ignition FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 3 of 1226

2006.0 Fiesta

Workshop Manual

Table of Contents

GROUP 1 General lnformation

Service lnformation

General lnformation

Identification Codes

Jacking and Lifting

Noise, Vibration and

Harshness

Suspension

Suspension System - General

lnformation

Front Suspension

Rear Suspension

Wheels and Tires

Driveline

Front Drive Halfshafts

Brake System

Brake System - General

Information

Drum Brake

Front Disc Brake

Rear Disc Brake

Parking Brake and Actuation

Hydraulic Brake Actuation

Power Brake Actuation

Anti-Lock Control

Anti-Lock Control

- Traction

Control

Anti-Lock Control

- Stability

Assist

Steering System

Steering System - General

lnformation

Power Steering Steering Linkage

Steering Column

Steering Column Switches

Engine

Engine System - General

lnformation

Engine

- 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l.GL Duratec-I 6V

(Sigma)

Engine

- 2.OL Duratec-HE

(MI41

Engine Cooling - 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma)

Engine Cooling

- 2.OL Duratec-HE

(MI41

Fuel Charging and Controls - 1.25L

Duratec-1 6V (Sigma)/l.4L

Duratec-16V (Sigma)/l.GL

Duratec-1 6V (Sigma)

Fuel Charging and Controls

- 2.OL

Duratec-HE (M14)

Accessory Drive

Starting System

Engine lgnition

Engine Ignition

- 2.OL Duratec-HE

(M14)

Engine Emission Control - 1.3L

Duratec-8V (Rocam)/l.25L

Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L

Duratec-1

6V (Sigma)

Engine Emission Control

- 2.OL

Duratec-HE (M14)

05/2005 2006.0 Fiesta

procarmanuals.com

Page 11 of 1226

GROUP

Powertrain

SECTION TITLE PAGE

Engine

Engine System . General Information ........................................................................\

.... 303-00

Enginel.25L Duratec-I 6V (Sigma)ll.4L Duratec-1 6V (Sigma)ll . 6L Duratec-I 6V

........................................................................\

.............................................. (Sigma) -303-0 I A

........................................................................\

............... Engine2.0L Duratec-HE (M14) .30 3-01 B

Engine

Cooling1.3L Duratec-8V (Rocam)ll.25L Duratec-I 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll . 6L Duratec-1 6V (Sigma) ...................................................... .30 3-03A

Engine

Cooling2.0L Duratec-HE (M14) ........................................................................\

.. 303-038

Fuel Charging and Controlsl.25L Duratec-1 6V (Sigma)ll.4L Duratec-1 6V

........................................................................\

... (Sigma)ll . 6L Duratec-1 6V (Sigma) .30 3-0414

Fuel Charging

and Controls2.0L Duratec-HE (M14) ....................................................... 303-04B

........................................................................\

.................................... Accessory Drive .30 3-05

Starting System

........................................................................\

...................................... 303-06

Engine Ignition

........................................................................\

....................................... 303-07A

Engine Ignition2.01 Duratec-HE (M14) ........................................................................\

... 303-07B

Engine Emission

Controll.3L Duratec-8V (Rocam)ll.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll . 6L Duratec-1 6V (Sigma) ...................................................... .30 3-08A

Engine Emission

Control2.0L Duratec-HE (M14) ........................................................... 303-088

........................................................................\

........ Intake Air Distribution and Filtering 303-1 2

........................................................................\

.......................... Evaporative

Emissions .30 3-13

........................................................................\

.................... Electronic Engine Controls .304 3-1

Automatic Transmission/Transaxle

Automatic Transmission/TransaxleVehicles With: 4-Speed Automatic Transmission

........................................................................\

......................................... (AW8 1 .40) .301 7.0

Transmission/Transaxle CoolingVehicles With: 4-Speed Automatic Transmission

........................................................................\

.......................................... (AW81-40) 307-02

Automatic

TransmissionlTransaxle External ControlsVehicles With: 4-Speed

........................................................................\

.. Automatic Transmission (AW81-40) .30 7.05

Manual Transmission/Transaxle. Clutch and Transfer Case

Manual Transmission/Transaxle and Clutch . General Information ............................... 308-00

