sensor FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 1117 of 1226

308-03-27 Manual TransmissionlTransaxle 308-03-27

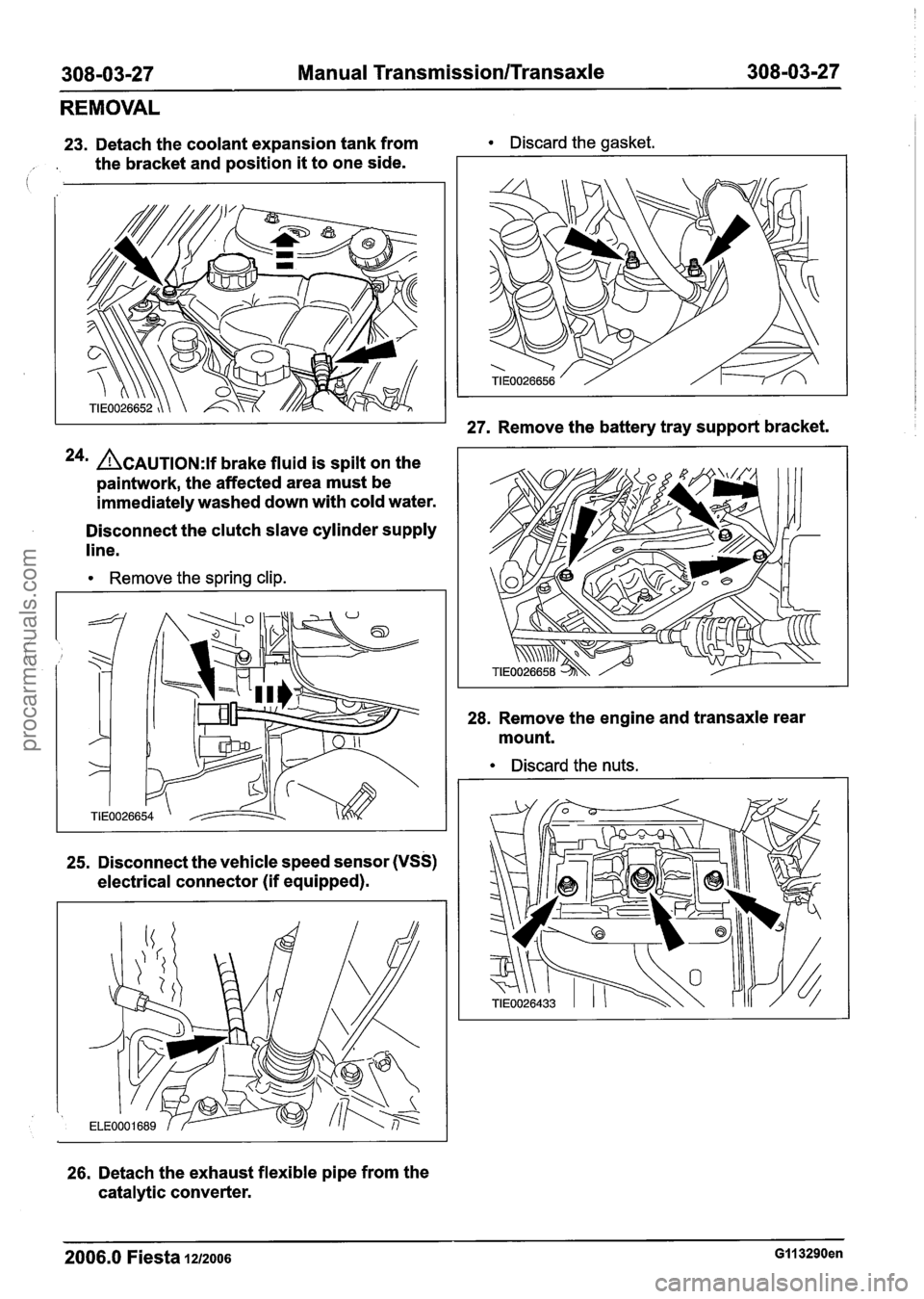

REMOVAL

23. Detach the coolant expansion tank from Discard the gasket.

, . the bracket and position it to one side.

24m ACAUTION:~~ brake fluid is spilt on the

paintwork, the affected area must be

immediately washed down with cold water.

Disconnect the clutch slave cylinder supply

line.

Remove the spring clip.

25. Disconnect the vehicle speed sensor (VSS)

electrical connector (if equipped).

26. Detach the exhaust flexible pipe from the

catalytic converter.

27. Remove the battery tray support bracket.

28. Remove the engine and transaxle rear

mount.

Discard the nuts.

