warning FORD GRANADA 1985 Service Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 191 of 255

13•14Body electrical system

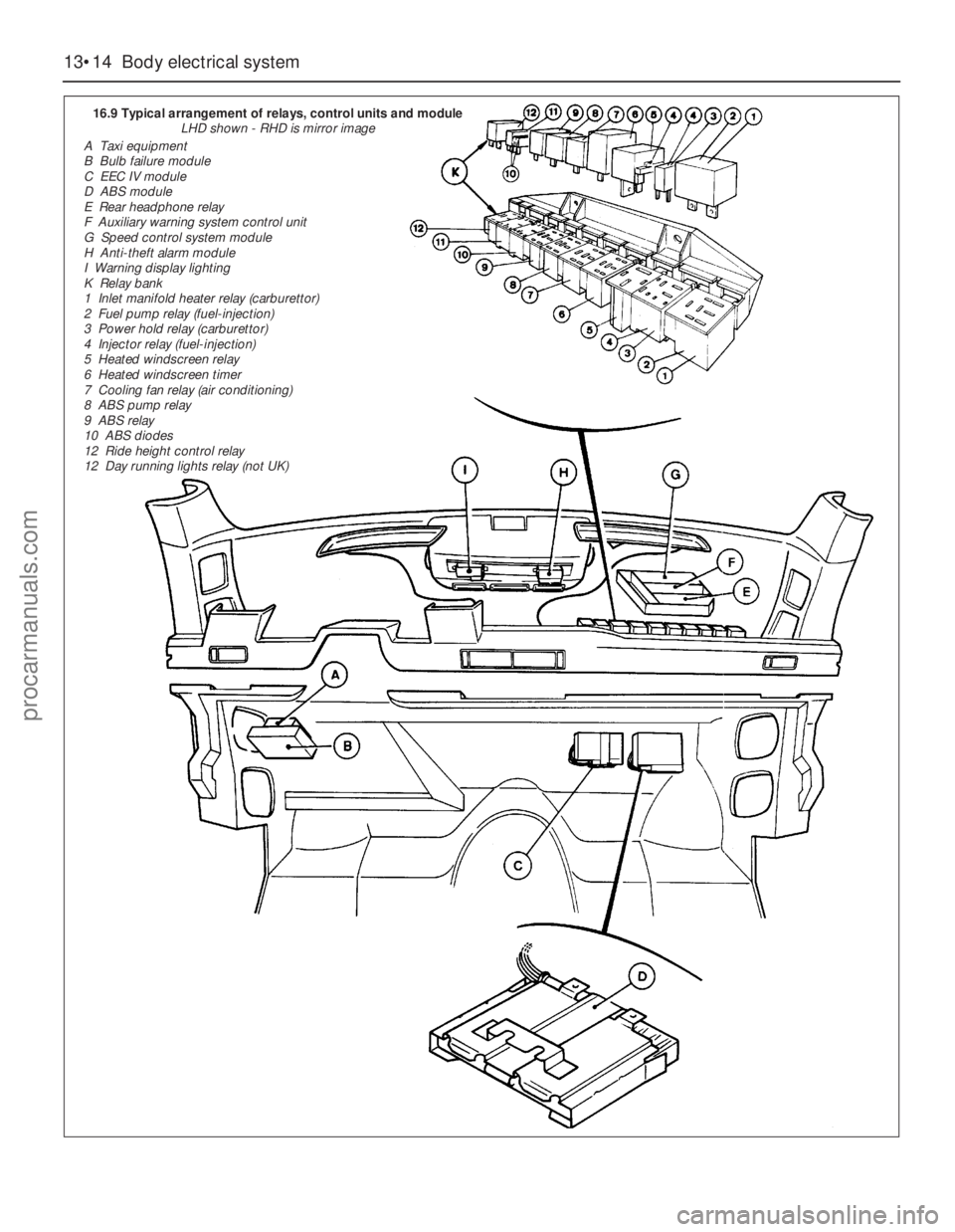

16.9 Typical arrangement of relays, control units and module

LHD shown - RHD is mirror image

A Taxi equipment

B Bulb failure module

C EEC IV module

D ABS module

E Rear headphone relay

F Auxiliary warning system control unit

G Speed control system module

H Anti-theft alarm module

I Warning display lighting

K Relay bank

1 Inlet manifold heater relay (carburettor)

2 Fuel pump relay (fuel-injection)

3 Power hold relay (carburettor)

4 Injector relay (fuel-injection)

5 Heated windscreen relay

6 Heated windscreen timer

7 Cooling fan relay (air conditioning)

8 ABS pump relay

9 ABS relay

10 ABS diodes

12 Ride height control relay

12 Day running lights relay (not UK)

procarmanuals.com

Page 195 of 255

Computer module and bulb

Models before April 1992

2Remove the instrument panel surround,

which is secured by four screws.

3Carefully pull the module from its location.

Release the multi-plug by pressing

downwards and disconnect it.