........................................................................\

.................................................... Clutch .301 8.0

........................................................................\

..................................... Clutch Controls .30 8.02

Manual

TransmissionlTransaxle ........................................................................\

............ 308-03

Manual

TransmissionlTransaxle External Controls ........................................................ 308-06

0512005 2006.0 Fiesta

procarmanuals.com

Page 26 of 1226

1 OO=OO-10 General Information 100-00-1 0

DESCRIPTION AND OPERATION

Dewaxing Engine Oils

See Solvents and Fuels (Kerosene). See Lubricants and Grease.

Dusts Exhaust Fumes

Powder, dusts or clouds may be irritant, harmful These contain asphyxiating, harmful and toxic

or toxic. Avoid breathing dusts from powdery chemicals and particles such as carbon oxides,

chemical materials or those arising from dry nitrogen oxides, aldehydes, lead and aromatic

abrasion operations. Wear respiratory protection hydrocarbons. Engines should be run only under

if ventilation is inadequate. conditions of adequate exhaust extraction or

Fine dusts of combustible material can present an general ventilation

and not in confined spaces.

explosion hazard. Avoid explosive limits and

sources of ignition.

Gasoline (petrol) engine

Electric Shock There may not be adequate warning of odor or of

irritation before toxic or harmful effects arise. These

Electric shock can result from the use of faulty may be immediate

or delayed.

electrical equipment or from the misuse of

equipment in good condition.

Diesel engine Make sure that electrical equipment is maintained

in good condition and frequently tested. Faulty

Soot, discomfort and irritation usually give

equipment should be labeled and preferably

adequate warning of hazardous fume

removed from the workstation. concentrations.

Make sure that flexes, cables, plugs and sockets

are not frayed, kinked, cut, cracked or otherwise

Fibre damaged.

Make sure that electrical equipment and flexes do

See also Dusts.

not come into contact with water.

Used in noise and sound insulation.

Make sure that electrical is protected The fibrous nature of surfaces and cut edges can by the correct rated fuse.

cause skin irritation. This is usually a physical and

Never misuse electrical equipment and never use

not a chemical effect.

equipment that is in any way faulty. The results

could be fatal. Precautions should

be taken to avoid excessive

skin contact through careful organization of work

Make sure that the cables of mobile electrical

practices and the

;se of gloves.

equipment cannot get trapped and damaged, such

as in a vehicle hoist.

-. Fire Make sure that the designated electrical workers

are trained in basic First Aid.

See also Welding, Foams, Legal Aspects.

In cases of electrocution:

Many of the materials found on or associated with

- switch off the power supply before approaching the repair of vehicles are highly flammable. Some

the victim. give

off toxic or harmful fumes if burnt.

- if this is not possible push or drag the victim

Observe strict fire safety when storing and handling

from the source of electricity using dry flammable materials

or solvents, particularly near

non-conductive material. electrical equipment or welding processes.

/

- commence resuscitation if trained to do so.

Make sure, before using electrical or welding 'L '

- SUMMON MEDICAL ASSISTANCE. equipment,

that there is no fire hazard present.

Have a suitable fire extinguisher available when

using welding or heating equipment.

procarmanuals.com

Page 28 of 1226

100-00-12 General Information 100-00-12

DESCRIPTION AND OPERATION

Gross or prolonged skin contact with high boiling

point gas oils may also cause serious skin

disorders including skin cancer.

Kerosene (Paraffin)

Used also as heating fuel, solvent and cleaning

agent.

Flammable

- observe No Smoking policy.

Irritation of the mouth and throat may result from

swallowing. The main hazard from swallowing

arises if liquid aspiration into the lungs occurs.

Liquid contact dries the skin and can cause

irritation or dermatitis. Splashes in the eye may be

slightly irritating.