2006.0 Fiesta 1212006 GI1 3290en

procarmanuals.com

Page 1126 of 1226

308-03-36 Manual Transmission/Transaxle 308-03-36

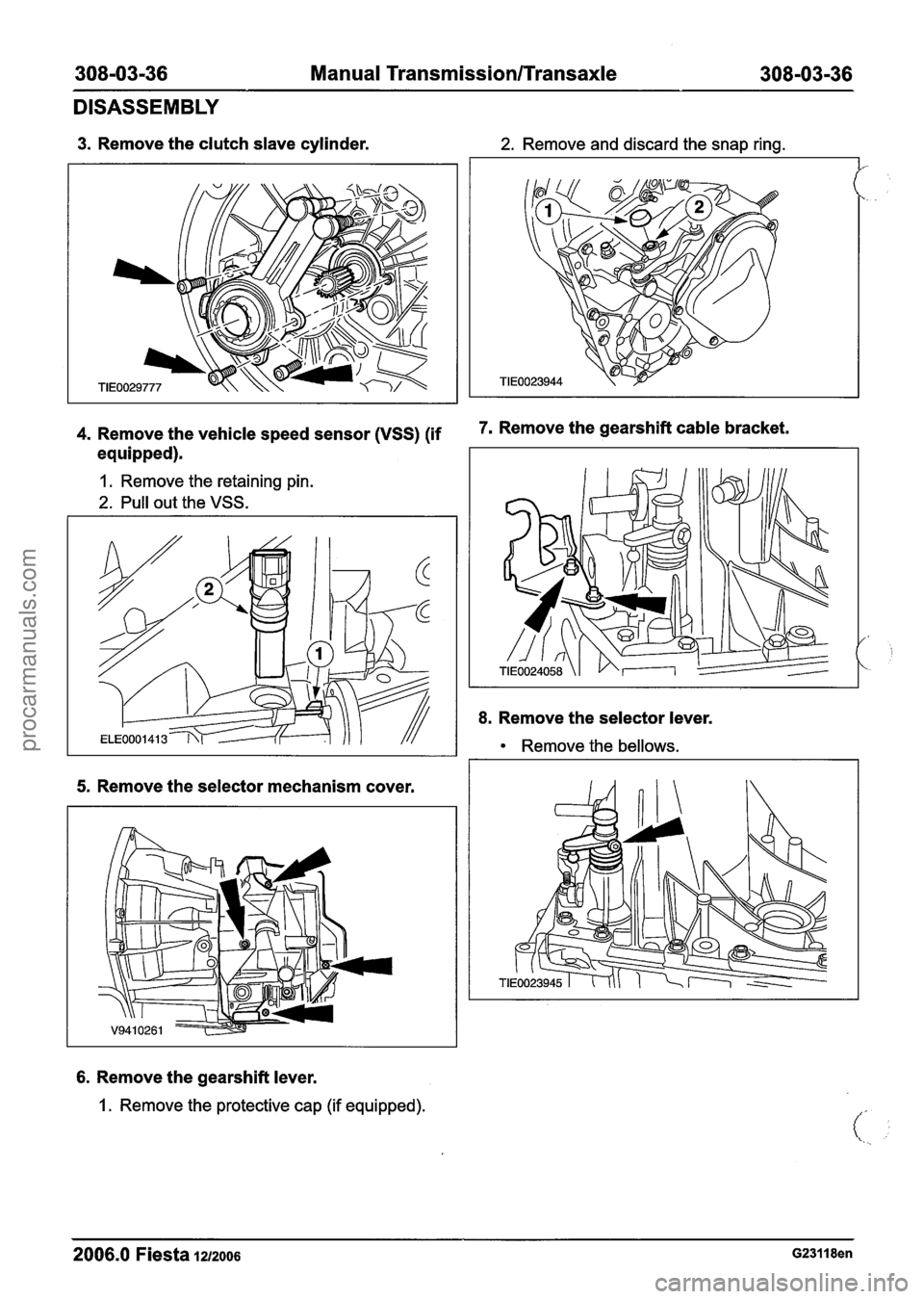

DISASSEMBLY

3. Remove the clutch slave cylinder. 2. Remove and discard the snap ring.

J'

4. Remove the vehicle speed sensor (VSS) (if 7m Remove the gearshift cable

equipped).

1. Remove the retaining pin.

2. Pull out the VSS.

5. Remove the selector mechanism cover.

6. Remove the gearshift lever.

1 . Remove the protective cap (if equipped).

8. Remove the selector lever.

Remove the bellows.