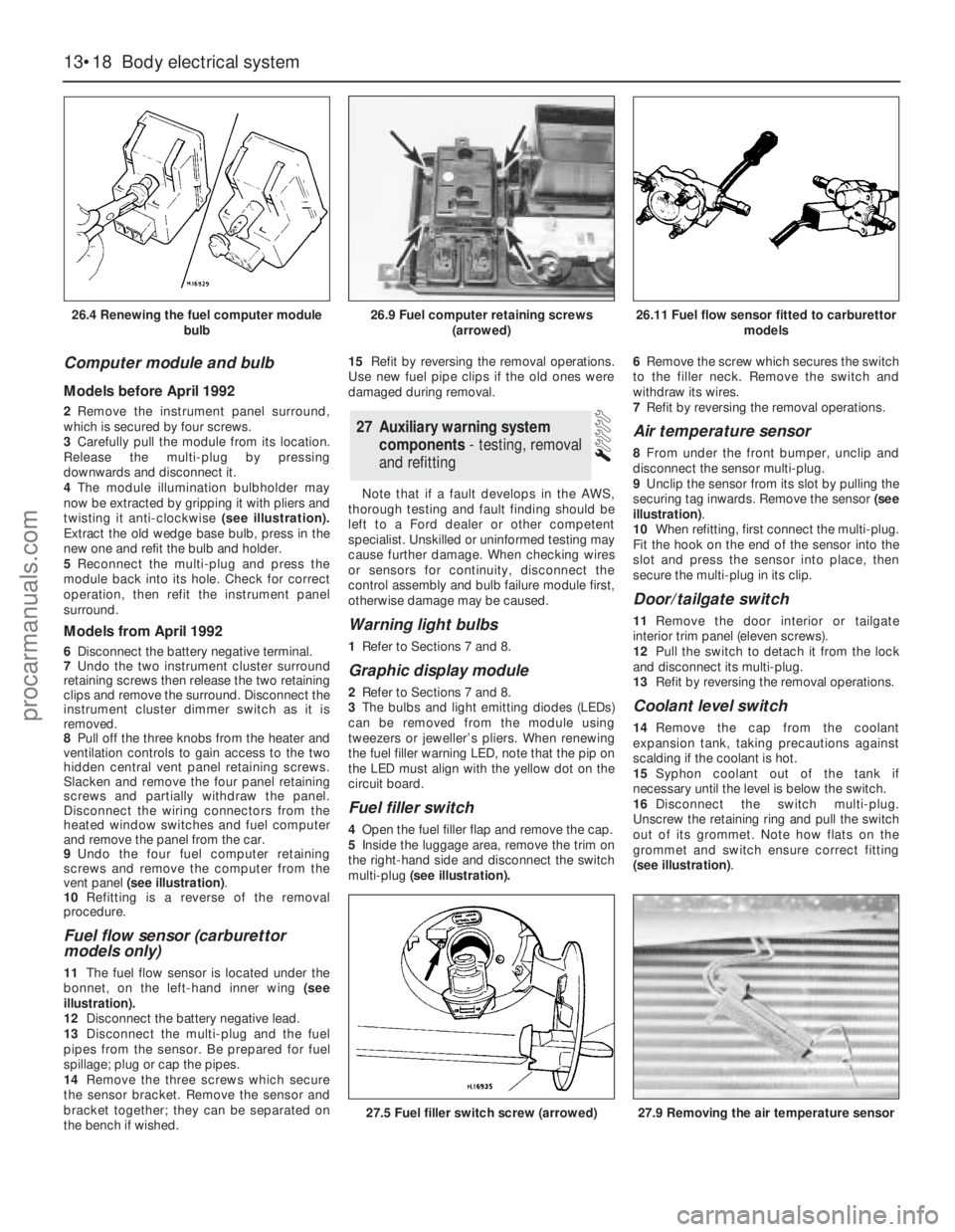

4The module illumination bulbholder may

now be extracted by gripping it with pliers and

twisting it anti-clockwise (see illustration).

Extract the old wedge base bulb, press in the

new one and refit the bulb and holder.

5Reconnect the multi-plug and press the

module back into its hole. Check for correct

operation, then refit the instrument panel

surround.

Models from April 1992

6Disconnect the battery negative terminal.

7Undo the two instrument cluster surround

retaining screws then release the two retaining

clips and remove the surround. Disconnect the

instrument cluster dimmer switch as it is

removed.

8Pull off the three knobs from the heater and

ventilation controls to gain access to the two

hidden central vent panel retaining screws.

Slacken and remove the four panel retaining

screws and partially withdraw the panel.

Disconnect the wiring connectors from the

heated window switches and fuel computer

and remove the panel from the car.

9Undo the four fuel computer retaining

screws and remove the computer from the

vent panel (see illustration).

10Refitting is a reverse of the removal

procedure.

Fuel flow sensor (carburettor

models only)

11The fuel flow sensor is located under the

bonnet, on the left-hand inner wing (see

illustration).

12Disconnect the battery negative lead.

13Disconnect the multi-plug and the fuel

pipes from the sensor. Be prepared for fuel

spillage; plug or cap the pipes.

14Remove the three screws which secure

the sensor bracket. Remove the sensor and

bracket together; they can be separated on

the bench if wished.15Refit by reversing the removal operations.

Use new fuel pipe clips if the old ones were

damaged during removal.

Note that if a fault develops in the AWS,

thorough testing and fault finding should be

left to a Ford dealer or other competent

specialist. Unskilled or uninformed testing may

cause further damage. When checking wires

or sensors for continuity, disconnect the

control assembly and bulb failure module first,

otherwise damage may be caused.

Warning light bulbs

1Refer to Sections 7 and 8.

Graphic display module

2Refer to Sections 7 and 8.

3The bulbs and light emitting diodes (LEDs)

can be removed from the module using

tweezers or jeweller’s pliers. When renewing

the fuel filler warning LED, note that the pip on

the LED must align with the yellow dot on the

circuit board.

Fuel filler switch

4Open the fuel filler flap and remove the cap.

5Inside the luggage area, remove the trim on

the right-hand side and disconnect the switch

multi-plug(see illustration).6Remove the screw which secures the switch

to the filler neck. Remove the switch and

withdraw its wires.

7Refit by reversing the removal operations.

Air temperature sensor

8From under the front bumper, unclip and

disconnect the sensor multi-plug.

9Unclip the sensor from its slot by pulling the

securing tag inwards. Remove the sensor (see

illustration).

10When refitting, first connect the multi-plug.

Fit the hook on the end of the sensor into the

slot and press the sensor into place, then

secure the multi-plug in its clip.

