key FORD FIESTA 2007 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 417 of 1226

21 I -04-9 Steering Column 2 1 1 -04-9

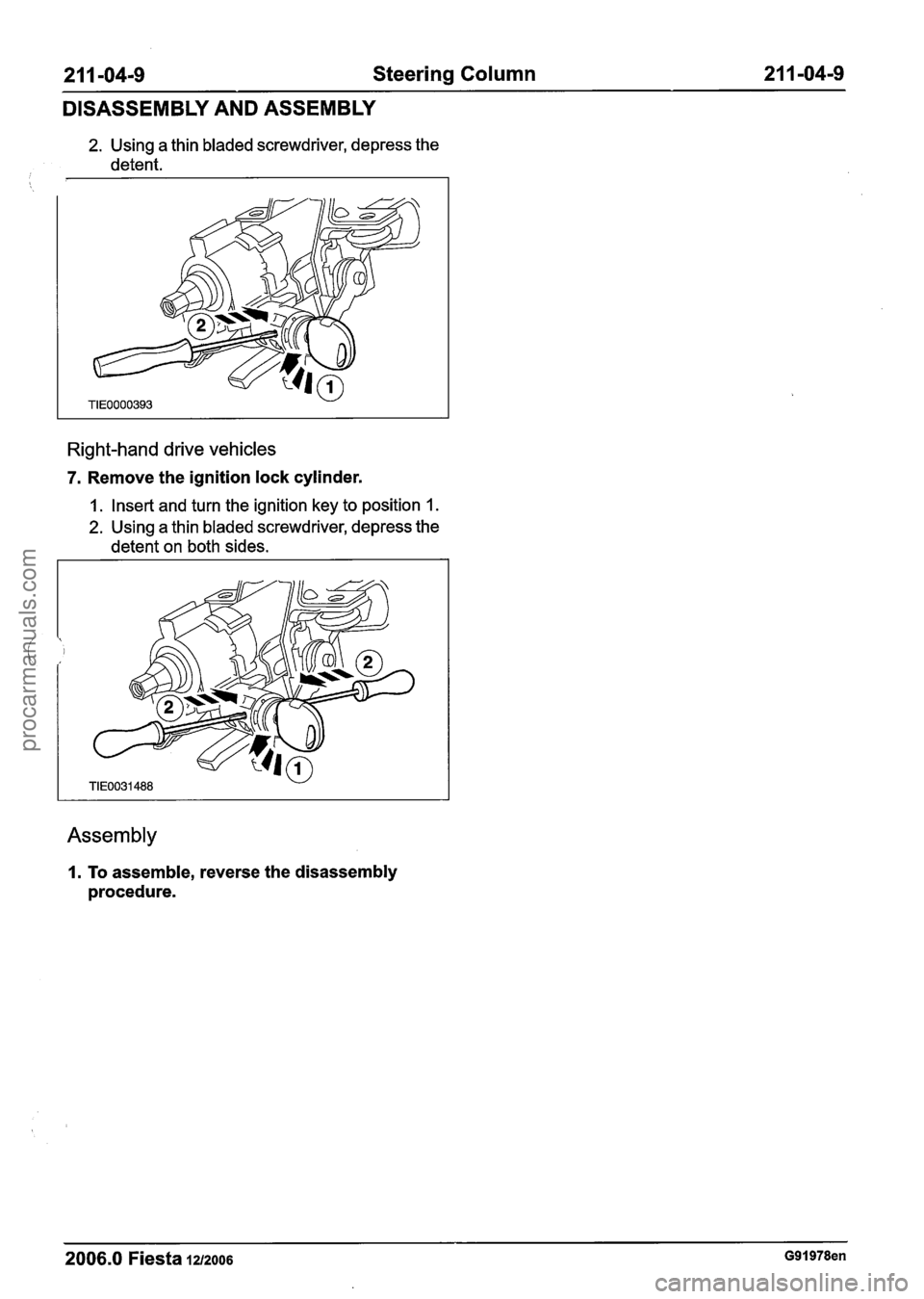

DISASSEMBLY AND ASSEMBLY

2. Using a thin bladed screwdriver, depress the

detent.

Right-hand drive vehicles

7. Remove the ignition lock cylinder.

1. Insert and turn the ignition key to position 1.

2. Using a thin bladed screwdriver, depress the

detent on both sides.

Assembly

1. To assemble, reverse the disassembly

procedure.

