brake FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 1003 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -43 Transmission (AW81-40) 307-01 -43

DESCRIPTION AND OPERATION

Backup lamp relay

The backup lamp relay is located in the relay box results inthe locking pin being pulled back, and

in the engine compartment. the

selector lever can be moved out of "P".

Item Description When the ignition is switched on, the selector lever

i 1 When the selector lever is in position "R the The ground connection to the solenoid for

the . , backup lamp relay receives a ground signal from ignition key removal inhibitor is also made via the

the TR sensor and actuates the backup lamps as selector lever lock solenoid in all selector lever

a result. positions except "P".

1

Consequences of signal failure:

backup lamps inoperative. Backup lamp relay

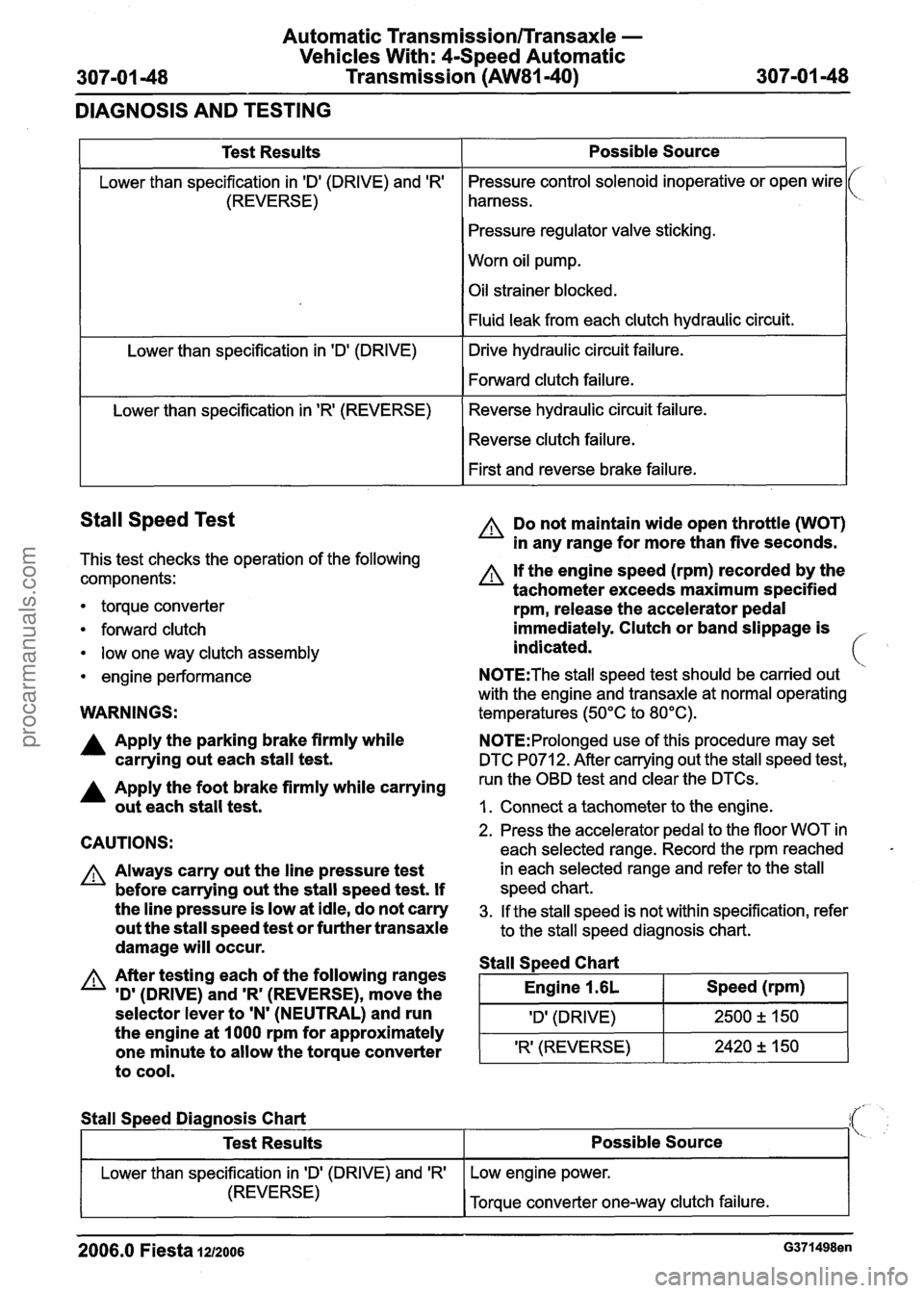

Selector

lever lock solenoid

lock solenoid is actuated by depressing the brake

pedal (sianal from the stoplamp switch). This

Item Description

1 I Locking pin

The selector lever lock solenoid is part of the

selector lever. Consequences of signal failure:

If the signal from the

stoplamp switch is missing

or the ground connection is interrupted, then

the selector lever can no longer be moved out

of the position

"P".

The selector lever lock can be manually released

by removing the cover and pressing a suitable

object into the opening on the selector lever until

the selector lever can be moved out of the position

IIPlr.

The selector lever then re-locks if it is moved back

to "P".

