steering wheel FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 3 of 1226

2006.0 Fiesta

Workshop Manual

Table of Contents

GROUP 1 General lnformation

Service lnformation

General lnformation

Identification Codes

Jacking and Lifting

Noise, Vibration and

Harshness

Suspension

Suspension System - General

lnformation

Front Suspension

Rear Suspension

Wheels and Tires

Driveline

Front Drive Halfshafts

Brake System

Brake System - General

Information

Drum Brake

Front Disc Brake

Rear Disc Brake

Parking Brake and Actuation

Hydraulic Brake Actuation

Power Brake Actuation

Anti-Lock Control

Anti-Lock Control

- Traction

Control

Anti-Lock Control

- Stability

Assist

Steering System

Steering System - General

lnformation

Power Steering Steering Linkage

Steering Column

Steering Column Switches

Engine

Engine System - General

lnformation

Engine

- 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l.GL Duratec-I 6V

(Sigma)

Engine

- 2.OL Duratec-HE

(MI41

Engine Cooling - 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma)

Engine Cooling

- 2.OL Duratec-HE

(MI41

Fuel Charging and Controls - 1.25L

Duratec-1 6V (Sigma)/l.4L

Duratec-16V (Sigma)/l.GL

Duratec-1 6V (Sigma)

Fuel Charging and Controls

- 2.OL

Duratec-HE (M14)

Accessory Drive

Starting System

Engine lgnition

Engine Ignition

- 2.OL Duratec-HE

(M14)

Engine Emission Control - 1.3L

Duratec-8V (Rocam)/l.25L

Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L

Duratec-1

6V (Sigma)

Engine Emission Control

- 2.OL

Duratec-HE (M14)

05/2005 2006.0 Fiesta

procarmanuals.com

Page 9 of 1226

GROUP

Chassis

SECTION TITLE PAGE

Suspension

Suspension

System . General Information .................................................................... 204-00

........................................................................\

................................. Front Suspension .201 4.0

........................................................................\

................................. Rear Suspension .20 4.02

........................................................................\

.................................. Wheels and Tires 204-04

Driveline

Front Drive Halfshafts ........................................................................\

............................ 205-04

' Brake System

Brake System . General Information ........................................................................\

...... 206-00

........................................................................\

.......................................... Drum Brake .20 6.02

Front Disc Brake

........................................................................\

................................... 206-03

Rear Disc Brake

........................................................................\

.................................... 206-04

Parking Brake and Actuation

........................................................................\

................. 206-05

Hydraulic Brake Actuation ........................................................................\

...................... 206-06

Power Brake Actuation

........................................................................\

.......................... 206-07

........................................................................\

.................................. An ti-Lock Control .20 6.09A

Anti-Lock Control . Traction Control ........................................................................\

....... 206-09B

Anti-Lock Control . Stability Assist ........................................................................\

......... 206-09C

Steering System

........................................................................\

. Steering System . General Information .21 1.00

........................................................................\

..................................... Power Steering -21 1-02

........................................................................\

.................................. Steering Linkage -21 1-03

Steering Column

........................................................................\

................................... 21 1-04

Steering Column Switches

........................................................................\

..................... 21 1-05

0512005 2006.0 Fiesta

procarmanuals.com

Page 22 of 1226

100-00-6 General Information 100-00-6

DESCRIPTION AND OPERATION

Health and Safety Precautions

Introduction

Many of the procedures associated with vehicle

maintenance and repair involve physical hazards

or other risks to health. This subsection lists,

alphabetically, some of these hazardous operations

and the materials and equipment associated with

them. Precautions necessary to avoid these

hazards are identified.

The list is not exhaustive and all operations and

procedures, and the handling of materials, should

be carried out with health and safety in mind.

Before using any product the Materials Safety Data

Sheet supplied by the manufacturer or supplier

should be consulted.

Acids and Alkalis

See also Battery Acids.

For example caustic soda, sulphuric acid.

Used in batteries and cleaning materials.

Irritant and corrosive to the skin, eyes, nose and

throat. Cause burns. Can destroy ordinary

protective clothing.

Avoid splashes to the skin, eyes and clothing. Wear

suitable protective impervious apron, gloves and

goggles. Do not breath mists.

Make sure access to eye wash bottles, shower and

soap are readily available for splashing accidents.

Display Eye Hazard sign.

Air Bags

See also Fire, Chemical Materials.

