lock FORD FIESTA 2007 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 139 of 1226

204-02-1 7 Rear Suspension 204-02-1 7

REMOVAL AND INSTALLATION

Rear Wheel Bearing

Special Tool(s)

General Equipment

17041

I Soft faced hammer I

Installer, Input Shaft Seal

307-2 1 0 (1 7-04 1 )

Vehicles with rear drum brakes

3. Release the parking brake.

4. Remove the brake drum and hub assembly.

Remove and discard the wheel hub retaining

nut.

I Wooden block I Vehicles with rear disc brakes

i , Removal

CAUTI0N:The brake drum and hub

assembly removal in this procedure is for

5. Remove the brake disc.

For additional information, refer to: Brake

Disc

(206-04 Rear Disc Brake, Removal and

Installation).

installing a new wheel bearing, not for

6. Remove the wheel hub.

access to brake system components.

Remove and discard the wheel hub retaining

nut.

All vehicles

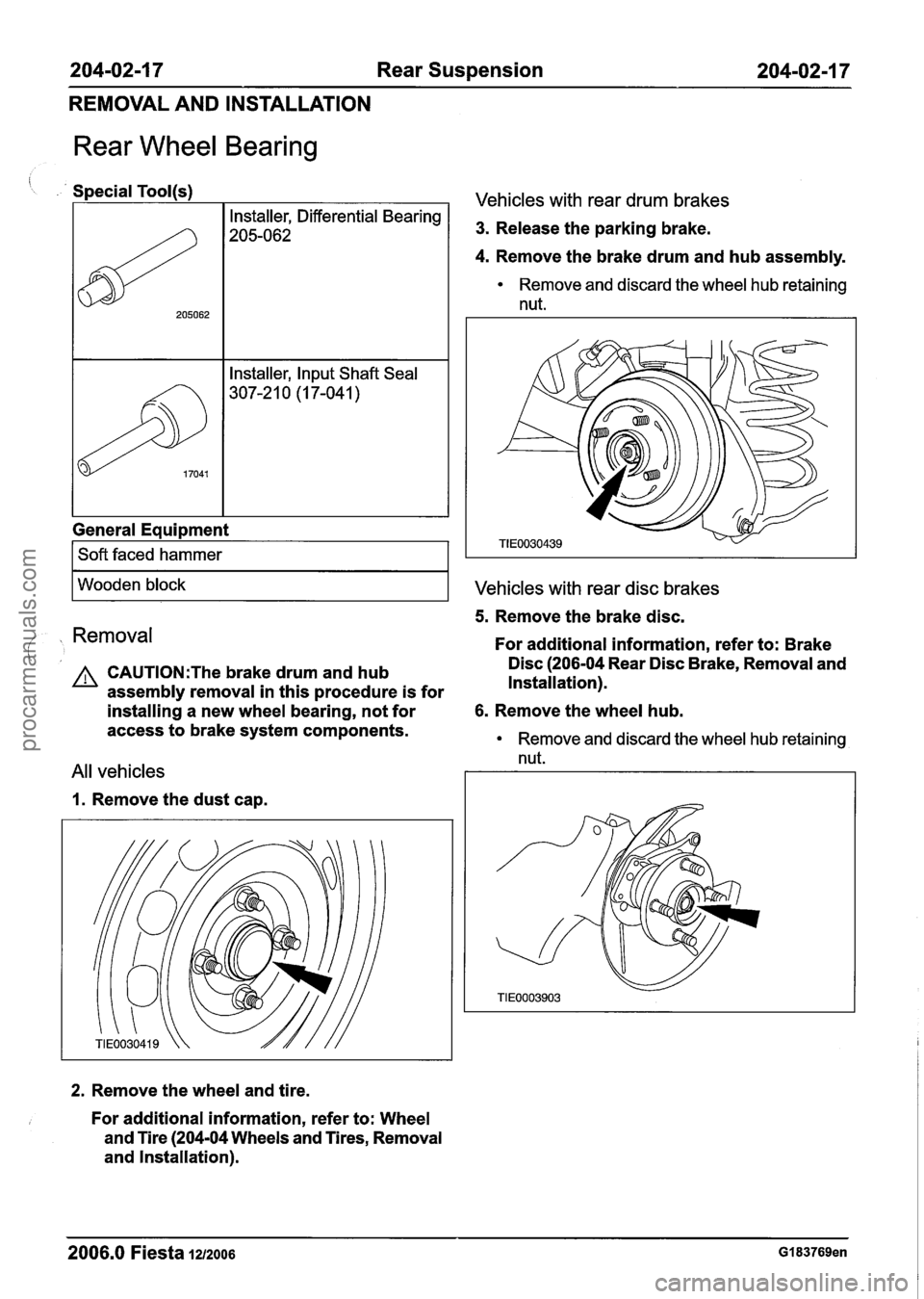

1. Remove the dust cap.

2. Remove the wheel and tire.

For additional information, refer to: Wheel

and Tire

(204-04 Wheels and Tires, Removal

and installation).

