engine oil FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 17 of 1226

100-00-1 General Information 100-00-1

. SECTION 100-00 General lnformation

VEHICLE APPLICATION:2006.0 Fiesta

CONTENTS

DESCRIPTION AND OPERATION

About This Manual

........................................................................\

......................................

........................................................................\

................................................. Introduction

Special Tools

........................................................................\

..............................................

Important Safety Instructions ........................................................................\

......................

Warnings. Cautions and Notes in This Manual ..................................................................

How to Use This Manual ........................................................................\

............................

Special Tools and Torque Figures ........................................................................\

..............

Health and Safety Precautions ........................................................................\

...................

........................................................................\

................................................. Introduction

........................................................................\

........................................ Acids and Alkalis

Air Bags

........................................................................\

......................................................

Air Conditioning Refrigerant ........................................................................\

.......................

........................................................................\

............................... Adhesives and Sealers

........................................................................\

................................................... Antifreeze

........................................................................\

..................................................... Asbestos

Battery Acids

........................................................................\

..............................................

Brake and Clutch Linings and Pads ........................................................................\

...........

Brake Fluids (Polyalkylene Glycols) ........................................................................\

...........

........................................................................\

....................................................... Brazing

Chemical Materials

........................................................................\

.....................................

................................................................... Chlorofluorocarbons (CFC) ... ..........................

Clutch Fluids ........................................................................\

...............................................

Clutch Linings and Pads ........................................................................\

.............................

Corrosion Protection Materials ........................................................................\

...................

........................................................................\

........................................................ Cutting

........................................................................\

.................................................... Dewaxing

........................................................................\

.......................................................... Dusts

Electric Shock

........................................................................\

.............................................

Engine Oils ........................................................................\

.................................................

Exhaust Fumes ........................................................................\

...........................................

........................................................................\

........................................... Fibre Insulation

Fire

........................................................................\

.............................................................

First Aid ........................................................................\

......................................................

........................................................................\

.......................................... Fluoroelastomer

Foams

. Polyurethane ........................................................................\

................................

........................................................................\

.......................................................... Freon

........................................................................\

........................................................... Fuels

........................................................................\

.............................................. Gas Cylinders

........................................................................\

......................................................... Gases

Gaskets (Fluoroelastomer)

........................................................................\

.........................

General Workshop Tools and Equipment ........................................................................\

...

High Pressure Air. Lubrication and Oil Test Equipment ......................................................

........................................................................\

.......................................................... Halon

........................................................................\

............................................. Legal Aspects

PAGE

procarmanuals.com

Page 26 of 1226

1 OO=OO-10 General Information 100-00-1 0

DESCRIPTION AND OPERATION

Dewaxing Engine Oils

See Solvents and Fuels (Kerosene). See Lubricants and Grease.

Dusts Exhaust Fumes

Powder, dusts or clouds may be irritant, harmful These contain asphyxiating, harmful and toxic

or toxic. Avoid breathing dusts from powdery chemicals and particles such as carbon oxides,

chemical materials or those arising from dry nitrogen oxides, aldehydes, lead and aromatic

abrasion operations. Wear respiratory protection hydrocarbons. Engines should be run only under

if ventilation is inadequate. conditions of adequate exhaust extraction or

Fine dusts of combustible material can present an general ventilation

and not in confined spaces.

explosion hazard. Avoid explosive limits and

sources of ignition.

Gasoline (petrol) engine

Electric Shock There may not be adequate warning of odor or of

irritation before toxic or harmful effects arise. These

Electric shock can result from the use of faulty may be immediate

or delayed.

electrical equipment or from the misuse of

equipment in good condition.

Diesel engine Make sure that electrical equipment is maintained

in good condition and frequently tested. Faulty

Soot, discomfort and irritation usually give

equipment should be labeled and preferably

adequate warning of hazardous fume

removed from the workstation. concentrations.

Make sure that flexes, cables, plugs and sockets

are not frayed, kinked, cut, cracked or otherwise

Fibre damaged.

Make sure that electrical equipment and flexes do

See also Dusts.

not come into contact with water.

Used in noise and sound insulation.

Make sure that electrical is protected The fibrous nature of surfaces and cut edges can by the correct rated fuse.

cause skin irritation. This is usually a physical and

Never misuse electrical equipment and never use

not a chemical effect.

equipment that is in any way faulty. The results

could be fatal. Precautions should

be taken to avoid excessive

skin contact through careful organization of work

Make sure that the cables of mobile electrical

practices and the

;se of gloves.

equipment cannot get trapped and damaged, such

as in a vehicle hoist.

-. Fire Make sure that the designated electrical workers

are trained in basic First Aid.

See also Welding, Foams, Legal Aspects.

In cases of electrocution:

Many of the materials found on or associated with

- switch off the power supply before approaching the repair of vehicles are highly flammable. Some

the victim. give

off toxic or harmful fumes if burnt.

- if this is not possible push or drag the victim

Observe strict fire safety when storing and handling

from the source of electricity using dry flammable materials

or solvents, particularly near

non-conductive material. electrical equipment or welding processes.

/

- commence resuscitation if trained to do so.

Make sure, before using electrical or welding 'L '

- SUMMON MEDICAL ASSISTANCE. equipment,

that there is no fire hazard present.

