key FORD FIESTA 2007 Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 1003 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -43 Transmission (AW81-40) 307-01 -43

DESCRIPTION AND OPERATION

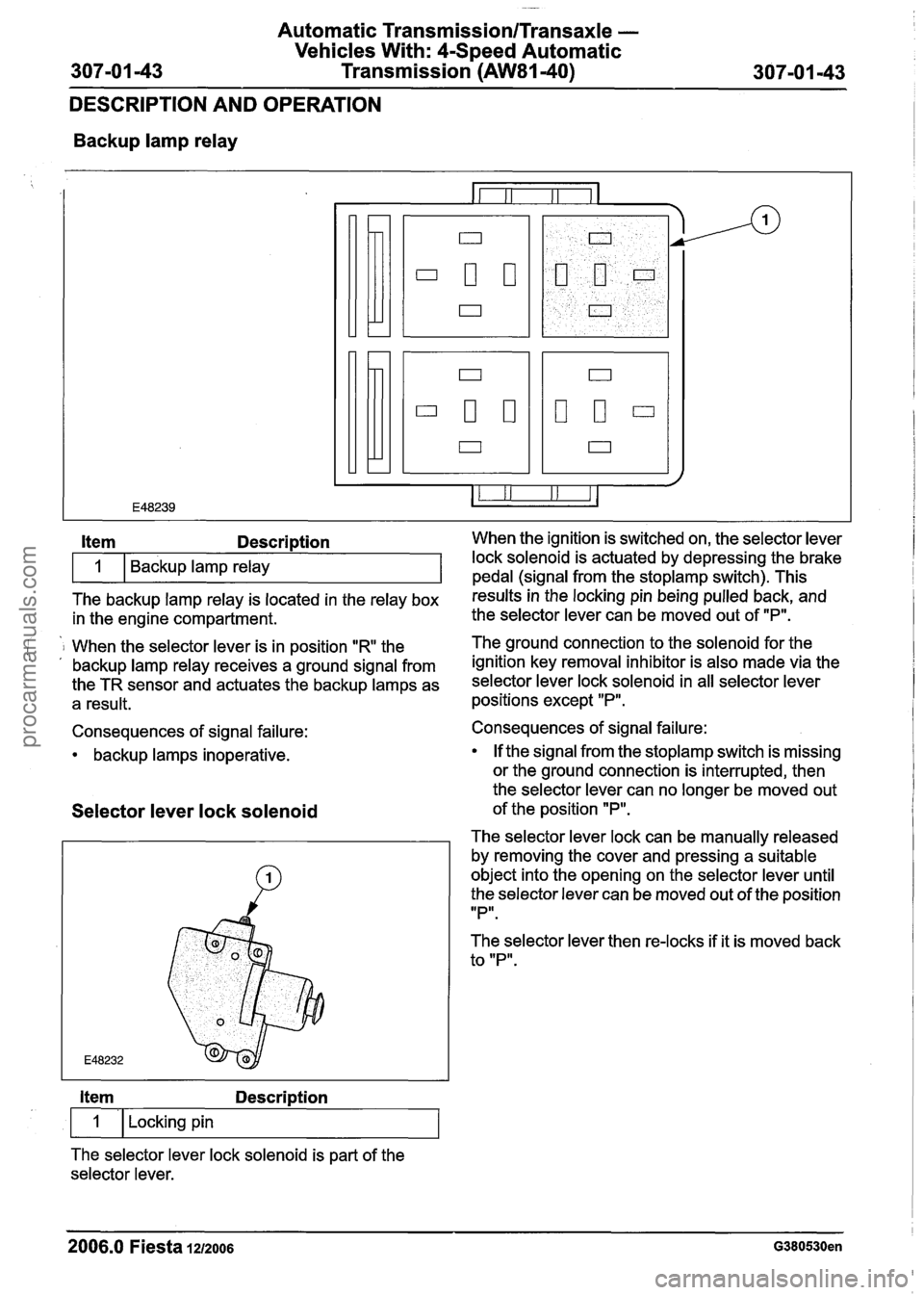

Backup lamp relay

The backup lamp relay is located in the relay box results inthe locking pin being pulled back, and

in the engine compartment. the

selector lever can be moved out of "P".

