torque FORD GRANADA 1985 Service Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 87 of 255

Make sure that the thermostat is the right way

round - the wax capsule fits into the cylinder

head, with the direction of flow arrow facing

forwards (see illustration).

8Refill the cooling system.

DOHC engines

9Disconnect the battery negative lead.

10Drain the cooling system.

11On fuel-injection models, for access to the

thermostat housing, loosen the clips and

remove the air inlet tube which connects the

plenum chamber to the inlet manifold.

12Disconnect the coolant hoses from the

thermostat housing (see illustrations).

13Disconnect the wiring plug from the

cooling fan switch mounted in the thermostat

housing (see illustration).

14Unscrew the three securing bolts, andwithdraw the thermostat housing (see

illustration).

15Manoeuvre the thermostat away from the

inlet manifold and recover the O-ring. If it is

necessary to prise the thermostat out, take

care not to damage the surface of the housing

in the inlet manifold.

16Refitting is a reversal of removal, bearing

in mind the following points:

a)Ensure that the O-ring seal is correctly

fitted around the edge of the thermostat.

b)When fitting the thermostat to the inlet

manifold ensure that the relief valve is

located in the 12 o’clock position (see

illustration).

c)Tighten the thermostat housing bolts to

the specified torque.

d)Refill the cooling system.

3•4Cooling, heating and ventilation systems

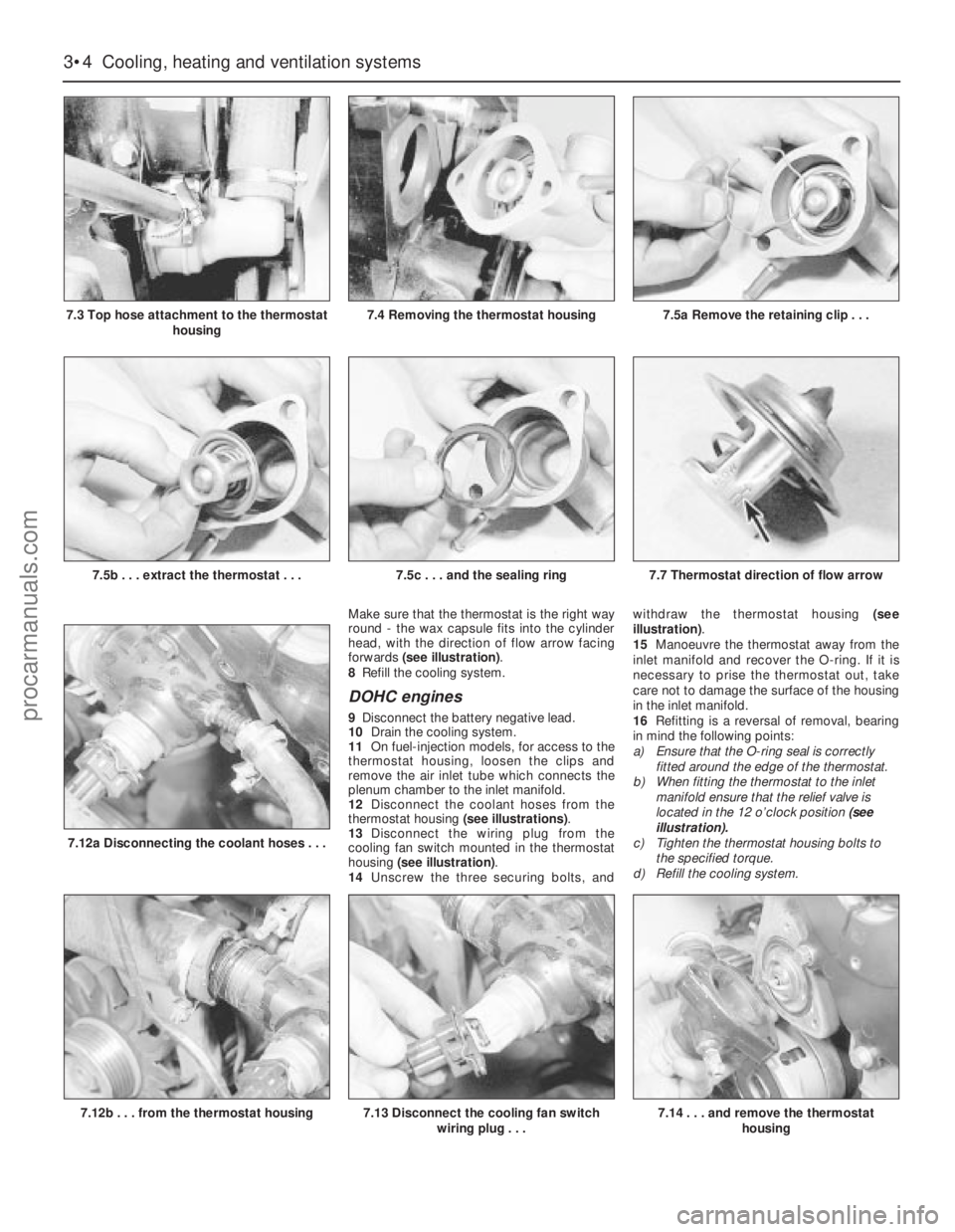

7.3 Top hose attachment to the thermostat

housing

7.12b . . . from the thermostat housing

7.5b . . . extract the thermostat . . .7.5c . . . and the sealing ring7.7 Thermostat direction of flow arrow

7.12a Disconnecting the coolant hoses . . .

7.13 Disconnect the cooling fan switch

wiring plug . . .7.14 . . . and remove the thermostat

housing

7.4 Removing the thermostat housing7.5a Remove the retaining clip . . .

procarmanuals.com

Page 89 of 255

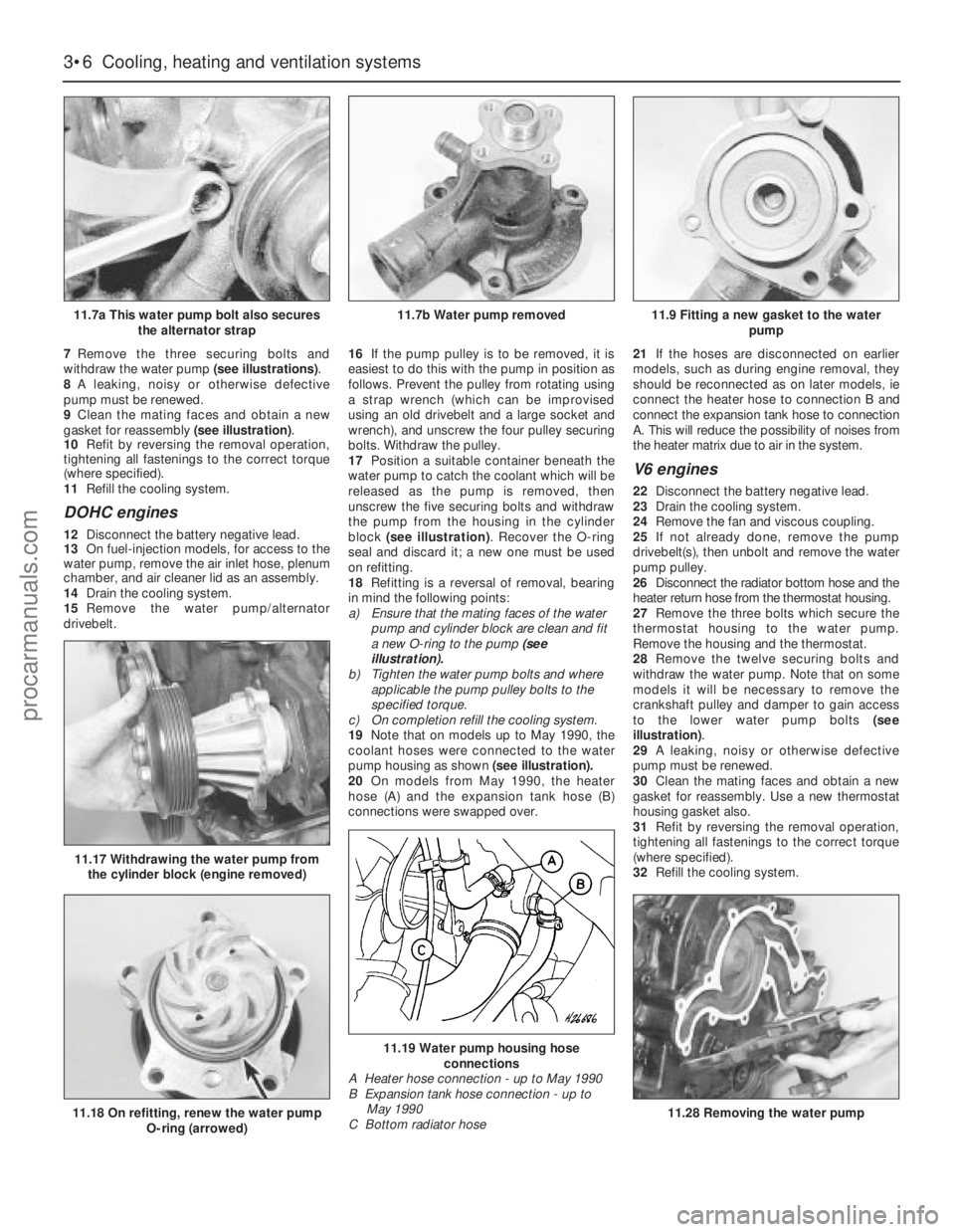

7Remove the three securing bolts and

withdraw the water pump (see illustrations).