2006.0 Fiesta 1212006 G23118en

procarmanuals.com

Page 1139 of 1226

308-0349 Manual Transmission/Transaxle 308-03-49

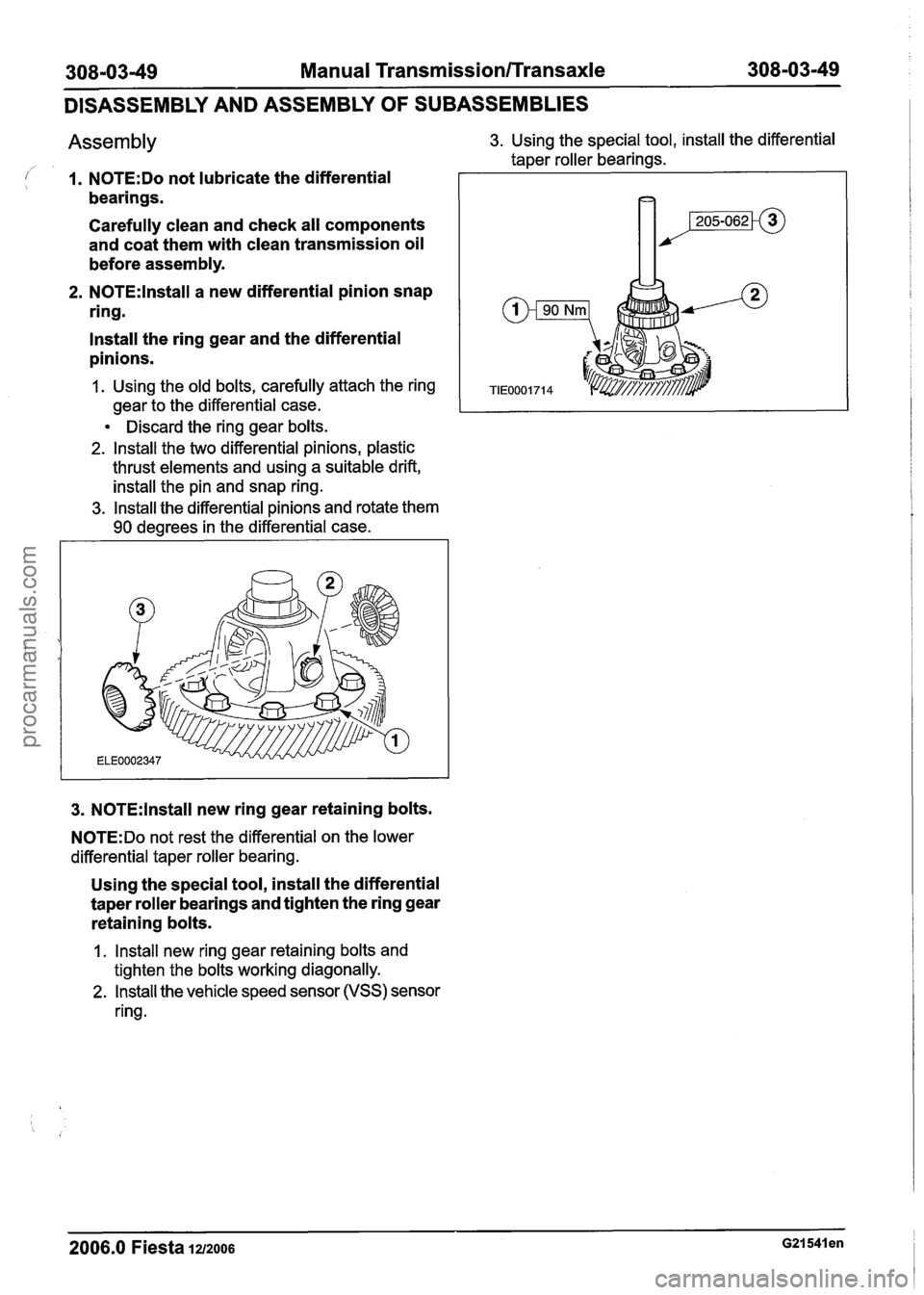

DISASSEMBLY AND ASSEMBLY OF SUBASSEMBLIES

Assembly 3. Using the special tool, install the differential

taper roller bearings.

I 1. N0TE:Do not lubricate the differential

bearings.

Carefully clean and check all components

and coat them with clean transmission oil

before assembly.

2. N0TE:lnstall a new differential pinion snap

ring.

lnstall the ring gear and the differential

pinions.

1. Using the old bolts, carefully attach the ring

gear to the differential case.

1 I

Discard the ring gear bolts.

2. lnstall the two differential pinions, plastic

thrust elements and using a suitable drift,

install the pin and snap ring.

3. lnstall the differential pinions and rotate them

90 degrees in the differential case.

3. N0TE:lnstall new ring gear retaining bolts.

N0TE:Do not rest the differential on the lower

differential taper roller bearing.

Using the special tool, install the differential

taper roller bearings and tighten the ring gear

retaining bolts.

1 . lnstall new ring gear retaining bolts and

tighten the bolts working diagonally.

2. lnstall the vehicle speed sensor (VSS) sensor

ring.

