sensor FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 956 of 1226

303-1 4-32 Electronic Engine Controls 303-1 4-32

REMOVAL AND INSTALLATION

Crankshaft Position (CKP) Sensor

General Equipment A~i~hten the M6 x 18 mm bolt finger-tight L,. '

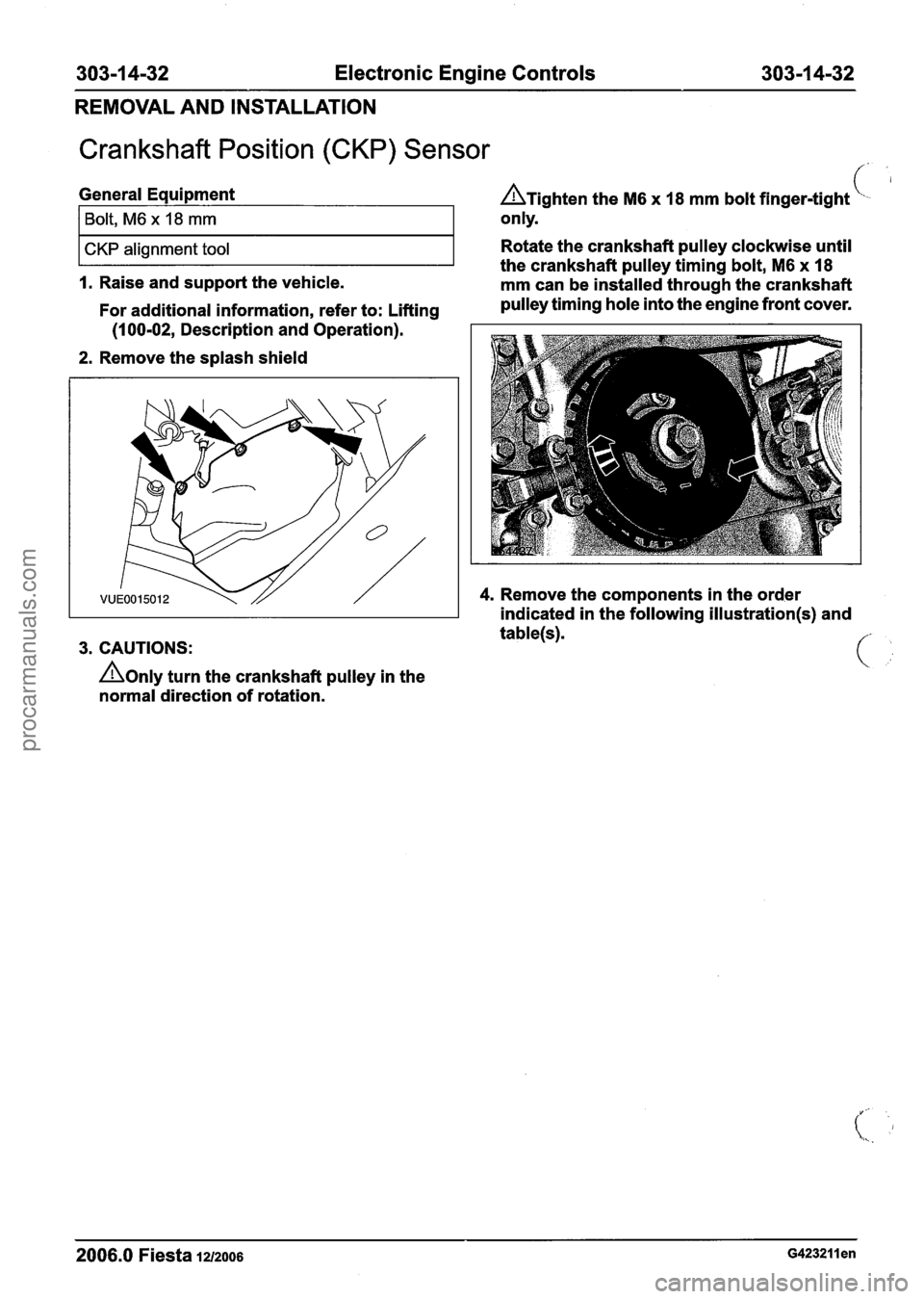

2. Remove the splash shield

I ~olt, ~6 x 18 mm

CKP alignment tool

3. CAUTIONS: only.

Rotate the crankshaft pulley clockwise until

A0nly turn the crankshaft pulley in the

normal direction of rotation. the

crankshaft pulley timing bolt,

M6 x 18

I. Raise and support the vehicle.

mm can be installed through the crankshaft

For additional information, refer to: Lifting pulley

timing hole into the engine front cover.

(1 00-02, Description and Operation).

