clutch FORD FIESTA 2007 Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 985 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -25 Transmission (AW81-40) 307-01 -25

DESCRIPTION AND OPERATION

Item Descriotion

I 1 I From the torque converter I

~l%ansmission input shaft I

1 4 1 Small sun gear I

1 6 1 Planet gear carrier I

1 8 1Short planet gear I

1 9 1 Long planet gear I

10 Annulus and

output wheel of the planetary

/ (gearset

I 11 I Intermediate gear stage I

1 12 1 Differential assembly I

1 13 12nd - 4th gear brake I

1 14 1 2nd gear one-way clutch I

1 15 1 Large sun gear I - --

1 16 14th gear brake I

1 17 1 3rdl4th gear clutch I

~Iianetary gearset, rear I

I B I Planetary gearset, front I

Drive is transmitted from the torque converter (I)

to the transmission input shaft (2) and via the

3rdl4th gear clutch (1 7) to the planet gear carrier

(6).

The large sun gear (15) is held by the 4th gear

brake

(16), the 2nd gear one-way clutch (14) and

the 2nd-4th gear brake

(1 3).

N0TE:The short planet gears (8) and the small

sun gear (4) co-rotate, but they have no influence

on the transmission ratio.

The long planet gears (9) drive the annulus (10) in

the same direction of rotation as the output from

the engine.

The annulus is fixedly connected to the output

wheel of the planetary

gearset and drives the

intermediate gear stage

(11) in the opposite

direction of rotation to the output from the engine.

The intermediate gear stage drives the differential

assembly

(12) in the same direction of rotation as

the output from the engine.

2006.0 Fiesta 1212006 G380528en

procarmanuals.com

Page 987 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -27 Transmission (AW81-40) 307-01 -27

DESCRIPTION AND OPERATION

Item Description

I 1 I From the torque converter I

1 2 I Transmission input shaft I

1 4 ISmaII sun gear I

11 Planet gear carrier I

1 7 1 Reverse gear brake I

1 8 1Short planet gear I

1 9 1 Long planet gear I

10 Annulus and output wheel

of the planetary

I (gearset

I 11 I Intermediate gear stage I

1 12 1 Differential assembly I

1 15 1 Large sun gear I

1 18 1 Reverse gear clutch I

I A I Planetary gearset, rear I

I B I Planetary gearset, front I

Drive is transmitted from the torque converter (1)

to the transmission input shaft

(2) and via the

r reverse gear clutch (1 8) to the large sun gear (1 5).

The planet gear carrier

(6) is held by the reverse

gear brake

(7).

The large sun gear drives the long planet gears

(9) in the opposite direction of rotation to the output

from the engine.

N0TE:The short planet gears (8) and the small

sun gear (4) co-rotate, but they have no influence

on the transmission ratio.

The long planet gears drive the annulus (1

0) in the

opposite direction of rotation to the output from the

engine.

The annulus is fixedly connected to the output

wheel of the planetary

gearset and drives the

intermediate gear stage (I

I ) in the same direction

of rotation as the output from the engine.

The intermediate gear stage drives the differential

assembly (1 2) in the opposite direction of rotation

to the output from the engine.

2006.0 Fiesta 1212006 G380528en

procarmanuals.com

Page 991 of 1226

Automatic TransmissionlTransaxle -

Vehicles With: 4-Speed Automatic

307-01 -31 Transmission (AW81-40) 307-01 -31

DESCRIPTION AND OPERATION

The transmission control unit determines hill climb

mode or trailer operation from the change in throttle

; valve position supplied by the PCM in relation to

the acceleration of the vehicle.

Depending on the driving resistance, the

transmission control unit chooses between two

gearshift maps which have been specially

programmed for this purpose and in which the shift

timings are again chosen as a function of the

accelerator pedal position and the vehicle speed..

Hill descent mode

The hill descent mode is used to take better

advantage of engine braking during hill descents.

A 'hill descent' situation is recognised by the

transmission control unit if the vehicle is

accelerating without operation of the accelerator

pedal.

If in addition the brake is also depressed then the

transmission control unit automatically shifts back

from 4th into 3rd gear.

( ' Cold start mode

In order to reach operating temperature as quickly

as possible under low ambient temperatures,

gearshifts into 4th gear and engagement of the

torque converter clutch (TCC) are suppressed if

one of the following conditions is met:

Transmission fluid temperature below +20 "C

Coolant temperature below - 40°C

The following are actuated: SSA shift solenoid valve,

SSB shift solenoid valve,

Shift solenoid valve, TCC.