2006.0 Fiesta 1212006 G21541 en

procarmanuals.com

Page 1150 of 1226

308-03-60 Manual Transmission/Transaxle 308-03-60

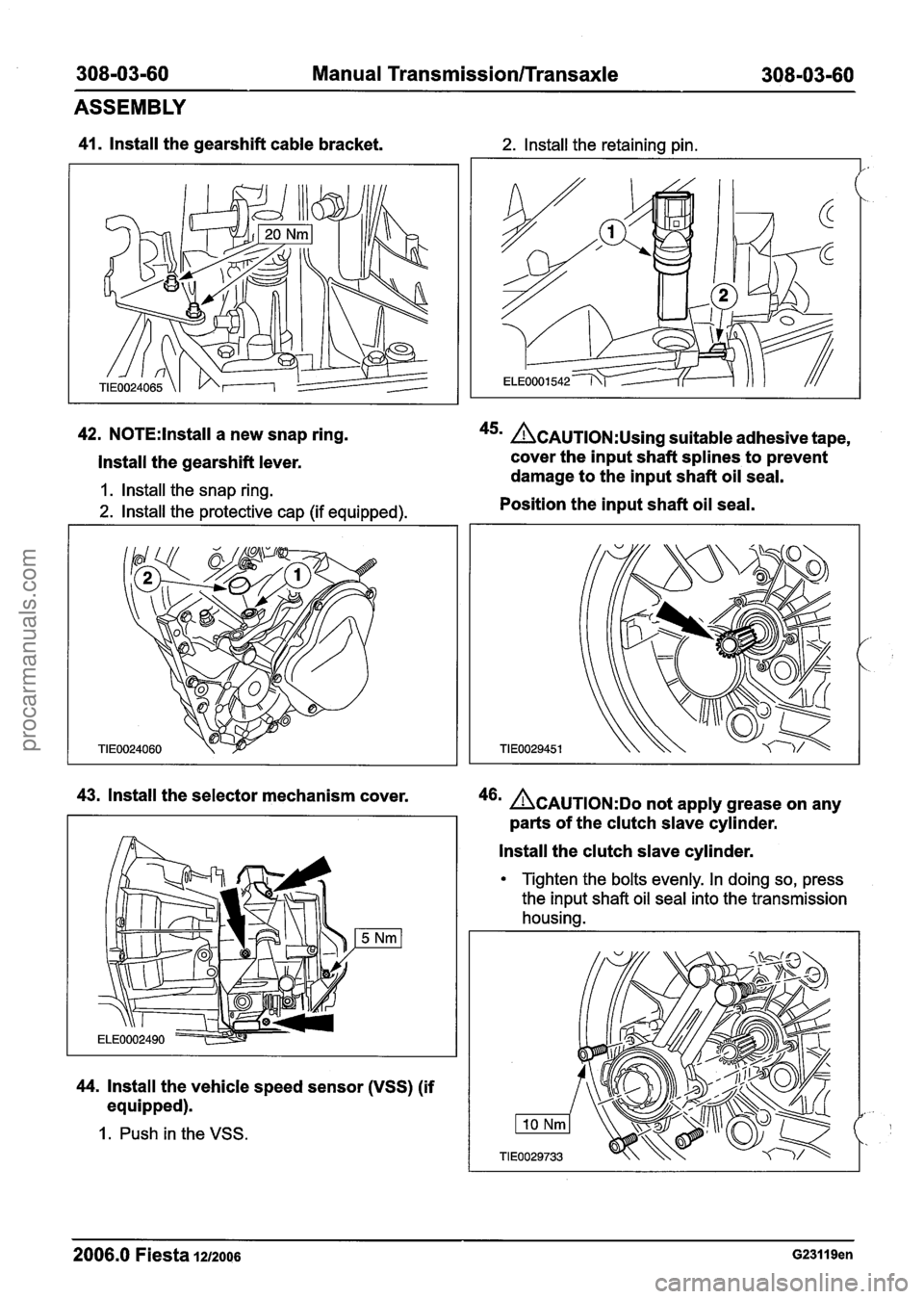

ASSEMBLY

41. lnstall the gearshift cable bracket. 2. lnstall the retaining pin.

42. N0TE:lnstall a new snap ring. 45m &AUTION:U~~~~ suitable adhesive tape,

Install the gearshift lever. cover

the input shaft splines to prevent

damage to the input shaft oil seal.

1. lnstall the snap ring.

2. lnstall the protective cap (if equipped). Position

the input shaft oil seal.

TIE

43. lnstall the selector mechanism cover. 46m ~CAUTION:DO not apply grease on any

parts of the clutch slave cylinder.

lnstall the clutch slave cylinder.

44. lnstall the vehicle speed sensor (VSS) (if

equipped).

1. Push in the VSS.

Tighten the bolts evenly. In doing so, press

the input shaft oil seal into the transmission

housing.