2006.0 Fiesta 1212006 G91978en

procarmanuals.com

Page 802 of 1226

Fuel Charging and Controls - 1.25L

Duratec-1 6V (Sigma)ll.4L Duratec-I 6V

303-04A-4 (Sigma)ll.GL Duratec-1 6V (Sigma) 303-04A-4

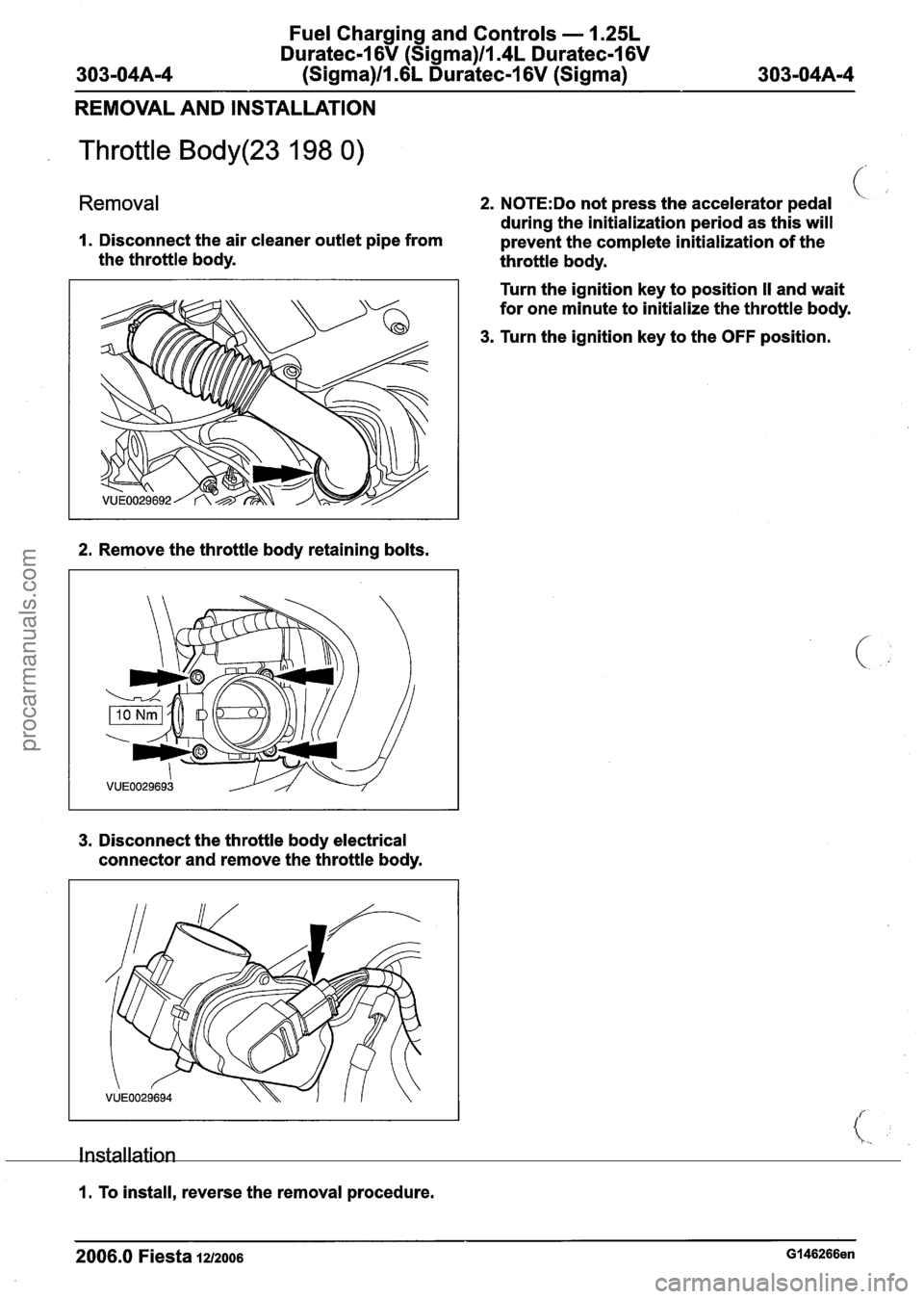

REMOVAL AND INSTALLATION

Throttle Body(23 198 0)

Removal 2. N0TE:Do not press the accelerator pedal

during the initialization period as this will

1. Disconnect the air cleaner outlet pipe from

prevent the complete initialization of the

the throttle body. throttle body.

2. Remove the throttle body retaining bolts. Turn

the ignition key to position

II and wait

for one minute to

initialize the throttle body.

3. Turn the ignition key to the OFF position.

3. Disconnect the throttle body electrical

connector and remove the throttle body.

