engine FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 920 of 1226

303-1 3-2 Evaporative Emissions 303-1 3-2

DESCRIPTION AND OPERATION

Evaporative Emissions

Overview

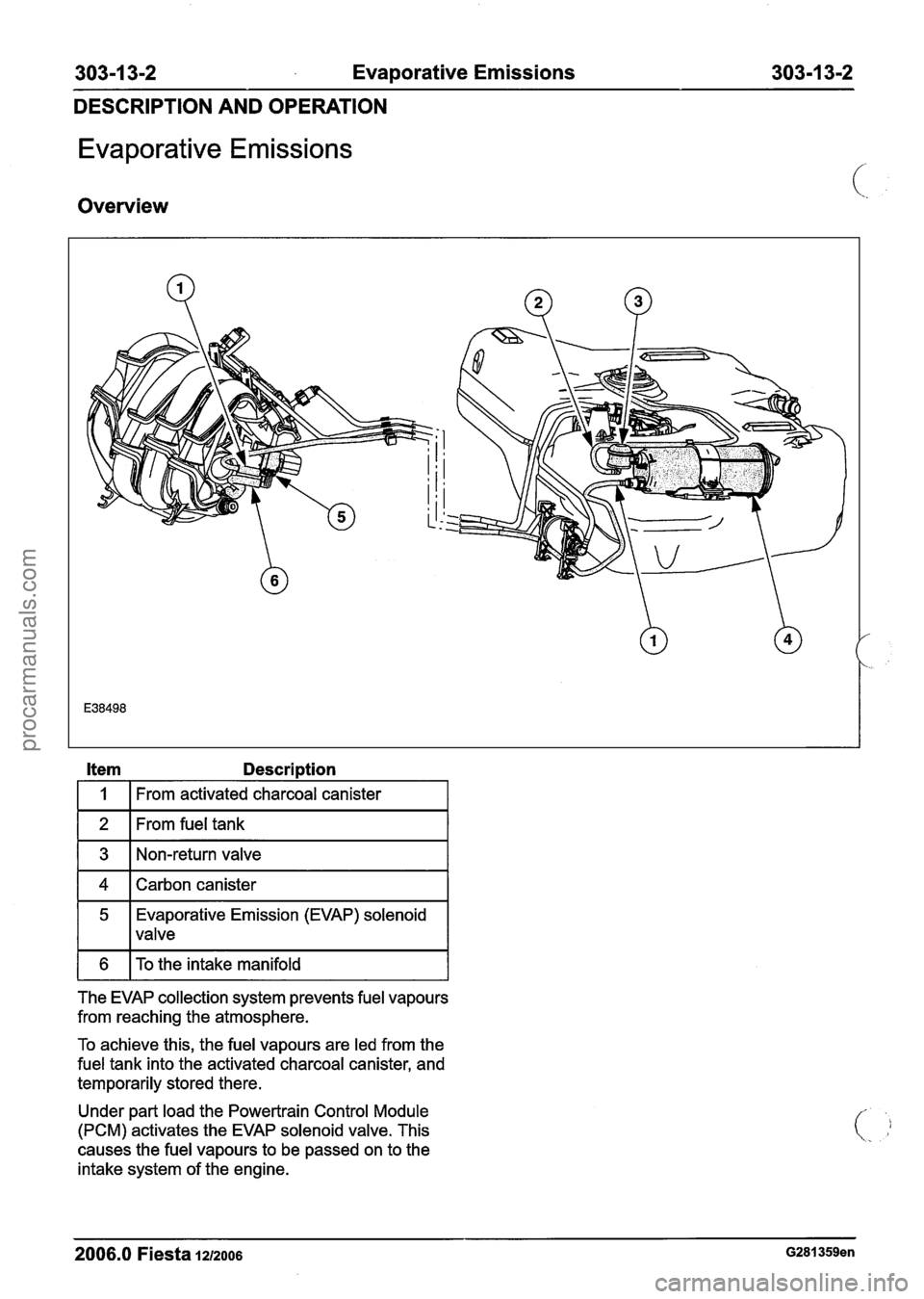

Item Description

I 1 I From activated charcoal canister I

1 2 1 From fuel tank I

1 3 1 Non-return valve I

1 4 1 Carbon canister I

5 Evaporative Emission (EVAP) solenoid

I 1 valve

1 6 1 To the intake manifold I

The EVAP collection system prevents fuel vapours

from reaching the atmosphere.

To achieve this, the fuel vapours are led from the

fuel tank into the activated charcoal canister, and

temporarily stored there.

Under part load the Powertrain Control Module

(PCM) activates the EVAP solenoid valve. This

causes the fuel vapours to be passed on to the

intake system of the engine.

2006.0 Fiesta 1212006 G281359en

procarmanuals.com

Page 925 of 1226

303-1 4-1 Electronic Engine Controls 303-1 4-1

SECTION 303-1 4 Electronic Engine Controls

VEHICLE APPLICATION:2006.0 Fiesta

CONTENTS PAGE

SPECIFICATIONS

Specifications ........................................................................\

.............................................. 303-1 4-2

DESCRIPTION AND OPERATION

Electronic Engine Controls . 1.25L Duratec-16V (Sigma)/l.4L Duratec-I 6V (Sigma)/l . 6L

Duratec-1 6V (Sigma) ........................................................................\

................................

