weight FORD GRANADA 1985 Service User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 68 of 255

meters and air inlet trunking. Also remove the

oil filler cap, which is connected to the

trunking by a crankcase ventilation hose.

5Release the securing clips and bolts and

remove the upper half of the fan shroud.

6Drain the cooling system and remove the

radiator.

7Disconnect the heater hoses from the

heater matrix and from the coolant outlet.

Unclip the hoses.

8Remove the fan and viscous clutch (where

fitted).

9Disconnect the following wiring:

a)Alternator

b)Temperature gauge sender

c)Engine management temperature sensor

d)Oil pressure switch

e)Idle speed control valve

f)Throttle position sensor

g)Injector nut-harness

h)Distributor multi-plug

i)Distributor-to-coil HT lead

10Disconnect the throttle cable. When

applicable, also disconnect the downshaft

cable or switch.

11Depressurise the fuel system and

disconnect the fuel supply and return lines

(see Chapter 4).

12Remove the steering pump and air

conditioning compressor drivebelts (as

applicable). Unbolt the steering pump and

compressor, move them aside within the limitsof their flexible hoses and support them by

wiring them to adjacent components.

13Remove the distributor cap and rotor.

14Remove the starter motor.

15Drain the engine oil. Unscrew the oil filter

with a strap or chain wrench and remove it; be

prepared for oil spillage.

16On manual gearbox models, disconnect

the clutch cable from the release lever.

17Unbolt the exhaust pipes from the

manifolds.

18On automatic transmission models, unbolt

the torque converter from the driveplate.

19Attach lifting tackle to the engine. If no

lifting eyes are fitted, pass ropes or chains

round the exhaust manifolds.

20Take the weight of the engine, then

remove the single nut on each side which

holds engine bearer to its mountings.

21From under the vehicle unbolt the engine

adapter plate from the bellhousing.

22Remove the engine-to-bellhousing bolts.

Also disconnect or unclip the battery negative

lead, the starter motor lead and the heat

shield.

23Support the transmission, preferably with

a trolley jack.

24Check that nothing has been overlooked,

then raise the engine and draw it forwards

clear of the transmission input shaft. Do not

allow the weight of the engine to hang on the

shaft, and do not lift the transmission by it.25With automatic transmission, make sure

that the torque converter stays engaged with

the oil pump in the transmission as the engine

is withdrawn.

26Lift the engine out of the engine bay and

take it to the bench.

2.4 & 2.9 litre engines

27The removal operations for these engines

are essentially as described for the 2.8 litre

version. Note the following points.

Coolant hoses

28Remove the hoses which run between the

thermostat housing and the water pump, and

the cooling system expansion tank.

29Remove the heater hoses which run

between the thermostat housing or coolant

distribution pipe and oil cooler (where fitted).

Vacuum hoses

30Disconnect the hose from the fuel

pressure regulator.

31Disconnect the hose from the plenum

chamber.

32Disconnect the hose from the throttle valve.

33Disconnect the hose from the T-piece

connector.

V6 engines 2C•7

2C

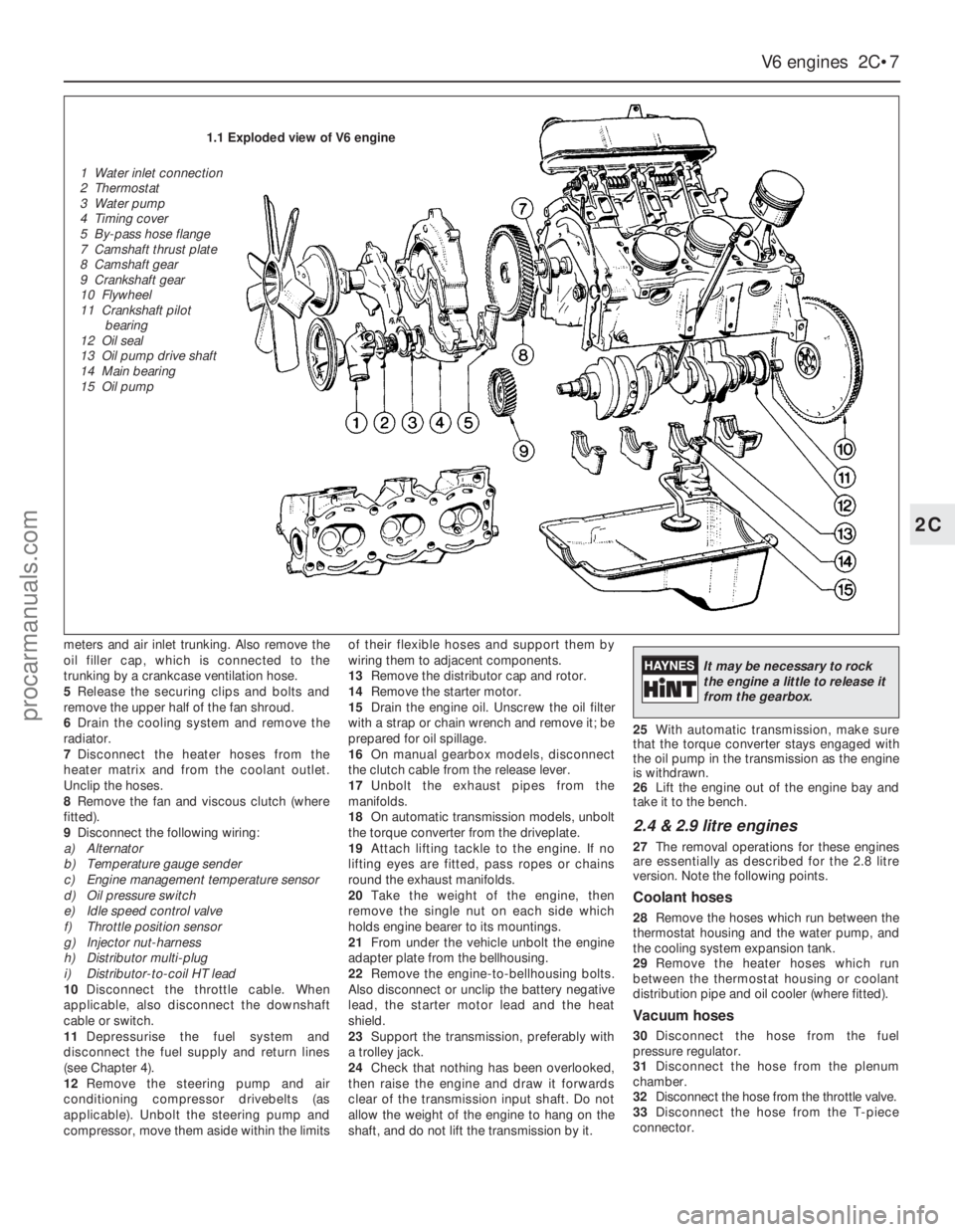

1.1 Exploded view of V6 engine

1 Water inlet connection

2 Thermostat

3 Water pump

4 Timing cover

5 By-pass hose flange

7 Camshaft thrust plate

8 Camshaft gear

9 Crankshaft gear

10 Flywheel

11 Crankshaft pilot

bearing

12 Oil seal

13 Oil pump drive shaft

14 Main bearing

15 Oil pump

It may be necessary to rock

the engine a little to release it

from the gearbox.

procarmanuals.com

Page 71 of 255

4Remove the auxiliary drivebelts.

5Remove the fan and viscous clutch if fitted).