2006.0 Fiesta 1212006 G23119en

procarmanuals.com

Page 1154 of 1226

308-03-64 Manual Transmission/Transaxle 308-03-64

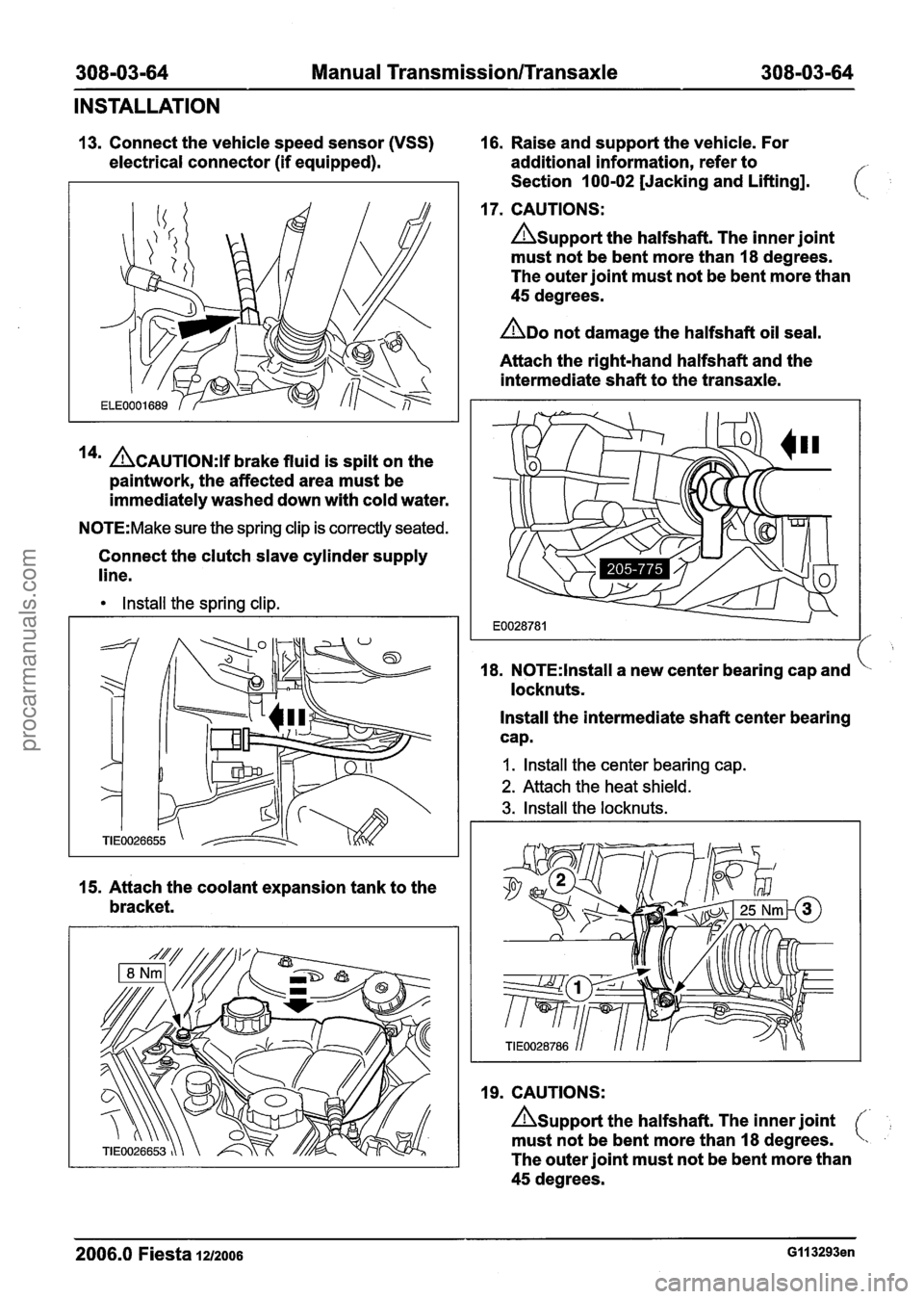

INSTALLATION

13. Connect the vehicle speed sensor (VSS) 16. Raise and support the vehicle. For

electrical connector (if equipped). additional information, refer to

Section 100-02 [Jacking and Lifting].

17. CAUTIONS:

Asupport the halfshaft. The inner joint

must not be bent more than 18 degrees.

The outer joint must not be bent more than

45 degrees.

ADO not damage the halfshaft oil seal.

Attach the right-hand halfshaft and the

intermediate shaft to the transaxle.

14' ACAUTION:~~ brake fluid is spilt on the

paintwork, the affected area must be

immediately washed down with cold water.

N0TE:Make sure the spring clip is correctly seated.

Connect the clutch slave cylinder supply

line.

Install the spring clip.

15. Attach the coolant expansion tank to the

bracket. 18.

N0TE:lnstall a

new center bearing cap and

locknuts.

Install the intermediate shaft center bearing

cap.

I. Install the center bearing cap.

2. Attach the heat shield.

3. Install the locknuts.

19. CAUTIONS:

Asupport the halfshaft. The inner joint

must not be bent more than 18 degrees.

The outer joint must not be bent more than

45 degrees.