Overview ........................................................................\

.....................................................

Throttle Control Unit (TCU) ........................................................................\

.........................

CPP switch ........................................................................\

..............................................

(Brake Pedal Position) BPP switch ........................................................................\

.........

APP sensor ........................................................................\

.............................................

Electronic Engine Controls - 2.OL Duratec-HE (M14) .......................................................

System Overview, 2.OL Duratec HE (M14) Engine .............................................................

........................................................................\

............................................... Components

DIAGNOSIS AND TESTING

Electronic Engine Controls ........................................................................\

..................... 303-1 4-1 4

Principles of Operation

........................................................................\

............................... 303-1 4-1 4

MIL Code List

........................................................................\

............................................. 303-14-1 7

Inspection and Verification ........................................................................\

.......................... 303-1 4-21

REMOVAL AND INSTALLATION

Powertrain Control Module (PCM) . 1.25L Duratec-1 6V (Sigma)/l.4L

Duratec-16V (Sigma)/l.GL Duratec-1 6V (Sigma) ......................................... (29 200 0) 303-14-22

Powertrain Control Module (PCM)

- 2.OL Duratec-HE (M14), Vehicles With: PCM Security

Shield

........................................................................\

................................................... 303-14-24

Powertrain Control Module (PCM)

- 2.OL Duratec-HE (M14), Vehicles Without: PCM

Security Shield

........................................................................\

.......................................... 303-1 4-27

Heated Oxygen Sensor

(H02S) .................................................................. (29 220 0) 303-14-30

Crankshaft Position (CKP) Sensor

........................................................................\

........... 303-1 4-32

Knock Sensor (KS)