In normal circumstances the low volatility does not

give rise to harmful vapors. Exposure to mists and

vapors from kerosene at elevated temperature

should be avoided (mists may arise in dewaxing).

Avoid skin and eye contact and make sure there

is adequate ventilation.

Alternative Fuel

Highly flammable. Observe "NO SMOKING" signs.

Make sure there is adequate ventilation when

working on alternative fuelled vehicles. Great care

must be taken to avoid the serious consequences

of inhalation in the event of vapor build up in

confined spaces.

Inhalation in high concentrations may cause

dizziness, headache, nausea and loss of

co-ordination. Very high concentrations may result

in loss of consciousness.

Contact with liquefied petroleum gas (LPG) or

compressed natural gas (CNG) to the skin may

cause cold burns and frost bite.

Long sleeved cotton overalls, steel toe capped

safety boots and rubber neoprene gloves should

be worn during removal and installation of

LPGICNG fuel system components.

LPGICNG fuel leaks could cause a fire and be a

hazard to health that can lead to personal injury,

illness or even death.

If a leak is detected, under no circumstances

attempt to seal the leak by tightening the

unionlconnection until the fuel in the system or

component is depressurized. Once tightened the

system should be checked for integrity following

the specified procedures. If

the fuel tank is to be removed for service or repair

the fuel must be evacuated using dedicated

equipment and following the specified

procedures. (

Gas Cylinders

See also Fire.

Gases such as oxygen, acetylene, argon and

propane are normally stored in cylinders at

pressures of up to

138 bar (2000 psi) and great

care should be taken in handling these cylinders

to avoid mechanical damage to them or to the valve

gear attached. The contents of each cylinder

should be clearly identified by appropriate

markings.

Cylinders should be stored in well-ventilated

enclosures, and protected from ice and snow, or

direct sunlight. Fuel gases, for example acetylene

and propane, should not be stored in close

proximity to oxygen cylinders.

Care should be exercised to prevent leaks from

gas cylinders and lines, and to avoid sources of

ignition.

Only trained personnel should undertake work

involving gas cylinders.

Gases

See Gas Cylinders.

Gaskets (Fluoroelastomer)

See Viton.

General Workshop Tools and

Equipment

It is essential that all tools and equipment are

maintained in good condition and that the correct

safety equipment is used where required.

Never use tools or equipment for any purpose other

than that for which they were designed. Never

overload equipment such as hoists, jacks, axle and

chassis stands or

lifting slings. Damage caused by

overloading is not always immediately apparent

and may result in a fatal failure the next time that

the equipment is used.

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 33 of 1226

100-00-1 7 General Information 100-00-1 7

DESCRIPTION AND OPERATION

The flame is bright, and eye protection should be - used, but the ultra-violet emission is much less

than that from arc welding, and lighter filters may

be used.

The process itself produces few toxic fumes, but

such fumes and gases may be produced from

coatings on the work, particularly during cutting

away of damaged body parts, and inhalation of the

fumes should be avoided.

In brazing, toxic fumes may be produced from the

metals in the brazing rod, and a severe hazard

may arise if brazing rods containing cadmium are

used. In this event particular care must be taken

2. Components or assemblies displaying the

to avoid inhalation of fumes and expert advice may

warning triangle with the 'electrified' arrow and

be required. open book symbol

give warning of inherent high

SPECIAL PRECAUTIONS MUST BE TAKEN voltages.

Never touch these with the engine

BEFORE ANY WELDING OR CUTTING TAKES running

or the ignition switched on. See Electric

PLACE ON VESSELS, WHICH HAVE Shock

in this subsection.

CONTAINED COMBUSTIBLE MATERIALS, FOR

EXAMPLE BOILING OR STEAMING OUT OF

FUEL TANKS.

Warning Symbols on Vehicles

( i Decals showing warning symbols will be found on

various vehicle components.

These decals must not be removed. The warnings

are for the attention of

owners/operators and

persons carrying out service or repair operations

on the vehicle.

