ECU FORD GRANADA 1985 Service Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 86 of 255

See Chapter 1, Section 46.

See Chapter 1, Section 46.

See Chapter 1, Section 46.

1Drain the radiator. There is no need to drain

the cylinder block. On DOHC engines the

electric cooling fan assembly must be removed

to gain the clearance to remove the radiator.

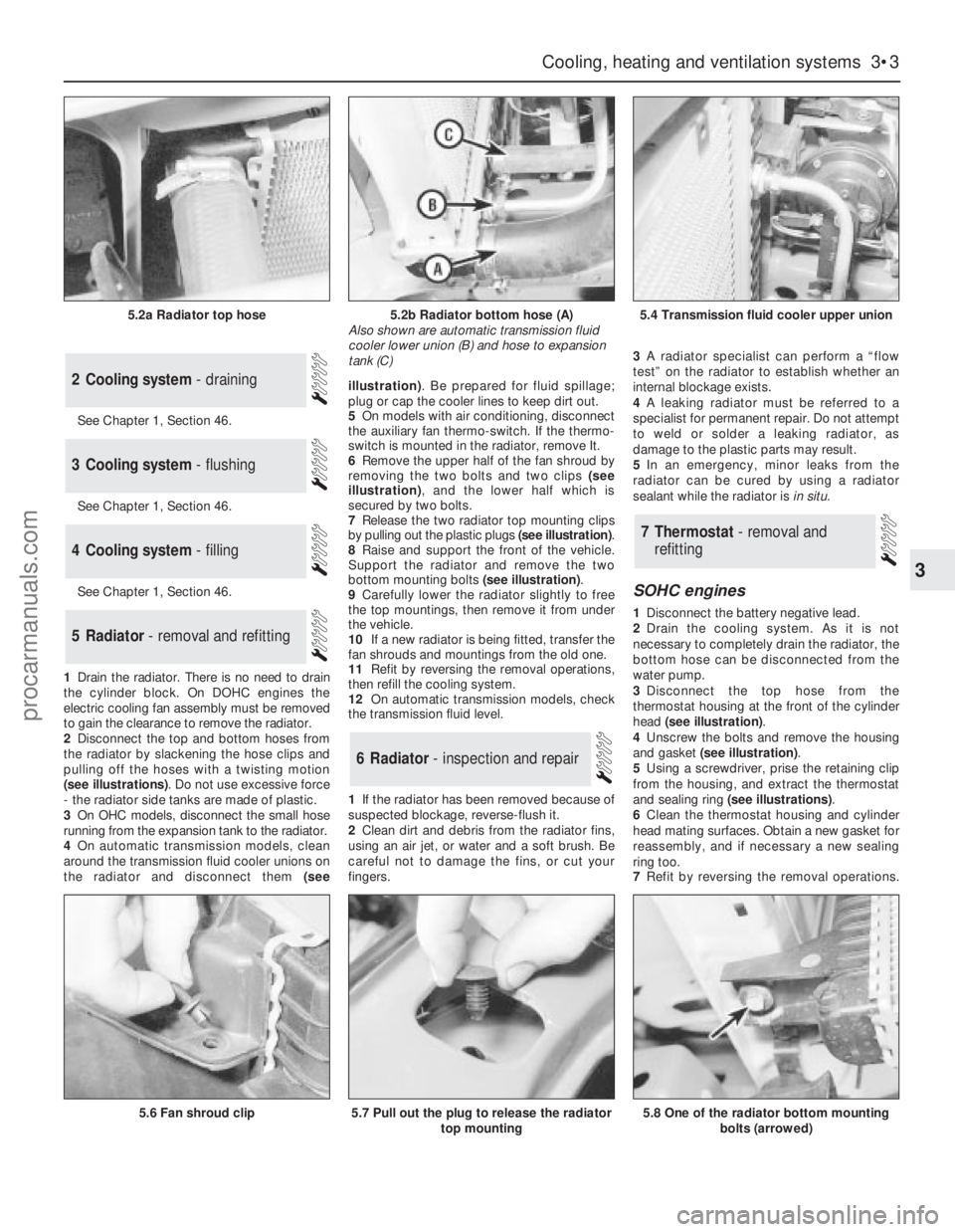

2Disconnect the top and bottom hoses from

the radiator by slackening the hose clips and

pulling off the hoses with a twisting motion

(see illustrations). Do not use excessive force

- the radiator side tanks are made of plastic.