Item Description When the ignition is switched on, the selector lever

i 1 When the selector lever is in position "R the The ground connection to the solenoid for

the . , backup lamp relay receives a ground signal from ignition key removal inhibitor is also made via the

the TR sensor and actuates the backup lamps as selector lever lock solenoid in all selector lever

a result. positions except "P".

1

Consequences of signal failure:

backup lamps inoperative. Backup lamp relay

Selector

lever lock solenoid

lock solenoid is actuated by depressing the brake

pedal (sianal from the stoplamp switch). This

Item Description

1 I Locking pin

The selector lever lock solenoid is part of the

selector lever. Consequences of signal failure:

If the signal from the

stoplamp switch is missing

or the ground connection is interrupted, then

the selector lever can no longer be moved out

of the position

"P".

The selector lever lock can be manually released

by removing the cover and pressing a suitable

object into the opening on the selector lever until

the selector lever can be moved out of the position

IIPlr.

The selector lever then re-locks if it is moved back

to "P".

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 1004 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01

-44 Transmission (AW81-40) 307-01 -44

DESCRIPTION AND OPERATION

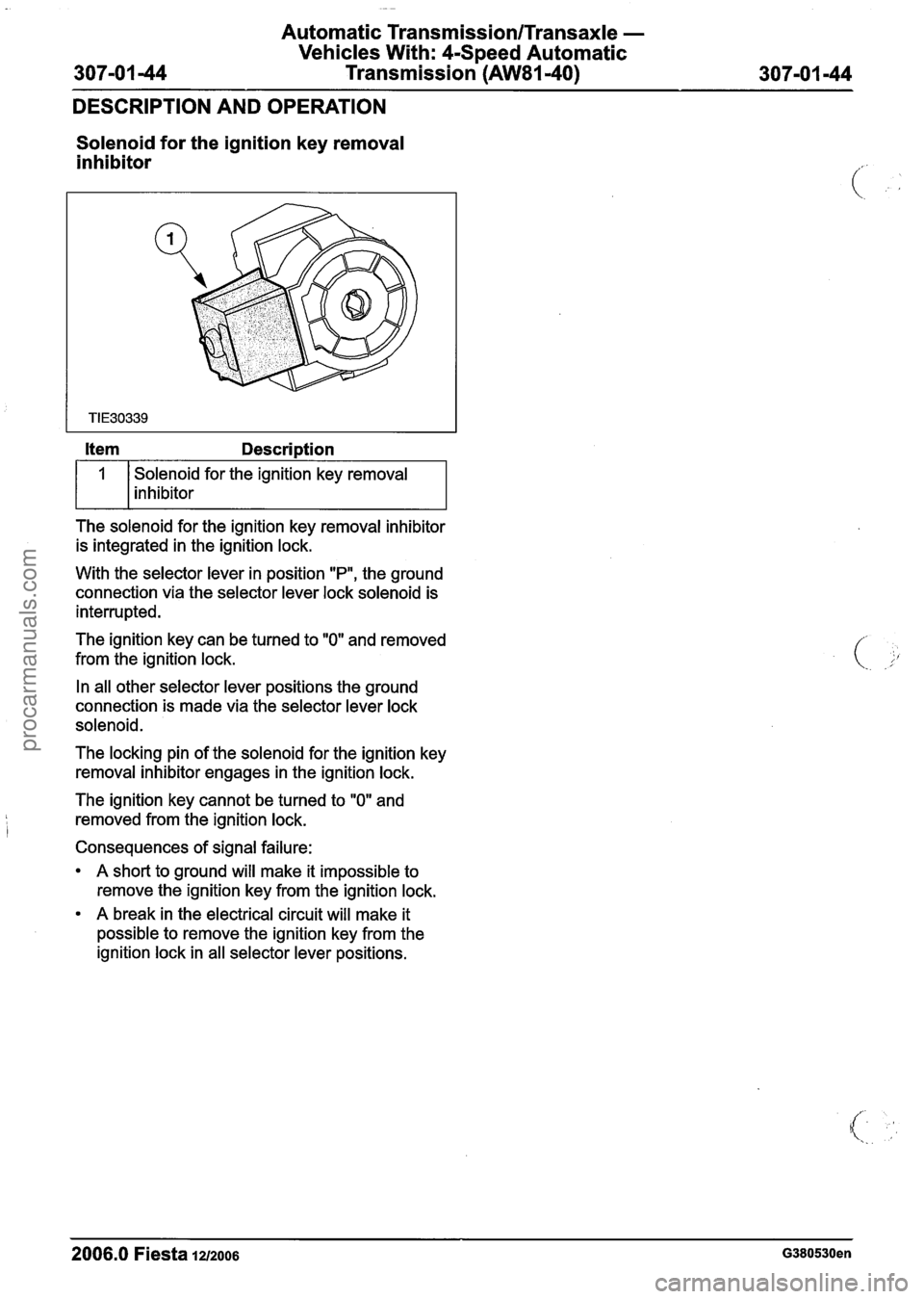

Solenoid for the ignition key removal

inhibitor

Solenoid for the ignition key removal

inhibitor

The solenoid for the ignition key removal inhibitor

is integrated in the ignition lock.

With the selector lever in position

"P", the ground

connection via the selector lever lock solenoid is

interrupted.

The ignition key can be turned to

"0" and removed

from the ignition lock.

In all other selector lever positions the ground

connection is made via the selector lever lock

solenoid.

The locking pin of the solenoid for the ignition key

removal inhibitor engages in the ignition lock.

The ignition key cannot be turned to

"0" and

removed from the ignition lock.

Consequences of signal failure:

A short to ground will make it impossible to

remove the ignition key from the ignition lock.

A break in the electrical circuit will make it

possible to remove the ignition key from the

ignition lock in all selector lever positions.

2006.0 Fiesta 12/2006 G380530en

procarmanuals.com

Page 1025 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission (AW81-40)