4. Remove the components in the order

indicated in the following

illustration(s) and

2006.0 Fiesta 1212006 ~423211 en

procarmanuals.com

Page 957 of 1226

303-1 4-33 Electronic Engine Controls 303-1 4-33

REMOVAL AND INSTALLATION

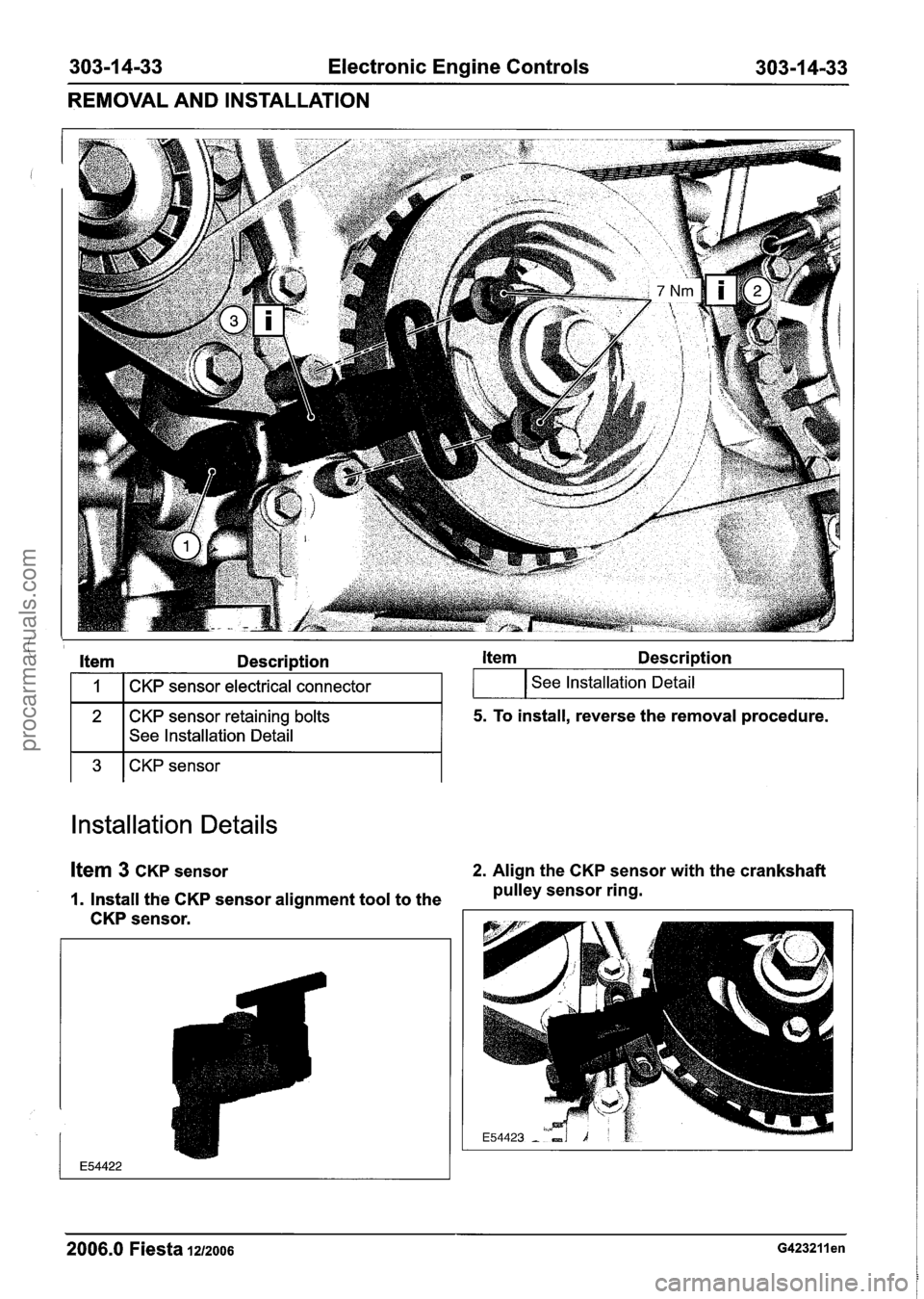

Item Description Item Description

1 3 1 CKP sensor

I 1 I CKP sensor electrical connector

2

Installation Details

I See Installation Detail

Item 3 CKP sensor 2. Align the CKP sensor with the crankshaft

1. Install the CKP sensor alignment tool to the pulley

sensor ring.

CKP sensor.

