coolant system FORD FIESTA 2007 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 755 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V (Sigma)ll.4L

303-03A-I 3 Duratec-1 6V (Sigma)ll.GL Duratec-1 6V (Sigma) 303-03A-I 3

DIAGNOSIS AND TESTING

Symptom Possible Sources Action

2006.0 Fiesta 1212006 GI 46258en

Coolant levellcondition.

Coolant concentration.

Radiator grille. CHECK

the coolant level.

REFILL the cooling system as

necessary.

REFER to: Cooling System

Draining, Filling and Bleeding

- 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V

(Sigma)ll .6L Duratec-1 6V

(Sigma) (303-03 Engine

Cooling

- 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V

(Sigma)ll .6L Duratec-1 6V

(Sigma), General Proced-

u res).

CHECK the coolant condition.

If the coolant is in poor condi-

tion drain and refill with new

coolant.

REFER to: Cooling System

Draining, Filling and Bleeding

- 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V

(Sigma)ll .6L Duratec-1 6V

(Sigma) (303-03 Engine

Cooling

- 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V

(Sigma)/l.6L Duratec-1 6V

(Sigma), General Proced-

u res).

REFER to: Specifications (303-

03 Engine Cooling

- 1.3L

Duratec-8V (Rocam)ll.25L

Duratec-16V (Sigma)ll.4L

Duratec-1 6V (Sigma)/l .6L

Duratec-16V (Sigma),

Specifications).

INSPECT the radiator grille for

air restrictions or damage.

REPAIR or INSTALL new parts

as necessary.

procarmanuals.com

Page 758 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-I 6V (Sigma)ll.4L

303-03A-16 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-03A-16

DIAGNOSIS AND TESTING

Component Tests

Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2.

Install the special tools to the coolant expansion

tank.

3. Pressurize the system to the

coolant expansion

tank cap

release pressure.

REFER to: Specifications (303-03 Engine

Cooling - 1.3L Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V (Sigma),

Specifications).

4. Observe the

cooling system pressure tester

gauge reading for

approximately two minutes.

The pressure

should not drop during this time.

If the system holds pressure, proceed to step

6.

If the system does not hold pressure, check

it

thoroughly for coolant leaks.

5. Check the engine for coolant leaks. Drain the

cooling system, repair any coolant leaks found

and

fill and bleed the cooling system as

necessary.

REFER to:

Cooling System Draining, Filling and

Bleeding - 1.3L Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V (Sigma) (303-03

Engine

Cooling - 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L Duratec-1 6V

(Sigma), General Procedures).

Clean the radiator thoroughly before leak testing

it, to prevent contamination of the water in the test

tank. Leak test the radiator in

clean water with 138(

kpa (20 psi) air pressure. Check it thoroughly for

air

leaks. INSTALL a new radiator if necessary.

REFER to: Radiator (303-03 Engine

Cooling - 1.3L

Duratec-8V (Rocam)/l.25L Duratec-I 6V

(Sigma)/l.4L Duratec-I 6V (Sigma)ll .6L

Duratec-I 6V (Sigma), Removal and Installation).

Coolant Expansion Tank Cap Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2. Use water to clean the area of the rubber seal

and pressure relief valve. Install the pressure

tester and adapter and immerse the

coolant

expansion tank cap in water .

N0TE:lf the plunger of the pump is depressed too

quickly, an erroneous pressure reading will result. l-

3. Slowly depress the plunger of the pressure test

pump until the pressure gauge reading stops

increasing, and note the highest pressure

reading obtained.

4.

Release pressure by turning the pressure relief

screw counterclockwise. Tighten the pressure

relief screw and repeat step 3 at least twice to

make sure the pressure test reading is

repeatable and within acceptable gauge reading

limits of the coolant expansion tank cap.

5.

If the pressure test gauge readings are not

within the

acceptable gauge reading limits,

INSTALL a new coolant expansion tank cap.

6. Recheck the system by repeating steps 3 and

4 at least twice.

Thermostat Test

Radiator Leak Test, Removed From Vehicle

A CAUTI0N:Radiator internal pressure must

not exceed

130 kpa (20 psi) or damage may

result.

1. Connect the WDS to the data link connector

(DLC).

2. Using the WDS

datalogger function, SELECT

the

following sensors (as applicable to the

application):

IAT - intake air temperature (IAT) sensor

ECT

- engine coolant temperature (ECT) sensort

CHT - cylinder head temperature (CHT) sensori

LOAD - engine load

VSS - vehicle speed sensor (VSS)

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 759 of 1226

Engine Cooling - I .3L Duratec-8V

(Rocam)llm25L Duratec-1 6V (Sigma)ll.4L

303-03A-17 Duratec-1 6V (Sigma)/lm6L Duratec-1 6V (Sigma) 303-03A-17

DIAGNOSIS AND TESTING

RPM - engine speed

i DSRPM - desired engine speed

The IAT sensor output is useful if the engine being

tested is cold or after an over-night cold soak. The

ECT sensor or CHT sensor and the IAT sensor

should either indicate the same value or be within

1 to 2 degrees Celsius of each other.

