brake fluid FORD FIESTA 2007 Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 336 of 1226

21 1-00-1 6 Steering System - General Information 21 I -00-1 6

DIAGNOSIS AND TESTING

8m ACAUTION:T~ prevent damage to the

steering linkage, turn the steering wheel to

move the steering linkage to the steering

lock stop.

Turn the steering wheel to position the steering

linkage against the left-hand steering lock stop.

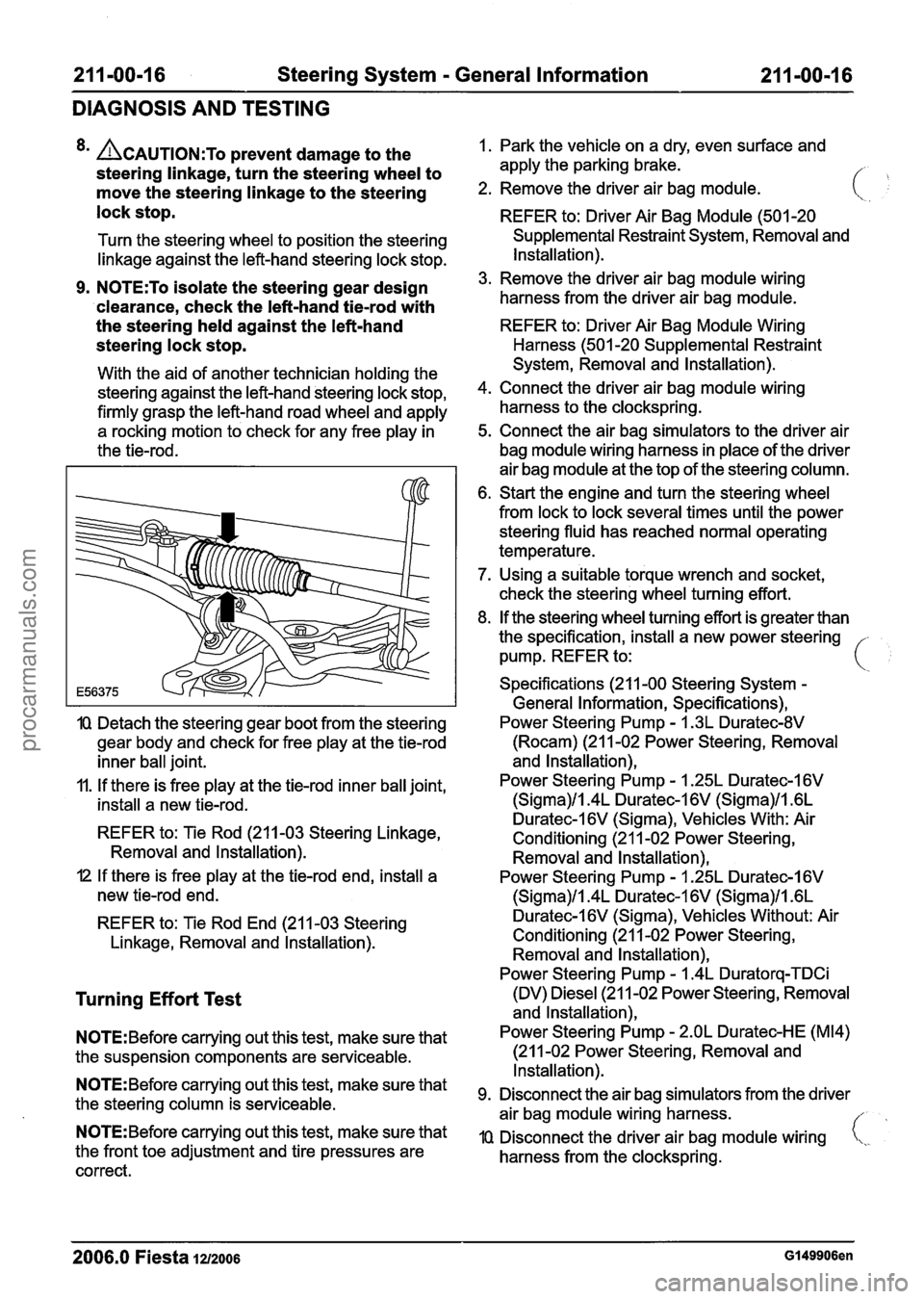

9. N0TE:To isolate the steering gear design

'clearance, check the left-hand

tiemrod with

the steering held against the left-hand

steering lock stop.

With the aid of another technician holding the

steering against the left-hand steering lock stop,

firmly grasp the left-hand road wheel and apply

a rocking motion to check for any free play in

the tie-rod.

IQ Detach the steering gear boot from the steering

gear body and check for free play at the tie-rod

inner ball joint.

11. If there is free play at the tie-rod inner ball joint,

install a new tie-rod.

REFER to: Tie Rod (211-03 Steering Linkage,

Removal and lnstallation).

I2 If there is free play at the tie-rod end, install a

new tie-rod end.

REFER to: Tie Rod End (21 1-03 Steering

Linkage, Removal and lnstallation).

Turning Effort Test

N0TE:Before carrying out this test, make sure that

the suspension components are serviceable.

N0TE:Before carrying out this test, make sure that

the steering column is serviceable.

N0TE:Before carrying out this test, make sure that

the front toe adjustment and tire pressures are

correct. 1.

Park the vehicle on a dry, even surface and

apply the parking brake.

/- ,

2. Remove the driver air bag module.

REFER to: Driver Air Bag Module (501 -20

Supplemental Restraint System, Removal and

Installation).

3. Remove the driver air bag module wiring

harness from the driver air bag module.

REFER to: Driver Air Bag Module Wiring

Harness (501 -20 Supplemental Restraint

System, Removal and Installation).

4. Connect the driver air bag module wiring

harness to the clockspring.

5. Connect the air bag simulators to the driver air

bag module wiring harness in place of the driver

air bag module at the top of the steering column.

6. Start the engine and turn the steering wheel

from lock to lock several times until the power

steering fluid has reached normal operating

temperature.

7. Using a suitable torque wrench and socket,

check the steering wheel turning effort.

