.

Chemical Materials

See also Legal Aspects.

Chemical materials such as solvents, sealers,

adhesives, paints, resin foams, battery acids,

antifreeze, brake fluids, fuels, oils and grease

should always be used with caution and stored and

handled with care. They may be toxic, harmful,

corrosive, irritant or highly flammable and give rise

to hazardous fumes and dusts.

The effects of excessive exposure to chemicals may be immediate or delayed; briefly experienced

or permanent; cumulative; superficial; life

threatening; or may reduce life expectancy.

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 28 of 1226

100-00-12 General Information 100-00-12

DESCRIPTION AND OPERATION

Gross or prolonged skin contact with high boiling

point gas oils may also cause serious skin

disorders including skin cancer.

Kerosene (Paraffin)

Used also as heating fuel, solvent and cleaning

agent.

Flammable

- observe No Smoking policy.

Irritation of the mouth and throat may result from

swallowing. The main hazard from swallowing

arises if liquid aspiration into the lungs occurs.

Liquid contact dries the skin and can cause

irritation or dermatitis. Splashes in the eye may be

slightly irritating.

In normal circumstances the low volatility does not

give rise to harmful vapors. Exposure to mists and

vapors from kerosene at elevated temperature

should be avoided (mists may arise in dewaxing).

Avoid skin and eye contact and make sure there

is adequate ventilation.

Alternative Fuel

Highly flammable. Observe "NO SMOKING" signs.

Make sure there is adequate ventilation when

working on alternative fuelled vehicles. Great care

must be taken to avoid the serious consequences

of inhalation in the event of vapor build up in

confined spaces.

Inhalation in high concentrations may cause

dizziness, headache, nausea and loss of

co-ordination. Very high concentrations may result

in loss of consciousness.

Contact with liquefied petroleum gas (LPG) or

compressed natural gas (CNG) to the skin may

cause cold burns and frost bite.

Long sleeved cotton overalls, steel toe capped

safety boots and rubber neoprene gloves should

be worn during removal and installation of

LPGICNG fuel system components.

LPGICNG fuel leaks could cause a fire and be a

hazard to health that can lead to personal injury,

illness or even death.

If a leak is detected, under no circumstances

attempt to seal the leak by tightening the

unionlconnection until the fuel in the system or

component is depressurized. Once tightened the

system should be checked for integrity following

the specified procedures. If

the fuel tank is to be removed for service or repair

the fuel must be evacuated using dedicated

equipment and following the specified

procedures. (

Gas Cylinders

See also Fire.

Gases such as oxygen, acetylene, argon and

propane are normally stored in cylinders at

pressures of up to

138 bar (2000 psi) and great

care should be taken in handling these cylinders

to avoid mechanical damage to them or to the valve

gear attached. The contents of each cylinder

should be clearly identified by appropriate

markings.

Cylinders should be stored in well-ventilated

enclosures, and protected from ice and snow, or

direct sunlight. Fuel gases, for example acetylene

and propane, should not be stored in close

proximity to oxygen cylinders.

Care should be exercised to prevent leaks from

gas cylinders and lines, and to avoid sources of

ignition.

Only trained personnel should undertake work

involving gas cylinders.

Gases

See Gas Cylinders.

Gaskets (Fluoroelastomer)

See Viton.

General Workshop Tools and

Equipment

It is essential that all tools and equipment are

maintained in good condition and that the correct

safety equipment is used where required.

Never use tools or equipment for any purpose other

than that for which they were designed. Never

overload equipment such as hoists, jacks, axle and

chassis stands or

lifting slings. Damage caused by

overloading is not always immediately apparent

and may result in a fatal failure the next time that

the equipment is used.

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 31 of 1226

General Information

DESCRIPTION AND OPERATION

Two Pack

Can also contain harmful and toxic unreacted

resins and resin hardening agents. The

manufacturers instructions should be followed. See

also Resin-based Adhesives and

Isocyanate

Adhesives and Sealers under Adhesives and

Sealers.

Spraying should preferably be carried out in

exhausted ventilated booths removing vapor and

spray mists from the breathing zone. Individuals

working in booths should wear appropriate

respiratory protection. Those doing small-scale

repair work in the open workshop should wear

air-fed respirators.

Pressurized Equipment

See High Pressure Air, Lubrication and Oil Test

Equipment.

Solder

Solders are mixtures of metals such that the

melting point of the mixture is below that of the

constituent metals (normally lead and tin). Solder

application does not normally give rise to toxic lead

fumes, provided a

gaslair flame is used.