8A leaking, noisy or otherwise defective

pump must be renewed.

9Clean the mating faces and obtain a new

gasket for reassembly (see illustration).

10Refit by reversing the removal operation,

tightening all fastenings to the correct torque

(where specified).

11Refill the cooling system.

DOHC engines

12Disconnect the battery negative lead.

13On fuel-injection models, for access to the

water pump, remove the air inlet hose, plenum

chamber, and air cleaner lid as an assembly.

14Drain the cooling system.

15Remove the water pump/alternator

drivebelt.16If the pump pulley is to be removed, it is

easiest to do this with the pump in position as

follows. Prevent the pulley from rotating using

a strap wrench (which can be improvised

using an old drivebelt and a large socket and

wrench), and unscrew the four pulley securing

bolts. Withdraw the pulley.

17Position a suitable container beneath the

water pump to catch the coolant which will be

released as the pump is removed, then

unscrew the five securing bolts and withdraw

the pump from the housing in the cylinder

block (see illustration). Recover the O-ring

seal and discard it; a new one must be used

on refitting.

18Refitting is a reversal of removal, bearing

in mind the following points:

a)Ensure that the mating faces of the water

pump and cylinder block are clean and fit

a new O-ring to the pump (see

illustration).

b)Tighten the water pump bolts and where

applicable the pump pulley bolts to the

specified torque.

c)On completion refill the cooling system.

19Note that on models up to May 1990, the

coolant hoses were connected to the water

pump housing as shown(see illustration).

20On models from May 1990, the heater

hose (A) and the expansion tank hose (B)

connections were swapped over.21If the hoses are disconnected on earlier

models, such as during engine removal, they

should be reconnected as on later models, ie

connect the heater hose to connection B and

connect the expansion tank hose to connection

A. This will reduce the possibility of noises from

the heater matrix due to air in the system.

V6 engines

22Disconnect the battery negative lead.

23Drain the cooling system.

24Remove the fan and viscous coupling.

25If not already done, remove the pump

drivebelt(s), then unbolt and remove the water

pump pulley.

26Disconnect the radiator bottom hose and the

heater return hose from the thermostat housing.

27Remove the three bolts which secure the

thermostat housing to the water pump.

Remove the housing and the thermostat.

28Remove the twelve securing bolts and

withdraw the water pump. Note that on some

models it will be necessary to remove the

crankshaft pulley and damper to gain access

to the lower water pump bolts (see

illustration).

29A leaking, noisy or otherwise defective

pump must be renewed.

30Clean the mating faces and obtain a new

gasket for reassembly. Use a new thermostat

housing gasket also.

31Refit by reversing the removal operation,

tightening all fastenings to the correct torque

(where specified).

32Refill the cooling system.

3•6Cooling, heating and ventilation systems

11.7a This water pump bolt also secures

the alternator strap

11.18 On refitting, renew the water pump

O-ring (arrowed)

11.17 Withdrawing the water pump from

the cylinder block (engine removed)

11.19 Water pump housing hose

connections

A Heater hose connection - up to May 1990

B Expansion tank hose connection - up to

May 1990

C Bottom radiator hose

11.28 Removing the water pump

11.7b Water pump removed11.9 Fitting a new gasket to the water

pump

procarmanuals.com

Page 96 of 255

Fuel and exhaust systems 4•3

4

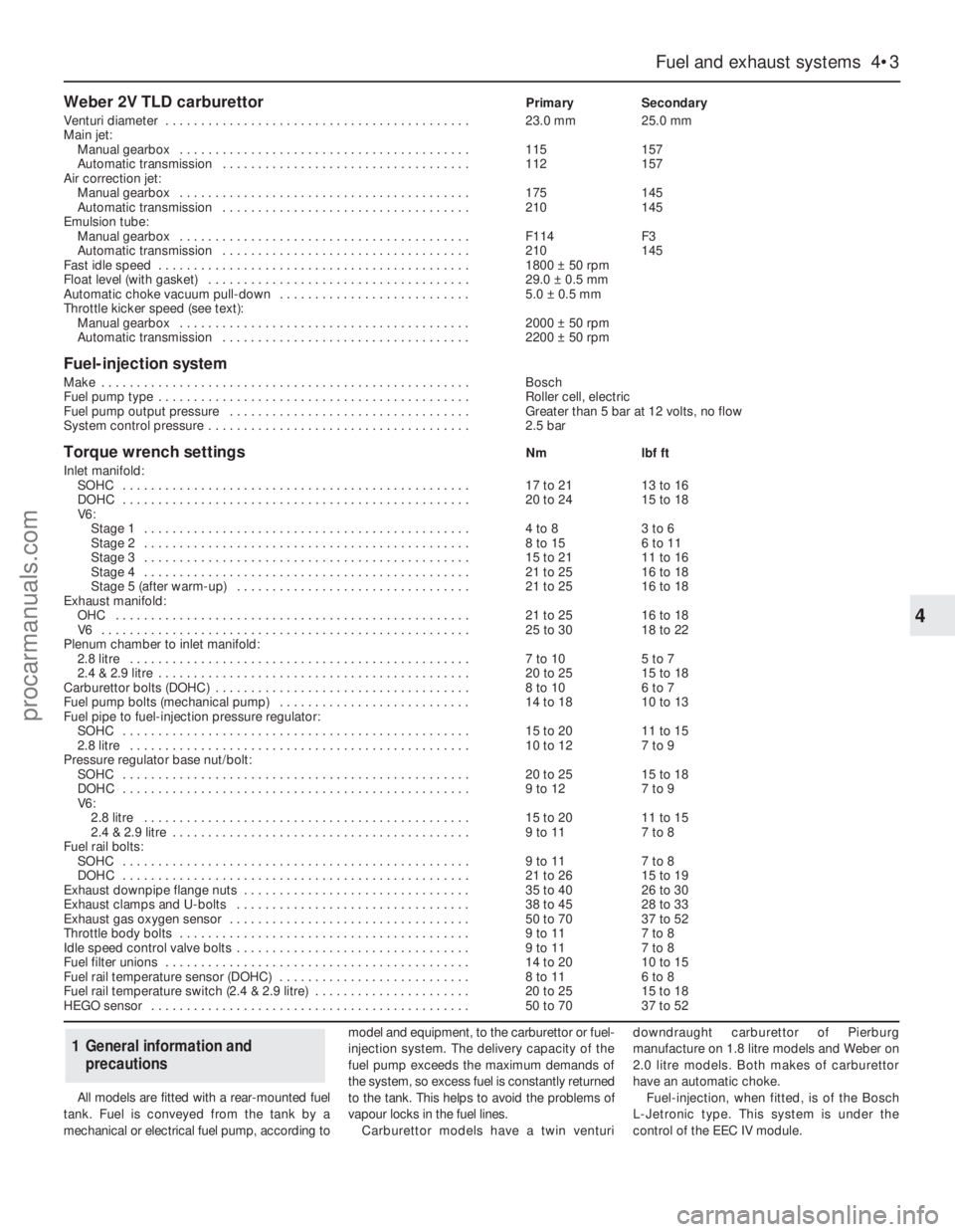

Weber 2V TLD carburettorPrimarySecondary

Venturi diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23.0 mm25.0 mm

Main jet:

Manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115157

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112157

Air correction jet:

Manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175145

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210145

Emulsion tube:

Manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F114F3

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210145

Fast idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1800 ±50 rpm

Float level (with gasket) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29.0 ±0.5 mm

Automatic choke vacuum pull-down . . . . . . . . . . . . . . . . . . . . . . . . . . .5.0 ±0.5 mm

Throttle kicker speed (see text):

Manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2000 ±50 rpm

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2200 ±50 rpm

Fuel-injection system

Make . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bosch

Fuel pump type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Roller cell, electric

Fuel pump output pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Greater than 5 bar at 12 volts, no flow

System control pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.5 bar

Torque wrench settingsNmlbf ft

Inlet manifold:

SOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 16

DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2415 to 18

V6:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 to 83 to 6

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 156 to 11

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 to 2111 to 16

Stage 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2516 to 18

Stage 5 (after warm-up) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2516 to 18

Exhaust manifold:

OHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2516 to 18

V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 to 3018 to 22

Plenum chamber to inlet manifold:

2.8 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 105 to 7

2.4 & 2.9 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Carburettor bolts (DOHC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 106 to 7

Fuel pump bolts (mechanical pump) . . . . . . . . . . . . . . . . . . . . . . . . . . .14 to 1810 to 13

Fuel pipe to fuel-injection pressure regulator:

SOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 to 2011 to 15

2.8 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 to 127 to 9

Pressure regulator base nut/bolt:

SOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 127 to 9

V6:

2.8 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 to 2011 to 15

2.4 & 2.9 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 117 to 8

Fuel rail bolts:

SOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 117 to 8

DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2615 to 19

Exhaust downpipe flange nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4026 to 30

Exhaust clamps and U-bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38 to 4528 to 33

Exhaust gas oxygen sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 to 7037 to 52

Throttle body bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 117 to 8

Idle speed control valve bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 117 to 8

Fuel filter unions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 to 2010 to 15

Fuel rail temperature sensor (DOHC) . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Fuel rail temperature switch (2.4 & 2.9 litre) . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

HEGO sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 to 7037 to 52

All models are fitted with a rear-mounted fuel

tank. Fuel is conveyed from the tank by a

mechanical or electrical fuel pump, according tomodel and equipment, to the carburettor or fuel-

injection system. The delivery capacity of the

fuel pump exceeds the maximum demands of

the system, so excess fuel is constantly returned

to the tank. This helps to avoid the problems of

vapour locks in the fuel lines.