8. If the steering wheel turning effort is greater than

the specification, install a new power steering -

pump. REFER to: i

Specifications (21 1-00 Steering System -

General Information, Specifications),

Power Steering Pump

- I .3L Duratec-8V

(Rocam) (21 1-02 Power Steering, Removal

and lnstallation),

Power Steering Pump

- 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V (Sigma)/l .6L

Duratec-l6V (Sigma), Vehicles With: Air

Conditioning (21 1-02 Power Steering,

Removal and lnstallation),

Power Steering Pump

- I .25L Duratec-I 6V

(Sigma)/l.4L Duratec-1 6V (Sigma)/l .6L

Duratec-I 6V (Sigma), Vehicles Without: Air

Conditioning (21 1-02 Power Steering, Removal and lnstallation),

Power Steering Pump

- 1.4L Duratorq-TDCi

(DV) Diesel (21 1-02 Power Steering, Removal

and lnstallation),

Power Steering Pump

- 2.OL Duratec-HE (M14)

(21 1-02 Power Steering, Removal and

Installation).

Disconnect the air bag simulators from the driver

air bag module wiring harness.

//

IQ Disconnect the driver air bag module wiring i,,.

harness from the clockspring.

2006.0 Fiesta 1212006 GI 49906en

procarmanuals.com

Page 502 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-26 Duratec-1 6V (Sigma)Il.GL Duratec-1 6V (Sigma) 303-01 A-26

IN-VEHICLE REPAIR

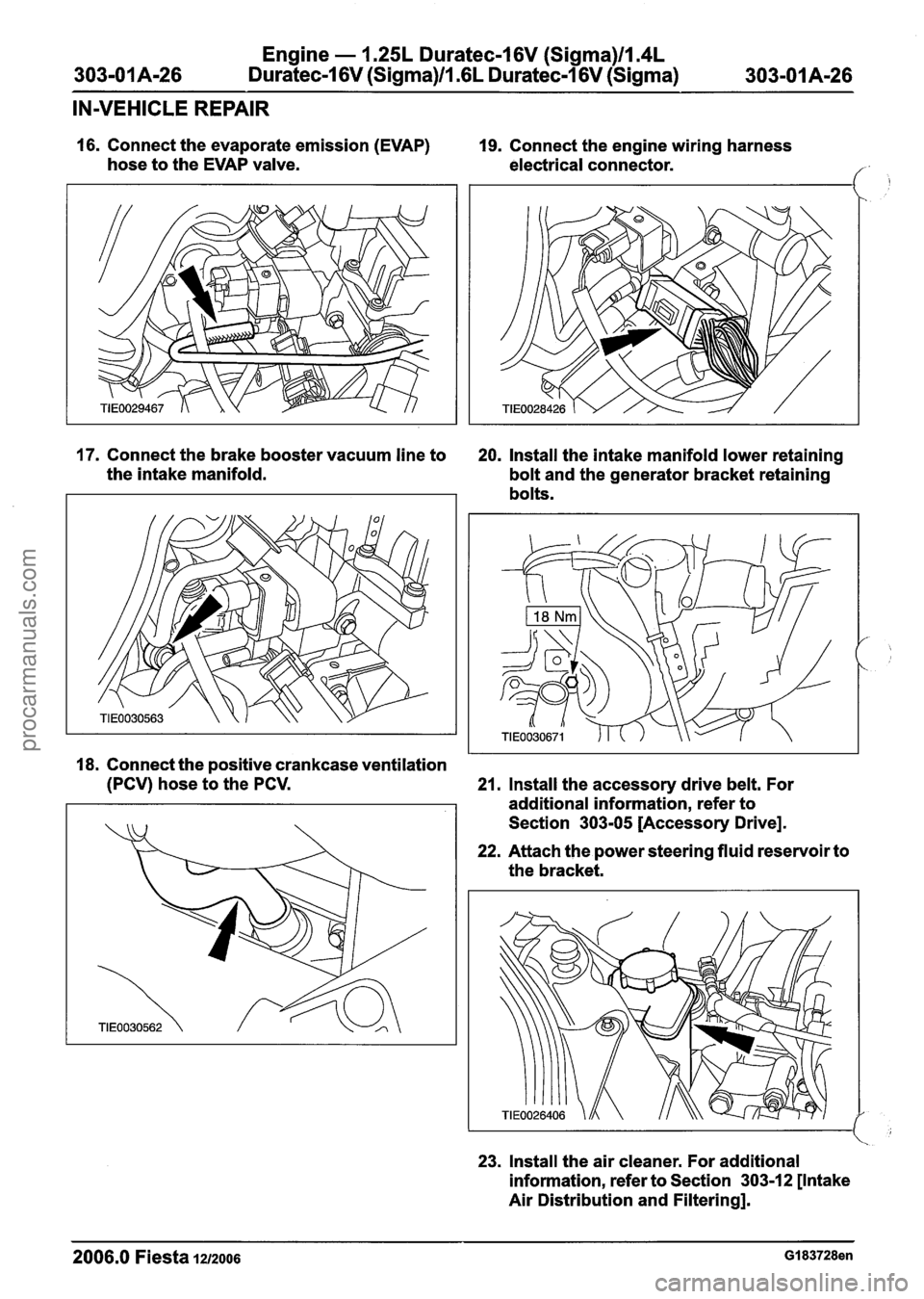

16. Connect the evaporate emission (EVAP)

hose to the EVAP valve.

17. Connect the brake booster vacuum line to

the intake manifold.

19. Connect the engine wiring harness

electrical connector.

20. Install the intake manifold lower retaining

bolt and the generator bracket retaining

bolts.

18. Connect the positive crankcase ventilation

(PCV) hose to the PCV.

21. Install the accessory drive belt. For

additional information, refer to

Section

303-05 [Accessory Drive].

22. Attach the power steering fluid reservoir to

the bracket.

23. Install the air cleaner. For additional

information, refer to Section

3031 2 [Intake

Air Distribution and Filtering].