........................................................................\

................................ 303-1 4-35

procarmanuals.com

Page 926 of 1226

303-1 4-2 Electronic Engine Controls 303-1 4-2

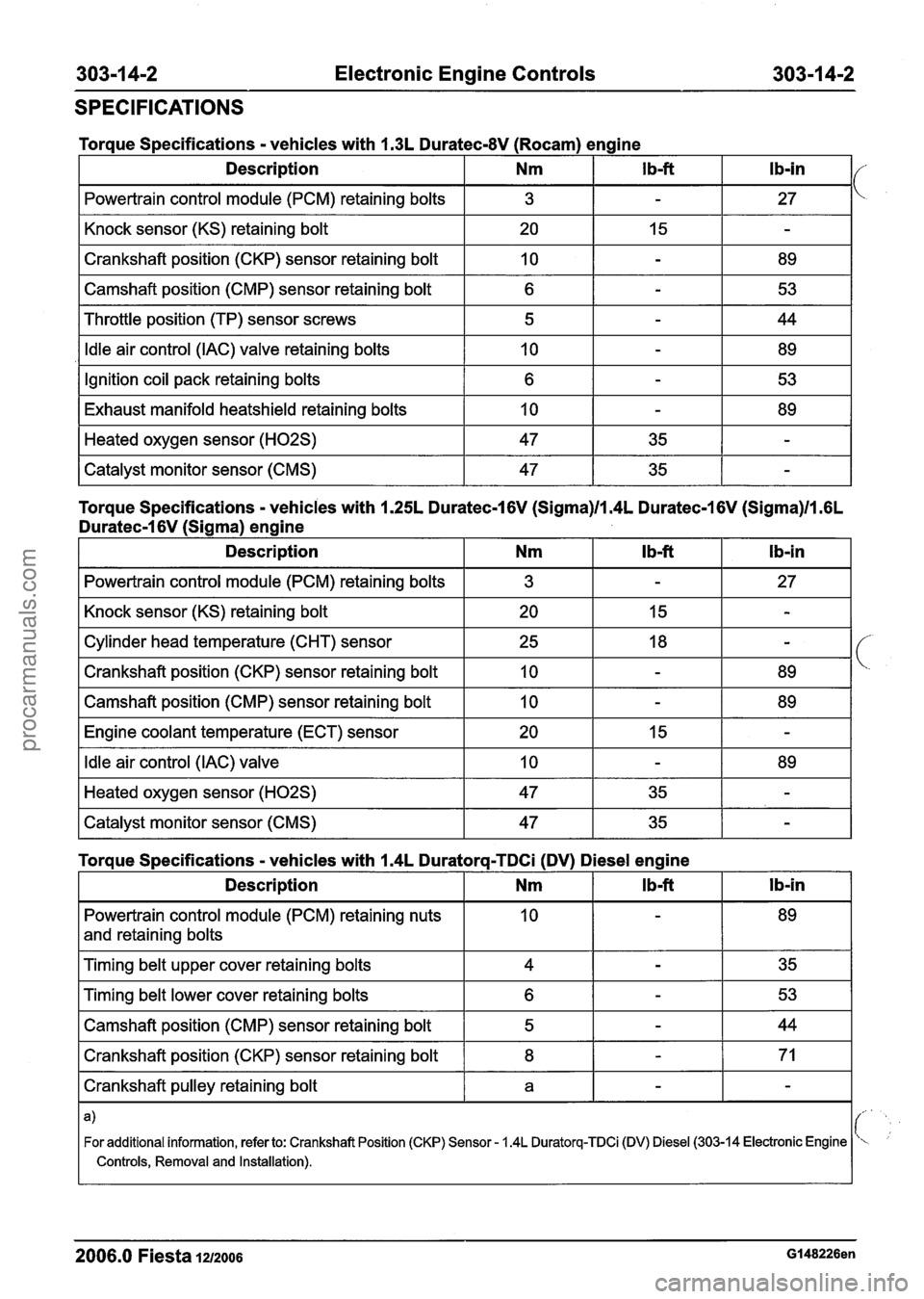

SPECIFICATIONS

I Powertrain control module (PCM) retaining bolts I 3 I - I 27 I

Torque Specifications - vehicles with 1.3L Duratec-8V (Rocam) engine

I Knock sensor (KS) retaining bolt I 20 I 15 I - I

Description

I Crankshaft position (CKP) sensor retaining bolt I 10 I - I 89 I

I Camshaft position (CMP) sensor retaining bolt I

I Throttle position (TP) sensor screws I 5 I - I 44 I

Ib-in I/ Nm

I Idle air control (IAC) valve retaining bolts I 10 I - I 89 I

I b-ft

Ignition coil pack retaining bolts

Exhaust manifold heatshield retaining

bolts

Torque Specifications - vehicles with 1.25L Duratec-1 6V (Sigma)ll.4L Duratec-1 6V (Sigma)ll .6L

Duratec-I 6V (Sigma) engine

Heated oxygen sensor (H02S)

Catalyst monitor sensor (CMS)

I Powertrain control module (PCM) retaining bolts I 3 I - I 27 I

6

10

I Knock sensor (KS) retaining bolt I 20 I 15 I - I

47

47

-

-

I Camshaft position (CMP) sensor retaining bolt I 10 I - I 89 I

53

89

35

35

Cylinder head temperature (CHT) sensor

Crankshaft position (CKP) sensor retaining bolt

I Engine coolant temperature (ECT) sensor I 20 I 15 I - I

-

-

I Idle air control (IAC) valve I 10 I - I 89 I

25

10

I Heated oxygen sensor (H02S) I 47 I 35 I - I -- --

I Catalyst monitor sensor (CMS) 47 I 35 1 - I

18

-

-

89

Powertrain control module (PCM) retaining nuts

and retaining bolts

Torque Specifications - vehicles with 1.4L Duratorq-TDCi (DV) Diesel engine

1 Timing belt upper cover retaining bolts I 4 I - I 35 I

I Timing belt lower cover retaining bolts I 6 I - I 53 I

l b-in

Description

I Camshaft position (CMP) sensor retaining bolt I 5 I - I 44 I

I Crankshaft position (CKP) sensor retaining bolt I 8 I - I 71 I

Nm

I Crankshaft pulley retaining bolt I a I - I - I

I b-ft

I- .

For additional information, refer to: Crankshaft Position (CKP) Sensor - 1.4L Duratorq-Ci D) Diesel (303-14 Electronic Engine ''

I Controls, Removal and Installation).