Carburettor models have a twin venturidowndraught carburettor of Pierburg

manufacture on 1.8 litre models and Weber on

2.0 litre models. Both makes of carburettor

have an automatic choke.

Fuel-injection, when fitted, is of the Bosch

L-Jetronic type. This system is under the

control of the EEC IV module.

1General information and

precautions

procarmanuals.com

Page 98 of 255

4With the engine cold, disconnect the cold

air inlet trunking from the spout. Look into the

spout and check that the flap valve is covering

the hot air inlet.

5Start the engine and allow it to idle. Check

that the flap moves to cover the cold air inlet. If

the flap does not move, check the diaphragm

and heat sensor as follows.

6Stop the engine. Disconnect the diaphragm

vacuum pipe from the heat sensor. Apply

vacuum to the diaphragm, using a vacuum

head pump or by connecting the pipe directly

to manifold vacuum. If the flap now moves, the

heat sensor or vacuum line was faulty. If the

flap still does not move, the diaphragm is

faulty or the flap is jammed.

7On completion reconnect the vacuum pipe

and the cold air trunking.

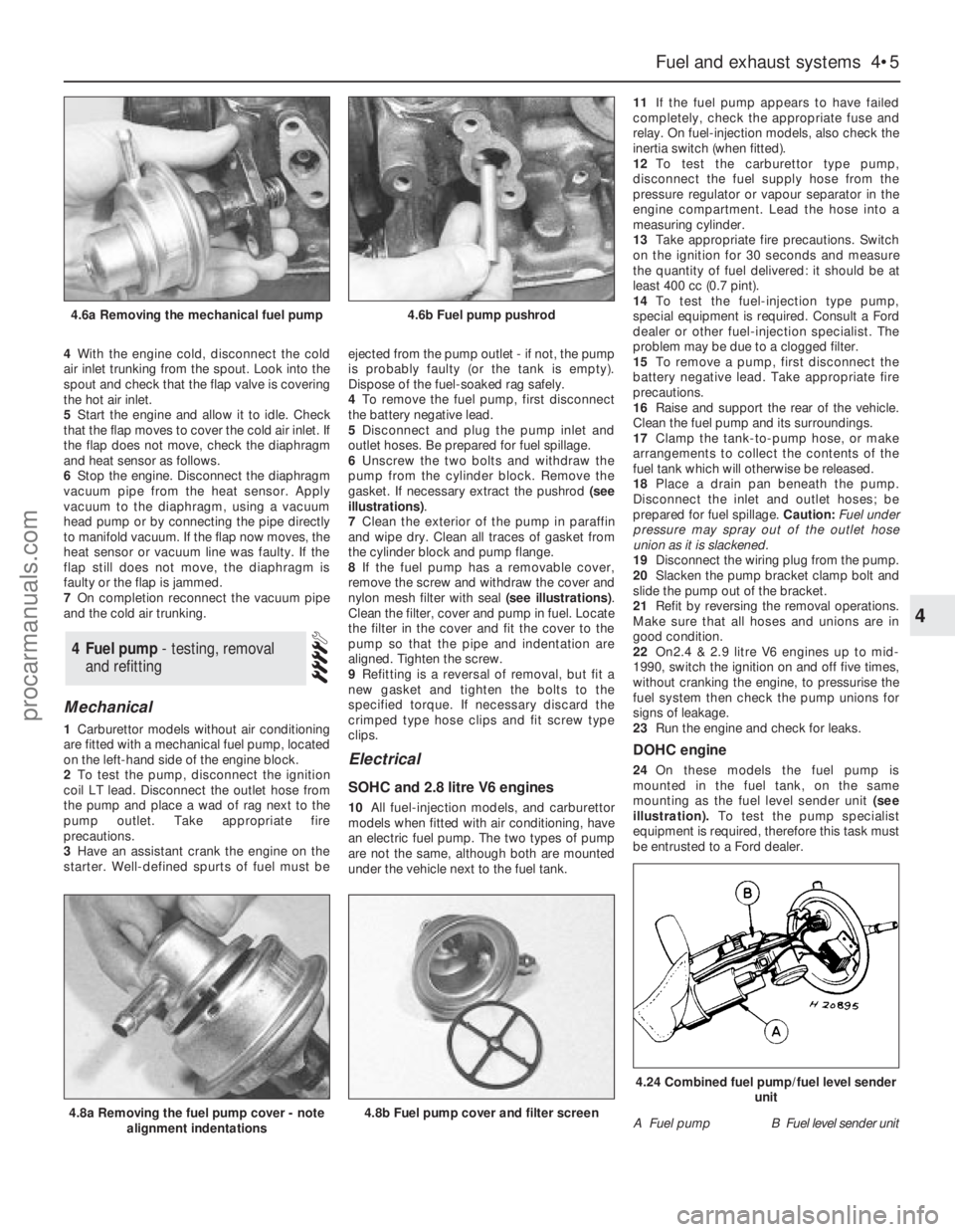

Mechanical

1Carburettor models without air conditioning

are fitted with a mechanical fuel pump, located

on the left-hand side of the engine block.

2To test the pump, disconnect the ignition

coil LT lead. Disconnect the outlet hose from

the pump and place a wad of rag next to the

pump outlet. Take appropriate fire

precautions.

3Have an assistant crank the engine on the

starter. Well-defined spurts of fuel must beejected from the pump outlet - if not, the pump

is probably faulty (or the tank is empty).

Dispose of the fuel-soaked rag safely.

4To remove the fuel pump, first disconnect

the battery negative lead.

5Disconnect and plug the pump inlet and

outlet hoses. Be prepared for fuel spillage.

6Unscrew the two bolts and withdraw the

pump from the cylinder block. Remove the

gasket. If necessary extract the pushrod (see

illustrations).

7Clean the exterior of the pump in paraffin

and wipe dry. Clean all traces of gasket from

the cylinder block and pump flange.

8If the fuel pump has a removable cover,

remove the screw and withdraw the cover and

nylon mesh filter with seal (see illustrations).

Clean the filter, cover and pump in fuel. Locate

the filter in the cover and fit the cover to the

pump so that the pipe and indentation are

aligned. Tighten the screw.

9Refitting is a reversal of removal, but fit a

new gasket and tighten the bolts to the

specified torque. If necessary discard the

crimped type hose clips and fit screw type

clips.

Electrical

SOHC and 2.8 litre V6 engines

10All fuel-injection models, and carburettor

models when fitted with air conditioning, have

an electric fuel pump. The two types of pump

are not the same, although both are mounted

under the vehicle next to the fuel tank.11If the fuel pump appears to have failed

completely, check the appropriate fuse and

relay. On fuel-injection models, also check the

inertia switch (when fitted).

12To test the carburettor type pump,

disconnect the fuel supply hose from the

pressure regulator or vapour separator in the

engine compartment. Lead the hose into a

measuring cylinder.

13Take appropriate fire precautions. Switch

on the ignition for 30 seconds and measure

the quantity of fuel delivered: it should be at

least 400 cc (0.7 pint).

14To test the fuel-injection type pump,

special equipment is required. Consult a Ford

dealer or other fuel-injection specialist. The

problem may be due to a clogged filter.

15To remove a pump, first disconnect the

battery negative lead. Take appropriate fire

precautions.

16Raise and support the rear of the vehicle.

Clean the fuel pump and its surroundings.

17Clamp the tank-to-pump hose, or make

arrangements to collect the contents of the

fuel tank which will otherwise be released.

18Place a drain pan beneath the pump.

Disconnect the inlet and outlet hoses; be

prepared for fuel spillage. Caution: Fuel under

pressure may spray out of the outlet hose

union as it is slackened.

19Disconnect the wiring plug from the pump.

20Slacken the pump bracket clamp bolt and

slide the pump out of the bracket.

21Refit by reversing the removal operations.

Make sure that all hoses and unions are in

good condition.

22On2.4 & 2.9 litre V6 engines up to mid-

1990, switch the ignition on and off five times,

without cranking the engine, to pressurise the

fuel system then check the pump unions for

signs of leakage.

23Run the engine and check for leaks.

DOHC engine

24On these models the fuel pump is

mounted in the fuel tank, on the same

mounting as the fuel level sender unit(see

illustration).To test the pump specialist

equipment is required, therefore this task must

be entrusted to a Ford dealer.