6Jam the crankshaft, either by engaging 5th

gear and applying the handbrake, or by

removing the starter motor and having an

assistant jam a screwdriver in the starter ring

gear teeth. Unbolt the crankshaft pulley. When

the pulley is secured to a vibration damper,

also remove the damper central bolt.

7Remove the pulley or damper, using a puller

if necessary.

8Disconnect the coolant hoses from the front

of the engine, including the water pump

bypass hose.

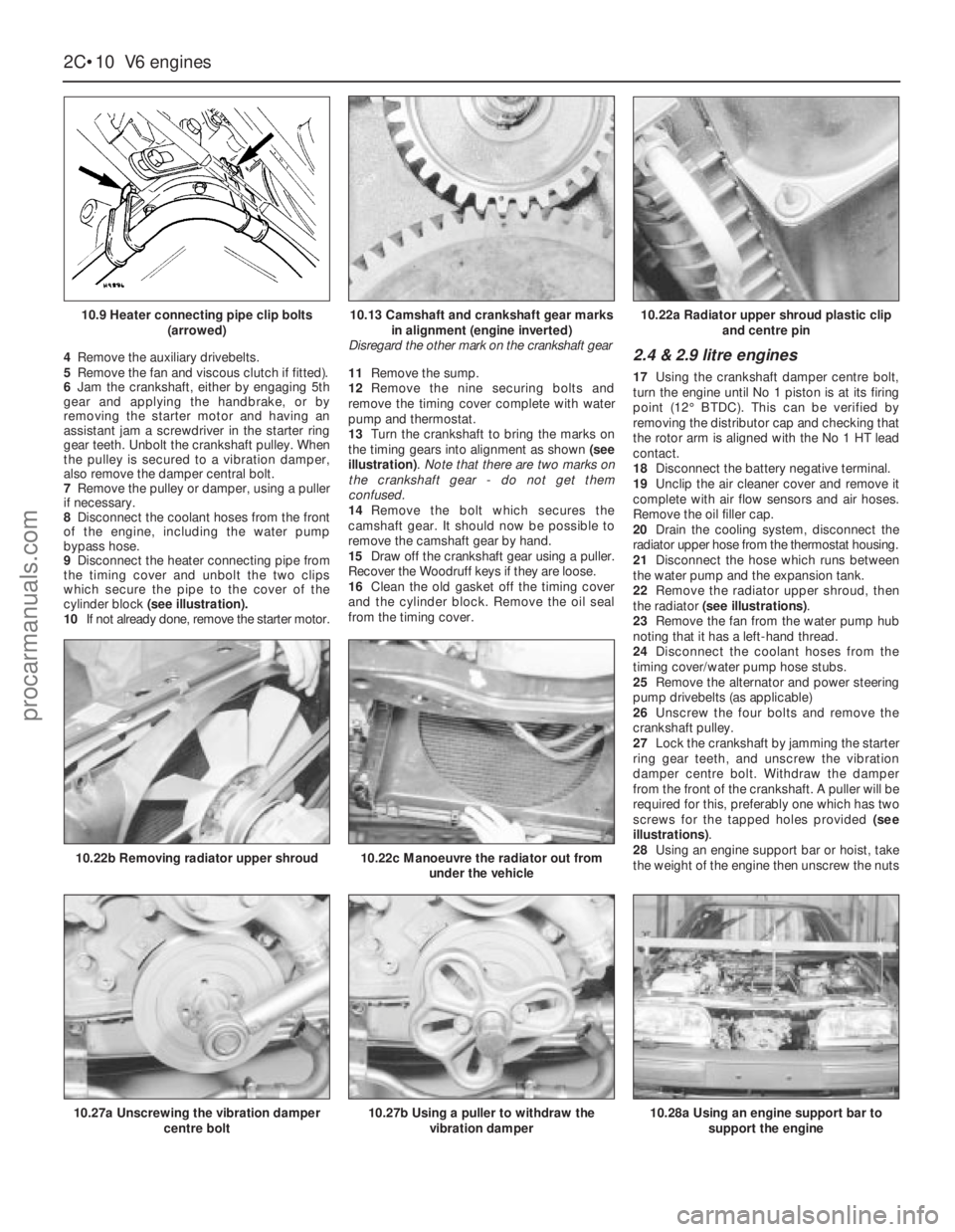

9Disconnect the heater connecting pipe from

the timing cover and unbolt the two clips

which secure the pipe to the cover of the

cylinder block (see illustration).

10If not already done, remove the starter motor.11Remove the sump.

12Remove the nine securing bolts and

remove the timing cover complete with water

pump and thermostat.

13Turn the crankshaft to bring the marks on

the timing gears into alignment as shown (see

illustration). Note that there are two marks on

the crankshaft gear - do not get them

confused.

14Remove the bolt which secures the

camshaft gear. It should now be possible to

remove the camshaft gear by hand.

15Draw off the crankshaft gear using a puller.

Recover the Woodruff keys if they are loose.

16Clean the old gasket off the timing cover

and the cylinder block. Remove the oil seal

from the timing cover.2.4 & 2.9 litre engines

17Using the crankshaft damper centre bolt,

turn the engine until No 1 piston is at its firing

point (12°BTDC). This can be verified by

removing the distributor cap and checking that

the rotor arm is aligned with the No 1 HT lead

contact.

18Disconnect the battery negative terminal.

19Unclip the air cleaner cover and remove it

complete with air flow sensors and air hoses.

Remove the oil filler cap.

20Drain the cooling system, disconnect the

radiator upper hose from the thermostat housing.

21Disconnect the hose which runs between

the water pump and the expansion tank.

22Remove the radiator upper shroud, then

the radiator (see illustrations).

23Remove the fan from the water pump hub

noting that it has a left-hand thread.

24Disconnect the coolant hoses from the

timing cover/water pump hose stubs.

25Remove the alternator and power steering

pump drivebelts (as applicable)

26Unscrew the four bolts and remove the

crankshaft pulley.

27Lock the crankshaft by jamming the starter

ring gear teeth, and unscrew the vibration

damper centre bolt. Withdraw the damper

from the front of the crankshaft. A puller will be

required for this, preferably one which has two

screws for the tapped holes provided (see

illustrations).

28Using an engine support bar or hoist, take

the weight of the engine then unscrew the nuts

2C•10V6 engines

10.9 Heater connecting pipe clip bolts

(arrowed)

10.27a Unscrewing the vibration damper

centre bolt

10.22b Removing radiator upper shroud10.22c Manoeuvre the radiator out from

under the vehicle

10.27b Using a puller to withdraw the

vibration damper10.28a Using an engine support bar to

support the engine

10.13 Camshaft and crankshaft gear marks

in alignment (engine inverted)

Disregard the other mark on the crankshaft gear10.22a Radiator upper shroud plastic clip

and centre pin

procarmanuals.com

Page 97 of 255

The exhaust system fitted in production is

made of aluminised steel, with stainless steel

used in the endplates and baffles of the rear

silencer. Individual sections of the system are

easily renewed in service.

Emission control for the UK market is

achieved largely by the inherent efficiency of

the fuel, ignition and engine management

systems. A welcome spin-off from such

efficiency is remarkably good fuel economy for

a vehicle of such size and weight.

