relay FORD FIESTA 2007 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 989 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission (AW81-40)

DESCRIPTION AND OPERATION

Item Description

1 5 1 Generic Electronic Module (GEM) I

I

1 6 1 Turbine Shaft Speed (TSS) sensor I

1 7 1 Output Shaft Speed (OSS) sensor I

1

2

3

4

l tem Description

Transmission control unit

Data Link Connector (DLC)

Powertrain Control Module (PCM)

Instrument cluster

1 8 I Transmission Range (TR) sensor I

1 9 1 Starter inhibit relay I

1 10 1 Backup lamp relay I

11 Transmission Fluid Temperature (TFT)

I I sensor

1 12 loverdrive switch I

1 13 1 Driver's side door ajar switch I

1 14 1 Solenoid valves in the main control body 1

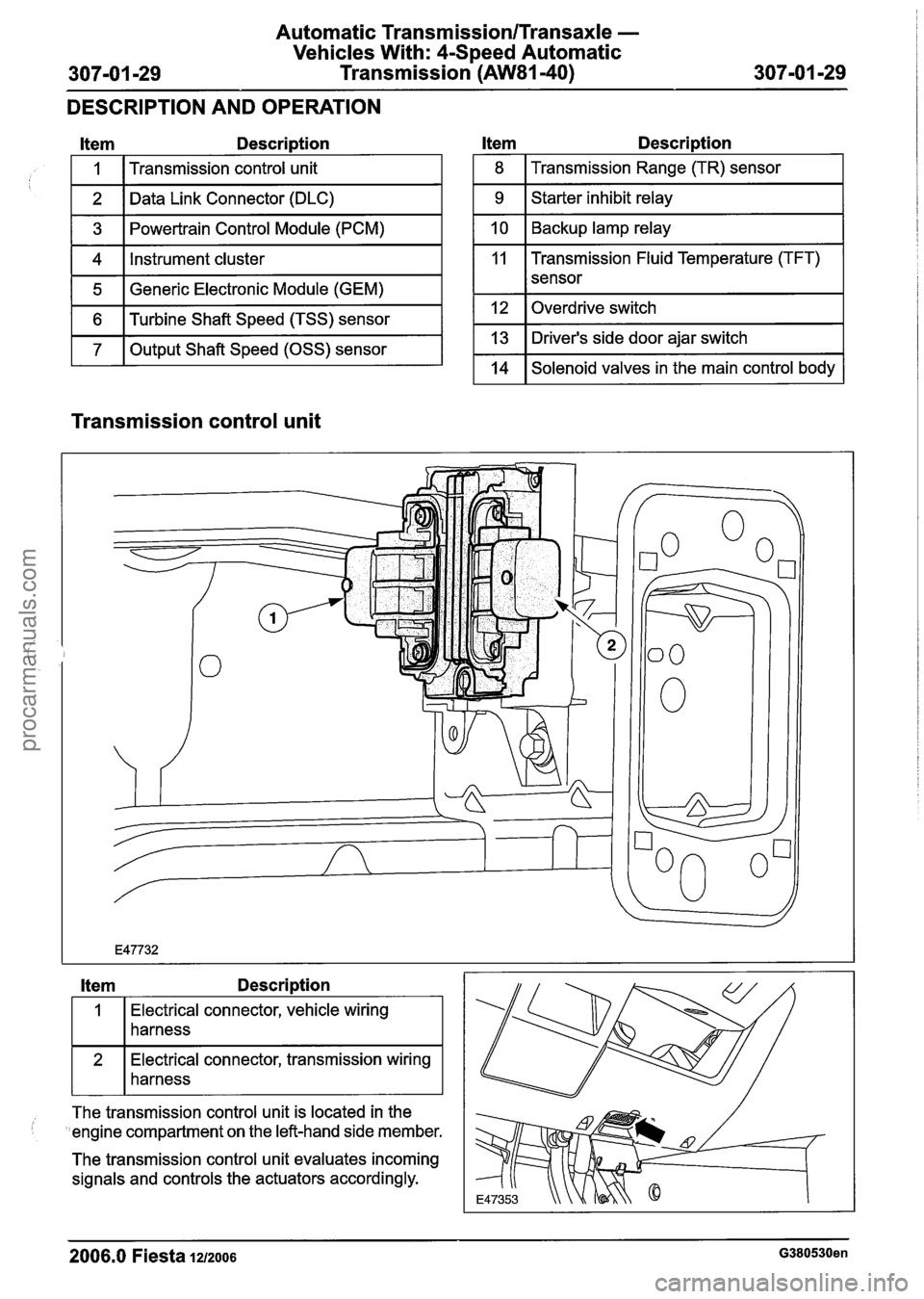

Transmission control unit

Item Description

Electrical connector, vehicle wiring

harness

connector, transmission wiring

harness

--

The transmission control unit is located in the

'engine compartment on the left-hand side member.

The transmission control unit evaluates incoming

signals and controls the actuators accordingly.

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 998 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4Speed Automatic

307-01 -38 Transmission (AW81-40) 307-01 -38

DESCRIPTION AND OPERATION

Consequences of signal failure:

NoTCC,

no torque reduction, no shift timing adaptation,

no 4th

gear.