Overheating protection mode

The overheating protection mode serves to protect

the transmission against overheating and the

serious damage that this can cause.

If the transmission fluid temperature reaches a

temperature of around 135

"C, the transmission

control employs a shift pattern designed to prevent

a further increase in the transmission fluid

temperature. When

the transmission fluid temperature drops

back below approx. 125

"C, the transmission

control exits the overheating protection mode.

The MIL warning lamp is actuated by the

transmission control unit if the transmission fluid

temperature reaches approximately 140

"C.

The MIL warning lamp goes out again when the

transmission fluid temperature drops back to below

around 130

"C.

Main line pressure control

In order to ensure the highest possible efficiency

of the automatic transmission and to limit the power

losses from the fluid pump, the main line pressure

is adapted accordingly by the main regulating valve

as a function of the accelerator pedal position

(driver torque demand) and the selector lever

position.

This is influenced by the following variables:

Accelerator pedal position and actuation

Selector lever position

The following are actuated:

Main 'regulating valve

Engagement of the TCC

The TCC is engaged in 3rd and 4th gear depending

on the current driving situation.

Engagement is controlled in accordance with the

shift map stored in the control unit.

This is influenced by the following variables:

Accelerator pedal position and actuation,

Vehicle speed,

Selector lever position,

Transmission fluid temperature,

Coolant temperature.

The following are actuated:

Shift solenoid valve, TCC.

Torque reduction during gearshifts

In order to improve the quality of gearshifts and to

avoid gearshift judder, the engine torque is reduced

by the PCM in response to a request from the

transmission control unit during gearshifts.

The engine torque is also reduced during

engagement and disengagement of the TCC.

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 992 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -32 Transmission

(AW81-40) 307-01 -32

DESCRIPTION AND OPERATION

This is influenced by the following variables:

Engine speed,

Engine load,

Transmission input speed,

Vehicle speed.

The following are actuated:

PCM (torque reduction request signal via the

CAN databus).

Pressure control during gearshifts

In order to ensure that the engagement of the

clutches and brakes is as judder-free as possible,

the main line pressure is reduced during gearshifts.

This is influenced by the following variables:

Enginespeed,

Engine load,

Transmission input speed,

Vehicle speed.

The following are actuated:

Main regulating valve.

Shift timing adaptation during upshifts

In order to ensure that the engagement of the

clutches and brakes is as judder-free as possible,

the timing of the gearshift processes is monitored

during upshifts.

In the event of any discrepancy from the target

values, the main line pressure is adapted

accordingly during the next gearshift.

The shift timing adaptation during upshifts is only

active at transmission fluid temperatures between

50

"C and 120 "C.

This is influenced by the following variables:

Engine load,

Accelerator pedal position,

Transmission input speed,

Vehicle speed,

Transmission fluid temperature,

Selector lever position.

The following are actuated:

Main regulating valve.

Shift timing adaptation during shifts from

3rd to 4th gear

The shift from 3rd gear into 4th gear is the only

gearshift during which a clutch is disengaged and

a brake is engaged simultaneously.

In order to control the synchronized switching of

the two components as exactly as possible, the

shifl timing solenoid valve is actuated accordingly.

In order to ensure that this particular gearshift is

performed as judder-free as possible throughout

the service life of the transmission, the gearshift is

monitored by the two rotational speed sensors and

the actuation of the shift timing solenoid valve is

adapted accordingly.

The shift timing adaptation for gearshifts from 3rd

gear into 4th gear is only active at transmission

fluid temperatures between 30

"C and 120 "C.

This is influenced by the following variables:

Engine load,

Accelerator pedal position,

Transmission input speed,

Vehicle speed,

Transmission fluid temperature,

Selector lever position.

The following are actuated:

Shift timing solenoid valve.

Shift timing adaptation during shifts from

4th to 3rd gear

The shift from 4th gear into 3rd gear is the only

gearshift during which a brake is disengaged and

a clutch is engaged simultaneously.

In order to control the engagement of the clutch as

precisely as possible, the main regulating valve is

actuated accordingly in order to build up the

actuating pressure at exactly the right time.

In order to ensure that this particular gearshift is

performed as judder-free as possible throughout

the service life of the transmission, the gearshift is

monitored by the two rotational speed sensors and

the actuation of the main regulating valve is

adapted accordingly.

The shift timing adaptation for gearshifts from 4th

-

gear into 3rd gear is only active at transmission (

fluid temperatures between 20 "C and 120 "C. .

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 993 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4Speed Automatic

307-01 -33 Transmission (AW81-40) 307-01 -33

DESCRIPTION AND OPERATION

This is influenced by the following variables: Vehicle

speed,

Engine load, Transmission fluid temperature.

