engine coolant FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 39 of 1226

100-00-23 General Information 100-00-23

DESCRIPTION AND OPERATION

RoadIRoller Testing

I Road or roller testing may be carried out for various

reasons and a procedure detailing pre-test checks,

engine starting and stopping, pre-driving checks,

on-test checks and final checks to be completed

on completion of the test is given below.

Unless complete vehicle performance is being

checked, the full road test procedure need not be

carried out. Instead, those items particularly

relevant to the

system(s) being checked can be

extracted.

Pre-Test Checks

A WARNING:lf the brake system hydraulic

fluid level is low, pedal travel is excessive

or a hydraulic leak is found, do not attempt

to road test the vehicle until the reason for

the low fluid level, excessive pedal travel

or hydraulic leak is found and rectified.

It is suggested that pre-test checks and functional

tests of those systems and circuits which affect the

safe and legal operations of the vehicle, such as

( , brakes, lights and steering, should always be

carried out before the road or roller test.

With the ignition switched off, check:

- the engine oil level.

- the engine coolant level.

- the tires, for correct pressure, compatible types

and tread patterns, and wear within limits.

- that there is sufficient fuel in the tank to

complete the test.

- all around the engine, transmission and under

the vehicle for oil, coolant, hydraulic and fuel

leaks. Make a note of any apparent leaks and

wipe off the surrounding areas to make it easier

to identify the extent of the leak on completion

of the test.

Starting the Engine

N0TE:On initial drive away from cold and within

the first 1.5 km (1 mile), do not depress the

accelerator pedal beyond half travel until the

vehicle has attained a minimum speed of

25 kmlh

(15 mileslh). Never operate at high engine speed

or with the accelerator pedal at full travel whilst the

engine is cold.

With the ignition switched off, check:

- that the parking brake is applied.

- that the gear lever is in the neutral position.

- that all instrument gauges (except fuel gauge)

read zero.

With the ignition switched on, check:

- that the ignition controlled warning lamps are

illuminated.

- that the engine temperature gauge registers a reading compatible with the engine temperature.

- that the fuel gauge registers a reading

appropriate to the fuel level in the tank.

- the operation of the parking brake warning lamp

and fluid level warning indicator.

Road or Roller Testing

A CAUTI0N:lf road testing, check the brake

operation while still traveling at low speed

before continuing with the test. If the

brakes pull to one side, or appear to be

otherwise faulty, do not continue with the

road test until the fault has been found and

rectified.

During the road or roller test, check:

- that the clutch pedal operation is not stiff or

heavy.

- that the initial gear engagement is smooth and

there is no evidence of clutch drag.

- that the parking brake control operates smoothly

and releases quickly and completely.

- that the clutch takes up the drive smoothly,

without slip or judder.

- that gear changing is smooth with no abnormal

noises or vibrations from the transmission.

- the engine power output is satisfactory, full

power is achieved, acceleration is smooth and

pedal operation is not stiff or heavy, and engine

speed returns to idle correctly.

- there is no excessive or abnormally colored

smoke from the engine under normal driving,

heavy load or overrun conditions.

- that steering operation, including power steering

(if equipped), is smooth, accurate, not

excessively heavy or with excessive free play

or vibration.

- that the steering does not pull to one side and

self centers smoothly after cornering.