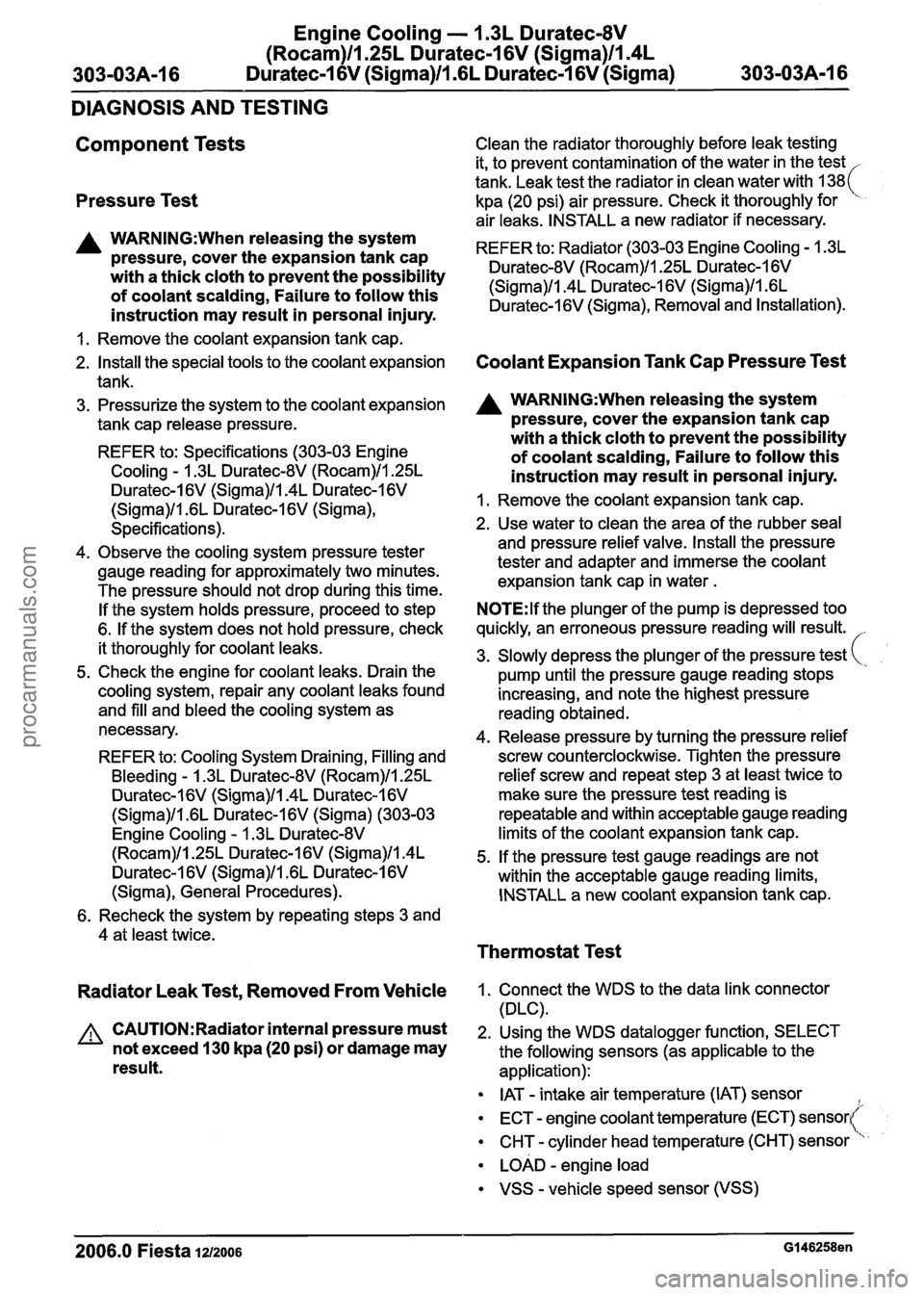

The ECT sensor output is important to display as

it indicates the engine warm-up and opening

temperature for the thermostat. It will initially

indicate a slightly higher reading just before the

thermostat opens and then drops back before

settling to a near flat line output (see graphic

below).

Item Description

I A I Thermostat opens I

B Thermostat settles into a cyclic open and

I I closure pattern

A CAUTI0N:lf the ECT sensor output reaches

the

120°C default line under normal cooling

system pressure, internal damage may be

caused to the engine and a diagnostic

trouble code (DTC) will be set in the PCM.

The test should be stopped and the cause

located and corrected. If the cooling

system does not pressurize, the coolant

will boil at

100°C which may also damage

the engine. CARRY OUT the Coolant

Expansion Tank Cap Pressure Test

Component Test in this section.

If the WDS only allows the ECT sensor to be

displayed in volts, refer to the following table for

corresponding Celsius values:

Volts

OCelsius

The CHT sensor output is useful to examine the

cylinder head temperature rise during the warm-up

cycle and later during the normal light throttle cruise

test. This sensor output may vary between vehicles

with manual transmission and vehicles with

automatic transmission and should be used for

reference only.

Volts

0.78

0.60

0.46

0.35

0.27

The

LOAD display is used for reference as it is

necessary to maintain a stable load line during the

test. It is necessary to carry out the test under

normal light throttle cruise driving conditions and

average loads, typically

40% to 70% of the load

value.

OCelsius

80

90

100

11 0

120

The VSS output is used for reference but can help

to identify misfires and sensors which fail during

the warm-up cycle.

The RPM display indicates the engine speed and can be compared with the DSRPM.

The DSRPM is the desired or calculated idle speed

which the PCM commands the engine to reach. If

the thermostat opens too early (before the correct

opening temperature has been reached), the

engine will not reach this value.

When using the WDS in data logger mode, the

signals recorded should remain within the

DEFAULT values set by the WDS.

3m AWARNING:M~~~ sure that the WDS is

placed in the vehicle so that it does not

interfere with the safe operation of the

vehicle. Do not place the WDS in the

deployment path of any air bag. Failure to

follow these instructions may result in personal injury.

N0TE:The road test is best carried out with the

aid of another technician in the vehicle to enable

the vehicle to be driven safely while the sensor

outputs are monitored within datalogger. If there

is only one technician available, the WDS can be

set up (using the

recordlcapture mode camera

icon) before leaving the workshop to record a

16

km (1 0 mile) test.

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 761 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V (Sigma)llI4L

303-03A-19 Duratec-1 6V (Sigma)lll6L Duratec-I 6V (Sigma) 303-03A-19

GENERAL PROCEDURES

Cooling System Draining, Filling and Bleeding - 1.3L Duratec-8V

I (Rocam)/l.25L Duratec-1 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l.6L Duratec-1 6V (Sigma)(24 122 0)

Draining 5. Install the radiator drain plug.