Accelerator pedal position, The following are actuated:

Transmission input speed, SSA shift solenoid valve,

Vehicle speed,

Transmission fluid temperature,

Selector lever position.

The

following are actuated:

Main

regulating valve.

Reverse gear safety strategy

SSB shift solenoid valve.

Torque reduction when pulling away

In order to protect the clutches against excessively

high torque when pulling away, the PCM reduces

the engine torque in response to a request from

the transmission

control.

If the accelerator pedal is depressed while the

The transmission control unit prevents shifts into vehicle is pulling away, then the transmission reverse gear while the vehicle is driving forwards, control unit sends a corresponding signal as otherwise serious transmission damage can be requesting a torque reduction via the CAN databus. caused.

The reverse gear safety strategy is active when This

is influenced by the

following variables:

reverse gear is engaged with the selector lever at ' Selector lever position,

vehicle speeds in excess of 11 kmlh. Accelerator pedal position,

In this

case the transmission control unit actuates ' Engine speed,

the shift timing solenoid valve, as a result of which Transmission input speed,

the actuating pressure does not reach the reverse

. Vehicle speed. gear clutch or the reverse gear brake.

The following are actuated:

The reverse gear safety strategy is deactivated

PCM (torque reduction request signal via the

when the vehicle speed is below 9 kmlh. The

actuating pressure can then reach the reverse gear CAN

databus).

clutch and the reverse gear brake and the gearshift

into reverse gear is performed.

Selector lever positions

This is influenced by the following variables:

Vehicle speed,

Selector lever position.

The

following are actuated:

Shift timing solenoid valve.

Selector lever position "P"

No gear is engaged in selector lever position "P".

The parking

pawl is engaged manually via the

selector lever cable and the selector shaft.

Avoidance of gearshift judder during

engagement of a transmission range Selector

lever position "R"

In order to prevent gearshift judder when moving The reverse gear is eWaged in selector lever

the selector lever from N to D, the transmission position "R.

control unit initially shifts into

2nd gear instead of

1 st gear, and then immediately shifts back into I st

gear before the gearshift process is finished. Selector lever position "N"

This reduces the amount of gearshift judder during No gear is engaged in selector lever position WNW. engagement of a forward drive range.

The powertrain is not blocked. This is influenced by the following variables:

Selector lever position,

Accelerator pedal position,

Transmission input speed,

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 997 of 1226

Automatic TransmissionlTransaxle -

Vehicles With: 4-Speed Automatic

307-01 -37 Transmission

(AW81-40) 307-01 -37

DESCRIPTION AND OPERATION

Sensors

OSS sensor

TSS sensor

The TSS sensor is an inductive pickup.

It measures the transmission input speed via the

outer plate carrier of the

3rdl4th gear clutch and

sends the signal to the transmission control unit.

The transmission control unit uses this signal for:

Torque reduction during gearshifts,

Pressure control during gearshifts,

Shift timing adaptation during upshifts,

Shift timing adaptation during shifts from 3rd to

4th gear,

Shift timing adaptation during shifts from 4th to

3rd gear,

Avoidance of gearshift judder during

engagement of a transmission range,

Torque reduction when pulling away.

Consequences of signal failure:

No TCC,

no torque reduction,

no shift timing adaptation,

no 4th gear. The

OSS sensor is a Hall sensor.

It is mechanically connected via a gear to the input

wheel of the differential assembly.

It measures the vehicle speed via the input wheel

of the differential assembly and sends the signal

to the transmission control unit.

The transmission control unit uses this signal for:

Gearshift control,

Engagement of the TCC,

Torque reduction during gearshifts,

Pressure control during gearshifts,

Shift timing adaptation during upshifts,

Shift timing adaptation during shifts from 3rd to

4th gear,

Shift timing adaptation during shifts from 4th to

3rd gear,

Reverse gear safety strategy,

Avoidance of gearshift judder during

engagement of a transmission range,

Torque reduction when pulling away,

Hill climb mode,

Hill descent mode.

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 1000 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -40 Transmission (AW81-40)

307-01 -40

DESCRIPTION AND

OPEMION

Driver's side door ajar switch

The door ajar switch is located in the door lock on

the driver's side.

When the door is closed a ground connection is

signalled to the transmission control unit.

When the door is opened this ground connection

is interrupted.

The transmission control unit uses the signal from

the driver's side door ajar switch to warn the driver

if the selector lever is not in position

"P" and the

driver's door is open.

In this case the transmission control unit transmits

the warning tone request via the CAN

databus to

the instrument cluster.