2006.0 Fiesta 1212006 GI 83728en

procarmanuals.com

Page 555 of 1226

Engine - 1.25L Duratec-I 6V (Sigma)llm4L

303-01A-79 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-01 A-79

REMOVAL

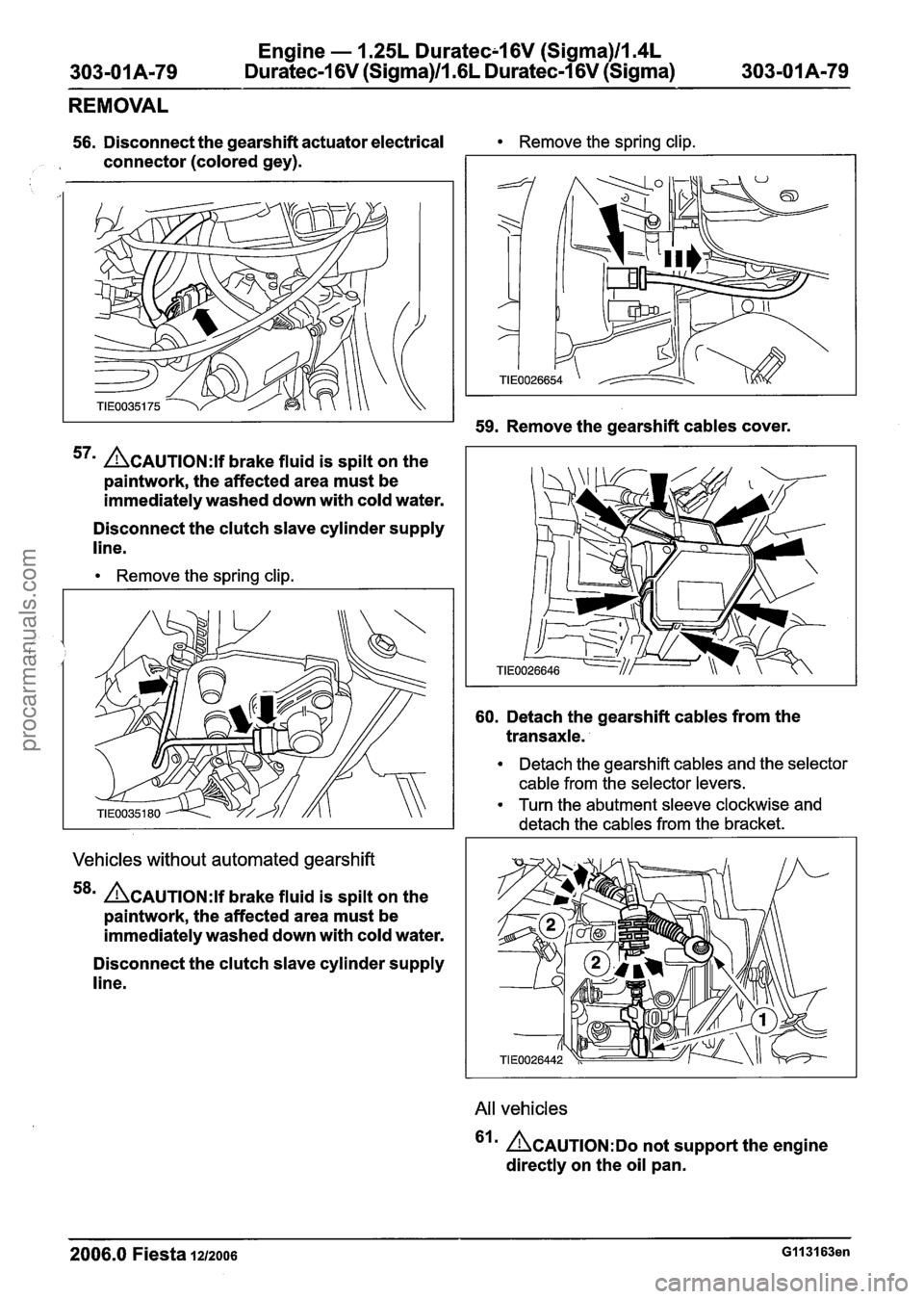

56. Disconnect the gearshift actuator electrical Remove the spring clip.

, connector (colored gey).

59. Remove the gearshift cables cover.

57m ACAUTION:I brake fluid is spilt on the

paintwork, the affected area must be

immediately washed down with cold water.

Disconnect the clutch slave cylinder supply

line.

Remove the spring clip.

Vehicles without automated gearshift

58' ACAUTION:~ brake fluid is spilt on the

paintwork, the affected area must be

immediately washed down with cold water.

Disconnect the clutch slave cylinder supply

line.

60. Detach the gearshift cables from the

transaxle.

Detach the gearshift cables and the selector

cable from the selector levers.

Turn the abutment sleeve clockwise and

detach the cables from the bracket.

All vehicles

'Irn ~CAUTION:DO not support the engine

directly on the oil pan.

2006.0 Fiesta 12/2oo6 G113163en

procarmanuals.com

Page 603 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-I 27 Duratec-1 6V (Sigma)ll .6L Duratec-1 6V (Sigma)