2006.0 Fiesta 1212006 GI 7375en

procarmanuals.com

Page 426 of 1226

303-004 Engine System - General Information 303-00-4

DIAGNOSIS AND TESTING

Engine

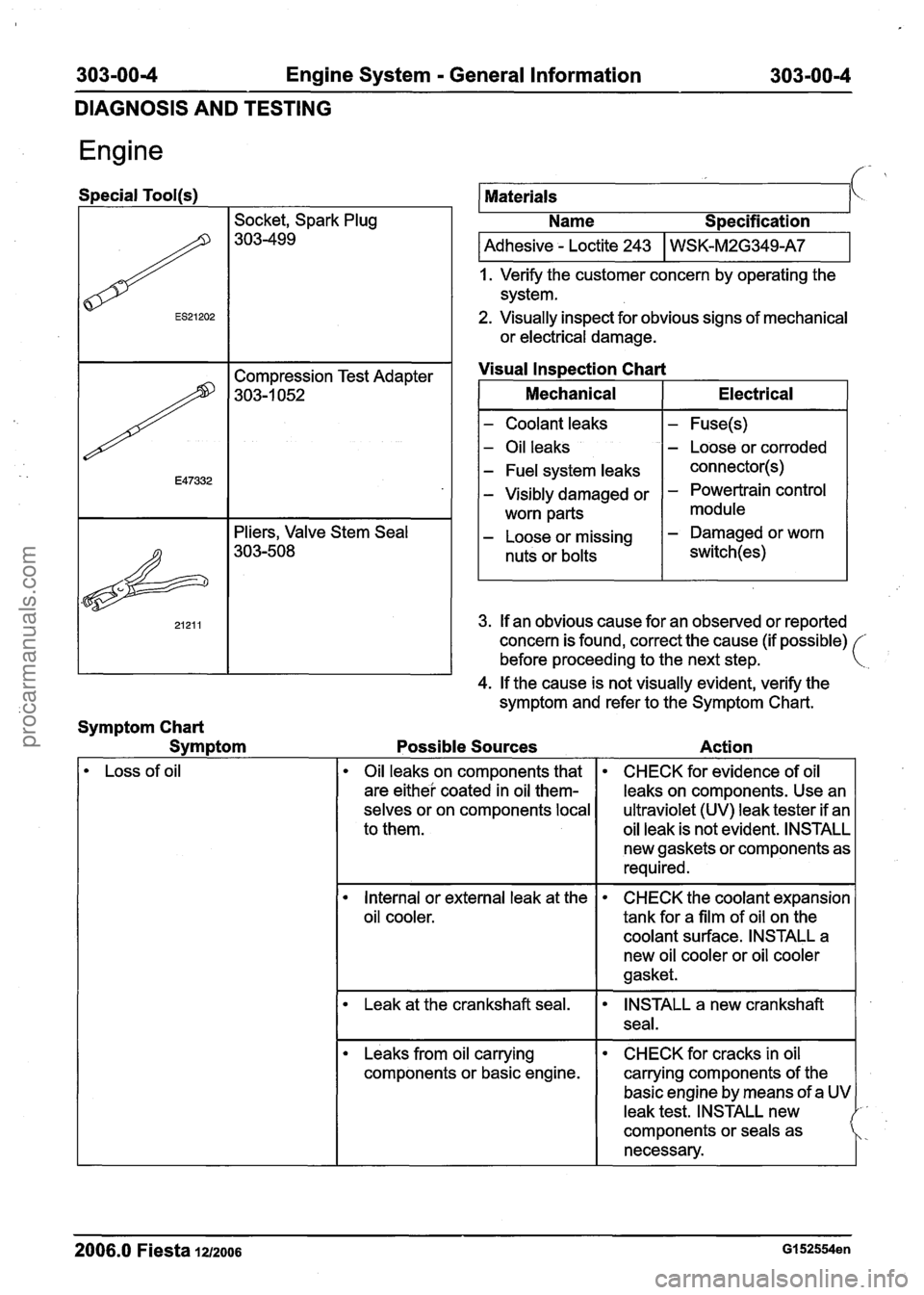

Special Tool(s)

Socket, Spark Plug

303-499

I Adhesive - Loctite 243 I WSK-M2G349A7 I

Materials

1. Verify the customer concern by operating the

system.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

k.

Name S~ecification

Leaks from oil carrying

components or basic engine.

E47332

&

21211

CHECK for cracks in oil

carrying components of the

basic engine by means of a

leak test. INSTALL new

components or seals as

necessary.

2006.0 Fiesta 1212006 GI 52554en

Compression Test Adapter

303-1 052

Pliers, Valve Stem Seal

303-508

4. If the cause is not visually evident, verify the

symptom and refer to the Symptom Chart.

Symptom Chart Symptom Possible Sources Action

Visual

Inspection Chart

Loss of oil Mechanical

- Coolant

leaks

- Oil leaks

- Fuel system leaks

- Visibly damaged or

worn parts

- Loose or missing

nuts or bolts Electrical

- Fuse(s)

- Loose

or corroded

connector(s)

- Powertrain control

module

- Damaged or worn

switch(es)

Oil leaks on components that

are

eithei coated in oil them-

selves or on components local

to them.

Internal or external leak at the

oil cooler.

Leak at the crankshaft seal.

3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

CHECK for evidence of oil

leaks on components. Use an

ultraviolet (UV) leak tester if an

oil leak is not evident, INSTALL

new gaskets or components as

required.

CHECK the coolant expansion

tank for a film of oil on the

coolant surface. INSTALL a

new oil cooler or oil cooler

gasket.

INSTALL a new crankshaft

seal.

procarmanuals.com

Page 429 of 1226

303-00-7 Engine System - General Information 303-00-7

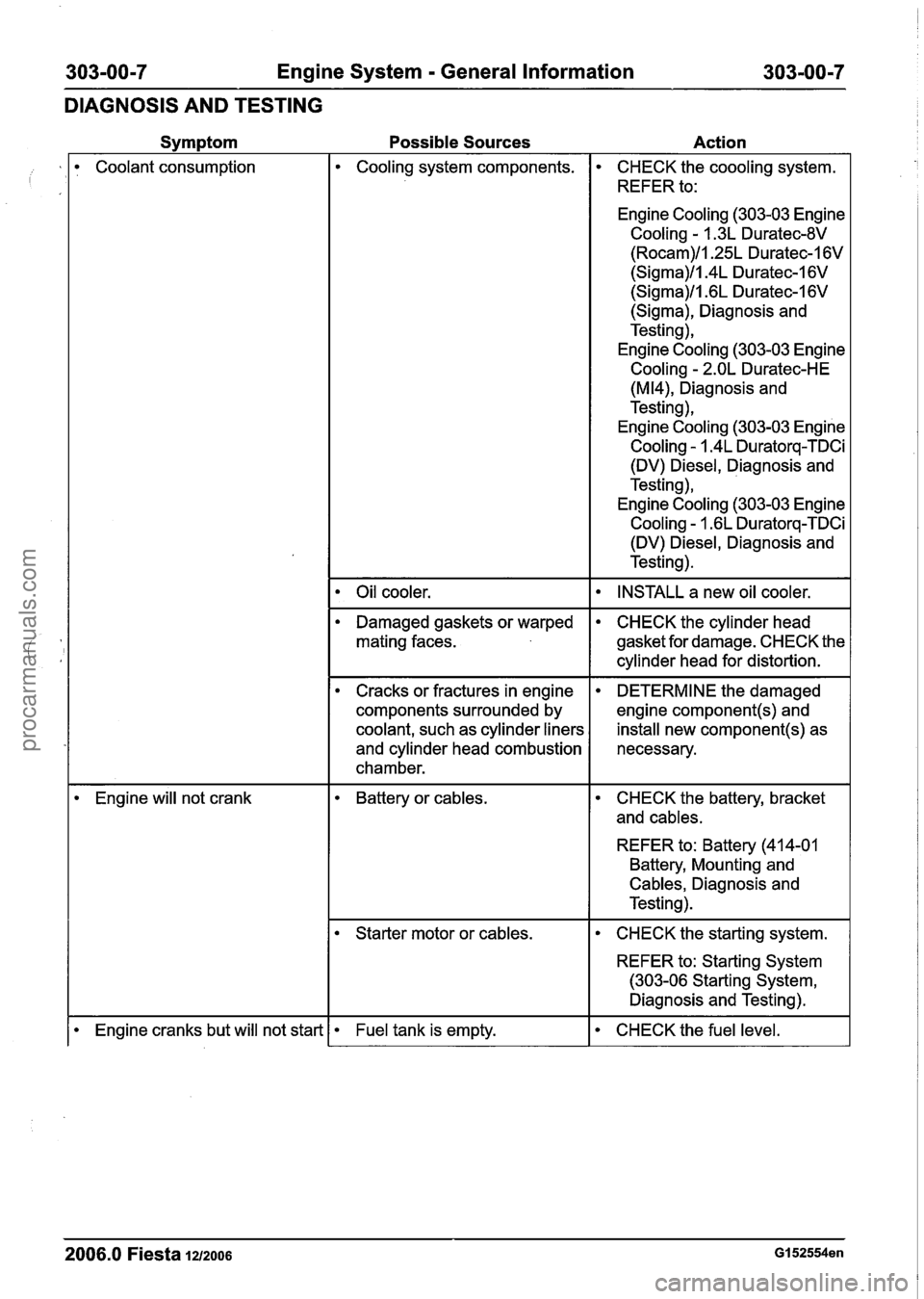

DIAGNOSIS AND TESTING

Svm~tom Possible Sources Action

Coolant consumption Cooling system components.