CKP sensor retaining bolts

See Installation Detail

2006.0 Fiesta 1212006 ~423211 en

I I J

5. To install, reverse the removal procedure.

procarmanuals.com

Page 958 of 1226

303-1 4-34 Electronic Engine Controls 303-1 4-34

REMOVAL AND INSTALLATION

Item 2 CKP sensor retaining bolts

I. Install the CKP sensor retaining bolts.

2. Remove the CKP sensor alignment tool.

2006.0 Fiesta iz1~006 ~423211 en

procarmanuals.com

Page 959 of 1226

303-1 4-35 Electronic Engine Controls 303-1 4-35

REMOVAL AND INSTALLATION

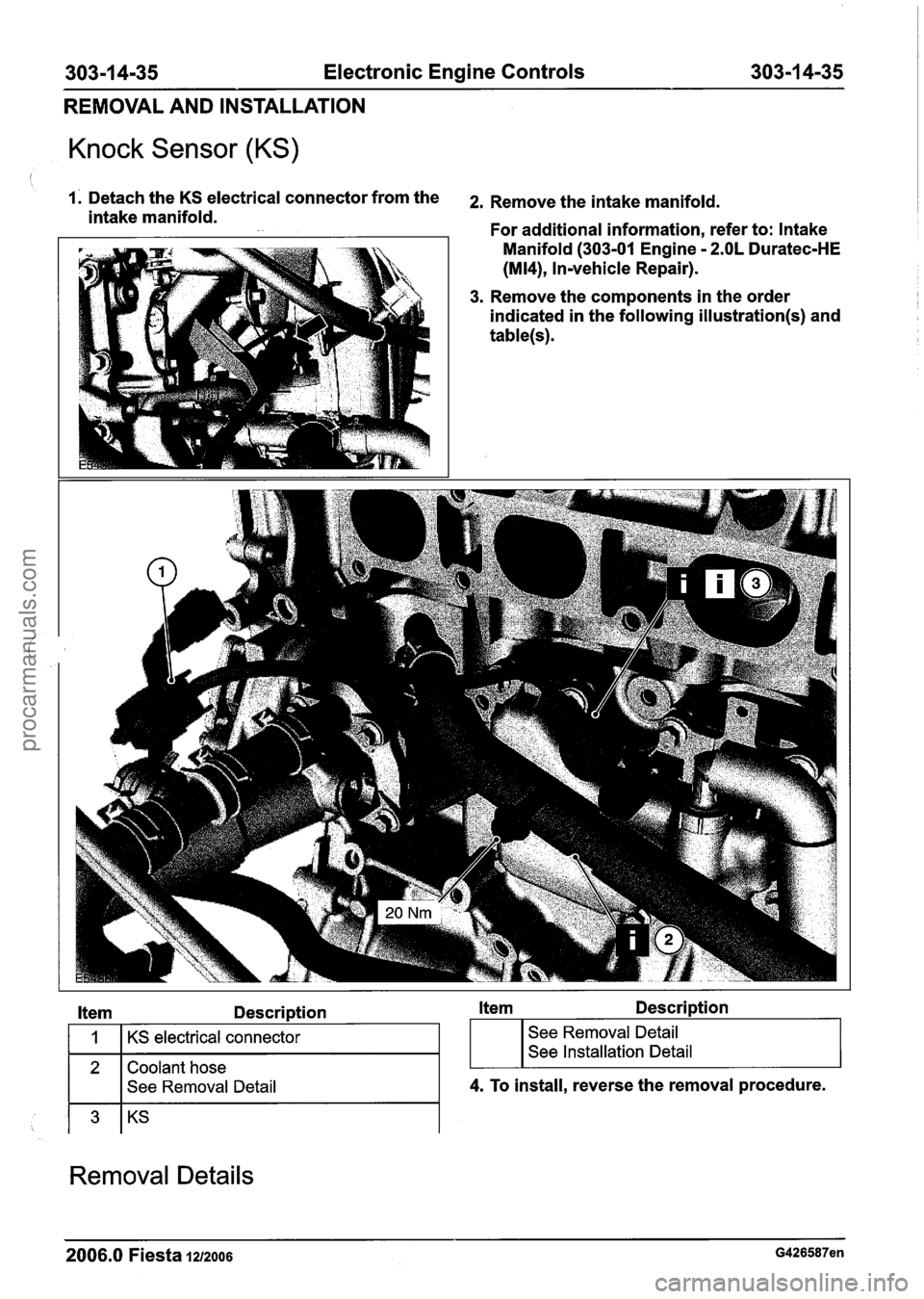

Knock Sensor (KS)

1. Detach the KS electrical connector from the 2, Remove the intake manifold. intake manifold.

For additional information, refer to: Intake

1 Manifold (303-01 Engine - 2.OL Duratec-HE

(M14), Invehicle Repair).

3. Remove the components in the order

indicated in the following

illustration(s) and

table(s).

Item Description Item Description

2 Coolant hose

I I See Removal Detail

1

I I

4. To install, reverse the removal procedure.

KS electrical connector

Removal Details

; I I

See Removal Detail

See Installation Detail

2006.0 Fiesta 1212006 G426587en

procarmanuals.com

Page 961 of 1226

Automatic Transmission/Transaxle .