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 1008 of 1226

Automatic TransmissionlTransaxle -

Vehicles With: 4-Speed Automatic

307-01 -48 Transmission (AW81-40) 307-01 -48

DIAGNOSIS AND TESTING

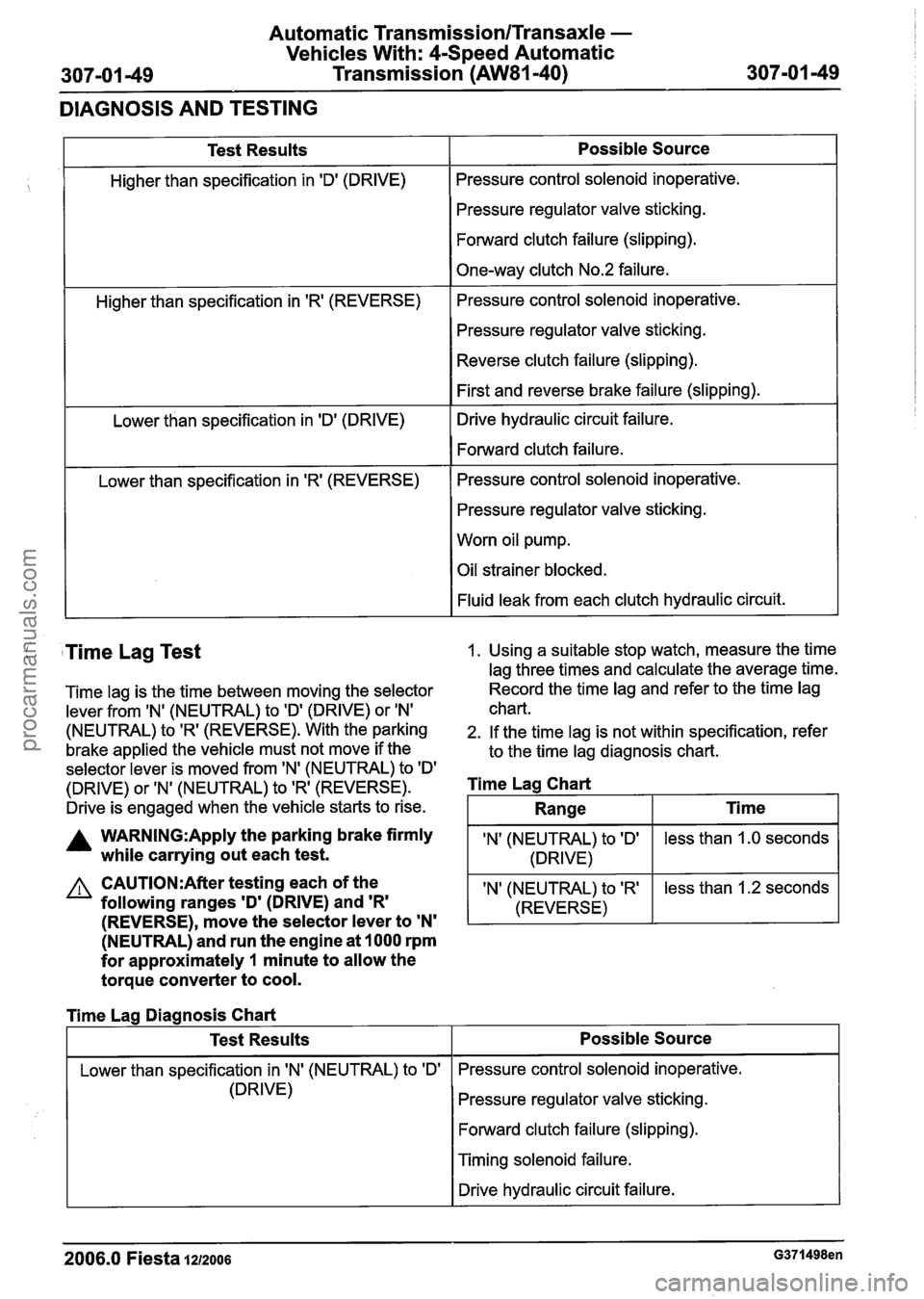

Stall Speed Test

This test checks the operation of the following

components:

1

Test Results

Lower than specification in 'Dl (DRIVE) and 'R'

(REVERSE)

Lower than specification in

'Dl (DRIVE)

Lower than specification in

'R' (REVERSE)

torque converter

forward clutch

low one way clutch assembly

engine performance

Possible Source

Pressure control solenoid inoperative or open wire

harness.

Pressure regulator valve sticking.

Worn oil pump.

Oil strainer blocked.

Fluid leak from each clutch hydraulic circuit.

Drive hydraulic circuit failure.

Forward clutch failure.

Reverse hydraulic circuit failure. Reverse clutch failure.

First and reverse brake failure.

WARNINGS:

A Do not maintain wide open throttle (WOT)

in any range for more than five seconds.

A If the engine speed (rpm) recorded by the

tachometer exceeds maximum specified

rpm, release the accelerator pedal

immediately. Clutch or band slippage is

indicated.

N0TE:The stall speed test should be carried out

with the engine and transaxle at normal operating

temperatures (50°C to 80°C).

A Apply the parking brake firmly while N0TE:Prolonged use of this procedure may set

carrying out each stall test. DTC PO71 2. After carrying out the stall speed test,

A Apply the foot brake firmly while carrying run the OBD test and clear the DTCs.

out each stall test. I. Connect a tachometer to the engine.