2006.0 Fiesta 1212006 GI I 3293en

procarmanuals.com

Page 1178 of 1226

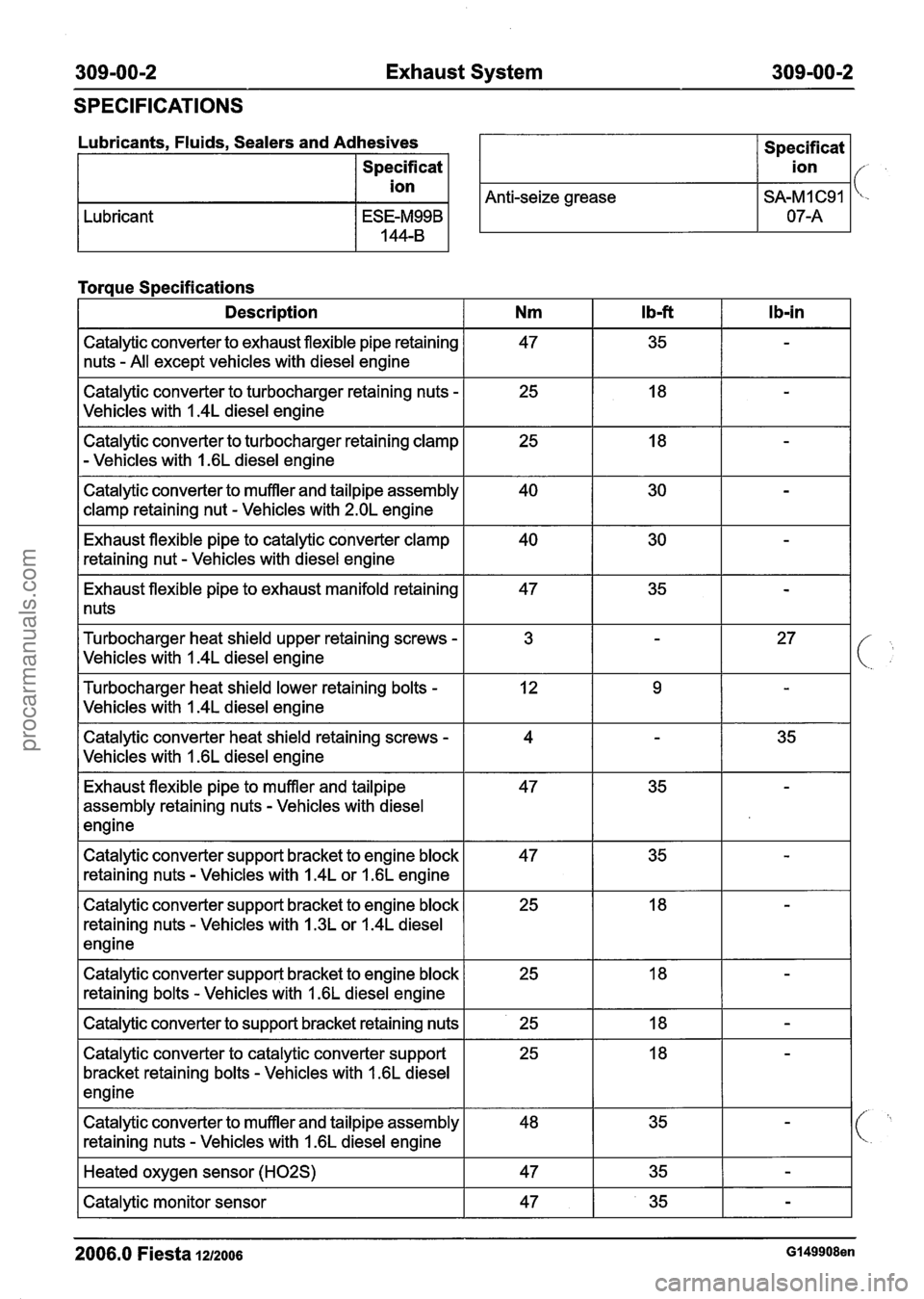

309-00-2 Exhaust System 309-00-2

SPECIFICATIONS

Lubricants. Fluids. Sealers and Adhesives I Specificat I

Specificat

I ion I

I ion I/- ,

Anti-seize grease I SA-MI C91 I 'c-

Lubricant

Torque Specifications

I Description I Nm I Ibf I Ib-in I

Catalytic converter to exhaust flexible pipe retaining

nuts

- All except vehicles with diesel engine

Catalytic converter to turbocharger retaining nuts

-

Vehicles with I .4L diesel engine

Catalytic converter to turbocharger retaining clamp

- Vehicles with 1.6L diesel engine

Catalytic converter to muffler and tailpipe assembly

clamp retaining nut

- Vehicles with 2.OL engine

Exhaust flexible pipe to catalytic converter clamp

retaining nut

- Vehicles with diesel engine

Exhaust flexible pipe to exhaust manifold retaining

1 nuts

Turbocharger heat shield upper retaining screws

-

Vehicles with I .4L diesel engine

Turbocharger heat shield lower retaining bolts

-

Vehicles with I .4L diesel engine

Catalytic converter heat shield retaining screws

-

Vehicles with I .6L diesel engine

Exhaust flexible pipe to muffler and tailpipe

assembly retaining nuts

- Vehicles with diesel

engine

Catalytic converter support bracket to engine block

retaining nuts

- Vehicles with 1.4L or 1.6L engine

Catalytic converter support bracket to engine block

retaining nuts

- Vehicles with 1.3L or 1.4L diesel

engine

Catalytic converter support bracket to engine block retaining bolts

- Vehicles with I .6L diesel engine

I Catalytic converter to support bracket retaining nuts I 25 I 18 I - 1

Catalytic converter to catalytic converter support

bracket retaining bolts

- Vehicles with 1.6L diesel

engine

Catalytic converter to muffler and tailpipe assembly

retaining nuts

- Vehicles with 1.6L diesel engine

I Heated oxygen sensor (H02S) I 47 I 35 I - I

I Catalytic monitor sensor I 47 I 35 I - I

2006.0 Fiesta 1212006 G149908en

procarmanuals.com

Page 1182 of 1226

309-00-6 Exhaust System 309-00-6

REMOVAL AND INSTALLATION

Catalytic Converter - 2.OL Duratec-HE (M14)

/'

Materials Support

the exhaust flexible pipe with a (,

support wrap or splint.

Name Specification

1 Grease I SA-M 1 C9107-A I --

N0TE:lf installing a new catalytic converter to the

original exhaust system, a new muffler and tailpipe

assembly must also be installed.

1. Raise and support the vehicle. For additional

information, refer to:

(1 00-02 Jacking and

Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

*' CAUTION:^^^^ bending of the exhaust

flexible pipe may cause damage resulting in 3. Remove the components in the order failure.

indicated in the following illustration(s) and

table(s).