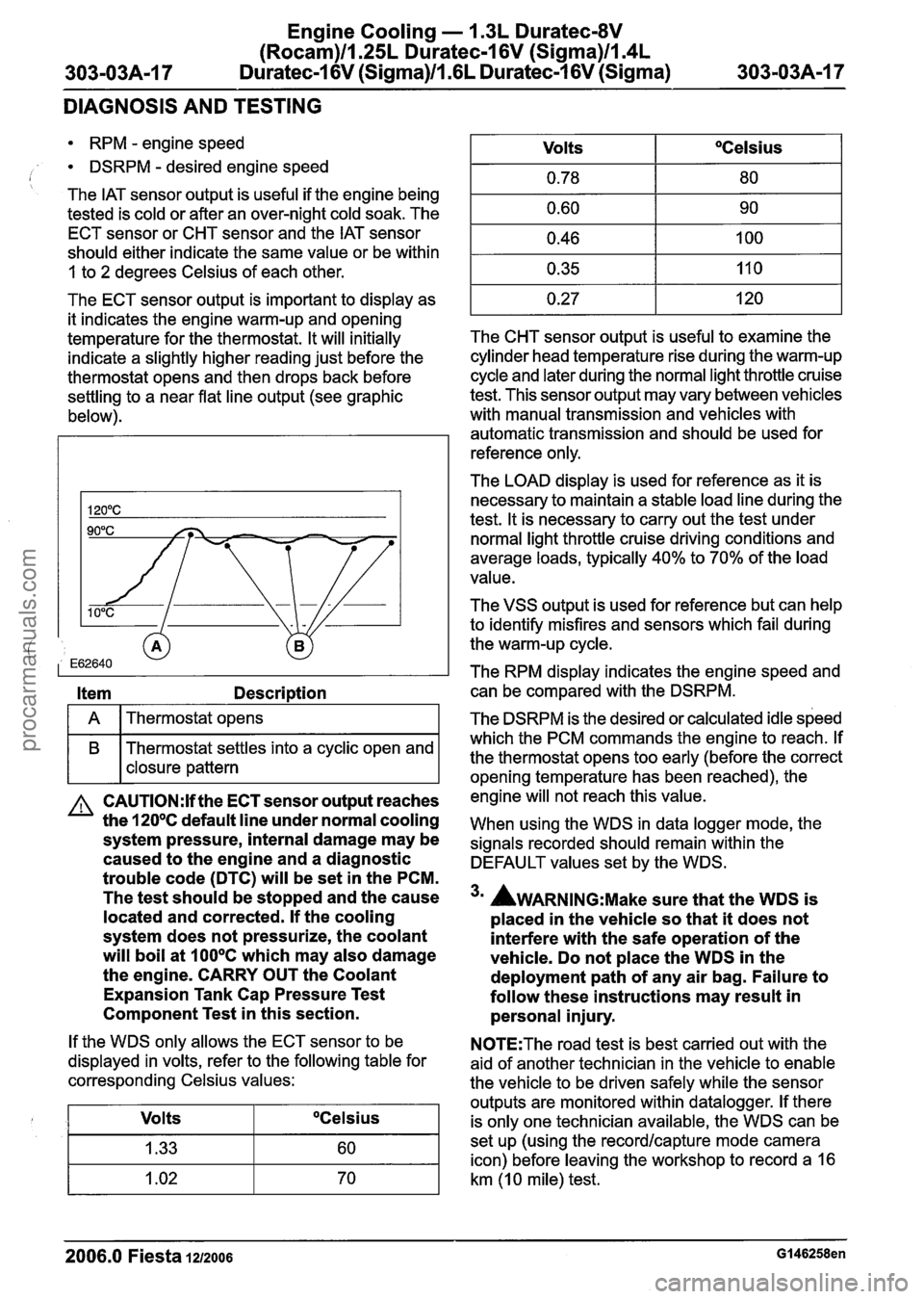

la AWARNING:~~~~ releasing the cooling 6. Lower the vehicle.

system pressure, cover the coolant

expansion tank cap with a thick cloth to

Filling and Bleeding

prevent the possibility of scalding. Failure 1. Remove the radiator bleed plug (if equipped). to follow this instruction may result in

personal injury.

Release the cooling system pressure by

slowly turning the coolant expansion tank

cap a quarter of a turn.