3. Vehicles and replacement components which

The most commonly found decals are reproduced

contain asbestos are identified by this symbol.

below together with an explanation of the warnings.

See Asbestos in this subsection.

1. Components or assemblies displaying the

caution triangle and open book symbol advise

consultation of the relevant section of the owner

literature before touching or attempting

adjustments of any kind. 4. Components or assemblies displaying this

symbol give warning that the component

contains a corrosive substance. See Acids and

Alkalis in this subsection.

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 36 of 1226

100-00-20 General Information 100-00-20

DESCRIPTION AND OPERATION

Towing the Vehicle

an instance, the discharged battery must

be recharged immediately after jump

A WARN1NG:When the vehicle is being starting

to avoid permanent damage. ( towed, the ignition switch must be in - Always make sure that the jumper cables are

position ll (steering lock released and adequate for the task. Heavy duty cables must

warning lamps illuminated). Only then will be used.

the turn signal lamps, horn and - Always make sure that the slave battery is of stop lamps be operational. Failure to follow the same voltage as the vehicle battery. The these instructions may result in personal batteries must be connected in parallel. injury. - Always make sure that switched electric circuits

N0TE:The removable towing eye (if equipped),

are switched off before connecting jumper

has a left-hand thread and must be fully tightened cables. This reduces the risk of arcing occurring

before towing can commence.

when the final connection is made.

When towing is necessary, the vehicle towing eyes

should be used. The rope must be securely

fastened to the towing eyes and must also be

attached to the other vehicle such that the rope will

not foul the bodywork.

When a vehicle with automatic transmission is

towed, the gear selector must be in position

N

(Neutral). Never tow a vehicle with automatic

transmission at a speed greater than 30 mph (50

kmlh) or for a distance greater than 30 miles (50

km). If it is necessary to tow the vehicle a greater

distance, the drive wheels must be lifted clear off

the ground.