Item Description Item Description

2006.0 Fiesta 1212006 G453448en

2

3

See Removal Detail

See Installation Detail

1

Catalytic converter monitor sensor

electrical connector

Catalytic converter monitor sensor

Exhaust hanger insulator

4 Catalytic converter to exhaust flexible pipe

retaining nuts

procarmanuals.com

Page 1185 of 1226

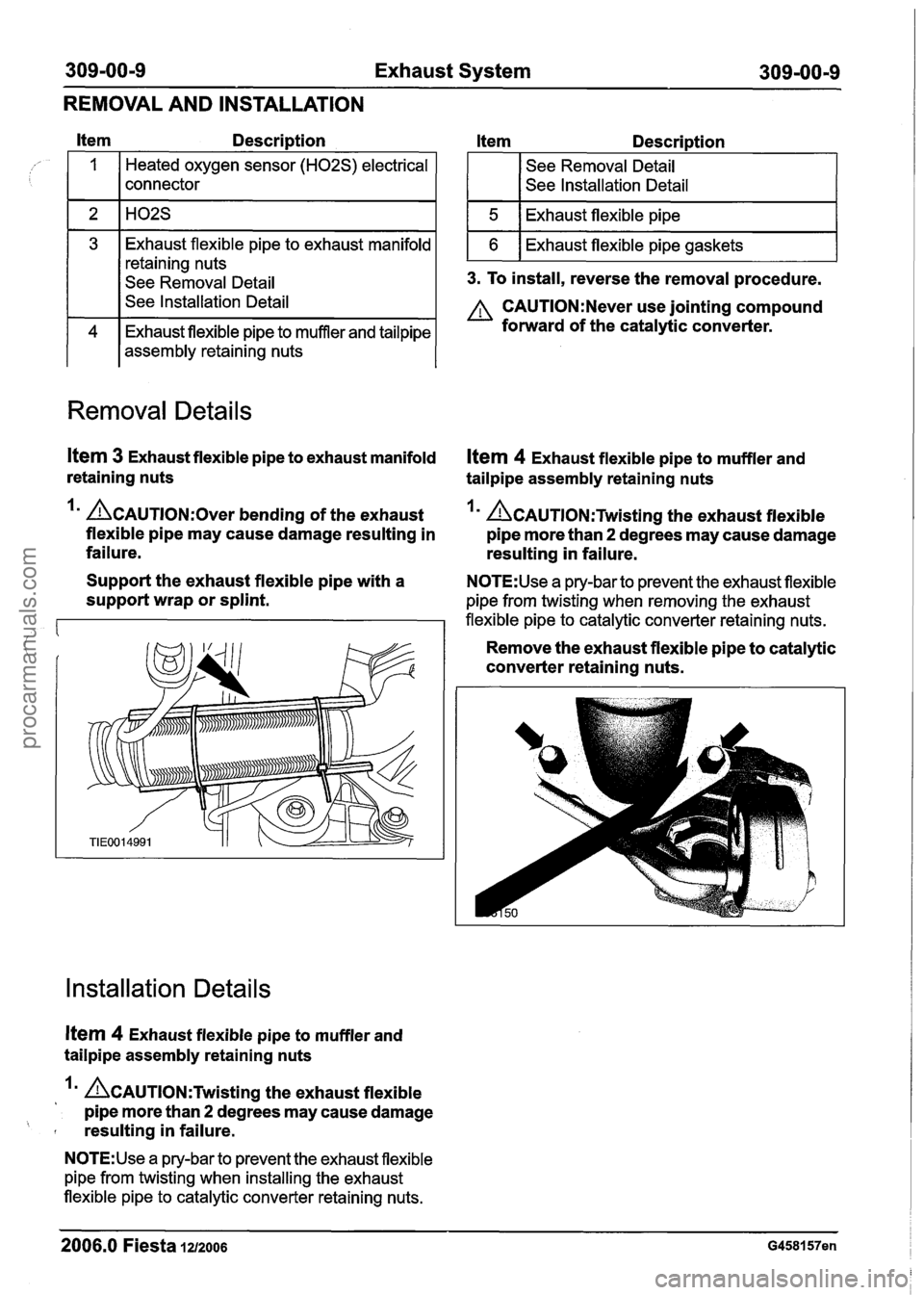

309-00-9 Exhaust System 309-00-9

REMOVAL AND INSTALLATION

Itern Description Item Descri~tion

Heated oxygen sensor (H02S) electrical

connector See

Removal Detail

See lnstallation Detail

3. To install, reverse the removal procedure.

3

A CAUTI0N:Never use jointing compound

Exhaust flexible pipe to muffler and tailpipe forward of the catalytic converter.

assembly retaining nuts Exhaust

flexible pipe to exhaust manifold

retaining nuts

See Removal Detail

Removal Details

Item 3 Exhaust flexible pipe to exhaust manifold Ifem 4 Exhaust flexible pipe to muffler and

retaining nuts tailpipe assembly retaining nuts

Im &AUTION:O~~~ bending of the exhaust Im &Au~l~N:Twistin~ the exhaust flexible

flexible pipe may cause damage resulting in pipe more than

2 degrees may cause damage

failure. resulting in failure.

Support the exhaust flexible pipe with a

N0TE:Use a pry-bar to prevent the exhaust flexible

support wrap or splint. pipe from twisting when removing the exhaust

flexible pipe to catalytic converter retaining nuts.

Remove the exhaust flexible pipe to catalytic

converter retaining nuts.

Installation Details

Item 4 Exhaust flexible pipe to muffler and

tailpipe assembly retaining nuts

A~AuT10~:Twistin~ the exhaust flexible

pipe more than

2 degrees may cause damage

' resulting in failure.

N0TE:Use a pry-bar to prevent the exhaust flexible

pipe from twisting when installing the exhaust

flexible pipe to catalytic converter retaining nuts.

2006.0 Fiesta 1212006 G458157en

procarmanuals.com

Page 1199 of 1226

31 0-01 -1 Fuel Tank and Lines 31 0-01 -1

1 SECTION 31 0-01 Fuel Tank and Lines

VEHICLE APPLICATION:2006.0 Fiesta

CONTENTS

SPECIFICATIONS

Specifications.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAGE

DESCRIPTION AND OPERATION

Fuel Tank and Lines - 1.25L Duratec-I 6V (Sigma)/l.4L Duratec-1 6V (Sigma)/l .6L

Duratec-I 6V (Sigma) ...... . . .. .. .... .. .... . . .... . . . . .... ...... .. .. . . . . ...... . . . . ........ .. .. .. .. . . . . . . . ... .. . . . . . . . . . . .. .... 31 0-01 -3

Overview..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1 0-0 1 -3

DIAGNOSIS AND TESTING

. Fuel Tank and Lines ........................................................................\

....................................