Door/tailgate switch

11Remove the door interior ortailgate

interior trim panel (eleven screws).

12Pull the switch to detach it from the lock

and disconnect its multi-plug.

13Refit by reversing the removal operations.

Coolant level switch

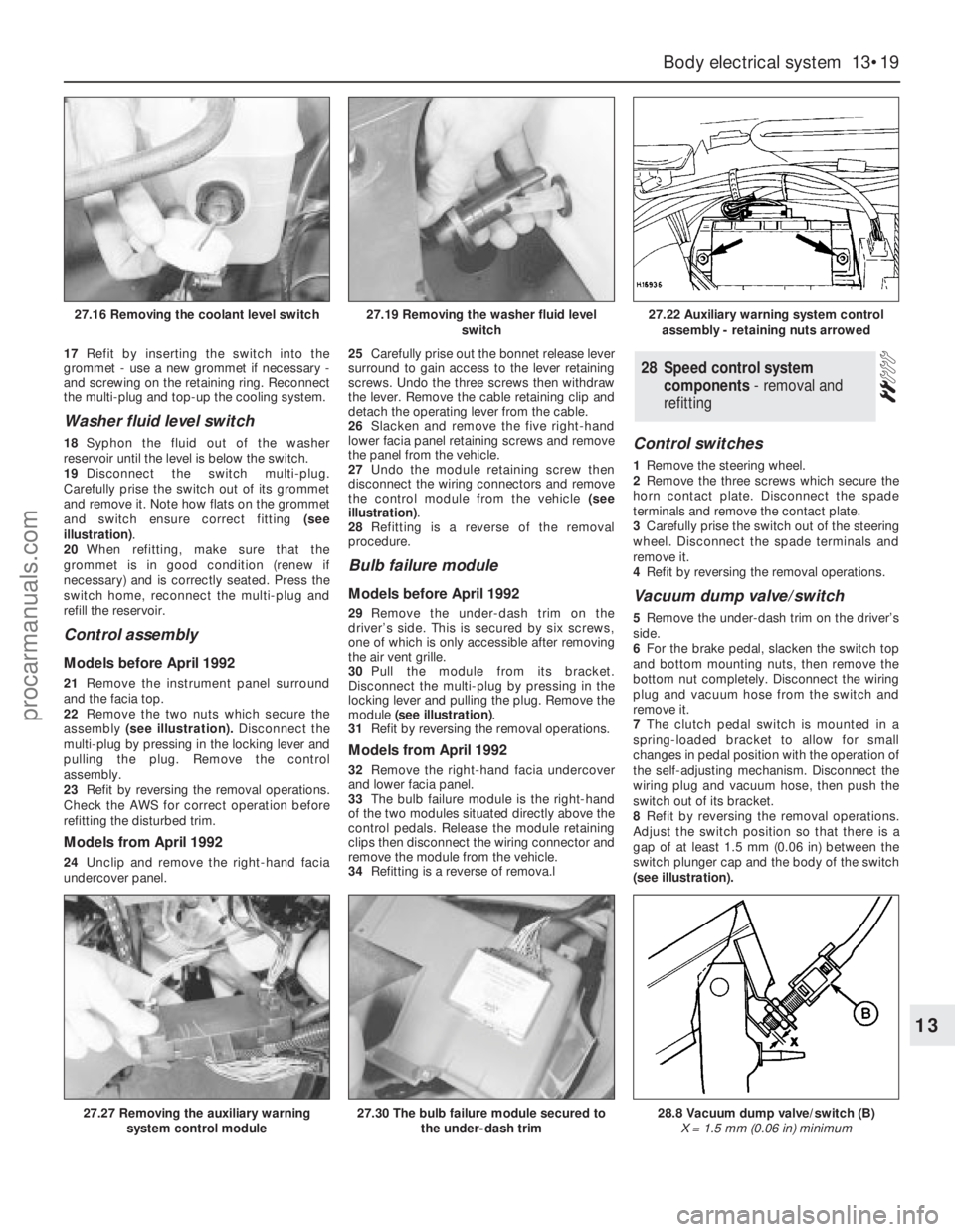

14Remove the cap from the coolant

expansion tank, taking precautions against

scalding if the coolant is hot.

15Syphon coolant out of the tank if

necessary until the level is below the switch.

16Disconnect the switch multi-plug.

Unscrew the retaining ring and pull the switch

out of its grommet. Note how flats on the

grommet and switch ensure correct fitting

(see illustration).

27Auxiliary warning system

components - testing, removal

and refitting

13•18Body electrical system

26.4 Renewing the fuel computer module

bulb

27.5 Fuel filler switch screw (arrowed)27.9 Removing the air temperature sensor

26.9 Fuel computer retaining screws

(arrowed)26.11 Fuel flow sensor fitted to carburettor

models

procarmanuals.com

Page 196 of 255

17Refit by inserting the switch into the

grommet - use a new grommet if necessary -

and screwing on the retaining ring. Reconnect

the multi-plug and top-up the cooling system.

Washer fluid level switch

18Syphon the fluid out of the washer

reservoir until the level is below the switch.

19Disconnect the switch multi-plug.

Carefully prise the switch out of its grommet

and remove it. Note how flats on the grommet

and switch ensure correct fitting (see

illustration).

20When refitting, make sure that the

grommet is in good condition (renew if

necessary) and is correctly seated. Press the

switch home, reconnect the multi-plug and

refill the reservoir.

Control assembly

Models before April 1992

21Remove the instrument panel surround

and the facia top.

22Remove the two nuts which secure the

assembly(see illustration).Disconnect the

multi-plug by pressing in the locking lever and

pulling the plug. Remove the control

assembly.

23Refit by reversing the removal operations.

Check the AWS for correct operation before

refitting the disturbed trim.