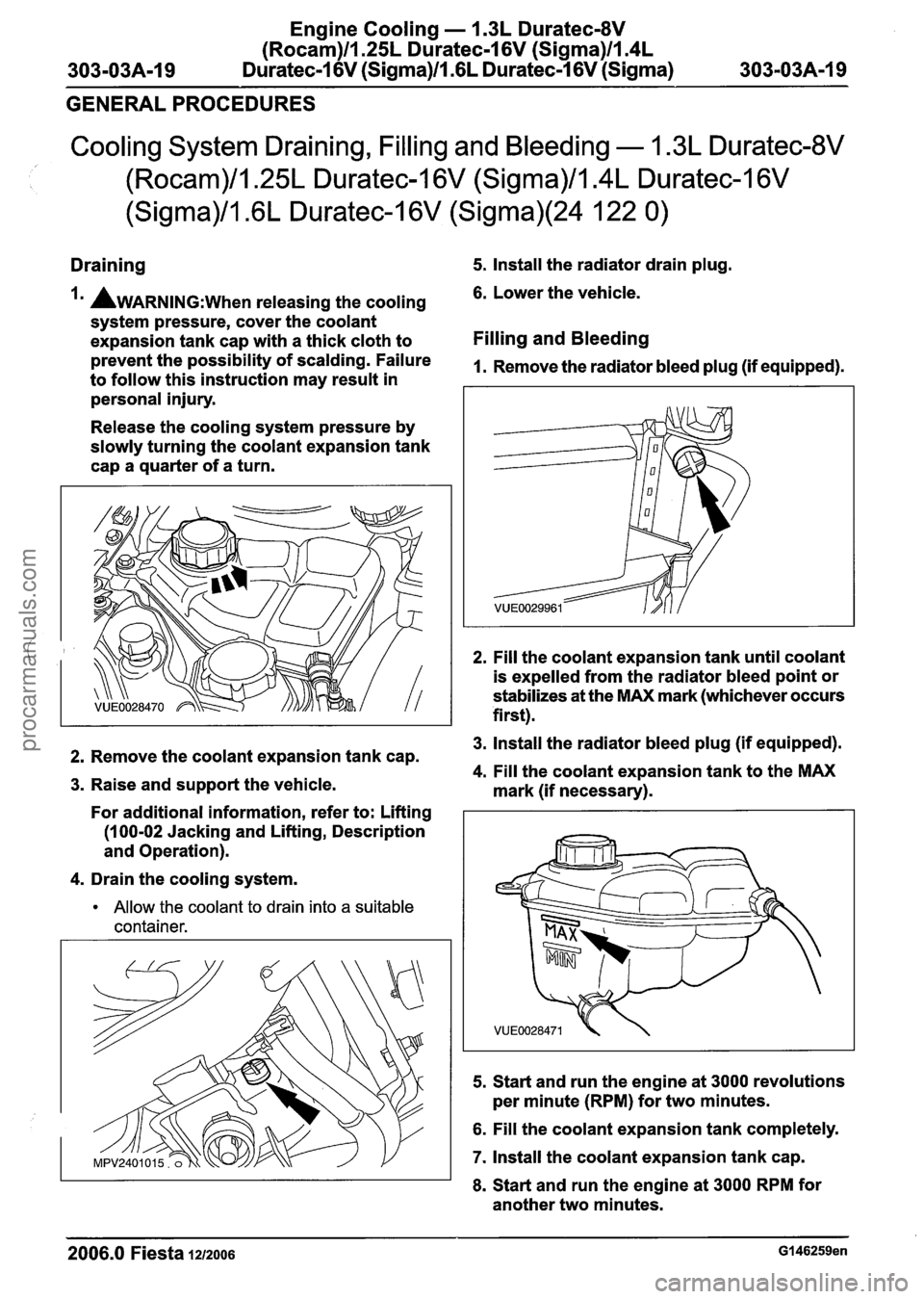

2. Fill the coolant expansion tank until coolant

is expelled from the radiator bleed point or

stabilizes at the MAX mark (whichever occurs

first).

3. Install the radiator bleed plug (if equipped). 2. Remove the coolant expansion tank cap. 4. Fill the coolant expansion tank to the MAX 3. Raise and support the vehicle.

mark (if necessary).

For additional information, refer to: Lifting

(1 00-02 Jacking and Lifting, Description

and Operation).

4. Drain the cooling system.

Allow the coolant to drain into a suitable

container.

5.

Start and run the engine at 3000 revolutions

per minute (RPM) for two minutes.

6. Fill the coolant expansion tank completely.

7. Install the coolant expansion tank cap.

8. Start and run the engine at 3000 RPM for

another two minutes.

2006.0 Fiesta 1212006 G146259en

procarmanuals.com

Page 763 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V (Sigma)ll.4L

303-03A-21 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-03A-21

REMOVAL AND INSTALLATION

Water Pump - 1.25L Duratec-1 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V (Sigma)(24 404 0)

Removal

Vehicles built up to 0412005

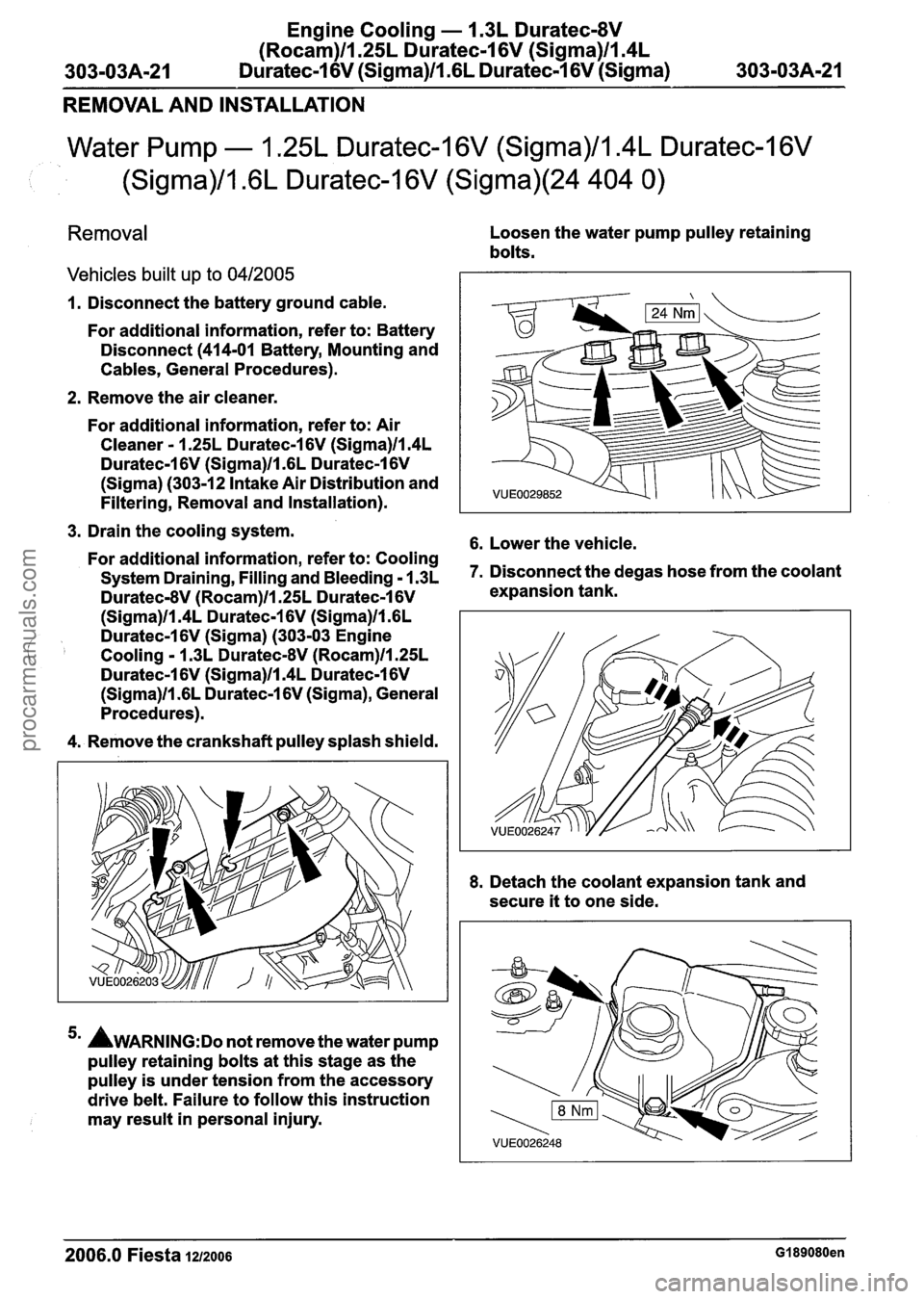

Loosen the water pump pulley retaining

bolts.

1. Disconnect the battery ground cable.

For additional information, refer to: Battery

Disconnect

(414-01 Battery, Mounting and

Cables, General Procedures).

2. Remove the air

cleaner.

For additional information, refer to: Air

Cleaner - 1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma) (303-12 Intake Air Distribution and

Filtering, Removal and Installation).