I nin

1. To install, reverse the removal procedure.

2006.0 Fiesta 1212006 GI 46266en

procarmanuals.com

Page 832 of 1226

Fuel Charging and Controls - 2.OL

303-04B-24 Duratec-HE (M14) 303-04B-24

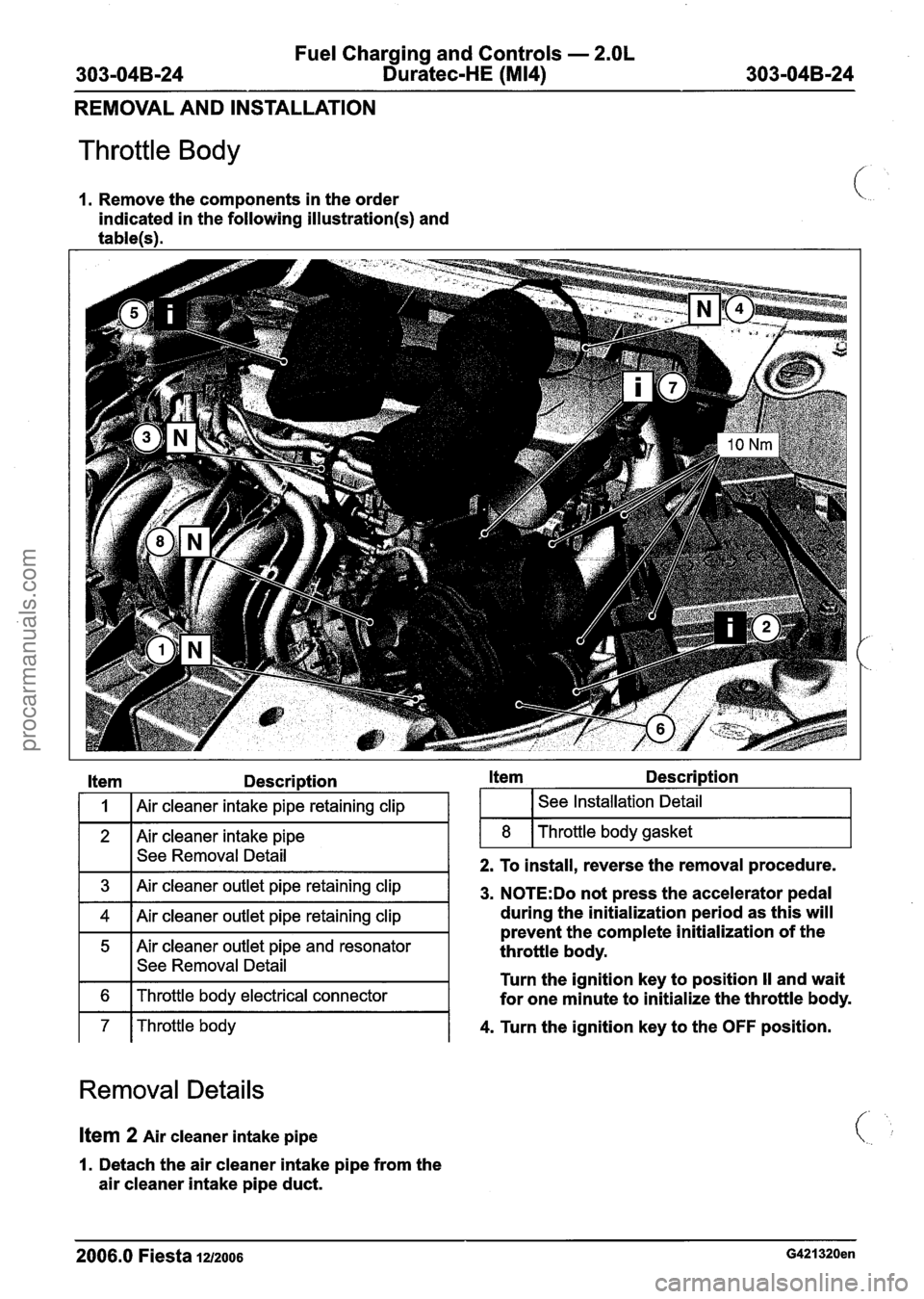

REMOVAL AND INSTALLATION

Throttle Body

1. Remove the components in the order

indicated in the following

illustration(s) and

tablelsl.

Item Description Item Description

See Removal ~etaii-

1 7 I Throttle body 1 4. Turn the ignition key to the OFF position.

1

2 I I

2. To install, reverse the removal procedure.

3

4

5

6

Removal Details

8

Air cleaner intake pipe retaining clip

Air cleaner intake pipe

Item 2 Air cleaner intake pipe

See Installation Detail

Throttle body gasket

Air cleaner outlet pipe retaining clip

Air cleaner outlet pipe retaining clip

Air cleaner outlet pipe and resonator

See Removal Detail

Throttle body electrical connector

1. Detach the air cleaner intake pipe from the

air cleaner intake pipe duct.

3. N0TE:Do not press the accelerator pedal

during the initialization period as this will

prevent the complete initialization of the

throttle body.

Turn the ignition key to position

II and wait

for one minute to initialize the throttle body.

2006.0 Fiesta 1212006 G421320en

procarmanuals.com

Page 867 of 1226

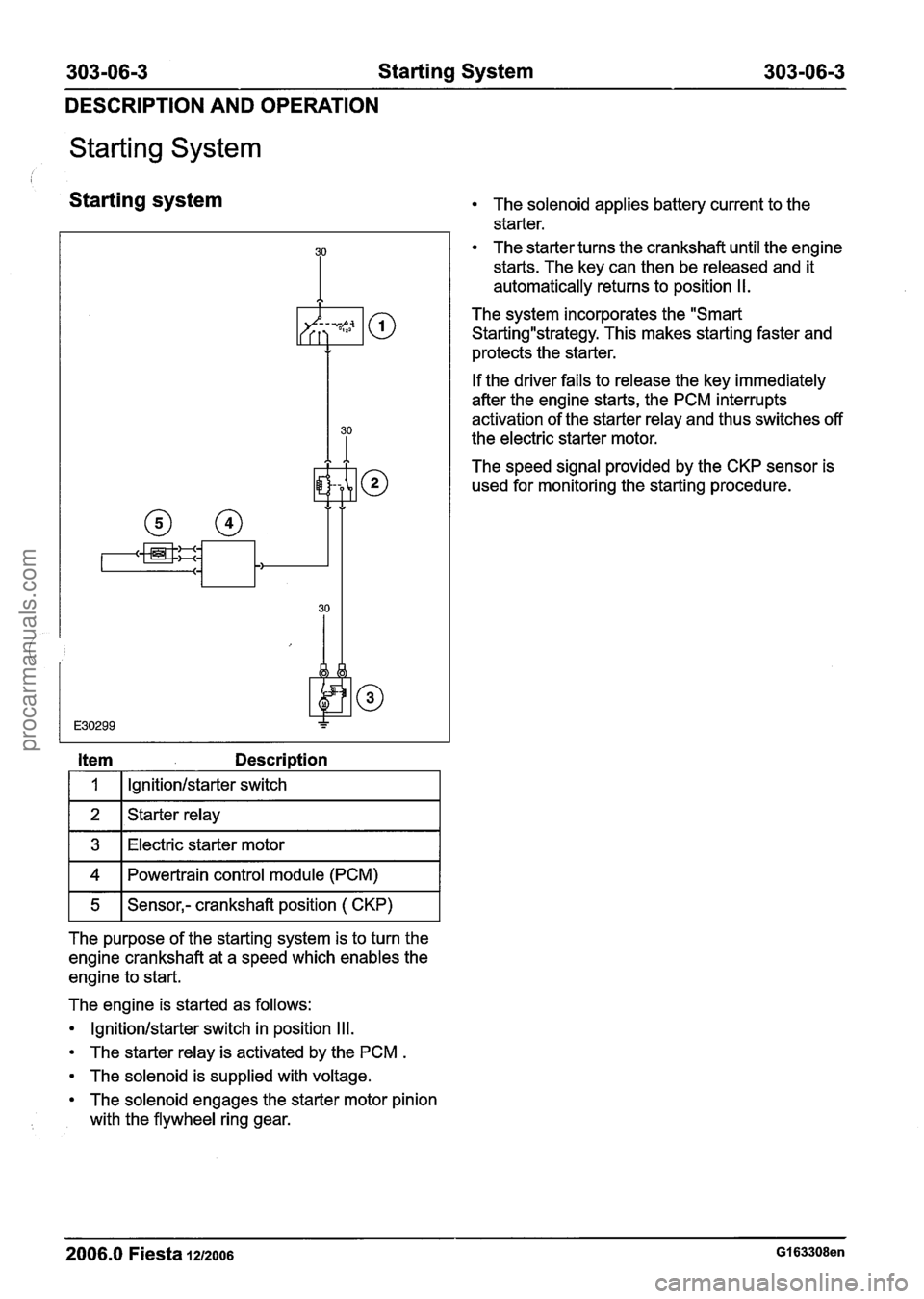

303-06-3 Starting System 303-06-3

DESCRIPTION AND OPERATION

Starting System

Starting system

1 tern Description

I 1 I lgnitionlstarter switch I

1 2 1 Starter relay I

1 3 1 Electric starter motor I

1 4 1 Powertrain control module (PCM) I

1 5 1 Sensor,- crankshaft position ( CKP) I

The purpose of the starting system is to turn the

engine crankshaft at a speed which enables the

engine to start.