Have a suitable fire extinguisher available when

using welding or heating equipment.

procarmanuals.com

Page 30 of 1226

![FORD FIESTA 2007 Workshop Manual

100-00-1 4 General Information 100-00-1 4

DESCRIPTION AND OPERATION

Marigold Industrial (Blue Nitrile range)]. If gloves

become torn or contaminated on the inside they

should be replaced. Eye FORD FIESTA 2007 Workshop Manual

100-00-1 4 General Information 100-00-1 4

DESCRIPTION AND OPERATION

Marigold Industrial (Blue Nitrile range)]. If gloves

become torn or contaminated on the inside they

should be replaced. Eye](/img/11/56936/w960_56936-29.png)

100-00-1 4 General Information 100-00-1 4

DESCRIPTION AND OPERATION

Marigold Industrial (Blue Nitrile range)]. If gloves

become torn or contaminated on the inside they

should be replaced. Eye protection with safety

glasses is appropriate. Use of an impervious apron

and arm protectors may be necessary if more

extensive exposure is possible. Use of skin barrier

creams suitable for work with mineral oil products

may offer some supplementary protection, but such

barrier creams should not be used in place of

protective clothing.

If accidental skin contact occurs with the fluids,

wash the area thoroughly with soap or skin

cleanser and water.

Accidental eye contact should be dealt with as per

normal first aid practices, by flushing the eyes with

an eye wash or clean cool water for

10 minutes,

after which medical attention should be obtained.

Remove and launder clothing which becomes

contaminated with the fluids. Do not place rags

contaminated with fluid in clothing pockets.

Wash thoroughly

after completing operations where

skin exposure may have occurred.

It is important that personnel do not smoke, eat or

drink whilst handling the fluids or affected

transmissions. These measures are designed to

limit the risk from accidental ingestion.

Label any decanted fluid

properlyluse an equivalent

label to that on original product containers.

Clean up any spills promptly using an inert

absorbent and wash down contaminated surfaces

with detergent and water.

Dispose of any waste fluids safely as hazardous

waste. Do

not employ used engine oils as lubricants or

for any application where appreciable skin contact

is likely to occur.

Environmental Precautions

Burning used engine oil in small space heaters or

boilers can be recommended only for units of

.

approved design. If in doubt check with the

appropriate local authority and manufacturer of

approved appliances.

Dispose of used oil and used oil filters through

authorized waste disposal contractors or licensed

waste disposal sites, or to the waste oil reclamation

trade. If in doubt, contact the relevant local

authority for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down

sewers or drains, or into watercourses.

Noise

Some operations may produce high noise levels,

which could, in time, damage hearing. In these

cases, suitable ear protection must be worn.

Noise Insulation Materials

See Foams, Fibre Insulation.

0-Rings (Fluoroelastomer)

See Viton.

Paints

Safety Data Sheets

See also Solvents, Chemical Materials.

Safety Data Sheets, which detail specific material handling instructions and precautions are available

from the respective national sales company, and

via internet

www.msds.ford .corn.

Used Engine Oil

Prolonged and repeated contact with mineral oil

will result in the removal of natural fats from the

skin, leading to dryness, irritation and dermatitis.

In addition, used engine oil contains potentially

harmful contaminants, which may cause skin

cancer. Adequate means of skin protection and

washing facilities must be provided. Highly flammable, flammable

- observe No

Smoking policy

One Pack

Can contain harmful or toxic pigments, driers and

other components as well as solvents. Spraying

should be carried out only with adequate

ventilation.

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 31 of 1226

General Information

DESCRIPTION AND OPERATION

Two Pack

Can also contain harmful and toxic unreacted

resins and resin hardening agents. The

manufacturers instructions should be followed. See

also Resin-based Adhesives and

Isocyanate

Adhesives and Sealers under Adhesives and

Sealers.

Spraying should preferably be carried out in

exhausted ventilated booths removing vapor and

spray mists from the breathing zone. Individuals

working in booths should wear appropriate

respiratory protection. Those doing small-scale

repair work in the open workshop should wear

air-fed respirators.

Pressurized Equipment

See High Pressure Air, Lubrication and Oil Test

Equipment.

Solder

Solders are mixtures of metals such that the

melting point of the mixture is below that of the

constituent metals (normally lead and tin). Solder

application does not normally give rise to toxic lead

fumes, provided a

gaslair flame is used.

Oxy-acetylene flames should not be used, as they

are much hotter and will cause lead fumes to be

produced.

Some fumes may be produced by the application

of any flame to surfaces coated with grease, and

inhalation of these should be avoided.

Removal of excess solder should be undertaken

with care, to make sure that fine lead dust is not

produced, which can give toxic effects if inhaled.

Respiratory protection may be necessary.

Solder spillage and filings should be collected and

removed promptly to prevent general air

contamination by lead.

High standards of personal hygiene are necessary

in order to avoid ingestion of lead or inhalation of

solder dust from clothing.

Solvents

See also Chemical Materials, Fuels (Kerosene),

Fire.

For example acetone, white spirit, toluene, xylene,

trichloroethane.

2006.0 Fiesta 1212006

Used in cleaning and dewaxing materials, paints,

plastics, resins and thinners.

Some may be highly flammable or flammable.

Skin contact will degrease the skin and may result

in irritation and dermatitis following repeated or

prolonged contact. Some can be absorbed through

the skin in toxic or harmful quantities.

Splashes in the eye may cause severe irritation

and could lead to loss of vision.

Brief exposure of high concentrations of vapors or

mists will cause eye and throat irritation,

drowsiness, dizziness, headaches and, in the worst

circumstances, unconsciousness.

Repeated or prolonged exposure to excessive but

lower concentrations of vapors or mists, for which

there might not be adequate warning indications,

can cause more serious toxic or harmful effects.

Aspiration into the lungs, for example through

vomiting, is the most serious consequence of

swallowing.