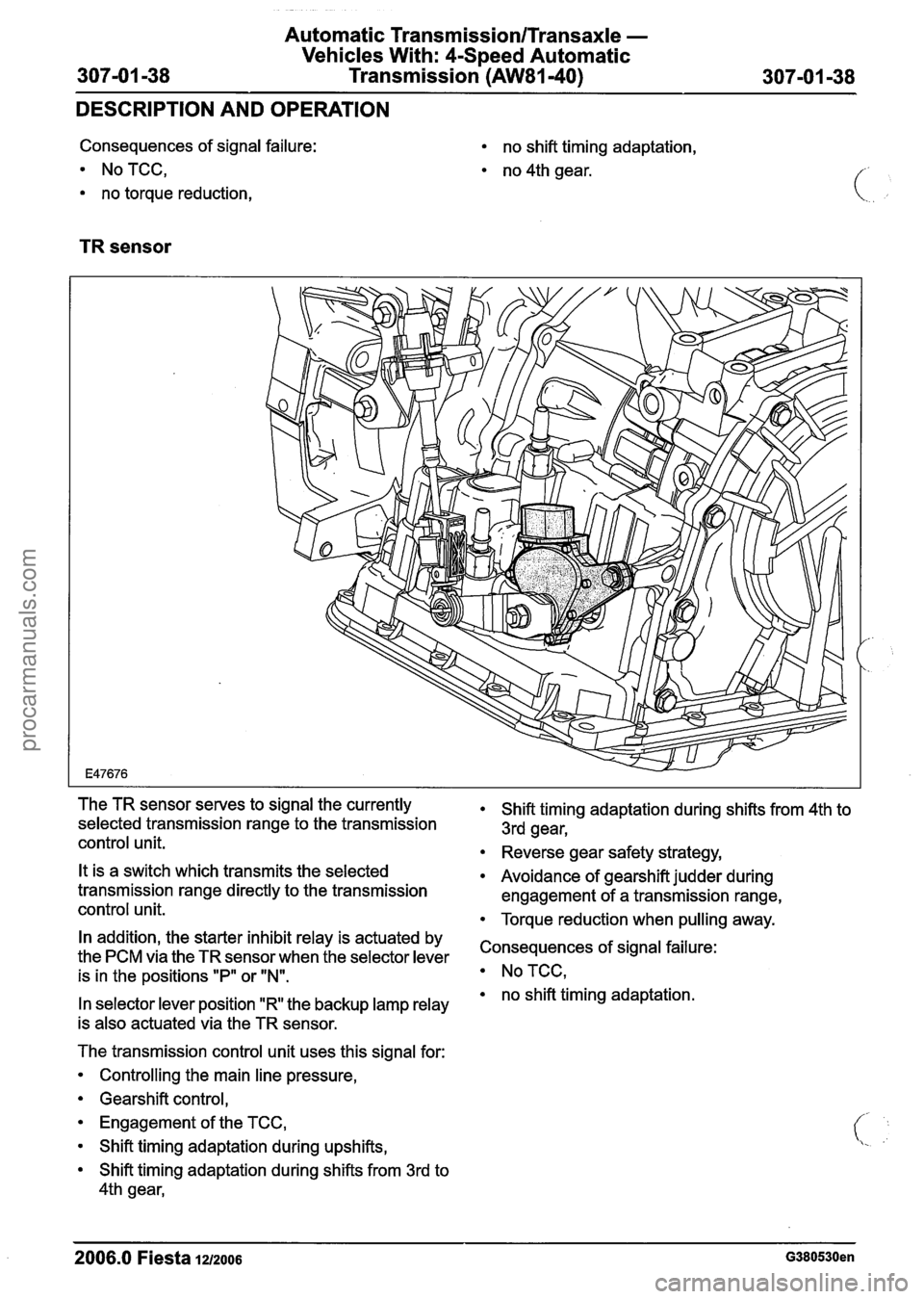

TR sensor

The TR sensor serves to signal the currently

selected transmission range to the transmission

control unit.

It is a switch which transmits the selected

transmission range directly to the transmission

control unit.

In addition, the starter inhibit relay is actuated by

the PCM via the TR sensor when the selector lever

is in the positions "P" or

N.

In selector lever position "R the backup lamp relay

is also actuated via the TR sensor.

The transmission control unit uses this signal for:

Controlling the main line pressure,

Gearshift control,

Engagement of the TCC,

Shift timing adaptation during upshifts,

Shift timing adaptation during shifts from 3rd to

4th gear,

Shift timing adaptation during shifts from 4th to

3rd gear,

Reverse gear safety strategy,

Avoidance of gearshift judder during

engagement of a transmission range,

Torque reduction when pulling away.

Consequences of signal failure:

NoTCC,

no shift timing adaptation.

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 1002 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40)