2006.0 Fiesta 1212006 Gl48226en

procarmanuals.com

Page 927 of 1226

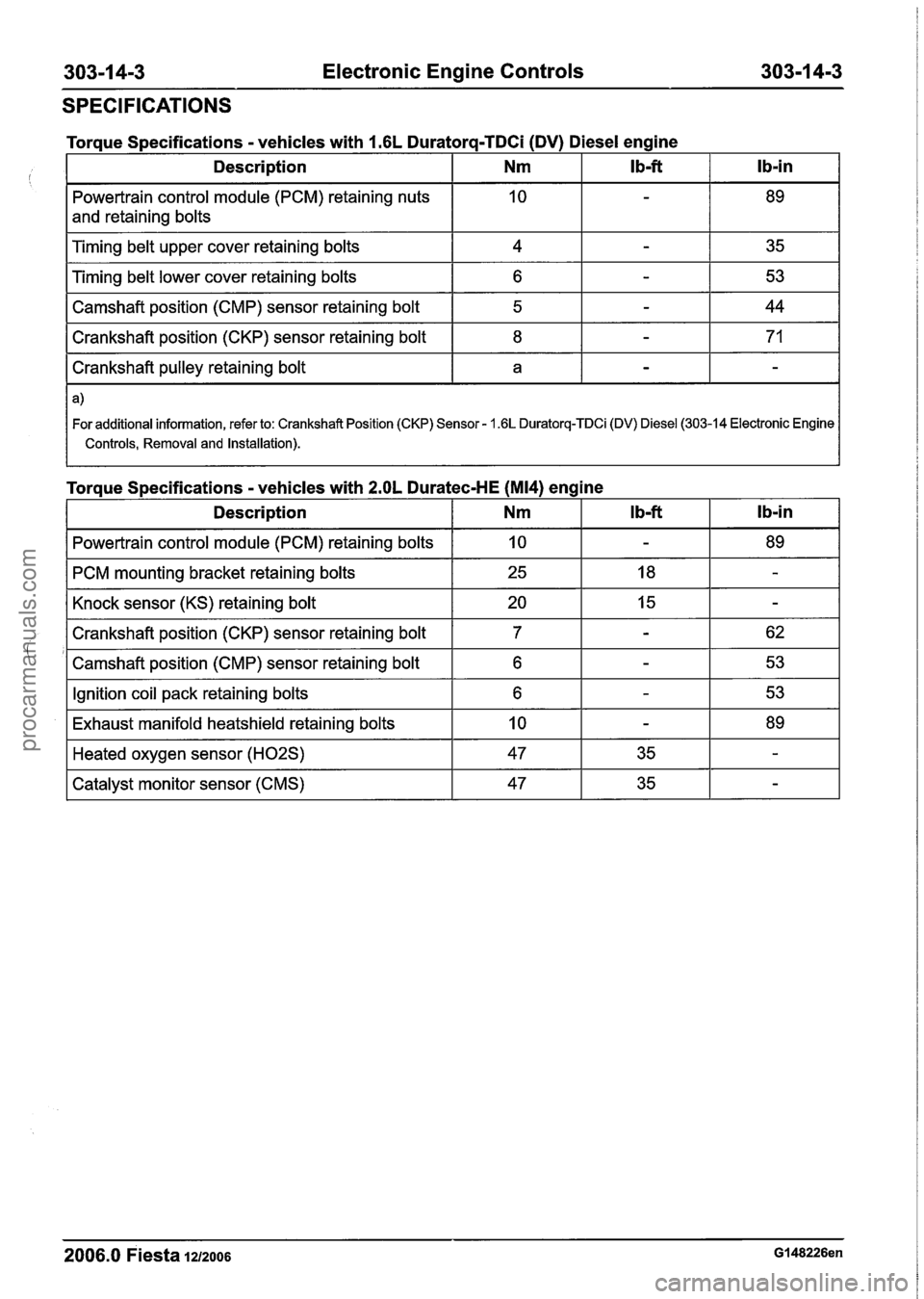

303-1 4-3 Electronic Engine Controls 303-1 4-3

SPECIFICATIONS

control module (PCM) retaining nuts

and retaining bolts

Torque

Specifications

- vehicles with 1.6L Duratorq-TDCi (DV) Diesel engine

I Camshaft position (cMP) sensor retaining bolt I 5 I - I 44 I

lb-in

Timing belt upper cover retaining bolts

Timing belt lower cover retaining bolts

I Crankshaft position (CKP) sensor retaining bolt I 8 I - I 71 I

Ib-ft Description

I Crankshaft pulley retaining bolt I a I - I - I

Nm

4

6

I For additional information, refer to: Crankshaft Position (CKP) Sensor - 1.6L Duratorq-TDCi (DV) Diesel (303-14 Electronic Engine I

I Controls, Removal and Installation). I

-

-

Torque Specifications - vehicles with 2.OL Duratec-HE (M14) eng 35

53

I Description I Nm

ine

I Powertrain control module

(PCM) retaining bolts I 10 I - I 89 I

I PCM mounting bracket retaining bolts I 25 I 18 I - I

I Knock sensor (KS) retaining bolt I 20 I 15 I - I

I Crankshaft position (CKP) sensor retaining bolt I 7

'1 Camshaft position (CMP) sensor retaining bolt I 6

I Ignition coil pack retaining bolts I 6 I - I 53 I

I Exhaust manifold heatshield retaining bolts I 10 I - I 89 I

2006.0 Fiesta 1212006 GI 48226en

-- -

Heated oxygen sensor (H02S)

Catalyst monitor sensor (CMS) 47

47

35

35

-

-

procarmanuals.com

Page 928 of 1226

303-1 4-4 Electronic Engine Controls 303-1 4-4

DESCRIPTION AND OPERATION

Electronic Engine Controls - 1.25L Duratec-1 6V (Sigma)/lAL

Duratec-I 6V (Sigma)/l.GL Duratec-1 6V (Sigma)