REMOVAL AND INSTALLATION

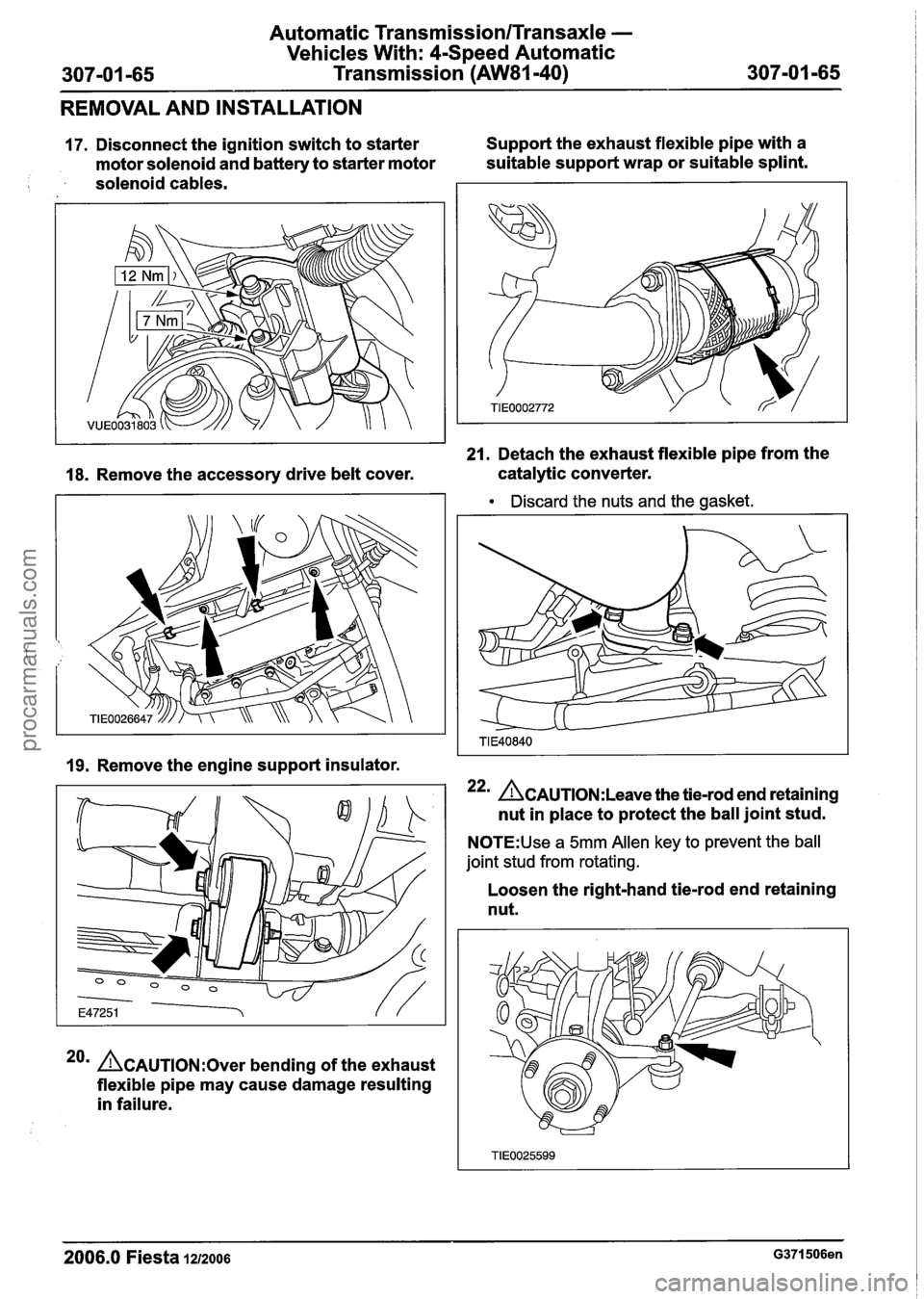

17. Disconnect the ignition switch to starter Support

the exhaust flexible pipe with a

motor solenoid and battery to starter motor suitable

support wrap or suitable splint.

solenoid cables.

21. Detach the exhaust flexible pipe from the

18. Remove the accessory drive belt cover. catalytic

converter.

Discard the nuts and the gasket.

19. Remove the engine support insulator.

22m &AUTION:L~~~~ the tie-rod end retaining

nut in place to protect the ball joint stud.

N0TE:Use a 5mm Allen key to prevent the ball

joint stud from rotating.

20m ACAUTION:~~~~ bending of the exhaust

flexible pipe may cause damage resulting

in failure. Loosen

the right-hand tie-rod end retaining

nut.