3On OHCmodels, disconnect the small hose

running from the expansion tank to the radiator.

4On automatic transmission models, clean

around the transmission fluid cooler unions on

the radiator and disconnect them (seeillustration). Be prepared for fluid spillage;

plug or cap the cooler lines to keep dirt out.

5On models with air conditioning, disconnect

the auxiliary fan thermo-switch. If the thermo-

switch is mounted in the radiator, remove It.

6Remove the upper half of the fan shroud by

removing the two bolts and two clips (see

illustration), and the lower half which is

secured by two bolts.

7Release the two radiator top mounting clips

by pulling out the plastic plugs (see illustration).

8Raise and support the front of the vehicle.

Support the radiator and remove the two

bottom mounting bolts (see illustration).

9Carefully lower the radiator slightly to free

the top mountings, then remove it from under

the vehicle.

10If a new radiator is being fitted, transfer the

fan shrouds and mountings from the old one.

11Refit by reversing the removal operations,

then refill the cooling system.

12On automatic transmission models, check

the transmission fluid level.

1If the radiator has been removed because of

suspected blockage, reverse-flush it.

2Clean dirt and debris from the radiator fins,

using an air jet, or water and a soft brush. Be

careful not to damage the fins, or cut your

fingers. 3A radiator specialist can perform a “flow

test” on the radiator to establish whether an

internal blockage exists.

4A leaking radiator must be referred to a

specialist for permanent repair. Do not attempt

to weld or solder a leaking radiator, as

damage to the plastic parts may result.

5In an emergency, minor leaks from the

radiator can be cured by using a radiator

sealant while the radiator is in situ.

SOHC engines

1Disconnect the battery negative lead.

2Drain the cooling system. As it is not

necessary to completely drain the radiator, the

bottom hose can be disconnected from the

water pump.