The instrument cluster passes this request on to

the GEM, which then generates a warning tone.

Consequences of signal failure:

no warning tone request.

Actuators

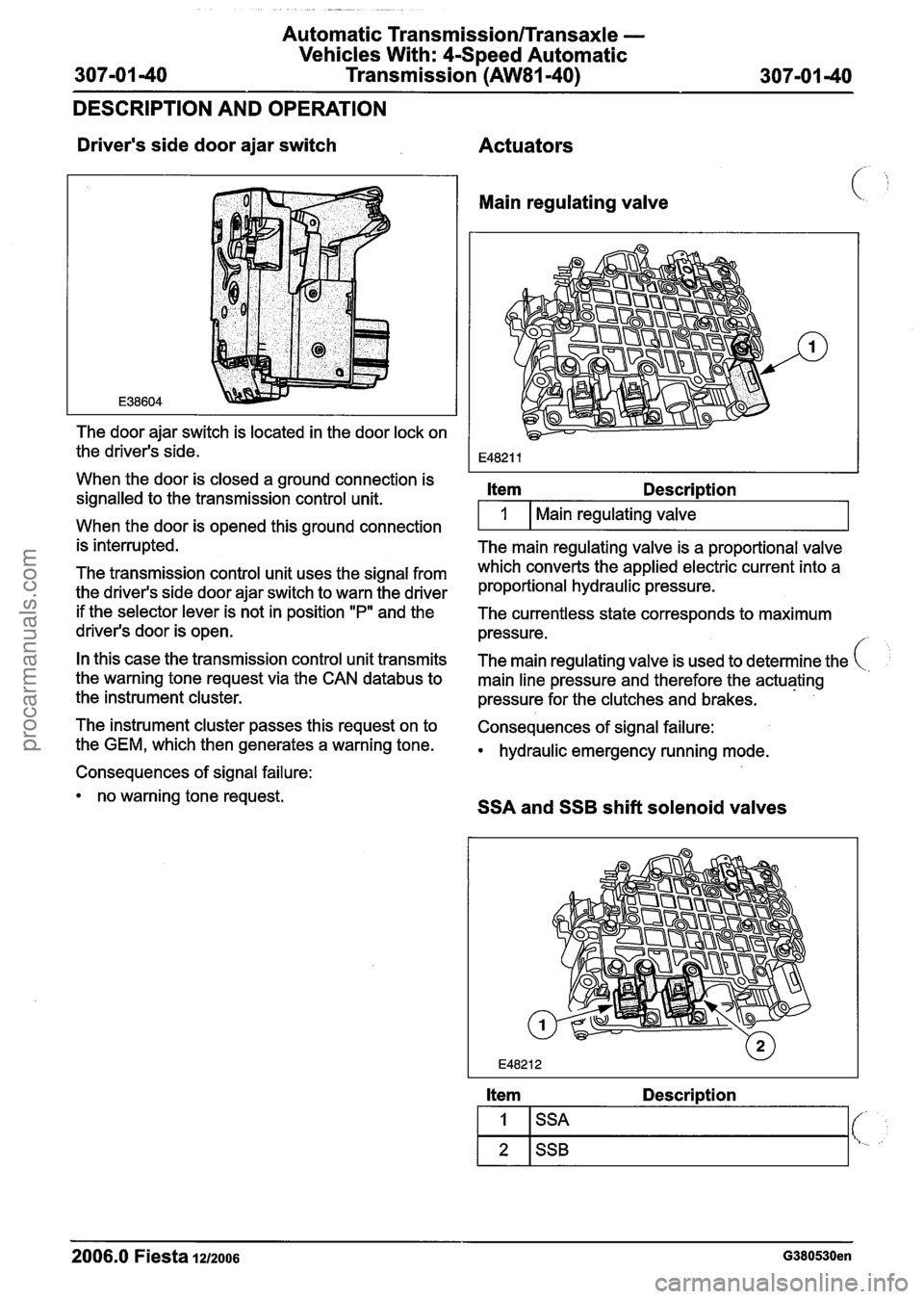

Main regulating valve

Item Description

I 1 I Main regulating valve I

The main regulating valve is a proportional valve

which converts the applied electric current into a

proportional hydraulic pressure.

The currentless state corresponds to maximum

pressure.

/

The main regulating valve is used to determine the

main line pressure and therefore the actuating

pressure for the clutches and brakes.

Consequences of signal failure:

hydraulic emergency running mode.