The engine is started as follows:

Ignitionlstarter switch in position

Ill.

The starter relay is activated by the PCM .

The solenoid is supplied with voltage.

The solenoid engages the starter motor pinion

with the flywheel ring gear.

The solenoid applies battery current to the

starter.

The starter turns the crankshaft until the engine

starts. The key can then be released and it

automatically returns to position

I I.

The system incorporates the "Smart

StartingWstrategy. This makes starting faster and

protects the starter.

If the driver fails to release the key immediately

after the engine starts, the PCM interrupts

activation of the starter relay and thus switches off

the electric starter motor.

The speed signal provided by the CKP sensor is

used for monitoring the starting procedure.

2006.0 Fiesta 1212006 GI 63308en

procarmanuals.com

Page 930 of 1226

303-1 4-6 Electronic Engine Controls 303-1 4-6

DESCRIPTION

AND OPERATION

Item Descri~tion

1 5 1 Crankshaft Position (CKP) sensor 1

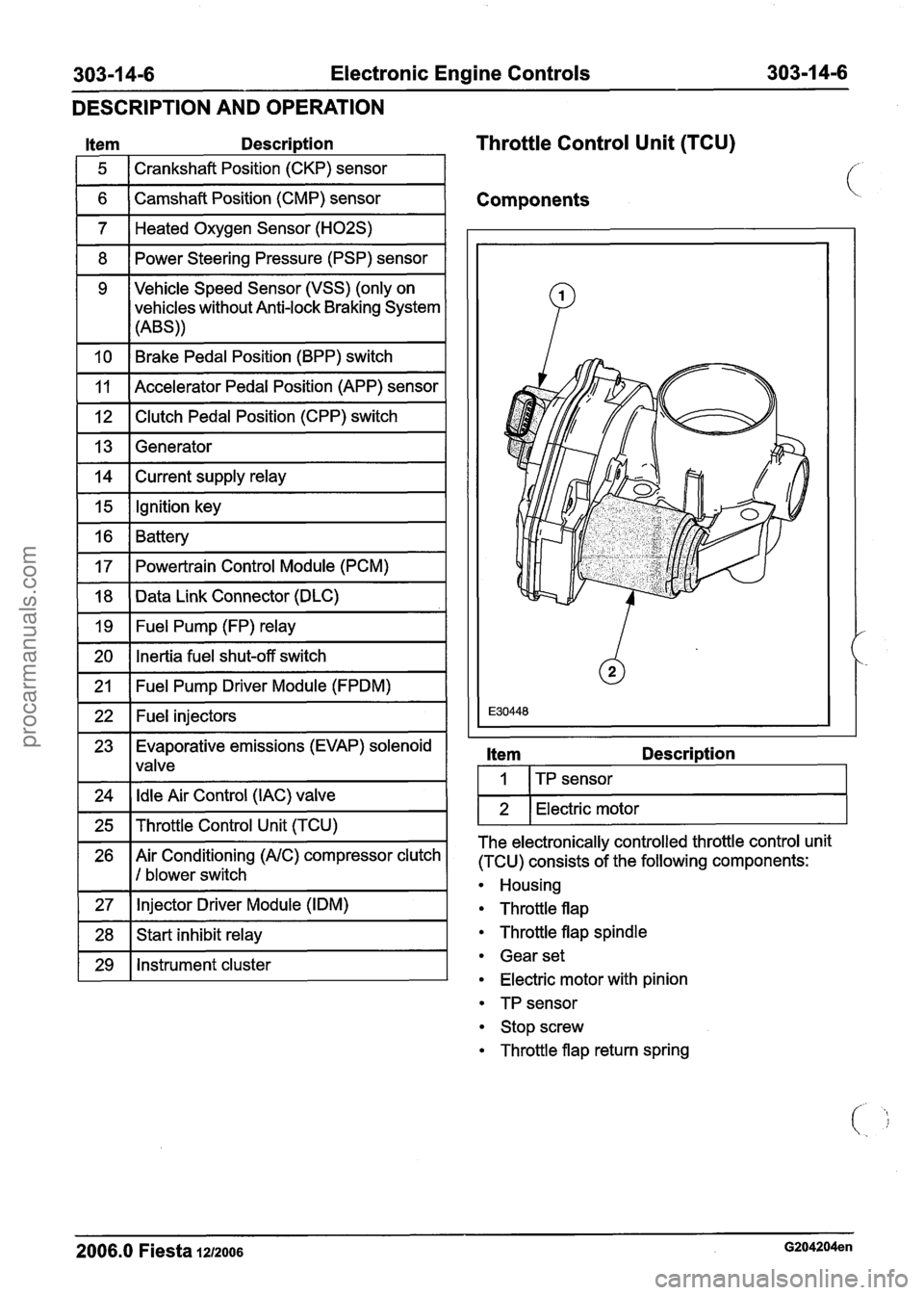

Throttle Control Unit (TCU)

1 6 ( Camshaft Position (CMP) sensor I Components

1 7 1 Heated Oxygen Sensor (H02S) I

1 8 1 Power Steering Pressure (PSP) sensor I

1 10 1 Brake Pedal Position (BPP) switch I

9 Vehicle Speed Sensor (VSS)

(only on

vehicles without Anti-lock Braking System

(ABS))