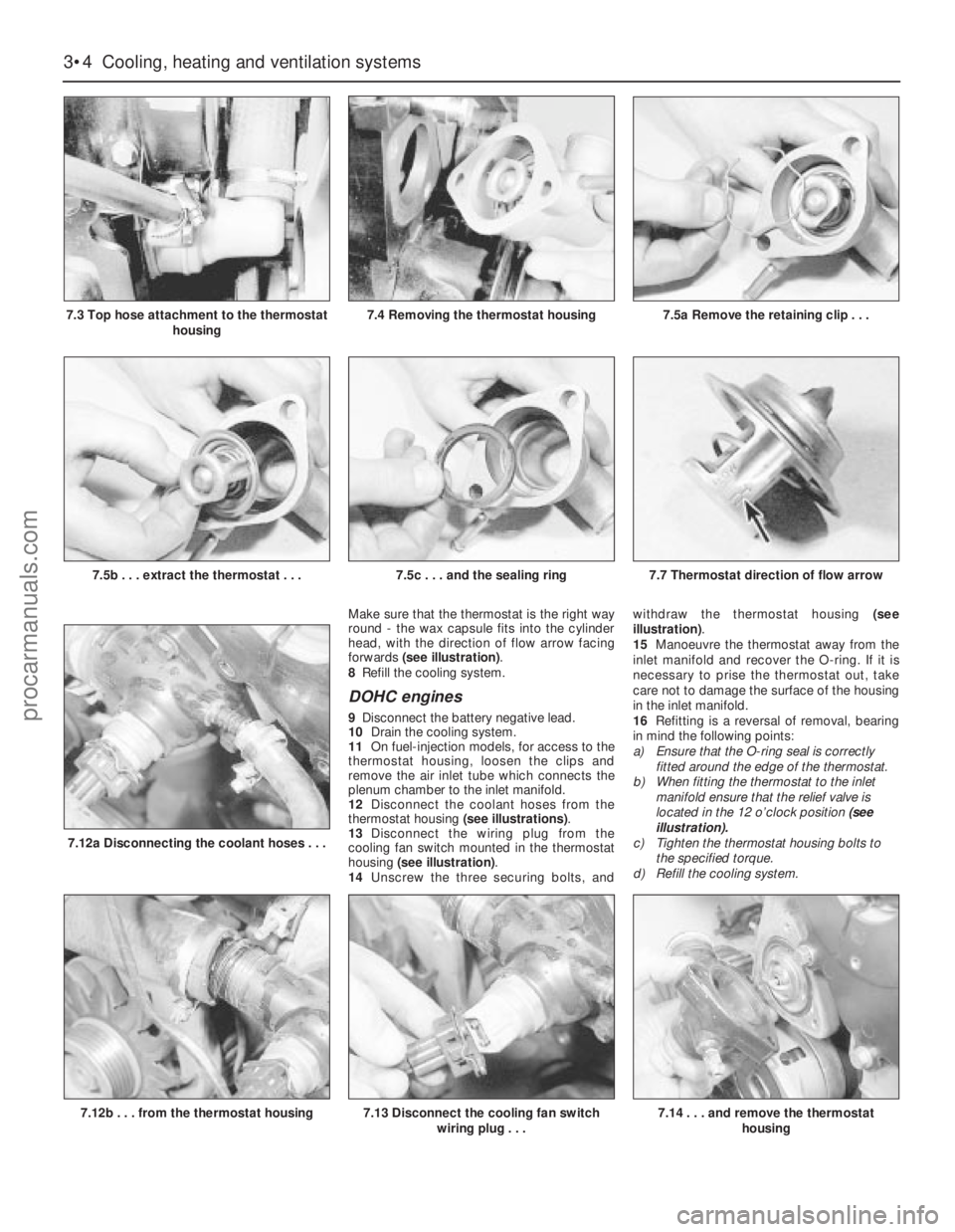

3Disconnect the top hose from the

thermostat housing at the front of the cylinder

head (see illustration).

4Unscrew the bolts and remove the housing

and gasket (see illustration).

5Using a screwdriver, prise the retaining clip

from the housing, and extract the thermostat

and sealing ring (see illustrations).

6Clean the thermostat housing and cylinder

head mating surfaces. Obtain a new gasket for

reassembly, and if necessary a new sealing

ring too.

7Refit by reversing the removal operations.

7Thermostat - removal and

refitting

6Radiator - inspection and repair

5Radiator - removal and refitting

4Cooling system - filling

3Cooling system - flushing

2Cooling system - draining

Cooling, heating and ventilation systems 3•3

3

5.2a Radiator top hose5.2b Radiator bottom hose (A)

Also shown are automatic transmission fluid

cooler lower union (B) and hose to expansion

tank (C)5.4 Transmission fluid cooler upper union

5.6 Fan shroud clip5.7 Pull out the plug to release the radiator

top mounting5.8 One of the radiator bottom mounting

bolts (arrowed)

procarmanuals.com

Page 87 of 255

Make sure that the thermostat is the right way

round - the wax capsule fits into the cylinder

head, with the direction of flow arrow facing

forwards (see illustration).

8Refill the cooling system.

DOHC engines

9Disconnect the battery negative lead.

10Drain the cooling system.

11On fuel-injection models, for access to the

thermostat housing, loosen the clips and

remove the air inlet tube which connects the

plenum chamber to the inlet manifold.

12Disconnect the coolant hoses from the

thermostat housing (see illustrations).

13Disconnect the wiring plug from the

cooling fan switch mounted in the thermostat

housing (see illustration).

14Unscrew the three securing bolts, andwithdraw the thermostat housing (see

illustration).

15Manoeuvre the thermostat away from the

inlet manifold and recover the O-ring. If it is

necessary to prise the thermostat out, take

care not to damage the surface of the housing

in the inlet manifold.