Oxy-acetylene flames should not be used, as they

are much hotter and will cause lead fumes to be

produced.

Some fumes may be produced by the application

of any flame to surfaces coated with grease, and

inhalation of these should be avoided.

Removal of excess solder should be undertaken

with care, to make sure that fine lead dust is not

produced, which can give toxic effects if inhaled.

Respiratory protection may be necessary.

Solder spillage and filings should be collected and

removed promptly to prevent general air

contamination by lead.

High standards of personal hygiene are necessary

in order to avoid ingestion of lead or inhalation of

solder dust from clothing.

Solvents

See also Chemical Materials, Fuels (Kerosene),

Fire.

For example acetone, white spirit, toluene, xylene,

trichloroethane.

2006.0 Fiesta 1212006

Used in cleaning and dewaxing materials, paints,

plastics, resins and thinners.

Some may be highly flammable or flammable.

Skin contact will degrease the skin and may result

in irritation and dermatitis following repeated or

prolonged contact. Some can be absorbed through

the skin in toxic or harmful quantities.

Splashes in the eye may cause severe irritation

and could lead to loss of vision.

Brief exposure of high concentrations of vapors or

mists will cause eye and throat irritation,

drowsiness, dizziness, headaches and, in the worst

circumstances, unconsciousness.

Repeated or prolonged exposure to excessive but

lower concentrations of vapors or mists, for which

there might not be adequate warning indications,

can cause more serious toxic or harmful effects.

Aspiration into the lungs, for example through

vomiting, is the most serious consequence of

swallowing.

Avoid splashes to the skin, eyes and clothing. Wear

protective gloves, goggles and clothing if

necessary.

Make sure there is good ventilation when in use,

avoid breathing fumes, vapors and spray mists and

keep containers tightly sealed. Do not use in

confined spaces.

When spraying materials containing solvents, for

example paints, adhesive, coatings, use extraction

ventilation or personal respiratory protection in the

absence of adequate general ventilation.

Do not apply heat or flame except under specific

and detailed manufacturers instructions.

Sound Insulation

See Fibre Insulation, Foams.

Suspended Loads

A CAUTI0N:Never improvise lifting tackle.

There is always a danger when loads are lifted or

suspended. Never work under an unsupported,

suspended or raised load, for example a

suspended engine.

Always make sure that lifting equipment such as

jacks, hoists, axle stands and slings are adequate

and suitable for the job, in good condition and

regularly maintained.