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40)

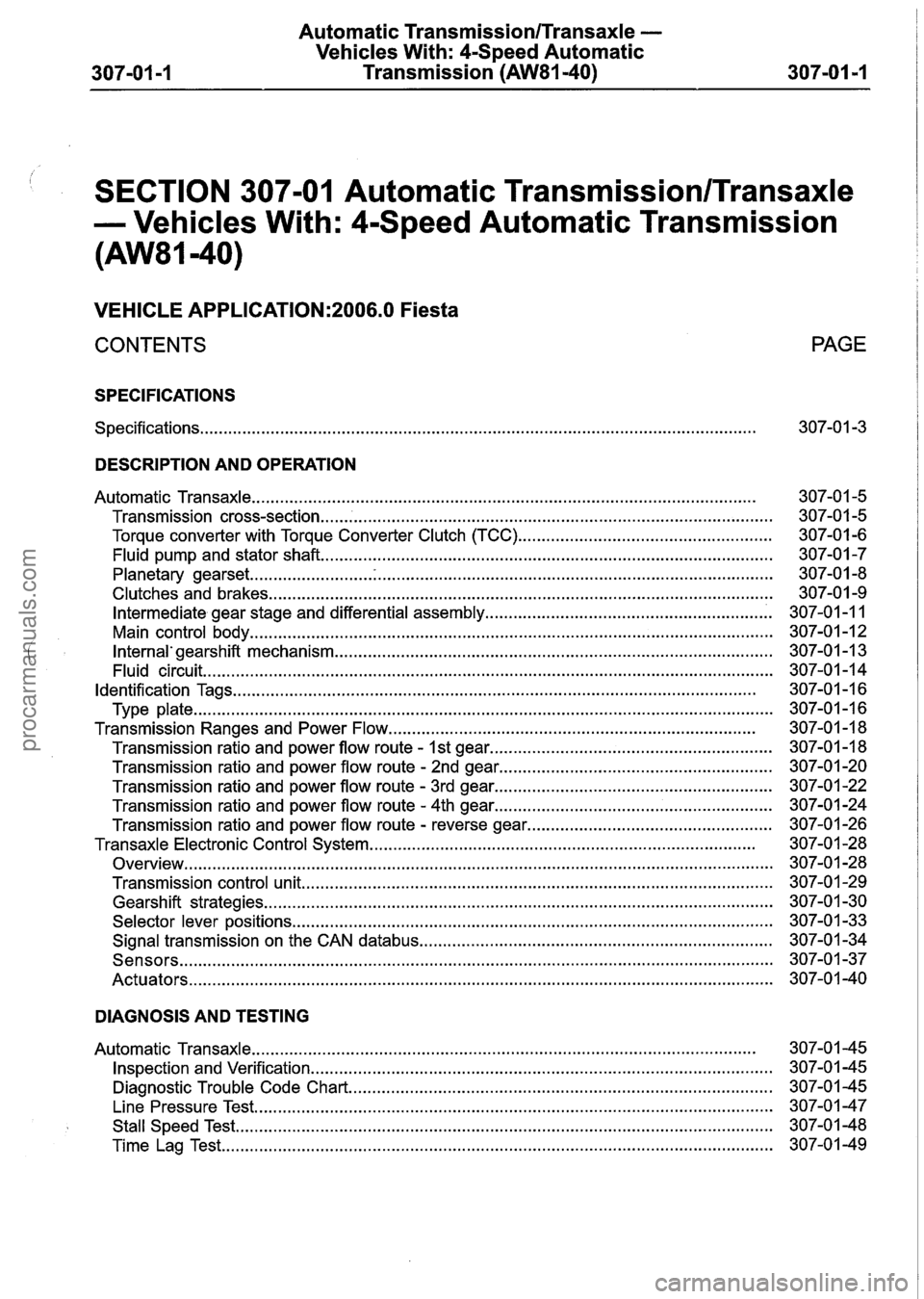

SECTION 307-01 Automatic Transmission/Transaxle

. Vehicles With: 4-Speed Automatic Transmission

(AW81-40)

VEHICLE APPLICATION:2006.0 Fiesta

CONTENTS PAGE

SPECIFICATIONS

Specifications

........................................................................\

.............................................. 307-0 1 -3

DESCRIPTION AND OPERATION

Automatic Transaxle

........................................................................\

...................................

Transmission cross-section ........................................................................\

........................

Torque converter with Torque Converter Clutch (TCC) ......................................................

Fluid pump and stator shaft ........................................................................\

........................

........................................................................\

......... Planetary gearset ......................... .:

Clutches and brakes ........................................................................\

...................................

Intermediate gear stage and differential assembly .............................................................

Main control body ........................................................................\

.......................................

Internal' gearshift mechanism ........................................................................\

.....................

Fluid circuit ........................................................................\

.................................................

........................................................................\

....................................... Identification Tags

Type plate

........................................................................\

...................................................

Transmission Ranges and Power Flow ........................................................................\

......

Transmission ratio and power flow route - 1st gear ............................................................

Transmission ratio and power flow route - 2nd gear ..........................................................

Transmission ratio and power flow route . 3rd gear ...........................................................

Transmission ratio and power flow route . 4th gear ...........................................................

Transmission ratio and power flow route . reverse gear ....................................................

Transaxle Electronic Control System ........................................................................\

..........

........................................................................\

..................................................... Overview

Transmission control unit

........................................................................\

............................