DESCRIPTION AND OPERATION

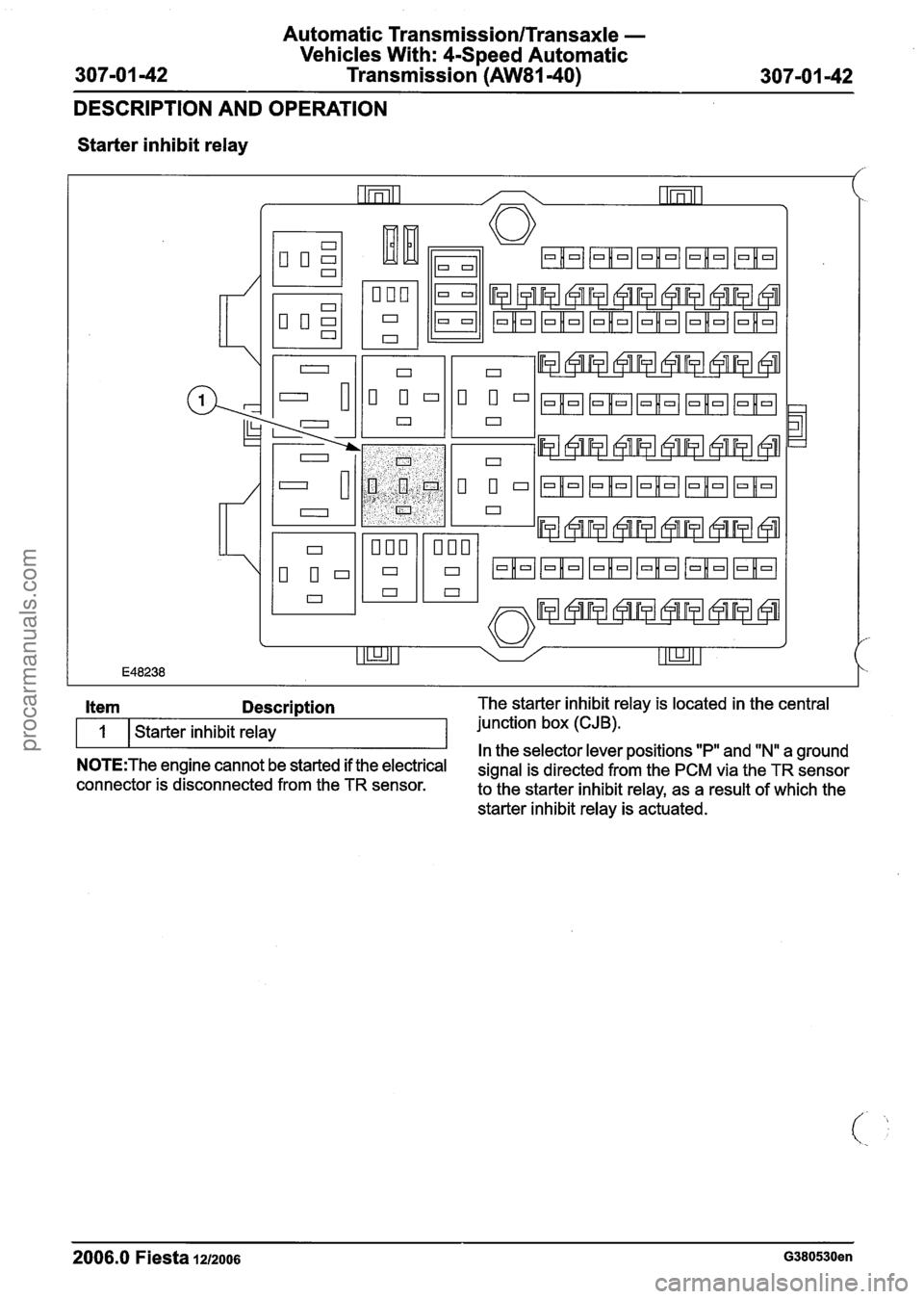

Starter inhibit relay

2006.0 Fiesta

12/2006 G380530en

Item Description The starter inhibit relay is located in the central

1 Starter inhibit relay junction

box (CJB).

In the selector lever positions "P" and "Nu a ground N0TE:The engine cannot be started if the electrical signal is directed from the PCM via the TR sensor connector is disconnected from the TR sensor.

to the starter inhibit relay, as a result of which the

starter inhibit relay is actuated.

procarmanuals.com

Page 1003 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -43 Transmission (AW81-40) 307-01 -43