Oil cooler.

CHECK the coooling system.

REFER to:

Engine

Cooling (303-03 Engine

Cooling - 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)ll .6L Duratec-1 6V

(Sigma), Diagnosis and

Testing),

Engine

Cooling (303-03 Engine

Cooling - 2.OL Duratec-HE

(M14), Diagnosis and

Testing),

Engine

Cooling (303-03 Engine

Cooling - 1.4L Duratorq-TDCi

(DV)

Diesel, Diagnosis and

Testing),

Engine

Cooling (303-03 Engine

Cooling - 1.6L Duratorq-TDCi

(DV)

Diesel, Diagnosis and

Testing).

INSTALL a new oil cooler.

Damaged gaskets or warped

mating faces. CHECK the cylinder head

gasket for damage. CHECK the

cylinder head for distortion. - -- - -

Cracks or fractures in engine

components surrounded by

coolant, such as cylinder liners

and cylinder head combustion

chamber.

- - - - - - - -

DETERMINE the damaged

engine

component(s) and

install new component(s) as

necessary.

Engine will not crank Battery or cables. CHECK the battery, bracket

and

cables.

REFER to: Battery (41 4-01

Battery, Mounting and

Cables, Diagnosis and

Testing).

Starter motor or cables. I CHECK the starting system.

REFER to: Starting System

(303-06 Starting System,

Diagnosis and Testing).

2006.0 Fiesta 1212006 GI 52554en

I Engine cranks but will not start Fuel tank is empty. CHECK the fuel level.

procarmanuals.com

Page 483 of 1226

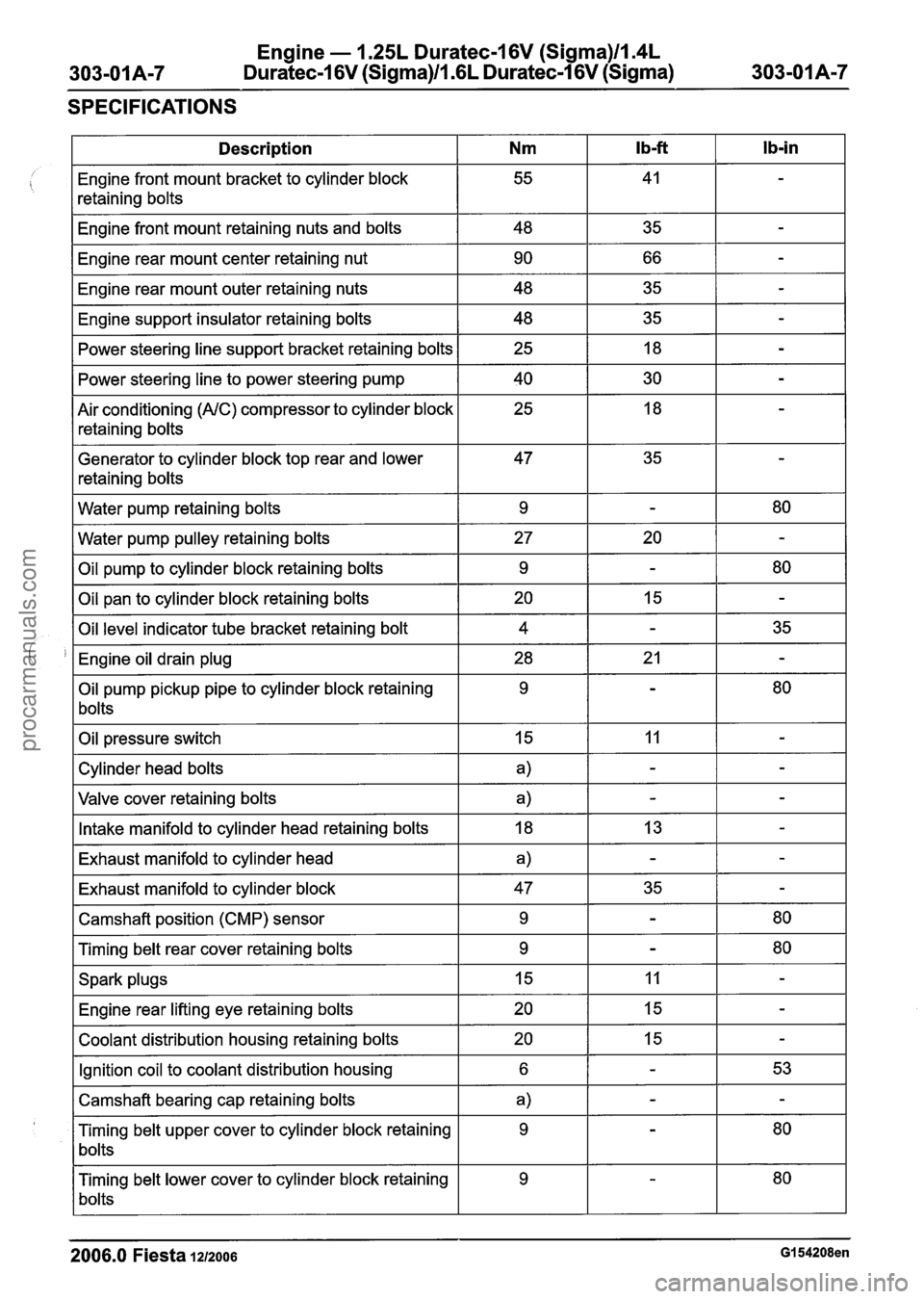

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)Il.GL Duratec-1 6V (Sigma)