4Fuel pump - testing, removal

and refitting

Fuel and exhaust systems 4•5

4

4.6a Removing the mechanical fuel pump4.6b Fuel pump pushrod

4.8a Removing the fuel pump cover - note

alignment indentations4.8b Fuel pump cover and filter screenA Fuel pumpB Fuel level sender unit

4.24 Combined fuel pump/fuel level sender

unit

procarmanuals.com

Page 110 of 255

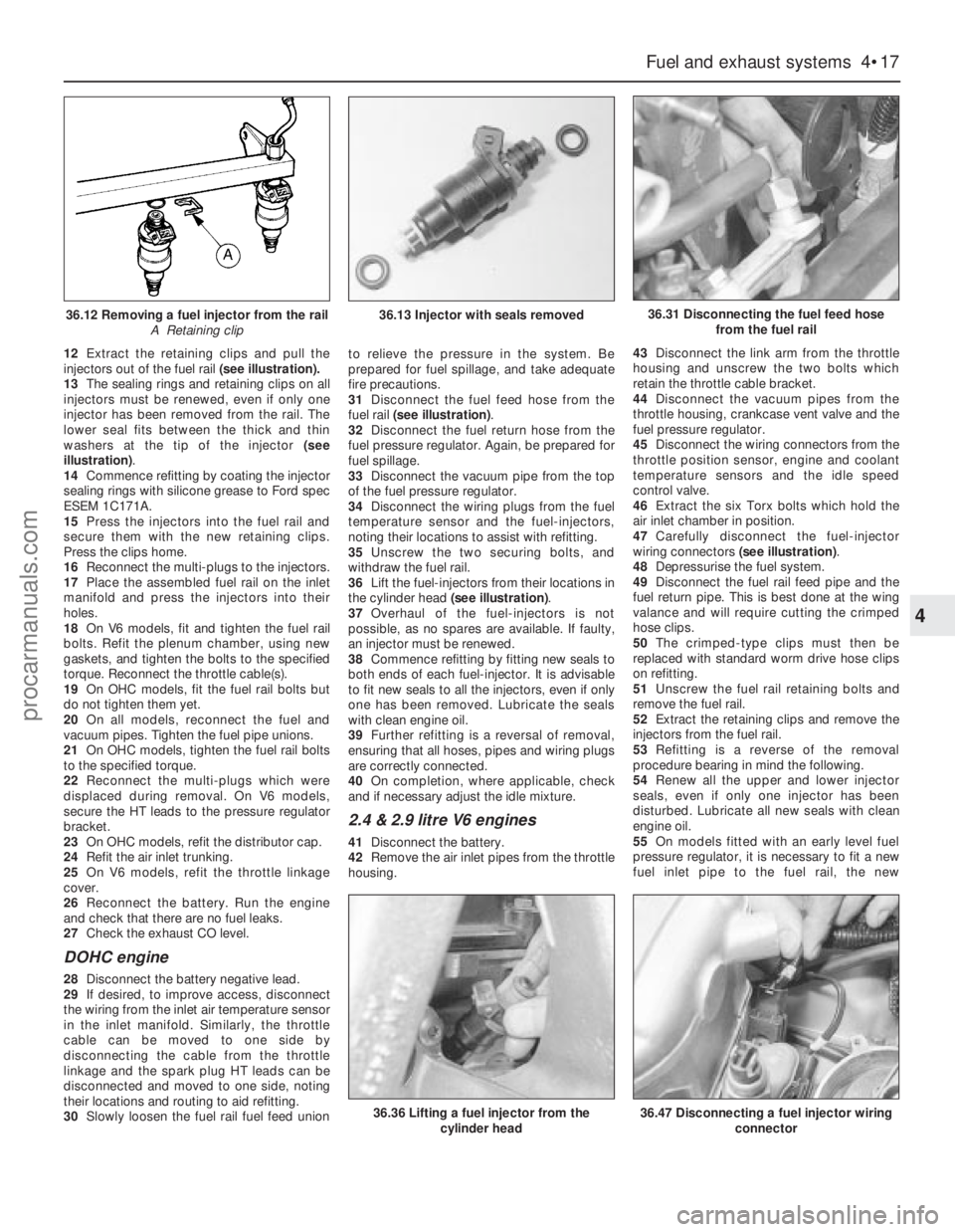

12Extract the retaining clips and pull the

injectors out of the fuel rail(see illustration).

13The sealing rings and retaining clips on all

injectors must be renewed, even if only one

injector has been removed from the rail. The

lower seal fits between the thick and thin

washers at the tip of the injector (see

illustration).

14Commence refitting by coating the injector

sealing rings with silicone grease to Ford spec

ESEM 1C171A.

15Press the injectors into the fuel rail and

secure them with the new retaining clips.

Press the clips home.

16Reconnect the multi-plugs to the injectors.

17Place the assembled fuel rail on the inlet

manifold and press the injectors into their

holes.

18On V6 models, fit and tighten the fuel rail

bolts. Refit the plenum chamber, using new

gaskets, and tighten the bolts to the specified

torque. Reconnect the throttle cable(s).

19On OHCmodels, fit the fuel rail bolts but

do not tighten them yet.

20On all models, reconnect the fuel and

vacuum pipes. Tighten the fuel pipe unions.

21On OHCmodels, tighten the fuel rail bolts

to the specified torque.

22Reconnect the multi-plugs which were

displaced during removal. On V6 models,

secure the HT leads to the pressure regulator

bracket.

23On OHCmodels, refit the distributor cap.

24Refit the air inlet trunking.

25On V6 models, refit the throttle linkage

cover.

26Reconnect the battery. Run the engine

and check that there are no fuel leaks.

27Check the exhaust CO level.

DOHC engine

28Disconnect the battery negative lead.

29If desired, to improve access, disconnect

the wiring from the inlet air temperature sensor

in the inlet manifold. Similarly, the throttle

cable can be moved to one side by

disconnecting the cable from the throttle

linkage and the spark plug HT leads can be

disconnected and moved to one side, noting

their locations and routing to aid refitting.

30Slowly loosen the fuel rail fuel feed unionto relieve the pressure in the system. Be

prepared for fuel spillage, and take adequate

fire precautions.

31Disconnect the fuel feed hose from the

fuel rail (see illustration).

32Disconnect the fuel return hose from the

fuel pressure regulator. Again, be prepared for

fuel spillage.

33Disconnect the vacuum pipe from the top

of the fuel pressure regulator.

34Disconnect the wiring plugs from the fuel

temperature sensor and the fuel-injectors,

noting their locations to assist with refitting.

35Unscrew the two securing bolts, and

withdraw the fuel rail.

36Lift the fuel-injectors from their locations in

the cylinder head (see illustration).

37Overhaul of the fuel-injectors is not

possible, as no spares are available. If faulty,

an injector must be renewed.

38Commence refitting by fitting new seals to

both ends of each fuel-injector. It is advisable

to fit new seals to all the injectors, even if only

one has been removed. Lubricate the seals

with clean engine oil.

39Further refitting is a reversal of removal,

ensuring that all hoses, pipes and wiring plugs

are correctly connected.

40On completion, where applicable, check

and if necessary adjust the idle mixture.

2.4 & 2.9 litre V6 engines

41Disconnect the battery.

42Remove the air inlet pipes from the throttle

housing.43Disconnect the link arm from the throttle

housing and unscrew the two bolts which

retain the throttle cable bracket.

44Disconnect the vacuum pipes from the

throttle housing, crankcase vent valve and the

fuel pressure regulator.

45Disconnect the wiring connectors from the

throttle position sensor, engine and coolant

temperature sensors and the idle speed

control valve.

46Extract the six Torx bolts which hold the

air inlet chamber in position.

47Carefully disconnect the fuel-injector

wiring connectors (see illustration).

48Depressurise the fuel system.

49Disconnect the fuel rail feed pipe and the

fuel return pipe. This is best done at the wing

valance and will require cutting the crimped

hose clips.

50The crimped-type clips must then be

replaced with standard worm drive hose clips

on refitting.

51Unscrew the fuel rail retaining bolts and

remove the fuel rail.

52Extract the retaining clips and remove the

injectors from the fuel rail.

53Refitting is a reverse of the removal

procedure bearing in mind the following.

54Renew all the upper and lower injector

seals, even if only one injector has been

disturbed. Lubricate all new seals with clean

engine oil.