CAUTIONS:

A Always carry out the line pressure test

before carrying out the stall speed test. If

the line pressure is low at idle, do not carry

out the stall speed test or further transaxle

damage will occur.

A After testing each of the following ranges

'D'

(DRIVE) and 'R' (REVERSE), move the

selector lever to

'N' (NEUTRAL) and run

the engine at 1000 rpm for approximately

one minute to allow the torque converter

to cool.

2. Press the accelerator pedal to the floor WOT in

each selected range. Record the rpm reached

in each selected range and refer to the stall

speed chart.

3. If the stall speed is not within specification, refer

to the stall speed diagnosis chart.

Stall S~eed Chart

I Engine 1.6L I Speed (rpm) I

I 'Dl (DRIVE) I 2500 2 150 1

'R' (REVERSE) 2420 +, 150 -

Stall

Speed Diagnosis Chart

2006.0 Fiesta 1212006 G371498en

Test Results

Lower than specification in ID' (DRIVE) and 'R'

(REVERSE)

Possible Source

Low engine power.

Torque converter one-way clutch failure.

procarmanuals.com

Page 1009 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 49 Transmission (AW81-40) 307-01 -49

DIAGNOSIS AND TESTING

Test Results

Higher than specification in 'Dl (DRIVE)

Higher than specification in

'R' (REVERSE)

Lower than specification in 'D' (DRIVE)

Lower than specification in

'R' (REVERSE)

Possible Source

Pressure control solenoid inoperative.

Pressure regulator valve sticking.

Forward clutch failure (slipping).

One-way clutch No.2 failure.

Pressure control solenoid inoperative.

Pressure regulator valve sticking.

Reverse clutch failure (slipping).

First and reverse brake failure (slipping).

Drive hydraulic circuit failure.

Forward clutch failure.

Pressure control solenoid inoperative.

Pressure regulator valve sticking.

Worn oil pump.

Oil strainer blocked.

Fluid leak from each clutch hydraulic circuit.

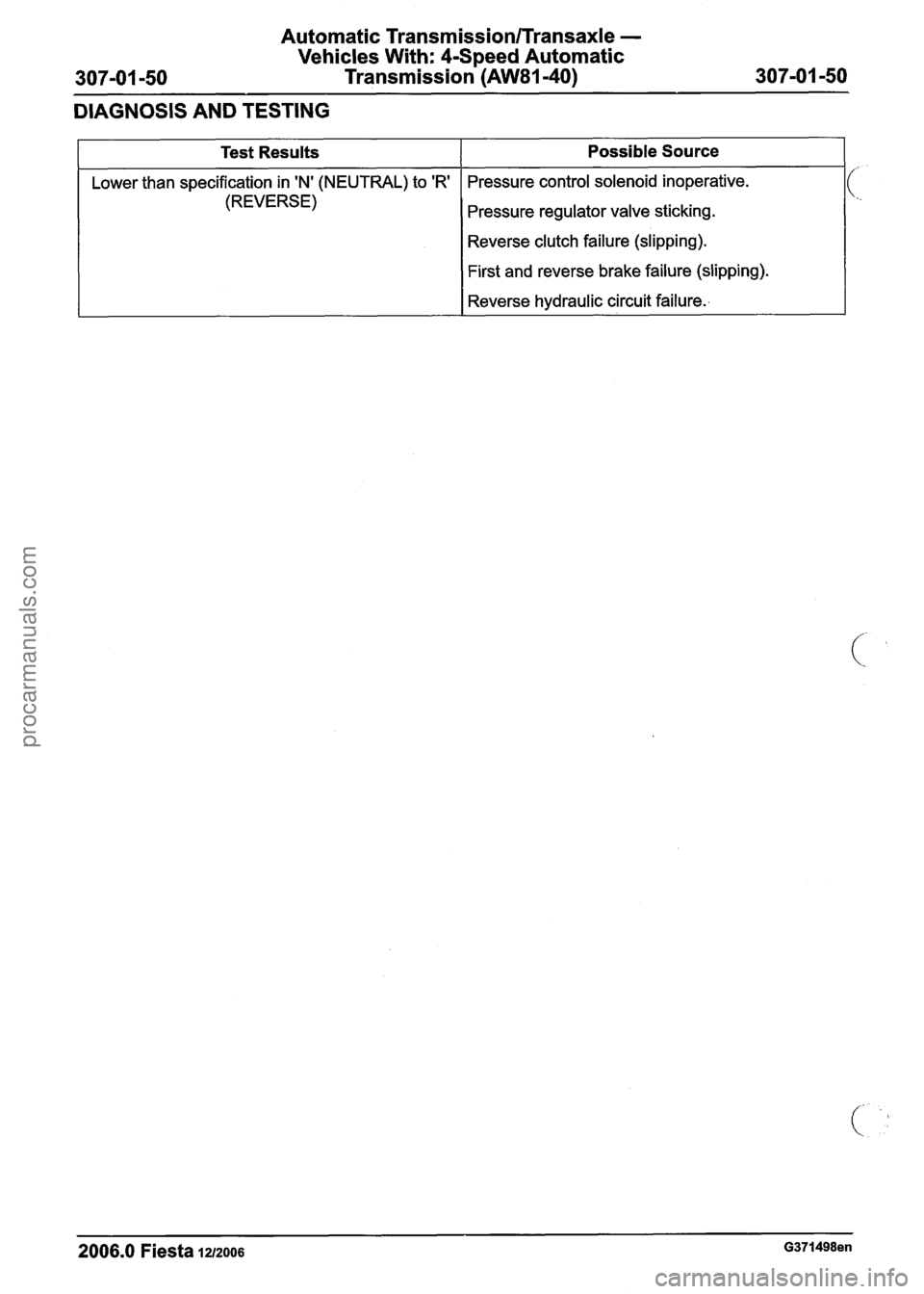

( Time Lag Test 1. Using a suitable stop watch, measure the time

lag three times and calculate the average time.