303-01 A-I 27

INSTALLATION

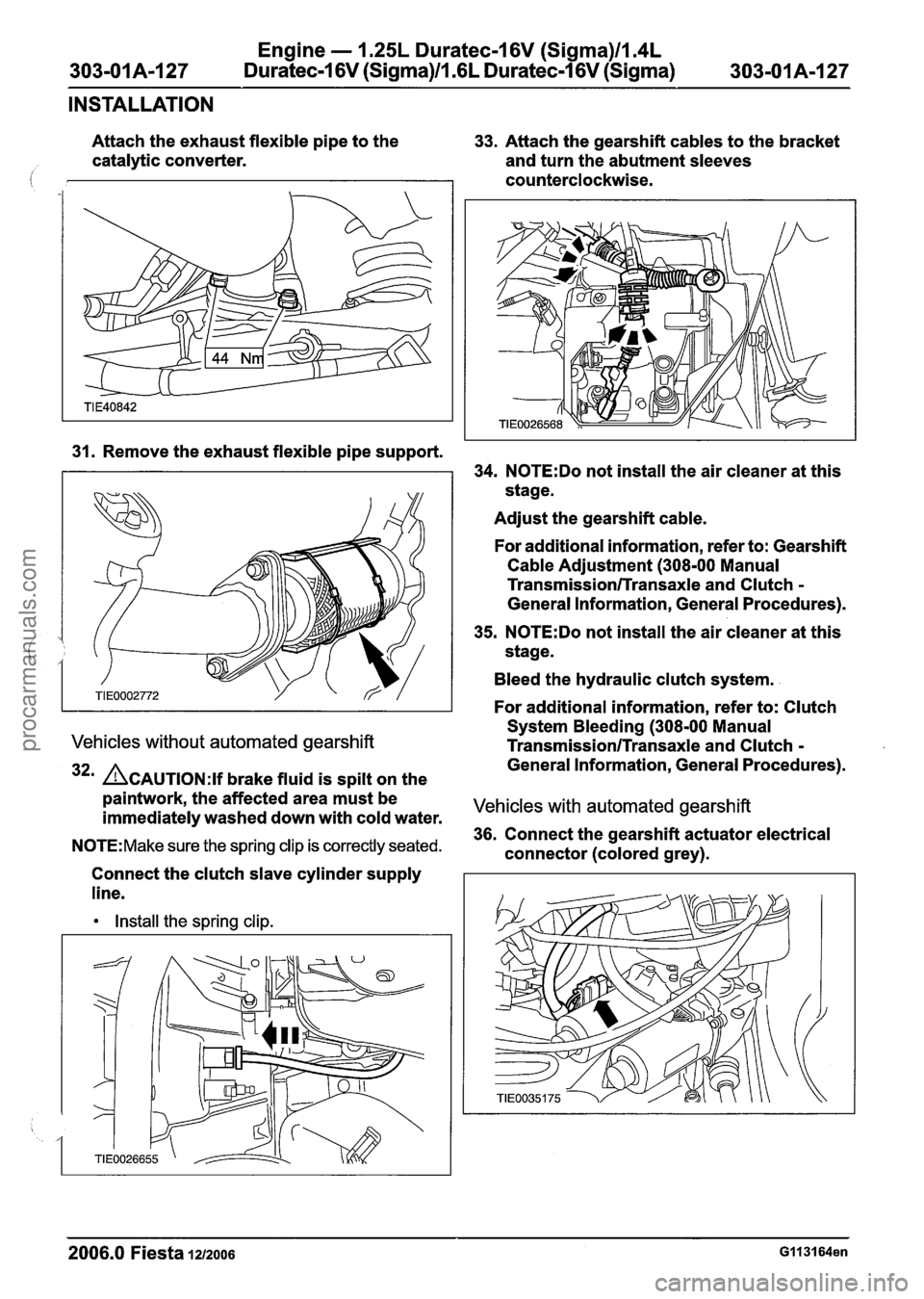

Attach the exhaust flexible pipe to the

33. Attach the gearshift cables to the bracket

catalytic converter.

and turn the abutment sleeves

counterclockwise.

31. Remove the exhaust flexible pipe support.

Vehicles without automated gearshift

32m ACAUTION:H brake fluid is spilt on the

paintwork, the affected area must be

immediately washed down with cold water.

N0TE:Make sure the spring clip is correctly seated.

Connect the clutch slave cylinder supply

line.

Install the spring clip.

34. N0TE:Do not install the air cleaner at this

stage.

Adjust the gearshift cable.

For additional information, refer to: Gearshift Cable Adjustment (308-00 Manual

Transmission/Transaxle and Clutch

General Information, General Procedures).

35.

N0TE:Do not install the air cleaner at this

stage.

Bleed the hydraulic clutch system.

For additional information, refer to: Clutch

System Bleeding (308-00 Manual

Transmission/Transaxle and Clutch -

General Information, General Procedures).

Vehicles with automated gearshift

36. Connect the gearshift actuator electrical

connector (colored grey).

2006.0 Fiesta 1212006

procarmanuals.com

Page 620 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-I 44 Duratec-I 6V (Sigma)ll .6L Duratec-1 6V (Sigma) 303-01 A-1 44

INSTALLATION

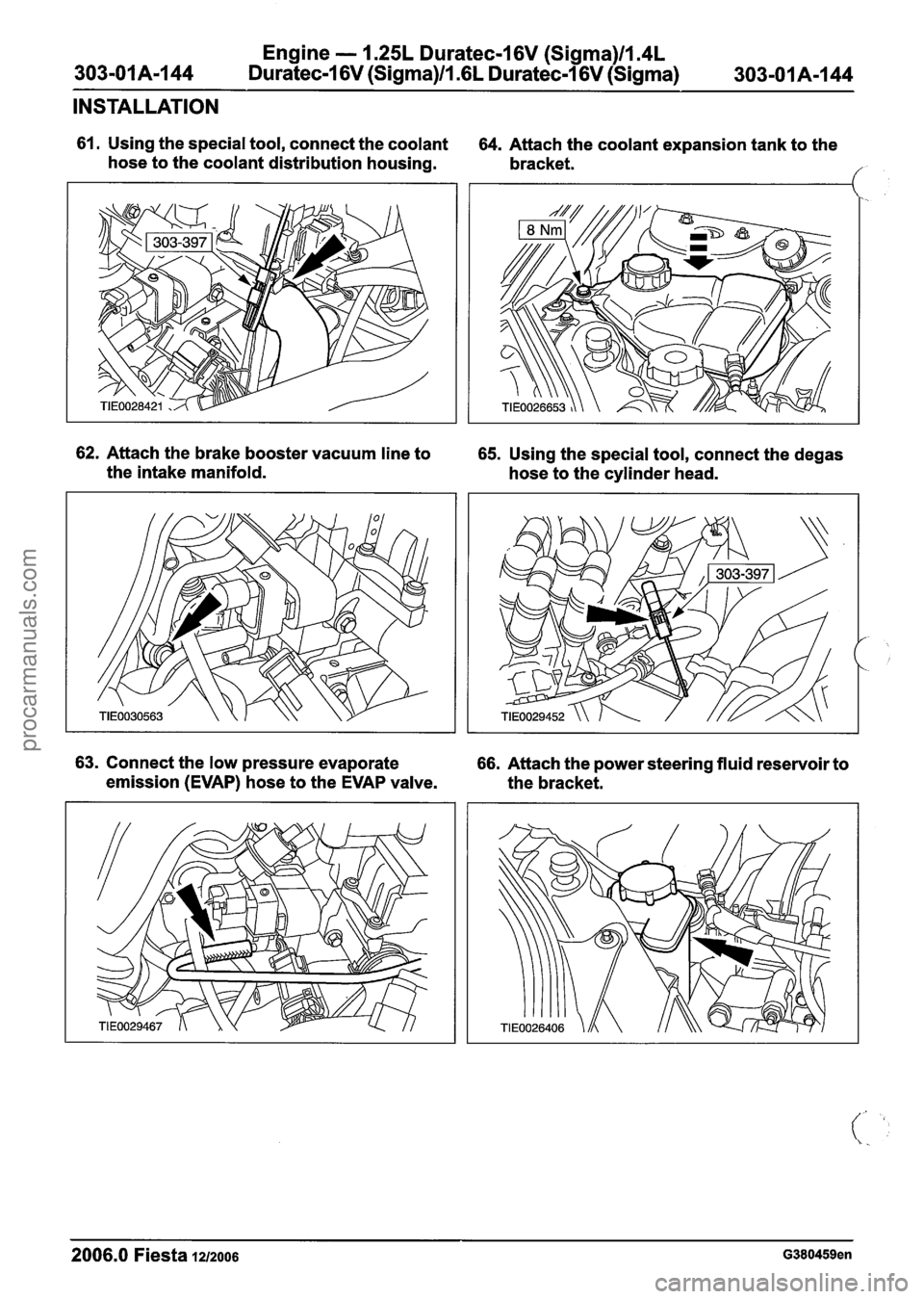

61. Using the special tool, connect the coolant

hose to the coolant distribution housing. 64. Attach the coolant expansion tank to the

bracket.