Highly flammable, explosive

- observe No Smoking

policy.

Used as a safety restraint system mounted in the

steering wheel and passenger side of the instrument panel.

The inflator contains a high-energetic propellant

which, when ignited, produces a VERY HOT GAS

(2500°C).

The gas

generant used in air bags is Sodium Azide.

This material is hermetically sealed in the module

and is completely consumed during deployment.

No attempt should be made to open an air bag inflator

as this will lead to the risk of exposure to

( '.

Sodium Azide. If a gas generator is ruptured, full

protective clothing should be worn when dealing

with the spillage.

After normal deployment, gloves and safety goggles must be worn during the handling process.

Deployed air bags should be disposed of in a

plastic bag in accordance with local regulations at

an approved chemical waste site.

Following any direct contact with gas generant.

- wash affected areas thoroughly with water.

- seek medical assistance if necessary.

Air Bags

- Do's

- Do store modules in an upright position.

- Do keep modules dry.

- Do carry modules with the cover side pointing

away from the body.

- Do place modules with their cover side upwards.

- Do carefully inspect modules for damage.

- Do stand to one side when connecting modules.

- Do make sure all test equipment is properly

calibrated and maintained.

- Do wash hands after handling deployed air

bags.

Air Bags

- Do Nots

- Do not store highly flammable material together

with modules or gas generators.

- Do not store gas generators at temperatures

exceeding 80°C.

- Do not store modules upside down.

- Do not attempt to open a gas generator housing.

- Do not expose gas generators to open flame or

sources of heat.

- Do not place anything on top of a module cover.

- Do not use damaged modules.

- Do not touch a fired module or gas generator

for at least

10 minutes.

- Do not use any electrical probes on the wiring

circuit.

Air Conditioning Refrigerant (1,

See also Chlorofluorocarbon, Chemical Materials

Highly flammable, combustible

- observe No

Smoking policy.

2006.0 Fiesta iu200s GI 7372en

procarmanuals.com

Page 29 of 1226

100-00-1 3 General Information 100-00-1 3

DESCRIPTION AND OPERATION

Do not use damaged or defective tools or

equipment, particularly high-speed equipment such

i as grinding wheels. A damaged grinding wheel can

disintegrate without warning and cause serious

injury.

Wear suitable eye protection when using grinding,

chiseling or sand blasting equipment.

Wear a suitable breathing mask when using

abrasive blasting equipment, working with

asbestos-based materials or using spraying

equipment.

Make sure there is adequate ventilation to control

dusts, mists and fumes.

High Pressure Air, Lubrication and Oil

Test Equipment

See also Lubricants and Greases.

Always keep high-pressure equipment in good

condition, and regularly maintained, particularly at

joints and unions.

Never direct a high-pressure nozzle, for example

diesel injector, at the skin as the fluid may

, penetrate to the underlying tissue, and cause

serious injury.

Halon

See CFCs.

Legal Aspects

There are many laws and regulations relating to

health and safety in the use and disposal of

materials and equipment in a workshop.

For a safe working environment and to avoid

environmental pollution, workshops should be

familiar, in detail, with the many health and safety

laws and regulations within their country, published

by both national and local authorities.

Lubricants and Greases

Avoid all prolonged and repeated contact with

mineral oils. All lubricants and greases may be

irritating to the eyes and skin.

'

Transmission Fluids

Safety instructions

Certain Transmission and Power Steering fluids

supplied to Ford may contain additives which have

the potential to cause skin disease (dermatitis) to

exposed persons. The dermatitis may be irritant

or allergic in nature. Risks are higher where

prolonged or repeated skin contact with a fluid may

occur. These fluids are used for vehicle initial

fill

and service purposes. This sub-section is to:

Inform Service personnel who may come into

contact with these vehicle fluids (hazard

communication).

Summarise appropriate workplace control

measures and personal protective equipment

requirements.

Draw attention to the existence of Material

Safety Datasheets (MSDS's) for the fluids

(available from Ford Customer Service Division).

These MSDS's contain detailed information on

hazards and appropriate controls.

Control measures

Workplace risk assessments made under national

chemical control regulations should identify

operations involving the fluids as potentially

hazardous and specify workplace control and

worker awareness measures. In such

circumstances, the relevant Material Safety

Datasheet (see the details specified below) which

specifies hazards and control measures in detail

should be made available for guidance.