........................................................................\

.................................... Gearshift strategies

Selector lever positions

........................................................................\

..............................

Signal transmission on the CAN databus ........................................................................\

...

........................................................................\

...................................................... Sensors

........................................................................\

.................................................... Actuators

DIAGNOSIS AND TESTING

Automatic Transaxle

........................................................................\

................................... 307-01

Inspection and Verification ........................................................................\

.................... 307-01

Diagnostic Trouble Code Chart

........................................................................\

.................. 307-01

........................................................................\

...................................... Line Pressure Test 307-01

Stall Speed Test

........................................................................\

....................................... 307-01

Time Lag Test

........................................................................\

............................................. 307-01

procarmanuals.com

Page 962 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40)

GENERAL PROCEDURES /' -

.. Transmission Fluid Level Check.. ........................................................................\

............... 307-01 - k

........................................................................\

............ Transmission Fluid Drain and Refill 307-01 -53

IN-VEHICLE REPAIR

........................................................................\

.............. Transmission Range (TR) Sensor 307-01 -55

Halfshaft Seal LH.. ........................................................................\

...................................... 307-01 -58

Halfshaft Seal RH ........................................................................\

....................................... 307-01 -59

Turbine Shaft Speed (TSS) Sensor ........................................................................\

......... 307-01-60

Vehicle Speed Sensor (VSS).. ........................................................................\

................ 307-01 -61

REMOVAL AND INSTALLATION

Transaxle.. ........................................................................\

.................................................. 307-01 -62

procarmanuals.com

Page 963 of 1226

Automatic TransmissionlTransaxle -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40)