55On models fitted with an early level fuel

pressure regulator, it is necessary to fit a new

fuel inlet pipe to the fuel rail, the new

Fuel and exhaust systems 4•17

4

36.12 Removing a fuel injector from the rail

A Retaining clip36.13 Injector with seals removed36.31 Disconnecting the fuel feed hose

from the fuel rail

36.36 Lifting a fuel injector from the

cylinder head36.47 Disconnecting a fuel injector wiring

connector

procarmanuals.com

Page 112 of 255

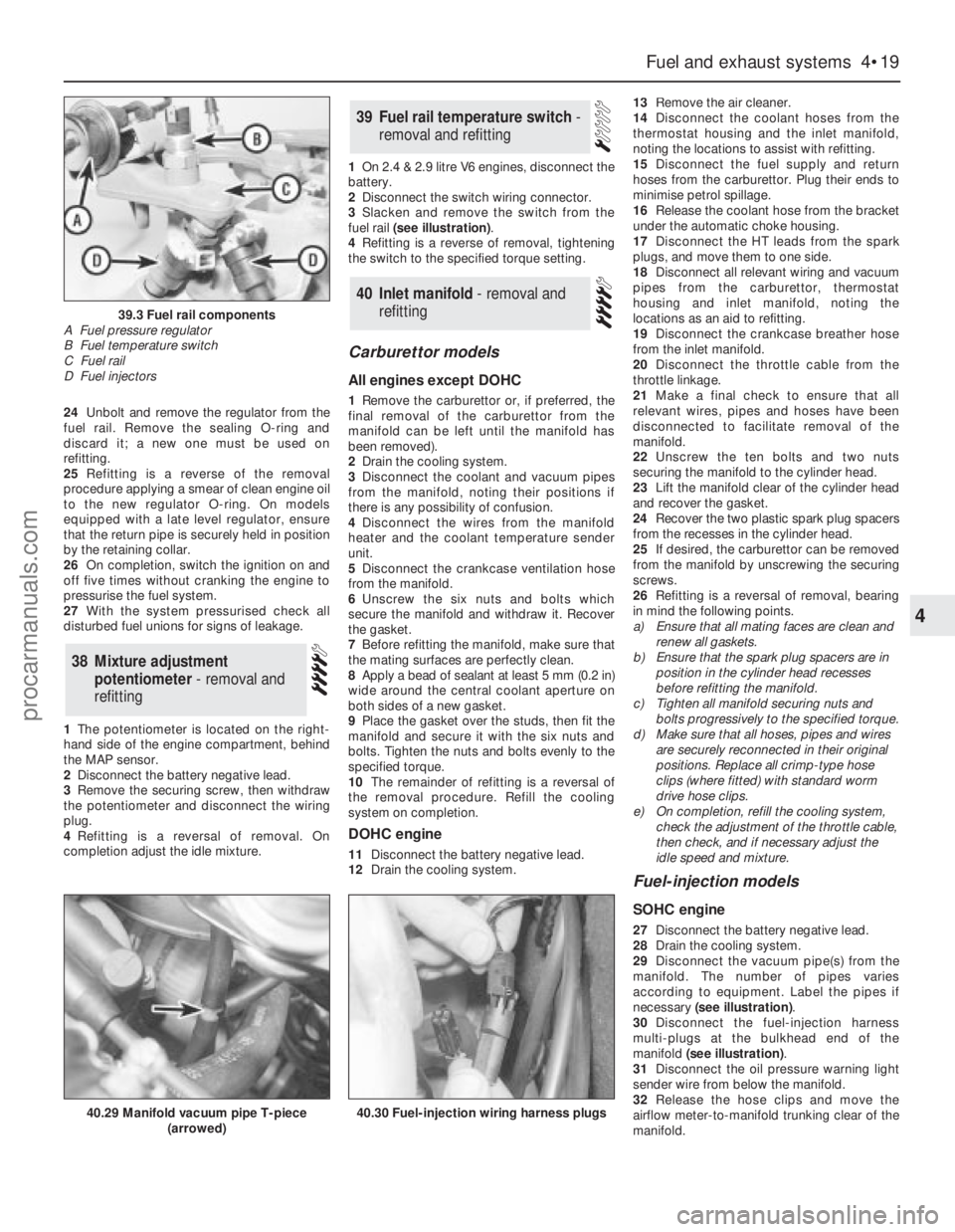

24Unbolt and remove the regulator from the

fuel rail. Remove the sealing O-ring and

discard it; a new one must be used on

refitting.

25Refitting is a reverse of the removal

procedure applying a smear of clean engine oil

to the new regulator O-ring. On models

equipped with a late level regulator, ensure

that the return pipe is securely held in position

by the retaining collar.

26On completion, switch the ignition on and

off five times without cranking the engine to

pressurise the fuel system.

27With the system pressurised check all

disturbed fuel unions for signs of leakage.

1The potentiometer is located on the right-

hand side of the engine compartment, behind

the MAP sensor.

2Disconnect the battery negative lead.

3Remove the securing screw, then withdraw

the potentiometer and disconnect the wiring

plug.

4Refitting is a reversal of removal. On

completion adjust the idle mixture.1On 2.4 & 2.9 litre V6 engines, disconnect the

battery.

2Disconnect the switch wiring connector.

3Slacken and remove the switch from the

fuel rail (see illustration).

4Refitting is a reverse of removal, tightening

the switch to the specified torque setting.

Carburettor models

All engines except DOHC

1Remove the carburettor or, if preferred, the

final removal of the carburettor from the

manifold can be left until the manifold has

been removed).

2Drain the cooling system.

3Disconnect the coolant and vacuum pipes

from the manifold, noting their positions if

there is any possibility of confusion.

4Disconnect the wires from the manifold

heater and the coolant temperature sender

unit.

5Disconnect the crankcase ventilation hose

from the manifold.

6Unscrew the six nuts and bolts which

secure the manifold and withdraw it. Recover

the gasket.

7Before refitting the manifold, make sure that

the mating surfaces are perfectly clean.

8Apply a bead of sealant at least 5 mm (0.2 in)

wide around the central coolant aperture on

both sides of a new gasket.

9Place the gasket over the studs, then fit the

manifold and secure it with the six nuts and

bolts. Tighten the nuts and bolts evenly to the

specified torque.

10The remainder of refitting is a reversal of

the removal procedure. Refill the cooling

system on completion.

DOHC engine

11Disconnect the battery negative lead.

12Drain the cooling system.13Remove the air cleaner.

14Disconnect the coolant hoses from the

thermostat housing and the inlet manifold,

noting the locations to assist with refitting.

15Disconnect the fuel supply and return

hoses from the carburettor. Plug their ends to

minimise petrol spillage.

16Release the coolant hose from the bracket

under the automatic choke housing.

17Disconnect the HT leads from the spark

plugs, and move them to one side.

18Disconnect all relevant wiring and vacuum

pipes from the carburettor, thermostat

housing and inlet manifold, noting the

locations as an aid to refitting.

19Disconnect the crankcase breather hose

from the inlet manifold.

20Disconnect the throttle cable from the

throttle linkage.

21Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate removal of the

manifold.

22Unscrew the ten bolts and two nuts

securing the manifold to the cylinder head.

23Lift the manifold clear of the cylinder head

and recover the gasket.

24Recover the two plastic spark plug spacers

from the recesses in the cylinder head.

25If desired, the carburettor can be removed

from the manifold by unscrewing the securing

screws.

26Refitting is a reversal of removal, bearing

in mind the following points.

a)Ensure that all mating faces are clean and

renew all gaskets.

b)Ensure that the spark plug spacers are in

position in the cylinder head recesses

before refitting the manifold.

c)Tighten all manifold securing nuts and

bolts progressively to the specified torque.

d)Make sure that all hoses, pipes and wires

are securely reconnected in their original

positions. Replace all crimp-type hose

clips (where fitted) with standard worm

drive hose clips.

e)On completion, refill the cooling system,

check the adjustment of the throttle cable,

then check, and if necessary adjust the

idle speed and mixture.

Fuel-injection models

SOHC engine

27Disconnect the battery negative lead.

28Drain the cooling system.

29Disconnect the vacuum pipe(s) from the

manifold. The number of pipes varies

according to equipment. Label the pipes if

necessary (see illustration).

30Disconnect the fuel-injection harness

multi-plugs at the bulkhead end of the

manifold (see illustration).

31Disconnect the oil pressure warning light

sender wire from below the manifold.

32Release the hose clips and move the

airflow meter-to-manifold trunking clear of the

manifold.