Avoid unprotected skin contact with the fluids, and

in particular, avoid prolonged or repeated skin

contact. Work practices should be organised so as

to minimise the potential for skin contact. This may

include the use of drip trays, absorbents, correct

fluid handling equipment (funnels etc), and

workplace housekeeping measures such as the

cleaning of contaminated surfaces.

Personnel engaged in operations where skin

contact could occur (such as fluid draining or filling)

should wear impervious gloves made from

nitrile

rubber, certified to a chemical protection standard,

e.g. Europe Standard EN374. This glove type is

widely available from reputable suppliers of gloves

for chemical protection [including the manufacturers

Ansell-Admont

(Solvex Range), North Safety

products (North

Nitrile Latex Gloves range), and

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 36 of 1226

100-00-20 General Information 100-00-20

DESCRIPTION AND OPERATION

Towing the Vehicle

an instance, the discharged battery must

be recharged immediately after jump

A WARN1NG:When the vehicle is being starting

to avoid permanent damage. ( towed, the ignition switch must be in - Always make sure that the jumper cables are

position ll (steering lock released and adequate for the task. Heavy duty cables must

warning lamps illuminated). Only then will be used.

the turn signal lamps, horn and - Always make sure that the slave battery is of stop lamps be operational. Failure to follow the same voltage as the vehicle battery. The these instructions may result in personal batteries must be connected in parallel. injury. - Always make sure that switched electric circuits

N0TE:The removable towing eye (if equipped),

are switched off before connecting jumper

has a left-hand thread and must be fully tightened cables. This reduces the risk of arcing occurring

before towing can commence.

when the final connection is made.

When towing is necessary, the vehicle towing eyes

should be used. The rope must be securely

fastened to the towing eyes and must also be

attached to the other vehicle such that the rope will

not foul the bodywork.

When a vehicle with automatic transmission is

towed, the gear selector must be in position

N

(Neutral). Never tow a vehicle with automatic

transmission at a speed greater than 30 mph (50

kmlh) or for a distance greater than 30 miles (50

km). If it is necessary to tow the vehicle a greater

distance, the drive wheels must be lifted clear off

the ground.

I A WARN1NG:Make sure that the ends of the Alternatively the vehicle can be transported on a jumper cables do not touch each other or low loader or a trailer. ground against the vehicle body at any