SPECIFICATIONS

2006.0 Fiesta 1212006 GI 54208en

Ib-in

-

-

-

-

-

-

-

-

-

80

-

80

-

35

-

80

-

-

-

-

-

-

80

80

-

-

-

53

-

80

80

Ib-ft

41

35

66

35 35 18

30

18

35

-

20

-

15

-

21

-

11

-

-

13

-

35

-

-

11

15

15

-

-

-

-

Description

Engine front mount bracket to cylinder block

retaining bolts

Engine front mount retaining nuts and bolts

Engine rear mount center retaining nut

Engine rear mount outer retaining nuts

Engine support insulator retaining bolts Power steering line support bracket retaining bolts

Power steering line to power steering pump

Air conditioning

(AIC) compressor to cylinder block

retaining bolts

Generator to cylinder block top rear and lower

retaining bolts

Water pump retaining bolts

Water pump pulley retaining bolts

Oil pump to cylinder block retaining bolts

Oil pan to cylinder block retaining bolts

Oil level indicator tube bracket retaining bolt

Engine oil drain plug

Oil pump pickup pipe to cylinder block retaining

bolts

Oil pressure switch

Cylinder head bolts

Valve cover retaining bolts

Intake manifold to cylinder head retaining bolts

Exhaust manifold to cylinder head

Exhaust manifold to cylinder block

Camshaft position (CMP) sensor

Timing belt rear cover retaining bolts

Spark plugs Engine rear lifting eye retaining bolts

Coolant distribution housing retaining bolts

Ignition coil to coolant distribution housing

Camshaft bearing cap retaining bolts

Timing belt upper cover to cylinder block retaining

bolts

Timing belt lower cover to cylinder block retaining

bolts

Nm

55

48 90

48

48 25

40 25

47

9

27 9

20 4

28 9

15

a)

a)

18

a)

47 9

9

15

20

20

6

a)

9

9

procarmanuals.com

Page 484 of 1226

Engine - I .25L Duratec-1 6V (Sigma)llI4L

Duratec-1 6V (Sigma)ll .6L Duratec-I 6V (Sigma)