/

62. Attach the brake booster vacuum line to 65. Using the special tool, connect the degas

the intake manifold.

hose to the cylinder head.

63. Connect the low pressure evaporate 66. Attach the power steering fluid reservoir to

emission (EVAP) hose to the EVAP valve.

the bracket.

2006.0 Fiesta 12/2006 G380459en

procarmanuals.com

Page 699 of 1226

303-01 B-77 Engine - 2.OL Duratec-HE (M14) 303-01 B-77

REMOVAL

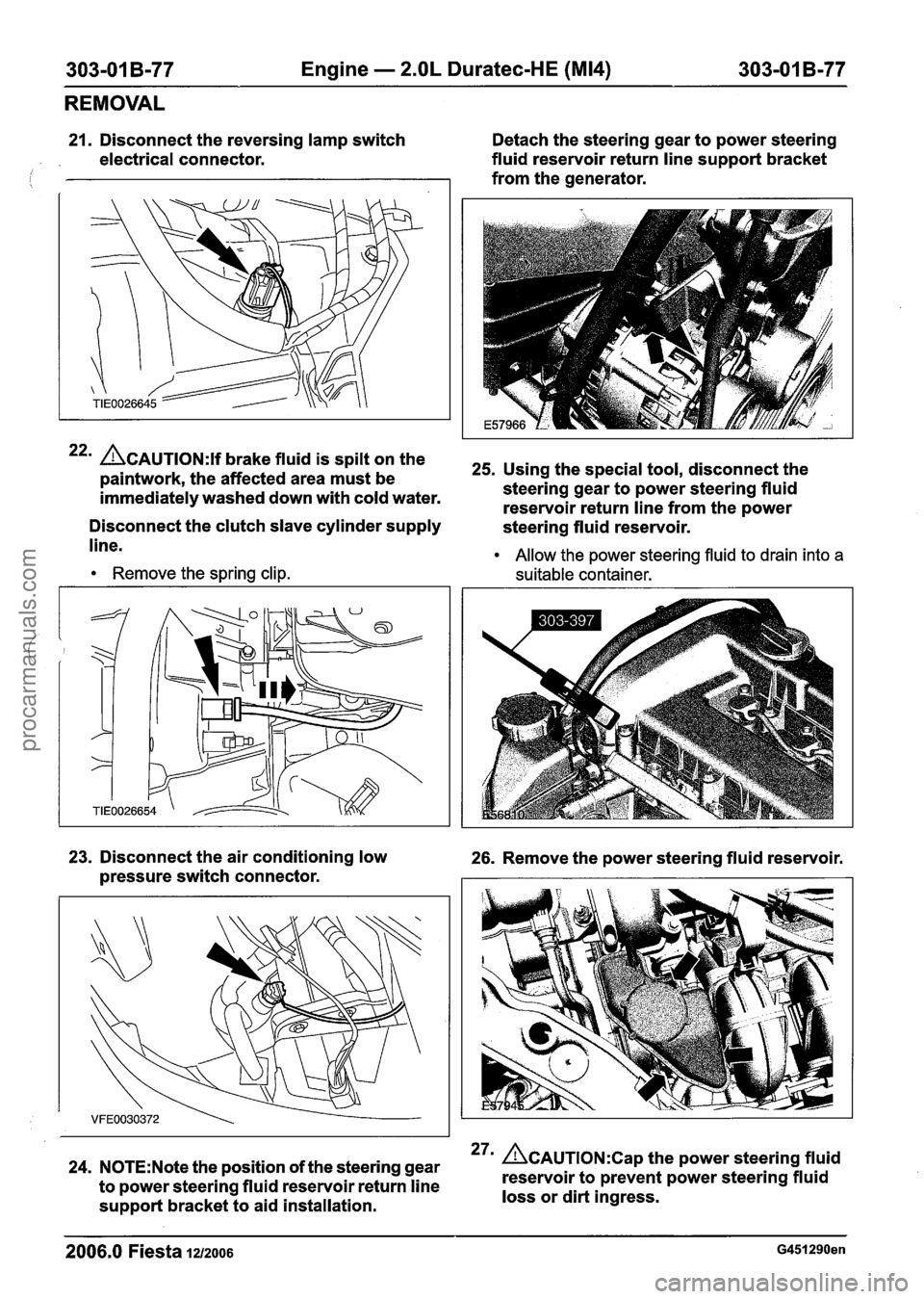

21. Disconnect the reversing lamp switch Detach the steering gear to power steering

electrical connector. fluid

reservoir return line support bracket

from the generator.

22m CAUTION:^^ brake fluid is spilt on the 25s Using the special tool, disconnect the paintwork, the affected area must be

immediately washed down with cold water. steering

gear to power steering fluid

reservoir return line from the power

Disconnect the clutch slave cylinder supply

steering fluid reservoir.

line.

Remove the spring clip. Allow

the power steering fluid to drain into a

suitable container.

23. Disconnect the air conditioning low 26. Remove the power steering fluid reservoir.

pressure switch connector.

24. N0TE:Note the position of the steering gear 27m &AUTION:C~~ the power steering fluid

to power steering fluid reservoir return line reservoir

to prevent power steering fluid

support bracket to aid installation. loss

or dirt ingress.