Time lag is the time between moving the selector Record the

time lag and refer to the time lag

lever from

IN' (NEUTRAL) to ID' (DRIVE) or IN' chart.

(NEUTRAL) to 'R' (REVERSE). With the parking 2. If the time lag is not within specification, refer

brake applied the vehicle must not move if the

to the time lag diagnosis chart.

selector lever is moved from 'N' (NEUTRAL) to

ID'

(DRIVE) or 'N' (NEUTRAL) to 'R' (REVERSE). Time Lag Chart

Drive is engaged when the vehicle starts to rise.

A WARN1NG:Apply the parking brake firmly IN' (NEUTRAL) to ID' while carrying out each test. 1 (DRIVE)

(NEUTRAL) and run the engine at 1000 rpm

for approximately

1 minute to allow the

torque converter to cool.

less than 1.0 seconds

CAUTI0N:After testing each of the

following ranges

'D' (DRIVE) and 'R'

Range

I Lower than specification in IN' (NEUTRAL) to 'Dl I Pressure control solenoid inoperative.

Ti me

(REVERSE), move the selector lever to 'N'

'N' (NEUTRAL) to 'R'

(REVERSE)

Time Lag Diagnosis Chart

(DRIVE) less

than 1.2 seconds

Test Results

Pressure regulator valve sticking.

Forward clutch failure (slipping).

Possible Source

I Timing solenoid failure.

I I Drive hydraulic circuit failure. I

2006.0 Fiesta IZIZOO~ G371498en

procarmanuals.com

Page 1010 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40)

DIAGNOSIS AND TESTING

Test Results

Lower than specification in 'N' (NEUTRAL) to 'R'

(REVERSE)

Possible Source

Pressure control solenoid inoperative.

Pressure regulator valve sticking.

Reverse clutch failure (slipping).

First and reverse brake failure (slipping).

Reverse hydraulic circuit failure.,

(I.

2006.0 Fiesta 1212006 G371498en

procarmanuals.com

Page 1011 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -51 Transmission (AW81-40) 307-01 -51 -