Precautions

Fuel

Many of the procedures in this Chapter

require the removal of fuel lines and

connections which may result in some fuel

spillage. Residual pressure in fuel-injection

systems will remain in the fuel lines long after

the vehicle was last used, therefore extra care

must be taken when disconnecting a fuel line

hose. Loosen any fuel hose slowly to avoid a

sudden release of pressure which may cause

fuel spray. As an added precaution place a rag

over each union as it is disconnected to catch

any fuel which is forcibly expelled. Before

carrying out any operation on the fuel system

refer to the precautions given in “Safety first!”

at the beginning of this Manual and follow

them implicitly. Petrol is a highly dangerous

and volatile liquid and the precautions

necessary when handling it cannot be

overstressed

Tamperproof adjustment screws

Certain adjustment points in the fuel system

(and elsewhere) are protected by tamperproof

caps, plugs or seals. The purpose of such

tamperproofing is to discourage, and to deter,

adjustment by unqualified operators.

In some EU countries (though not yet in the

UK) it is an offence to drive a vehicle with

missing or broken tamperproof seals. Before

disturbing a tamperproof seal, satisfy yourself

that you will not be breaking local or national

anti-pollution regulations by doing so. Fit a

new seal when adjustment is complete when

this is required by law.

Do not break tamperproof seals on a vehicle

which is still under warranty.

Catalytic converter

The catalytic converter is a reliable and

simple device which needs no maintenance in

itself, but there are some facts of which an

owner should be aware if the converter is to

function properly for the full service life.

a)DO NOT use leaded petrol in a car

equipped with a catalytic converter the

lead will coat the precious metals,

reducing their converting efficiency and

will eventually destroy the converter.

b)Always keep the ignition and fuel systems

well-maintained in accordance with the

manufacturer’s schedule - particularly,

ensure that the air cleaner filter element,

the fuel filter and the spark plugs are

renewed at the correct interval - if the inletair/fuel mixture is allowed to become too

rich due to neglect, the unburned surplus

will enter and burn in the catalytic

converter, overheating the element and

eventually destroying the converter.

c)If the engine develops a misfire, do not

drive the car at all (or at least as little as

possible) until the fault is cured - the

misfire will allow unburned fuel to enter

the converter, which will result in

overheating, as noted above.

d)DO NOT push- or tow-start the car - this

will soak the catalytic converter in

unburned fuel, causing it to overheat when

the engine does start - see b) above.

e)DO NOT switch off the ignition at high

engine speeds - if the ignition is switched

off at anything above idle speed,

unburnedfuel will enter the (very hot)

catalytic converter, with the possible risk

of igniting on the element and damaging

the converter.

f)DO NOT use fuel or engine oil additives -

these may contain substances harmful to

the catalytic converter.

g)DO NOT continue to use the car if the

engine burns oil to the extent of leaving a

visible trail of blue smoke - the unburned

carbon deposits will clog the converter

passages and reduce the efficiency; in

severe cases the element will overheat.

h)Remember that the catalytic converter

operates at very high temperatures -

hence the heat shields on the car’s

underbody and the casing will become hot

enough to ignite combustible materials

which brush against it - DO NOT,

therefore, park the car in dry undergrowth,

over long grass or piles of dead leaves.

i)Remember that the catalytic converter is

FRAGILE, do not strike it with tools during

servicing work, take great care when

working on the exhaust system, ensure

that the converter is well clear of any jacks

or other lifting gear used to raise the car

and do not drive the car over rough

ground, road humps, etc, in such a way as

to “ground” the exhaust system.

j)In some cases, particularly when the car is

new and/or is used for stop/start driving, a

sulphurous smell (like that of rotten eggs)may be noticed from the exhaust. This is

common to many catalytic converter-

equipped cars and seems to be due to the

small amount of sulphur found in some

petrols reacting with hydrogen in the

exhaust to produce hydrogen sulphide

(H

2S) gas; while this gas is toxic, it is not

produced in sufficient amounts to be a

problem. Once the car has covered a few

thousand miles the problem should

disappear - in the meanwhile a change of

driving style or of the brand of petrol used

may effect a solution.

k)The catalytic converter, used on a well-

maintained and well-driven car, should

last for between 50 000 and 100 000 miles

- from this point on, careful checks should

be made at all specified service intervals

of the CO level to ensure that the

converter is still operating efficiently - if

the converter is no longer effective it must

be renewed.

See Chapter 1, Section 38.

1On carburettor models only, the air cleaner

can take in both hot and cold air. Hot air is

obtained from a shroud bolted to the exhaust

manifold.

2A flap valve in the air cleaner spout

determines the mix of hot and cold air. The

valve is operated by a vacuum diaphragm.

Vacuum is obtained from the inlet manifold

and is applied via a heat-sensing valve, which

cuts off the vacuum as the temperature of the

incoming air rises. Thus the air cleaner takes in

only hot air on starting from cold, changing

progressively to cold air as the engine warms

up (see illustrations).

3If the system fails, either the engine will take

a long time to warm up (flap stuck in “cold”

position), or it may run roughly and not

develop full power when warm (flap stuck in

“hot” position). Check it as follows.

3Air cleaner temperature control

- description and testing

2Air cleaner and element -

removal and refitting

4•4Fuel and exhaust systems

3.2b Air cleaner heat sensor3.2a Air cleaner vacuum diaphragm unit

procarmanuals.com

Page 150 of 255

6When refitting, screw the track rod end onto

the track rod as far as the locknut, then back it

off half a turn.

7Insert the ball-pin into the steering arm.

Tighten the balljoint nut to the specified torque

and secure with a new split pin. Nip up the

track rod end locknut, but do not tighten it fully

yet.

8Refit the roadwheel, lower the vehicle and

tighten the wheel nuts to the specified torque.

9Check the toe setting as described in the

following Section. (This may not be strictly

necessary if the same track rod end has been

refitted, but is certainly advisable if any

components have been renewed.)

10Tighten the track rod end locknut when

toe is correct.