2006.0 Fiesta 12/2006 G451290en

procarmanuals.com

Page 739 of 1226

303-01 B-I17 Engine - 2.OL Duratec-HE (M14) 303-01 B-117

INSTALLATION

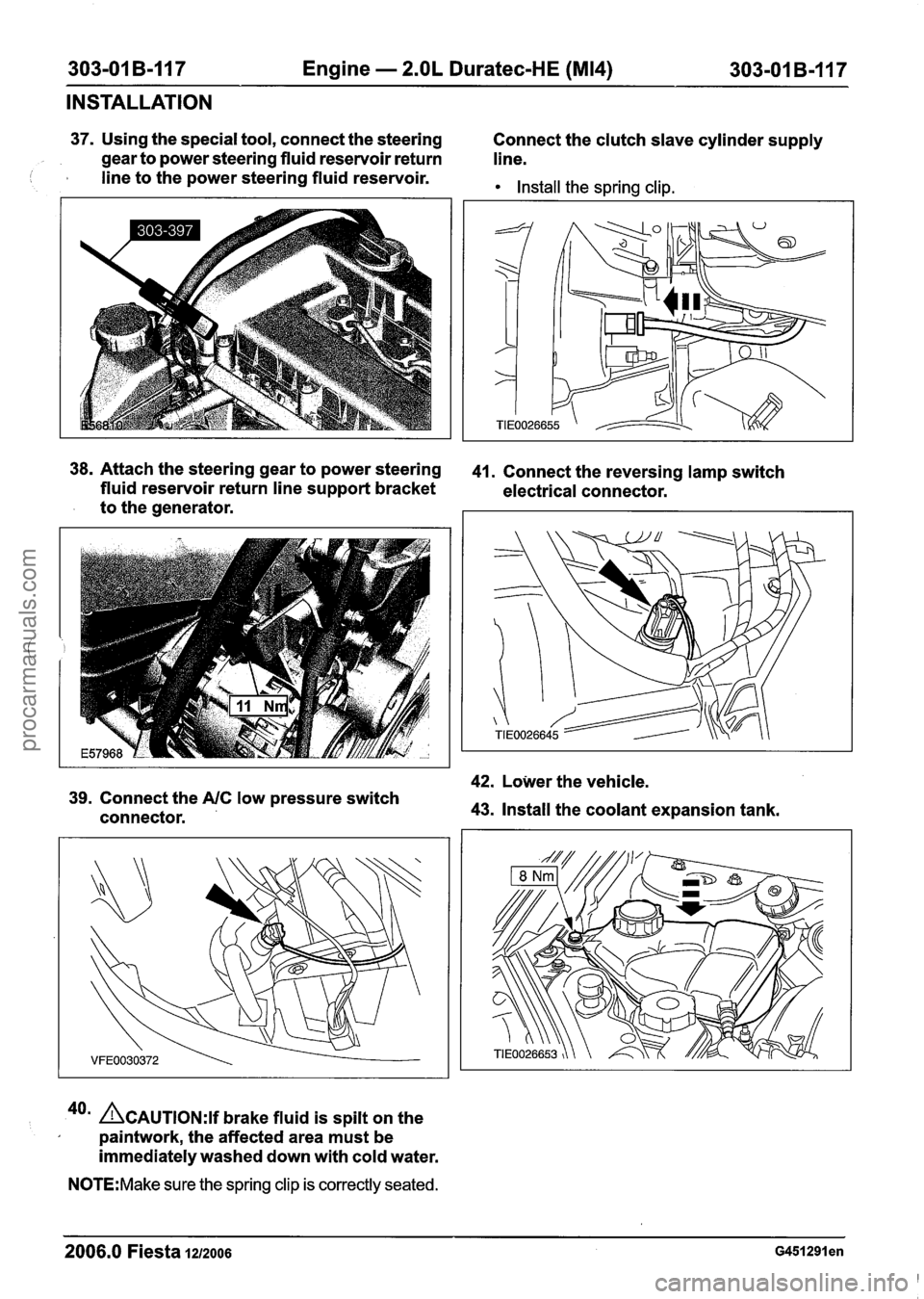

37. Using the special tool, connect the steering

Connect the clutch slave cylinder supply

gear to power steering fluid reservoir return

line.

I I line to the power steering fluid reservoir. Install the spring clip.

38.

Attach the steering gear to power steering 41. Connect the reversing lamp switch

fluid reservoir return line support bracket

electrical connector.

to the generator.

42. Lower the vehicle.

39. Connect the A/C low pressure switch

connector. 43. Install the coolant expansion tank.

40a &AUTION:I~ brake fluid is spilt on the

paintwork, the affected area must be

immediately washed down with cold water.

N0TE:Make sure the spring clip is correctly seated.

2006.0 Fiesta 1212006 ~451291 en

procarmanuals.com

Page 961 of 1226

Automatic Transmission/Transaxle .

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40)