time while the cables are attached to the

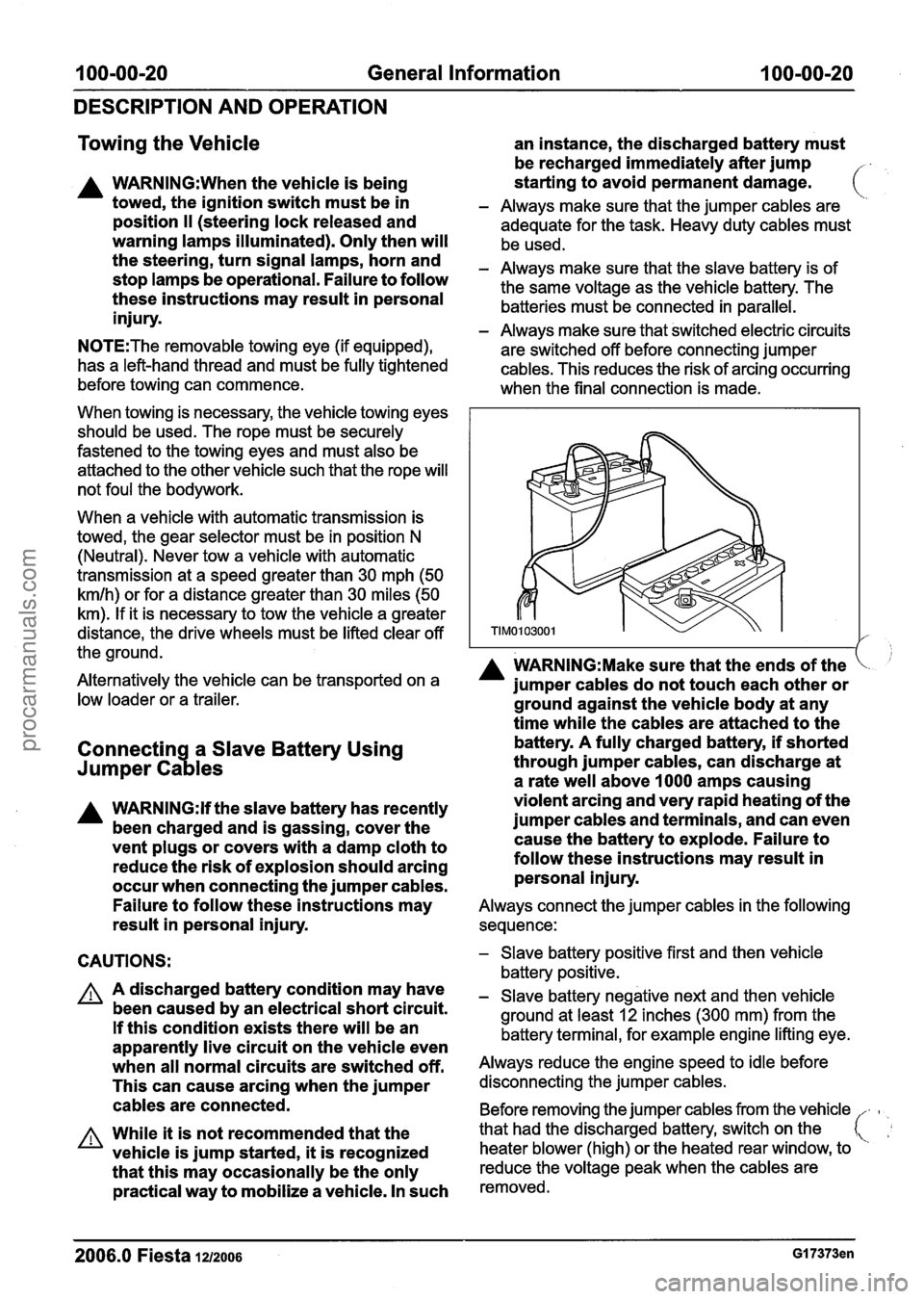

Connectin a Slave Battery Using

73

battery. A fully charged battery, if shorted

Jumper Ca les through jumper cables, can discharge at

a rate well above

I000 amps causing

A WARNING:H the slave battery has recently violent arcing

and very rapid heating of the

been charged and is gassing, cover the jumper cables and

terminals, and can even

vent plugs or covers with a damp cloth to cause

the battery to explode. Failure to

reduce the risk of explosion should arcing follow

these instructions may result in

occur when connecting the jumper cables. personal injury.

Failure to follow these instructions may

Always connect the jumper cables in the following

result in personal injury. sequence:

CAUTIONS:

A A discharged battery condition may have

been caused by an electrical short circuit.

If this condition exists there will be an

apparently live circuit on the vehicle even

when all normal circuits are switched off.

This can cause arcing when the jumper

cables are connected.

A While it is not recommended that the

vehicle is jump started,

it is recognized

that this may occasionally be the only

practical way to mobilize a vehicle. In such

- Slave battery positive first and then vehicle

battery positive.

- Slave battery negative next and then vehicle

ground at least

12 inches (300 mm) from the

battery terminal, for example engine lifting eye.

Always reduce the engine speed to idle before

disconnecting the jumper cables.

Before removing the jumper cables from the vehicle

-

heater blower (high) or the heated rear window, to

that

had the discharged battery, switch on the

reduce the voltage peak when the cables are

removed.

2006.0 Fiesta 1~12006 GI 7373en

procarmanuals.com

Page 40 of 1226

100-00-24 General Information 100-00-24

DESCRIPTION AND OPERATION

- that the speedometer, coolant temperature - oil, coolant, hydraulic, air and fuel leaks.

gauge and tachometer (if equipped) register the - abnormal temperature of any moving

correct readings and operate correctly.

components or assemblies, for example wheel

(

- that the switches and controls operate smoothly hubs, transmission and axle, which might

and positively, warning and indicator lamps

indicate over tightness or lack of lubrication.

operate correctly and the direction indicator

control self cancels when the steering is

returned to the straight ahead position.

- that the heating and ventilation systems operate

correctly and effectively.

- the brake operation and efficiency.

Brake Testing

A WARNING:When brake testing, avoid

breathing the fumes from hot brakes, this

may contain asbestos dust which is

hazardous to health. Failure to follow this

instruction may result in personal injury.

For additional information, refer to: Health

and Safety Precautions

(1 00-00 General

Information, Description and Operation).