DESCRIPTION AND OPERATION

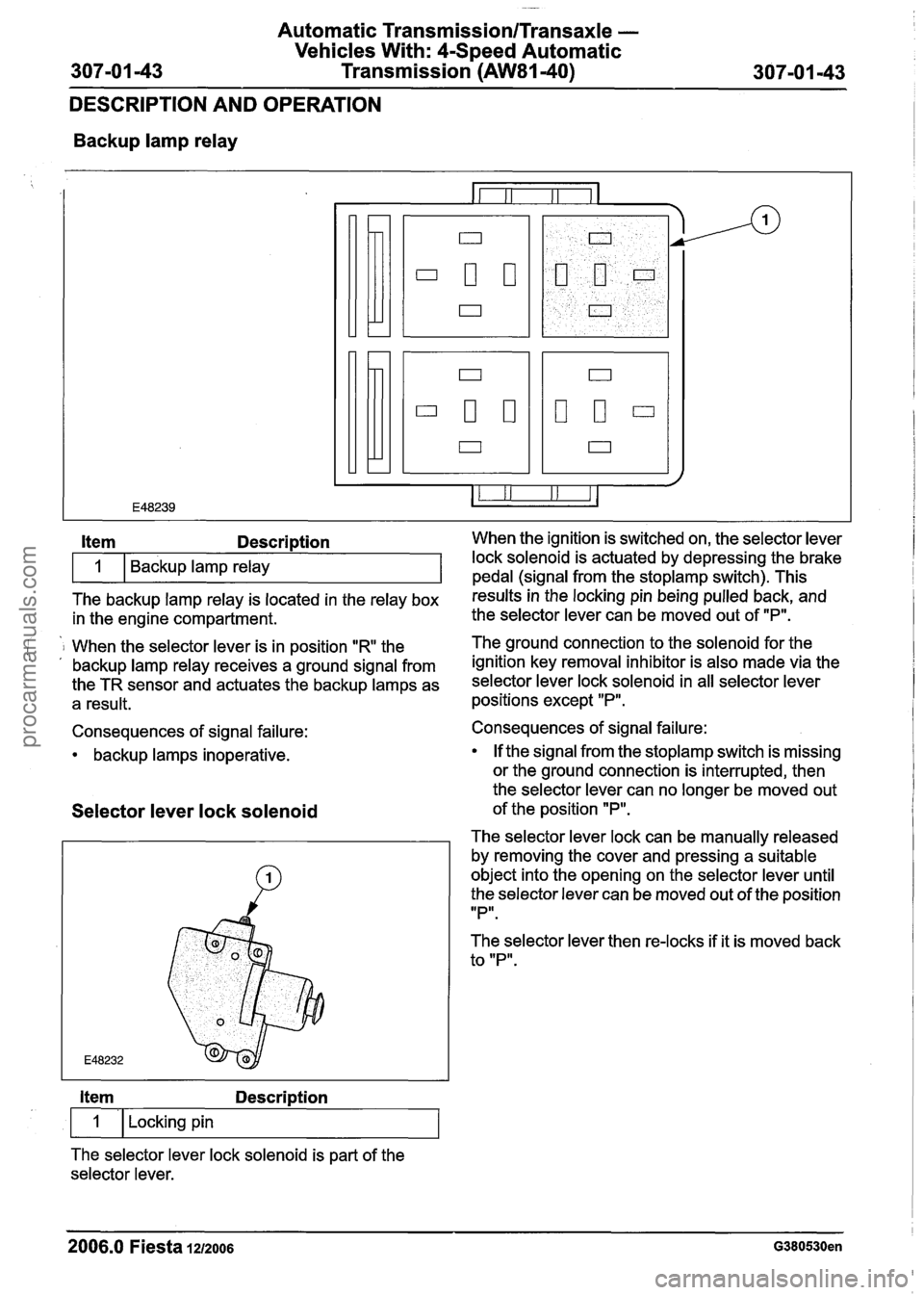

Backup lamp relay

The backup lamp relay is located in the relay box results inthe locking pin being pulled back, and

in the engine compartment. the

selector lever can be moved out of "P".

Item Description When the ignition is switched on, the selector lever

i 1 When the selector lever is in position "R the The ground connection to the solenoid for

the . , backup lamp relay receives a ground signal from ignition key removal inhibitor is also made via the

the TR sensor and actuates the backup lamps as selector lever lock solenoid in all selector lever

a result. positions except "P".

1

Consequences of signal failure:

backup lamps inoperative. Backup lamp relay

Selector

lever lock solenoid

lock solenoid is actuated by depressing the brake

pedal (sianal from the stoplamp switch). This

Item Description

1 I Locking pin

The selector lever lock solenoid is part of the

selector lever. Consequences of signal failure:

If the signal from the

stoplamp switch is missing

or the ground connection is interrupted, then

the selector lever can no longer be moved out

of the position

"P".

The selector lever lock can be manually released

by removing the cover and pressing a suitable

object into the opening on the selector lever until

the selector lever can be moved out of the position

IIPlr.

The selector lever then re-locks if it is moved back

to "P".

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 1218 of 1226

Acceleration Control - 1.3L Duratec-8V

(Rocam)llI25L Duratec-1 6V (Sigma)llI4L

31 0-02A-4 Duratec-1 6V (Sigma)/l .6L

Duratec-1 6V (Sigma)