3. Drain the cooling system.

6. Lower the vehicle. For additional information, refer to: Cooling

System Draining, Filling and Bleeding - 1.3~ 7. Disconnect the degas hose from the coolant

Duratec-8V (Rocam)ll.25L Duratec-1 6V expansion tank.

(Sigma)ll.4L Duratec-1 6V (Sigma)ll .6L

Duratec-1 6V (Sigma) (303-03 Engine

Cooling - 1.3L DuratecdV (Rocam)ll.25L

Duratec-1 6V (Sigma)ll.4L Duratec-1 6V

(Sigma)ll .6L Duratec-1 6V (Sigma), General

Procedures).

4. Remove the crankshaft

pulley splash shield.

5m AWARNING:D~ not remove the water pump

pulley retaining bolts at this stage as the

pulley is under tension from the accessory

drive

belt. Failure to follow this instruction

may

result in personal injury. 8.

Detach the

coolant expansion tank and

secure

it to one side.

2006.0 Fiesta 1212006 GI 89080en

procarmanuals.com

Page 764 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V (Sigma)llI4L

303-03A-22 Duratec-1 6V (Sigma)lIl6L Duratec-1 6V (Sigma) 303-03A-22

REMOVAL AND INSTALLATION

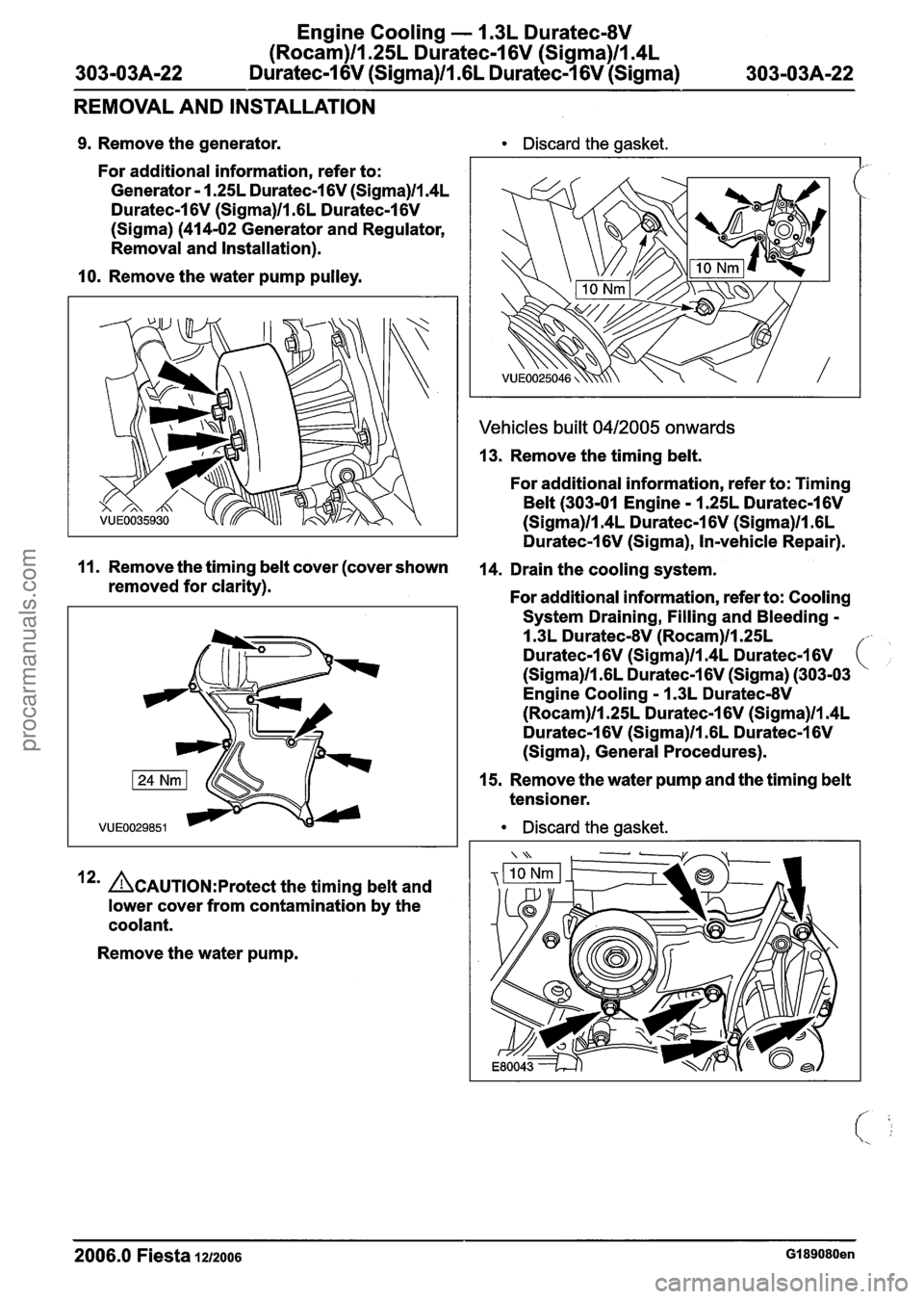

9. Remove the generator.

For

additional information, refer to:

Generator

- 1.25L Duratec-1 6V (Sigma)/l.4L

Duratec-I 6V (Sigma)/l .6L Duratec-I 6V

(Sigma)

(414-02 Generator and Regulator,

Removal and Installation).

10. Remove the water pump pulley.

Discard the gasket.

Vehicles built 0412005 onwards

13. Remove the timing belt.

For additional information, refer to: Timing

Belt (303-01 Engine - 1.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V (Sigma)ll .6L

Duratec-1 6V (Sigma), ln-vehicle Repair).

11. Remove the timing belt cover (cover shown 14. Drain the cooling system,

removed for clarity). For additional information, refer to: Cooling

12' &AUTION:P~~~~~~ the timing belt and

lower cover from contamination by the

coolant.

Remove the water pump. System

Draining,

Filling and Bleeding -

1.3L Duratec-8V (Rocam)ll.25L

Duratec-1 6V (Sigma)ll.4L Duratec-1 6V (,

(Sigma)ll .6L Duratec-1 6V (Sigma) (303-03

Engine

Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-I 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma), General Procedures).

15. Remove the water pump and the timing

belt

tensioner.