procarmanuals.com

Page 97 of 1226

204-00-1 7 Suspension System - General Information 204-00-1 7

GENERAL PROCEDURES

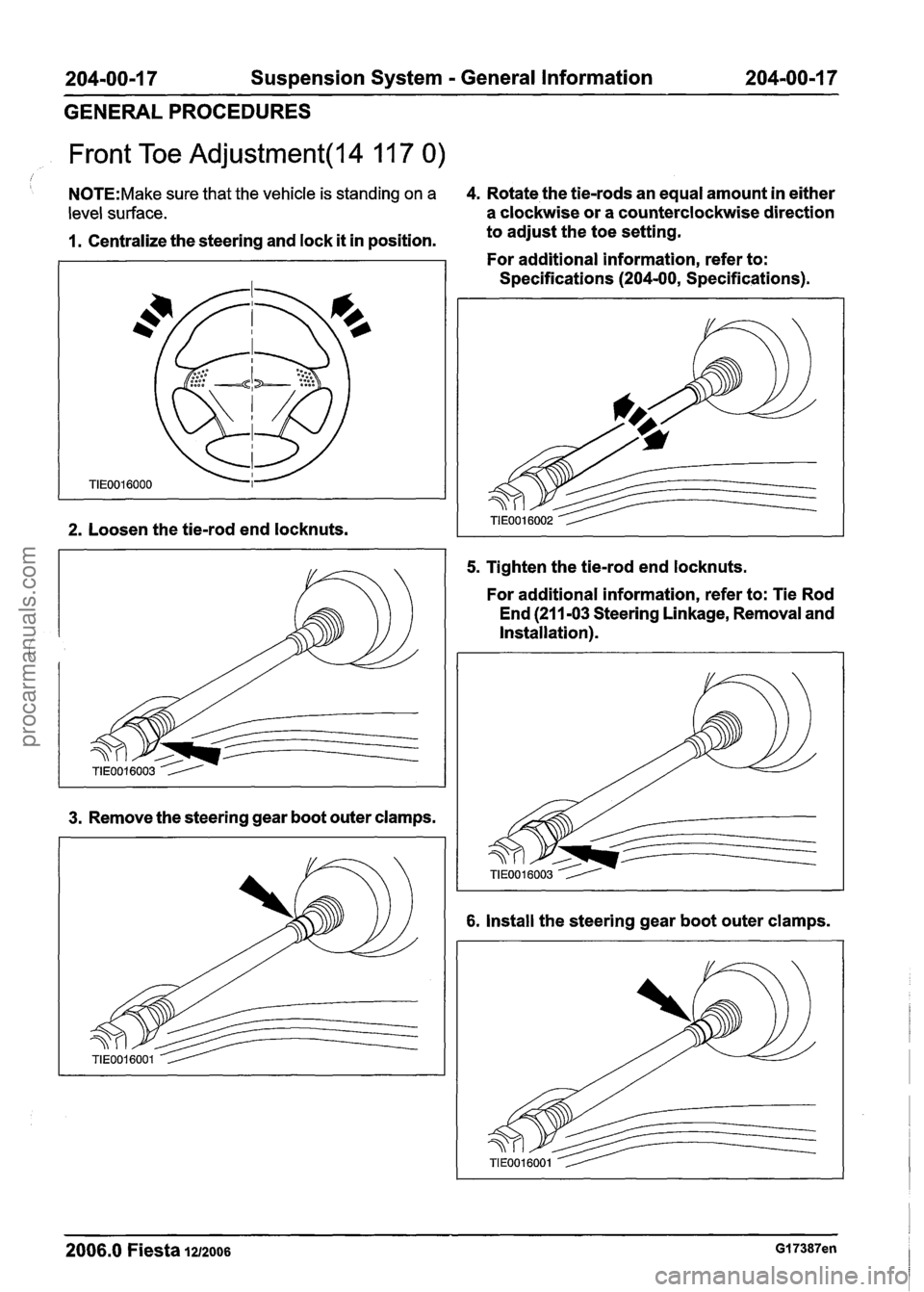

Front Toe Adjustment(l4 11 7 0)

I

N0TE:Make sure that the vehicle is standing on a 4. Rotate the tie-rods an equal amount in either

level surface. a clockwise or a counterclockwise direction

1. Centralize the steering and lock it in position. to

adjust the toe setting.

For additional information, refer to:

Specifications

(204-00, Specifications).

2. Loosen the tie-rod end locknuts.

3. Remove the steering gear boot outer clamps.

5. Tighten the tie-rod end locknuts.

For additional information, refer to: Tie Rod

End (21

1-03 Steering Linkage, Removal and

Installation).

6. Install the steering gear boot outer clamps.

2006.0 Fiesta 1212006 GI 7387en

procarmanuals.com

Page 121 of 1226

204-01 -23 Front Suspension 204-01 -23

DISASSEMBLY AND ASSEMBLY

Front Strut and Spring Assembly(l4 783 4)