2006.0 Fiesta 1212006 G371506en

procarmanuals.com

Page 1032 of 1226

Automatic Tra

Vehicles Wit

307-01 -72 Transm nsmission/Transaxle -

h: 4-Speed Automatic

ission

(AW81-40) 307-01 -72

REMOVAL AND INSTALLATION

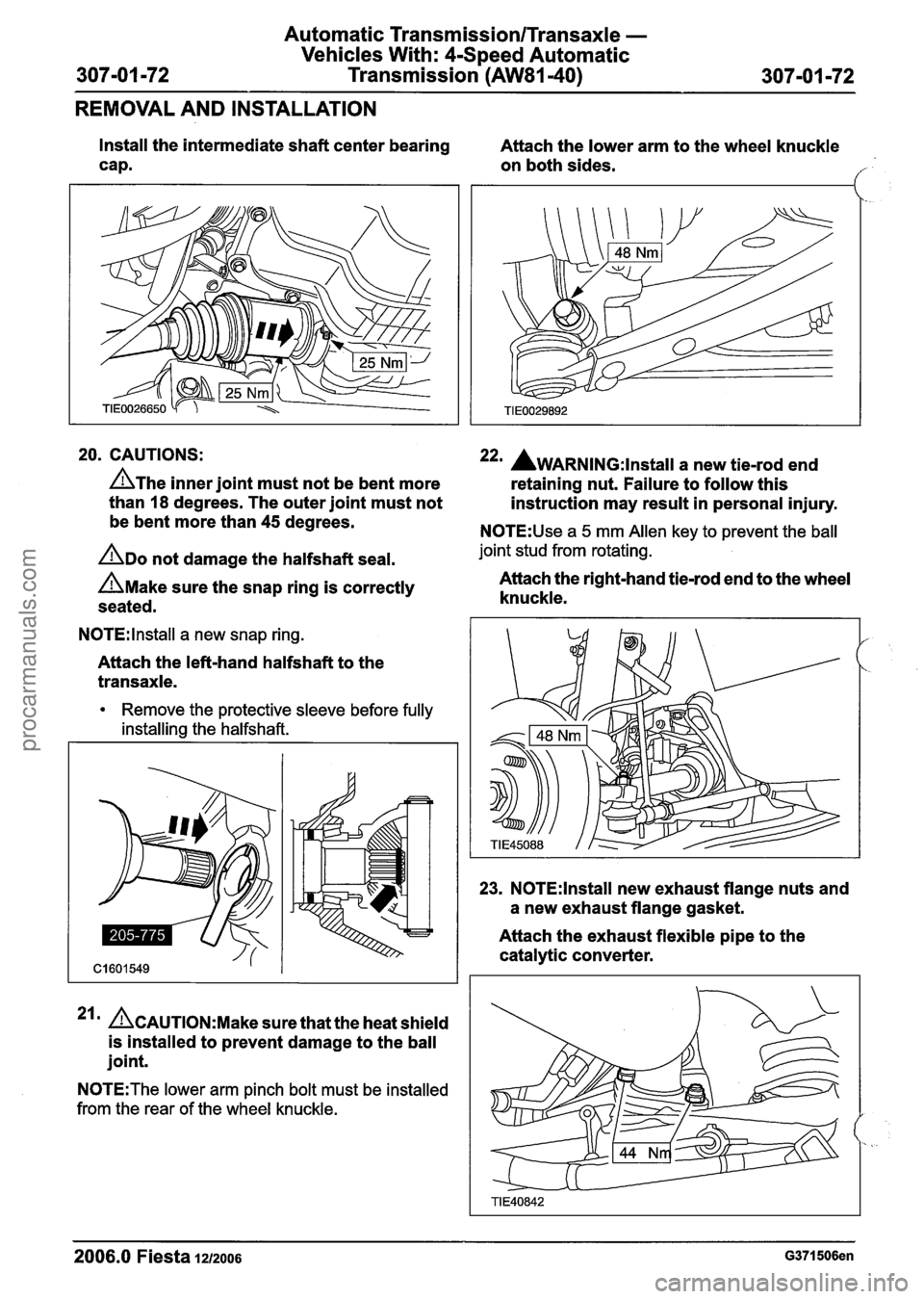

Install the intermediate shaft center bearing

cap. Attach

the lower arm to the wheel knuckle

on both sides.

f

20. CAUTIONS: 22m AwARNING:~~~~~~~ a new tie-rod end

A~he inner joint must not be bent more

retaining nut. Failure to follow this

than

18 degrees. The outer joint must not

instruction may result in personal injury.

be bent more than 45 degrees.

N0TE:Use a 5 mm Allen key to prevent the ball

ADO not damage the halfshaft seal. joint stud from rotating.

A~ake sure the snap ring is correctly Attach the right-hand tie-rod end

to the wheel

seated. knuckle.

N0TE:lnstall a

new snap ring.

Attach the left-hand halfshaft to the

transaxle.

Remove the protective sleeve before fully

installing the halfshaft.

ACAUTION:M~~~ sure that the heat shield

is installed to prevent damage to the ball

joint.

N0TE:The lower arm pinch bolt must be installed

from the rear of the wheel knuckle.

23. N0TE:lnstall new exhaust flange nuts and

a new exhaust flange gasket.

Attach the exhaust flexible pipe to the

catalytic converter.