Discard the gasket.

2006.0 Fiesta 1212006 GI 89080en

procarmanuals.com

Page 771 of 1226

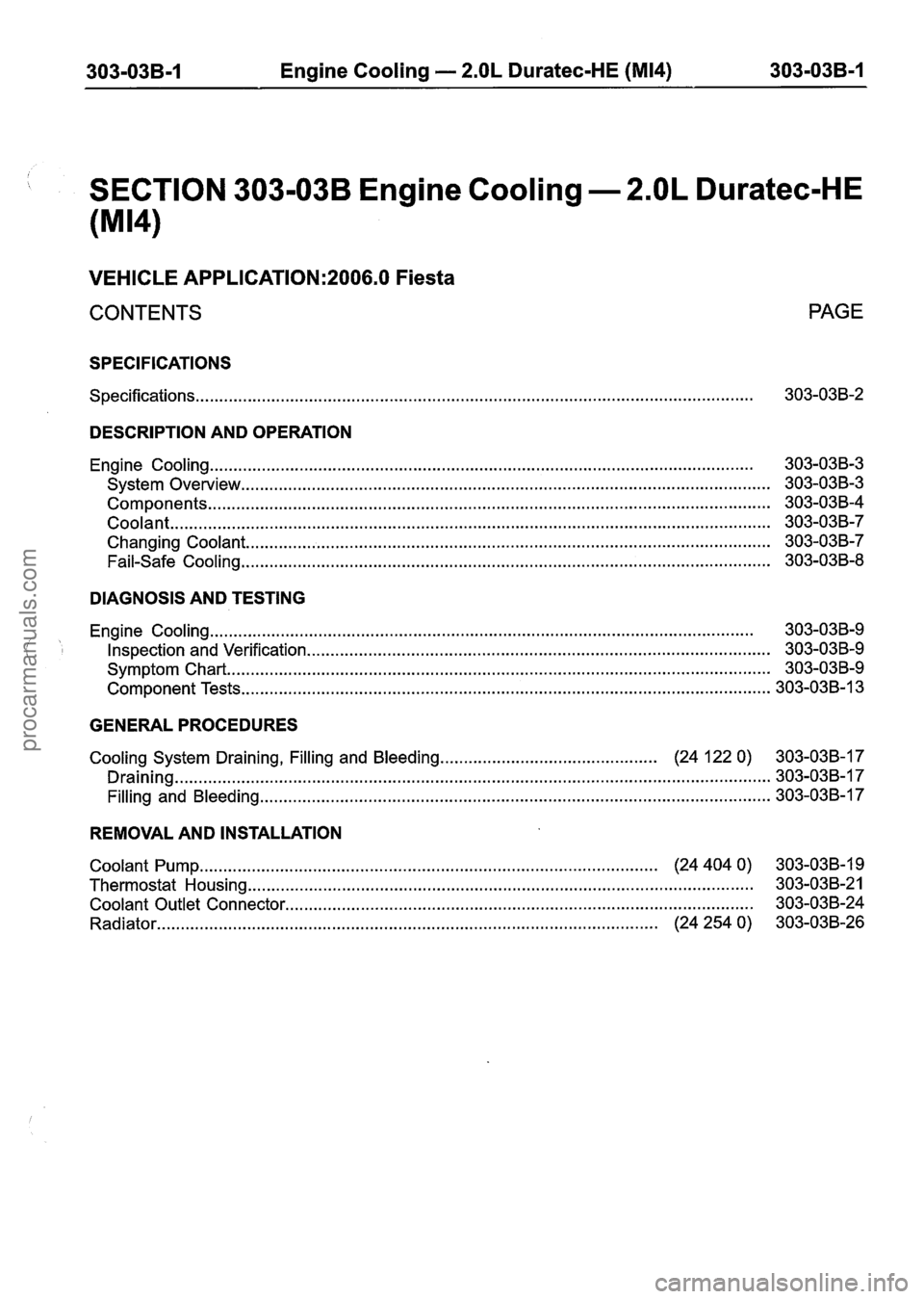

303-03B-1 Engine Cooling -- 2.OL Duratec-HE (M14) 303-03B-1

SECTION 303-03B Engine Cooling . 2.OL Duratec-HE

VEHICLE APPLICATION:2006.0 Fiesta

CONTENTS PAGE

SPECIFICATIONS

Specifications

........................................................................\

.............................................. 303-038-2

DESCRIPTION AND OPERATION

Engine Cooling

........................................................................\

...................................... 303-038-3

System Overview

........................................................................\

.................................. 303-038-3

........................................................................\

............................................... Components 303-038-4

........................................................................\

....................................................... Coolant 303-038-7

........................................................................\

....................................... Changing Coolant 303-038-7

Fail-safe Cooling

........................................................................\

........................................ 303-038-8

DIAGNOSIS AND TESTING

........................................................................\

........................................... , Engine Cooling 303-038-9 ........................................................................\

.......................... , Inspection and Verification 303-038-9

Symptom Chart ........................................................................\

........................................... 303-038-9

........................................................................\

........................................ Component Tests 303-038-1 3

GENERAL PROCEDURES

.............................................. Cooling System Draining. Filling and Bleeding (24 1 22 0) 303-038-1