SPECIFICATIONS

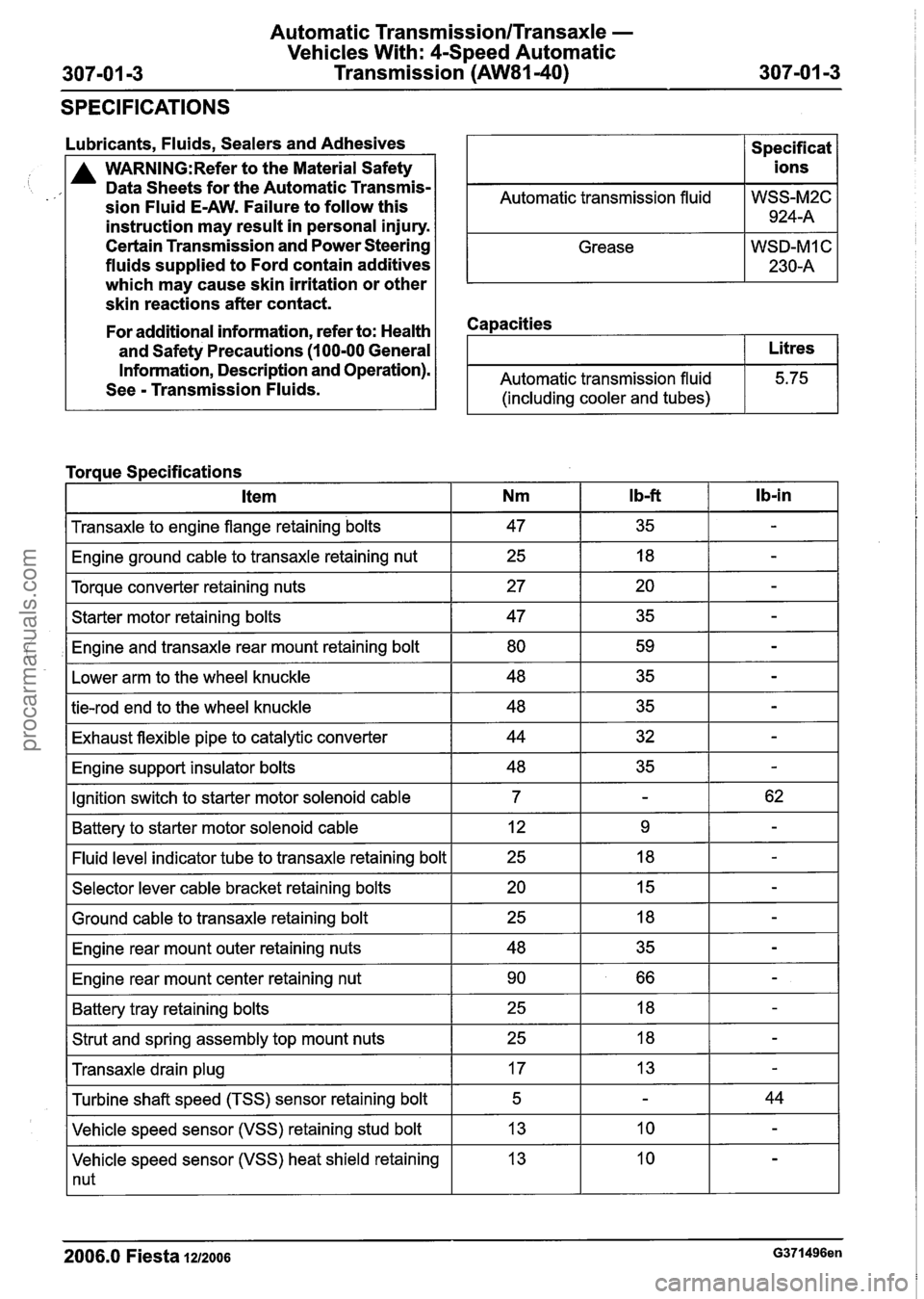

Lubricants, Fluids, Sealers and Adhesives

A WARN1NG:Refer to the Material Safety

Data Sheets for the Automatic Transmis-

sion Fluid E-AW. Failure to follow this

instruction may result in personal injury.

Certain Transmission and Power Steering

fluids supplied to Ford contain additives

which may cause skin irritation or other

skin reactions after contact.

Automatic transmission fluid

Grease

Capacities

Specif icat

ions

WSS-M2C 924-A

WSD-MI C

230-A

For additional information, refer to: Health

and Safety Precautions

(1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids. Automatic transmission fluid

(including cooler and tubes)

I Transaxle to engine flange retaining bolts I 47 I 35 I - I

Litres

5.75

Torque Specifications

I Engine ground cable to transaxle retaining nut I 25 I 18 I - I

I Torque converter retaining nuts I 27 I 20 I - I

lb-in Item

I Starter motor retaining bolts I 47 I 35 I - I

,I Engine and transaxle rear mount retaining bolt I 80 I 59 I - I

Nm

I Lower arm to the wheel knuckle I 48 I 35 I - I

I b-ft

I tie-rod end to the wheel knuckle I 48 I 35 I - I

I Exhaust flexible pipe to catalytic converter I 44 I 32 I - I

I Engine support insulator bolts I 48 I 35 I - I

IGnition switch to starter motor solenoid cable I 7 I - I 62 I

I Battery to starter motor solenoid cable I 12 I 9 I - I

-I indicator tube to transaxle retaining bolt I 25 I 18 I - I

I Selector lever cable bracket retaining bolts I 20 I 15 I - I - -

I Ground cable to transaxle retaining bolt

I Engine rear mount outer retaining nuts

I Engine rear mount center retaining nut I 90 I 66 I - I

I Battery tray retaining bolts I 25 I 18 I - I

I Strut and spring assembly top mount nuts I 25 I 18 I - I - -

Transaxle drain plug

Vehicle speed sensor (VSS) heat shield retaining

1 nut

Turbine

shaft speed (TSS) sensor retaining bolt

Vehicle speed sensor (VSS) retaining stud bolt

2006.0 Fiesta 1212006 G371496en

17

5

13 13 -

-

10

44

-

procarmanuals.com

Page 964 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40)