31 0-02A-4

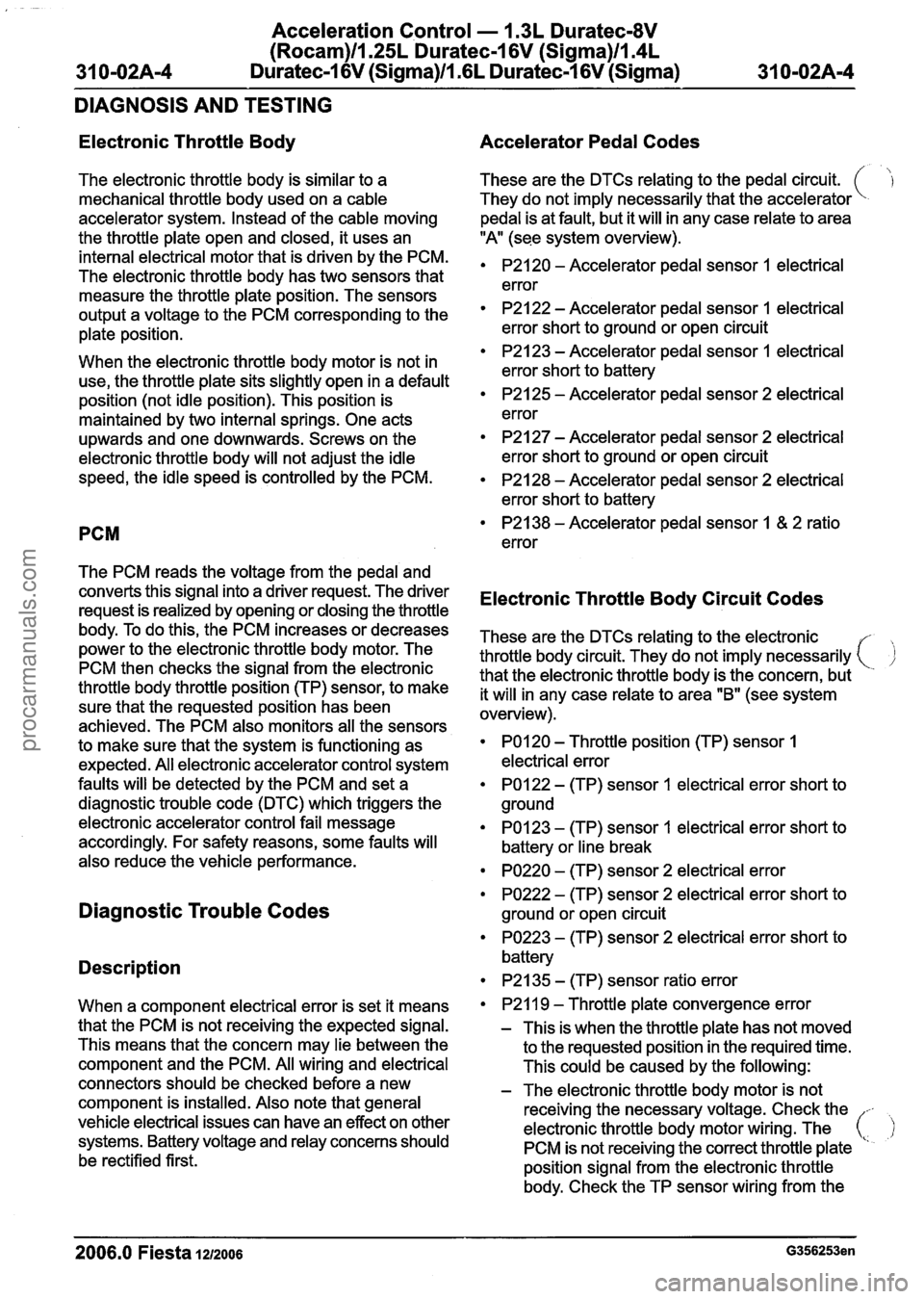

DIAGNOSIS AND TESTING

Electronic Throttle Body

The electronic throttle body is similar to a

mechanical throttle body used on a cable

accelerator system. Instead of the cable moving

the throttle plate open and closed, it uses an

internal electrical motor that is driven by the PCM.

The electronic throttle body has two sensors that

measure the throttle plate position. The sensors

output a voltage to the PCM corresponding to the

plate position.

When the electronic throttle body motor is not in

use, the throttle plate sits slightly open in a default

position (not idle position). This position is

maintained by two internal springs. One acts

upwards and one downwards. Screws on the

electronic throttle body will not adjust the idle

speed, the idle speed is controlled by the PCM.

PCM

The PCM reads the voltage from the pedal and

converts this signal into a driver request. The driver

request is realized by opening or closing the throttle

body. To do this, the PCM increases or decreases

power to the electronic throttle body motor. The

PCM then checks the signal from the electronic

throttle body throttle position (TP) sensor, to make

sure that the requested position has been

achieved. The PCM also monitors all the sensors

to make sure that the system is functioning as

expected. All electronic accelerator control system

faults will be detected by the PCM and set a

diagnostic trouble code (DTC) which triggers the

electronic accelerator control fail message

accordingly. For safety reasons, some faults will

also reduce the vehicle performance.

Diagnostic Trouble Codes

Description

When a component electrical error is set it means

that the PCM is not receiving the expected signal.

This means that the concern may lie between the

component and the PCM. All wiring and electrical

connectors should be checked before a new

component is installed. Also note that general

vehicle electrical issues can have an effect on other

systems. Battery voltage and relay concerns should

be rectified first.