SSA and SSB shift solenoid valves

Item Description

2006.0 Fiesta 1212006 G380530en

1

2

SSA

SSB

(- t..

procarmanuals.com

Page 1001 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01

-41 Transmission (AW81-40) 307-01 -41

DESCRIPTION AND OPERATION

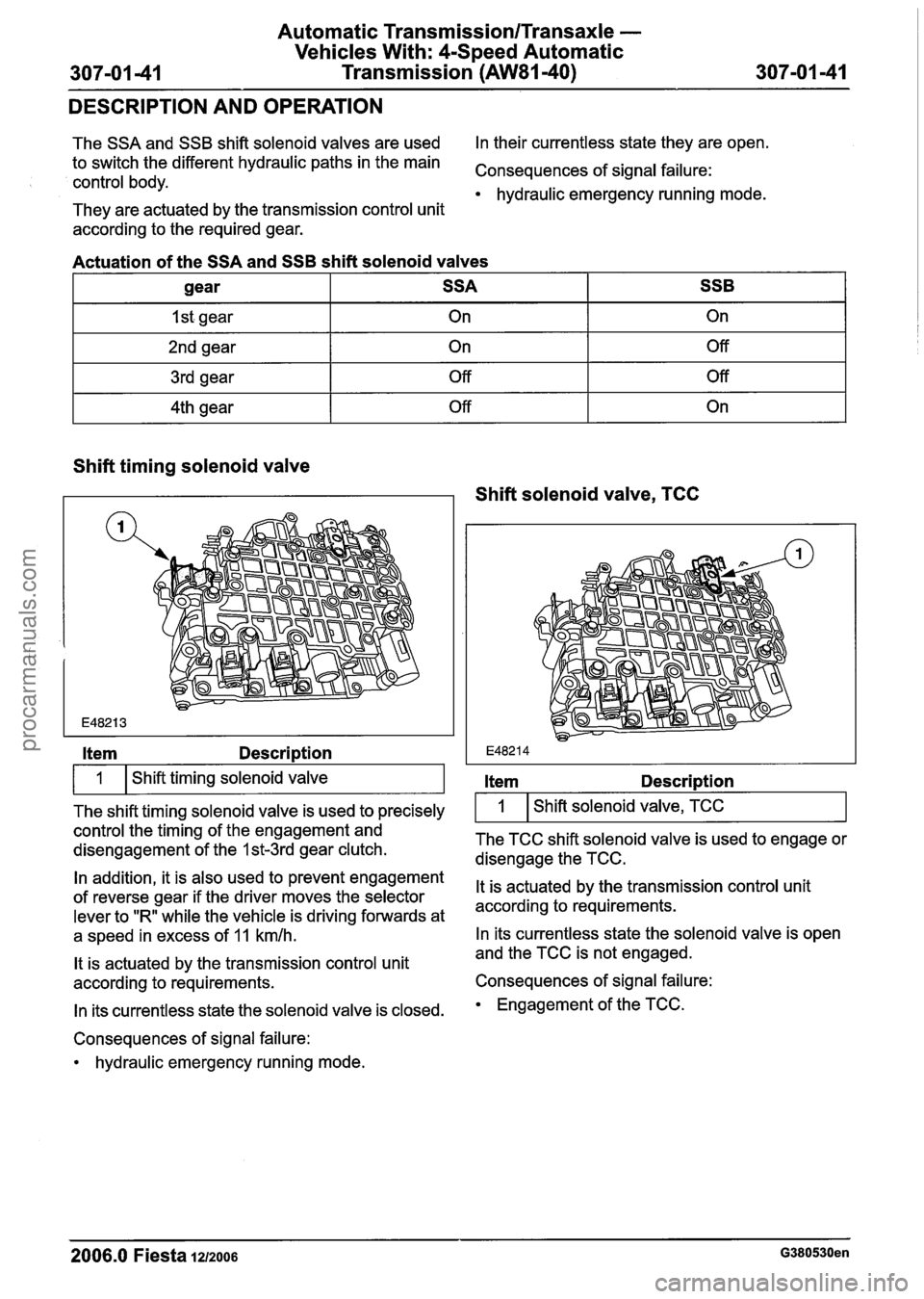

The SSA and SSB shift solenoid valves are used In

their currentless state they are open.

to switch the different hydraulic paths in the main

Consequences of signal failure: control body. hydraulic emergency running mode.

They are actuated by the transmission control unit

according to the required gear.

Actuation of the SSA and SSB shift solenoid valves

Shift timing solenoid valve

gear

I st gear

2nd gear

3rd gear

4th gear

kern Descri~tion

I 1 I Shift timing solenoid valve I

SSA On

On Off

Off

The shift timing solenoid valve is used to precisely SSB

On Off

Off

On

control the timing of the engagement and

disengagement of the

I st3rd gear clutch.