1 12 1 Clutch Pedal Position (CPP) switch I

11

1 13 1 Generator I

Accelerator Pedal Position (APP) sensor

1 14 1 Current supply relay I

1 15 1 Ignition key I -

16

17

1 20 1 Inertia fuel shut-off switch I

Battery

Powertrain Control Module (PCM)

-

18

19

1 21 1 Fuel Pump Driver Module (FPDM) I

Data Link Connector (DLC)

Fuel Pump (FP) relay

1 22 1 Fuel injectors I

23 Evaporative emissions (EVAP) solenoid

1 lvalve

1 24 1 Idle Air Control (IAC) valve 1

1 25 1 Throttle Control Unit (TCU) I

26 Air Conditioning (AIC) compressor clutch

1 I 1 blower switch

1 27 1 Injector Driver

Module (IDM) I

1 28 1 Start inhibit relay I

1 29 1 Instrument cluster I

Item Descri~tion

I I ITP sensor I

1 2 1 Electric motor I

The electronically controlled throttle control unit

(TCU) consists of the following components:

Housing

Throttle flap

Throttle flap spindle

Gear set

Electric motor with pinion

TP sensor

Stop screw

Throttle flap return spring

2006.0 Fiesta 1212006 G204204en

procarmanuals.com

Page 938 of 1226

303-1 4-1 4 Electronic Engine Controls 303-1 4-1 4

DIAGNOSIS AND TESTING

Electronic Engine Controls

General Equipment

I Worldwide Diagnostic system (WDS)

Principles of Operation

For Principles of Operation on the electronic

accelerator control system

REFER to: Acceleration Control (31

0-02A,

Diagnosis and Testing).

European On-Board Diagnostics (EOBD)

EOBD is a diagnostic system integrated into the

powertrain control module (PCM). This system

continuously monitors vehicle emission

components. The system includes a malfunction

indicator lamp (MIL) which indicates when there is

a concern that can affect emissions or the system

malfunctions. Data stored within the module DTC

memory can be accessed using a generic scan

tool or WDS.

EOBD is mandated within European Union

regulations from the year 2000 for passenger

vehicles with petrol engines and from 2003 onwards for passenger vehicles with diesel

engines.

EOBD Functions:

Establishes when and how emissions control

faults must be indicated.

Actuates emission control malfunction indicator

lamp (MIL) and fault memory.

Indicates operating conditions in which the

concern occurred (freeze frame data).

Standardized output of operating data such as

engine speed, engine coolant temperature etc.

Standardized names and abbreviations for

components and systems.

Standardized

DTCs for all manufacturers.

Standardized communication with the diagnostic

equipment.

Standardized 16-pin data link connector (DLC)

in area of the instrument panel.

Concern display must be possible using a

generic scan tool.

EOBD consists of the following elements:

Warm-up Cycle C'

The warm-up cycle is an operation that consists of

key on, engine start and a coolant temperature

increase of

22"C, exceeding 71 OC on completion.

Drive Cycle

A drive cycle commences when the engine is

started (cold or warm) and ends when the engine

is switched off.

Trip

A trip begins when the engine is started and is

complete when all the EOBD monitors have

completed a self-test. This may take place over a

number of drive cycles. On diesel variants, the

information gathered from one drive cycle is not

carried over to a subsequent cycle or cycles.

When a concern has been rectified, particularly

after electronic engine control components have

been changed, the DTC memory, which is part of

the EEPROM must be cleared of all trouble codes.

When the DTC memory has been cleared, the code

.

PI000 (known as the readiness code) is set in the

PCM memory, which indicates that since the

EEPROM has been cleared, not all of the

monitoring systems have completed their tests.

PI000 can only be cleared by carrying out a trip,

which includes driving the vehicle under variable

conditions of speed, load and time so that all of the

monitors are completed. As

PI000 will not

illuminate the MIL it is not necessary to carry out

the trip before returning the vehicle to the customer.

Freeze Frame Data

When a concern is detected, various data is stored

depending on application including:

Diagnostic trouble code.

Vehicle speed.

Engine coolant temperature.

Engine speed.

Engine load.

Mixture formation trim value (trim value for

engine wear) (All except vehicles with diesel

engine).

State of oxygen sensor control (open and closed

loop) (All except vehicles with diesel engine).

Distance covered since the concern was first

registered.

2006.0 Fiesta 1212006 G384566en

procarmanuals.com

Page 940 of 1226

Electronic Engine Controls

DIAGNOSIS AND TESTING

detected in either the STFT or LTFT, and it is still

present on a second trip, the MIL will be switched

on.

Heated Oxygen Sensor (H02S) Monitor (All except

vehicles with diesel engine)

This monitors the operation of the pre (upstream)

and post (downstream) catalytic converter

H02S

sensors. It will detect deviations in airlfuel ratios

(AFR) and sensor faults.

The

H02S will cause emission increase when its

response time increases too much. To diagnose

a sensor a period is measured and the number of

leanlrich transitions are counted. The sum of valid

periods is then calculated. To avoid

non-representative measurements, the period is

valid only if the

H02S has been below a low

threshold and above a high threshold between 2

consecutive leanlrich transitions.

A failure is

declared when the sum of the measured periods

exceeds the sum of the corresponding limit (held

within the PCM) and the MIL is illuminated.

Catalytic Converter Efficiency Monitor (All except

vehicles with diesel engine)

The efficiency of a catalytic converter is measured

by its ability to store and later release oxygen to

convert harmful gases. The efficiency is reduced

if the converter becomes contaminated as it ages,

and at high gas flow rates, because the exhaust

gas does not remain in the converter long enough

to complete the conversion process. switches

over or until the end of a delay. If this

delay expires or the sensor does not switch, the

sensor is treated as failed.