CAUTIONS:

A Avoid brake testing on busy roads where

it may cause inconvenience or danger to

other road users.

A Brake testing which includes heavy brake

applications should not be carried out with

new brake

padsldiscs or liningsldrums

until the components have bedded-in. New

brake friction components will not reach

full efficiency until the bedding-in process

is complete.

Test the brakes at several speeds within the normal

operating range using both light and heavy pedal

pressure. Note any tendency to snatch, pull or

drag, and any undue delay in application or

release.

Allow the vehicle to coast and note any tendency

to pull to one side, or evidence that the brakes are

binding.

After stopping the vehicle (not immediately after a

period of heavy braking), carefully check the brake

temperature.

A brake disc or brake drum that feels

hot or is appreciably hotter than the others,

indicates that the brake is binding.

After completion of the test, check for:

2006.0 Fiesta 1212006 GI 7375en

procarmanuals.com

Page 62 of 1226

100-04-6 Noise, Vibration and Harshness 100-04-6

DIAGNOSIS AND TESTING

2. AccelerationIDeceleration: With slow

acceleration and deceleration, a shake is

sometimes noticed in the steering

wheellcolumn,

seats, front floor panel, front door trim panel or

front end sheet metal. It is a low frequency

vibration (around

9-1 5 cycles per second). It

may or may not be increased by applying the

brakes lightly. REFER to

Idle

BoomIShakeNibration in the Driveline Noise

and Vibration Symptom Chart.

High Speed: A vibration is felt in the front floor

panel or seats with no visible shake, but with

an accompanying sound or rumble, buzz, hum,

drone or booming noise. Coast with the clutch

pedal depressed (manual transmission) or shift

control selector lever in "N" (NEUTRAL)

(automatic transmission) and engine idling. If

vibration is still evident, it may be related to

wheels, tires, front brake discs, wheel hubs or

front wheel bearings. REFER to Shake and

Vibration While Driving in the Driveline Noise

and Vibration Symptom Chart.

4. Engine rpm Sensitive: A vibration is felt

whenever the engine reaches a particular rpm.

It will disappear in neutral coasts. The vibration

can be duplicated by operating the engine at

the problem rpm while the vehicle is stationary.

It can be caused by any component, from the

accessory drive belt to the clutch or torque

converter which turns at engine speed when the

vehicle is stopped. REFER to Shake and

Vibration While Driving in the Driveline Noise

and Vibration Symptom Chart.

5. Noise and Vibration While Turning: Clicking,

popping or grinding noises may be due to the

following:

worn, damaged or incorrectly installed front

wheel bearing.

damaged

powertrainldrivetrain mounts.

Road Conditions

An experienced technician will always establish a

route that will be used for all NVH diagnosis road

tests. The road selected should be reasonably

smooth, level and free of undulations (unless a

particular condition needs to be identified). A

smooth asphalt road that allows driving over a

range of speeds is best. Gravel or bumpy roads

are unsuitable because of the additional road noise produced.

Once the route is established and

consistently used, the road noise variable is

eliminated from the test results.

N0TE:Some concerns may be apparent only on

smooth asphalt roads.

If a customer complains of a noise or vibration on

a particular road and only on a particular road, the

source of the concern may be the road surface. If

possible, try to test the vehicle on the same type

of road.

Vehicle Preparation

Carry out a thorough visual inspection of the

vehicle before carrying out the road test. Note

anything which is unusual. Do not repair or adjust

any condition until the road test is carried out,

unless the vehicle is inoperative or the condition

could pose a hazard to the technician. After

verifying that the condition has been corrected,

make sure all components removed have been

installed.

Power Steering Conditions

c !

Check for the noise in the following conditions to

verify the customer concern.

Check for the noise in several temperature

conditions.

Is the noise from when the vehicle was new?

Can the noise be repeated constantly or is it

random?

Check the condition of the vehicle age, mileage

and service record.

Interview the customer to find the operating

condition in which the noise will occur. Test the

vehicle based on the

detail(s) from the customer

interview.

Follow the power steering operation noise

condition tables below, to find which condition

the noise will occur.

Power Steering Operation Noise Check

Step 1 : Check for NVH concerns from non-steering

components, which may sound like noises coming

from the steering system.