Accelerator Pedal Codes

These are the DTCs relating to the pedal circuit.

They do not imply necessarily that the accelerator

pedal is at fault, but it will in any case relate to area

"A (see system overview).

P2120 - Accelerator pedal sensor 1 electrical

error

P2122 - Accelerator pedal sensor I electrical

error short to ground or open circuit

P2123 - Accelerator pedal sensor I electrical

error short to battery

P2125 - Accelerator pedal sensor 2 electrical

error

P2127 - Accelerator pedal sensor 2 electrical

error short to ground or open circuit

P2128 - Accelerator pedal sensor 2 electrical

error short to battery

P2138 - Accelerator pedal sensor 1 & 2 ratio

error

Electronic Throttle Body Circuit Codes

These are the DTCs relating to the electronic

throttle body circuit. They do not imply necessarily

( ,)

that the electronic throttle body is the concern, but

it will in any case relate to area "B" (see system

overview).

PO1 20 - Throttle position (TP) sensor 1

electrical error

PO122 - (TP) sensor 1 electrical error short to

ground

PO123 - (TP) sensor 1 electrical error short to

battery or line break

PO220 - (TP) sensor 2 electrical error

PO222 - (TP) sensor 2 electrical error short to

ground or open circuit

PO223 - (TP) sensor 2 electrical error short to

battery

P2135 - (TP) sensor ratio error

P21

I 9 - Throttle plate convergence error

- This is when the throttle plate has not moved

to the requested position in the required time.

This could be caused by the following:

- The electronic throttle body motor is not

receiving the necessary voltage. Check the

--

electronic throttle body motor wiring. The ( PCM is not receiving the correct throttle plate '

position signal from the electronic throttle

body. Check the TP sensor wiring from the

2006.0 Fiesta 1212006 G356253en

procarmanuals.com

Page 1220 of 1226

Acceleration Control - I .3L Duratec-8V

(Rocam)llI25L Duratec-I 6V (Sigma)llI4L

31 0-02A-6 Duratec-I 6V (Sigma)/l .6L Duratec-1 6V (Sigma)