Combustion Noise Monitor (Vehicles with common

rail fuel injection)

In diesel variants, the Combustion Noise Monitor

is used to trim the fuel injection pulse lengths. Each

fuel injector has an associated set of correction

data that is determined during a production end of

line test. The Combustion Noise Monitor is used

to determine how the fuel injector characteristic

changes from this initial calibration over the life of

the fuel injector.

EGR Monitor (Vehicles with diesel engine)

The functionality of the EGR system is checked by

comparing either the MAP sensor output or EGR

valve lift potentiometer output (depending upon

application) with expected values.

Diagnostic Requirements

Vehicles equipped with EOBD, can be diagnosed

using the WDS. In order for the EOBD system to

be invoked, a number of criteria must be met. After

any repair, which could affect emissions, a trip must

be carried out on the vehicle, to make sure that

engine management system operates correctly.

Malfunction Indicator Lamp (MIL)

The MIL is located in the instrument cluster and is

fitted to alert the driver to the fact that an abnormal

This monitor checks for the oxygen storage condition

has developed in the engine management

capacity (OSC) of the catalytic converter. During system,

that is having an adverse effect on

a controlled period, the catalyst monitor sensor emissions.

In cases of misfires which are likely to

signal is analyzed to evaluate the OSC of the cause

catalytic converter damage, it is switched

catalyst. It represents the quantity of oxygen that on immediately.

With all other faults it will illuminate

is really used for the oxidation-reduction reaction continuously

from the second trip after the condition

by the catalytic converter If a fault has occurred occurred.

Under normal operation it should

with the catalyst monitor sensor during the catalyst illuminate

at key-on and go out almost as soon as

diagnosis, a sensor diagnosis is carried out. During the

engine is started.

the controlled diagnosis phase, the catalyst monitor

Diagnostic Trouble Codes (DTCs) sensor activity is measured and is compared to the

OSC of the catalyst. If this activity is high (low The

DTCs given

by the PCM are standardized,

0SC)theMILwillbeilluminated.Ifthroughoutthe whichmeansthatgenericscantoolscanread

controlled phase, repeated several times, the results from

all vehicles.

downstream sensor output has not moved, the

closed loop mode is delayed in order to test the

sensor. If the catalyst monitor sensor is set to rich,

the injection time is forced to lean and conversely

if the downstream sensor is set to lean, the

injection time is forced to rich until the sensor

2006.0 Fiesta 1212006 G384566en

procarmanuals.com

Page 945 of 1226

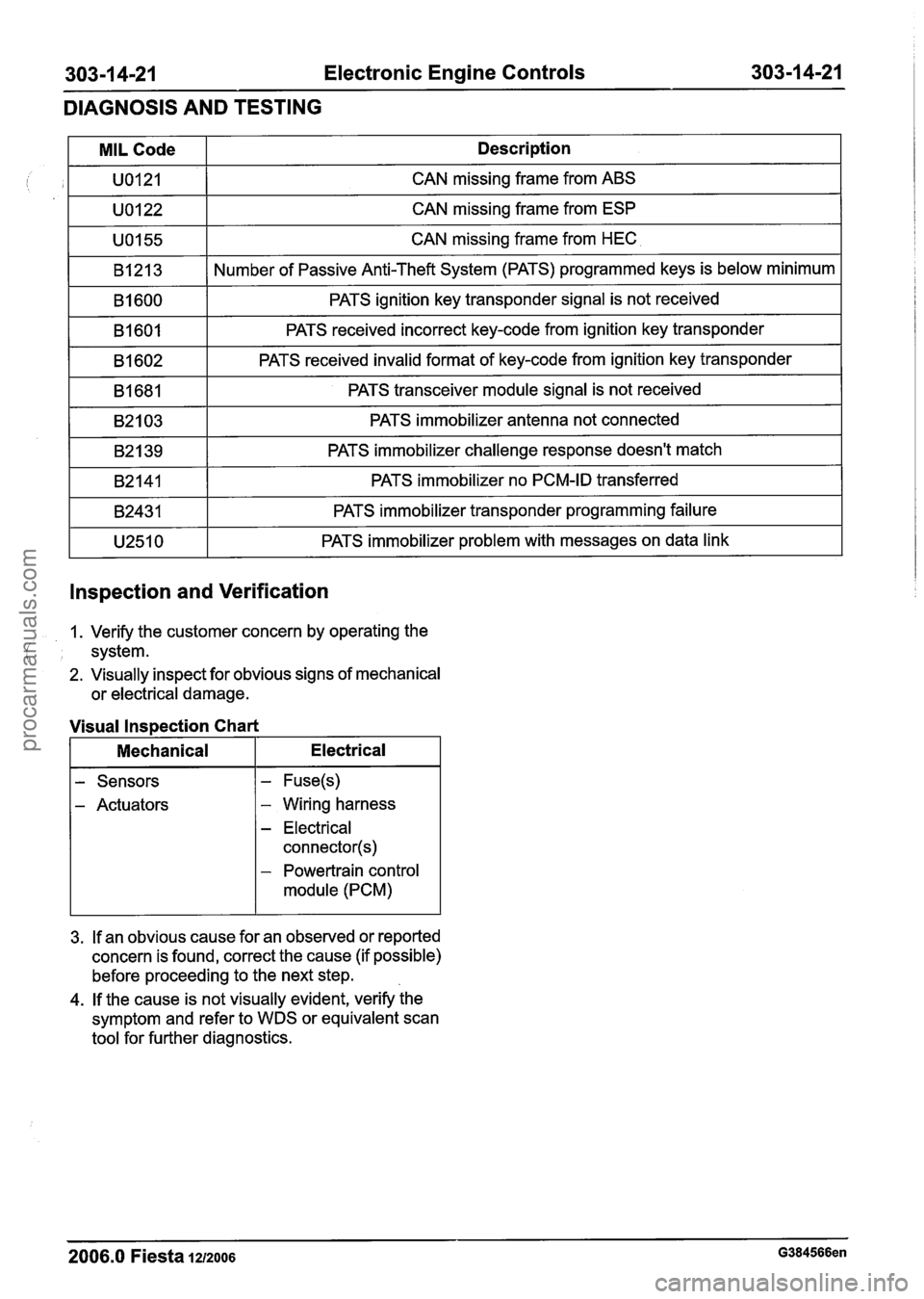

303-1 4-21 Electronic Engine Controls 303-1 4-21

DIAGNOSIS AND TESTING

lnspection and Verification

MIL Code

U0121

U0122

U0155

B1213

B1600

B1601

B1602

B1681

B2103

B2139

B2141

B2431

U2510

1. Verify the customer concern by operating the

( I system.