Overview

2006.0 Fiesta 1212006 G204204en

procarmanuals.com

Page 929 of 1226

303-1 4-5 Electronic Engine Controls 303-1 4-5

DESCRIPTION AND OPERATION

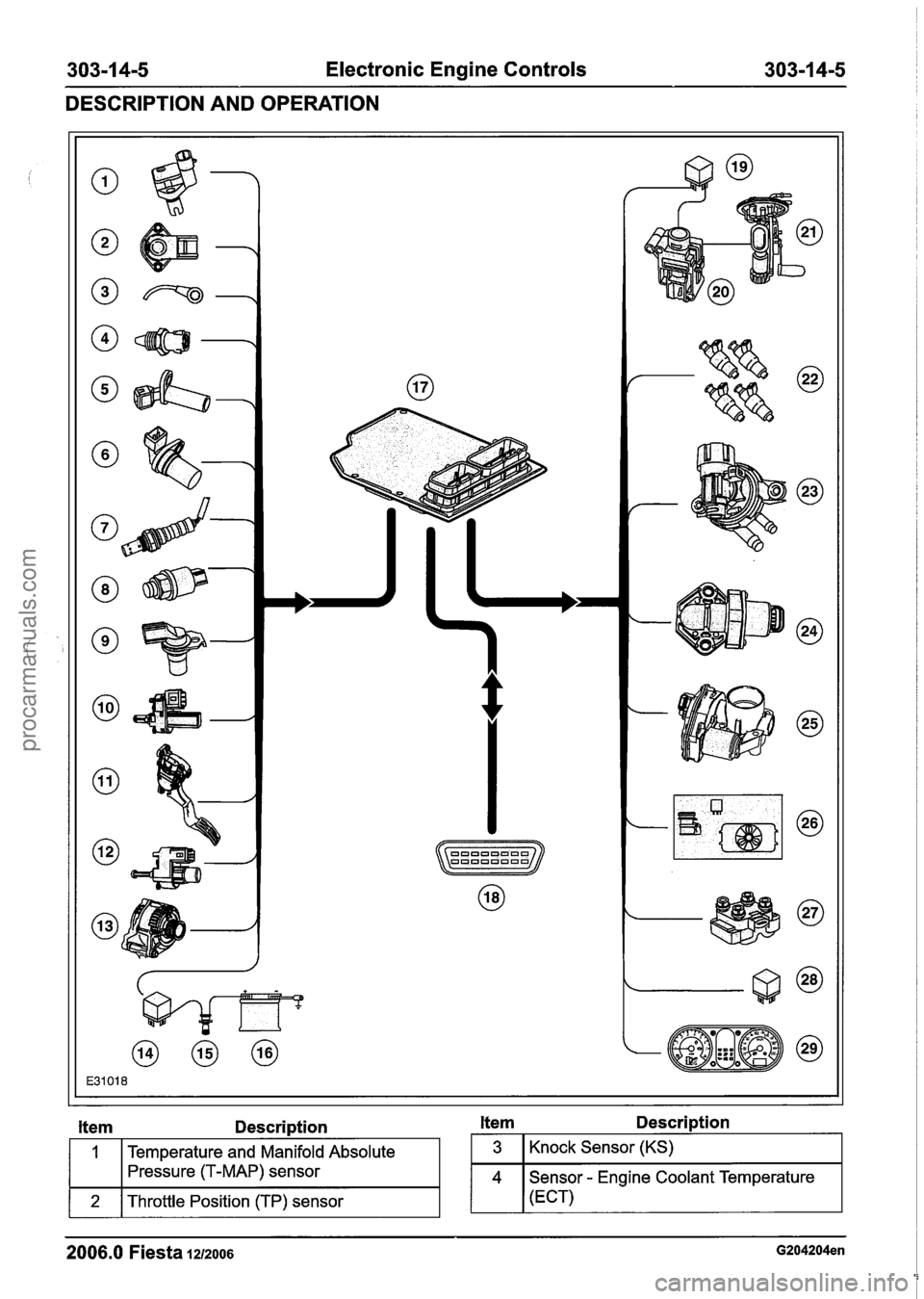

Item Description Item Description

2006.0 Fiesta 1212006 G204204en

I 1 I Temperature and Manifold Absolute

2 3 1 Knock Sensor (KS)

pressure (T-MAP) sensor

Throttle Position (TP) sensor

4 Sensor - Engine Coolant Temperature

(ECT)

procarmanuals.com

Page 930 of 1226

303-1 4-6 Electronic Engine Controls 303-1 4-6

DESCRIPTION

AND OPERATION

Item Descri~tion

1 5 1 Crankshaft Position (CKP) sensor 1

Throttle Control Unit (TCU)

1 6 ( Camshaft Position (CMP) sensor I Components

1 7 1 Heated Oxygen Sensor (H02S) I

1 8 1 Power Steering Pressure (PSP) sensor I

1 10 1 Brake Pedal Position (BPP) switch I

9 Vehicle Speed Sensor (VSS)

(only on

vehicles without Anti-lock Braking System

(ABS))

1 12 1 Clutch Pedal Position (CPP) switch I

11

1 13 1 Generator I

Accelerator Pedal Position (APP) sensor

1 14 1 Current supply relay I

1 15 1 Ignition key I -

16

17

1 20 1 Inertia fuel shut-off switch I

Battery

Powertrain Control Module (PCM)

-

18

19

1 21 1 Fuel Pump Driver Module (FPDM) I

Data Link Connector (DLC)