2006.0 Fiesta 1212006 G371506en

procarmanuals.com

Page 1076 of 1226

308-01 4 Clutch 308-01 -4

DESCRIPTION AND OPERATION

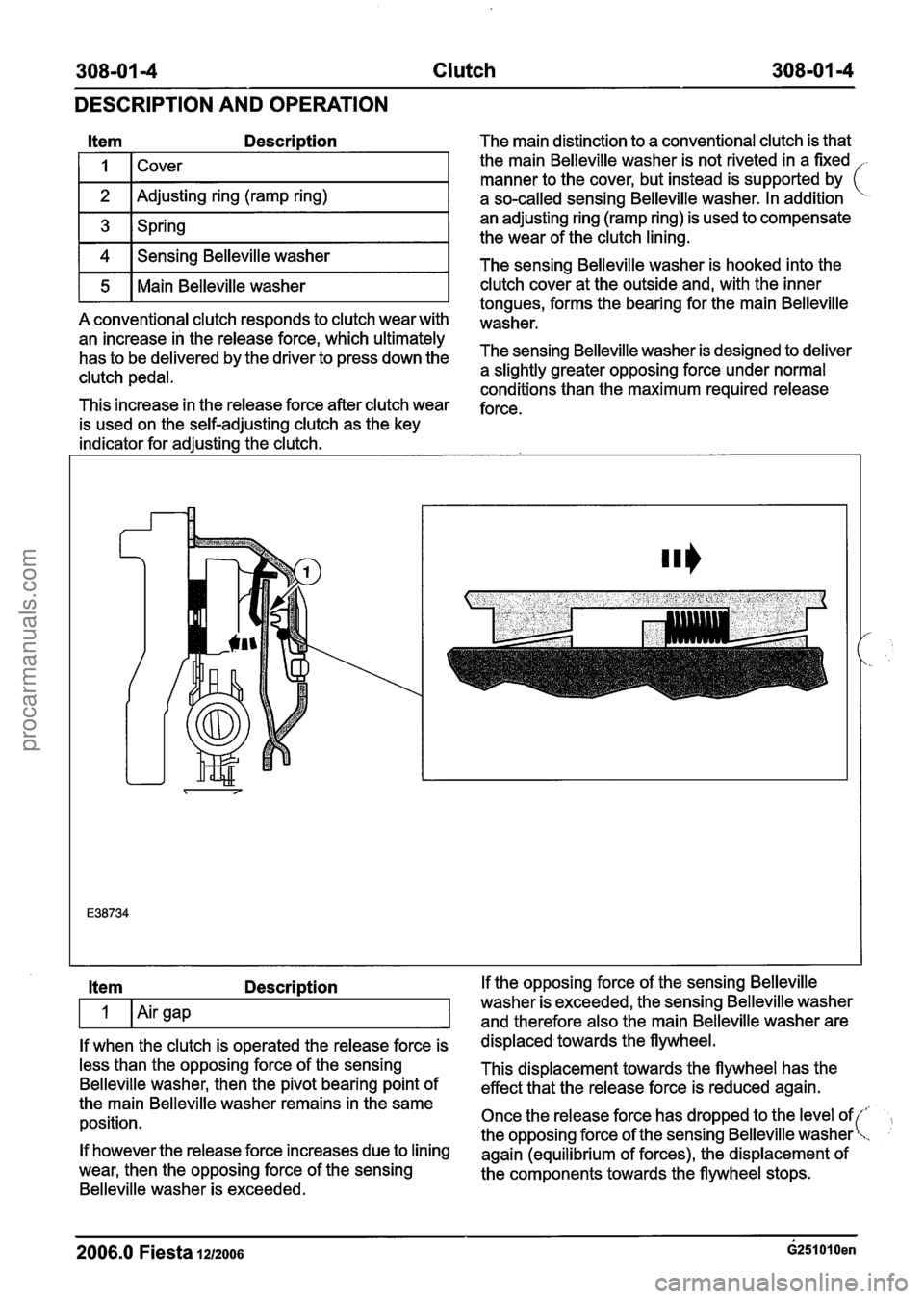

Item Description

I I 1 Cover I

1 2 I Adjusting ring (ramp ring) I

1 3 1 Spring I

1 4 1 Sensing Belleville washer I

r5 1 Main Belleville washer I

A conventional clutch responds to clutch wear with

an increase in the release force, which ultimately

has to be delivered by the driver to press down the

clutch pedal.

This increase in the release force after clutch wear

is used on the self-adjusting clutch as the key

indicator for adjusting the clutch. The main

distinction to a conventional clutch is that

the main Belleville washer is not riveted in a fixed

-

manner to the cover, but instead is supported by (

a so-called sensing Belleville washer. In addition

an adjusting ring (ramp ring) is used to compensate

the wear of the clutch lining.

The sensing Belleville washer is hooked into the

clutch cover at the outside and, with the inner

tongues, forms the bearing for the main Belleville

washer.

The sensing Belleville washer is designed to deliver

a slightly greater opposing force under normal

conditions than the maximum required release

force.

Item Description

If when the clutch is operated the release force is

less than the opposing force of the sensing

Belleville washer, then the pivot bearing point of

the main Belleville washer remains in the same

position.

If however the release force increases due to lining

wear, then the opposing force of the sensing

Belleville washer is exceeded. If the

opposing force of the sensing Belleville

washer is exceeded, the sensing Belleville washer

and therefore also the main Belleville washer are

displaced towards the flywheel.

This displacement towards the flywheel has the

effect that the release force is reduced again.

Once the release force has dropped to the level of

the opposing force of the sensing Belleville washer

again (equilibrium of forces), the displacement of

the components towards the flywheel stops.