Models from April 1992

24Unclip and remove the right-hand facia

undercover panel.25Carefully prise out the bonnet release lever

surround to gain access to the lever retaining

screws. Undo the three screws then withdraw

the lever. Remove the cable retaining clip and

detach the operating lever from the cable.

26Slacken and remove the five right-hand

lower facia panel retaining screws and remove

the panel from the vehicle.

27Undo the module retaining screw then

disconnect the wiring connectors and remove

the control module from the vehicle (see

illustration).

28Refitting is a reverse of the removal

procedure.

Bulb failure module

Models before April 1992

29Remove the under-dash trim on the

driver’s side. This is secured by six screws,

one of which is only accessible after removing

the air vent grille.

30Pull the module from its bracket.

Disconnect the multi-plug by pressing in the

locking lever and pulling the plug. Remove the

module (see illustration).

31Refit by reversing the removal operations.

Models from April 1992

32Remove the right-hand facia undercover

and lower facia panel.

33The bulb failure module is the right-hand

of the two modules situated directly above the

control pedals. Release the module retaining

clips then disconnect the wiring connector and

remove the module from the vehicle.

34Refitting is a reverse of remova.l

Control switches

1Remove the steering wheel.

2Remove the three screws which secure the

horn contact plate. Disconnect the spade

terminals and remove the contact plate.

3Carefully prise the switch out of the steering

wheel. Disconnect the spade terminals and

remove it.

4Refit by reversing the removal operations.

Vacuum dump valve/switch

5Remove the under-dash trim on the driver’s

side.

6For the brake pedal, slacken the switch top

and bottom mounting nuts, then remove the

bottom nut completely. Disconnect the wiring

plug and vacuum hose from the switch and

remove it.

7The clutch pedal switch is mounted in a

spring-loaded bracket to allow for small

changes in pedal position with the operation of

the self-adjusting mechanism. Disconnect the

wiring plug and vacuum hose, then push the

switch out of its bracket.

8Refit by reversing the removal operations.

Adjust the switch position so that there is a

gap of at least 1.5 mm (0.06 in) between the

switch plunger cap and the body of the switch

(see illustration).

28Speed control system

components - removal and

refitting

Body electrical system 13•19

13

27.16 Removing the coolant level switch27.19 Removing the washer fluid level

switch27.22 Auxiliary warning system control

assembly - retaining nuts arrowed

27.27 Removing the auxiliary warning

system control module27.30 The bulb failure module secured to

the under-dash trim28.8 Vacuum dump valve/switch (B)

X = 1.5 mm (0.06 in) minimum

procarmanuals.com

Page 200 of 255

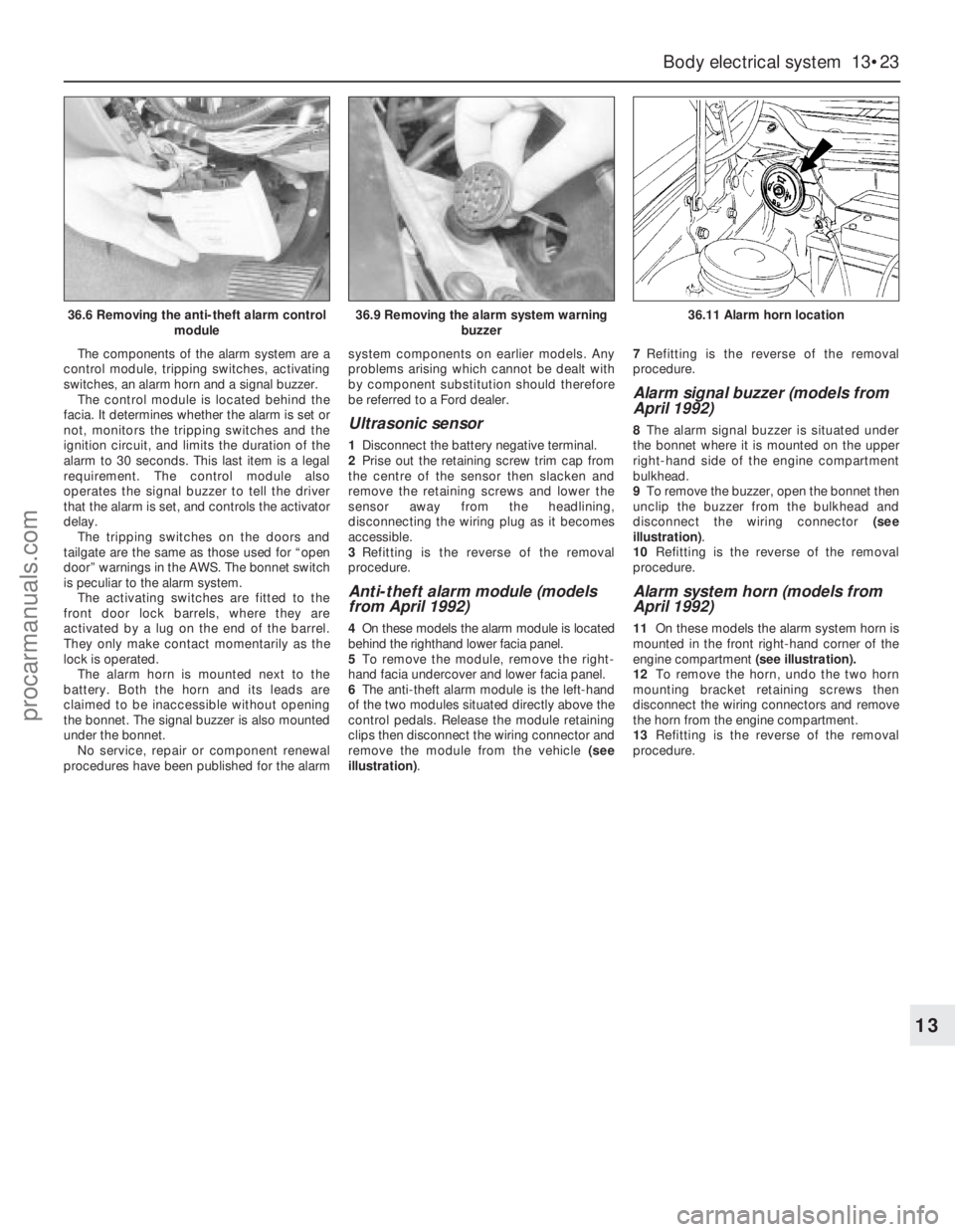

The components of the alarm system are a

control module, tripping switches, activating

switches, an alarm horn and a signal buzzer.