GENERAL PROCEDURES

~ransmission Fluid Level Check

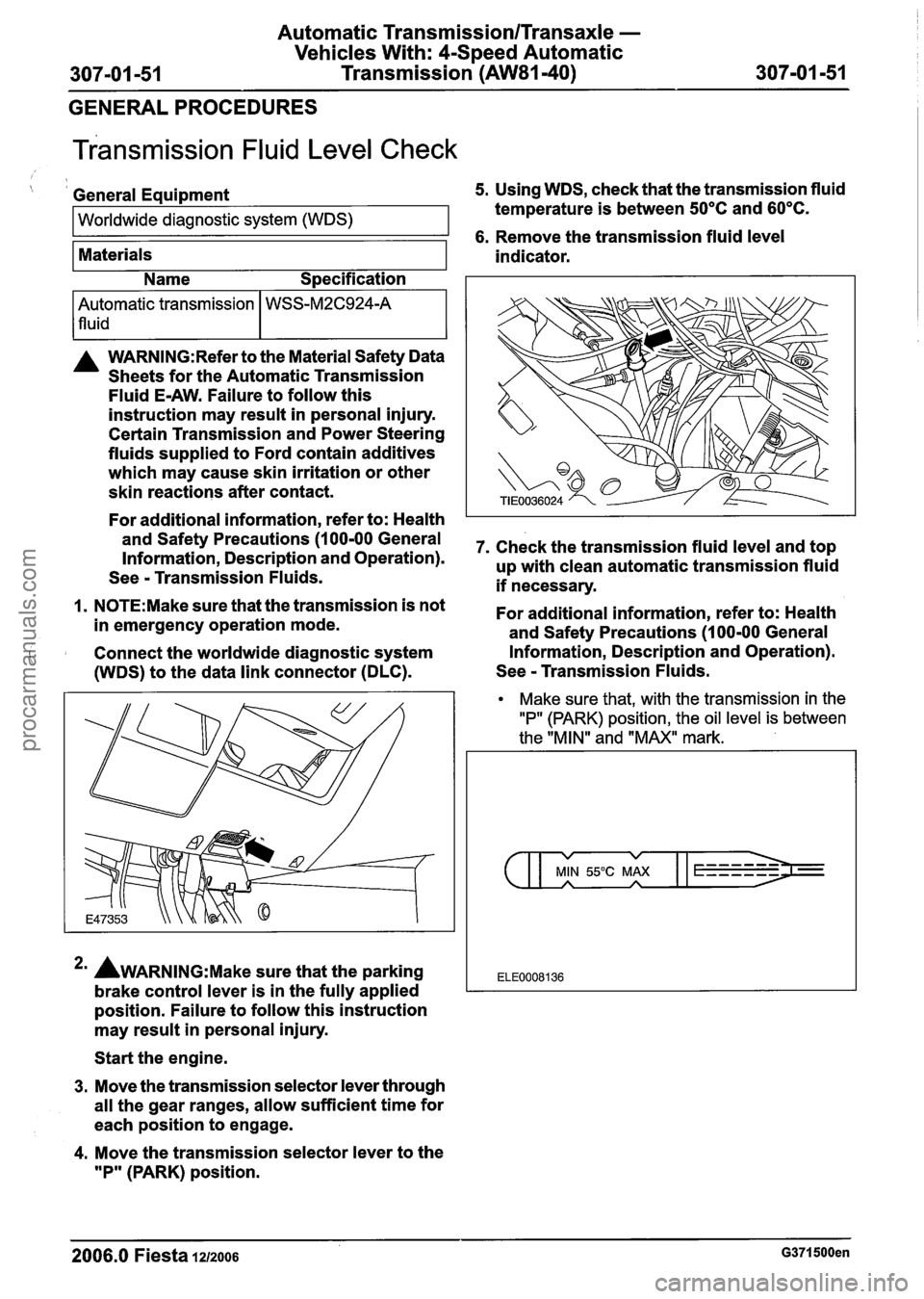

( I General Equipment 5. Using WDS, check that the transmission fluid

Worldwide diagnostic system (WDS) temperature is between 50°C and 60°C.

1 6. Remove the transmission fluid level

Materials

A WARN1NG:Refer to the Material Safety Data

Sheets for the Automatic Transmission

Fluid

E-AW. Failure to follow this

instruction may result in personal injury.

Certain Transmission and Power Steering

fluids supplied to Ford contain additives

which may cause skin irritation or other

skin reactions after contact.

For additional information, refer to: Health

and Safety Precautions (1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

1. N0TE:Make sure that the transmission is not

in emergency operation mode.

Connect the worldwide diagnostic system

(WDS) to the data link connector (DLC). indicator.

Automatic transmission

lfluid

*' AWARNING:M~~~ sure that

the parking

brake control lever is in the fully applied

position. Failure to follow this instruction

may result in personal injury.

Name

Specification

WSS-M2C924-A

Start the engine.

3. Move the transmission selector lever through

all the gear ranges, allow sufficient time for

each position to engage.

4. Move the transmission selector lever to the

"P" (PARK) position. 7.

Check the transmission fluid level and top

up with clean automatic transmission fluid

if necessary.

For additional information, refer to: Health

and Safety Precautions (1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

Make sure that, with the transmission in the

"P" (PARK) position, the oil level is between

the "MIN" and "MAX" mark.

v v

MIN 55°C MAX A A

ELE0008136

2006.0 Fiesta 1212006 G371500en

procarmanuals.com

Page 1045 of 1226

Automatic Transmission/Transaxle External

Controls -Vehicles With:

CSpeed Automatic

Transmission

(AW81-40)

I I

SECTION 307-05 Automatic Transmission/Transaxle

External Controls -Vehicles With: 4-Speed Automatic

Transmission (AW81-40)

VEHICLE APPLICATION:2006.0 Fiesta

CONTENTS

SPECIFICATIONS

........................................................................\

............................................ Specifications..

DESCRIPTION AND OPERATION

External Controls ........................................................................\

........................................

........................................................................\

.................................... Selector lever cable

GENERAL PROCEDURES

Selector Lever Cable Adjustment ........................................................................\

................

PAGE

REMOVAL AND INSTALLATION

i 1 ........................................................................\

.................... Brake Shift Interlock Actuator. 307-05-6

........................................................................\

.................................. Selector Lever Cable 307-05-7

Selector Lever

........................................................................\

............................................. 307-05-1 0

Selector Lever Bezel..

........................................................................\

........................... 307-05-1 2

Selector Lever Knob ........................................................................\

................................... 307-05-1 3

DISASSEMBLY AND ASSEMBLY

Selector Lever.. ........................................................................\

........................................... 307-05-1 4

procarmanuals.com

Page 1050 of 1226

Automatic Transmission/Transaxle External

Controls -Vehicles With:

4Speed Automatic

307-05-6 Transmission (AW81-40) 307-05-6

REMOVAL AND INSTALLATION

Brake Shift Interlock Actuator

Removal

1. Remove the floor console. 3. Install the bolt.

2. Disconnect the overdrive (OID) switch

electrical connector (selector lever assembly

shown removed for clarity).

3. Remove the brake shift interlock actuator.

1. Remove the bolt.

2. Remove the knob.

3. Remove the brake shift interlock actuator.

Installation

1. Install the brake shift interlock actuator.

1. Install the brake shift interlock actuator.

2. Position the knob.

2. Connect the OID switch electrical connector

(selector lever assembly shown removed for

clarity).