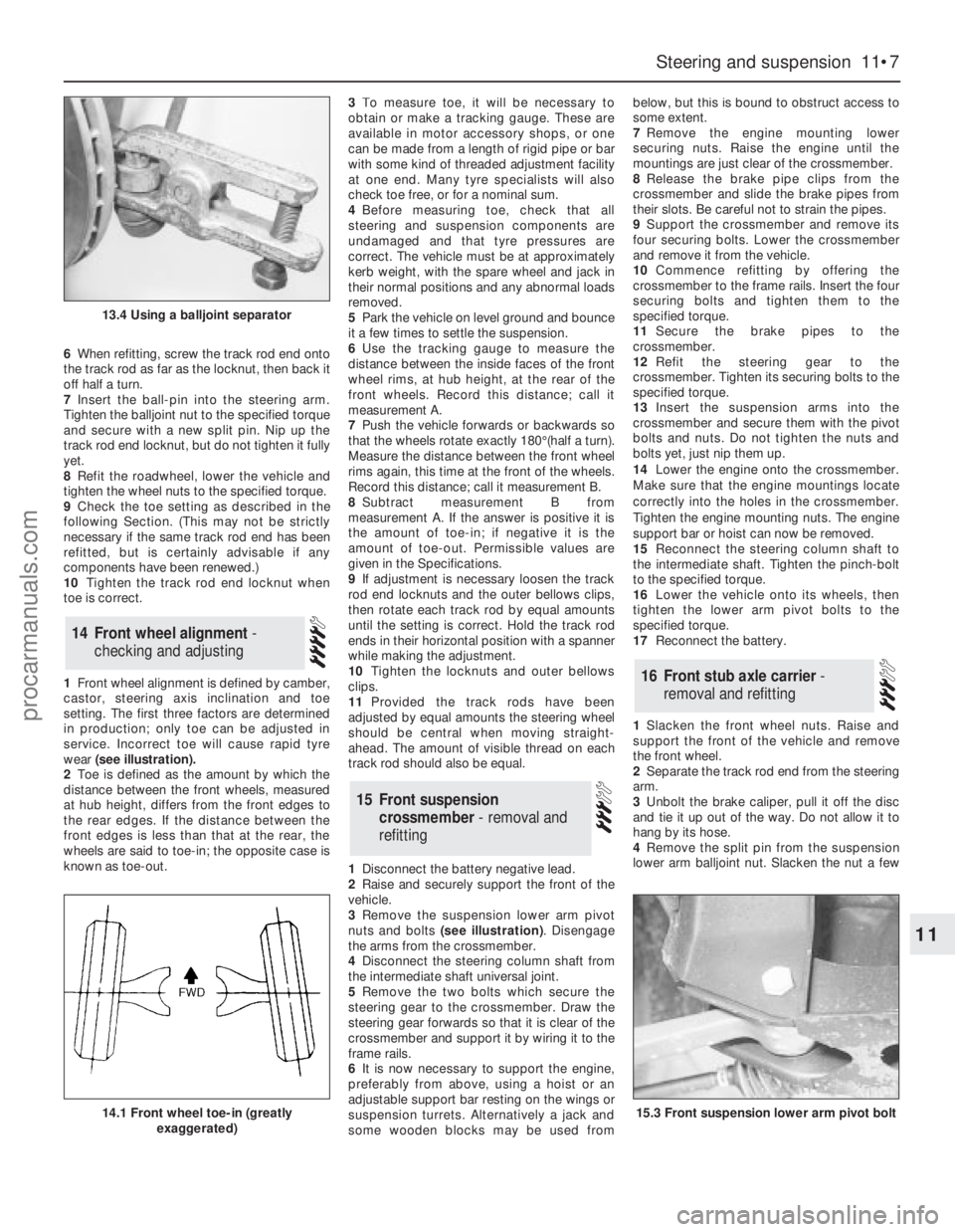

1Front wheel alignment is defined by camber,

castor, steering axis inclination and toe

setting. The first three factors are determined

in production; only toe can be adjusted in

service. Incorrect toe will cause rapid tyre

wear (see illustration).

2Toe is defined as the amount by which the

distance between the front wheels, measured

at hub height, differs from the front edges to

the rear edges. If the distance between the

front edges is less than that at the rear, the

wheels are said to toe-in; the opposite case is

known as toe-out.3To measure toe, it will be necessary to

obtain or make a tracking gauge. These are

available in motor accessory shops, or one

can be made from a length of rigid pipe or bar

with some kind of threaded adjustment facility

at one end. Many tyre specialists will also

check toe free, or for a nominal sum.

4Before measuring toe, check that all

steering and suspension components are

undamaged and that tyre pressures are

correct. The vehicle must be at approximately

kerb weight, with the spare wheel and jack in

their normal positions and any abnormal loads

removed.

5Park the vehicle on level ground and bounce

it a few times to settle the suspension.

6Use the tracking gauge to measure the

distance between the inside faces of the front

wheel rims, at hub height, at the rear of the

front wheels. Record this distance; call it

measurement A.

7Push the vehicle forwards or backwards so

that the wheels rotate exactly 180°(half a turn).

Measure the distance between the front wheel

rims again, this time at the front of the wheels.

Record this distance; call it measurement B.

8Subtract measurement B from

measurement A. If the answer is positive it is

the amount of toe-in; if negative it is the

amount of toe-out. Permissible values are

given in the Specifications.

9If adjustment is necessary loosen the track

rod end locknuts and the outer bellows clips,

then rotate each track rod by equal amounts

until the setting is correct. Hold the track rod

ends in their horizontal position with a spanner

while making the adjustment.

10Tighten the locknuts and outer bellows

clips.

11Provided the track rods have been

adjusted by equal amounts the steering wheel

should be central when moving straight-

ahead. The amount of visible thread on each

track rod should also be equal.

1Disconnect the battery negative lead.

2Raise and securely support the front of the

vehicle.

3Remove the suspension lower arm pivot

nuts and bolts (see illustration). Disengage

the arms from the crossmember.

4Disconnect the steering column shaft from

the intermediate shaft universal joint.

5Remove the two bolts which secure the

steering gear to the crossmember. Draw the

steering gear forwards so that it is clear of the

crossmember and support it by wiring it to the

frame rails.

6It is now necessary to support the engine,

preferably from above, using a hoist or an

adjustable support bar resting on the wings or

suspension turrets. Alternatively a jack and

some wooden blocks may be used frombelow, but this is bound to obstruct access to

some extent.

7Remove the engine mounting lower

securing nuts. Raise the engine until the

mountings are just clear of the crossmember.

8Release the brake pipe clips from the

crossmember and slide the brake pipes from

their slots. Be careful not to strain the pipes.

9Support the crossmember and remove its

four securing bolts. Lower the crossmember

and remove it from the vehicle.

10Commence refitting by offering the

crossmember to the frame rails. Insert the four

securing bolts and tighten them to the

specified torque.

11Secure the brake pipes to the

crossmember.

12Refit the steering gear to the

crossmember. Tighten its securing bolts to the

specified torque.

13Insert the suspension arms into the

crossmember and secure them with the pivot

bolts and nuts. Do not tighten the nuts and

bolts yet, just nip them up.

14Lower the engine onto the crossmember.

Make sure that the engine mountings locate

correctly into the holes in the crossmember.

Tighten the engine mounting nuts. The engine

support bar or hoist can now be removed.

15Reconnect the steering column shaft to

the intermediate shaft. Tighten the pinch-bolt

to the specified torque.

16Lower the vehicle onto its wheels, then

tighten the lower arm pivot bolts to the

specified torque.

17Reconnect the battery.

1Slacken the front wheel nuts. Raise and

support the front of the vehicle and remove

the front wheel.

2Separate the track rod end from the steering

arm.

3Unbolt the brake caliper, pull it off the disc

and tie it up out of the way. Do not allow it to

hang by its hose.

4Remove the split pin from the suspension

lower arm balljoint nut. Slacken the nut a few

16Front stub axle carrier -

removal and refitting

15Front suspension

crossmember - removal and

refitting

14Front wheel alignment -

checking and adjusting

Steering and suspension 11•7

11

13.4 Using a balljoint separator

14.1 Front wheel toe-in (greatly

exaggerated)15.3 Front suspension lower arm pivot bolt

procarmanuals.com

Page 152 of 255

1Raise the vehicle on ramps or on a hoist, so

that the weight is still on the wheels.

2Remove the lower arm pivot nut and bolt

(see illustration).

3Remove the anti-roll bar end nut, dished

washer and plastic cover. Note which way

round these components are fitted.

4Now raise and support the vehicle so that

the front wheels are off the ground.

5Remove the split pin from the lower arm

balljoint nut. Back off the nut a few turns,

break the taper with a balljoint separator, then

remove the nut and free the balljoint from the

stub axle carrier.

6Pull the lower arm off the anti-roll bar and

remove it.

7If the balljoint is defective, the whole arm

must be renewed. The dust boot can be

renewed separately if required.