SPECIFICATIONS

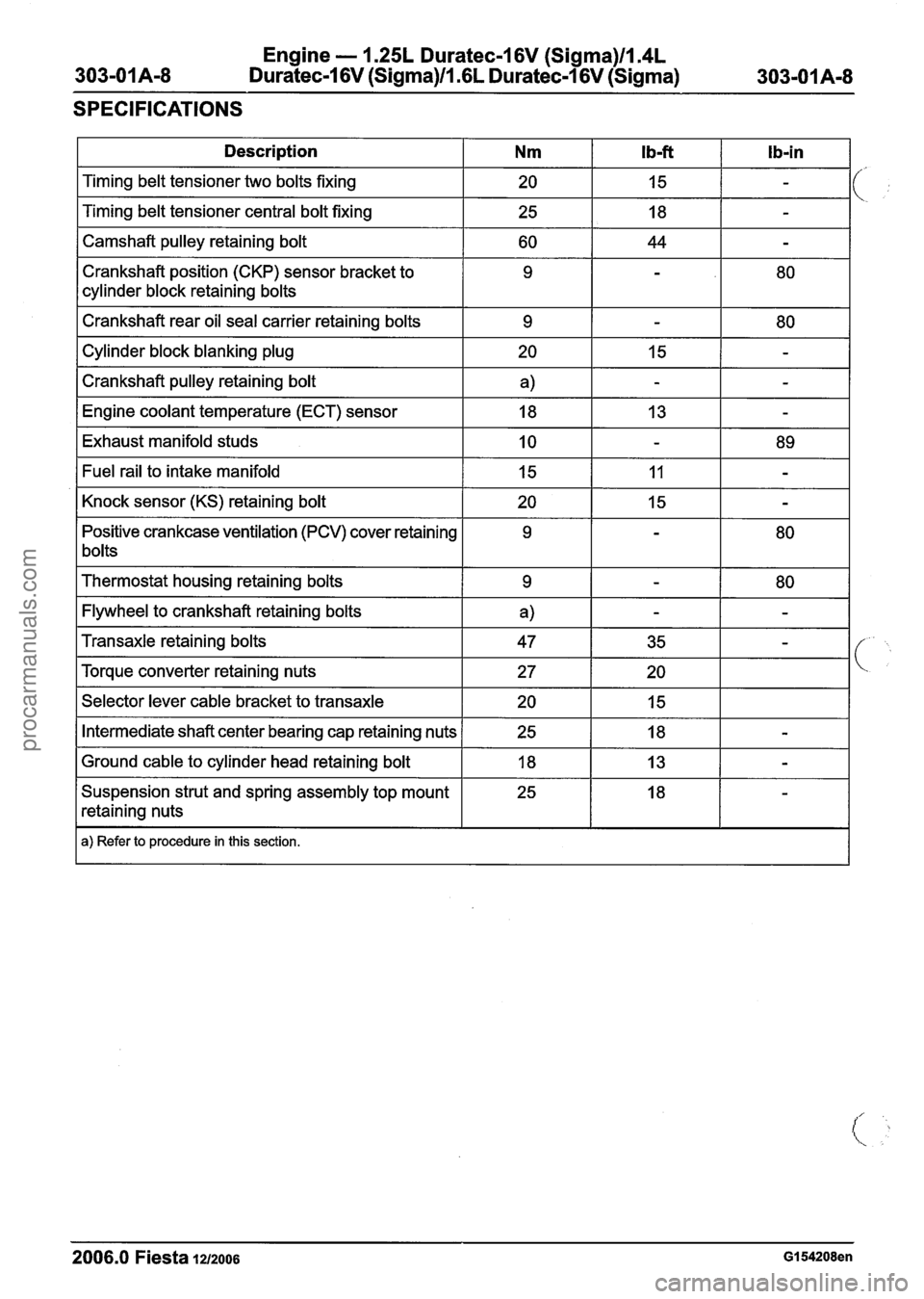

1 Description I Nm I Ib-ft I Ib-in I

I Camshaft pulley retaining bolt I 60 I 44 I - I

Timing belt tensioner two bolts fixing

Timing belt tensioner central bolt fixing

Crankshaft position (CKP) sensor bracket to

cylinder block retaining bolts

I Crankshaft rear oil seal carrier retaining bolts I 9 1 - I 80 I

20

25

I Cylinder block blanking plug I 20 I 15 1 - I

I Crankshaft pulley retaining bolt I a) I - I - I

15

18

I Engine coolant temperature (ECT) sensor I 18 I 13 I - I

-

-

I Exhaust manifold studs I 10 I - I 89 I

Positive crankcase ventilation (PCV) cover retaining

1 bolts Fuel

rail to intake manifold

Knock sensor (KS) retaining bolt

I Thermostat housing retaining bolts I 9 I - 1 80 I

I Flywheel to crankshaft retaining bolts I a) I - I - I

15

20

I Selector lever cable bracket to transaxle I 20 I 15 I I

11

15

Transaxle retaining bolts

Torque converter retaining nuts

I Intermediate shaft center bearing cap retaining nuts 1 25 I 18 I - I

-

-

I Ground cable to cylinder head retaining bolt I 18 I 13 I - I

47

27

Suspension strut and spring assembly top mount

retaining nuts

I a) Refer to procedure in this section.

35

20

2006.0 Fiesta 1212006 GI 54208en

-

procarmanuals.com

Page 497 of 1226

Engine - 1.25L Duratec-I 6V (Sigma)ll14L

Duratec-1 6V (Sigma)ll16L Duratec-1 6V (Sigma)

IN-VEHICLE REPAIR

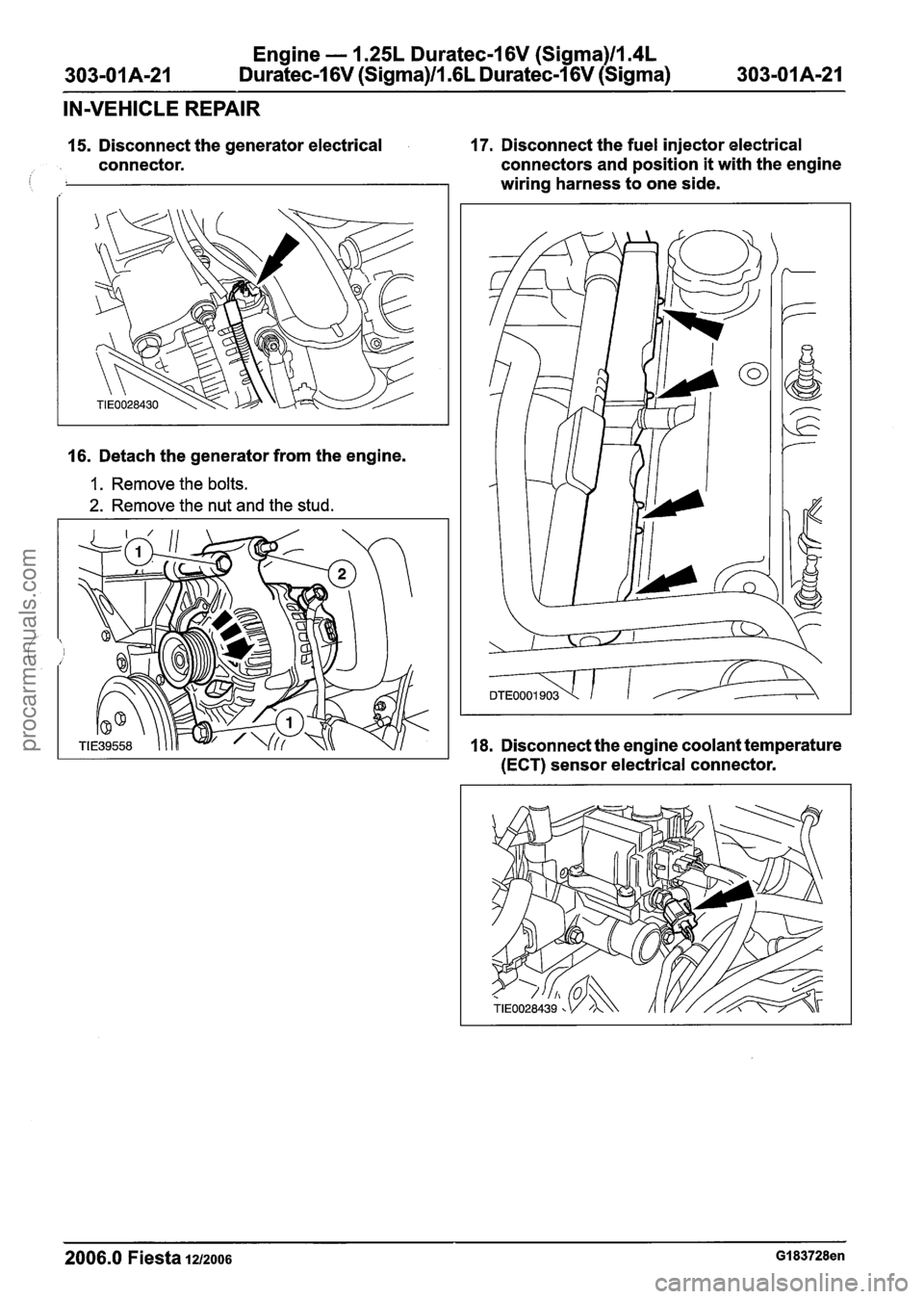

15. Disconnect the generator electrical 17. Disconnect the fuel injector electrical

connector. connectors and

position it with the engine

i wiring harness to one side.

16. Detach the generator from the engine.

1. Remove the bolts.

2. Remove the nut and the stud.

18. Disconnect the engine coolant temperature

(ECT) sensor electrical connector.