3. Install the floor console.

2006.0 Fiesta 1212006 G294547en

procarmanuals.com

Page 1058 of 1226

Automatic Transmission/Transaxle External

Controls -Vehicles With: 4-Speed Automatic

307-05-1 4 Transmission (AW81-40) 307-05-1 4

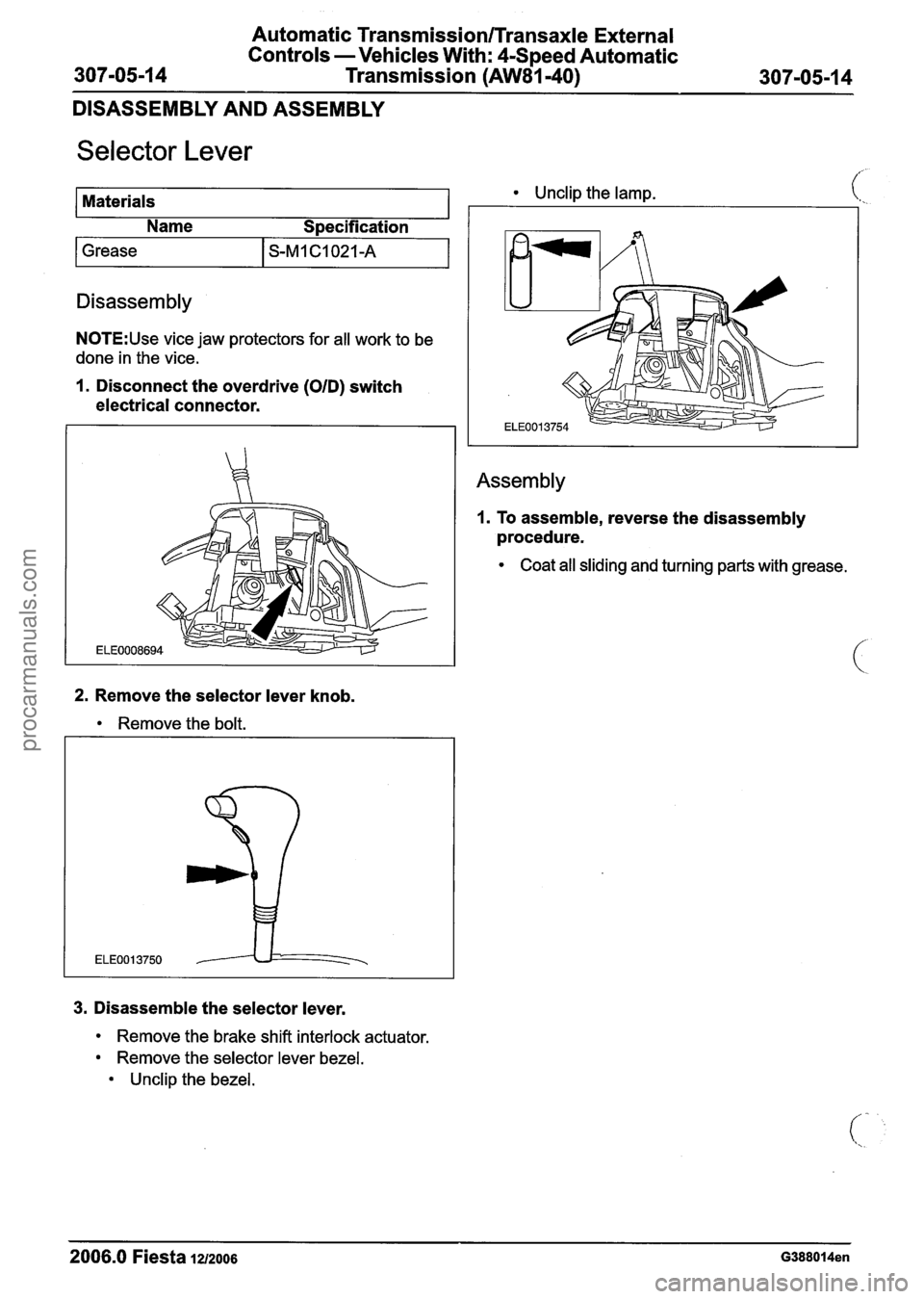

DISASSEMBLY AND ASSEMBLY

Selector Lever

Materials Unclip the lamp.

I I Name S~ecification

1 Grease I S-MlC1021-A I

Disassembly

N0TE:Use vice jaw protectors for all work to be

done in the vice.

1. Disconnect the overdrive (OID) switch

electrical connector.

Assembly

1. To assemble, reverse the disassembly

procedure.

Coat all sliding and turning parts with grease.

2. Remove the selector lever knob.

Remove the bolt.

3. Disassemble the selector lever.

Remove the brake shift interlock actuator.

Remove the selector lever bezel.

Unclip the bezel.