Avoid splashes to the skin, eyes and clothing. Wear

protective gloves, goggles and clothing if

necessary.

Make sure there is good ventilation when in use,

avoid breathing fumes, vapors and spray mists and

keep containers tightly sealed. Do not use in

confined spaces.

When spraying materials containing solvents, for

example paints, adhesive, coatings, use extraction

ventilation or personal respiratory protection in the

absence of adequate general ventilation.

Do not apply heat or flame except under specific

and detailed manufacturers instructions.

Sound Insulation

See Fibre Insulation, Foams.

Suspended Loads

A CAUTI0N:Never improvise lifting tackle.

There is always a danger when loads are lifted or

suspended. Never work under an unsupported,

suspended or raised load, for example a

suspended engine.

Always make sure that lifting equipment such as

jacks, hoists, axle stands and slings are adequate

and suitable for the job, in good condition and

regularly maintained.

procarmanuals.com

Page 33 of 1226

100-00-1 7 General Information 100-00-1 7

DESCRIPTION AND OPERATION

The flame is bright, and eye protection should be - used, but the ultra-violet emission is much less

than that from arc welding, and lighter filters may

be used.

The process itself produces few toxic fumes, but

such fumes and gases may be produced from

coatings on the work, particularly during cutting

away of damaged body parts, and inhalation of the

fumes should be avoided.

In brazing, toxic fumes may be produced from the

metals in the brazing rod, and a severe hazard

may arise if brazing rods containing cadmium are

used. In this event particular care must be taken

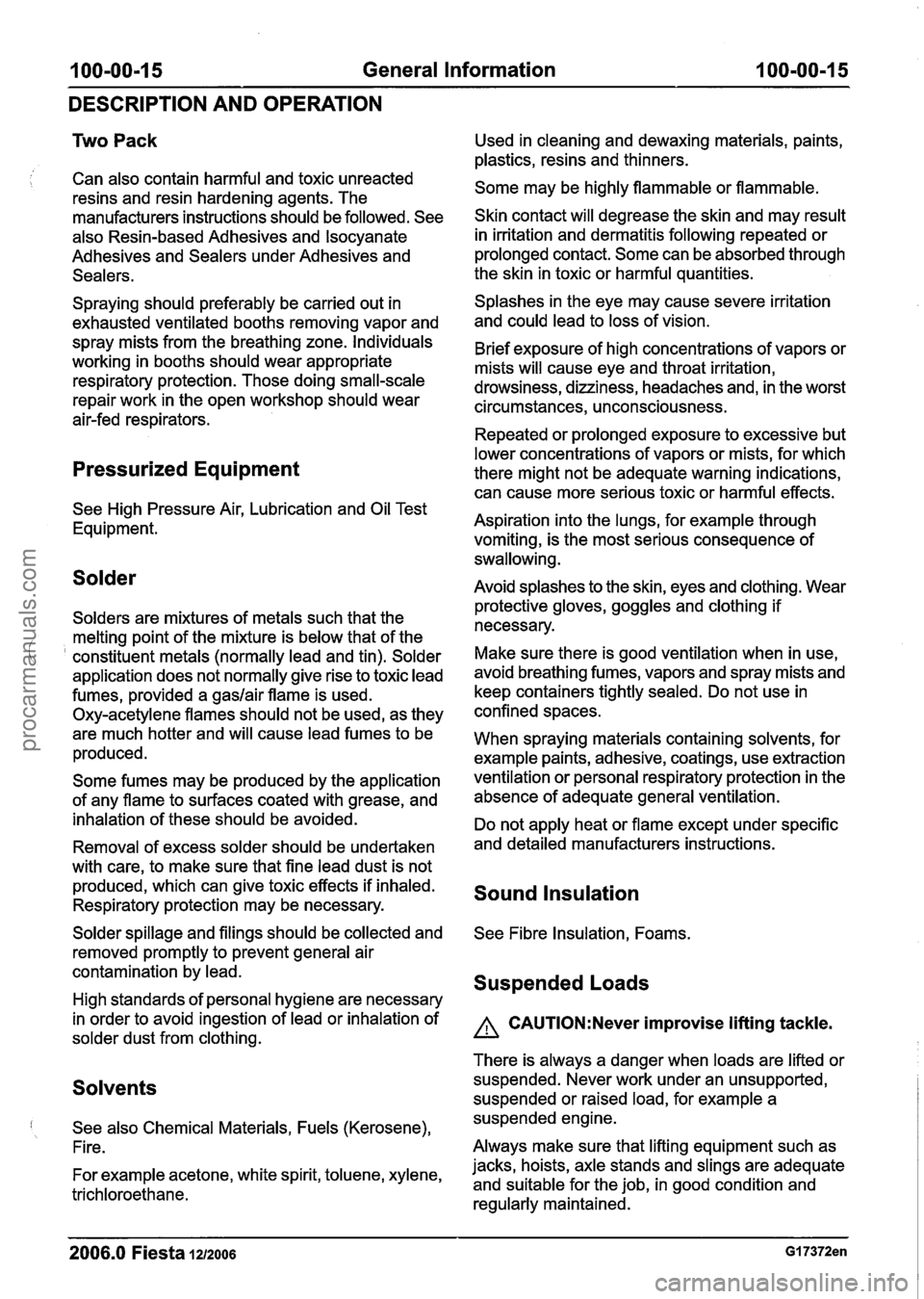

2. Components or assemblies displaying the

to avoid inhalation of fumes and expert advice may

warning triangle with the 'electrified' arrow and

be required. open book symbol

give warning of inherent high

SPECIAL PRECAUTIONS MUST BE TAKEN voltages.