The control module is located behind the

facia. It determines whether the alarm is set or

not, monitors the tripping switches and the

ignition circuit, and limits the duration of the

alarm to 30 seconds. This last item is a legal

requirement. The control module also

operates the signal buzzer to tell the driver

that the alarm is set, and controls the activator

delay.

The tripping switches on the doors and

tailgate are the same as those used for “open

door” warnings in the AWS. The bonnet switch

is peculiar to the alarm system.

The activating switches are fitted to the

front door lock barrels, where they are

activated by a lug on the end of the barrel.

They only make contact momentarily as the

lock is operated.

The alarm horn is mounted next to the

battery. Both the horn and its leads are

claimed to be inaccessible without opening

the bonnet. The signal buzzer is also mounted

under the bonnet.

No service, repair or component renewal

procedures have been published for the alarmsystem components on earlier models. Any

problems arising which cannot be dealt with

by component substitution should therefore

be referred to a Ford dealer.

Ultrasonic sensor

1Disconnect the battery negative terminal.

2Prise out the retaining screw trim cap from

the centre of the sensor then slacken and

remove the retaining screws and lower the

sensor away from the headlining,

disconnecting the wiring plug as it becomes

accessible.

3Refitting is the reverse of the removal

procedure.

Anti-theft alarm module (models

from April 1992)

4On these models the alarm module is located

behind the righthand lower facia panel.

5To remove the module, remove the right-

hand facia undercover and lower facia panel.

6The anti-theft alarm module is the left-hand

of the two modules situated directly above the

control pedals. Release the module retaining

clips then disconnect the wiring connector and

remove the module from the vehicle (see

illustration).7Refitting is the reverse of the removal

procedure.

Alarm signal buzzer (models from

April 1992)

8The alarm signal buzzer is situated under

the bonnet where it is mounted on the upper

right-hand side of the engine compartment

bulkhead.

9To remove the buzzer, open the bonnet then

unclip the buzzer from the bulkhead and

disconnect the wiring connector (see

illustration).

10Refitting is the reverse of the removal

procedure.

Alarm system horn (models from

April 1992)

11On these models the alarm system horn is

mounted in the front right-hand corner of the

engine compartment (see illustration).

12To remove the horn, undo the two horn

mounting bracket retaining screws then

disconnect the wiring connectors and remove

the horn from the engine compartment.

13Refitting is the reverse of the removal

procedure.