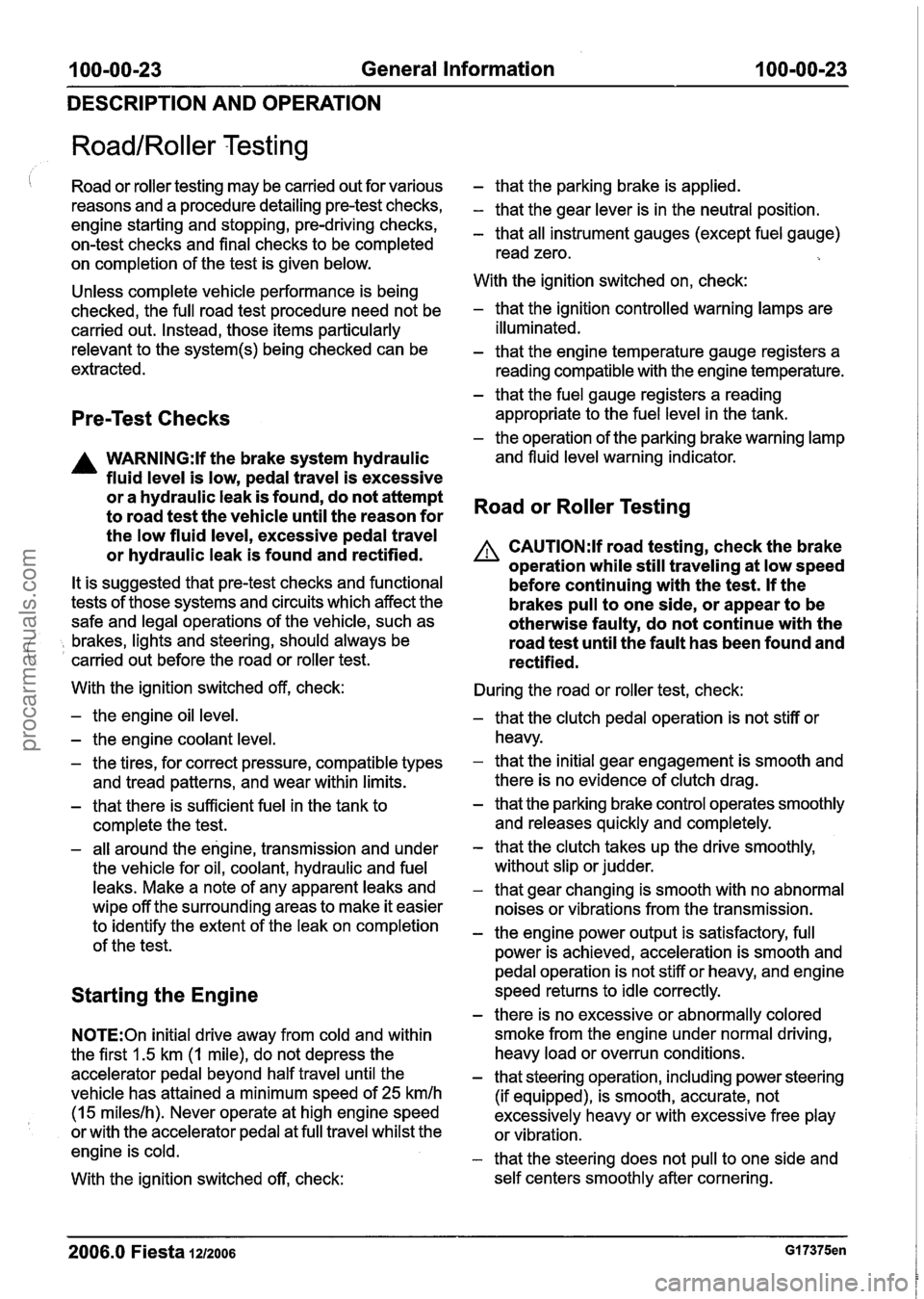

I A WARN1NG:Make sure that the ends of the Alternatively the vehicle can be transported on a jumper cables do not touch each other or low loader or a trailer. ground against the vehicle body at any

time while the cables are attached to the

Connectin a Slave Battery Using

73

battery. A fully charged battery, if shorted

Jumper Ca les through jumper cables, can discharge at

a rate well above

I000 amps causing

A WARNING:H the slave battery has recently violent arcing

and very rapid heating of the

been charged and is gassing, cover the jumper cables and

terminals, and can even

vent plugs or covers with a damp cloth to cause

the battery to explode. Failure to

reduce the risk of explosion should arcing follow

these instructions may result in

occur when connecting the jumper cables. personal injury.

Failure to follow these instructions may

Always connect the jumper cables in the following

result in personal injury. sequence:

CAUTIONS:

A A discharged battery condition may have

been caused by an electrical short circuit.

If this condition exists there will be an

apparently live circuit on the vehicle even

when all normal circuits are switched off.

This can cause arcing when the jumper

cables are connected.

A While it is not recommended that the

vehicle is jump started,

it is recognized

that this may occasionally be the only

practical way to mobilize a vehicle. In such

- Slave battery positive first and then vehicle

battery positive.

- Slave battery negative next and then vehicle

ground at least

12 inches (300 mm) from the

battery terminal, for example engine lifting eye.

Always reduce the engine speed to idle before

disconnecting the jumper cables.

Before removing the jumper cables from the vehicle

-

heater blower (high) or the heated rear window, to

that

had the discharged battery, switch on the

reduce the voltage peak when the cables are

removed.

2006.0 Fiesta 1~12006 GI 7373en

procarmanuals.com

Page 39 of 1226

100-00-23 General Information 100-00-23

DESCRIPTION AND OPERATION

RoadIRoller Testing

I Road or roller testing may be carried out for various

reasons and a procedure detailing pre-test checks,

engine starting and stopping, pre-driving checks,

on-test checks and final checks to be completed

on completion of the test is given below.

Unless complete vehicle performance is being

checked, the full road test procedure need not be

carried out. Instead, those items particularly

relevant to the

system(s) being checked can be

extracted.