7

Draining

........................................................................\

...................................................... 303-038-1 7

Filling and Bleeding

........................................................................\

.................................... 303-038-1 7

REMOVAL AND INSTALLATION

Coolant Pump

........................................................................\

....................... (24 404 0) 303-038-19

Thermostat Housing

........................................................................\

................................ 303-038-21

Coolant Outlet Connector

........................................................................\

........................... 303-038-24

........................................................................\

.................................. Radiator (24 254 0) 303-038-26

procarmanuals.com

Page 773 of 1226

303-03B-3 Engine Cooling - 2.OL Duratec-HE (M14) 303-03B-3

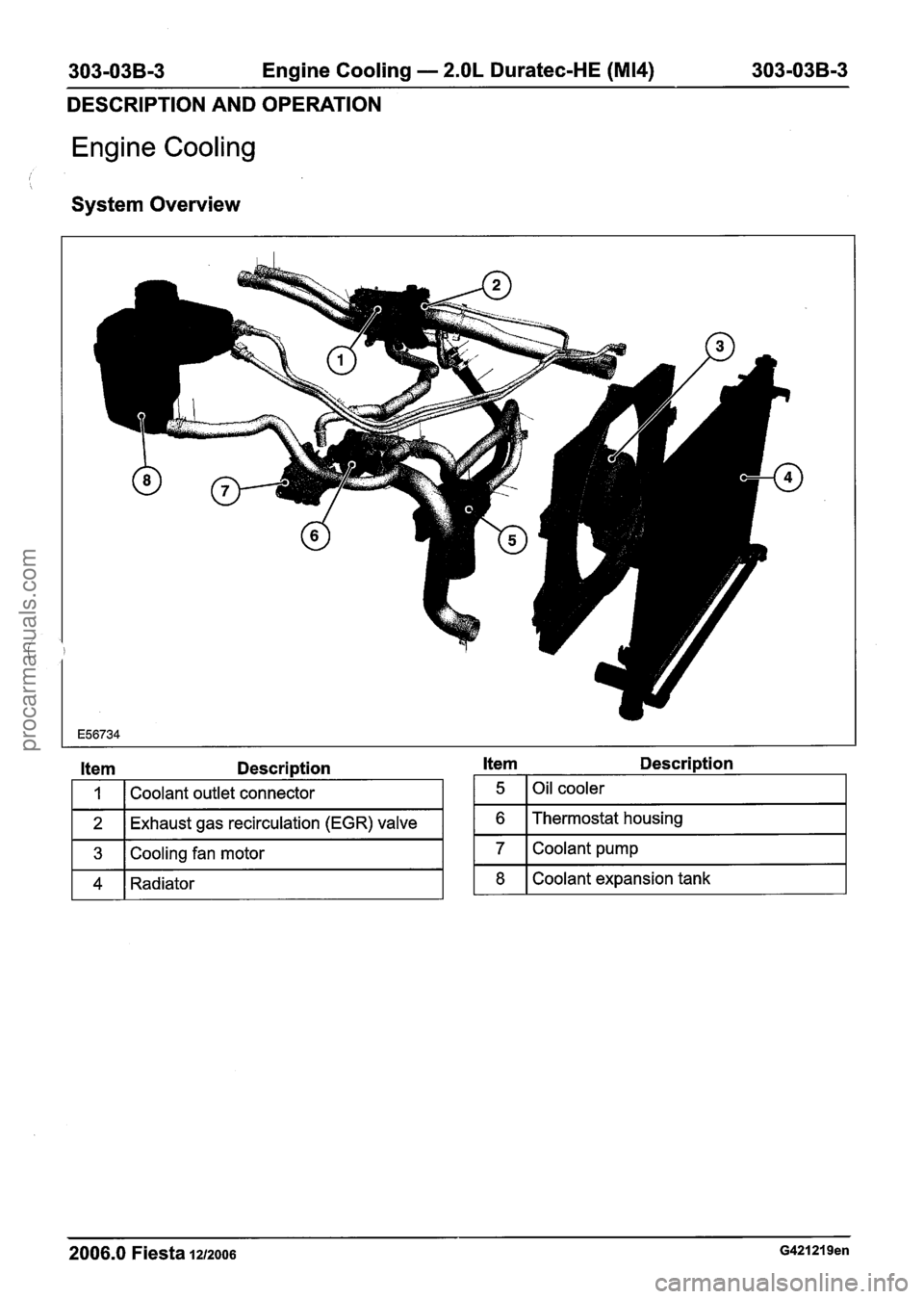

DESCRIPTION AND OPERATION

Engine Cooling

I I

System Overview

Item Description

I 1 I Coolant outlet connector I

1 2 1 Exhaust gas recirculation (EGR) valve I

1 3 1 Cooling fan motor I

1 4 1 Radiator I

Item Description

1 5 1 Oil cooler I

1 6 I Thermostat housing I

2006.0 Fiesta 1212006 G421219en

7

8

Coolant pump

Coolant expansion tank

procarmanuals.com

Page 777 of 1226

303-03B-7 Engine Cooling - 2.OL Duratec-HE (M14) 303-03B-7

DESCRIPTION AND OPERATION

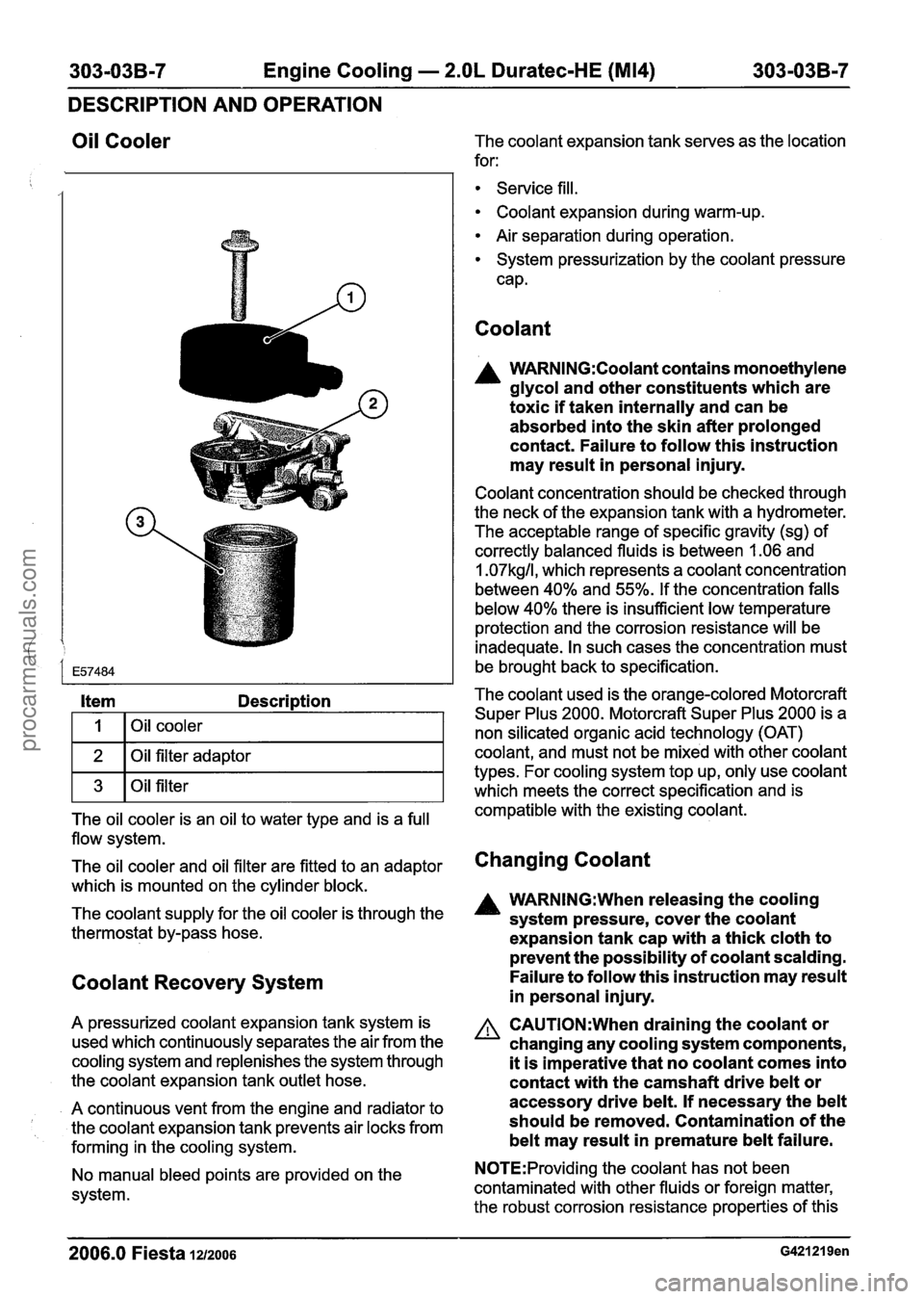

Oil Cooler

Item Description

I I I Oil cooler I

1 2 1 Oil filter adaptor I

1 3 1 Oil filter I

The oil cooler is an oil to water type and is a full

flow system.

The oil cooler and oil filter are fitted to an adaptor

which is mounted on the cylinder block.

The coolant supply for the oil cooler is through the

thermostat by-pass hose.

Coolant Recovery System

A pressurized coolant expansion tank system is

used which continuously separates the air from the

cooling system and replenishes the system through

the coolant expansion tank outlet hose.

A continuous vent from the engine and radiator to

I the coolant expansion tank prevents air locks from

forming in the cooling system.

No manual bleed points are provided on the

system. The coolant expansion tank serves

as the location

for:

Service fill.

Coolant expansion during warm-up.

Air separation during operation.

System pressurization by the coolant pressure

cap.

Coolant

A WARN1NG:Coolant contains monoethylene

glycol and other constituents which are

toxic if taken internally and can be

absorbed into the skin after prolonged

contact. Failure to follow this instruction

may result in personal injury.

Coolant concentration should be checked through

the neck of the expansion tank with a hydrometer.

The acceptable range of specific gravity (sg) of

correctly balanced fluids is between

1.06 and

1.07kg/l, which represents a coolant concentration

between 40% and 55%. If the concentration falls

below 40% there is insufficient low temperature

protection and the corrosion resistance will be

inadequate. In such cases the concentration must

be brought back to specification.

The coolant used is the orange-colored Motorcraft

Super Plus 2000. Motorcraft Super Plus 2000 is a

non silicated organic acid technology (OAT)

coolant, and must not be mixed with other coolant

types. For cooling system top up, only use coolant

which meets the correct specification and is