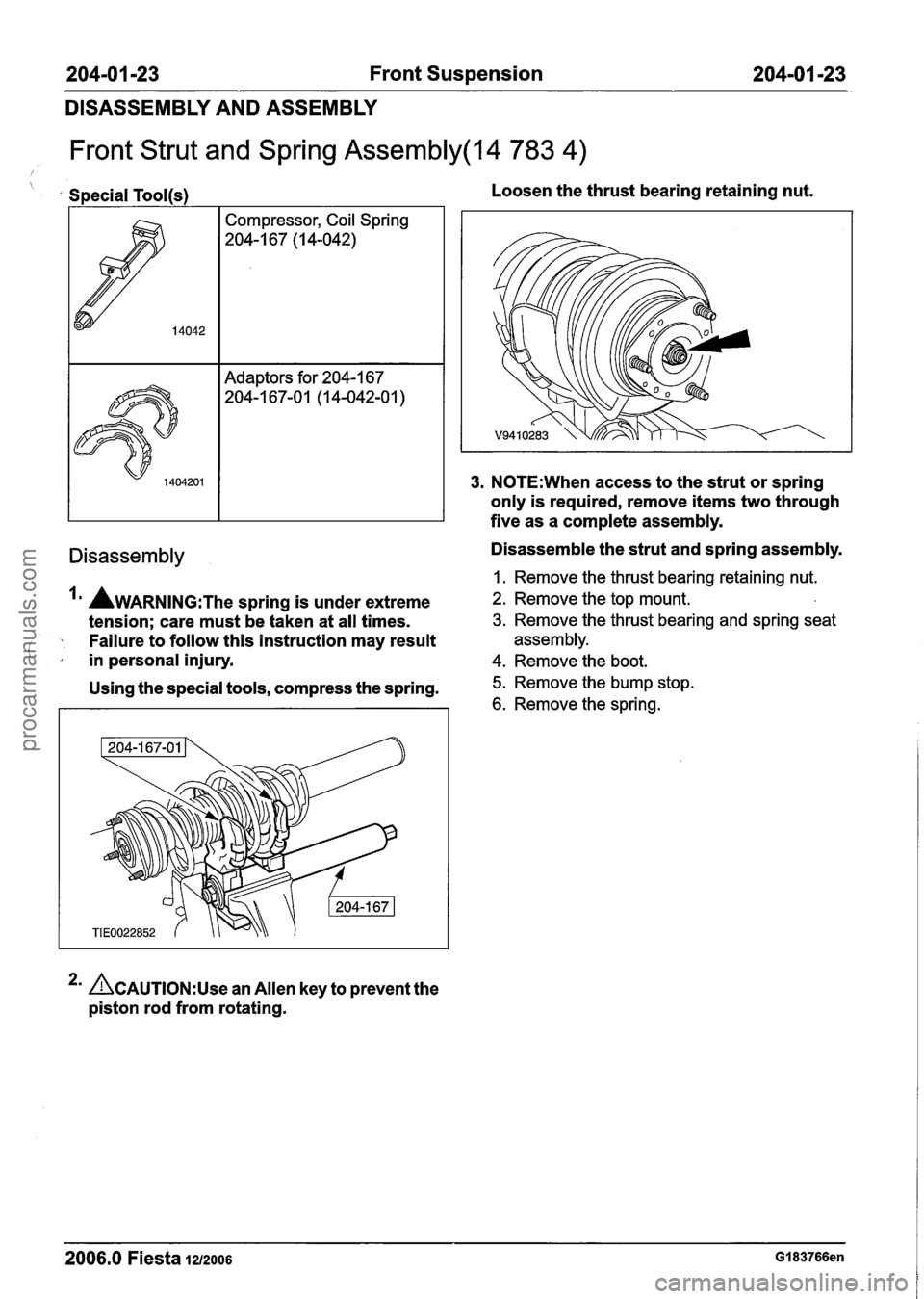

Special Tool(s) I Compressor, Coil Spring

204-1 67 (I 4-042)

Adaptors for 204-1 67

204-1 67-0 1 (1 4-042-0 1

)