Pre-Test Checks

A WARNING:lf the brake system hydraulic

fluid level is low, pedal travel is excessive

or a hydraulic leak is found, do not attempt

to road test the vehicle until the reason for

the low fluid level, excessive pedal travel

or hydraulic leak is found and rectified.

It is suggested that pre-test checks and functional

tests of those systems and circuits which affect the

safe and legal operations of the vehicle, such as

( , brakes, lights and steering, should always be

carried out before the road or roller test.

With the ignition switched off, check:

- the engine oil level.

- the engine coolant level.

- the tires, for correct pressure, compatible types

and tread patterns, and wear within limits.

- that there is sufficient fuel in the tank to

complete the test.

- all around the engine, transmission and under

the vehicle for oil, coolant, hydraulic and fuel

leaks. Make a note of any apparent leaks and

wipe off the surrounding areas to make it easier

to identify the extent of the leak on completion

of the test.

Starting the Engine

N0TE:On initial drive away from cold and within

the first 1.5 km (1 mile), do not depress the

accelerator pedal beyond half travel until the

vehicle has attained a minimum speed of

25 kmlh

(15 mileslh). Never operate at high engine speed

or with the accelerator pedal at full travel whilst the

engine is cold.

With the ignition switched off, check:

- that the parking brake is applied.

- that the gear lever is in the neutral position.

- that all instrument gauges (except fuel gauge)

read zero.

With the ignition switched on, check:

- that the ignition controlled warning lamps are

illuminated.

- that the engine temperature gauge registers a reading compatible with the engine temperature.

- that the fuel gauge registers a reading

appropriate to the fuel level in the tank.

- the operation of the parking brake warning lamp

and fluid level warning indicator.

Road or Roller Testing

A CAUTI0N:lf road testing, check the brake

operation while still traveling at low speed

before continuing with the test. If the

brakes pull to one side, or appear to be

otherwise faulty, do not continue with the

road test until the fault has been found and

rectified.

During the road or roller test, check:

- that the clutch pedal operation is not stiff or

heavy.

- that the initial gear engagement is smooth and

there is no evidence of clutch drag.

- that the parking brake control operates smoothly

and releases quickly and completely.

- that the clutch takes up the drive smoothly,

without slip or judder.

- that gear changing is smooth with no abnormal

noises or vibrations from the transmission.

- the engine power output is satisfactory, full

power is achieved, acceleration is smooth and

pedal operation is not stiff or heavy, and engine

speed returns to idle correctly.

- there is no excessive or abnormally colored

smoke from the engine under normal driving,

heavy load or overrun conditions.

- that steering operation, including power steering

(if equipped), is smooth, accurate, not

excessively heavy or with excessive free play

or vibration.

- that the steering does not pull to one side and

self centers smoothly after cornering.