2. Visually inspect for obvious signs of mechanical

or electrical damage. Description

CAN missing frame from ABS

CAN missing frame from ESP

CAN missing frame from HEC

Number of Passive Anti-Theft System (PATS) programmed keys is below minimum

PATS ignition key transponder signal is not received

PATS received incorrect key-code from ignition key transponder

PATS received invalid format of key-code from ignition key transponder

PATS transceiver module signal is not received

PATS immobilizer antenna not connected

PATS immobilizer challenge response doesn't match

PATS immobilizer no PCM-ID transferred

PATS immobilizer transponder programming failure

PATS immobilizer problem with messages on data link

Visual Inspection Chart

Mechanical

I Electrical

- Sensors

- Actuators - Wiring harness

- Electrical

connector(s)

- Powertrain control

module (PCM)

3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the

symptom and refer to WDS or equivalent scan

tool for further diagnostics.

- -

2006.0 Fiesta 1212006 G384566en

procarmanuals.com

Page 947 of 1226

303-1 4-23 Electronic Engine Controls 303-1 4-23

REMOVAL AND INSTALLATION

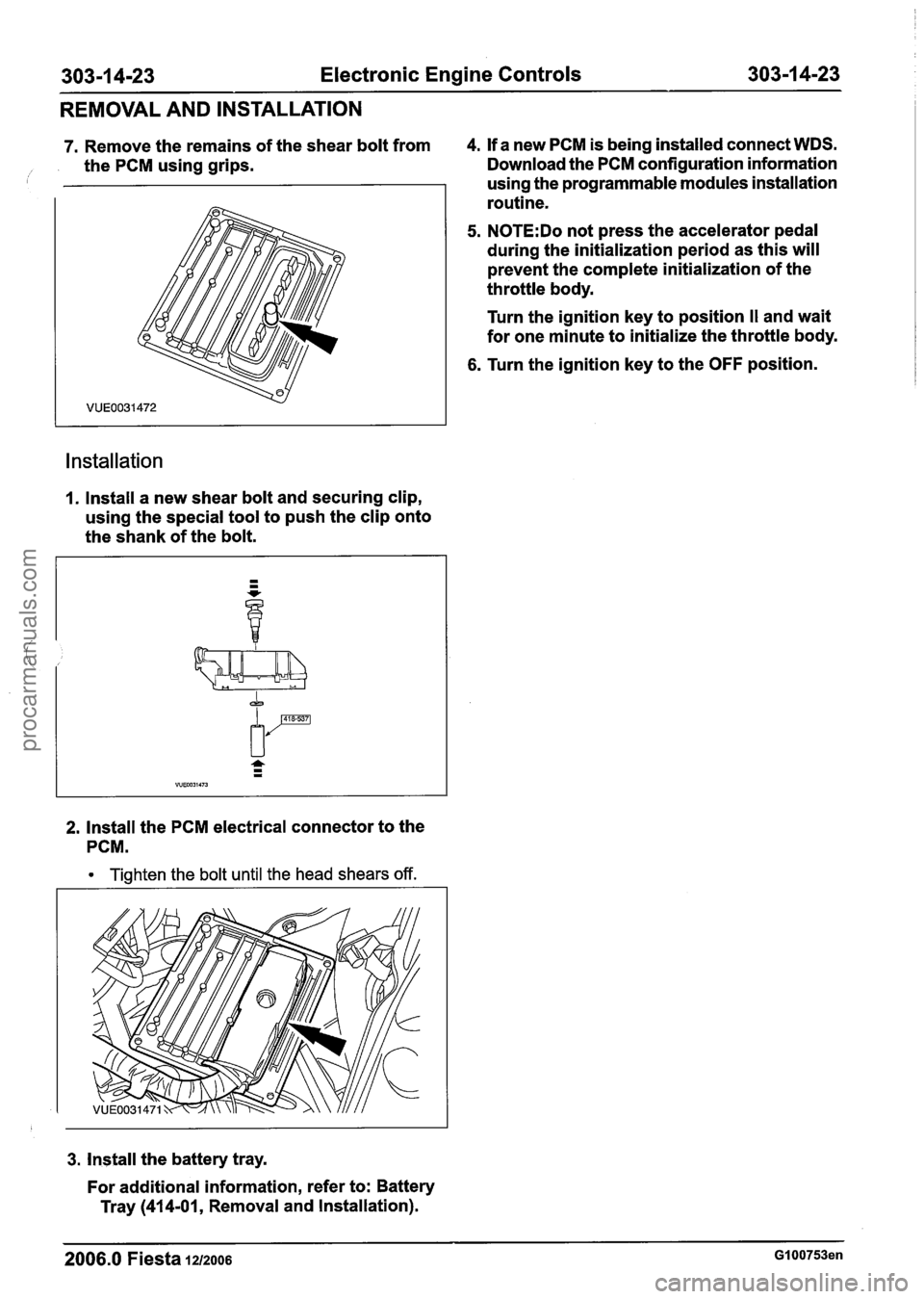

7. Remove the remains of the shear bolt from 4.

If a new PCM is being installed connect WDS.

/ the PCM using grips. Download the PCM configuration information

using the programmable modules installation

routine.

5. N0TE:Do not press the accelerator pedal

during the initialization period as this will

prevent the complete initialization of the

throttle body.