Never touch these with the engine

BEFORE ANY WELDING OR CUTTING TAKES running

or the ignition switched on. See Electric

PLACE ON VESSELS, WHICH HAVE Shock

in this subsection.

CONTAINED COMBUSTIBLE MATERIALS, FOR

EXAMPLE BOILING OR STEAMING OUT OF

FUEL TANKS.

Warning Symbols on Vehicles

( i Decals showing warning symbols will be found on

various vehicle components.

These decals must not be removed. The warnings

are for the attention of

owners/operators and

persons carrying out service or repair operations

on the vehicle.

3. Vehicles and replacement components which

The most commonly found decals are reproduced

contain asbestos are identified by this symbol.

below together with an explanation of the warnings.

See Asbestos in this subsection.

1. Components or assemblies displaying the

caution triangle and open book symbol advise

consultation of the relevant section of the owner

literature before touching or attempting

adjustments of any kind. 4. Components or assemblies displaying this

symbol give warning that the component

contains a corrosive substance. See Acids and

Alkalis in this subsection.

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 39 of 1226

100-00-23 General Information 100-00-23

DESCRIPTION AND OPERATION

RoadIRoller Testing

I Road or roller testing may be carried out for various

reasons and a procedure detailing pre-test checks,

engine starting and stopping, pre-driving checks,

on-test checks and final checks to be completed

on completion of the test is given below.

Unless complete vehicle performance is being

checked, the full road test procedure need not be

carried out. Instead, those items particularly

relevant to the

system(s) being checked can be

extracted.

Pre-Test Checks

A WARNING:lf the brake system hydraulic

fluid level is low, pedal travel is excessive

or a hydraulic leak is found, do not attempt

to road test the vehicle until the reason for

the low fluid level, excessive pedal travel

or hydraulic leak is found and rectified.

It is suggested that pre-test checks and functional

tests of those systems and circuits which affect the

safe and legal operations of the vehicle, such as

( , brakes, lights and steering, should always be

carried out before the road or roller test.

With the ignition switched off, check:

- the engine oil level.

- the engine coolant level.

- the tires, for correct pressure, compatible types

and tread patterns, and wear within limits.

- that there is sufficient fuel in the tank to

complete the test.

- all around the engine, transmission and under

the vehicle for oil, coolant, hydraulic and fuel

leaks. Make a note of any apparent leaks and

wipe off the surrounding areas to make it easier

to identify the extent of the leak on completion

of the test.

Starting the Engine

N0TE:On initial drive away from cold and within

the first 1.5 km (1 mile), do not depress the

accelerator pedal beyond half travel until the

vehicle has attained a minimum speed of

25 kmlh

(15 mileslh). Never operate at high engine speed

or with the accelerator pedal at full travel whilst the

engine is cold.

With the ignition switched off, check:

- that the parking brake is applied.

- that the gear lever is in the neutral position.

- that all instrument gauges (except fuel gauge)

read zero.

With the ignition switched on, check:

- that the ignition controlled warning lamps are

illuminated.

- that the engine temperature gauge registers a reading compatible with the engine temperature.

- that the fuel gauge registers a reading

appropriate to the fuel level in the tank.

- the operation of the parking brake warning lamp

and fluid level warning indicator.

Road or Roller Testing

A CAUTI0N:lf road testing, check the brake

operation while still traveling at low speed

before continuing with the test. If the

brakes pull to one side, or appear to be

otherwise faulty, do not continue with the

road test until the fault has been found and

rectified.

During the road or roller test, check:

- that the clutch pedal operation is not stiff or

heavy.

- that the initial gear engagement is smooth and

there is no evidence of clutch drag.

- that the parking brake control operates smoothly

and releases quickly and completely.

- that the clutch takes up the drive smoothly,

without slip or judder.

- that gear changing is smooth with no abnormal

noises or vibrations from the transmission.

- the engine power output is satisfactory, full

power is achieved, acceleration is smooth and

pedal operation is not stiff or heavy, and engine

speed returns to idle correctly.

- there is no excessive or abnormally colored

smoke from the engine under normal driving,

heavy load or overrun conditions.

- that steering operation, including power steering

(if equipped), is smooth, accurate, not

excessively heavy or with excessive free play

or vibration.

- that the steering does not pull to one side and

self centers smoothly after cornering.