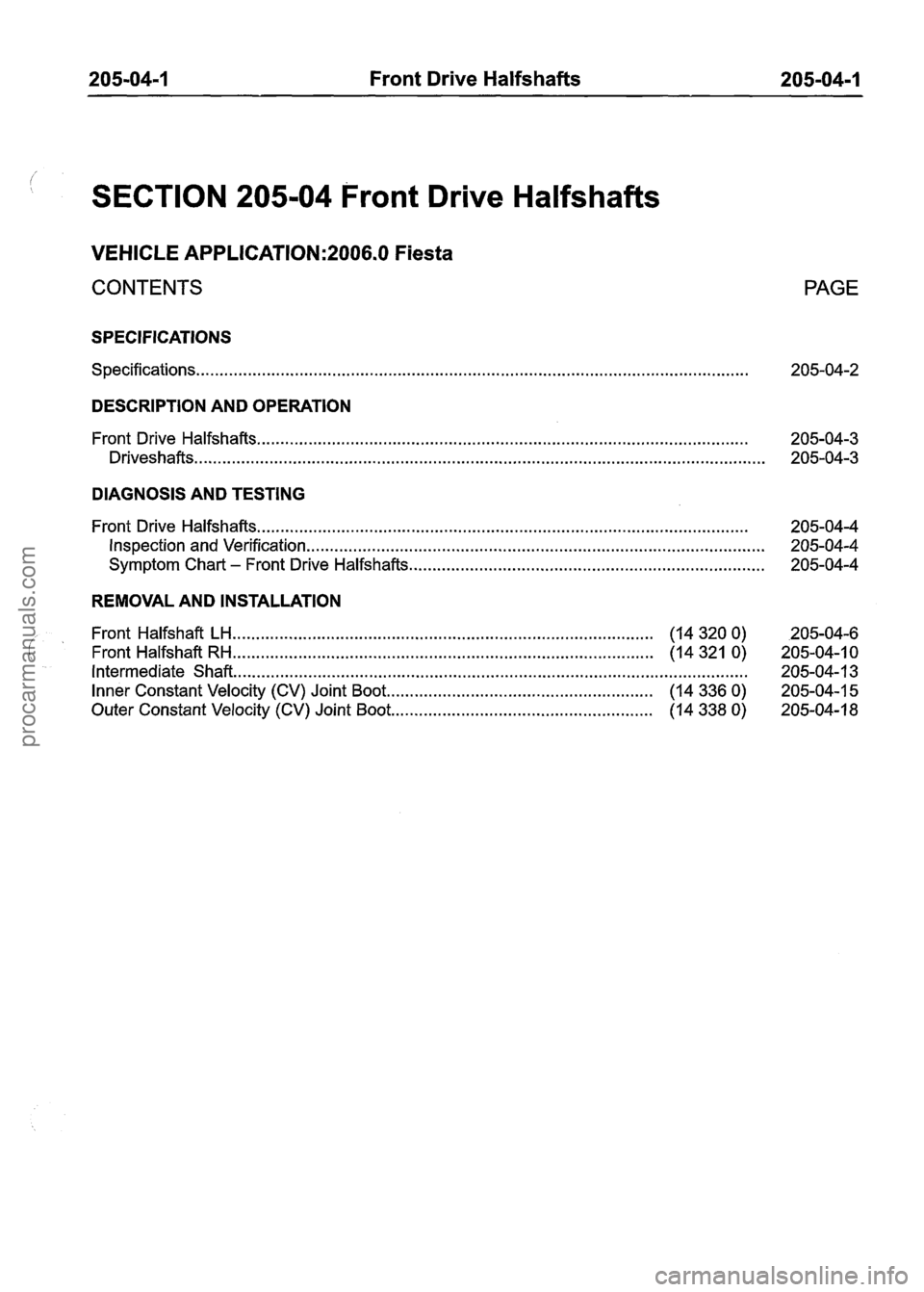

Loosen the thrust bearing retaining nut.

3. N0TE:When access to the strut or spring

only is required, remove items two through

five as a complete assembly.

Disassembly Disassemble the strut and spring assembly.

I. Remove the thrust bearing retaining nut.

AWARNING:T~~ spring is under extreme 2. Remove the top mount.

tension; care must be taken at all times. 3. Remove the thrust bearing and spring seat

Failure to follow this instruction may result assembly.

( ,' in personal injury. 4. Remove the boot.

Using the special tools, compress the spring. 5. Remove the bump stop.

6. Remove the spring.

2' &AUTION:U~~ an Allen key to prevent the

piston rod from rotating.

2006.0 Fiesta 1212006 GI 83766en

procarmanuals.com

Page 153 of 1226

205-04-1 Front Drive Halfshafts 205-04-1

SECTION 205-04 Front Drive Halfshafts

VEHICLE APPLICATION:2006.0 Fiesta

CONTENTS

SPECIFICATIONS

Specifications ........................................................................\

..............................................

PAGE

DESCRIPTION AND OPERATION

........................................................................\

................................. Front Drive Halfshafts 205-04-3

........................................................................\

.................................................. Driveshafts 205-04-3

DIAGNOSIS AND TESTING

........................................................................\

................................. Front Drive Halfshafts 205-04-4

Inspection and Verification ........................................................................\

.......................... 205-04-4

........................................................................\

.... Symptom Chart - Front Drive Halfshafts 205-04-4

REMOVAL AND INSTALLATION

........................................................................\

.................. Front Halfshaft LH (14 320 0) 205-04-6

........................................................................\

.................. Front Halfshaft RH (14 321 0) 205-04-1 0

Intermediate Shaft ........................................................................\

...................................... 205-04-1 3

......................................................... Inner Constant Velocity (CV) Joint Boot (14 336 0) 205-04-1 5