I:. ':

2006.0 Fiesta 121zoo6 G37349en

procarmanuals.com

Page 64 of 1226

I 00-04-8 Noise, Vibration and Harshness 100-04-8

DIAGNOSIS AND TESTING

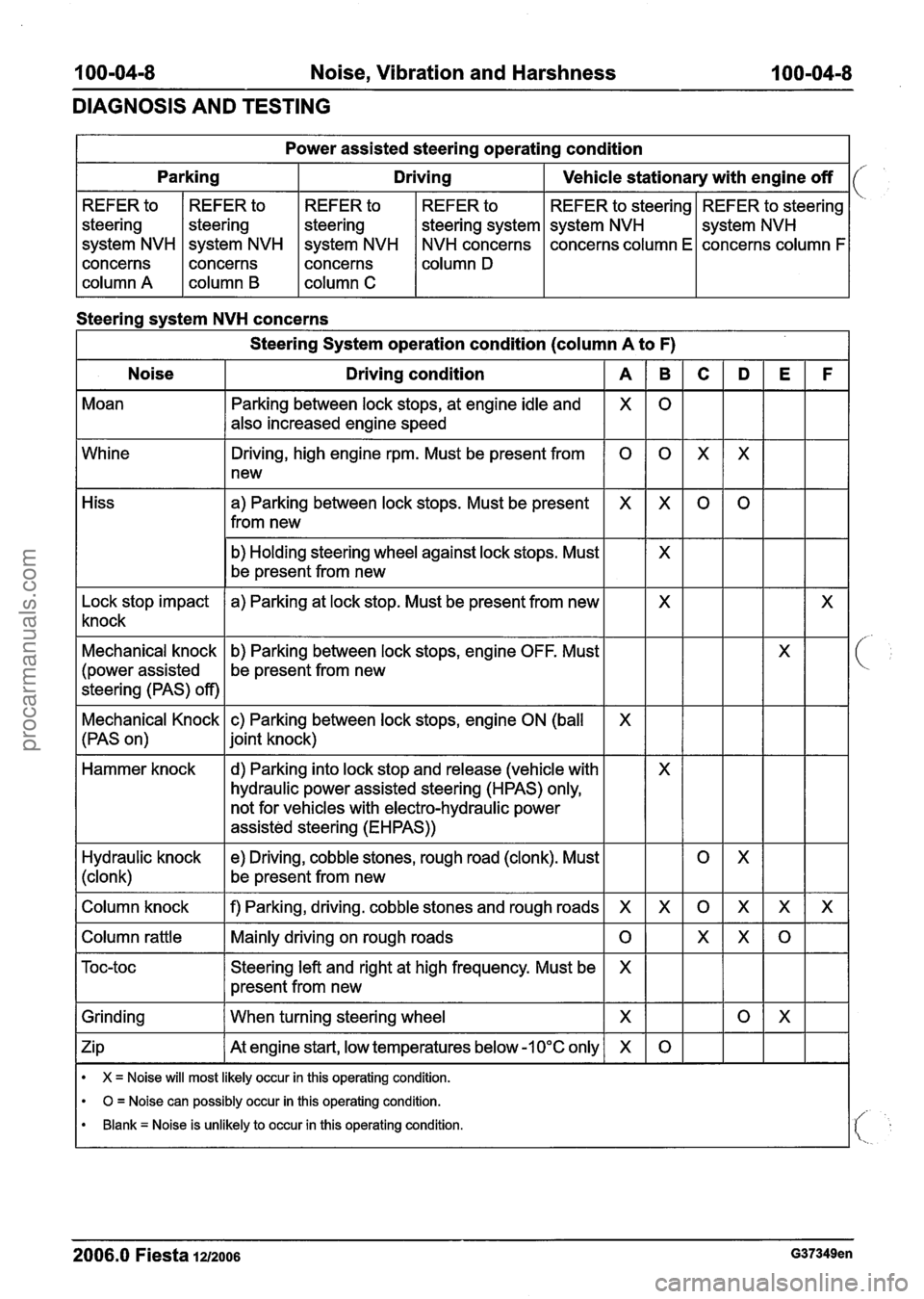

Steering system NVH concerns Power

assisted steering operating condition

I Steering System operation condition (column A to F) 1

Noise I Driving condition I A

Parking

Moan REFER

to

steering

system NVH

concerns

column A REFER

to

steering

system NVH

concerns

column

B

Driving

Whine REFER

to

steering

system NVH

concerns

column C

Vehicle stationary with engine off

Parking between lock stops, at engine idle and

also increased engine speed REFER

to

steering system

NVH concerns

column

D

REFER to steering

system NVH

concerns column E

X

Hiss REFER

to steering

system NVH

concerns column F

Driving, high engine rpm. Must be present from

1 new

0

b) Holding steering wheel against lock stops. Must

be present from new

a) Parking between lock

stops. Must be present

from new

X

Lock stop impact

knock a) Parking

at lock stop. Must be present from new

Mechanical knock

(power assisted

steering (PAS) off) b)