2006.0 Fiesta 1212006 GI 83769en

procarmanuals.com

Page 140 of 1226

204-02-1 8 Rear Suspension 204-02-1 8

REMOVAL AND INSTALLATION

All vehicles Using the special tool, install the new wheel

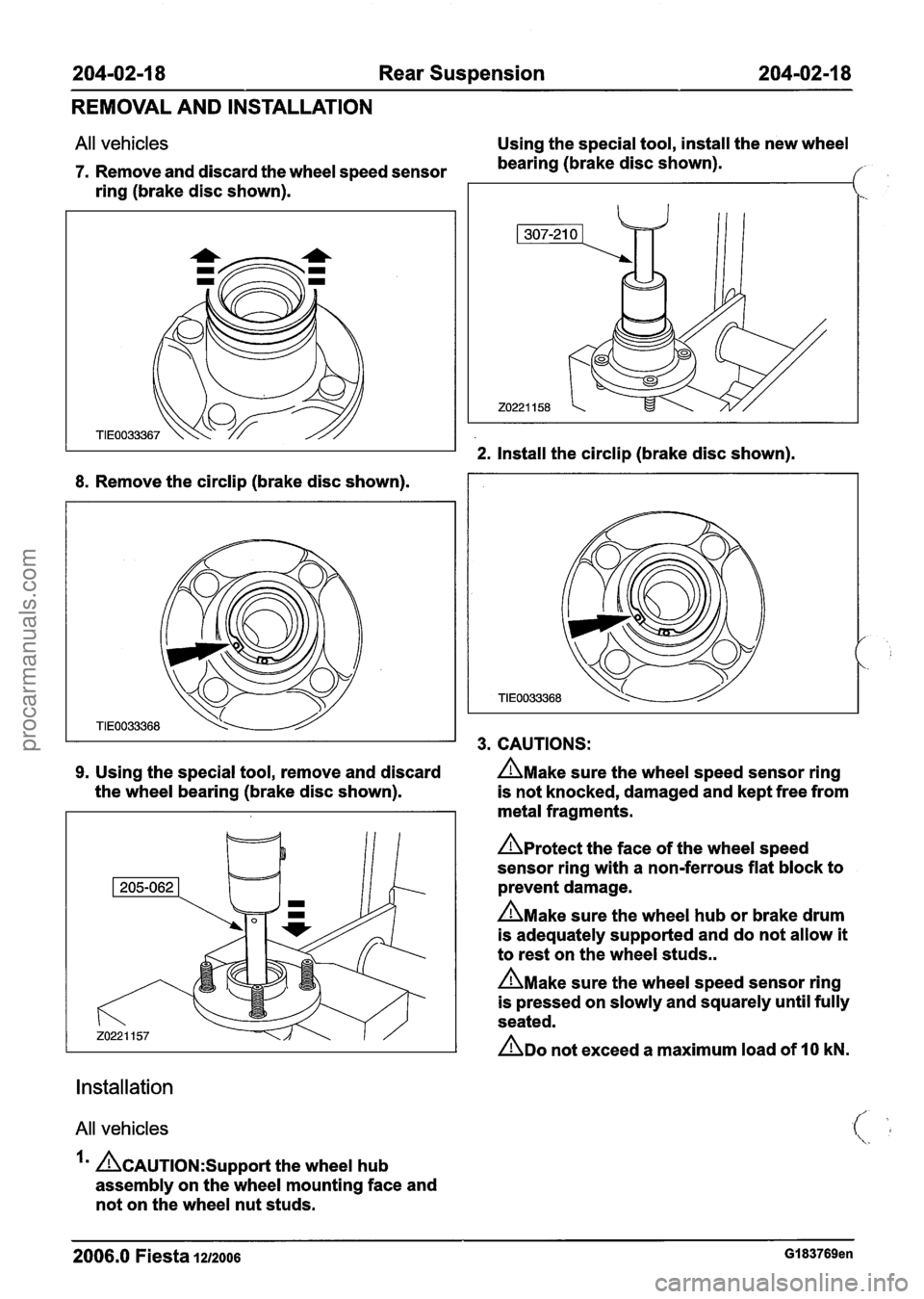

7. Remove and discard the wheel speed sensor bearing (brake

disc shown).

ring (brake disc shown).

2. Install the circlip (brake disc shown).

8. Remove the circlip (brake disc shown).

3. CAUTIONS:

9. Using the special tool, remove and discard AMake sure the wheel speed sensor ring

the wheel bearing (brake disc shown).

is not knocked, damaged and kept free from

metal fragments.

A~rotect the face of the wheel speed

sensor ring with a non-ferrous flat block to

prevent damage.

A~ake sure the wheel hub or brake drum

is adequately supported and do not allow

it

to rest on the wheel studs..

AMake sure the wheel speed sensor ring

is pressed on slowly and squarely until fully

seated.

ADO not exceed a maximum load of 10 kN.

Installation

All vehicles

&AUTION:SU~~O~~ the wheel hub

assembly on the wheel mounting face and

not on the wheel nut studs.