8The anti-roll bar bushes (compliance

bushes) can be removed by cutting off their

flanges with a chisel, then pressing or tapping

out the remains. Fit new bushes by tapping

them home with a tube or socket.

9The pivot bush can be pressed out using a

bench vice and a couple of large sockets or

suitable pieces of tube. The new pivot bush

should be lubricated with soap or glycerine

(notoil or grease) before being fitted in a

similar fashion. Do not keep the new bush

compressed in the tube for longer than

necessary, in case it becomes permanently

distorted.

10Commence refitting by offering the arm to

the anti-roll bar. Make sure that the shallow

dished washer and the plastic cover are fitted

on the inboard side of the bar (furthest from

the nut).

11Refit the balljoint to the stub axle carrier.

Tighten the castellated nut to the specified

torque and secure it with a new split pin.

12Fit the pivot end of the arm into the

crossmember and secure it with the pivot nut

and bolt. Jacking the vehicle up or down to

vary the loading on the wheels may help to get

the holes lined up. Do not tighten the pivot nut

and bolt yet.

13Lower the vehicle back onto its wheels.14Fit the deep dished washer and the plastic

cover over the end of the anti-roll bar. Fit the

nut and tighten it to the specified torque.

15Tighten the lower arm pivot nut and bolt to

the specified torque.

1Raise the vehicle on ramps or a hoist, so

that the weight is still on the wheels.

2Unbolt the two anti-roll bar clamps (see

illustration).

3Now raise and support the vehicle with the

wheels free.

4Remove the two nuts which hold the ends

of the anti-roll bar to the lower arms. Recover

the plastic covers and deep dished washers.

5Remove one lower arm pivot nut and bolt.

Prise the lower arm out of the crossmember

and work the anti-roll bar free from it.

6Pull the anti-roll bar out of the other lower

arm and remove it. Recover the other

compliance bush covers and washers.

7Refit by reversing the removal operations,

but do not finally tighten any fastenings until

the weight of the vehicle is back on the

wheels. Tighten in the following order:

a)Anti-roll bar clamps

b)Anti-roll bar-to lower arm nuts

c)Lower arm pivot nut and bolt

8Make sure that the anti-roll bar clamp

bushes are not twisted on completion.

Compliance bushes

1These are described in Section 18. It is not

strictly necessary to remove the lower arms to

renew these bushes, though obviously access

is not good with the arms installed.

Clamp bushes

2Although it is possible to remove and refit

the clamp bushes without removing the anti-

roll bar, since the bushes are split, this is not

recommended by the makers.

3Remove the anti-roll bar as described in the

previous Section.4Slide the clamp bushes off the anti-roll bar,

if necessary prising them open a little first.

5Lubricate the new bushes with glycerine or

soap and slide them into position with the split

facing forwards.

6Refit the anti-roll bar.

1Slacken the front wheel nuts, raise and

support the vehicle and remove the front

wheel.

2Disconnect the battery negative lead.

3Unbolt the brake caliper and suspend it

nearby so that the flexible hose is not strained.

4Remove the ABS sensor from the stub axle

carrier.

5Separate the track rod end and suspension

lower arm balljoints from the stub axle carrier.

6Unclip the ABS/brake pad wear wiring from

the strut.

7Remove the dust cover from the top of the

strut.

8Have an assistant support the strut.

Remove the three nuts which secure the strut

to the turret (see illustration).Do notundo

the centre nut.

9Lower the strut out of the turret and remove

it.

10Refit by reversing the removal operations.

Do not fully tighten the strut-to-turret nuts until

the weight of the vehicle is back on its wheels.

21Front suspension strut -

removal and refitting

20Front anti-roll bar bushes -

renewal

19Front anti-roll bar - removal

and refitting

18Front suspension lower arm -

removal, overhaul and refitting

Steering and suspension 11•9

11

19.2 A front anti-roll bar clamp

21.8 Two of the three nuts (arrowed)

securing the suspension strut to the turret

18.2 Front suspension lower arm components

A Anti-roll bar

B Rear dished washer and cover

C Bushes

D Balljoint

E Front dished washer and cover

F Locknut

G Pivot bush

procarmanuals.com

Page 155 of 255

7Unbolt the guide plate from the body on the

side concerned.

8Carefully lower the jack until the spring is no

longer under tension. Remove the spring and

the rubber buffer.

9Refit by reversing the removal operations,

tightening all fastenings to the specified torque

when known.

Note: Ford tool No 15-014, or locally made

equivalent, will be required for this job.

1Raise and support the rear of the vehicle.

2Flatten the lockwasher which secures the

guide plate centre bolt. Remove the centre

bolt and the two bolts which hold the guide

plate to the floor; remove the guide plate.

3Wedge a piece of wood between the

crossmember and the floor.

4Draw the insulator out with the special tool

(see illustration).

5Smear the new insulator with glycerine or

liquid soap, then press it in as follows.

6Use the special tool spindle or other long

M12 bolt. Screw a nut up to the bolt head,

then fit a plain washer and the insulator onto

the bolt. Pass the bolt through the hole in the

crossmember and screw it into the floor, then

press the insulator home by winding the nut

and washer up the bolt.

7Remove the installation tool and the wood.

8Refit the guide plate, tightening the bolts to

the specified torque. Secure the centre bolt

with the lockwasher.

9Lower the vehicle.

1Remove the rear hub.

2Disconnect both rear brake flexible hoses

from the brake pipes. Free the brake pipes

from the brackets on the lower arms.

3Unclip the handbrake cable from the lower

arm.

4Remove the rear spring.

5Remove the lower arm-to-crossmember

bolts. Withdraw the lower arm.6Renew the rubber bushes if wished, using

lengths of tube or sockets and a vice, or large

nuts and bolts. Lubricate the new bushes with

glycerine or liquid soap.

7Refit by reversing the removal operations,

tightening the lower arm-to-crossmember

bolts with the weight of the vehicle back on its

wheels. Bleed the brake hydraulic system on

completion.

1Raise and support the rear of the vehicle.

2Separate the anti-roll bar from the link rods

on each side by prising them free (see

illustration).

3Unbolt the two anti-roll bar brackets.

Remove the bar, brackets and bushes (see

illustration).

4Refit by reversing the removal operations.

Tighten the bracket bolts to the specified

torque.

1Working inside the vehicle, remove the

luggage area side trim to gain access to the

shock absorber top mounting.

2Raise and support the rear of the vehicle.

Raise a jack under the rear suspension lower

arm to take the load off the shock absorber.3On models with ride height control,

disconnect the air line from the shock

absorber.

4Unbolt the shock absorber top mounting

(see illustration).

5Unbolt the shock absorber lower mounting

(see illustration). Pull the shock absorber out

of the lower mounting bracket and remove it.

6Refit by reversing the removal operations.

Tighten the shock absorber mountings to the

specified torque. On models with ride height

control, use new O-rings on the air line union.

The ride height control system is an optional

extra, designed to keep the rear suspension

height constant regardless of vehicle load.

This is obviously useful if heavy loads are often

carried, or if the vehicle is used for towing.

The main components of the system are a

height sensor, a compressor and two special

rear shock absorbers. The compressor

supplies air to the shock absorbers, so

“pumping up” the rear suspension, when so

commanded by the height sensor. Other

components include the connecting pipes,

electrical wiring and a compressor relay. The

relay is mounted behind the glovebox.