2006.0 Fiesta 1212006 GI 7375en

procarmanuals.com

Page 78 of 1226

100-04-22 Noise, Vibration and Harshness I 00-04-22

DIAGNOSIS AND TESTING

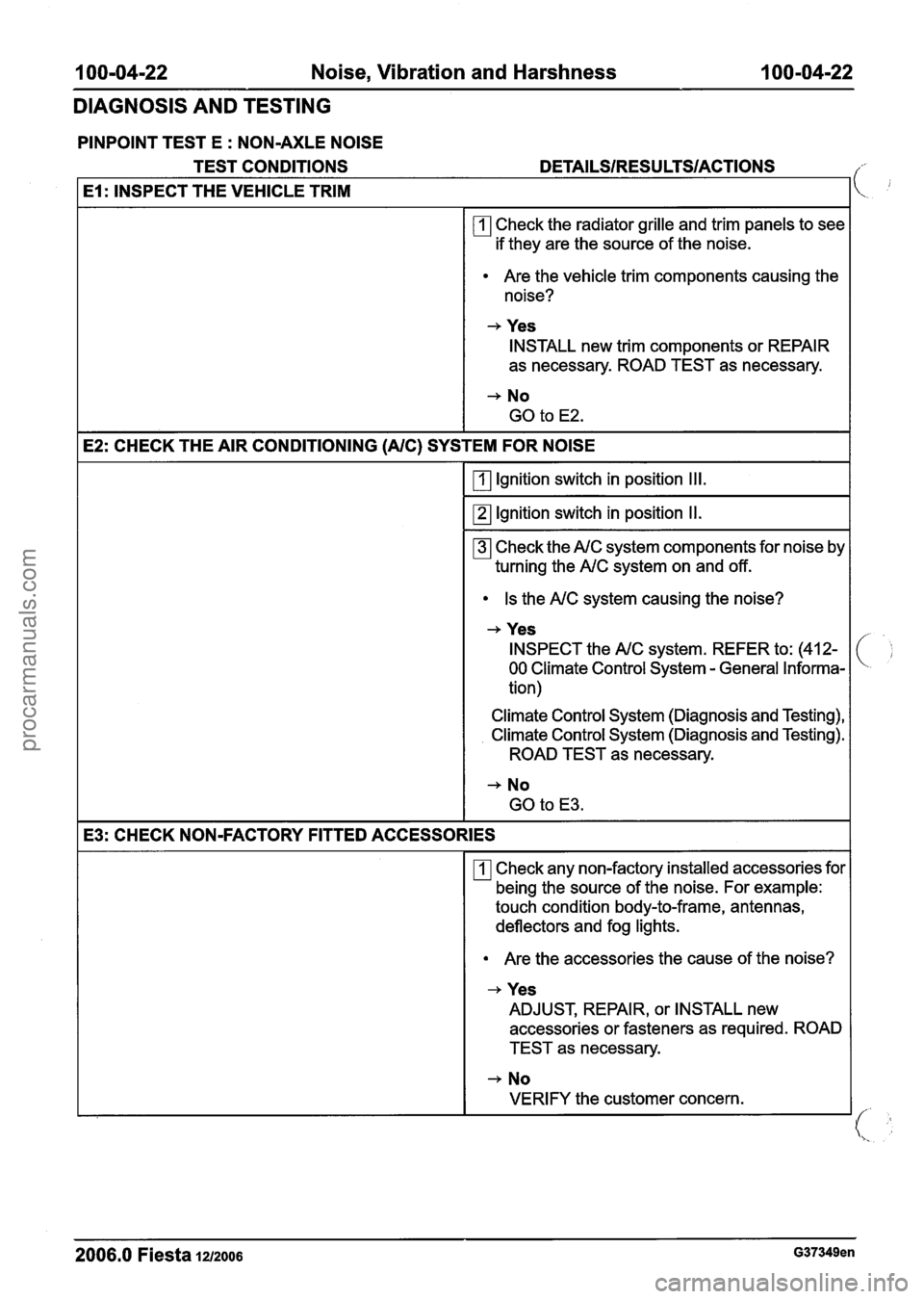

PINPOINT TEST E : NON-AXLE NOISE

TEST CONDITIONS

DETAILSIRESULTSIACTIONS

I El : INSPECT THE VEHICLE TRIM I

Check the radiator grille and trim panels to see

if they are the source of the noise.

Are the vehicle trim components causing the

noise?

+ Yes INSTALL new trim components or REPAIR

as necessary. ROAD TEST as necessary.

I E2: CHECK THE AIR CONDITIONING (AIC) SYSTEM FOR NOISE I

I Ignition switch in position Ill. I

I lgnition switch in position II.

Check the NC system components for noise by

turning the

NC system on and off.

Is the

NC system causing the noise?

+ Yes

INSPECT the

NC system. REFER to: (412-

00 Climate Control System - General Informa-

tion)

Climate Control System (Diagnosis and Testing),

Climate Control System (Diagnosis and Testing).

ROAD TEST as necessary.