2006.0 Fiesta 1~12006 GI 83728en

procarmanuals.com

Page 498 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)llI4L

Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma)

IN-VEHICLE REPAIR

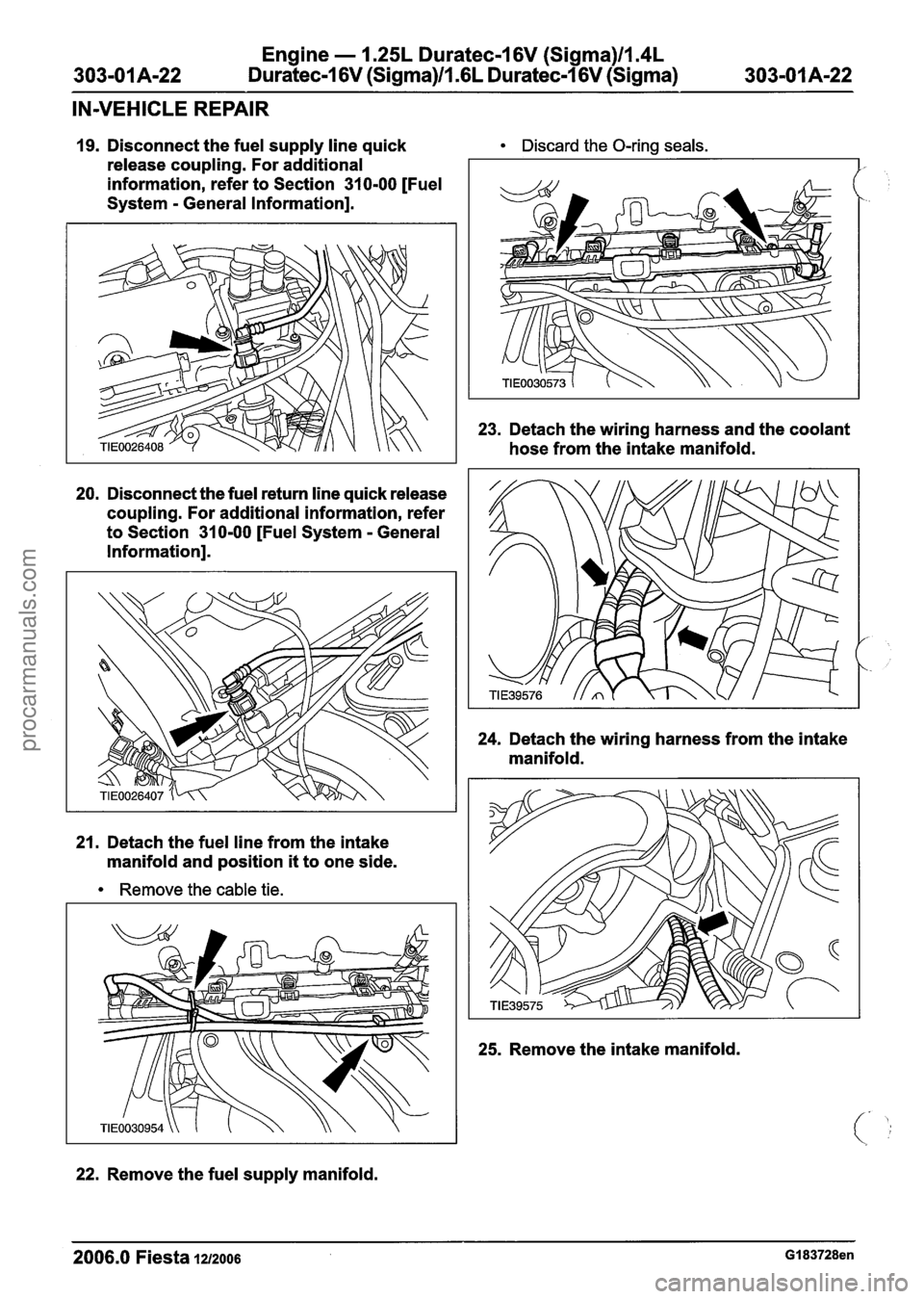

19. Disconnect the fuel supply line quick Discard the O-ring seals.

release coupling. For additional

information, refer to Section

31 0-00 [Fuel

System

- General Information].

20. Disconnect the fuel return line quick release

coupling. For additional information, refer

to Section

31 0-00 [Fuel System - General

Information].

21. Detach the fuel line from the intake

manifold and position

it to one side.

Remove the cable tie.

22.

Remove the fuel supply manifold.

23. Detach the wiring harness and the coolant

hose from the intake manifold.

24. Detach the wiring harness from the intake

manifold.

25. Remove the intake manifold.

2006.0 Fiesta 1212006 GI 83728en

procarmanuals.com

Page 499 of 1226

Engine - 1.25L Dura

303-01 A-23 Duratec-1

6V (Sigma)ll .(

:ec-I 6V (Sigma)llm4L

L

Duratec-1 6V (Sigma)