In addition, it is also used to prevent engagement

of reverse gear if the driver moves the selector

lever to "R" while the vehicle is driving forwards at

a speed in excess of

11 kmlh.

It is actuated by the transmission control unit

according to requirements.

In its currentless state the solenoid valve is closed.

Consequences of signal failure: hydraulic emergency running mode.

Shift solenoid valve, TCC

Item Description

I 1 I Shift solenoid valve, TCC I

The TCC shift solenoid valve is used to engage or

disengage the TCC.

It is actuated by the transmission control unit

according to requirements.

In its currentless state the solenoid valve is open

and the TCC is not engaged.

Consequences of signal failure:

Engagement of the TCC.

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 1006 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4Speed Automatic

307-01 -46 Transmission

(AW81-40) 307101 -46

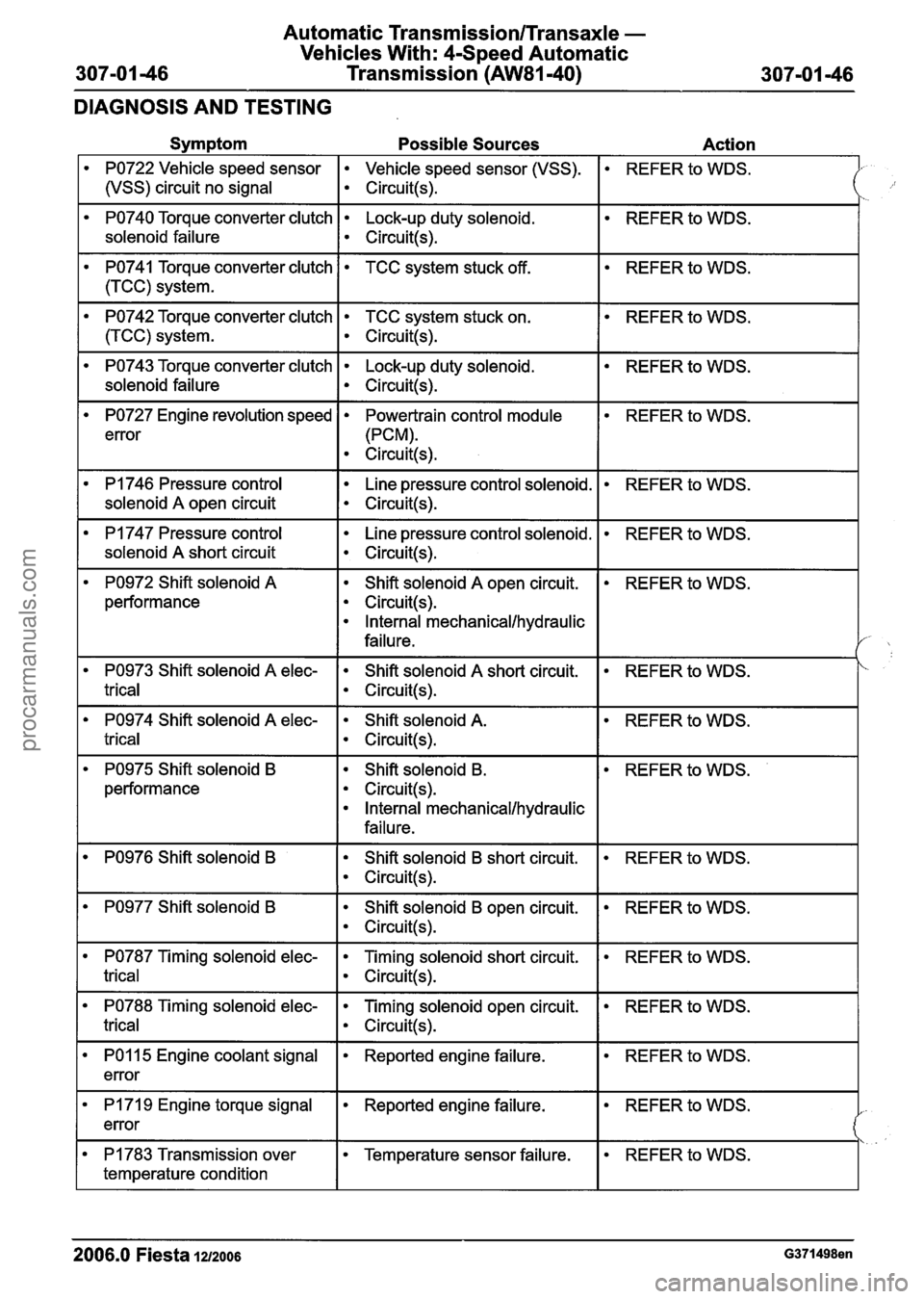

DIAGNOSIS AND TESTING

Symptom Possible Sources Action

PO722 Vehicle speed sensor Vehicle speed sensor (VSS).