40Inlet manifold - removal and

refitting

39Fuel rail temperature switch -

removal and refitting

38Mixture adjustment

potentiometer - removal and

refitting

Fuel and exhaust systems 4•19

4

39.3 Fuel rail components

A Fuel pressure regulator

B Fuel temperature switch

C Fuel rail

D Fuel injectors

40.29 Manifold vacuum pipe T-piece

(arrowed)40.30 Fuel-injection wiring harness plugs

procarmanuals.com

Page 113 of 255

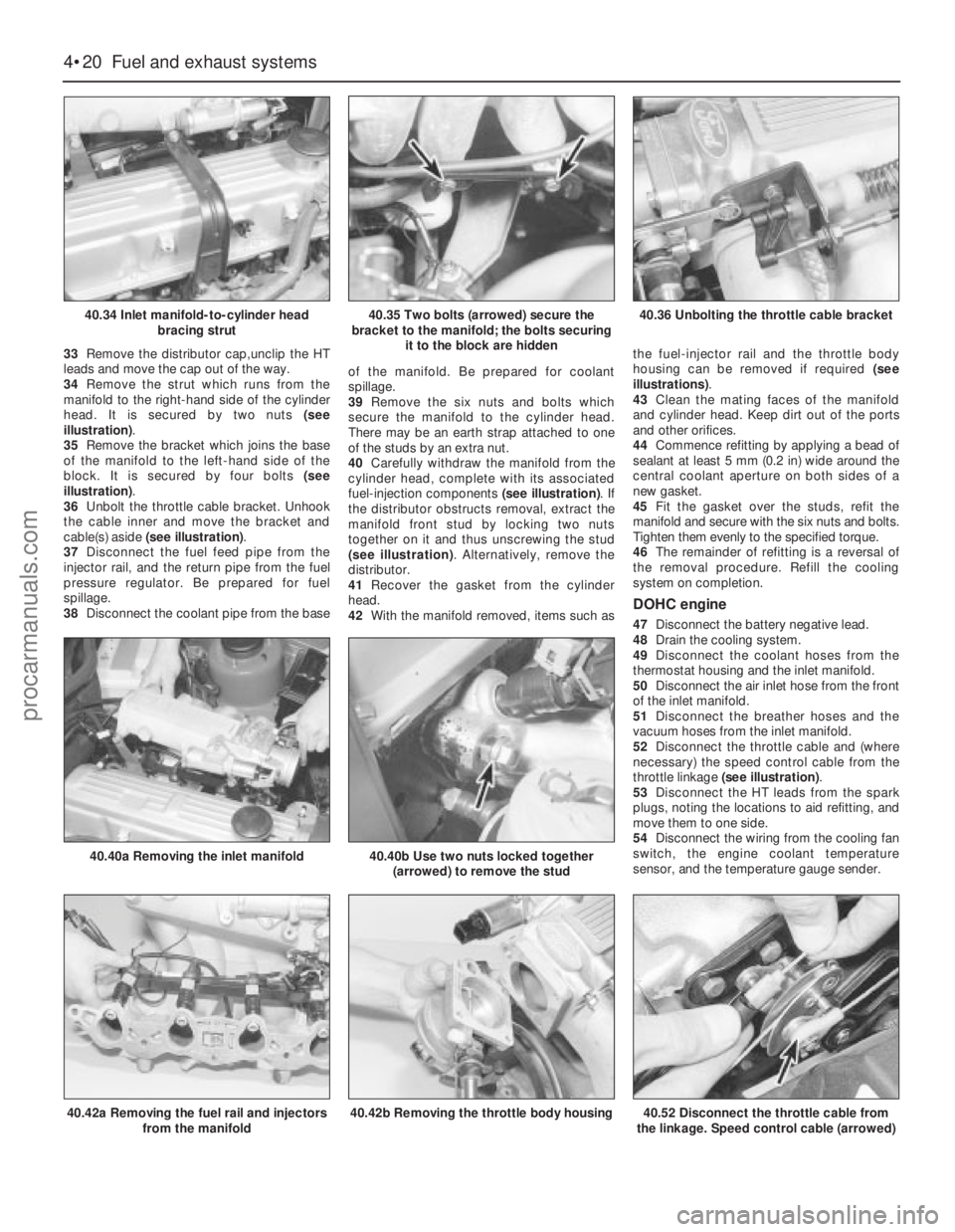

33Remove the distributor cap,unclip the HT

leads and move the cap out of the way.

34Remove the strut which runs from the

manifold to the right-hand side of the cylinder

head. It is secured by two nuts (see

illustration).

35Remove the bracket which joins the base

of the manifold to the left-hand side of the

block. It is secured by four bolts (see

illustration).

36Unbolt the throttle cable bracket. Unhook

the cable inner and move the bracket and

cable(s) aside (see illustration).

37Disconnect the fuel feed pipe from the

injector rail, and the return pipe from the fuel

pressure regulator. Be prepared for fuel

spillage.

38Disconnect the coolant pipe from the baseof the manifold. Be prepared for coolant

spillage.

39Remove the six nuts and bolts which

secure the manifold to the cylinder head.

There may be an earth strap attached to one

of the studs by an extra nut.

40Carefully withdraw the manifold from the

cylinder head, complete with its associated

fuel-injection components (see illustration). If

the distributor obstructs removal, extract the

manifold front stud by locking two nuts

together on it and thus unscrewing the stud

(see illustration). Alternatively, remove the

distributor.

41Recover the gasket from the cylinder

head.

42With the manifold removed, items such asthe fuel-injector rail and the throttle body

housing can be removed if required (see

illustrations).

43Clean the mating faces of the manifold

and cylinder head. Keep dirt out of the ports

and other orifices.

44Commence refitting by applying a bead of

sealant at least 5 mm (0.2 in) wide around the

central coolant aperture on both sides of a

new gasket.

45Fit the gasket over the studs, refit the

manifold and secure with the six nuts and bolts.

Tighten them evenly to the specified torque.

46The remainder of refitting is a reversal of

the removal procedure. Refill the cooling

system on completion.

DOHC engine

47Disconnect the battery negative lead.

48Drain the cooling system.

49Disconnect the coolant hoses from the

thermostat housing and the inlet manifold.

50Disconnect the air inlet hose from the front

of the inlet manifold.

51Disconnect the breather hoses and the

vacuum hoses from the inlet manifold.

52Disconnect the throttle cable and (where

necessary) the speed control cable from the

throttle linkage (see illustration).

53Disconnect the HT leads from the spark

plugs, noting the locations to aid refitting, and

move them to one side.

54Disconnect the wiring from the cooling fan

switch, the engine coolant temperature

sensor, and the temperature gauge sender.

4•20Fuel and exhaust systems

40.34 Inlet manifold-to-cylinder head

bracing strut

40.42a Removing the fuel rail and injectors

from the manifold

40.40a Removing the inlet manifold40.40b Use two nuts locked together

(arrowed) to remove the stud

40.42b Removing the throttle body housing40.52 Disconnect the throttle cable from

the linkage. Speed control cable (arrowed)

40.35 Two bolts (arrowed) secure the

bracket to the manifold; the bolts securing

it to the block are hidden40.36 Unbolting the throttle cable bracket

procarmanuals.com

Page 114 of 255

55Release the throttle position sensor wiring

connector from the clip under the throttle

body, and separate the two halves of the

connector.

56Remove the fuel-injectors.

57Check that all relevant wiring, hoses and

pipes have been disconnected to facilitate

removal of the manifold.

58Unscrew the ten bolts and two nuts

securing the inlet manifold to the cylinder

head, and carefully withdraw the manifold.

Recover the gasket.

59Recover the two plastic spark plug

spacers from the recesses in the cylinder head

(see illustration).

60If desired, the manifold can be dismantled

with reference to the relevant paragraphs of

this Chapter.

61Refitting is a reversal of removal, bearing

in mind the following points.

a)Ensure that the spark plug spacers are in

position in the cylinder head recesses

before refitting the manifold.

b)Ensure manifold and cylinder head mating

surfaces are clean and dry and fit a new

gasket.

c)Tighten the manifold retaining nuts and

bolts evenly and progressively to the

specified torque.

d)Refit the fuel-injectors.

e)Make sure that all hoses, pipes and wires

are securely reconnected in their original

positions.

f)On completion, refill the cooling system.

g)Check the adjustment of the throttle cable

and where necessary, adjust the speed

control cable so that only a small amount

of slack is present in the cable.

h)Where applicable, check and if necessary

adjust the idle speed and mixture.

V6 engines

62Disconnect the battery negative lead.

63Drain the cooling system.

64Remove the throttle linkage cover.

65Release the hose clips and move the

airflow meter-to-manifold trunking aside.

Unclip or remove the crankcase ventilation

hose.

66Disconnect the radiator top hose and the

heater hose from the outlet at the front of the

manifold. Be prepared for some coolant spillage.67Disconnect the multi-plugs from the idle

speed control valve, the temperature gauge

sender unit; the coolant temperature sensor

and the throttle position sensor. Also

disconnect the injector wiring harness.

68Disconnect the throttle cable from the

linkage, unclip it and move it aside. On

automatic transmission models, also

disconnect the downshift cable or multi-plug,

as applicable.

69Disconnect the fuel feed and return pipes.

Be prepared for fuel spillage.

70Remove the HT leads and the distributor.

71Remove the plenum chamber, which is

secured by eight bolts.

72Remove the rocker covers, which are each

secured by seven bolts.

73Disconnect the water pump bypass hose

from the inlet manifold.

74Remove the eight bolts which secure the

inlet manifold to the cylinder heads.

75Lift off the manifold complete with fuel

pressure regulator, fuel rail, throttle body

housing etc. If it is stuck, carefully lever it free.

Do not apply leverage at the mating faces.

Recover the gasket.

76Clean all mating faces, being careful to

keep dirt out of ports and other orifices.

Obtain new gaskets for both the cylinder head

and plenum chamber sides of the manifold,

and for the rocker covers.

77Commence refitting by applying sealant

(Ford part No A70X-19554-BA, or equivalent)

around the ports and coolant passages on the

cylinder head.

78Apply sealant around the apertures on

both sides of the gasket. then fit the gasket to

the cylinder heads.