Body electrical system 13•23

13

36.6 Removing the anti-theft alarm control

module36.9 Removing the alarm system warning

buzzer36.11 Alarm horn location

procarmanuals.com

Page 201 of 255

WD•0

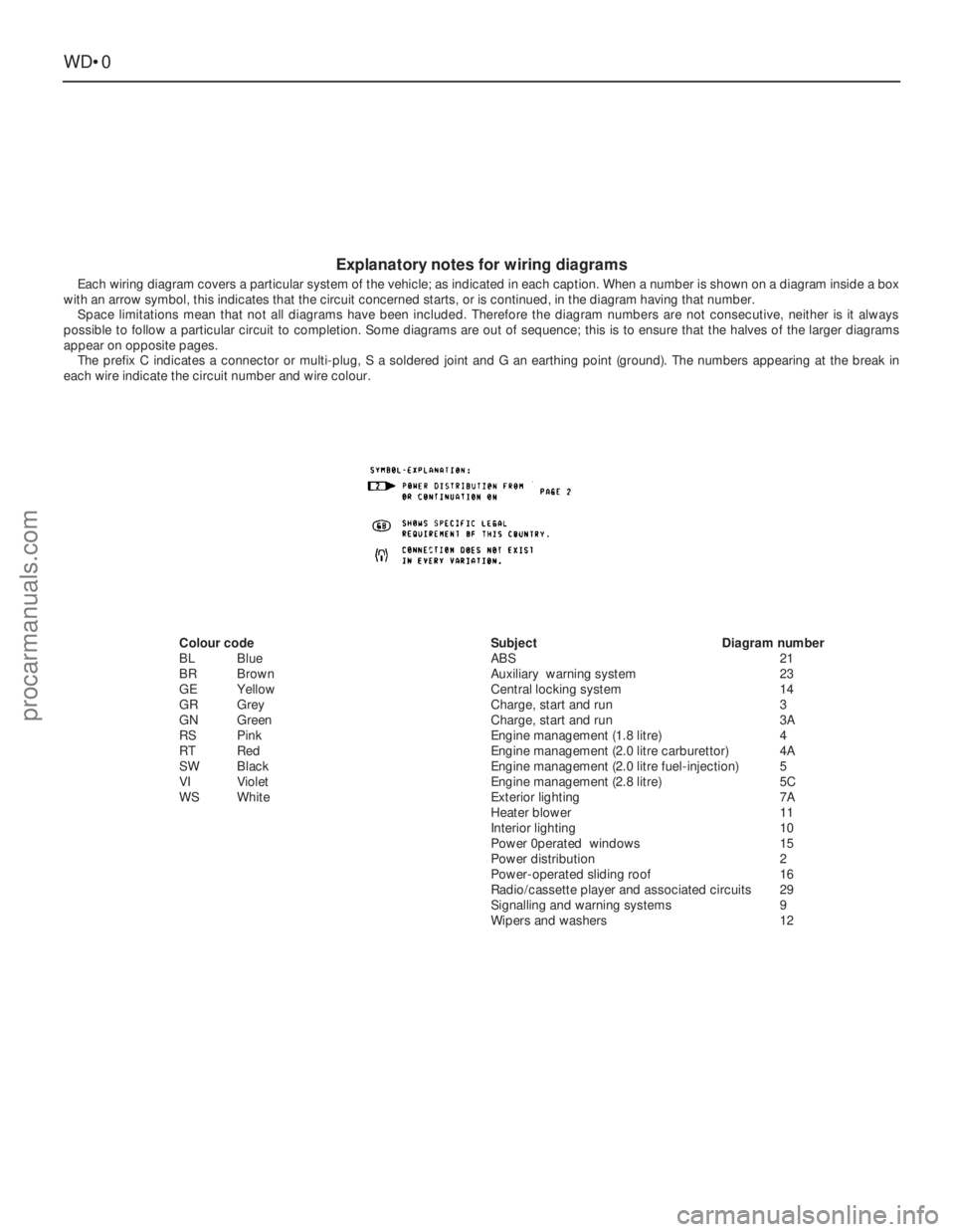

Explanatory notes for wiring diagrams

Each wiring diagram covers a particular system of the vehicle; as indicated in each caption. When a number is shown on a diagram inside a box

with an arrow symbol, this indicates that the circuit concerned starts, or is continued, in the diagram having that number.

Space limitations mean that not all diagrams have been included. Therefore the diagram numbers are not consecutive, neither is it always

possible to follow a particular circuit to completion. Some diagrams are out of sequence; this is to ensure that the halves of the larger diagrams

appear on opposite pages.

The prefix C indicates a connector or multi-plug, S a soldered joint and G an earthing point (ground). The numbers appearing at the break in

each wire indicate the circuit number and wire colour.