REMOVAL AND INSTALLATION

Fuel Tank ..... . . ...... . . . ... . . ...... .... .. . . . . . . . . . . . . . . . . . . . . . . . . . ...... . . . . . . . . . . . . . . . . . . . (23 554 0)

31 0-01 -6

Fuel Pump Module. ........................................................................\

........ . (23 534 0)

31 0-01 -1 1

Fuel Tank Filler Pipe ........................................................................\

............... (23 572 0) 31 0-01-12

Fuel Level Sensor ..... . . . . . . . . . .. .... .. .. .... .. .. . . .. .. .. . . . . . . . . . . . . .. ...... .. . . .. .... . . .. . . . . .. . . .. .... . ... .. .. .. . . .. . . . . . . .. . 31 0-01 -1 4

Fuel Level Resistor Card ..... . . . . .. .. . . .. . . . . .. . . . . .. ...... . . . . . . . ..... . . . ..... . . . . . . . . . . . . . . . . . . . . . . 31 0-01 -1 5

procarmanuals.com

Page 1200 of 1226

31 0-01 -2 Fuel Tank and Lines 31 0-01 -2

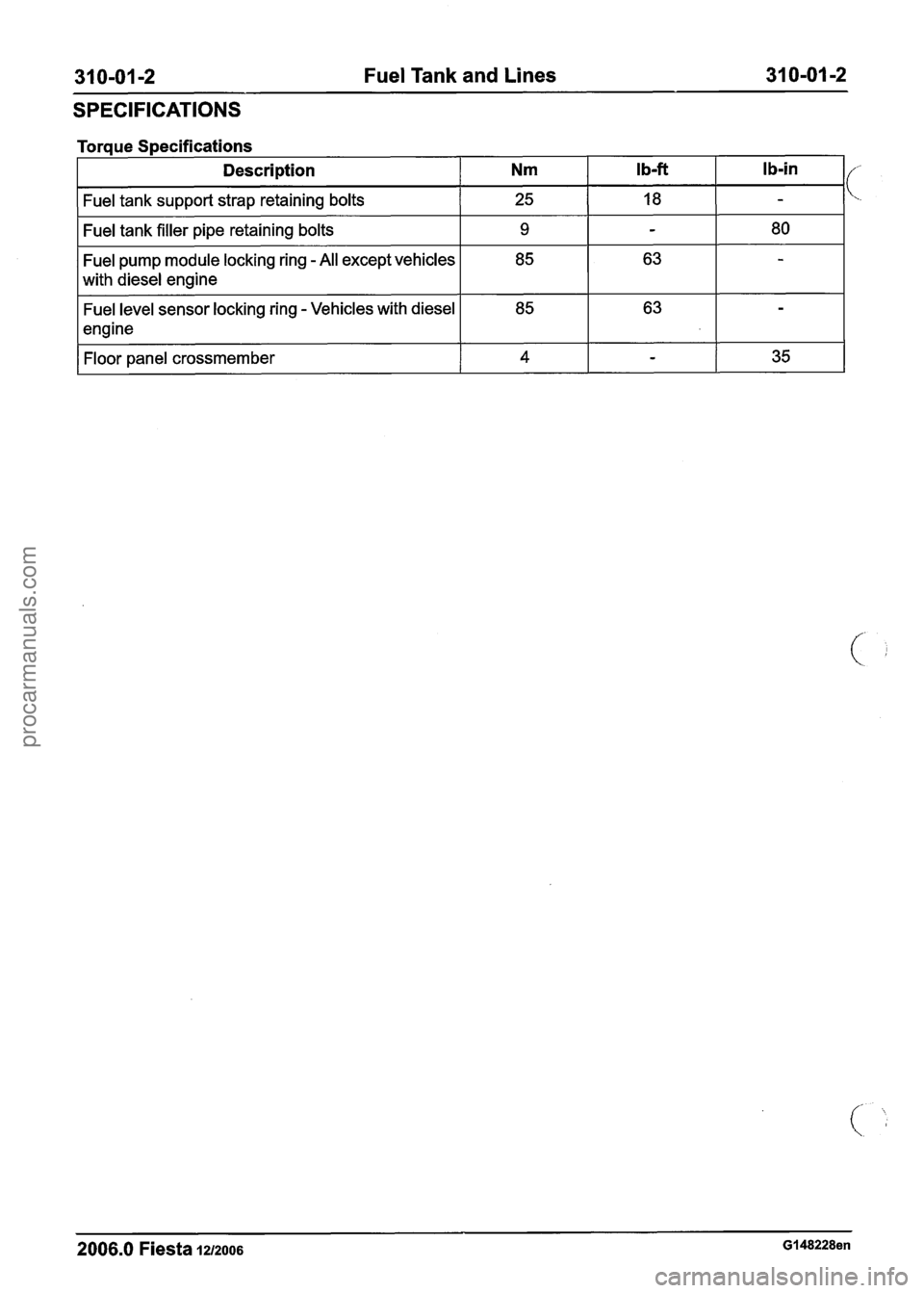

SPECIFICATIONS

Torque Specifications

Description

Nm Ib-ft I b-in I/

Fuel tank support strap retaining bolts I 25 I 18 I -

Fuel tank filler pipe retaining bolts I 9 I - I 80 I

Fuel pump module locking ring - All except vehicles

with diesel engine

Fuel level sensor locking ring

- Vehicles with diesel

engine

Floor panel crossmember

I 4 I - I 35 I

2006.0 Fiesta 1212006 GI 48228en

procarmanuals.com