1 (vSS) circuit no signal I circuit(+

REFER to WDS.

PO740 Torque converter clutch Lock-up duty solenoid.

solenoid failure

I ~ircuit(s).

REFER to WDS.

REFER to WDS.

PO741 Torque converter clutch

1 (TCC) system.

PO742 Torque converter clutch TCC system stuck on.

I circuit(s).

TCC system stuck off.

REFER to WDS.

PO743 Torque converter clutch Lock-up duty solenoid.

solenoid failure

I circuit(s).

REFER to WDS.

REFER to WDS.

PO727 Engine revolution speed

error

PI 746 Pressure control

I solenoid A open circuit

Powertrain control module

(PCM).

Circuit(s).

I

Line pressure control solenoid.

Circuit(s).

REFER to WDS.

PI 747 Pressure control

solenoid

A short circuit

Line pressure control solenoid.

Circuit(s).

REFER to WDS.

PO972 Shift solenoid A

performance Shift solenoid

A open

circuit.

Circuit(s).

Internal mechanical/hydraulic

failure.

REFER to WDS.

REFER to WDS.

PO974 Shift solenoid A elec- Shift solenoid A.

trical I circuit(!+

PO973 Shift solenoid A elec-

trical

REFER to WDS. Shift solenoid A short circuit.

Circuit(s).

PO975 Shift solenoid B

performance Shift solenoid

B.

Circuit(s).

Internal mechanical/hydraulic

failure.

REFER

to WDS.

PO976 Shift solenoid B Shift solenoid B short circuit.

Circuit(s).

REFER to WDS.

PO977 Shift solenoid B Shift solenoid B open circuit.

Circuit(s).

REFER to WDS.

PO787 Timing solenoid elec- Timing solenoid short circuit.

trical I circuit(s).

REFER to WDS.

REFER to WDS. PO788 Timing solenoid elec-

trical

-- - -

Timing solenoid open circuit.

Circuit(s).

REFER to WDS. PO1 15 Engine coolant signal

error Reported engine failure.

REFER to WDS. I PI 71 9 Engine torque signal

error Reported engine failure.

REFER to WDS. PI 783 Transmission over

temperature condition

2006.0 Fiesta 12/2006 G371498en

Temperature sensor failure.