Colour code

BLBlue

BRBrown

GEYellow

GRGrey

GNGreen

RSPink

RT Red

SWBlack

VIViolet

WSWhiteSubjectDiagram number

ABS21

Auxiliary warning system23

Central locking system14

Charge, start and run3

Charge, start and run3A

Engine management (1.8 litre)4

Engine management (2.0 litre carburettor)4A

Engine management (2.0 litre fuel-injection)5

Engine management (2.8 litre)5C

Exterior lighting7A

Heater blower11

Interior lighting10

Power 0perated windows15

Power distribution2

Power-operated sliding roof16

Radio/cassette player and associated circuits29

Signalling and warning systems9

Wipers and washers12

procarmanuals.com

Page 219 of 255

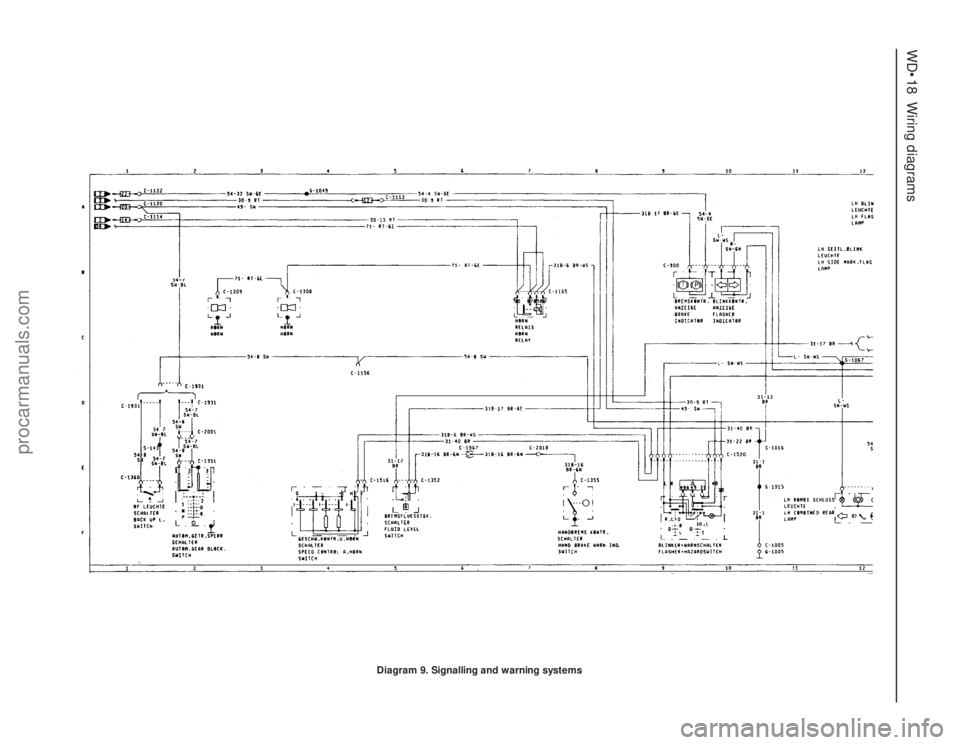

WD•18Wiring diagrams

Diagram 9. Signalling and warning systems

procarmanuals.com

Page 220 of 255

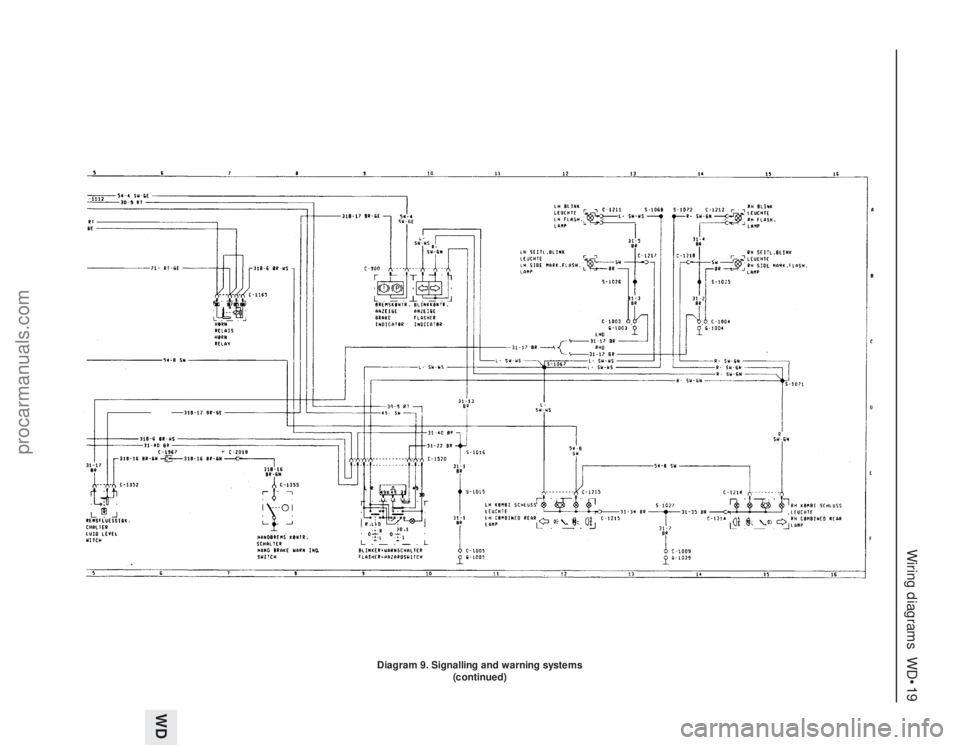

Wiring diagrams WD•19

WD

Diagram 9. Signalling and warning systems

(continued)