2006.0 Fiesta lazoos ~251010en

procarmanuals.com

Page 1197 of 1226

31 0-00-1 I Fuel System - General Information 31 0-00-1 1

GENERAL PROCEDURES

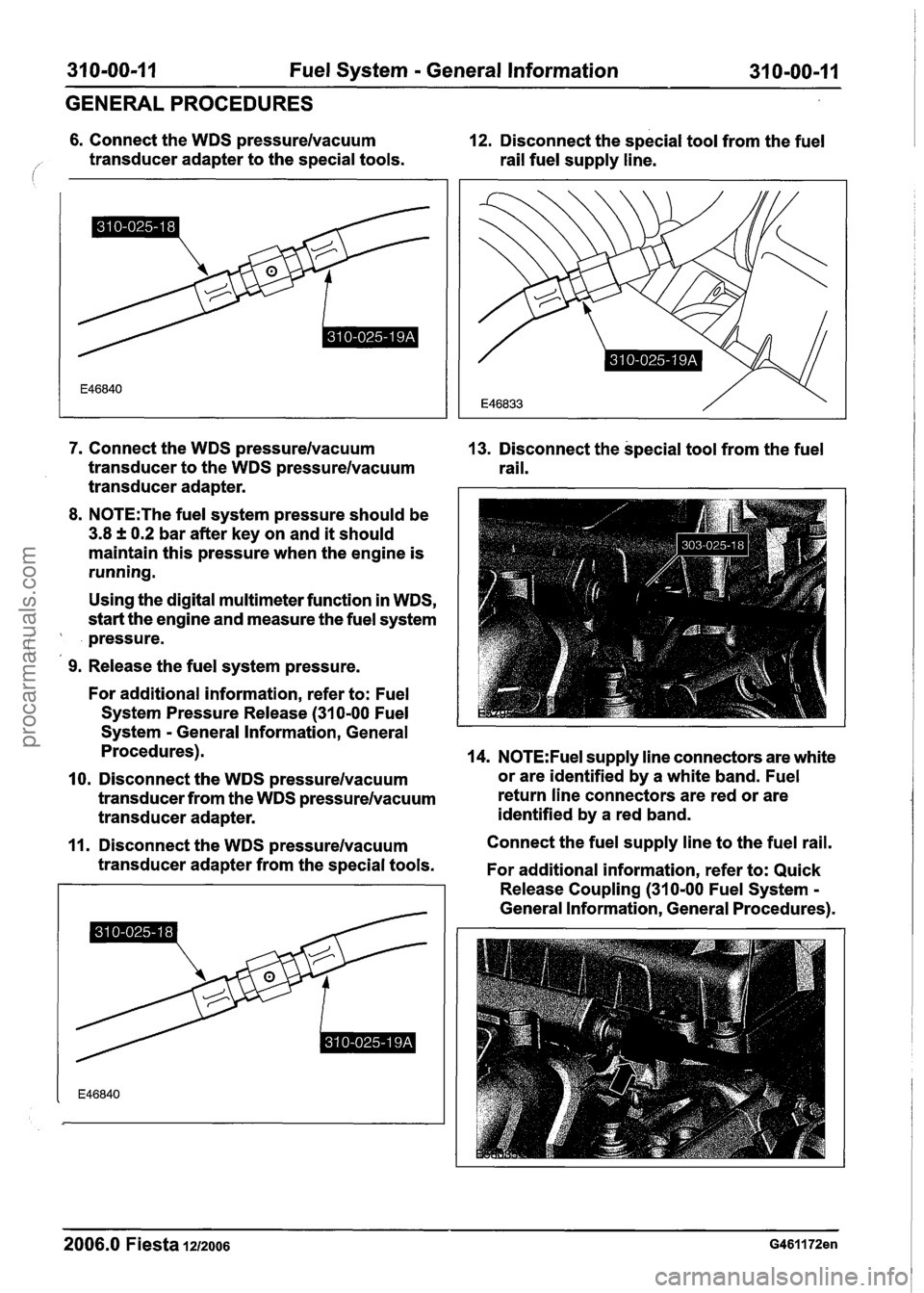

6. Connect the WDS pressurelvacuum 12. Disconnect the special tool from the fuel

/' transducer adapter to the special tools.

rail fuel supply line.

7. Connect the WDS pressurelvacuum

transducer to the WDS pressurelvacuum

transducer adapter.