303-01 Am23

IN-VEHICLE REPAIR

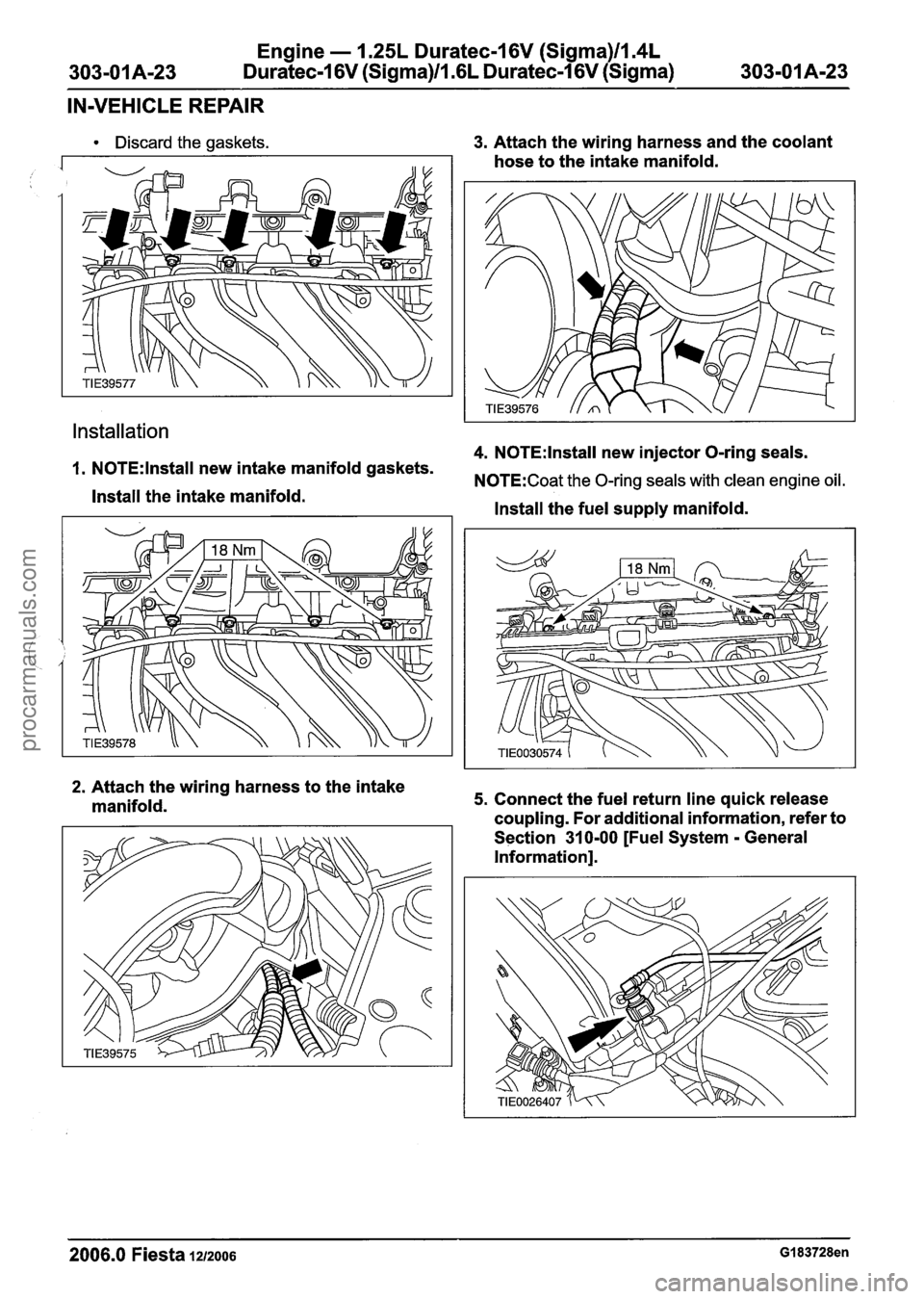

Discard the gaskets.

Installation

3. Attach the wiring harness and the coolant

hose to the intake manifold.

4. N0TE:lnstall new injector O-ring seals.

1. N0TE:lnstall new intake manifold gaskets. N0TE:Coat the 0-rina seals with clean enaine oil.

Install the intake manifold. V "

Install the fuel supply manifold.

2. Attach the wiring harness to the intake

manifold. 5. Connect the fuel return line quick release

coupling. For additional information, refer to

Section

31 0-00 [Fuel System - General

Information].

2006.0 Fiesta 1212006 GI 83728en

procarmanuals.com

Page 500 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)llI4L

Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma)

IN-VEHICLE REPAIR

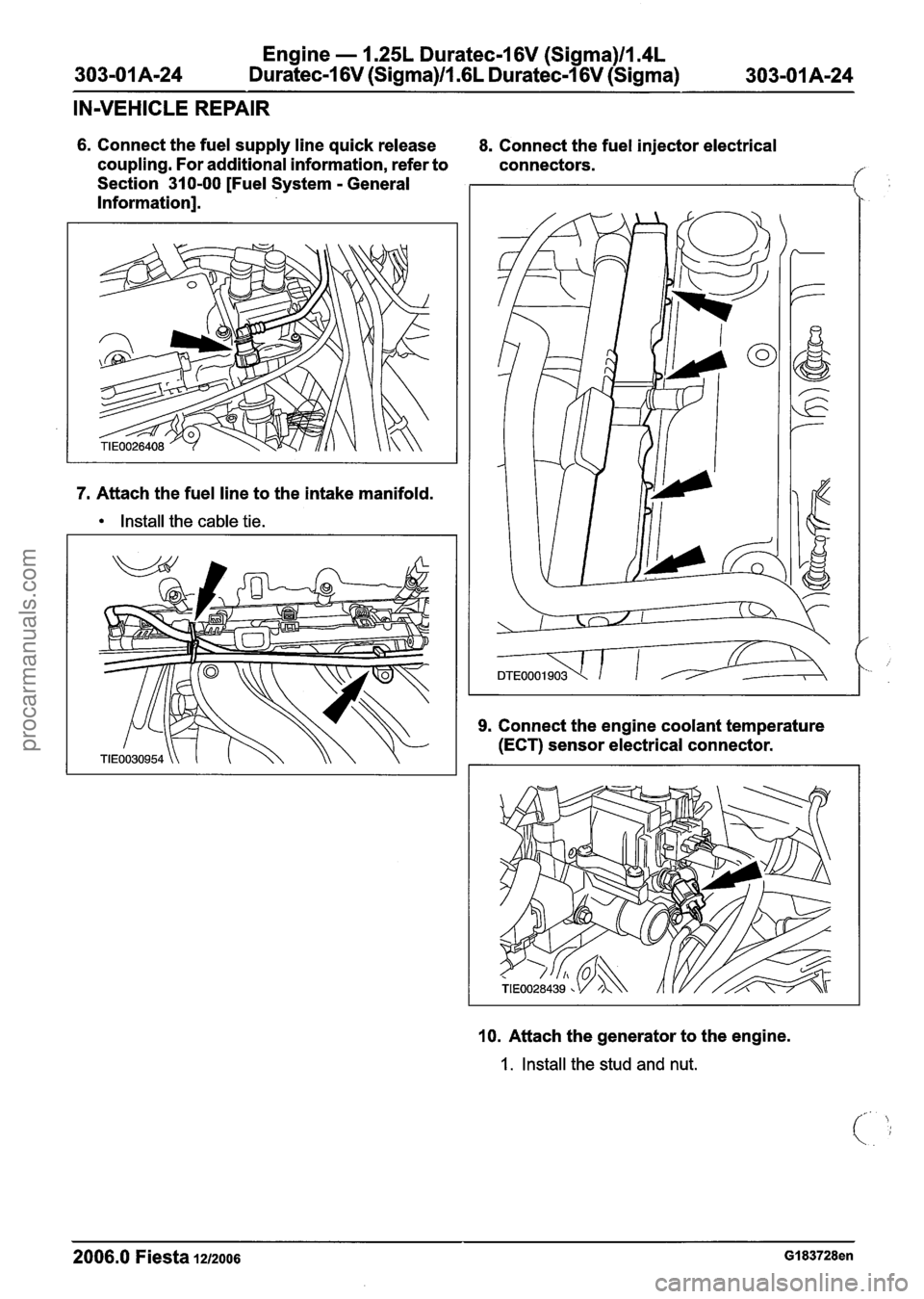

6. Connect the fuel supply line quick release

coupling. For additional information, refer to

Section 310-00 [Fuel System

- General

Information].