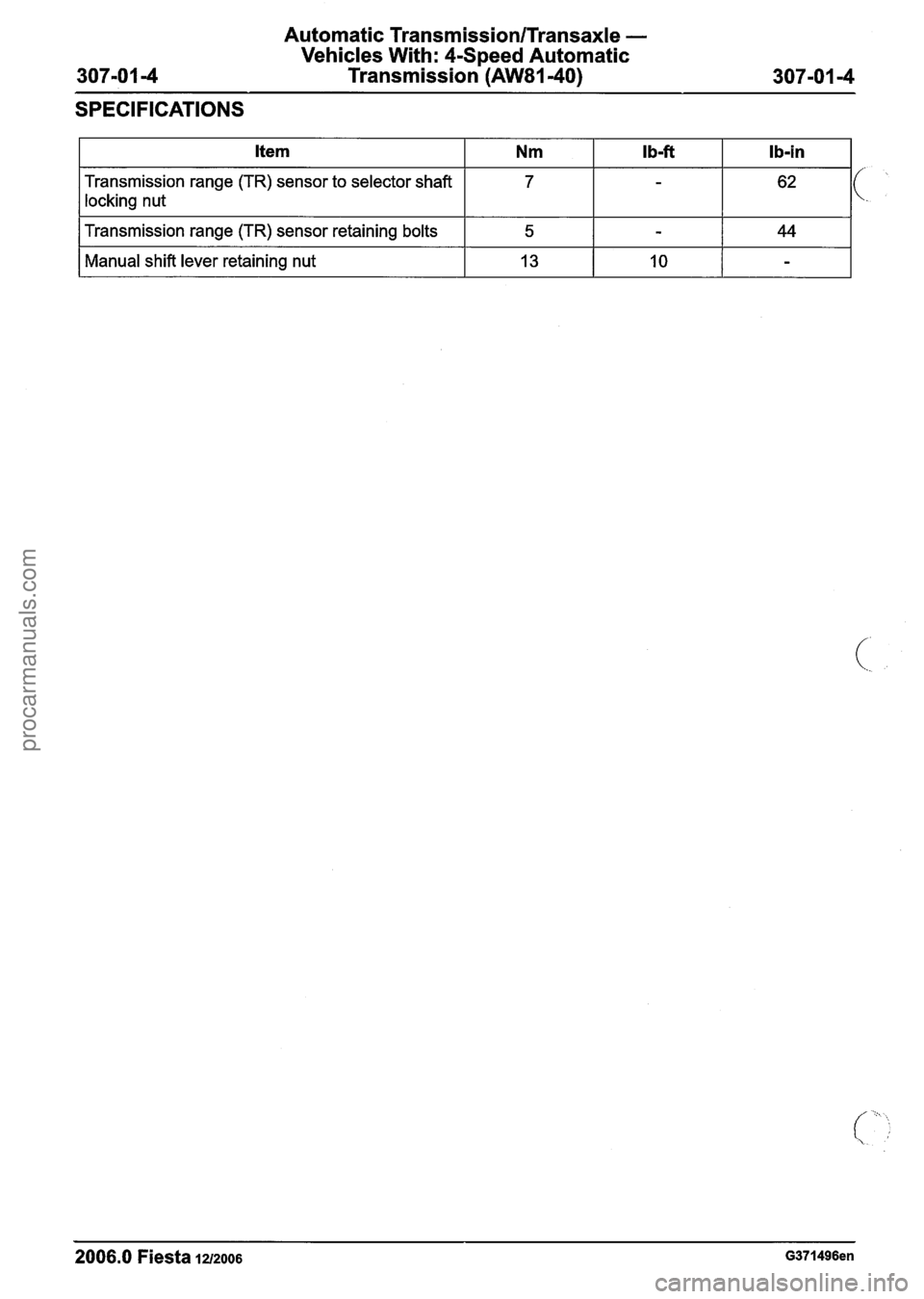

SPECIFICATIONS

Transmission range (TR) sensor to selector shaft 7 -

locking nut

I Transmission range (TR) sensor retaining bolts I 5 I - I 44 I

I Manual shift lever retaining nut I 13 I 10 I - I

2006.0 Fiesta 1212006 G371496en

procarmanuals.com

Page 989 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission (AW81-40)