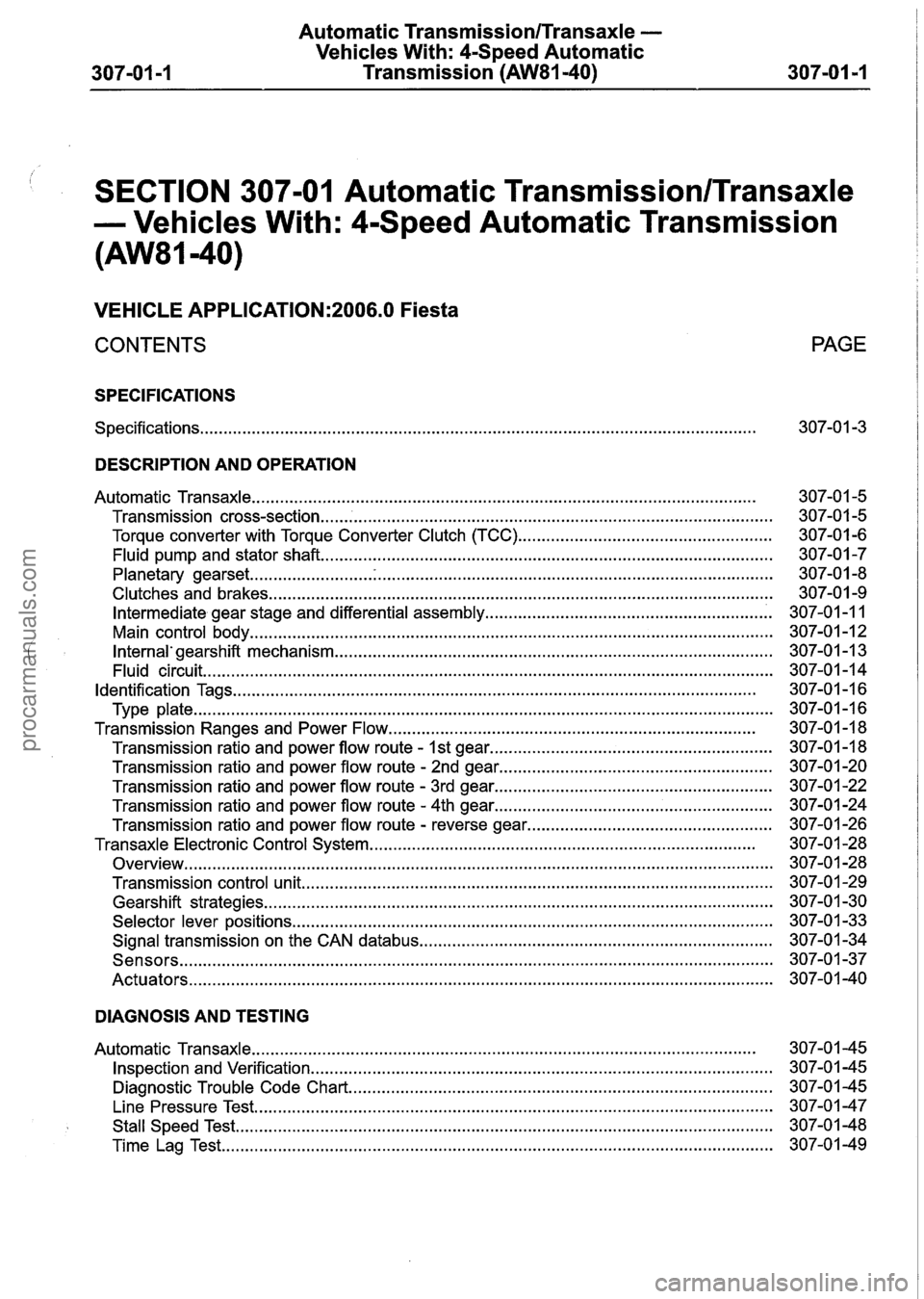

SECTION 307-01 Automatic Transmission/Transaxle

. Vehicles With: 4-Speed Automatic Transmission

(AW81-40)

VEHICLE APPLICATION:2006.0 Fiesta

CONTENTS PAGE

SPECIFICATIONS

Specifications

........................................................................\

.............................................. 307-0 1 -3

DESCRIPTION AND OPERATION

Automatic Transaxle

........................................................................\

...................................

Transmission cross-section ........................................................................\

........................

Torque converter with Torque Converter Clutch (TCC) ......................................................

Fluid pump and stator shaft ........................................................................\

........................

........................................................................\

......... Planetary gearset ......................... .:

Clutches and brakes ........................................................................\

...................................

Intermediate gear stage and differential assembly .............................................................

Main control body ........................................................................\

.......................................

Internal' gearshift mechanism ........................................................................\

.....................

Fluid circuit ........................................................................\

.................................................

........................................................................\

....................................... Identification Tags

Type plate

........................................................................\

...................................................

Transmission Ranges and Power Flow ........................................................................\

......

Transmission ratio and power flow route - 1st gear ............................................................

Transmission ratio and power flow route - 2nd gear ..........................................................

Transmission ratio and power flow route . 3rd gear ...........................................................

Transmission ratio and power flow route . 4th gear ...........................................................

Transmission ratio and power flow route . reverse gear ....................................................

Transaxle Electronic Control System ........................................................................\

..........

........................................................................\

..................................................... Overview

Transmission control unit

........................................................................\

............................

........................................................................\

.................................... Gearshift strategies

Selector lever positions

........................................................................\

..............................

Signal transmission on the CAN databus ........................................................................\

...

........................................................................\

...................................................... Sensors

........................................................................\

.................................................... Actuators

DIAGNOSIS AND TESTING

Automatic Transaxle

........................................................................\

................................... 307-01

Inspection and Verification ........................................................................\

.................... 307-01

Diagnostic Trouble Code Chart

........................................................................\

.................. 307-01

........................................................................\

...................................... Line Pressure Test 307-01

Stall Speed Test

........................................................................\

....................................... 307-01

Time Lag Test

........................................................................\

............................................. 307-01

procarmanuals.com

Page 966 of 1226

Automatic Tr;