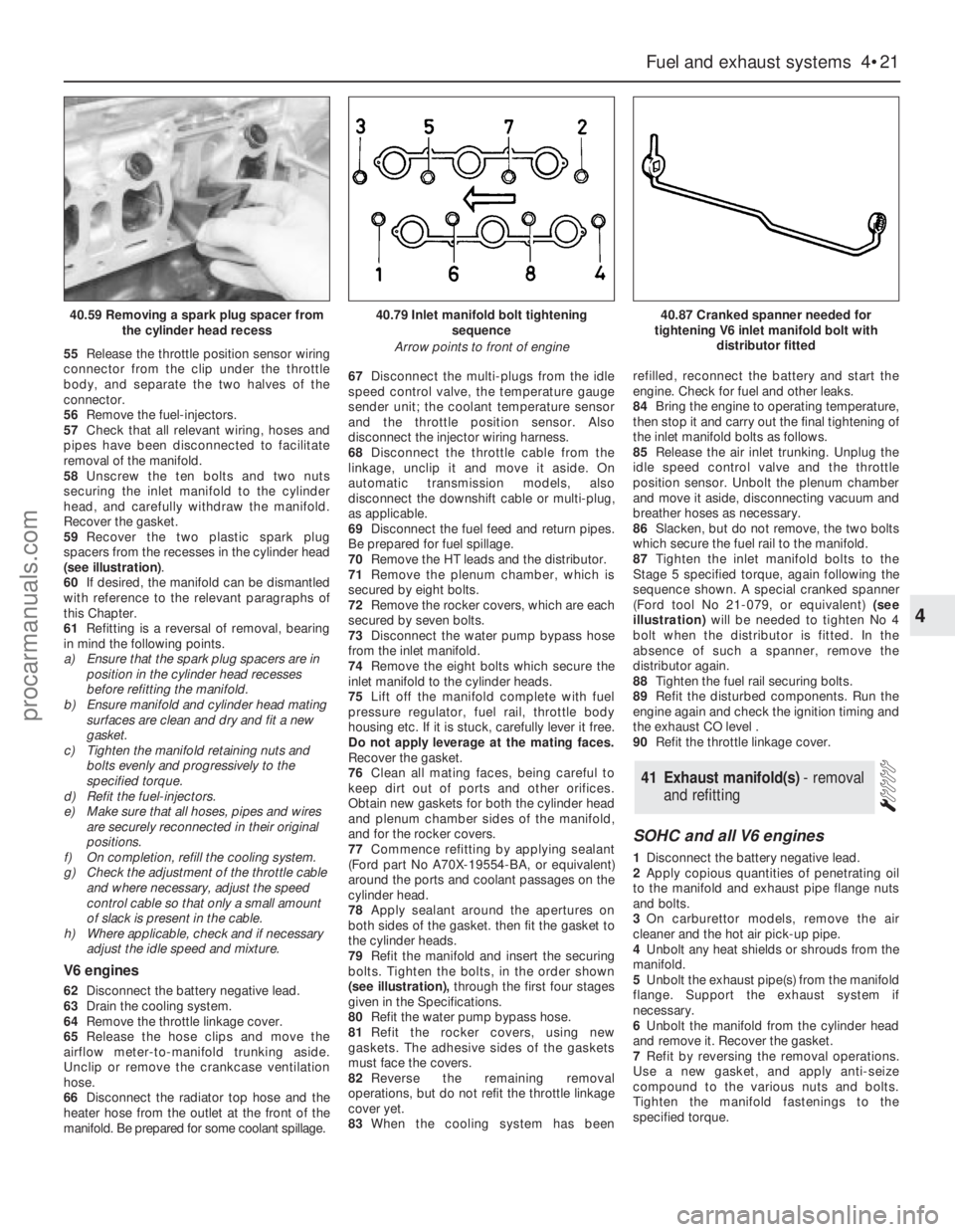

79Refit the manifold and insert the securing

bolts. Tighten the bolts, in the order shown

(see illustration),through the first four stages

given in the Specifications.

80Refit the water pump bypass hose.

81Refit the rocker covers, using new

gaskets. The adhesive sides of the gaskets

must face the covers.

82Reverse the remaining removal

operations, but do not refit the throttle linkage

cover yet.

83When the cooling system has beenrefilled, reconnect the battery and start the

engine. Check for fuel and other leaks.

84Bring the engine to operating temperature,

then stop it and carry out the final tightening of

the inlet manifold bolts as follows.

85Release the air inlet trunking. Unplug the

idle speed control valve and the throttle

position sensor. Unbolt the plenum chamber

and move it aside, disconnecting vacuum and

breather hoses as necessary.

86Slacken, but do not remove, the two bolts

which secure the fuel rail to the manifold.

87Tighten the inlet manifold bolts to the

Stage 5 specified torque, again following the

sequence shown. A special cranked spanner

(Ford tool No 21-079, or equivalent)(see

illustration)will be needed to tighten No 4

bolt when the distributor is fitted. In the

absence of such a spanner, remove the

distributor again.

88Tighten the fuel rail securing bolts.

89Refit the disturbed components. Run the

engine again and check the ignition timing and

the exhaust CO level .

90Refit the throttle linkage cover.

SOHC and all V6 engines

1Disconnect the battery negative lead.

2Apply copious quantities of penetrating oil

to the manifold and exhaust pipe flange nuts

and bolts.

3On carburettor models, remove the air

cleaner and the hot air pick-up pipe.

4Unbolt any heat shields or shrouds from the

manifold.

5Unbolt the exhaust pipe(s) from the manifold

flange. Support the exhaust system if

necessary.

6Unbolt the manifold from the cylinder head

and remove it. Recover the gasket.

7Refit by reversing the removal operations.

Use a new gasket, and apply anti-seize

compound to the various nuts and bolts.

Tighten the manifold fastenings to the

specified torque.

41Exhaust manifold(s) - removal

and refitting

Fuel and exhaust systems 4•21

4

40.59 Removing a spark plug spacer from

the cylinder head recess40.79 Inlet manifold bolt tightening

sequence

Arrow points to front of engine40.87 Cranked spanner needed for

tightening V6 inlet manifold bolt with

distributor fitted

procarmanuals.com

Page 115 of 255

DOHC carburettor engine

8This procedure is essentially as described

above, noting the following points:

a)Note the plastic bush which is fitted to the

rear manifold stud. This must be removed

before the gasket can be withdrawn.

b)On refitting ensure that the mating

surfaces are clean and dry and fit new

gaskets.

c)Apply a thin coat of anti-seize compound

to the manifold studs to aid future

removal.

d)Tighten the manifold nuts to the specified

torque settings.

DOHC fuel-injection engine

9Disconnect the battery negative lead.

10Disconnect the wiring plug from the idle

speed control valve at the front of the plenum

chamber.

11Loosen the clamp, and detach the air inlet

hose from the air inlet tubing.

12Unscrew the securing nut, and release the

air inlet tube from the bracket on the engine

compartment front panel.

13Release the air cleaner lid securing clips,

then lift away the air inlet tube, plenum

chamber and air cleaner lid as an assembly,

disconnecting the breather hose from the air

inlet tube.

14On models fitted with a catalytic

converter, disconnect the exhaust gas oxygen

sensor wiring plug.

15Unscrew the securing nuts and disconnect

the exhaust downpipe from the manifold.

Recover the gasket. Support the exhaust

downpipe from underneath the vehicle (eg

with an axle stand) to avoid placing

unnecessary strain on the exhaust system.

16Unscrew the six securing nuts, and lift the

manifold from the cylinder head. Recover the

gasket.

17Refitting is a reversal of removal, bearing

in mind the following points.

a)Ensure that all mating faces are clean, and

use a new gasket.

b)Tighten the manifold securing nuts and

the downpipe securing nuts progressively

to the specified torque (where given).

SOHC and 2.8 litre V6 engines

1Periodically inspect the exhaust system for

freedom from corrosion and security of

mountings. Large holes will be obvious; small

holes may be found more easily by letting the

engine idle and partly obstructing the tailpipe

with a wad of cloth.

2Check the condition of the rubber

mountings by applying downward pressure on

the exhaust system and observing the

mountings for splits or cracks. Renew

deteriorated mountings.

3The exhaust systems fitted in production

have fewer sections than those available for

repair. Repair sections may be fitted to

production systems by cutting at the

appropriate point.

4The production exhaust systems are made

of aluminised and stainless steel. Repair

systems are available to the same standard, or

in standard quality (SQ) painted mild steel.

5It is recommended that the whole exhaust

system be removed even if only part requires

renewal, since separation of old joints, cutting

pipes etc is much easier away from the

vehicle. Proceed as follows.

6Disconnect the battery negative lead. Raise

and support the vehicle.

7Unbolt the manifold-to-downpipe flanged

joint(s).

8On V6 models, unbolt the left-hand front

silencer mounting.

9Release any earth straps.

10With the help of an assistant, unhook the

system from its mountings and remove it.

11Renew sections as necessary. Apply

exhaust jointing compound to sliding and

flanged joints, but do not tighten their clamps

yet. Use new sealing rings where necessary

(see illustration).

12Offer the system to the vehicle and hook it

onto the mountings.

13Refit any earth straps. On V6 models, also

refit the left-hand front silencer mounting.

14Loosely fit the manifold flange nuts.

Correct the alignment of the system, then

tighten all clamp nuts and bolts, starting at the

manifold flange(s) and working rearwards.

15Check that the system alignment is still

satisfactory then reconnect the battery. Run

the engine and check for leaks.

16When the system has warmed up, stop the

engine and carefully check the tightness of the

clamp nuts and bolts.

DOHC and 2.4 & 2.9 litre V6

engines

17Follow the above procedure, noting that

flanged joints incorporating gaskets may be

used to join exhaust sections on these

models. Where applicable, renew the gaskets

on refitting.

18On models fitted with a catalyticconverter, disconnect the battery negative

terminal and disconnect the exhaust gas

oxygen (HEGO) sensor wiring plug before

removing the downpipe.