Variations in vehicle height are not

recognised by the system for approximately

20 seconds, in order to prevent responses to

temporary changes such as those induced by

32Ride height control system -

general information

31Rear shock absorber -

removal and refitting

30Rear anti-roll bar - removal

and refitting

29Rear suspension lower arm -

removal and refitting

28Rear crossmember insulator

- removal and refitting

11•12Steering and suspension

28.4 Drawing out an insulator with the

special tool

31.4 Undoing a rear shock absorber top

mounting31.5 Undoing a rear shock absorber lower

mounting

30.2 Rear anti-roll bar link rod30.3 A rear anti-roll bar bracket - bolt

arrowed

procarmanuals.com

Page 158 of 255

Chapter 12

Bodywork and fittings

Bonnet - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Bonnet insulation panel - removal and refitting . . . . . . . . . . . . . . . .26

Bonnet release cable - removal and refitting . . . . . . . . . . . . . . . . . .11

Boot lid lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . . .18

Boot lid - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . .9

Bumper mouldings - removal and refitting . . . . . . . . . . . . . . . . . . . .36

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .42

Door - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Door exterior handle - removal and refitting . . . . . . . . . . . . . . . . . .13

Door interior trim panel - removal and refitting . . . . . . . . . . . . . . . .22

Door latch assembly - removal and refitting . . . . . . . . . . . . . . . . . .15

Door lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . . . . .14

Door striker plate - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Door weatherstrip - removal and refitting . . . . . . . . . . . . . . . . . . . .16

Door window frame mouldings - removal and refitting . . . . . . . . . .31

Door window glass - removal and refitting . . . . . . . . . . . . . . . . . . . .23

Door window regulator mechanism - removal and refitting . . . . . . .24

Exterior mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .39

Facia panels and trim - removal and refitting . . . . . . . . . . . . . . . . . .41

Front bumper - height adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .34

Front seat - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Front seat air cushion - removal and refitting . . . . . . . . . . . . . . . . .45

Front seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . .47

Front spoiler - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .37Fuel filler lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . .21

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Headlining - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .38

Interior mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .40

Maintenance - bodywork and underframe . . . . . . . . . . . . . . . . . . . . .2

Maintenance - upholstery and carpets . . . . . . . . . . . . . . . . . . . . . . . .3

Major body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Minor body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Motifs and emblems - removal and refitting . . . . . . . . . . . . . . . . . .33

Overhead console - removal and refitting . . . . . . . . . . . . . . . . . . . .43

Radiator grille - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .27

Rear parcel shelf - removal and refitting . . . . . . . . . . . . . . . . . . . . .50

Rear quarter window moulding - removal and refitting . . . . . . . . . .32

Rear seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .48

Rear seat components - removal and refitting . . . . . . . . . . . . . . . . .49

Seat belts - care and maintenance . . . . . . . . . . . . . . . . . . . . . . . . .46

Side mouldings - removal and refitting . . . . . . . . . . . . . . . . . . . . . .28

Sliding roof - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .10

Tailgate - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Tailgate latch assembly - removal and refitting . . . . . . . . . . . . . . . .19

Tailgate lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . . .17

Tailgate strut - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .20

Tailgate window mouldings - removal and refitting . . . . . . . . . . . . .30

Windscreen and fixed glass - removal and refitting . . . . . . . . . . . . .25

Windscreen mouldings - removal and refitting . . . . . . . . . . . . . . . .29

Torque wrench settingsNm lbf ft

Front seat belt buckle to seat frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 to 64 38 to 47

Seat belt retractor bolts (front and rear) . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 45 18 to 33

Other seat belt anchorages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 45 18 to 33

Rear seat back hinge to body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 to 25 16 to 18

Rear seat back latch striker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 to 60 30 to 44

Front seat retaining bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 32 18 to 24

Front seat frame-to-slide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 32 18 to 24

Rear bumper mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 16

Front bumper adjuster lockbolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 16

12•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

12

The bodyshell and floorpan are of pressed

steel, and form an integral part of the vehicle’s

structure. Various reinforcing and mounting

components beneath the floorpan are made of

HSLA (High Strength Low Alloy) and REPHOS

(rephosphorised) steels, which have superiorstrength-to-weight characteristics when

compared with conventional steels.

Extensive use is made of plastic for

peripheral components such as the radiator

grille, bumpers and wheel trims, and for much

of the interior trim.

Interior fittings are to the high standard

expected in a vehicle of this class, with even

the basic level models well equipped. A wide

range of options is available, including air

conditioning and leather upholstery.The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy, but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

2 Maintenance - bodywork and

underframe1 General information

procarmanuals.com

Page 244 of 255

Transmission fluid brown, or has burned smell

m m

Transmission fluid level low, or fluid in need of renewal (Chapter 1).

General gear selection problems

m m

The most likely cause of gear selection problems is a faulty or

poorly-adjusted gear selector mechanism. The following are common

problems associated with a faulty selector mechanism:

a)Engine starting in gears other than Park or Neutral.

b)Indicator on gear selector lever pointing to a gear other than

the one actually being used.

c)Vehicle moves when in Park or Neutral.

d)Poor gear shift quality, or erratic gear changes.

m

mRefer any problems to a Ford dealer, or an automatic transmission

specialist.

Transmission will not downshift (kickdown) with

accelerator pedal fully depressed

m m

Low transmission fluid level (Chapter 1).

m

mIncorrect selector adjustment (Chapter 7B).

Engine will not start in any gear, or starts in gears

other than Park or Neutral

m m

Faulty starter inhibitor switch (Chapter 7B).

m

mIncorrect selector adjustment (Chapter 7B).

Transmission slips, shifts roughly, is noisy, or has no

drive in forward or reverse gears

m m

There are many probable causes for the above problems, but the

home mechanic should be concerned with only one possibility - fluid

level. Before taking the vehicle to a dealer or transmission specialist,

check the fluid level and condition of the fluid as described in Chapter 1.

Correct the fluid level as necessary, or change the fluid and filter if

needed. If the problem persists, professional help will be necessary.

REF•9Fault Finding

7Propeller shaft

Clunking or knocking noise when taking up drive

m m

Worn universal joints (Chapter 8).m

mLoose flange bolt (Chapter 8).

Vibration when accelerating or decelerating

m m

Worn centre bearing or universal joints (Chapter 8).m

mBent or distorted shaft (Chapter 8).m

mDeteriorated rubber insulator on centre bearing ( Chapter 8)

8Final drive and driveshafts

Excessive final drive noise

m m

Oil level low, or incorrect grade (Chapter 1)m

mWorn bearings (Chapter 9)m

mWorn or badly adjusted crownwheel and pinion (Chapter 9)m

mLoose or deteriorated final drive mountings (Chapter 9)

Oil leakage from final drive

m m

Pinion or output flange oil seal leaking (Chapter 9)

m

mRear cover leaking (Chapter 9)

m

mCover or casing cracked (Chapter 9)

Grating, knocking or vibration from driveshafts

m m

Flange screws loose (Chapter 9)

m

mCV joints worn (Chapter 9)

m

mDriveshaft bent (Chapter 9)

9Braking system

Note:Make sure that the tyres are in good condition and correctly

inflated, that the front wheel alignment is correct, and that the vehicle is

not loaded with weight in an unequal manner. Apart from checking the

condition of all pipe and hose connections, any faults occurring on the

anti-lock braking system should be referred to a Ford dealer for diagnosis.