2006.0 Fiesta 1212006 GI 83769en

procarmanuals.com

Page 141 of 1226

204-02-1 9 Rear Suspension 204-02-1 9

REMOVAL AND INSTALLATION

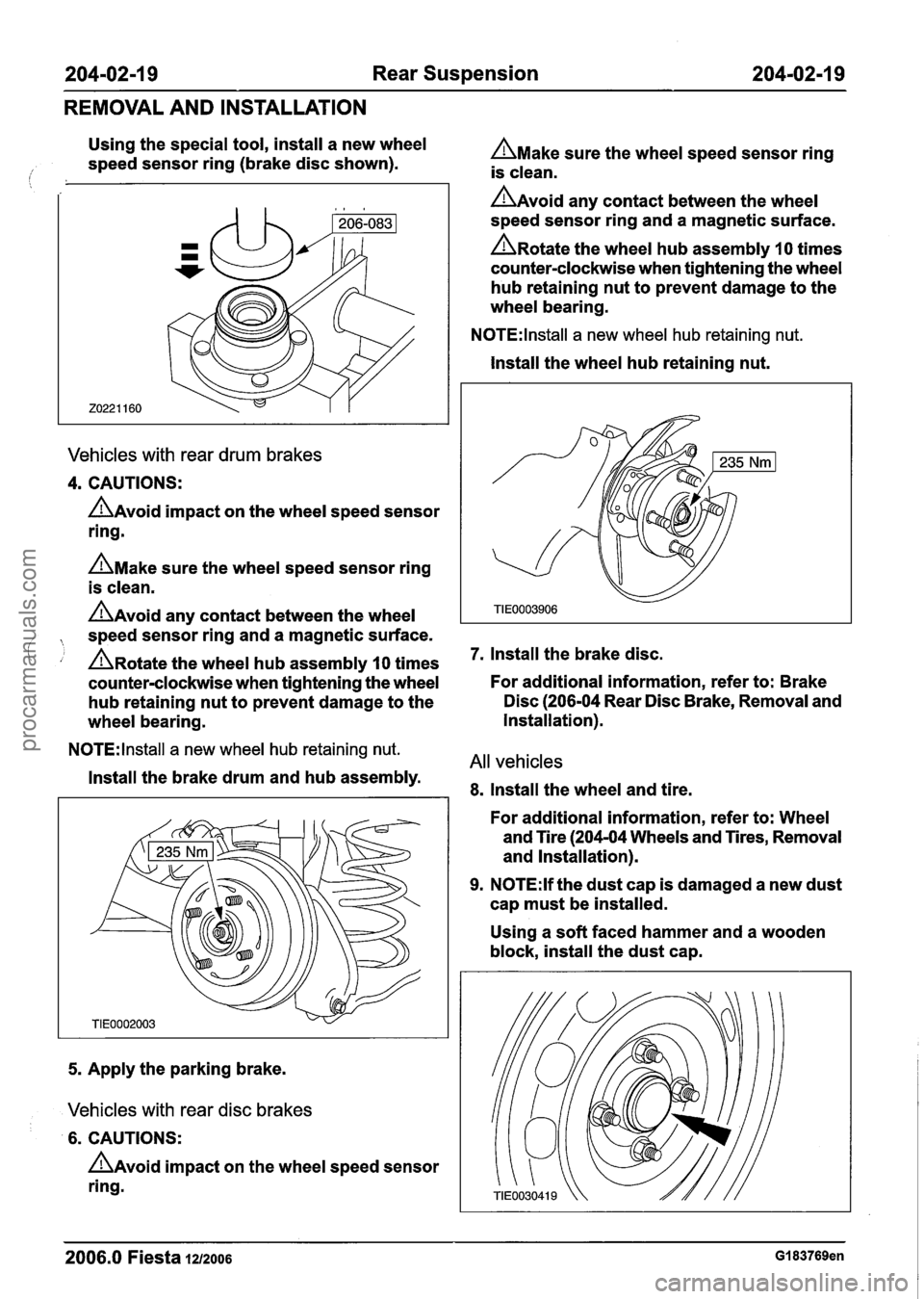

Using the special tool, install a new wheel

speed sensor ring (brake disc shown).

Vehicles with rear drum brakes

4. CAUTIONS:

AAvoid impact on the wheel speed sensor

ring.

AMake sure the wheel speed sensor ring

is clean.

AAvoid any contact between the wheel

, speed sensor ring and a magnetic surface.

' , A~otate the wheel hub assembly 10 times

counter-clockwise when tightening the wheel

hub retaining nut to prevent damage to the

wheel bearing.

N0TE:lnstall a new wheel hub retaining nut.

Install the brake drum and hub assembly.

5. Apply the parking brake.

Vehicles with rear disc brakes

6. CAUTIONS:

AAvoid impact on the wheel speed sensor

ring.

AMake sure the wheel speed sensor ring

is clean.

AAvoid any contact between the wheel

speed sensor ring and a magnetic surface.

A~otate the wheel hub assembly 10 times

counter-clockwise when tightening the wheel

hub retaining nut to prevent damage to the

wheel bearing.

N0TE:lnstall a new wheel hub retaining nut.

Install the wheel hub retaining nut.

7. lnstall the brake disc.

For additional information, refer to: Brake

Disc (206-04 Rear Disc Brake, Removal and

Installation).

All vehicles

8. Install the wheel and tire.

For additional information, refer to: Wheel

and Tire (204-04 Wheels and Tires, Removal

and Installation).

9. N0TE:lf the dust cap is damaged a new dust

cap must be installed.

Using a soft faced hammer and a wooden

block, install the dust cap.

2006.0 Fiesta 1212006 GI 83769en

procarmanuals.com

Page 165 of 1226

205-04-1 3 Front Drive Halfshafts 205-04-1 3

REMOVAL AND INSTALLATION

Intermediate Shaft

I

Materials

Name Specification

Removal

Manual transmission

1 fluid

A WARN1NG:Refer to the Material Safety Data

Sheets for the Automatic Transmission

Fluid E-AW. Failure to follow this

instruction may result in personal injury.

Certain Transmission and Power Steering

fluids supplied to Ford contain additives

which may cause skin irritation or other

skin reactions after contact.