DOHC engine

Note: The exhaust gas oxygen (HEGO) sensor

is delicate and will not work if it is dropped or

knocked, if the power supply is disrupted, or if

any cleaning materials are used on it. Never

touch the tip of the sensor as this can also

damage it.

1Ensure that the engine and the exhaust

system are cold.

2Disconnect the battery negative lead.

3Apply the handbrake, then jack up the front

of the vehicle, and support it securely on axle

stands (see “Jacking”).

4Disconnect the sensor wiring plug halves by

releasing the locktabs and pulling on the plug

halves, not the wiring.

5Slide the heat shield (where fitted) from the

sensor.

6Bearing in mind the note made at the start

of this operation, unscrew the sensor from the

exhaust downpipe, and recover the sealing

ring (see illustration).

7Commence refitting by ensuring that the

sensor threads and the corresponding threads

in the downpipe are clean.

8Refit the sensor using a new sealing ring,

and tighten it to the specified torque.

9Further refitting is a reversal of removal, but

on completion start the engine, and check for

leaks around the sensor sealing ring.

V6 engines

10The sensors fitted to these models can be

removed and refitted using the information

given above, noting that on early models there

was only one sensor, which was fitted at the

point where the two downpipes meet below

the engine, and on some later models there

are two sensors, one in each downpipe.

43Exhaust gas oxygen (HEGO)

sensor (models with catalytic

converter) - removal and

refitting

42Exhaust system - inspection,

repair and renewal

4•22Fuel and exhaust systems

43.6 Exhaust gas oxygen (HEGO) sensor

(viewed from underneath)

42.11 Exhaust pipe flanged joint

A Sealing ring

B Flange

procarmanuals.com

Page 119 of 255

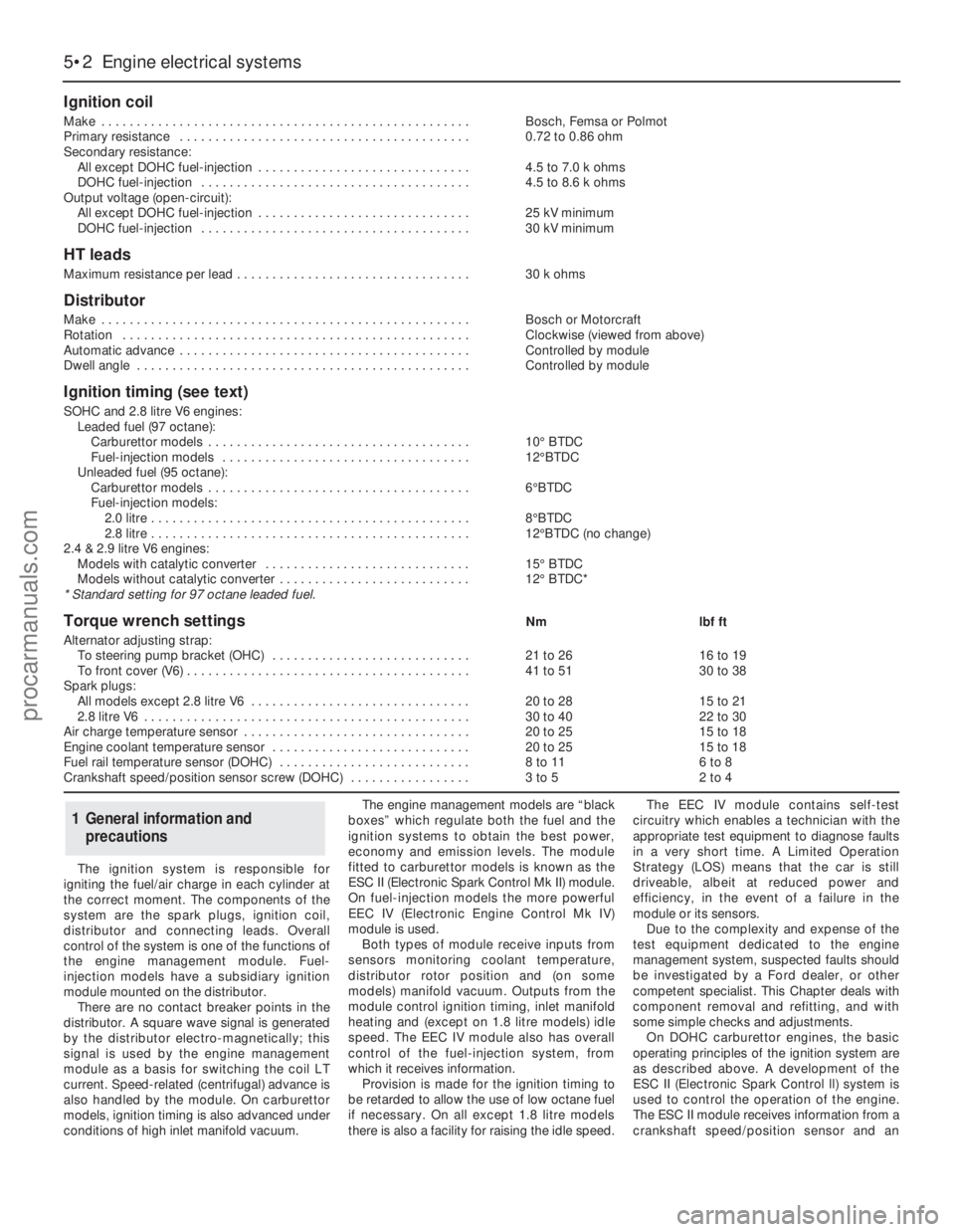

The ignition system is responsible for

igniting the fuel/air charge in each cylinder at

the correct moment. The components of the

system are the spark plugs, ignition coil,

distributor and connecting leads. Overall

control of the system is one of the functions of

the engine management module. Fuel-

injection models have a subsidiary ignition

module mounted on the distributor.

There are no contact breaker points in the

distributor. A square wave signal is generated

by the distributor electro-magnetically; this

signal is used by the engine management

module as a basis for switching the coil LT

current. Speed-related (centrifugal) advance is

also handled by the module. On carburettor

models, ignition timing is also advanced under

conditions of high inlet manifold vacuum.The engine management models are “black

boxes” which regulate both the fuel and the

ignition systems to obtain the best power,

economy and emission levels. The module

fitted to carburettor models is known as the

ESC II (Electronic Spark Control Mk II) module.

On fuel-injection models the more powerful

EEC IV (Electronic Engine Control Mk IV)

module is used.

Both types of module receive inputs from

sensors monitoring coolant temperature,

distributor rotor position and (on some

models) manifold vacuum. Outputs from the

module control ignition timing, inlet manifold

heating and (except on 1.8 litre models) idle

speed. The EEC IV module also has overall

control of the fuel-injection system, from

which it receives information.

Provision is made for the ignition timing to

be retarded to allow the use of low octane fuel

if necessary. On all except 1.8 litre models

there is also a facility for raising the idle speed.The EEC IV module contains self-test

circuitry which enables a technician with the

appropriate test equipment to diagnose faults

in a very short time. A Limited Operation

Strategy (LOS) means that the car is still

driveable, albeit at reduced power and

efficiency, in the event of a failure in the

module or its sensors.

Due to the complexity and expense of the

test equipment dedicated to the engine

management system, suspected faults should

be investigated by a Ford dealer, or other

competent specialist. This Chapter deals with

component removal and refitting, and with

some simple checks and adjustments.

On DOHC carburettor engines, the basic

operating principles of the ignition system are

as described above. A development of the

ESC II (Electronic Spark Control ll) system is

used to control the operation of the engine.

The ESC II module receives information from a

crankshaft speed/position sensor and an

1General information and

precautions

5•2Engine electrical systems

Ignition coil

Make . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bosch, Femsa or Polmot

Primary resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.72 to 0.86 ohm

Secondary resistance:

All except DOHC fuel-injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.5 to 7.0 k ohms

DOHC fuel-injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.5 to 8.6 k ohms

Output voltage (open-circuit):

All except DOHC fuel-injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 kV minimum

DOHC fuel-injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 kV minimum

HT leads

Maximum resistance per lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 k ohms

Distributor

Make . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bosch or Motorcraft

Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Clockwise (viewed from above)

Automatic advance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Controlled by module

Dwell angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Controlled by module

Ignition timing (see text)

SOHC and 2.8 litre V6 engines:

Leaded fuel (97 octane):

Carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10°BTDC

Fuel-injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12°BTDC

Unleaded fuel (95 octane):

Carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6°BTDC

Fuel-injection models:

2.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8°BTDC

2.8 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12°BTDC (no change)

2.4 & 2.9 litre V6 engines:

Models with catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15°BTDC

Models without catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . .12°BTDC*

* Standard setting for 97 octane leaded fuel.

Torque wrench settingsNmlbf ft

Alternator adjusting strap:

To steering pump bracket (OHC) . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2616 to 19

To front cover (V6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 to 5130 to 38

Spark plugs:

All models except 2.8 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2815 to 21

2.8 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 to 4022 to 30

Air charge temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Engine coolant temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Fuel rail temperature sensor (DOHC) . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Crankshaft speed/position sensor screw (DOHC) . . . . . . . . . . . . . . . . .3 to 52 to 4

procarmanuals.com