compatible with the existing coolant.

Changing Coolant

A WARN1NG:When releasing the cooling

system pressure, cover the coolant

expansion tank cap with a thick cloth to

prevent the possibility of coolant scalding.

Failure to follow this instruction may result

in personal injury.

A CAUTI0N:When draining the coolant or

changing any cooling system components,

it is imperative that no coolant comes into

contact with the camshaft drive belt or

accessory drive belt. If necessary the belt

should be removed. Contamination of the

belt may result in premature belt failure.

N0TE:Providing the coolant has not been

contaminated with other fluids or foreign matter,

the robust corrosion resistance properties of this

2006.0 Fiesta 1212006 G421219en

procarmanuals.com

Page 778 of 1226

303-03B-8 Engine Cooling - 2.OL Duratec-HE (M14) 303-038-8

DESCRIPTION AND OPERATION

coolant means that it can be re-used after changing If the engine temperature still continues to rise,

an aluminium cooling system component, although

stage

3 of the strategy will commence. This will

the concentration should always be checked and

result in the engine being totally disabled before

(

maintained within specification.

major engine damage or seizure occurs. The MIL .

This coolant should be changed after a period of will begin-to

flash, indicating to the driver that the

10 years or 150 000 miles, whichever occurs first. engine will

be switched off after 30 seconds. This

Refill the cooling system with coolant which meets allows the driver time to choose a suitable parking

the correct specification and is compatible with the place.

existing coolant.

Fail-Safe Cooling

The vehicle has a strategy built into the powertrain

control module (PCM) that will control the engine

if the engine starts to overheat.

If the engine starts to overheat, stage

1 of the

strategy will commence. The ECT sensor transmits

a signal to the PCM which then moves the

temperature gauge pointer into the red zone.

If the engine is not switched off and the

temperature continues to rise, the malfunction

indicator lamp (MIL) is illuminated. This indicates

to the driver that the engine is approaching critical

limits and should stop. At this point DTC

PI285 is

set in the PCM which can be retrieved using WDS.

If the MIL and temperature gauge are ignored by

the driver, stage 2 of the strategy will commence.

The PCM will start to control the engine by cutting

out two cylinders and restricting the RPM to below

3000 RPM. The MIL will remain illuminated. This

indicates that long term engine damage may occur

and vehicle emissions will be affected. At this point

DTC

PI299 is set in the PCM which can be

retrieved using WDS.

Air is drawn into the deactivated cylinders which

helps to control the temperature of the engine

internal components. The deactivated cylinders

are alternated to allow even cooling of all the

cylinders.

N0TE:lf the driver is using a high percentage of

throttle travel (for example, an overtaking

maneuver) when the PCM starts engine

deactivation (stage 2), the deactivation will be

delayed for 10 seconds.

N0TE:After 2-cylinder operation has begun, the

engine will not revert to 4-cylinder operation, even

if the temperature should fall, until the ignition is

switched off and then on again.

N0TE:The MIL can only be extinguished by using

WDS after the fault has been rectified and the DTC

cleared.

2006.0 Fiesta 1212006 G421219en

procarmanuals.com