WSD-M2C200-C

For additional information, refer to: Health

and Safety Precautions

(1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

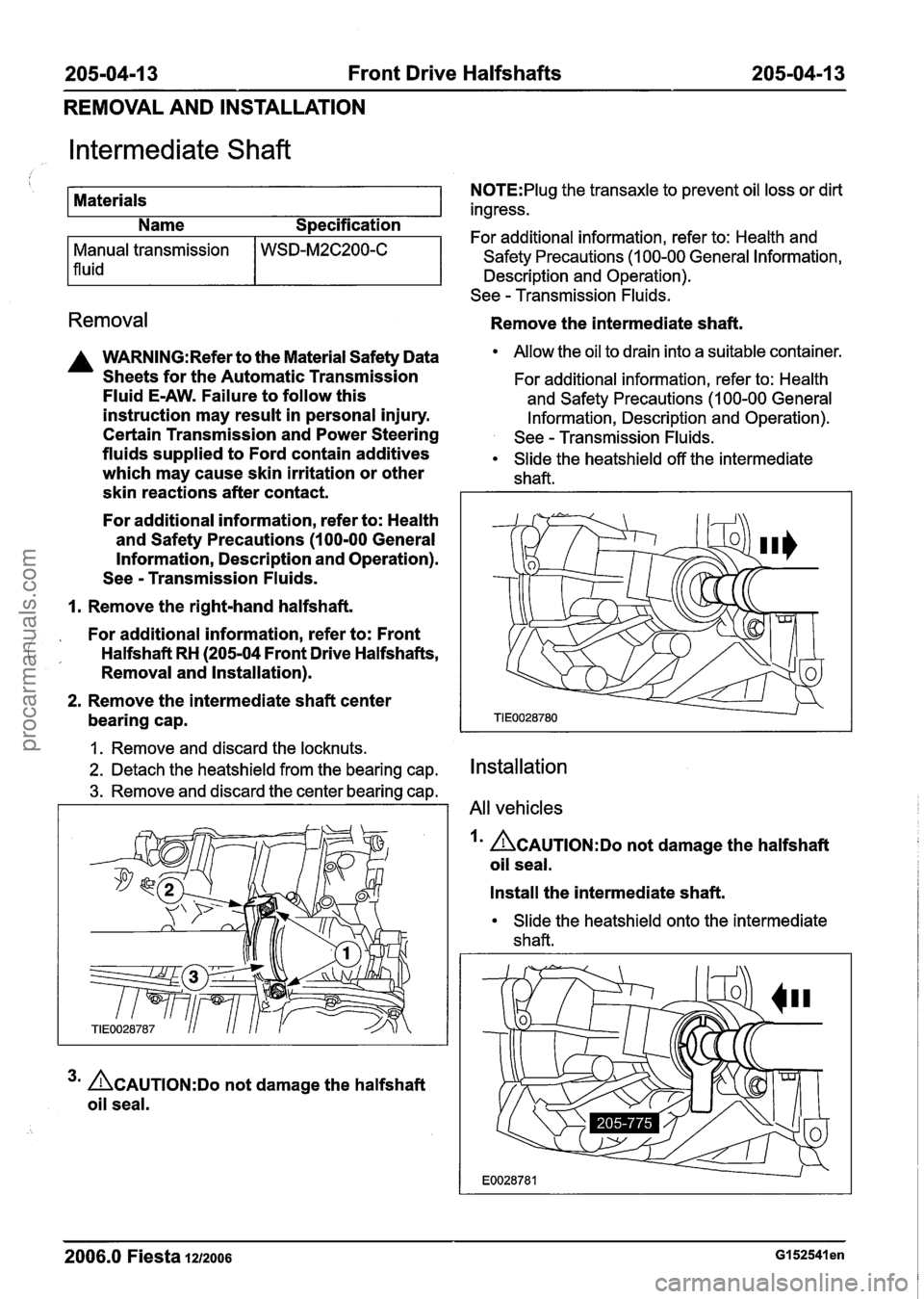

I. Remove the right-hand halfshaft.

, For additional information, refer to: Front

i, Halfshaft RH (205-04 Front Drive Halfshafts,

Removal and Installation).

2. Remove the intermediate shaft center

bearing cap.

1. Remove and discard the locknuts.

2. Detach the heatshield from the bearing cap.

3. Remove and discard the center bearing cap.

3m ACAUTION:D~ not damage the halfshaft

oil seal.

N0TE:Plug the transaxle to prevent oil loss or dirt

ingress.

For additional information, refer to: Health and

Safety Precautions

(1 00-00 General Information,

Description and Operation).

See

- Transmission Fluids.

Remove the intermediate shaft.

Allow the oil to drain into a suitable container.

For additional information, refer to: Health

and Safety Precautions

(I 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

Slide the heatshield off the intermediate

shaft.

Installation

All vehicles

I' ACAUTION:D~ not damage the halfshaft

oil seal.

Install the intermediate shaft.

Slide the heatshield onto the intermediate

shaft.