2006.0 Fiesta 1212006 GI 7375en

procarmanuals.com

Page 119 of 1226

204-01 -21 Front Suspension 204-01 -21

REMOVAL AND INSTALLATION

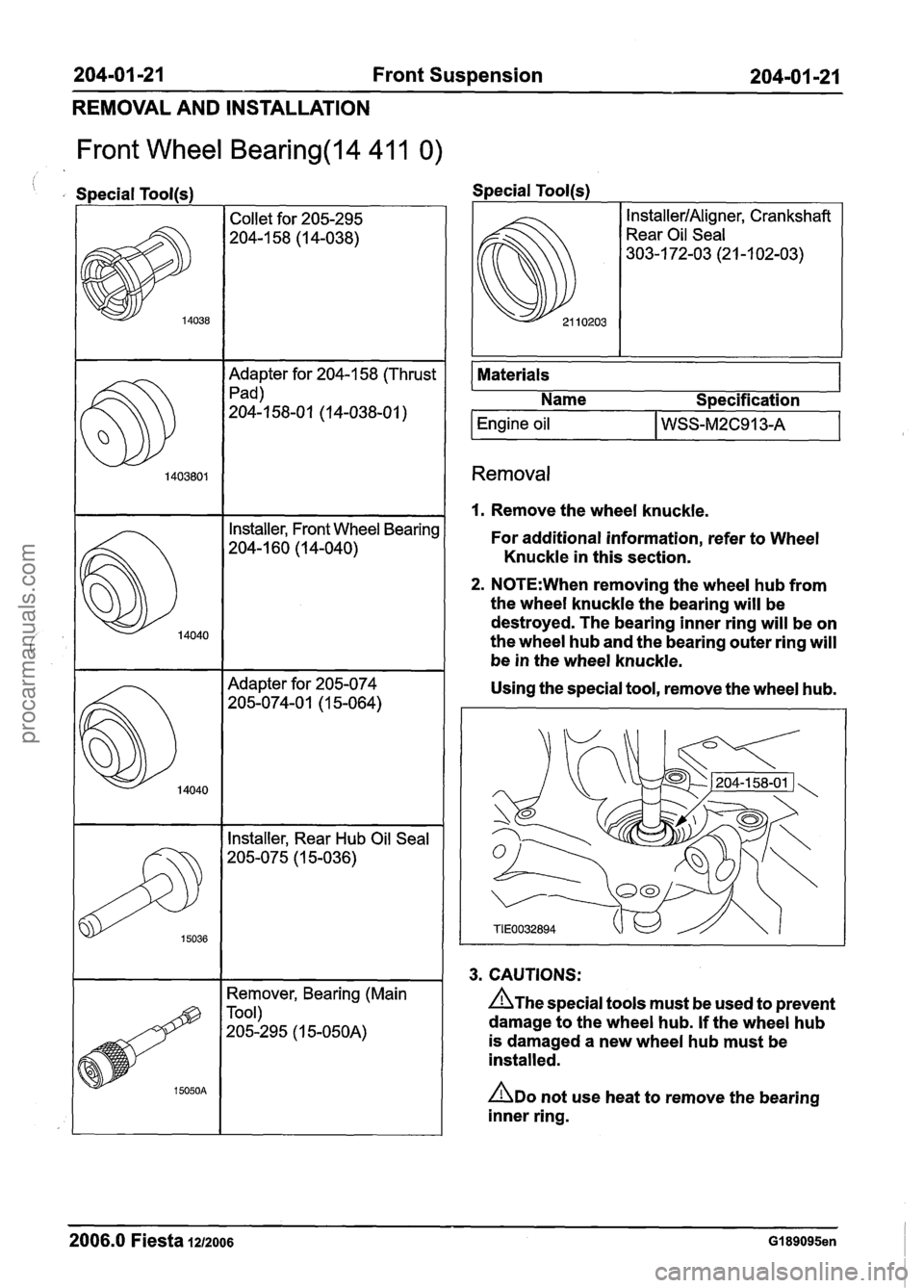

Front Wheel Bearing(l4 41 1 0)

, Special Toolls) Special Tool(s)

Adapter for 204-1 58 (Thrust

Pad)

204-1 58-01 (1 4-038-01

)

Installer, Rear Hub Oil Seal

205-075 (1 5-036)

14040

14040

Remover, Bearing (Main

Tool)

205-295 (1

5-050A)

Installer, Front Wheel Bearing

204-1 60 (1 4-040)

Adapter for 205-074

205-074-0 1 (1 5-064)

I I

Materials 1

@l 0203

I Name I Specification

Engine oil I WSS-M2C913-A

InstallerIAligner, Crankshaft

Rear Oil Seal

303-1 72-03 (2 1 -1 02-03)

Removal

I. Remove the wheel knuckle.

For additional information, refer to Wheel

Knuckle in this section.

2. N0TE:When removing the wheel hub from

the wheel knuckle the bearing will be

destroyed. The bearing inner ring will be on

the wheel hub and the bearing outer ring will

be in the wheel knuckle.

Using the special tool, remove the wheel hub.

3. CAUTIONS:

n~he special tools must be used to prevent

damage to the wheel hub. If the wheel hub

is damaged a new wheel hub must be

installed.

ADO not use heat to remove the bearing

inner ring.