2006.0 Fiesta 1212006 G388014en

procarmanuals.com

Page 1060 of 1226

Manual Transmission/Transaxle and Clutch -

General Information

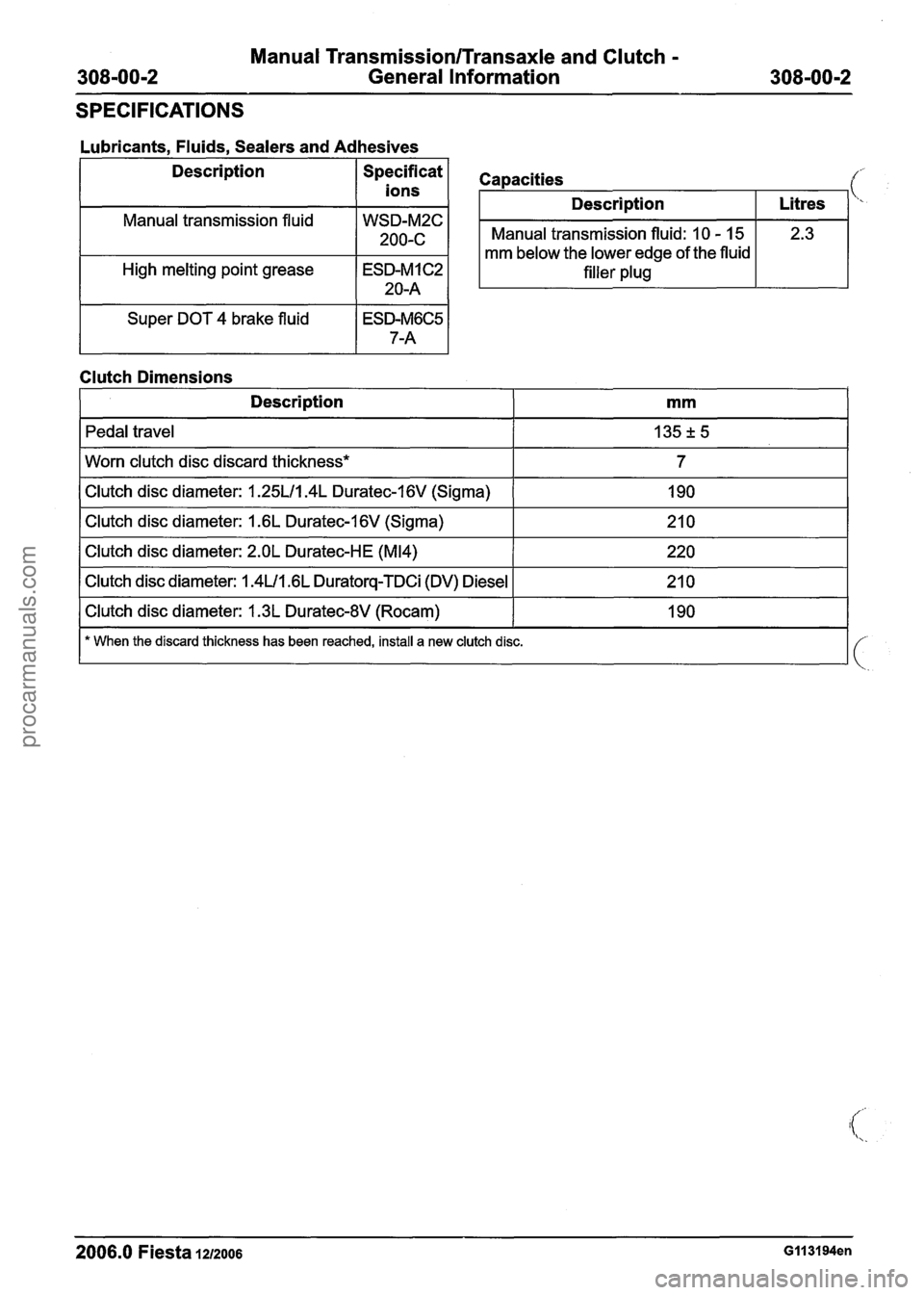

SPECIFICATIONS

Lubricants, Fluids, Sealers and Adhesives

Description Specificat

I ions I

Manual transmission fluid

I High melting point grease

Super DOT 4 brake fluid

Clutch Dimensions

I Description I Litres 1 '"<

fluid: 10 - 15

mm below the lower edge of the fluid

filler plug

--

2.3

Description

Pedal travel

Worn clutch disc discard thickness*

Clutch disc diameter:

1.25Ll1.4L Duratec-1 6V (Sigma)

Clutch disc diameter:

1.6L Duratec-I 6V (Sigma)

Clutch disc diameter:

2.OL Duratec-HE (M14)

Clutch disc diameter: 1.4U1.6L Duratorq-TDCi (DV) Diesel

Clutch disc diameter:

1.3L Duratec-8V (Rocam)

mm

135k5

7

190

210

220

210 190

* When the discard thickness has been reached, install a new clutch disc.