I E3: CHECK NO~FACTORY FITTED ACCESSORIES I

rn Check any non-factory installed accessories for

being the source of the noise. For example:

touch condition body-to-frame, antennas, deflectors and fog lights.

Are the accessories the cause of the noise?

+ Yes

ADJUST, REPAIR, or INSTALL new

accessories or fasteners as required. ROAD

TEST as necessary.

+ No

VERIFY the customer concern.

2006.0 Fiesta iuzoos G37349en

procarmanuals.com

Page 184 of 1226

206=00-I 2 Brake System - General Information 206-00-1 2

DIAGNOSIS AND TESTING

TEST CONDITIONS

I A5: CHECK PRESSURE CONTROL VALVE-LEI T-HAND REAR I

Install pressure gauges in the right-hand front

and left-hand rear bleed nipples. Apply the brake

to read 6895

kPa (1000 psi) at the right-hand

front wheel.

- Read the pressure at left-hand rear wheel.

Does the pressure gauge read between 4692-

5164

kPa (680-750 psi) at the left-hand rear

wheel?

+ Yes

INSPECT the brake calipers and INSTALL

new components as required. REFER to:

Brake Shoes (206-02 Drum Brake, Removal and Installation),

Brake Pads (206-03 Front Disc Brake, Removal

and Installation),

Brake Pads (206-04 Rear Disc Brake, Removal

and Installation).

TEST the system for normal operation.

+ No

INSTALL a new left-hand rear brake pressure

control valve. BLEED the brake system.

REFER to: (206-00 Brake System

- General

Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General Procedures).

TEST the system for normal operation.

PINPOINT TEST B

: BRAKE WARNING INDICATOR ALWAYS ON

TEST CONDITIONS

DETAILS/RESULTS/ACTIONS

I B1: CHECK BRAKE WARNING INDICATOR I

N0TE:The brake warning indicator should only illuminate when the ignition switch is in the START or

RUN position and the parking brake is applied.

I Ignition switch in position II.

Release the parking brake.

- Check the fluid level in the reservoir is at the

MAX mark.

Does the brake warning indicator illuminate?

+ Yes

REFER to: lnstrument Cluster

- Vehicles Built

Up To: 1 012005 (41 3-01 lnstrument Cluster,

Diagnosis and Testing).

2006.0 Fiesta 12/2006 G28494en

procarmanuals.com

Page 185 of 1226

206-00-1 3 Brake System - General Information 206-00-1 3

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESU LTSIACTIONS

I B2: CHECK BRAKE SYSTEM FOR LEAKAGE 1

rn Check the brake master cylinder reservoir

sealing points and external brake and clutch

system for leaks. Refer to the brake master

cylinder component tests in this section.

Does the system leak?

-+ Yes

REPAIR as necessary. ADD fluid and BLEED

the brake system. REFER to: (206-00 Brake

System

- General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General Procedures).

TEST the system for normal operation.

183: CHECK BRAKE WARNING SWITCH OR WIRING I

I rn Ignition switch in position II. I

Remove the brake master cylinder reservoir

filler cap or switch. Allow the float to rest at its

lowest point.

Does the brake warning indicator illuminate?

-+ Yes

The switch or wiring is OK. TEST the system

for normal operation.

-+ No

REFER to: lnstrument Cluster - Vehicles Built I Up To: 1012005 (41 3-01 Instrument Cluster,

I Diagnosis and Testing).

PINPOINT TEST C : VIBRATION WHEN BRAKES ARE APPLIED

TEST CONDITIONS

DETAl LSIRESU LTSIACTIONS

Cl : ROAD TEST THE VEHICLE

Road test the vehicle without applying the

brakes at 40-80 kmlh (25-50 mph).

Is a vibration present?

-+ Yes

REFER to: Noise, Vibration and Harshness

(NVH) (1 00-04 Noise, Vibration and Harsh-

ness, Diagnosis and Testing).

After servicing, TEST the system for normal operation.

-+ No

GO to C2.

2006.0 Fiesta 1212006 G28494en

procarmanuals.com