2006.0 Fiesta 1212006 GI 52541 en

procarmanuals.com

Page 166 of 1226

205-04-1 4 Front Drive Halfshafts 205-04-1 4

REMOVAL AND INSTALLATION

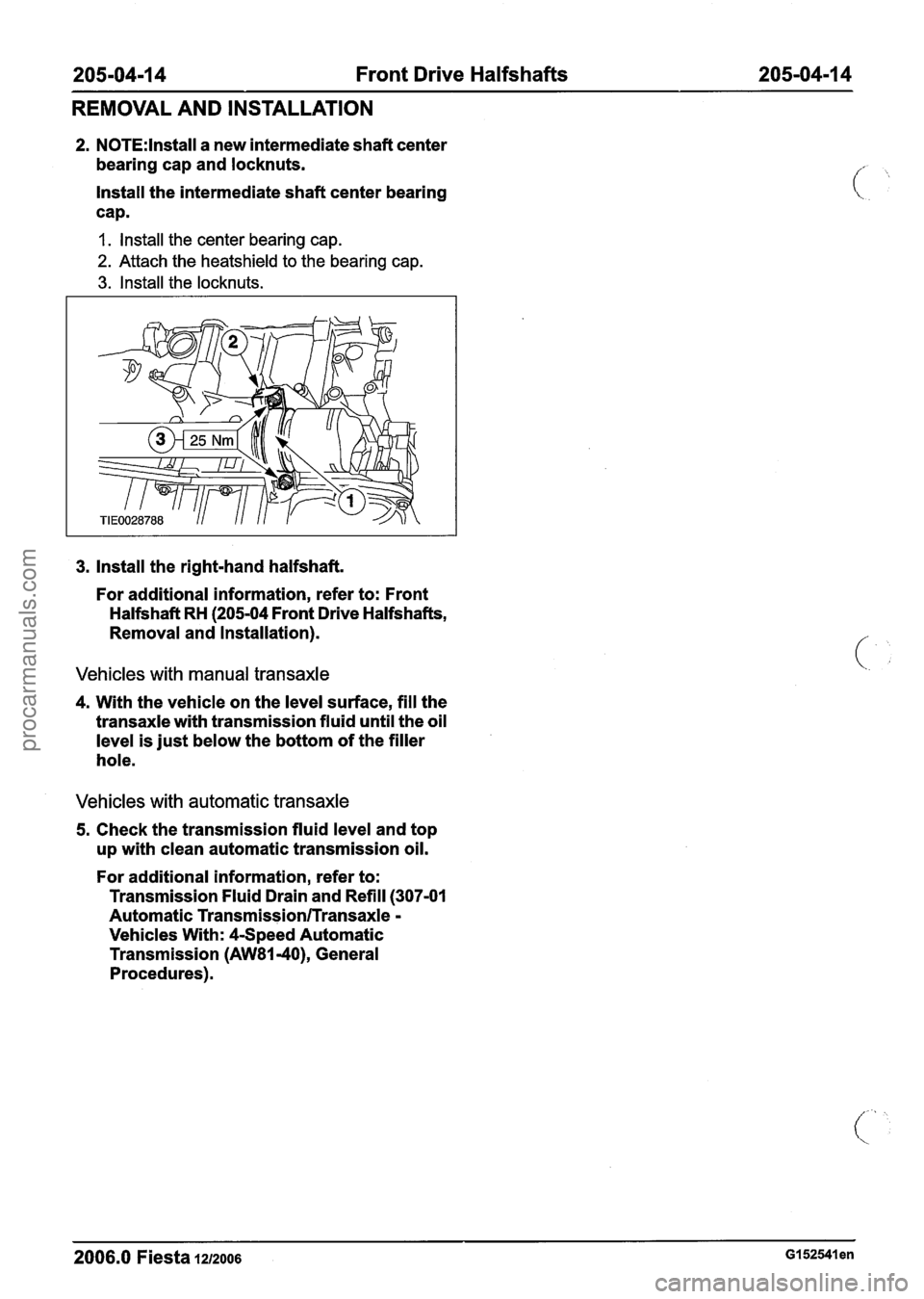

2. N0TE:lnstall a new intermediate shaft center

bearing cap and locknuts.

Install the intermediate shaft center bearing

cap.

I. Install the center bearing cap.

2. Attach the heatshield to the bearing cap.

3. Install the locknuts.

3. Install the right-hand halfshaft.

For additional information, refer to: Front

Halfshaft RH (205-04 Front Drive Halfshafts,

Removal and Installation).

Vehicles with manual transaxle

4. With the vehicle on the level surface, fill the

transaxle with transmission fluid until the oil

level is just below the bottom of the filler

hole.

Vehicles with automatic transaxle

5. Check the transmission fluid level and top

up with clean automatic transmission oil.

For additional information, refer to:

Transmission Fluid Drain and Refill

(307-01

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40), General

Procedures).