31 0-02A-6

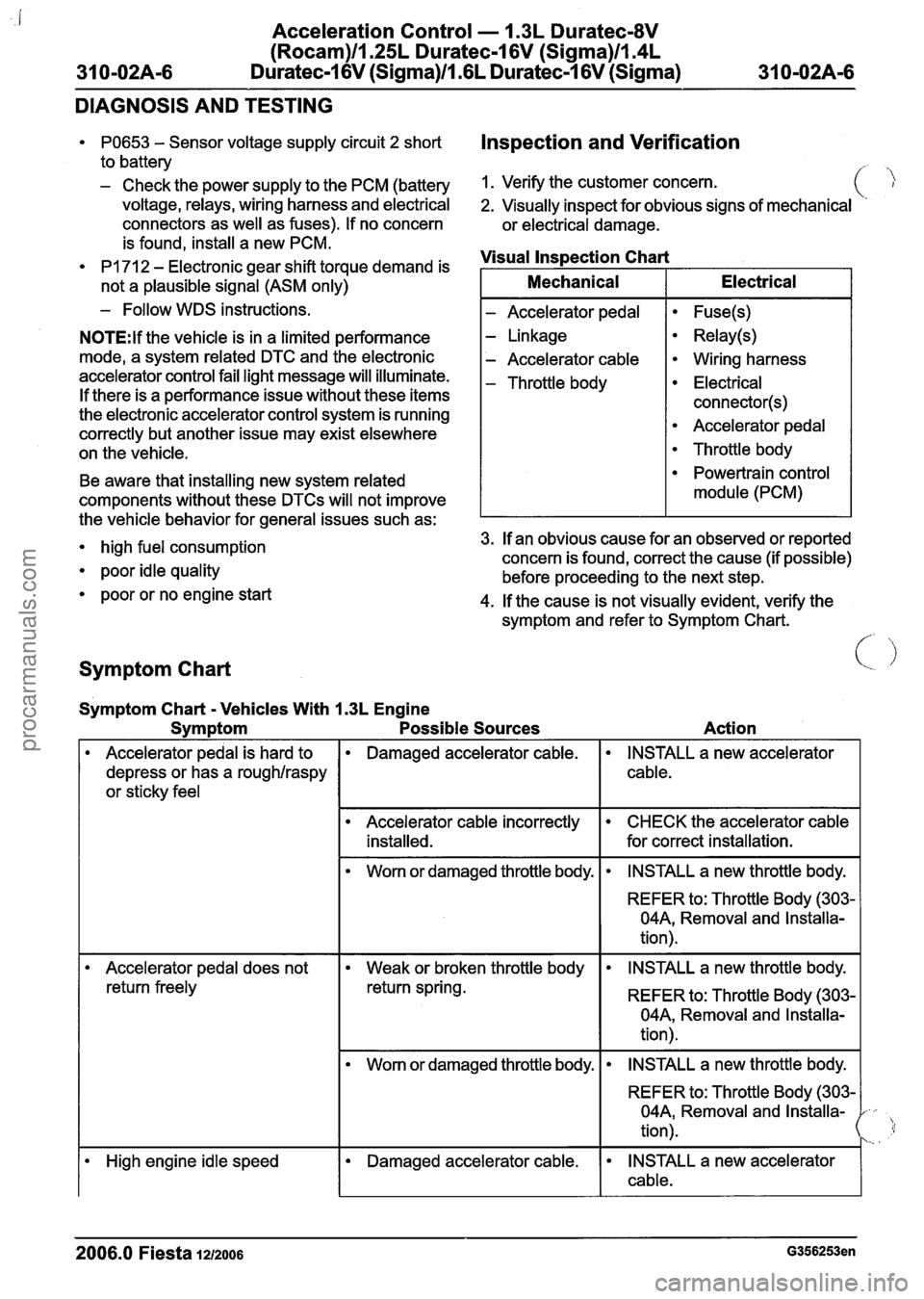

DIAGNOSIS AND TESTING

PO653 - Sensor voltage supply circuit 2 short Inspection and Verification

to battery

- Check the power supply to the PCM (battery 1. Verify the customer concern.

voltage, relays, wiring harness and electrical 2. Visually inspect for obvious signs of mechanical

connectors as well as fuses). If no concern

or electrical damage.

- Follow WDS instructions. I - Accelerator pedal I Fuse(s) I

- is found, install a new PCM.

PI 71 2 - Electronic gear shift torque demand is Visual

Inspection Chart

N0TE:lf the vehicle is in a limited performance

mode, a system related DTC and the electronic

accelerator control fail light message will illuminate.

If there is a performance issue without these items

the electronic accelerator control system is running

correctly but another issue may exist elsewhere

on the vehicle.

not

a plausible signal (ASM only) - Linkage

- Accelerator cable

- Throttle body

Relay(s)

Wiring harness

Electrical

connector(s)

Accelerator pedal

Throttle body

Mechanical

Electrical

Symptom Chart < .I

Be

aware that installing new system related

components without these

DTCs will not improve

Symptom Chart

- Vehicles With 1.3L Engine

Symptom Possible Sources

Powertrain control

module (PCM)

Action

the

vehicle behavior for general issues such as:

high fuel consumption 3.

If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

poor idle quality before proceeding to the next step.

poor or no engine start

4. If the cause is not visually evident, verify the

symptom and refer to Symptom Chart.

f

Accelerator pedal is hard to

depress or has a

roughlraspy

or sticky feel

Damaged accelerator cable.

REFER to: Throttle Body (303-

04A, Removal and Installa-

tion).

INSTALL a new accelerator

cable.

Accelerator cable incorrectly installed.

Worn or damaged throttle body.

I Accelerator pedal does not I Weak or broken throttle body I INSTALL a new throttle body. I

CHECK the accelerator cable

for correct installation.

INSTALL a new throttle body.

return freely REFER to: Throttle Body (303-

04A, Removal and Installa-

tion).

I Worn or damaged throttle body. I INSTALL a new throttle body. I

I I I REFER to: Throttle Body (303- 1 04A, Removal and Installa-

tion).

High engine idle speed Damaged accelerator cable. INSTALL a new accelerator

I cable.

2006.0 Fiesta 1212006 G356253en

procarmanuals.com