........................................................ Outer Constant Velocity (CV) Joint Boot (14 338 0) 205-04-18

procarmanuals.com

Page 154 of 1226

205-04-2 Front Drive Halfshafts 205-04-2

SPECIFICATIONS

Lubricants, Fluids, Sealers and Adhesives

Description

/ Specificat 1

ions

Manual transmission fluid

Grease, outer constant velocity (CV) WSS-MI C

joint

1 259-A1 1

Grease, inner constant velocity (CV) WSS-MI C

joint

1 259-A1 1

Toraue S~ecifications

Outer constant velocity (CV) joint boot

Constant Velocity (CV) Joint Boot Capacities

Inner constant velocity (CV)

joint boot

Description

I Lower arm ball joint pinch bolt nut I 48 I 35 I - I

Grams

I Intermediate shaft center bearing cap retaining nuts I 25 I 18 I - I

I Wheel hub retaining nut 1 290 1214 1 - I

I Strut and spring assembly top mount retaining nuts I 25 I 18 I - I

I CV joint boot clamps I 21 I 15 I - I

2006.0 Fiesta iu200s GII 3103en

procarmanuals.com

Page 155 of 1226

205-04-3 Front Drive Halfshafts 205-04-3

DESCRIPTION AND OPERATION

Front Drive Halfshafts

Drives hafts

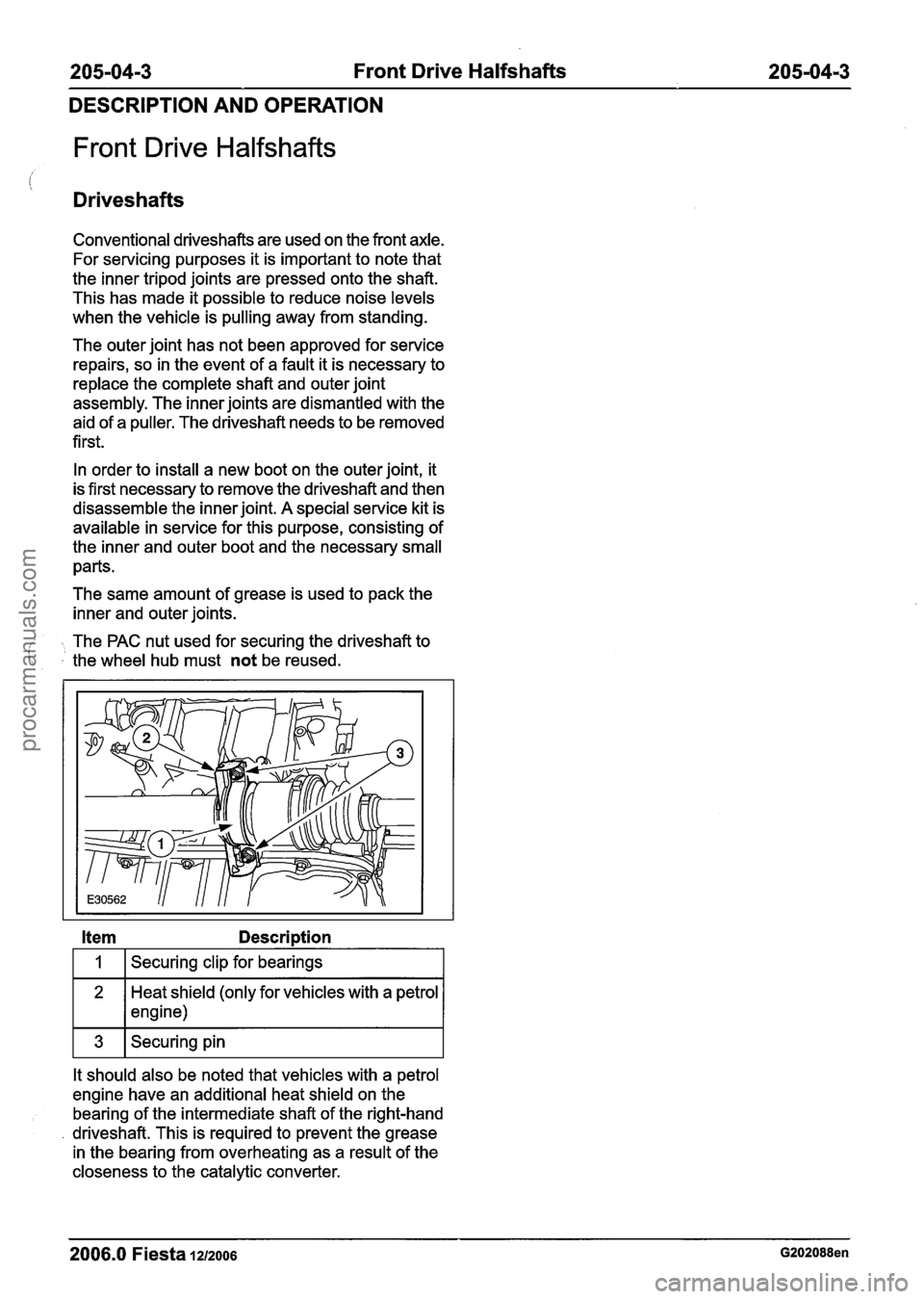

Conventional driveshafts are used on the front axle.