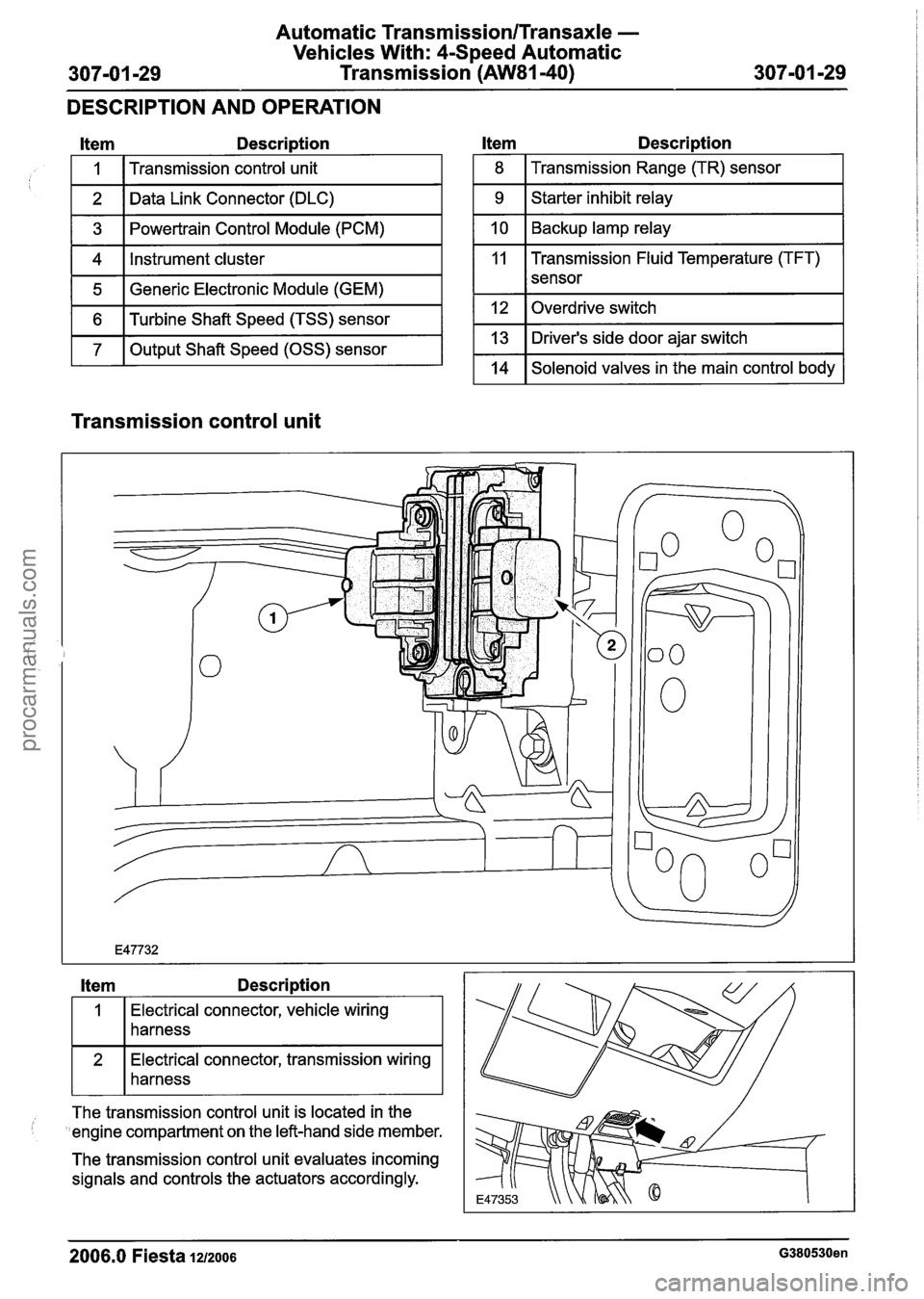

DESCRIPTION AND OPERATION

Item Description

1 5 1 Generic Electronic Module (GEM) I

I

1 6 1 Turbine Shaft Speed (TSS) sensor I

1 7 1 Output Shaft Speed (OSS) sensor I

1

2

3

4

l tem Description

Transmission control unit

Data Link Connector (DLC)

Powertrain Control Module (PCM)

Instrument cluster

1 8 I Transmission Range (TR) sensor I

1 9 1 Starter inhibit relay I

1 10 1 Backup lamp relay I

11 Transmission Fluid Temperature (TFT)

I I sensor

1 12 loverdrive switch I

1 13 1 Driver's side door ajar switch I

1 14 1 Solenoid valves in the main control body 1

Transmission control unit

Item Description

Electrical connector, vehicle wiring

harness

connector, transmission wiring

harness

--

The transmission control unit is located in the

'engine compartment on the left-hand side member.

The transmission control unit evaluates incoming

signals and controls the actuators accordingly.

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 992 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -32 Transmission

(AW81-40) 307-01 -32

DESCRIPTION AND OPERATION

This is influenced by the following variables:

Engine speed,

Engine load,

Transmission input speed,

Vehicle speed.

The following are actuated:

PCM (torque reduction request signal via the

CAN databus).

Pressure control during gearshifts

In order to ensure that the engagement of the

clutches and brakes is as judder-free as possible,

the main line pressure is reduced during gearshifts.

This is influenced by the following variables:

Enginespeed,

Engine load,

Transmission input speed,

Vehicle speed.

The following are actuated:

Main regulating valve.

Shift timing adaptation during upshifts

In order to ensure that the engagement of the

clutches and brakes is as judder-free as possible,

the timing of the gearshift processes is monitored

during upshifts.

In the event of any discrepancy from the target

values, the main line pressure is adapted

accordingly during the next gearshift.

The shift timing adaptation during upshifts is only

active at transmission fluid temperatures between

50

"C and 120 "C.

This is influenced by the following variables:

Engine load,

Accelerator pedal position,

Transmission input speed,

Vehicle speed,

Transmission fluid temperature,

Selector lever position.

The following are actuated:

Main regulating valve.

Shift timing adaptation during shifts from

3rd to 4th gear

The shift from 3rd gear into 4th gear is the only

gearshift during which a clutch is disengaged and

a brake is engaged simultaneously.

In order to control the synchronized switching of

the two components as exactly as possible, the

shifl timing solenoid valve is actuated accordingly.

In order to ensure that this particular gearshift is

performed as judder-free as possible throughout

the service life of the transmission, the gearshift is

monitored by the two rotational speed sensors and

the actuation of the shift timing solenoid valve is

adapted accordingly.

The shift timing adaptation for gearshifts from 3rd

gear into 4th gear is only active at transmission

fluid temperatures between 30

"C and 120 "C.

This is influenced by the following variables:

Engine load,

Accelerator pedal position,

Transmission input speed,

Vehicle speed,

Transmission fluid temperature,

Selector lever position.

The following are actuated:

Shift timing solenoid valve.

Shift timing adaptation during shifts from

4th to 3rd gear

The shift from 4th gear into 3rd gear is the only

gearshift during which a brake is disengaged and

a clutch is engaged simultaneously.

In order to control the engagement of the clutch as

precisely as possible, the main regulating valve is

actuated accordingly in order to build up the

actuating pressure at exactly the right time.

In order to ensure that this particular gearshift is

performed as judder-free as possible throughout

the service life of the transmission, the gearshift is

monitored by the two rotational speed sensors and

the actuation of the main regulating valve is

adapted accordingly.

The shift timing adaptation for gearshifts from 4th

-

gear into 3rd gear is only active at transmission (

fluid temperatures between 20 "C and 120 "C. .

2006.0 Fiesta 1212006 G380530en

procarmanuals.com