Fuel Pump (FP) relay

1 22 1 Fuel injectors I

23 Evaporative emissions (EVAP) solenoid

1 lvalve

1 24 1 Idle Air Control (IAC) valve 1

1 25 1 Throttle Control Unit (TCU) I

26 Air Conditioning (AIC) compressor clutch

1 I 1 blower switch

1 27 1 Injector Driver

Module (IDM) I

1 28 1 Start inhibit relay I

1 29 1 Instrument cluster I

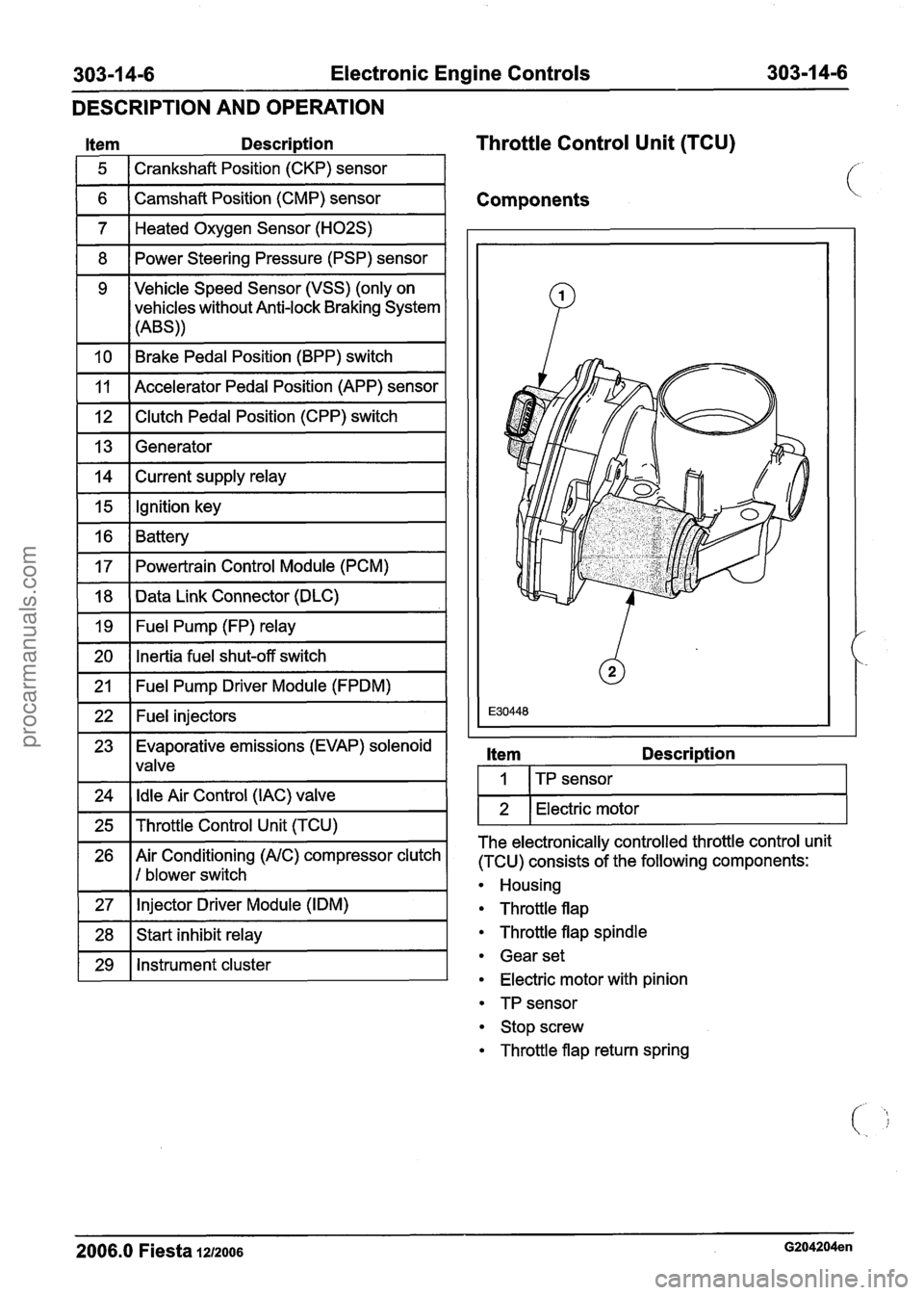

Item Descri~tion

I I ITP sensor I

1 2 1 Electric motor I

The electronically controlled throttle control unit

(TCU) consists of the following components:

Housing

Throttle flap

Throttle flap spindle

Gear set

Electric motor with pinion

TP sensor

Stop screw

Throttle flap return spring

2006.0 Fiesta 1212006 G204204en

procarmanuals.com

Page 931 of 1226

303-1 4-7 Electronic Engine Controls 303-1 4-7

DESCRIPTION AND OPERATION

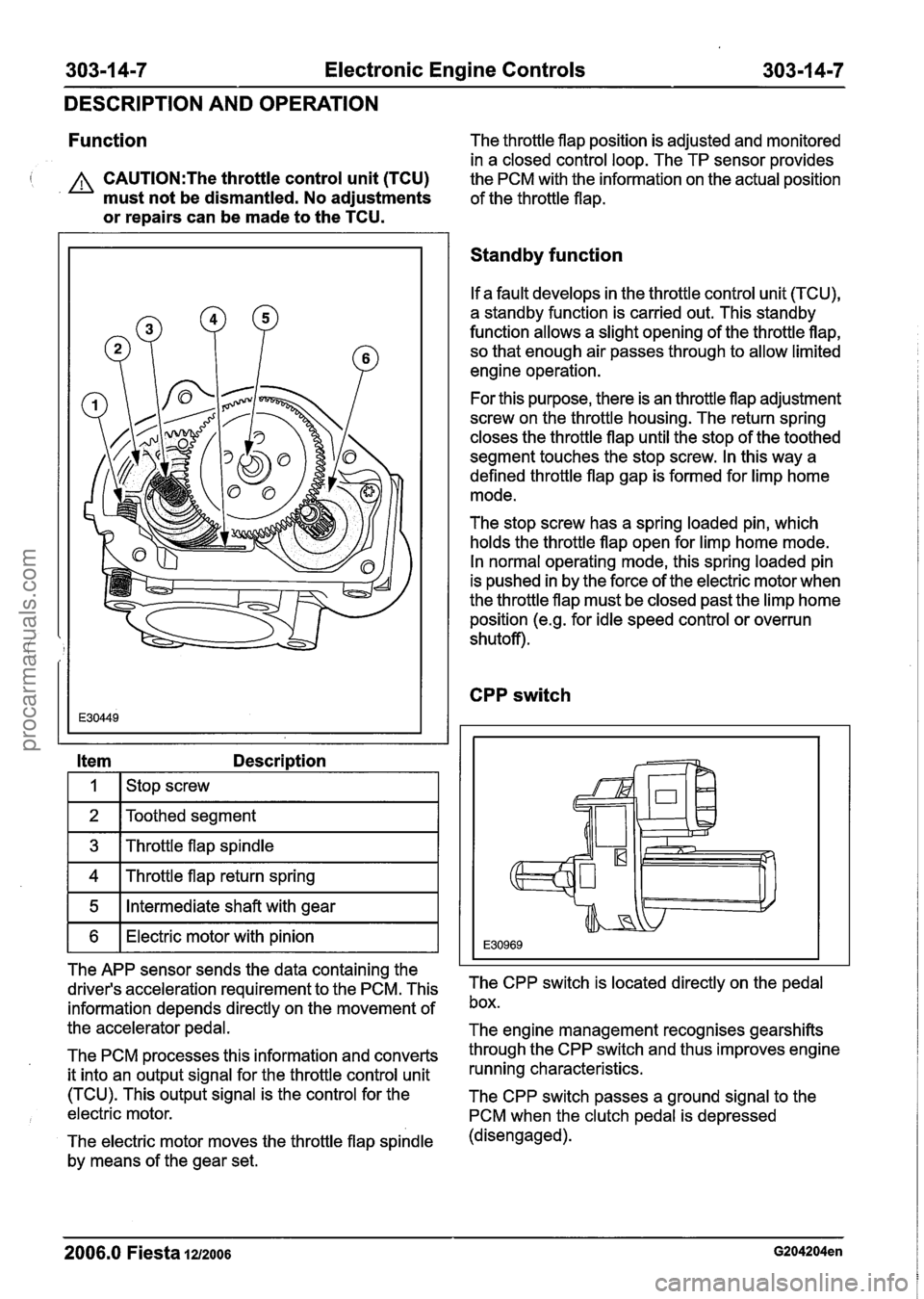

Function The throttle flap position is adjusted and monitored

in a closed control loop. The TP sensor provides

I A CAUTI0N:The throttle control unit (TCU)

the PCM with the information on the actual position

must not be dismantled. No adjustments

of the throttle flap.

or repairs can be made to the TCU.

Item Description

I I I stop screw I

1 2 IToothed segment I

1 3 1 Throttle flap spindle I

1 4 1 Throttle flap return spring I

1 5 1 Intermediate shaft with gear I

1 6 1 Electric motor with pinion I

The APP sensor sends the data containing the

driver's acceleration requirement to the PCM. This

information depends directly on the movement of

the accelerator pedal.

The PCM processes this information and converts

it into an output signal for the throttle control unit

(TCU). This output signal is the control for the

electric motor.

The electric motor moves the throttle flap spindle

by means of the gear set.

Standby function

If a fault develops in the throttle control unit (TCU),

a standby function is carried out. This standby

function allows a slight opening of the throttle flap, so that enough air passes through to allow limited

engine operation.

For this purpose, there is an throttle flap adjustment

screw on the throttle housing. The return spring

closes the throttle flap until the stop of the toothed

segment touches the stop screw. In this way a

defined throttle flap gap is formed for limp home

mode.

The stop screw has a spring loaded pin, which

holds the throttle flap open for limp home mode.

In normal operating mode, this spring loaded pin

is pushed in by the force of the electric motor when

the throttle flap must be closed past the limp home

position

(e.g. for idle speed control or overrun

shutoff).

CPP switch

The CPP switch is located directly on the pedal

box.

The engine management recognises gearshifts

through the CPP switch and thus improves engine

running characteristics.

The CPP switch passes a ground signal to the

PCM when the clutch pedal is depressed

(disengaged).

2006.0 Fiesta 1212006 G204204en

procarmanuals.com

Page 932 of 1226

Electronic Engine Controls

DESCRIPTION AND OPERATION

(Brake Pedal Position) BPP switch

APP sensor

There are two brake pedal switches at the pedal

box: the brake lamp switch and the BPP switch.

The brake lamp switch only serves to switch on

the brake lamps. The BPP switch is used for engine

management purposes.

The BPP switch provides the PCM with the

information that the vehicle will be decelerated.