For servicing purposes it is important to note that

the inner tripod joints are pressed onto the shaft.

This has made it possible to reduce noise levels

when the vehicle is pulling away from standing.

The outer joint has not been approved for service

repairs, so in the event of a fault it is necessary to

replace the complete shaft and outer joint

assembly. The inner joints are dismantled with the

aid of a puller. The driveshaft needs to be removed

first.

In order to install a new boot on the outer joint, it

is first necessary to remove the driveshaft and then

disassemble the inner joint. A special service kit is

available in service for this purpose, consisting of

the inner and outer boot and the necessary small

parts.

The same amount of grease is used to pack the

inner and outer joints.

- The PAC nut used for securing the driveshaft to ' the wheel hub must not be reused.

Item Description

I 1 I Securing clip for bearings I

Heat shield (only for vehicles with a petrol

1 * 1 engine)

It should also be noted that vehicles with a petrol

engine have an additional heat shield on the bearing of the intermediate shaft of the right-hand

driveshaft. This is required to prevent the grease

in the bearing from overheating as a result of the

closeness to the catalytic converter.

2006.0 Fiesta 1212006 G202088en

procarmanuals.com

Page 156 of 1226

205-0414 Front Drive Halfshafts 205-04-4

DIAGNOSIS AND TESTING

Front Drive Halfshafts

Inspection and Verification 3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible) c.# '

1. Verify the customer concern. before proceeding

to the next step.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Symptom Chart - Front Drive Halfshafts

Symptom Chart

Symptom

Possible Sources Action

Clicking, Popping or Grinding

Noises While Turning Inadequate or contaminated INSPECT, CLEAN and

I lubricant in the inner or outer I LUBRICATE as necessary.

I Outer Constant Velocity (CV)

I Joint Boot - in this section.

front drive halfshaft constant

velocity (CV) joint.

REFER to Constant

Velocity (CV) Joint Boot -

Wheel bearings, brakes,

suspension or steering

components.

Another component contacting

front drive halfshaft assembly.

--

INSPECT and REPAIR as

necessary. REFER to

Section 204-00 [Suspension

System

- General Information]

1 206-00 [Brake System -

General Information] I 21 1-00

[Steering System

- General

Information].

INSPECT and REPAIR as

necessary.

- --

Vibration at Highway Speeds

Shudder Vibration During

Acceleration. Out of balance front wheels or

tires. Balance wheels and tires as

necessary.

I Incorrectly seated outer I REPAIR or INSTALL new as I

Out-of-round tires.

constant velocity (CV) joint in necessary.

front wheel hub.

I REFER to Halfshaft LH -

REPAIR or INSTALL new as

necessary.

I I I Halfshaft RH - in this section. I

Excessively high CV joint

operating angles caused by

incorrect ride height. CHECK the ride height,

VERIFY correct spring rate.

CHECK items under Halfshaft

Joint Pullout. REPAIR or INSTALL

new as necessary.

Excessively worn or damaged

I inner or outer front drive half-

- - - - --

2006.0 Fiesta 1212006 G25403en

INSPECT and INSTALL new

as necessary.

shaft constant velocity (CV)

joint. REFER

to Halfshaft LH

-

I Halfshaft RH - in this sectionk 1;