2006.0 Fiesta 1212006 GI 89095en

procarmanuals.com

Page 120 of 1226

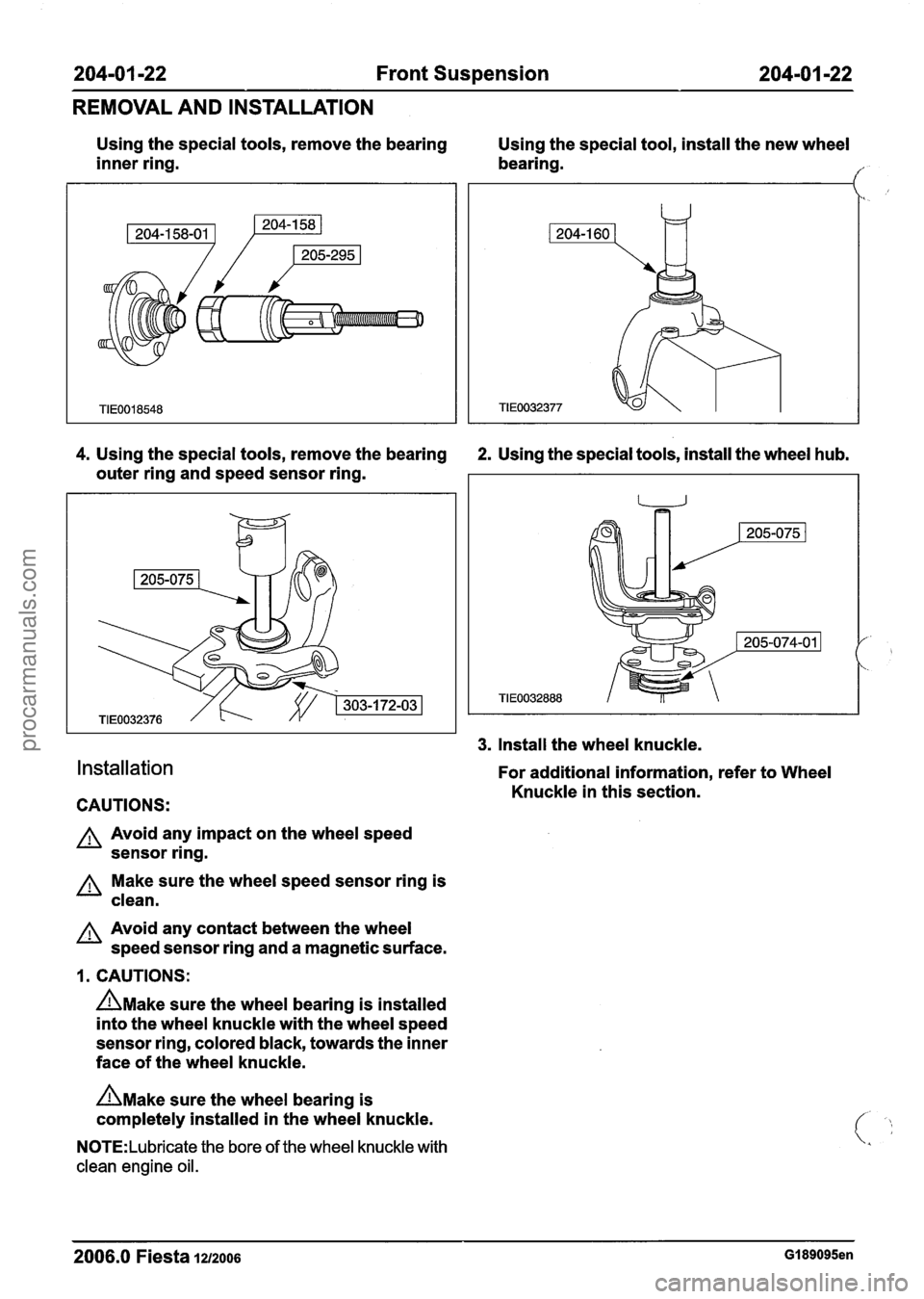

204-01 -22 Front Suspension 204101 122

REMOVAL AND INSTALLATION

Using the special tools, remove the bearing

Using the special tool, install the new wheel

inner ring. bearing.

I"

4. Using the special tools, remove the bearing 2. Using the special tools, install the wheel hub.

outer ring and speed sensor ring.

Installation

CAUTIONS:

A Avoid any impact on the wheel speed

sensor ring.

Make sure the wheel speed sensor ring is

clean.

A Avoid any contact between the wheel

speed sensor ring and a magnetic surface.

1. CAUTIONS:

n~ake sure the wheel bearing is installed

into the wheel knuckle with the wheel speed

sensor ring, colored black, towards the inner

face of the wheel knuckle.

n~ake sure the wheel bearing is

completely installed in the wheel knuckle.

N0TE:Lubricate the bore of the wheel knuckle with

clean engine oil.

3. Install the wheel knuckle.

For additional information, refer to Wheel

Knuckle in this section.