procarmanuals.com

Page 1061 of 1226

Manual Transmission/Transaxle and Clutch -

308-00-3 General Information 308-00-3

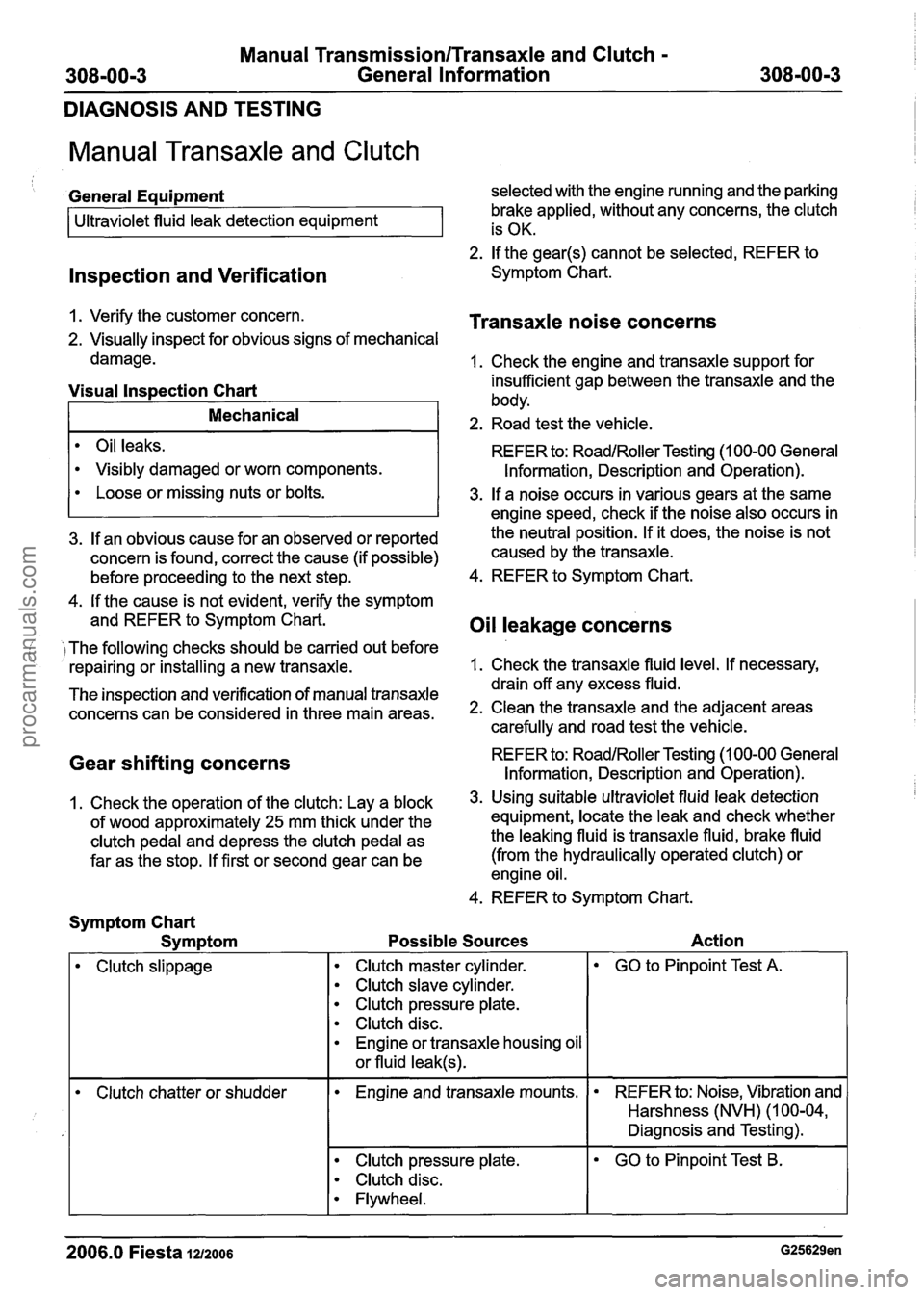

DIAGNOSIS AND TESTING

Manual Transaxle and Clutch

lnspection and Verification

General Equipment selected with the engine running and the parking

brake applied, without any concerns, the clutch

2. If the gear@) cannot be selected, REFER to

Symptom Chart.

Ultraviolet

fluid leak detection equipment

1. Verify the customer concern.

Transaxle noise concerns

2. Visually inspect for obvious signs of mechanical is

OK.

damage. 1. Check the engine and transaxle support for

Oil leaks.

Visibly damaged or worn components.

Visual lnspection Chart insufficient gap between the transaxle and the

body.

REFER to:

RoadlRoller Testing (1 00-00 General

Information, Description and Operation).

Mechanical 2. Road test the vehicle.

4. If the cause is not evident, verify the symptom

and REFER to Symptom Chart.

Oil leakage concerns

Loose or missing nuts or bolts.

( I The following checks should be carried out before

repairing or installing a new transaxle. 1.

Check the transaxle fluid level. If necessary,

3. If a noise occurs in various gears at the same

- - drain off any excess fluid.

The inspection and verification of manual transaxle

concerns can be considered in three main areas. 2. Clean the transaxle and the adjacent areas

carefully and road test the vehicle.

engine speed,

check if the noise also occurs in

3. If an obvious cause for an observed or reported the neutral position.

If it does, the noise is not

concern is found, correct the cause (if possible) caused

by the transaxle.

before proceeding to the next step. 4.

REFER to Symptom Chart.

Gear shifting concerns REFER to: RoadlRoller Testing (1 00-00 General

Information, Description and Operation).

1, Check the operation of the clutch: Lay a block 3. U~ing suitable ultraviolet fluid leak detection

of wood approximately

25 mm thick under the equipment, locate

the leak and check whether

clutch pedal and depress the clutch pedal as the leaking fluid

is transaxle fluid, brake fluid

far as the stop. If first or second gear can be (from the hydraulically operated clutch)

or

engine oil.

4. REFER to Symptom Chart.

Symptom Chart

Symptom Possible Sources Action

I

Clutch slippage Clutch master

cylinder.

Clutch slave cylinder.

Clutch pressure plate.

Clutch disc.

Engine or transaxle housing oil

or fluid

leak@).

GO to Pinpoint Test A.

Clutch chatter or shudder Engine and transaxle

mounts. REFER to:

Noise, Vibration and

Harshness (NVH) (1 00-04,

Diagnosis and Testing).

Clutch pressure plate.

Clutch disc.

Flywheel.

--

GO to Pinpoint Test B.

- -

2006.0 Fiesta 1212006 G25629en

procarmanuals.com