16Refitting is a reversal of removal, bearing

in mind the following points:

a)Ensure that the O-ring seal is correctly

fitted around the edge of the thermostat.

b)When fitting the thermostat to the inlet

manifold ensure that the relief valve is

located in the 12 o’clock position (see

illustration).

c)Tighten the thermostat housing bolts to

the specified torque.

d)Refill the cooling system.

3•4Cooling, heating and ventilation systems

7.3 Top hose attachment to the thermostat

housing

7.12b . . . from the thermostat housing

7.5b . . . extract the thermostat . . .7.5c . . . and the sealing ring7.7 Thermostat direction of flow arrow

7.12a Disconnecting the coolant hoses . . .

7.13 Disconnect the cooling fan switch

wiring plug . . .7.14 . . . and remove the thermostat

housing

7.4 Removing the thermostat housing7.5a Remove the retaining clip . . .

procarmanuals.com

Page 88 of 255

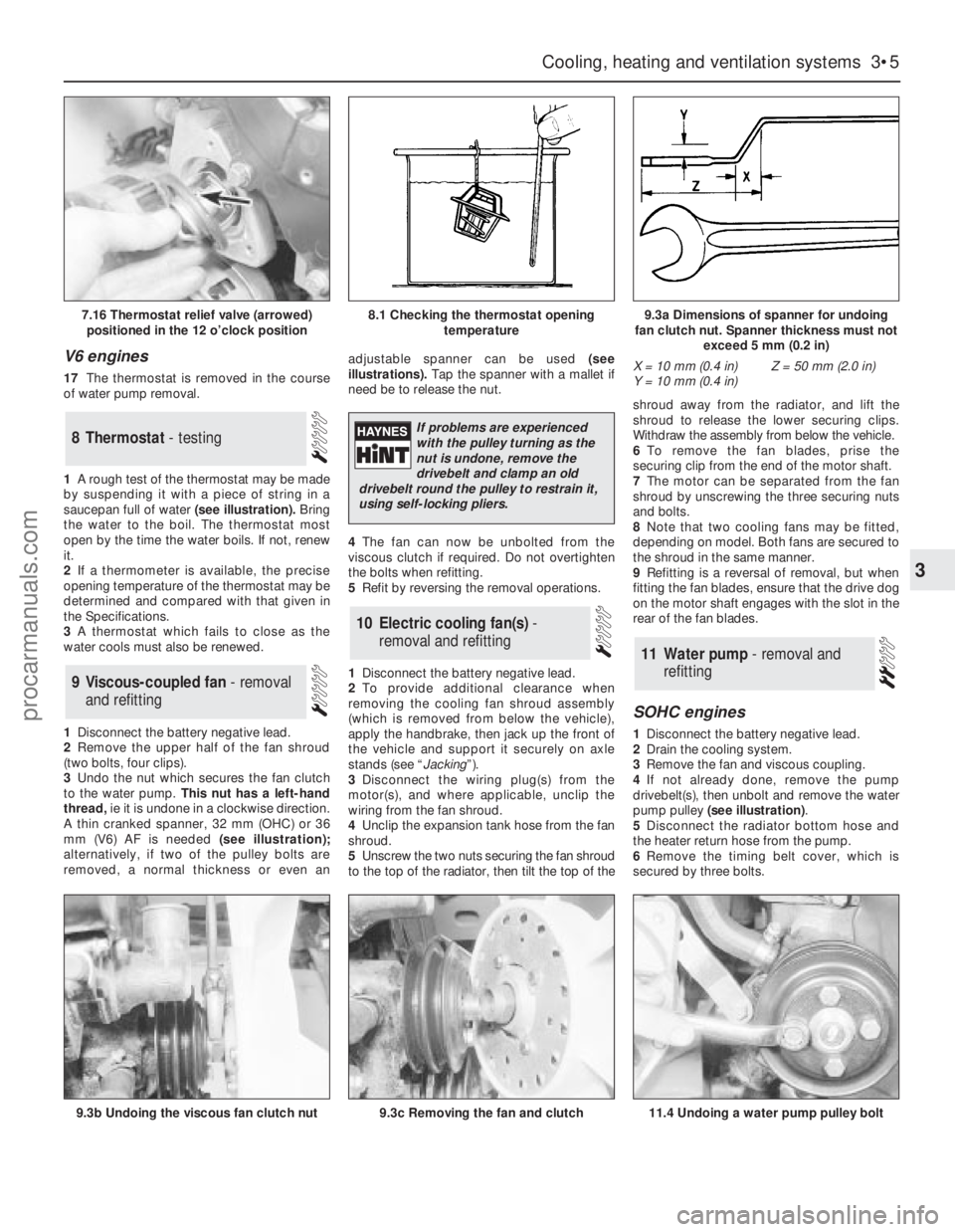

V6 engines

17The thermostat is removed in the course

of water pump removal.

1A rough test of the thermostat may be made

by suspending it with a piece of string in a

saucepan full of water(see illustration).Bring

the water to the boil. The thermostat most

open by the time the water boils. If not, renew

it.

2If a thermometer is available, the precise

opening temperature of the thermostat may be

determined and compared with that given in

the Specifications.

3A thermostat which fails to close as the

water cools must also be renewed.

1Disconnect the battery negative lead.

2Remove the upper half of the fan shroud

(two bolts, four clips).

3Undo the nut which secures the fan clutch

to the water pump.This nut has a left-hand

thread, ie it is undone in a clockwise direction.

A thin cranked spanner, 32 mm (OHC) or 36

mm (V6) AF is needed(see illustration);

alternatively, if two of the pulley bolts are

removed, a normal thickness or even anadjustable spanner can be used (see

illustrations). Tap the spanner with a mallet if

need be to release the nut.

4The fan can now be unbolted from the

viscous clutch if required. Do not overtighten

the bolts when refitting.

5Refit by reversing the removal operations.

1Disconnect the battery negative lead.

2To provide additional clearance when