procarmanuals.com

Page 231 of 255

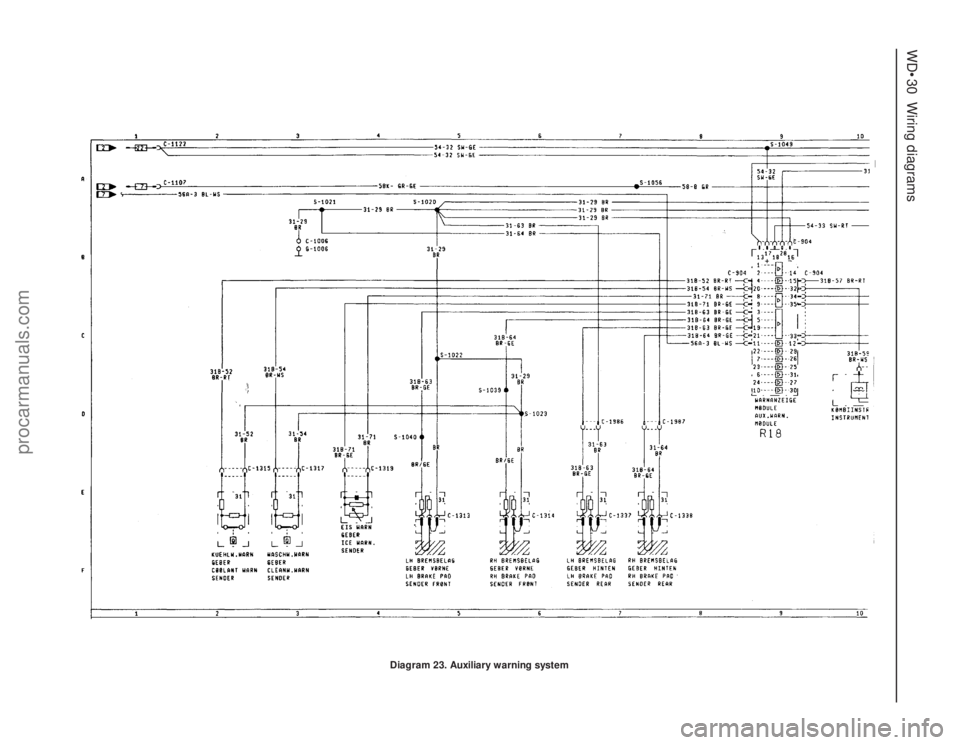

WD•30Wiring diagrams

Diagram 23. Auxiliary warning system

procarmanuals.com

Page 232 of 255

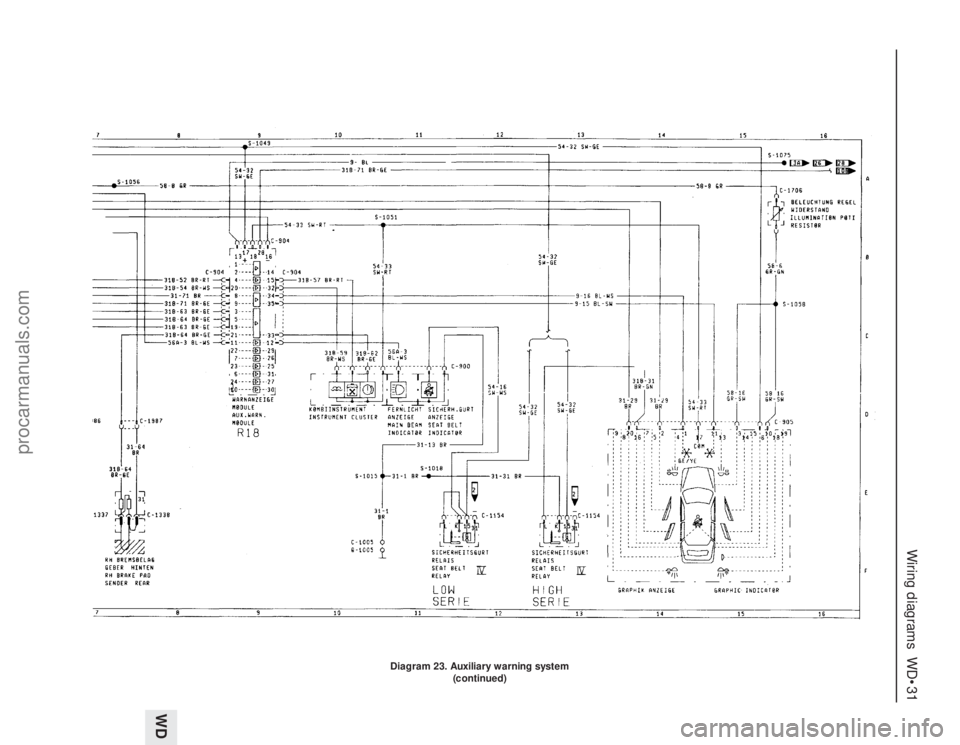

Wiring diagrams WD•31

WD

Diagram 23. Auxiliary warning system

(continued)

procarmanuals.com

Page 240 of 255

The vehicle owner who does his or her own maintenance according

to the recommended service schedules should not have to use this

section of the manual very often. Modern component reliability is such

that, provided those items subject to wear or deterioration are

inspected or renewed at the specified intervals, sudden failure is

comparatively rare. Faults do not usually just happen as a result of

sudden failure, but develop over a period of time. Major mechanical

failures in particular are usually preceded by characteristic symptoms

over hundreds or even thousands of miles. Those components which

do occasionally fail without warning are often small and easily carried

in the vehicle.With any fault-finding, the first step is to decide where to begin

investigations. Sometimes this is obvious, but on other occasions, a

little detective work will be necessary. The owner who makes half a

dozen haphazard adjustments or replacements may be successful in

curing a fault (or its symptoms), but will be none the wiser if the fault

recurs, and ultimately may have spent more time and money than was

necessary. A calm and logical approach will be found to be more

satisfactory in the long run. Always take into account any warning

signs or abnormalities that may have been noticed in the period

preceding the fault - power loss, high or low gauge readings, unusual

smells, etc - and remember that failure of components such as fuses or

REF•5Fault Finding

Engine1

m mEngine fails to rotate when attempting to start

m mStarter motor turns engine slowly

m mEngine rotates, but will not start

m mEngine difficult to start when cold

m mEngine difficult to start when hot

m mStarter motor noisy or excessively-rough in engagement

m mEngine starts, but stops immediately

m mEngine idles erratically

m mEngine misfires at idle speed

m mEngine misfires throughout the driving speed range

m mEngine hesitates on acceleration

m mEngine stalls

m mEngine lacks power

m mEngine backfires

m mOil pressure warning light illuminated with engine running

m mEngine runs-on after switching off

m mEngine noises

Cooling system2

m

mOverheating

m mOvercooling

m mExternal coolant leakage

m mInternal coolant leakage

m mCorrosion

Fuel and exhaust systems3

m

mExcessive fuel consumption

m mFuel leakage and/or fuel odour

m mExcessive noise or fumes from exhaust system

Clutch4

m

mPedal travels to floor - no pressure or very little resistance

m mClutch fails to disengage (unable to select gears)

m mClutch slips (engine speed increases, with no increase in vehicle

speed)

m mJudder as clutch is engaged

m mNoise when depressing or releasing clutch pedal

Manual gearbox5

m

mNoisy in neutral with engine running

m mNoisy in one particular gear

m mDifficulty engaging gears

m mJumps out of gear

m mVibration

m mLubricant leaks

Automatic transmission6

m

mFluid leakage

m mTransmission fluid brown, or has burned smellm mGeneral gear selection problems

m mTransmission will not downshift (kickdown) with accelerator fully

depressed

m mEngine will not start in any gear, or starts in gears other than Park

or Neutral

m mTransmission slips, shifts roughly, is noisy, or has no drive in

forward or reverse gears

Propeller shaft7

m

mClicking or knocking noise on turns (at slow speed on full-lock)

m mVibration when accelerating or decelerating

Final drive and driveshafts8

m

mExcessive final drive noise

m mOil leakage from final drive

m mGrating, knocking or vibration from driveshafts

Braking system9

m

mVehicle pulls to one side under braking

m mNoise (grinding or high-pitched squeal) when brakes applied

m mExcessive brake pedal travel

m mBrake pedal feels spongy when depressed

m mExcessive brake pedal effort required to stop vehicle

m mJudder felt through brake pedal or steering wheel when braking

m mPedal pulsates when braking hard

m mBrakes binding

m mRear wheels locking under normal braking

Suspension and steering systems10

m

mVehicle pulls to one side

m mWheel wobble and vibration

m mExcessive pitching and/or rolling around corners, or during braking

m mWandering or general instability

m mExcessively-stiff steering

m mExcessive play in steering

m mLack of power assistance

m mTyre wear excessive

Electrical system11

m

mLights inoperative

m mIgnition/no-charge warning light remains illuminated with engine

running

m mIgnition/no-charge warning light fails to come on

m mBattery will not hold a charge for more than a few days

m mInstrument readings inaccurate or erratic

m mHorn inoperative, or unsatisfactory in operation

m mWindscreen/tailgate wipers inoperative, or unsatisfactory in

operation

m mWindscreen/tailgate washers inoperative, or unsatisfactory in

operation

m mElectric windows inoperative, or unsatisfactory in operation

m mCentral locking system inoperative, or unsatisfactory in operation

Introduction

procarmanuals.com