7. Attach the fuel line to the intake manifold.

Install the cable tie. 8.

Connect the fuel injector electrical

connectors.

9. Connect the engine coolant temperature

(ECT) sensor electrical connector.

10. Attach the generator to the engine.

1. Install the stud and nut.

2006.0 Fiesta 1212006 GI 83728en

procarmanuals.com

Page 513 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)lIl4L

303-01 A-37 Duratec-1 6V (Sigma)ll.GL Duratec-1 6V (Sigma) 303-01A-37

IN-VEHICLE REPAIR

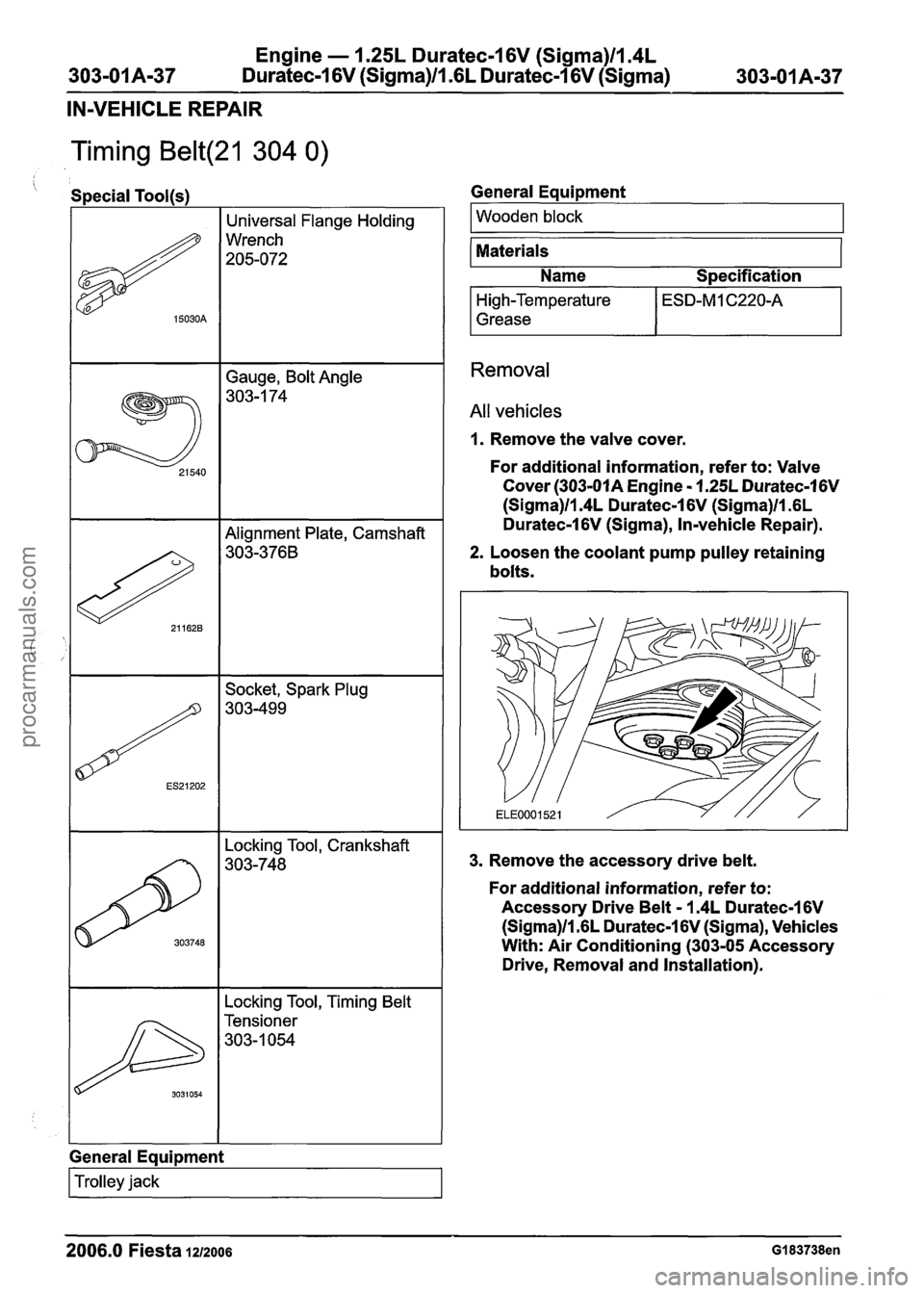

Timing Belt(21 304 0)

Gauge, Bolt Angle

303-1 74

' Special Tool(s)

# 15030A

Locking Tool, Timing Belt

I Tensioner

303-1054

Universal Flange Holding

Wrench

205-072

303748

General Equipment

Locking Tool, Crankshaft

303-748

I Trolley jack I

General Eaui~ment

I Wooden block I - --

Materials

Name

S~ecification

High-Temperature

Grease

Removal

All vehicles

1. Remove the valve cover.

For additional information, refer to: Valve

Cover

(303-01A Engine - 1.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V (Sigma)ll .6L

Duratec-1

6V (Sigma), In-vehicle Repair).

2. Loosen the coolant pump pulley retaining

bolts.

3. Remove the accessory drive belt.

For additional information, refer to:

Accessory Drive Belt

- 1.4L Duratec-I 6V

(Sigma)/l.GL Duratec-1 6V (Sigma), Vehicles

With: Air Conditioning (303-05 Accessory

Drive, Removal and Installation).

2006.0 Fiesta 1212006 GI 83738en

procarmanuals.com