Turn the ignition key to position

I1 and wait

for one minute to initialize the throttle body.

6. Turn the ignition key to the OFF position.

Installation

I. Install a new shear bolt and securing clip,

using the special tool to push the clip onto

the shank of the bolt.

2. Install the PCM electrical connector to the

PCM.

Tighten the bolt until the head shears off.

3. Install the battery tray.

For additional information, refer to: Battery

Tray

(414-01, Removal and Installation).

procarmanuals.com

Page 972 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -1 2 Transmission (AW81-40) 307-01 -1 2 --

DESCRIPTION AND OPERATION

Item Description The output wheel of the planetary gearset drives

I 1 I Output wheel, planetary gearset

2

I I 1

The annulus of the planetary gearset is fixedly Any differences in rotational speed between the

connected to the output

wheel of the planetary two halfshafts are compensated by the differential.

gearset.

the input wheel of the intermediate gear stage.

3

4

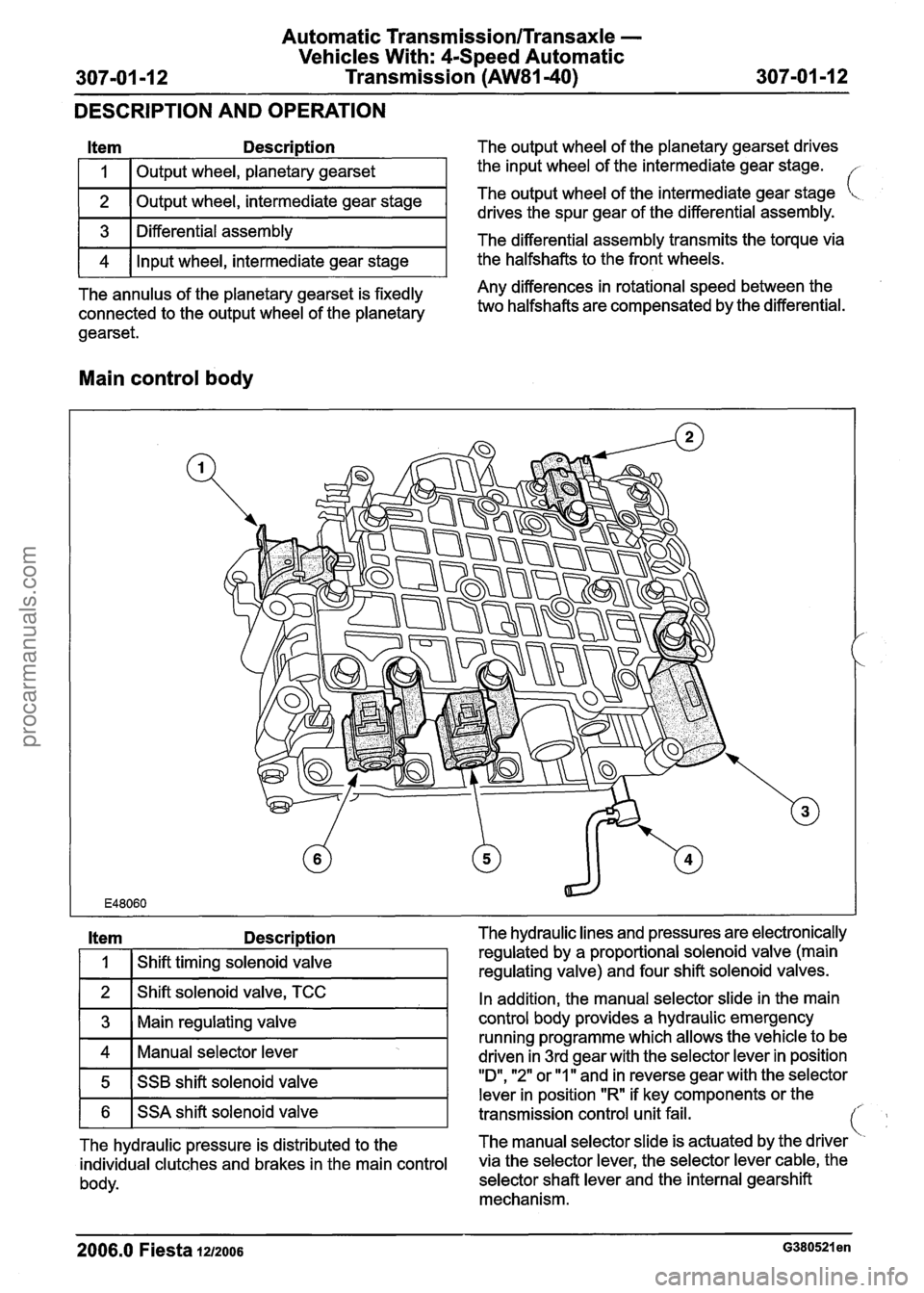

Main control body

Output wheel, intermediate gear stage

Item Descri~tion The hydraulic lines and pressures are electronically

The output

wheel of

the intermediate gear stage [<.

drives the spur gear of the differential assembly.

Differential assembly

Input wheel, intermediate gear stage The

differential assembly transmits the torque

via

the halfshafts to the front wheels.

In addition, the manual selector slide in the main

control body provides a hydraulic emergency

running programme which

allows the vehicle to be

Manual selector lever driven in 3rd aear with the selector lever in position

.

1

Shift timing solenoid valve

5

2006.0 Fiesta 1212006 ~380521 en

regulated by a proportional solenoid valve (main

regulating valve) and four shift solenoid valves.

1 6 1 SSA shift solenoid valve

SSB

shift solenoid valve

transmission control unit-fail. -

"D", "2" or "ll'and in reverse gear with the selector

lever in position "R if key components or the

The hydraulic pressure is distributed to the The

manual selector slide is actuated by the driver

individual clutches and brakes in the main control via the selector lever, the selector lever cable, the

body. selector shaft lever and the internal gearshift

mechanism.

procarmanuals.com