2006.0 Fiesta 1212006 GI 52541 en

procarmanuals.com

Page 174 of 1226

206-00-2 Brake System - General Information 206-00-2

DESCRIPTION AND OPERATION

Brake System

Overview

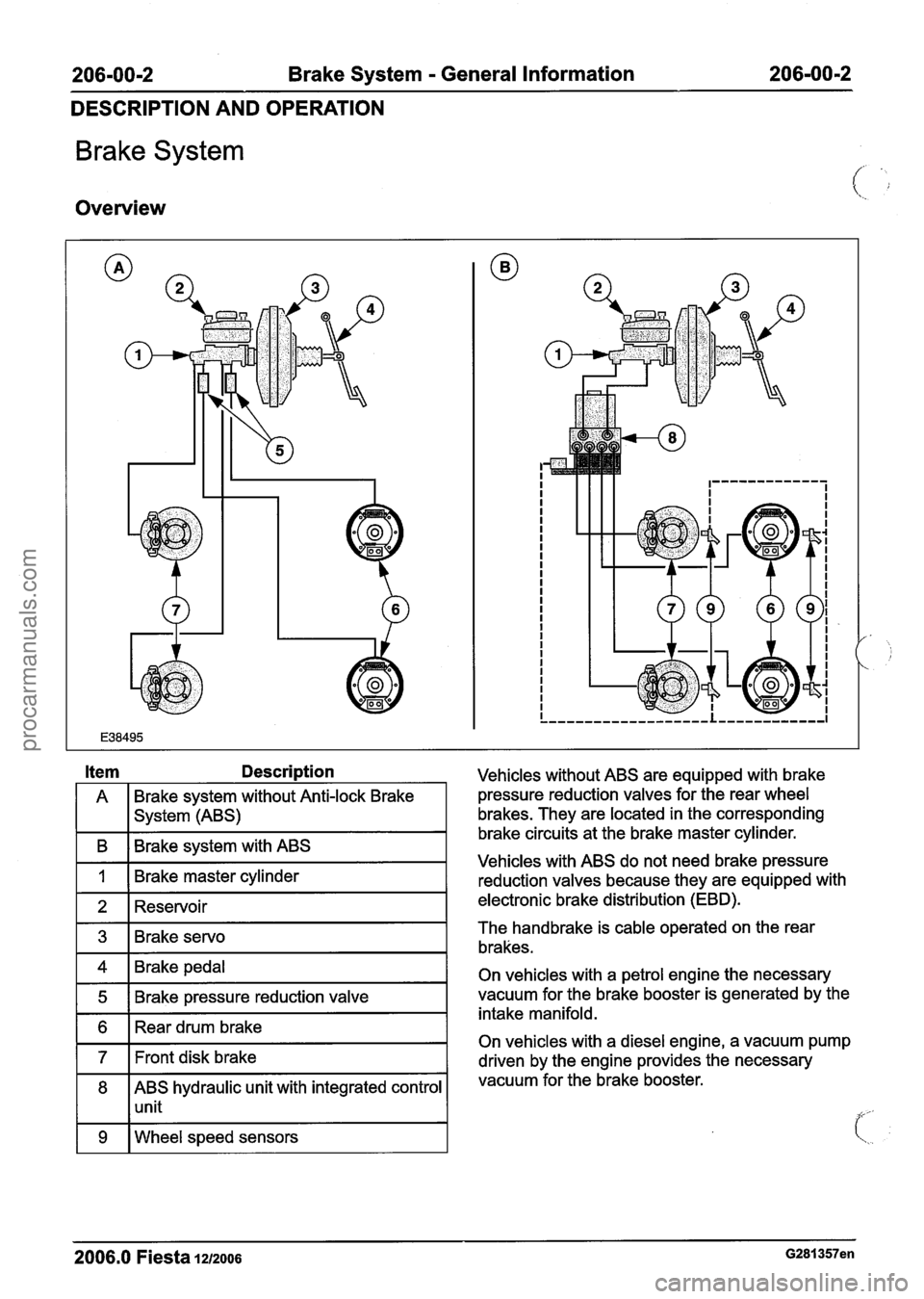

A Brake system without Anti-lock

Brake

I I system (ABS)

I B I Brake system with ABS I

I 1 I Brake master cylinder I -

1 2 1 Reservoir I

1 4 1 Brake pedal I

1 5 1 Brake pressure reduction valve I

1 6 1 Rear drum brake I

171t disk brake I

8 ABS hydraulic unit with integrated control

1 1 unit

1 9 I Wheel speed sensors I

Vehicles without ABS are equipped with brake

pressure reduction valves for the rear wheel

brakes. They are located in the corresponding

brake circuits at the brake master cylinder.

Vehicles with ABS do not need brake pressure

reduction valves because they are equipped with

electronic brake distribution (EBD).

The handbrake is cable operated on the rear

brakes.

On vehicles with a petrol engine the necessary

vacuum for the brake booster is generated by the

intake manifold.

On vehicles with a diesel engine, a vacuum pump

driven by the engine provides the necessary

vacuum for the brake booster.

2006.0 Fiesta lu2006 G281357en

procarmanuals.com

Page 175 of 1226

206-00-3 Brake System - General Information 206-00-3

DIAGNOSIS AND TESTING

Brake System

The brakes system operates by transferring effort

applied to the brake pedal by the driver to the

brakes at each wheel.

The braking effort is distributed to each wheel,

using a hydraulic system. The system is assisted

using a vacuum brake booster that reduces pedal

effort and increases hydraulic pressure.

The parking brake operates on the rear wheels

and is applied using a hand operated control.

lnspection and Verification

N0TE:Before carrying out any diagnosis, make

sure that the brake system warning indicator is

functional.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

damage.

3. If an obvious cause for an observed or reported

concern is found, correct the case (if possible)

before proceeding to the next step.

4. If the cause if not visually evident, verify the

symptom and refer to the Symptom Chart.

Visual lnspection Chart

Road Test

1.

Perform a road test to compare actual vehicle

braking performance with the performance

standards expected by the driver. The ability of the

test driver to make valid comparisons and detect

performance deficiencies will depend on

experience.

Mechanical

- Tire pressure

- Wheels and tires

- Fluid leak from brake line(s)

The driver should have a thorough knowledge of

the brake system operation and accepted general

performance guidelines to make good comparisons

, and detect performance concerns.

An experienced technician will always establish a

route that will be used for all brake diagnosis road

tests. The road selected will be reasonably smooth and level. Gravel

or bumpy roads are not suitable

because the surface does not allow the tires to grip

the road equally. Crowned roads should be avoided

because of the large amount of weight shifted to

the low set of wheels on this type of road. Once

the route is established and consistently used, the

road surface variable can be eliminated from the

test results.

Before a road test, get a complete description of

the customer concerns or suspected condition.

From the description, the technician will be able to

match possible causes with symptoms. Certain

components will be identified as possible sources

while others will be eliminated by the evidence.

More importantly, the customer description can

reveal unsafe conditions which should be checked

or corrected before a road test. The description will

also help form the basic approach to the road test

by narrowing the concern to specific components,

vehicle speed or conditions.

Begin the road test with a general brake

performance check. Using the description of the

concern, test the brakes at different vehicle speeds

using both light and heavy pedal pressure.

Determine if the concern is in the front or rear

braking system. First use the foot brake and then

the parking brake. If the condition

(i.e. pull,

vibration, pulsation) occurs only on operation of

the parking brake, the concern is in the rear brake

system.

If the condition occurs when the foot brake

is depressed, the concern is in the front brake

system.