Vehicles Wil

307-01 -6 Transn

~nsmission/Transaxle -

:h: 4-Speed Automatic

~ission (AW81-40) --

DESCRIPTION AND OPERATION

Item Description

I 1 I I st - 3rd gear clutch 1

1 2 14th gear brake I

1 3 1 Reverse gear clutch I

1 4 )2nd - 4th gear brake I

1 5 1 Reverse gear brake I

1 6 1 3rdl4th gear clutch I

1 7 ITorque converter 1

1 8 1 Transmission input shaft I

1 9 I Fluid pump I - --

[ 10 1 Differential assembly I

~l~put wheel, planetary gearset I

11

1 13 1 Planetary gearset I

Intermediate gear stage

vlIlstgear one-way clutch I

1 15 1 2nd gear one-way clutch I

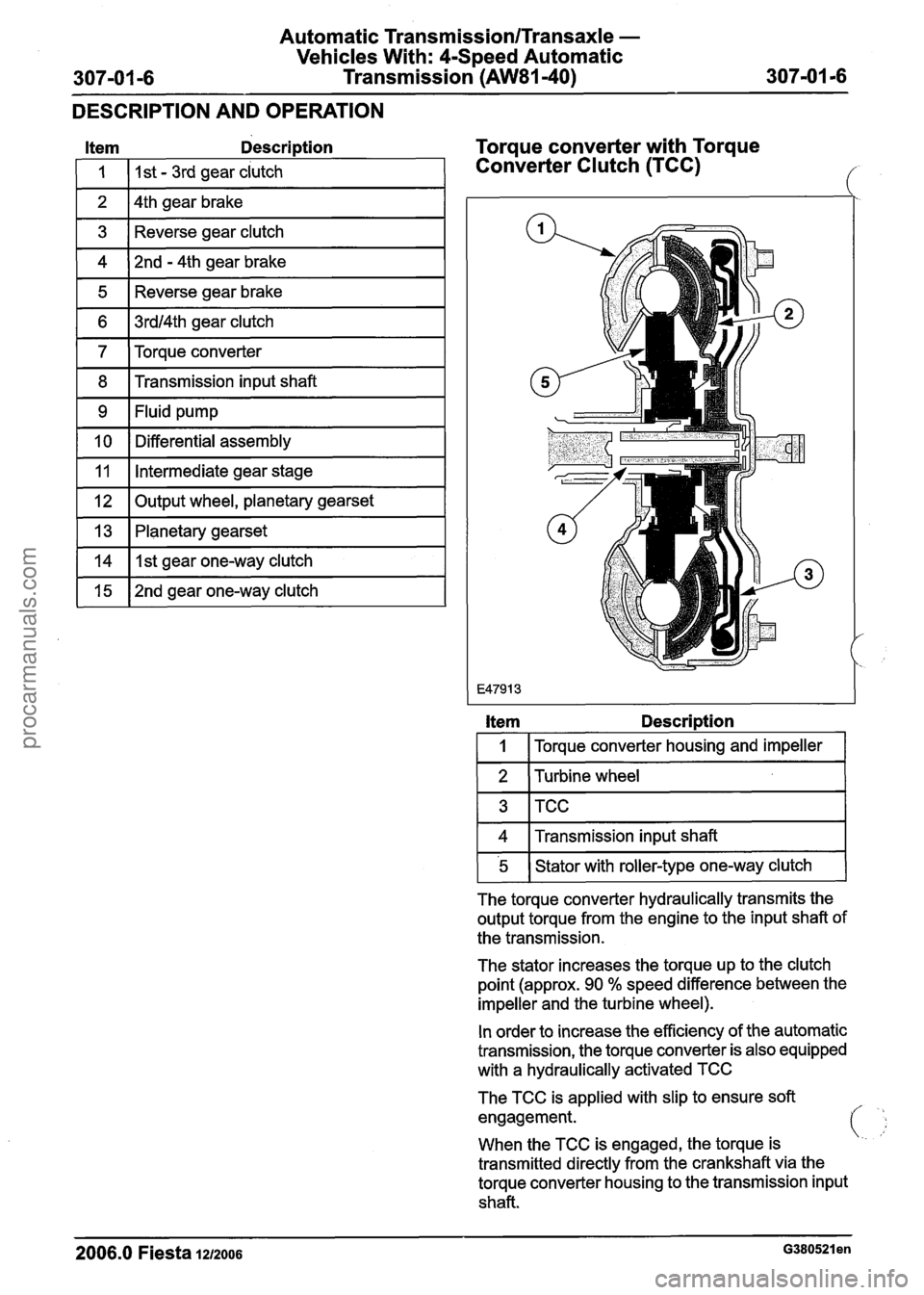

Torque converter with Torque

Converter Clutch (TCC)

Item Description

I 1 I Torque converter housing and impeller I

1 2 1 Turbine wheel 1

1 4 1 Transmission input shaft I

FlGwith roller-type one-way clutch (

The torque converter hydraulically transmits the

output torque from the engine to the input shaft of

the transmission.

The stator increases the torque up to the clutch

point (approx. 90

% speed difference between the

impeller and the turbine wheel).

In order to increase the efficiency of the automatic

transmission, the torque converter is also equipped

with a hydraulically activated TCC

The TCC is applied with slip to ensure soft

engagement.

i

When the TCC is engaged, the torque is '..

transmitted directly from the crankshaft via the

torque converter housing to the transmission input

shaft.

2006.0 Fiesta 1212006 ~380521 en

procarmanuals.com

Page 974 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40)

DESCRIPTION AND OPERATION

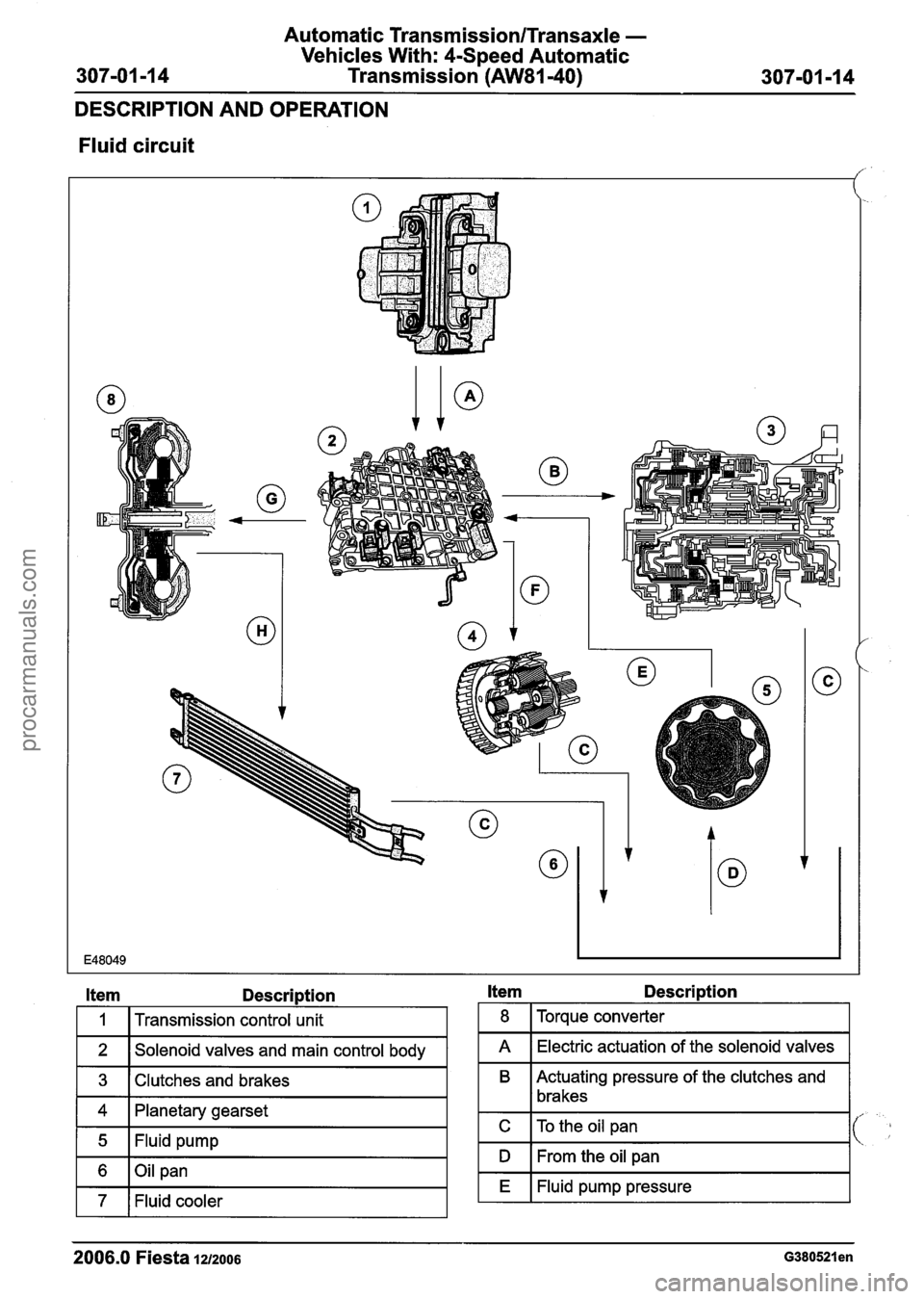

Fluid circuit

Item Description

I 1 I Transmission control unit

1 2 1 Solenoid valves and main control body I

1 3 I Clutches and brakes I

1 4 1 Planetary gearset

1 5 1 Fluid pump I

1 6 1Oil pan I

1 7 1 Fluid cooler I

Item Description

1 8 I Torque converter I

I A I Electric actuation of the solenoid valves I

B Actuating pressure of the clutches and

1 lbrakes

I C ITo the oil pan I

I D I From the oil pan I

I E I Fluid pump pressure I

2006.0 Fiesta 121~006 ~380521 en

procarmanuals.com