procarmanuals.com

Page 163 of 1226

205-04-1 1 Front Drive Halfshafts 205-04-1 1

REMOVAL AND INSTALLATION

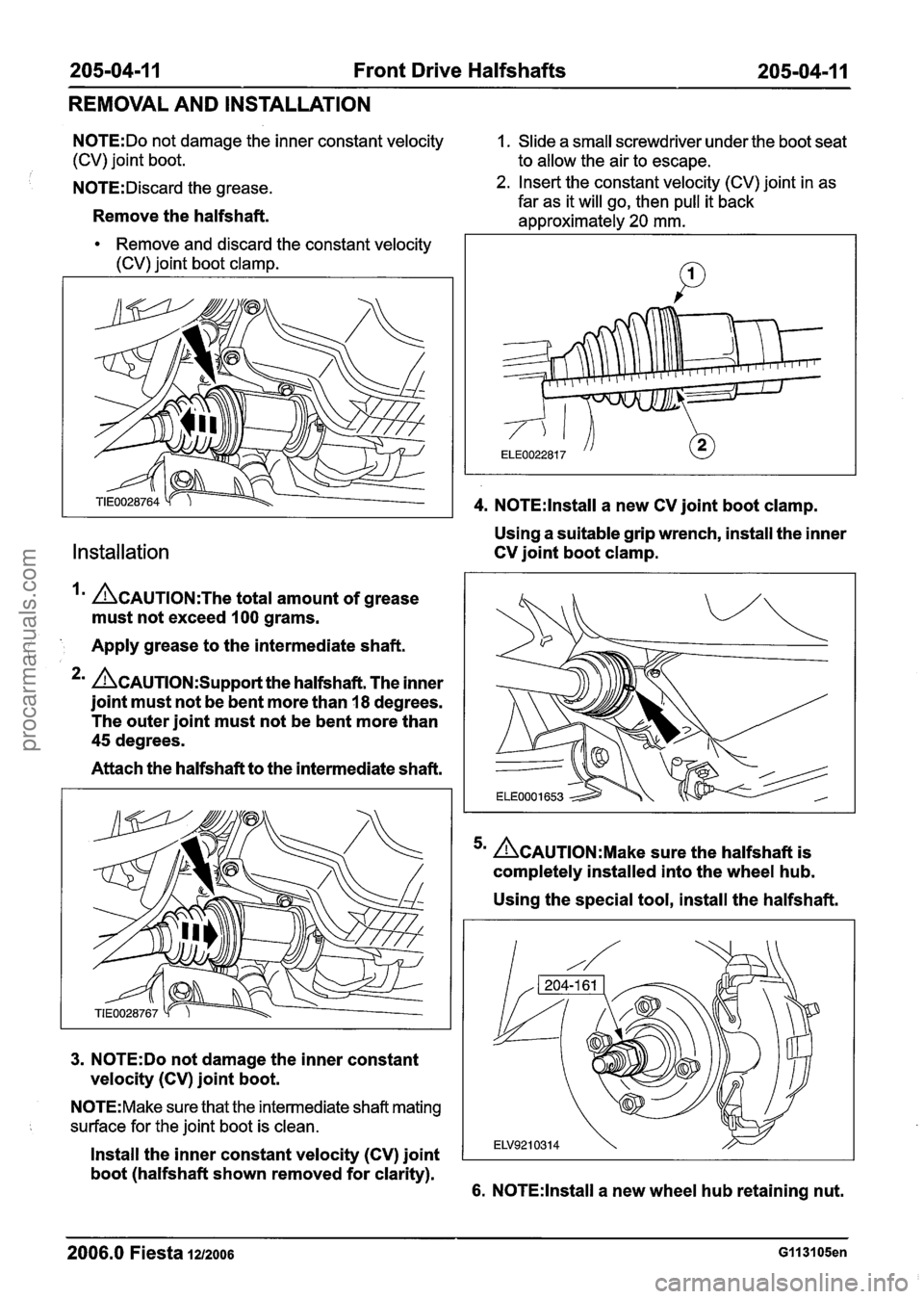

N0TE:Do not damage the inner constant velocity 1. Slide a small screwdriver under the boot seat

(CV) joint boot. to allow the air to escape.

N0TE:Discard the grease.

Remove the halfshaft.

Remove and discard the constant velocity

(CV) joint boot clamp.

Installation

Im &AUTION:T~~ total amount of grease

must not exceed

100 grams.

i Apply grease to the intermediate shaft.

*' &AUTION:S~~~~~~ the halfshaft. The inner

joint must not be bent more than

18 degrees.

The outer joint must not be bent more than

45 degrees.

Attach the halfshaft to the intermediate shaft.

3. N0TE:Do not damage the inner constant

velocity (CV) joint boot.

N0TE:Make sure that the intermediate shaft mating

surface for the joint boot is clean.

2. Insert the constant velocity (CV) joint in as

far as it will go, then pull it back

approximately

20 mm.

4. N0TE:lnstall a new CV joint boot clamp.

Using a suitable grip wrench, install the inner

CV joint boot clamp.

5m ~CAUTION:M~~~ sure the halfshaft is

completely installed into the wheel hub.

Using the special tool, install the halfshaft.

Install the inner constant velocity (CV) joint

boot (halfshaft shown removed for clarity).

6. N0TE:lnstall a new wheel hub retaining nut.

2006.0 Fiesta 1212006 GI 131 05en

procarmanuals.com