Vehicle pulls to one side under braking

m m

Worn, defective, damaged or contaminated front or rear brake

pads on one side (Chapters 1 and 10).

m mSeized or partially-seized front or rear brake caliper piston (Chapter 10).m

mA mixture of brake pad lining materials fitted between sides

(Chapter 10).

m mBrake caliper mounting bolts loose (Chapter 10).m

mWorn or damaged steering or suspension components (Chapters 1

and 11).

Noise (grinding or high-pitched squeal) when brakes

applied

m m

Brake pad friction material worn down to metal backing (Chapters 1

and 10).

m mExcessive corrosion of brake disc - may be apparent after the

vehicle has been standing for some time (Chapters 1 and 10).

Excessive brake pedal travel

m m

Faulty master cylinder (Chapter 10).

m

mAir in hydraulic system (Chapter 10).

m

mFaulty vacuum servo unit (Chapter 10).

Brake pedal feels spongy when depressed

m m

Air in hydraulic system (Chapter 10).

m

mDeteriorated flexible rubber brake hoses (Chapters 1 and 10).

m

mMaster cylinder mountings loose (Chapter 10).

m

mFaulty master cylinder (Chapter 10).

Excessive brake pedal effort required to stop vehicle

m m

Faulty vacuum servo unit (Chapter 10).

m

mDisconnected, damaged or insecure brake servo vacuum hose

(Chapters 1 and 10).

m mPrimary or secondary hydraulic circuit failure (Chapter 10).

m

mSeized brake caliper piston(s) (Chapter 10).

m

mBrake pads incorrectly fitted (Chapter 10).

m

mIncorrect grade of brake pads fitted (Chapter 10).

m

mBrake pads contaminated (Chapter 10).

procarmanuals.com

Page 249 of 255

REF•14Glossary of Technical Terms

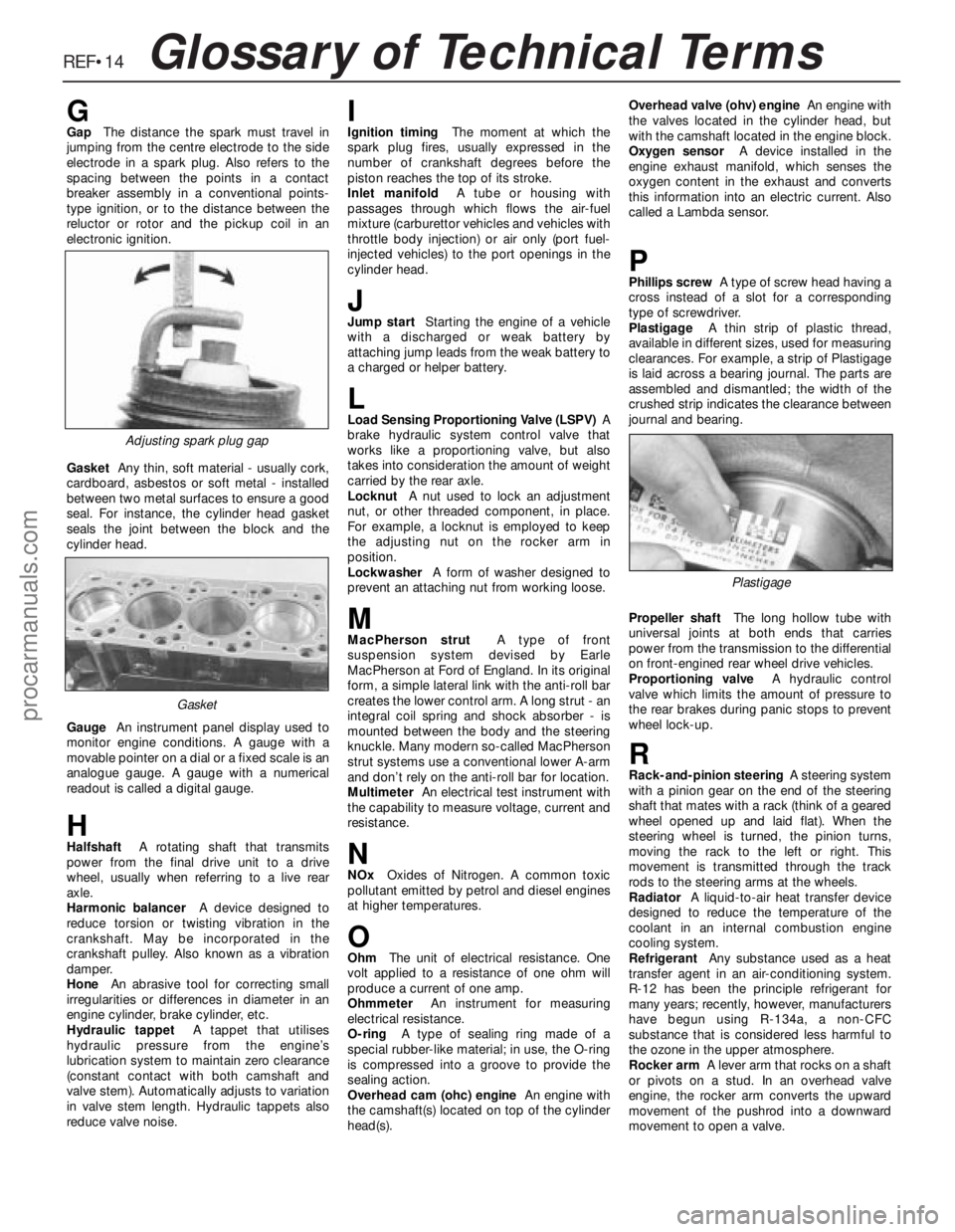

GGapThe distance the spark must travel in

jumping from the centre electrode to the side

electrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.

Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful to

the ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

Adjusting spark plug gap

Plastigage

Gasket

procarmanuals.com

Page 251 of 255

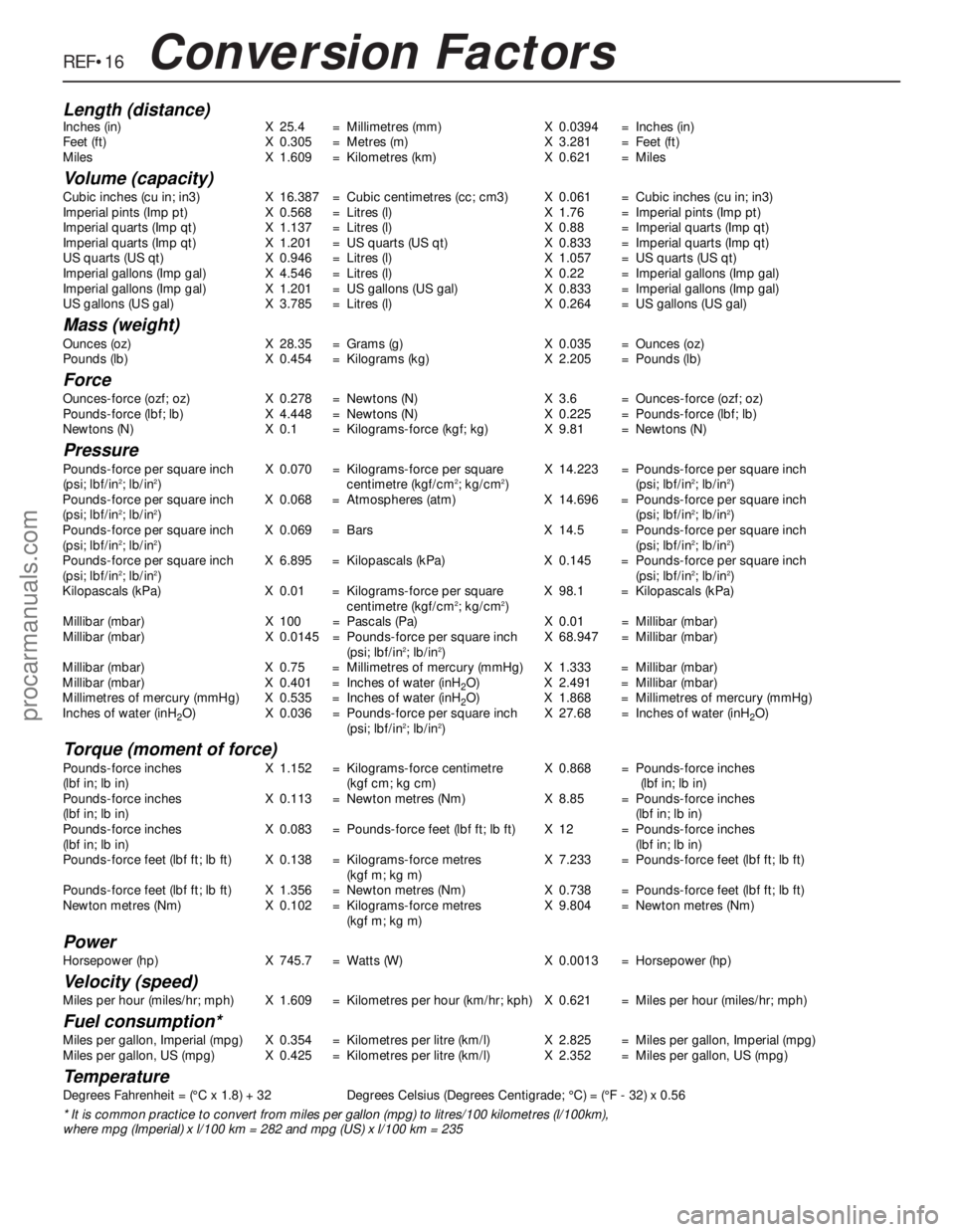

REF•16

Length (distance)Inches (in)X25.4=Millimetres (mm)X0.0394=Inches (in)

Feet (ft)X0.305=Metres (m)X3.281=Feet (ft)

MilesX1.609=Kilometres (km)X0.621=Miles

Volume (capacity)

Cubic inches (cu in; in3)X16.387=Cubic centimetres (cc; cm3)X0.061=Cubic inches (cu in; in3)

Imperial pints (Imp pt)X0.568=Litres (l)X1.76=Imperial pints (Imp pt)

Imperial quarts (Imp qt)X1.137=Litres (l)X0.88=Imperial quarts (Imp qt)

Imperial quarts (Imp qt)X1.201=US quarts (US qt)X0.833=Imperial quarts (Imp qt)

US quarts (US qt)X0.946=Litres (l)X1.057=US quarts (US qt)

Imperial gallons (Imp gal)X4.546=Litres (l)X0.22=Imperial gallons (Imp gal)

Imperial gallons (Imp gal)X1.201=US gallons (US gal)X0.833=Imperial gallons (Imp gal)

US gallons (US gal)X3.785=Litres (l)X0.264=US gallons (US gal)

Mass (weight)

Ounces (oz)X28.35=Grams (g)X0.035=Ounces (oz)

Pounds (lb)X0.454=Kilograms (kg)X2.205=Pounds (lb)

Force

Ounces-force (ozf; oz)X0.278=Newtons (N)X3.6=Ounces-force (ozf; oz)

Pounds-force (lbf; lb)X4.448=Newtons (N)X0.225=Pounds-force (lbf; lb)

Newtons (N)X0.1=Kilograms-force (kgf; kg)X9.81=Newtons (N)

Pressure

Pounds-force per square inchX0.070=Kilograms-force per squareX14.223=Pounds-force per square inch

(psi; lbf/in2; lb/in2)centimetre (kgf/cm2; kg/cm2)(psi; lbf/in2; lb/in2)

Pounds-force per square inchX0.068=Atmospheres (atm)X14.696=Pounds-force per square inch

(psi; lbf/in

2; lb/in2)(psi; lbf/in2; lb/in2)

Pounds-force per square inchX0.069=BarsX14.5=Pounds-force per square inch

(psi; lbf/in

2; lb/in2)(psi; lbf/in2; lb/in2)

Pounds-force per square inchX6.895=Kilopascals (kPa)X0.145=Pounds-force per square inch

(psi; lbf/in

2; lb/in2)(psi; lbf/in2; lb/in2)

Kilopascals (kPa)X0.01=Kilograms-force per squareX98.1=Kilopascals (kPa)

centimetre (kgf/cm

2; kg/cm2)

Millibar (mbar)X100=Pascals (Pa)X0.01=Millibar (mbar)

Millibar (mbar)X0.0145=Pounds-force per square inchX68.947=Millibar (mbar)

(psi; lbf/in

2; lb/in2)

Millibar (mbar)X0.75=Millimetres of mercury (mmHg)X1.333=Millibar (mbar)

Millibar (mbar)X0.401=Inches of water (inH

2O)X2.491=Millibar (mbar)

Millimetres of mercury (mmHg)X0.535=Inches of water (inH

2O)X1.868=Millimetres of mercury (mmHg)

Inches of water (inH

2O)X0.036=Pounds-force per square inchX27.68=Inches of water (inH2O)

(psi; lbf/in2; lb/in2)

Torque (moment of force)

Pounds-force inchesX1.152=Kilograms-force centimetreX0.868=Pounds-force inches

(lbf in; lb in)(kgf cm; kg cm)(lbf in; lb in)

Pounds-force inchesX0.113=Newton metres (Nm)X8.85=Pounds-force inches

(lbf in; lb in)(lbf in; lb in)

Pounds-force inchesX0.083=Pounds-force feet (lbf ft; lb ft)X12=Pounds-force inches

(lbf in; lb in)(lbf in; lb in)

Pounds-force feet (lbf ft; lb ft)X0.138=Kilograms-force metresX7.233=Pounds-force feet (lbf ft; lb ft)

(kgf m; kg m)

Pounds-force feet (lbf ft; lb ft)X1.356=Newton metres (Nm)X0.738=Pounds-force feet (lbf ft; lb ft)

Newton metres (Nm)X0.102=Kilograms-force metresX9.804=Newton metres (Nm)

(kgf m; kg m)

Power

Horsepower (hp)X745.7=Watts (W)X0.0013=Horsepower (hp)

Velocity (speed)

Miles per hour (miles/hr; mph)X1.609=Kilometres per hour (km/hr; kph)X0.621=Miles per hour (miles/hr; mph)

Fuel consumption*

Miles per gallon, Imperial (mpg)X0.354=Kilometres per litre (km/l)X2.825=Miles per gallon, Imperial (mpg)

Miles per gallon, US (mpg)X0.425=Kilometres per litre (km/l)X2.352=Miles per gallon, US (mpg)

Temperature

Degrees Fahrenheit = (°C x 1.8) + 32Degrees Celsius (Degrees Centigrade; °C) = (°F - 32) x 0.56

* It is common practice to convert from miles per gallon (mpg) to litres/100 kilometres (l/100km),

where mpg (Imperial) x l/100 km = 282 and mpg (US) x l/100 km = 235

Conversion Factors

procarmanuals.com