The BPP switch is closed in the rest state (brake

pedal not depressed) and sends a ground signal

to the PCM.

If when the APP sensor has failed, the BPP is

operated, the engine will be controlled to run at

idle speed by the PCM.

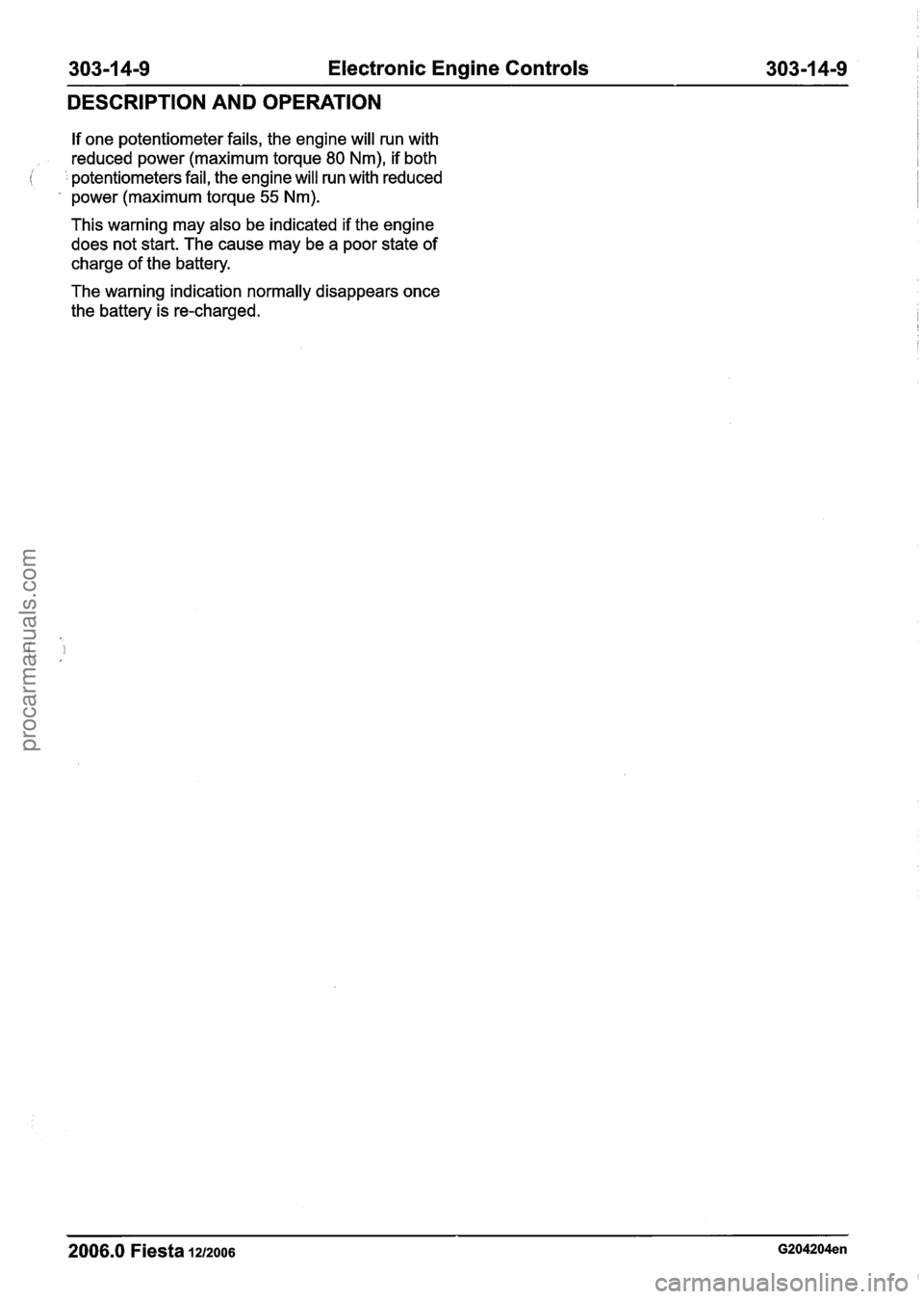

In order that the engine power output can be

matched to that required by the driver, the PCM

needs to know the position of the APP sensor.

The APP sensor is a variable resistor whose

resistance varies with the accelerator position. It

is a sliding contact potentiometer

(2 potentiometers

in total).

If a fault occurs in the APP sensor or the throttle

control unit (TCU) during vehicle operation, then

this will be

briefly indicated by a digital display in

the instrument cluster after the ignition is switched

on, and a trouble code will be stored in the PCM.

2006.0 Fiesta 1212006 G204204en

procarmanuals.com

Page 933 of 1226

303-1 4-9 Electronic Engine Controls 303-1 4-9

DESCRIPTION AND OPERATION

If one potentiometer fails, the engine will run with

reduced power (maximum torque

80 Nm), if both

potentiometers fail, the engine will run with reduced

power (maximum torque

55 Nm).

This warning may also be indicated if the engine

does not start. The cause may be a poor state of

charge of the battery.

The warning indication normally disappears once

the battery is re-charged.

2006.0 Fiesta 1212006 G204204en

procarmanuals.com