Avoid locking the brakes and sliding the tires. This

condition will not indicate brake efficiency. A heavily

braked but turning wheel will stop the vehicle in a

shorter distance than locked wheels.

If the concern becomes evident during this check,

make sure it fits the description given before the

road test. If the concern is not evident, attempt to

duplicate the condition using the information from

the description.

If a concern exists, use the Brake System Symptom

Chart in order to isolate it to a specific sub-system

and condition description. From this description, a

list of possible sources can be used to further

narrow the cause to a specific component or

condition.

- -

2006.0 Fiesta 1212006 G28494en

procarmanuals.com

Page 180 of 1226

206-00-8 Brake System - General Information 206-00-8

DIAGNOSIS AND TESTING

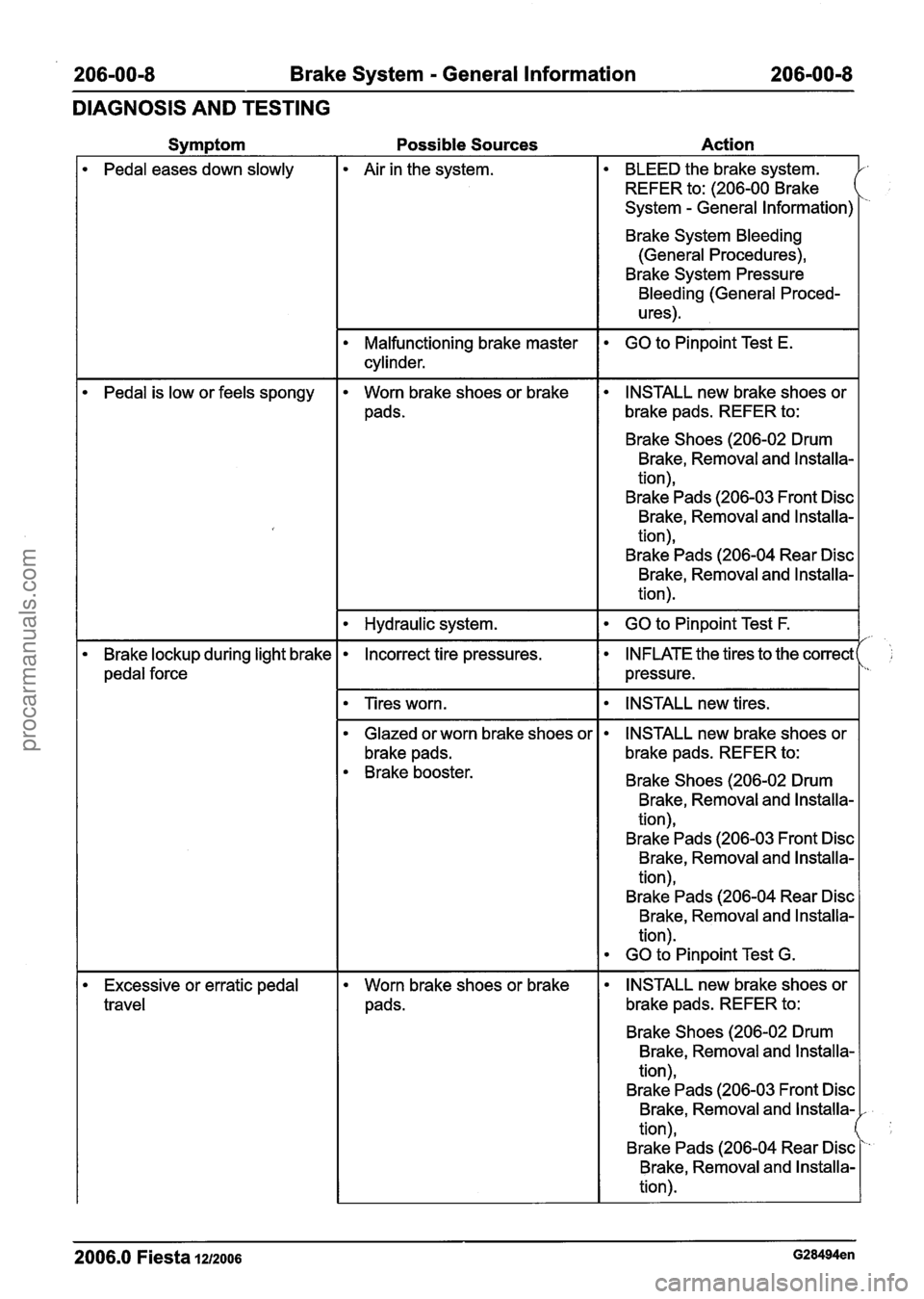

Svm~tom Possible Sources Action

Pedal eases down slowly Air in the system.

Malfunctioning brake master

cylinder.

BLEED the brake system.

REFER to: (206-00 Brake

System

- General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General Proced-

ures).

GO to Pinpoint Test E.

Brake, Removal and Installa-

tion),

Brake Pads (206-03 Front Disc

Brake, Removal and Installa-

tion),

Brake Pads (206-04 Rear Disc

Brake, Removal and Installa-

Pedal is low or feels spongy

I tion). I

Brake lockup during light brake I

Worn brake shoes or brake

pads.

pedal force INSTALL new brake shoes or

brake pads. REFER to:

Hydraulic system.

Incorrect tire pressures.

Tires worn.

Glazed or worn brake shoes or

brake pads.

Brake booster.

GO to Pinpoint Test F. I

INFLATE the tires to the correct

pressure.

INSTALL new tires. I

brake pads. REFER to:

Brake Shoes (206-02 Drum

Brake, Removal and Installa-

tion),

Brake Pads (206-03 Front Disc Brake, Removal and Installa-

tion),

Brake Pads (206-04 Rear Disc

Brake, Removal and Installa-

tion).