Parking between lock stops, engine OFF. Must

be present from new

Mechanical Knock c) Parking between lock stops, engine

ON (ball

(PAS on)

1 joint knock)

X

Hammer knock

Column knock

I f) Parking, driving. cobble stones and rough roads I X

- -

d) Parking into lock stop and release (vehicle

hydraulic power assisted steering (HPAS) only,

not for vehicles with electro-hydraulic power

assisted steering (EHPAS))

Hydraulic knock

(clonk)

Column rattle I Mainly driving on rough roads 1 0

e) Driving, cobble stones, rough road (clonk). Must

be present from new

Grinding

I When turning steering wheel I

Steering left and right at high frequency. Must be

present from new

Zip

I At engine start, -1 0°C only I X

X

X = Noise will most likely occur in this operating condition.

0 = Noise can possibly occur in this operating condition.

Blank = Noise is unlikely to occur in this operating condition.

2006.0 Fiesta 1212006 G37349en

procarmanuals.com

Page 65 of 1226

100-04-9 Noise, Vibration and Harshness 1 00-04-9

DIAGNOSIS AND TESTING

Step 3: According to each identified operating

condition (Column A, B,

C, D, E, F), check each

possible Steering System

NVH concern with the

detail symptom charts below.

Before conducting a vehicle test to identify a

NVH

concern carry out the following checks.

1. Check the tire pressures and adjust to

specification, as necessary.

2. Make sure the steering system fluid is correct,

the system is free of leaks and is operating

correctly.

3. Make sure the vehicle steering system

temperature is the same as described at the

customer interview.

4. All evaluations must take place in a relatively

quiet location.

5. The heating

- air conditioning (AIC) fan and

radio must be turned off during evaluations and

the windows closed.

Symptom Chart

Power Steering Moan Noise

Test Condition

Listen for steering moan noise with the vehicle

parked, transmission in neutral and all windows

closed in the following test conditions.

1. Engine speed at idle with no steering action.

2. Engine speed at idle with slow 90 degrees per

second turning of the steering wheel.

3. Engine speed at 1250 +I- 50 rpm with no

steering action.

4. Engine speed at 1250 +I- 50 rpm with slow 90

degrees per second turning of the steering

wheel.