procarmanuals.com

Page 1008 of 1226

Automatic TransmissionlTransaxle -

Vehicles With: 4-Speed Automatic

307-01 -48 Transmission (AW81-40) 307-01 -48

DIAGNOSIS AND TESTING

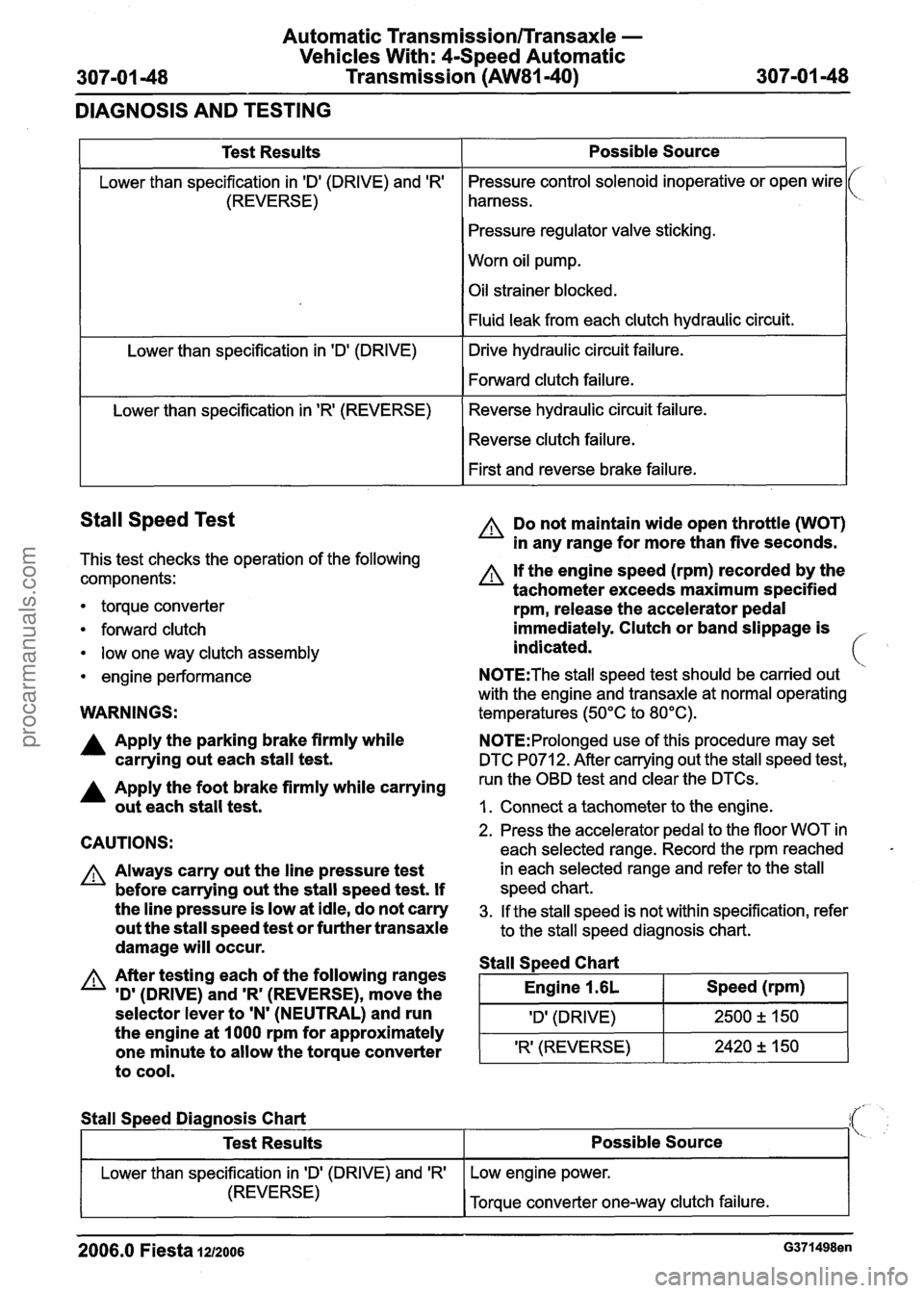

Stall Speed Test

This test checks the operation of the following

components:

1

Test Results

Lower than specification in 'Dl (DRIVE) and 'R'

(REVERSE)

Lower than specification in

'Dl (DRIVE)

Lower than specification in

'R' (REVERSE)

torque converter

forward clutch

low one way clutch assembly

engine performance

Possible Source

Pressure control solenoid inoperative or open wire

harness.

Pressure regulator valve sticking.

Worn oil pump.

Oil strainer blocked.

Fluid leak from each clutch hydraulic circuit.

Drive hydraulic circuit failure.

Forward clutch failure.

Reverse hydraulic circuit failure. Reverse clutch failure.

First and reverse brake failure.

WARNINGS:

A Do not maintain wide open throttle (WOT)

in any range for more than five seconds.

A If the engine speed (rpm) recorded by the

tachometer exceeds maximum specified

rpm, release the accelerator pedal

immediately. Clutch or band slippage is

indicated.

N0TE:The stall speed test should be carried out

with the engine and transaxle at normal operating

temperatures (50°C to 80°C).

A Apply the parking brake firmly while N0TE:Prolonged use of this procedure may set

carrying out each stall test. DTC PO71 2. After carrying out the stall speed test,

A Apply the foot brake firmly while carrying run the OBD test and clear the DTCs.

out each stall test. I. Connect a tachometer to the engine.

CAUTIONS:

A Always carry out the line pressure test

before carrying out the stall speed test. If

the line pressure is low at idle, do not carry

out the stall speed test or further transaxle

damage will occur.

A After testing each of the following ranges

'D'

(DRIVE) and 'R' (REVERSE), move the

selector lever to

'N' (NEUTRAL) and run

the engine at 1000 rpm for approximately

one minute to allow the torque converter

to cool.

2. Press the accelerator pedal to the floor WOT in

each selected range. Record the rpm reached

in each selected range and refer to the stall

speed chart.

3. If the stall speed is not within specification, refer

to the stall speed diagnosis chart.

Stall S~eed Chart

I Engine 1.6L I Speed (rpm) I

I 'Dl (DRIVE) I 2500 2 150 1

'R' (REVERSE) 2420 +, 150 -

Stall

Speed Diagnosis Chart

2006.0 Fiesta 1212006 G371498en

Test Results

Lower than specification in ID' (DRIVE) and 'R'

(REVERSE)

Possible Source

Low engine power.

Torque converter one-way clutch failure.

procarmanuals.com