GO to Pinpoint Test G.

Excessive or erratic pedal

travel Worn brake shoes or brake

pads. INSTALL new brake shoes or

brake pads. REFER to:

Brake Shoes (206-02 Drum Brake, Removal and Installa-

tion),

Brake Pads (206-03 Front Disc Brake, Removal and Installa-

tion),

I

Brake Pads (206-04 Rear Disc

Brake, Removal and Installa-

tion).

2006.0 Fiesta 1212006 G28494en

procarmanuals.com

Page 192 of 1226

206-00-20 Brake System - General Information 206=00-20

DIAGNOSIS AND TESTING

TEST CONDITIONS

DETAILSIRESULTSIACTIONS

F4: BLEED THE BRAKE SYSTEM

rn Check for air in the brake system. Bleed the

brake system. REFER to: (206-00 Brake System

- General lnformation)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General Procedures)

.

Is the condition still present?

+ Yes

GO to F5.

+ No

Vehicle OK.

F5: CHECK FRONT WHEEL HUB RETAINING NUT

Check the front wheel hub retaining nut for

looseness.

Is the front wheel hub retaining nut loose?

+ Yes

INSTALL a new front wheel hub retaining nut.

REFER to: Specifications (204-01 Front

Suspension, Specifications).

Do not reuse the

frontwheel hub retaining nut.

TEST the system for normal operation.

+ No

CHECK the parking bake adjustment. REFER

to: (206-05 Parking Brake and Actuation)

Parking Brake Cable Adjustment

- Vehicles With:

Rear Drum Brakes (General Procedures),

Parking Brake Cable Adjustment

- Vehicles With:

Rear Disc Brakes (General Procedures).

PINPOINT TEST G

: BRAKE LOCK UP DURING LIGHT BRAKE PEDAL FORCE

TEST CONDITIONS

DETAILSIRESULTSIACTIONS

I GI : ROAD TEST-THE VEHICLE I

Road test the vehicle and apply the brake pedal

lightly.

Do the rear brakes lock up?

+ Yes

GO to G2. GO to Pinpoint Test G.

+ No

Vehicle OK.

2006.0 Fiesta 12/2006 G28494en

procarmanuals.com

Page 202 of 1226

Brake System - General Information

DIAGNOSIS AND TESTING

evidence of a brake concern. Check for the brake

warning indicator illumination and the fluid level in

the master cylinder reservoir.

Normal Conditions

The following conditions are considered normal

and are not indications that the brake master

cylinder is in need of service.

- Modern brake systems are not designed to

produce as hard a pedal effort as in the past.

Complaints of light pedal efforts should be

compared to pedal efforts of another vehicle, of

the same model and year.

- During normal operation of the brake the fluid

level in the reservoir will rise during brake

application and fall during release. The net fluid

level

(i.e., after brake application and release)

will remain unchanged.

- A trace of brake fluid will exists on the brake

booster shell below the master cylinder

mounting flange. This results from the normal

lubricating action of the master cylinder bore

end seal.

- The fluid level will fall with brake shoe and lining

wear.

Abnormal Conditions

N0TE:Prior to performing any diagnosis, make

sure the brake system warning indicator is

functional.

Changes in brake pedal feel or travel are indicators

that something could be wrong with the braking system. The diagnostic procedure and techniques

use brake pedal feel, warning indicator illumination

and low brake fluid level as indicators in diagnosing

braking system concerns. The following conditions

are considered abnormal and indicate that the

brake master cylinder is in need of service.

- The brake pedal effort is excessive. This may

be caused by a bind or obstruction in the pedal

.

or linkage, clogged fluid control valve or ( ' insufficient booster vacuum.

- The rear brakes lock up during light pedal force.

This may be caused by incorrect tire pressures,

grease or fluid on the brake shoes and linings,

damaged brake shoes and linings, incorrectly

adjusted parking brake, or damaged or

contaminated brake pressure control valves.

- The brake pedal effort is erratic. This condition

could be caused by a brake booster malfunction,

extreme caliper piston knock back or incorrectly

installed brake shoes and linings.

- The brake warning indicator is ON. This may

be caused by low fluid level, ignition wire routing

too close to the fluid level indicator assembly,

or float assembly damage.

Bypass Condition Test

1. Check the fluid in brake master cylinder. Fill the

brake master cylinder reservoir if low or empty.

2. Observe the fluid level in the brake master

cylinder reservoir. If after several brake

applications, the fluid level remains the same,

measure the wheel turning torque required to

rotate the wheels with the brakes applied as

follows:

Place the transaxle in NEUTRAL and raise and

support the vehicle. REFER to: (1 00-02 Jacking

and Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

Apply the brakes with a minimum of 445 N (100

Ib) and hold for approximately 15 seconds. With

the brakes still applied, exert a torque on the front

wheels of 10.1 Nm (75

1b.R). If either wheel rotates,

install a new brake master cylinder. REFER to:

(206-06 Hydraulic Brake Actuation)

- The brake pedal goes down fast. This could be Brake Master Cylinder - RHD (Removal and

caused by an external or internal leak. Installation),

- The brake

pedal eases down slowly. This could Brake Master Cylinder - LHD

(Removal and

be caused by an external or internal leak. Installation).

- The

brake pedal is low and or feels spongy. This

condition may be caused by no fluid in the brake

Non-Pressure Leaks master cylinder reservoir, reservoir cap vent

holes clogged or air in the hydraulic system.

Any empty brake master cylinder reservoir

condition may be caused by two types of

non-pressure external leaks.

2006.0 Fiesta 1212006

procarmanuals.com