2006.0 Fiesta 12/2006 G37349en

procarmanuals.com

Page 66 of 1226

100-04-1 0 Noise, Vibration and Harshness 100-04-10

DIAGNOSIS AND TESTING

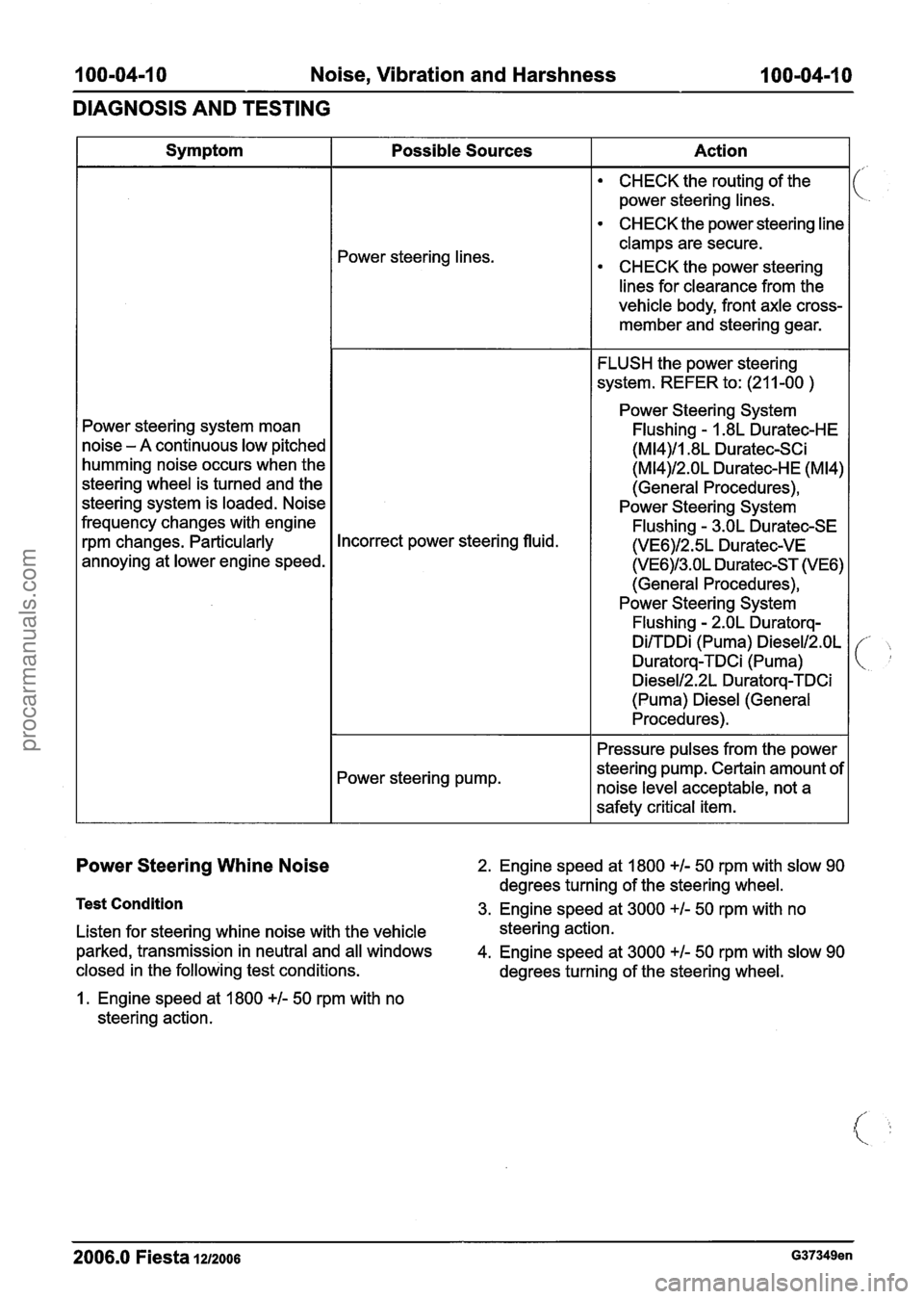

Power Steering Whine Noise 2. Engine speed at 1800 +/- 50 rpm with slow 90

degrees turning of the steering wheel.

Test Condition 3. Engine speed at 3000 +I- 50 rpm with no

Listen for steering whine noise with the vehicle steering action.

parked, transmission in neutral and all windows

4. Engine speed at 3000

+I- 50 rpm with slow 90

closed in the following test conditions. degrees turning of the steering wheel.

1. Engine speed at 1800

+I- 50 rpm with no

steering action. Symptom

Power steering system moan

noise

- A continuous low pitched

humming noise occurs when the

steering wheel is turned and the

steering system is loaded. Noise

frequency changes with engine

rpm changes. Particularly

annoying at lower engine speed.

2006.0 Fiesta 1212006 G37349en

Possible Sources

Power steering lines.

Incorrect power steering fluid.

Power steering pump. Action

CHECK

the routing of the

power steering lines.

CHECK the power steering line

clamps are secure.

CHECK the power steering

lines for clearance from the

vehicle body, front axle cross-

member and steering gear.

FLUSH the power steering

system. REFER to: (21 1-00

)

Power Steering System

Flushing

- I .8L Duratec-HE

(M14)/1.8L Duratec-SCi

(M14)/2.OL Duratec-HE (M14)

(General Procedures),

Power Steering System

Flushing

- 3.OL Duratec-SE

(VE6)/2.5L Duratec-VE

(VE6)/3.OL Duratec-ST (VE6)

(General Procedures),

Power Steering System

Flushing

- 2.OL Duratorq-

DirrDDi (Puma) Diesel12.0L

Duratorq-TDCi (Puma)

Diesell2.2L Duratorq-TDCi

(Puma) Diesel (General

Procedures).

Pressure pulses from the power

steering pump. Certain amount of

noise level acceptable, not a

safety critical item.

procarmanuals.com