--

2006.0 Fiesta 1212006 GI 89095en

procarmanuals.com

Page 325 of 1226

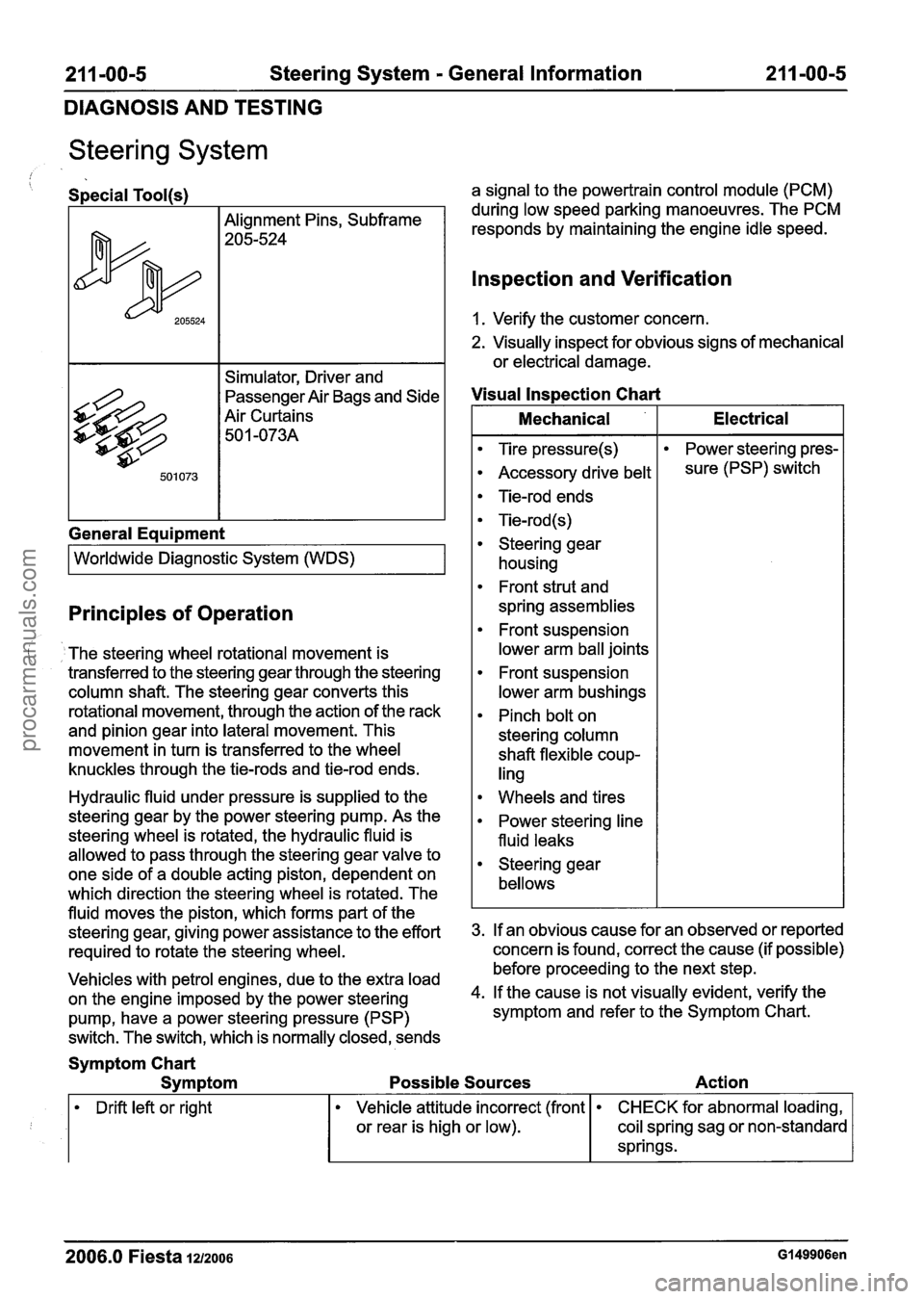

211 -00-5 Steering System - General Information 211 -00-5

DIAGNOSIS AND TESTING

Steering System

/ Special Tool(s)

Alignment Pins, Subframe

205-524

Simulator, Driver and

passenger ~ir Bags and Side

Air Curtains 50

1 -073A

General Eaui~ment

I Worldwide Diagnostic System (WDS) I

Principles of Operation

The steering wheel rotational movement is

transferred to the steering gear through the steering

column shaft. The steering gear converts this

rotational movement, through the action of the rack

and pinion gear into lateral movement. This

movement in turn is transferred to the wheel

knuckles through the tie-rods and tie-rod ends.

Hydraulic fluid under pressure is supplied to the

steering gear by the power steering pump. As the

steering wheel is rotated, the hydraulic fluid is

allowed to pass through the steering gear valve to

one side of a double acting piston, dependent on

which direction the steering wheel is rotated. The

fluid moves the piston, which forms part of the

steering gear, giving power assistance to the effort

required to rotate the steering wheel.

Vehicles with petrol engines, due to the extra load

on the engine imposed by the power steering

pump, have a power steering pressure (PSP)

switch. The switch, which is normally closed, sends a signal

to the powertrain control module (PCM)

during low speed parking manoeuvres. The PCM

responds by maintaining the engine idle speed.

lnspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Visual lnspection Chart

I Mechanical I Electrical I

Tire pressure(s)

Accessory drive belt

Tie-rod ends

Tie-rod (s)

Steering gear housing

Front strut and

spring assemblies

Front suspension

lower arm ball joints

Front suspension

lower arm bushings

Pinch bolt on

steering column

shaft flexible coup-

ling Power

steering pres-

sure (PSP) switch

Wheels and tires

Power steering line

fluid leaks

Steering gear

bellows

3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the

symptom and refer to the Symptom Chart.

Symptom Chart

Symptom Possible Sources Action

Drift left or right

2006.0 Fiesta 1212006 Gl49906en

Vehicle attitude incorrect (front

or rear is high or low). CHECK for abnormal loading,

coil spring sag or non-standard

springs.