8. N0TE:The fuel system pressure should be

3.8 f 0.2 bar after key on and it should

maintain this pressure when the engine is

running.

Using the digital multimeter function in WDS,

start the engine and measure the fuel system

pressure.

(,

9. Release the fuel system pressure.

For additional information, refer to: Fuel

System Pressure Release

(31 0-00 Fuel

System

- General Information, General

Procedures).

10. Disconnect the WDS pressurelvacuum

transducer from the WDS pressurelvacuum

transducer adapter.

11. Disconnect the WDS pressurelvacuum

transducer adapter from the special tools.

2006.0 Fiesta 1212006

13. Disconnect the special tool from the fuel

rail.

14. N0TE:Fuel supply line connectors are white

or are identified by a white band. Fuel

return line connectors are red or are

identified by a red band.

Connect the fuel supply line to the fuel rail.

For additional information, refer to: Quick

Release Coupling

(310-00 Fuel System -

General Information, General Procedures).

procarmanuals.com

Page 1219 of 1226

Acceleration Control - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V (Sigma)ll.4L

31 0-02A-5 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma)

31 0-02A-5

DIAGNOSIS AND TESTING

PCM to the electronic throttle body including

the electrical connectors in area "B" (see

system overview).

- There is an obstruction inside the throttle

body bore. Remove the air cleaner outlet pipe

and check for obstructions.

- There is an obstruction inside the electronic

throttle body. Remove the air cleaner outlet

pipe and check that the plate moves freely

against the springs and returns to a slightly

open position. If it does not, install a new

electronic throttle body.

P2176 - Throttle plate adaptation error

- When the ignition is turned off, the throttle

body carries out an adaptation cycle and

spring check. This can be audible after a

short delay (up to 30 seconds) following the ignition key being turned to position

0 and

can be visually observed with the air cleaner

outlet pipe removed. The throttle plate is

moved through a series of positions to check

the TP sensor value and relearn the

electronic throttle body characteristics. If a

concern is detected during this test,

P2176

DTC will be set. If there are already any of

I the other DTCs, the adaptation test could

potentially fail. Therefore the other DTCs

should be resolved first

(e.g. low battery

voltage) and a retest can be carried out by

clearing the DTCs and keying on and off

again. Check the whole area "B" (see system

overview) for any concerns and if no concern

is found, install a new electronic throttle body.

P2100 - H bridge error

- A fault has been detected on the circuit

connecting the electronic throttle body motor

and the PCM. Check for any other

non-electronic accelerator control related

DTCs and rectify them first. Check area "B"

(see system overview) and if no failure is

found, install a new PCM.

PCM Related Codes

The PCM continuously monitors all the sensors. It

also checks that the monitor is functioning as

expected. If there is a fault with the monitor, the

following DTCs will be set.

P2107 - Processor monitoring on the main

controller fault.

P2108 -Analogue to digital converter

- Inferred intake mass air flow lower than

expected

- Engine speed monitor ratio error

- Pedal ratio monitor error

- TP sensor ratio monitor error

- Fault in torque generation

- Fault present in engine speed limitation

Multiple sensor faults can make the PCM assume

that there is a monitor fault. If other DTCs exist,

rectify these first. These DTCs indicate a failure in

area

"A or "B" and they are also related to the

manifold absolute pressure and temperature

(MAPT) sensor and the crankshaft position (CKP)

sensor. If no other failures are found, install a new

PCM.

Indirect Codes

There are two brake pedal switches located under

the brake pedal. Check that both of these are

connected and functioning correctly. A brake pedal

switch concern will only cause the "EAC FAIL"

message to be displayed, it will not lead to a limited

performance mode. Follow WDS instructions.

PO571 - Brake switch error

If the voltage to the accelerator pedal and the

electronic throttle body cannot be regulated

correctly, the components may not operate as

expected. Therefore it is important to detect if there

is a concern in the supply voltage

PO641 - Sensor voltage supply circuit I noisy

signal

PO642 - Sensor voltage supply circuit 1 short

to ground or open circuit

PO643 - Sensor voltage supply circuit 1 short

to battery

PO651 - Sensor voltage supply circuit 2 noisy

signal

PO652 - Sensor voltage supply circuit 2 short

to ground or open circuit

2006.0 Fiesta 1212006 G356253en

procarmanuals.com