procarmanuals.com

Page 423 of 1226

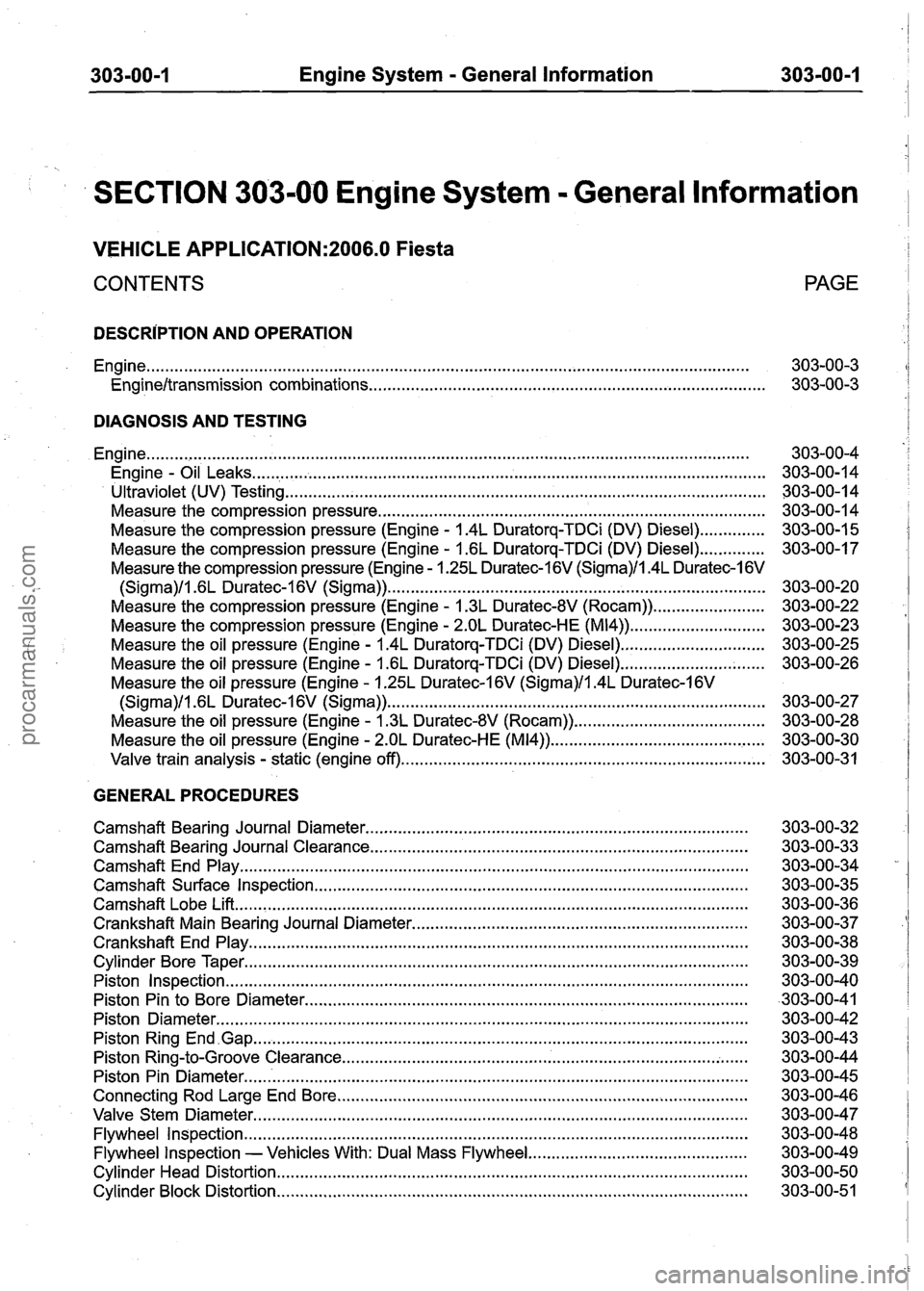

303-00-1 Engine System = General Information 303-00-1

SECTION 303-00 Engine System . General lnformation

VEHICLE APPLICATION:2006.0 Fiesta

CONTENTS PAGE

DESCRIPTION AND

OPERATION

Engine

........................................................................\

......................................................... 303-00-3

Engineltransmission combinations ........................................................................\

........ 303-00-3

DIAGNOSIS AND TESTING

........................................................................\

.......................................................... Engine

. Engine Oil Leaks ........................................................................\

........................................

Ultraviolet (UV) Testing ........................................................................\

...............................

Measure the compression pressure ........................................................................\

...........

.............. Measure the compression pressure (Engine . 1.4L Duratorq-TDCi (DV) Diesel)

Measure the compression pressure (Engine

. 1.6L Duratorq-TDCi (DV) Diesel) ..............

Measure the compression pressure (Engine . 1.25L Duratec-I 6V (Sigma)/l.4L Duratec-I 6V

........................................................................\

......... (Sigma)ll . 6L Duratec-I 6V (Sigma))

Measure the compression pressure (Engine

. 1.3L Duratec-8V (Rocam)) ........................

Measure the compression pressure (Engine . 2.OL Duratec-HE (M14)) .............................

. Measure the oil pressure (Engine 1.4L Duratorq-TDCi (DV) Diesel) ...............................

Measure the oil pressure (Engine . 1.6L Duratorq-TDCi (DV) Diesel) ...............................

Measure the oil pressure (Engine . 1.25L Duratec-1 6V (Sigma)/l.4L Duratec-1 6V

........................................................................\

......... (Sigma)/l . 6L Duratec-1 6V (Sigma))

. Measure the oil pressure (Engine 1.3L Duratec-8V (Rocam)) .........................................

. Measure the oil pressure (Engine 2.OL Duratec-HE (M14)) ...............................................

Valve train analysis . static (engine off) ........................................................................\

......

GENERAL PROCEDURES

Camshaft Bearing Journal Diameter

........................................................................\

..........

Camshaft Bearing Journal Clearance ........................................................................\

.........

Camshaft End Play ........................................................................\

.....................................

Camshaft Surface Inspection ........................................................................\

.....................

........................................................................\

...................................... Camshaft Lobe Lift

Crankshaft Main Bearing Journal Diameter

........................................................................\

Crankshaft End Play ........................................................................\

...................................

Cylinder Bore Taper ........................................................................\

....................................

Piston Inspection ........................................................................\

........................................

Piston Pin to Bore Diameter ........................................................................\

.......................

Piston Diameter ........................................................................\

..........................................

Piston Ring End .Gap ........................................................................\

...................................

............................................ ................................... Piston Ring-to-Groove Clearance ......

Piston Pin Diameter ........................................................................\

.....................................

Connecting Rod Large End Bore ........................................................................\

................

Valve Stem Diameter ........................................................................\

..................................

Flywheel Inspection ........................................................................\

....................................

............................................... Flywheel Inspection - Vehicles With: Dual Mass Flywheel

Cylinder Head Distortion ........................................................................\

.............................

Cylinder Block Distortion ........................................................................\

.............................

procarmanuals.com