removing the cooling fan shroud assembly

(which is removed from below the vehicle),

apply the handbrake, then jack up the front of

the vehicle and support it securely on axle

stands (see “Jacking”).

3Disconnect the wiring plug(s) from the

motor(s), and where applicable, unclip the

wiring from the fan shroud.

4Unclip the expansion tank hose from the fan

shroud.

5Unscrew the two nuts securing the fan shroud

to the top of the radiator, then tilt the top of theshroud away from the radiator, and lift the

shroud to release the lower securing clips.

Withdraw the assembly from below the vehicle.

6To remove the fan blades, prise the

securing clip from the end of the motor shaft.

7The motor can be separated from the fan

shroud by unscrewing the three securing nuts

and bolts.

8Note that two cooling fans may be fitted,

depending on model. Both fans are secured to

the shroud in the same manner.

9Refitting is a reversal of removal, but when

fitting the fan blades, ensure that the drive dog

on the motor shaft engages with the slot in the

rear of the fan blades.

SOHC engines

1Disconnect the battery negative lead.

2Drain the cooling system.

3Remove the fan and viscous coupling.

4If not already done, remove the pump

drivebelt(s), then unbolt and remove the water

pump pulley (see illustration).

5Disconnect the radiator bottom hose and

the heater return hose from the pump.

6Remove the timing belt cover, which is

secured by three bolts.

11Water pump - removal and

refitting

10Electric cooling fan(s) -

removal and refitting

9Viscous-coupled fan - removal

and refitting

8Thermostat - testing

Cooling, heating and ventilation systems 3•5

3

7.16 Thermostat relief valve (arrowed)

positioned in the 12 o’clock position8.1 Checking the thermostat opening

temperature9.3a Dimensions of spanner for undoing

fan clutch nut. Spanner thickness must not

exceed 5 mm (0.2 in)

9.3b Undoing the viscous fan clutch nut9.3c Removing the fan and clutch11.4 Undoing a water pump pulley bolt

X = 10 mm (0.4 in)

Y = 10 mm (0.4 in)Z = 50 mm (2.0 in)

If problems are experienced

with the pulley turning as the

nut is undone, remove the

drivebelt and clamp an old

drivebelt round the pulley to restrain it,

using self-locking pliers.

procarmanuals.com

Page 89 of 255

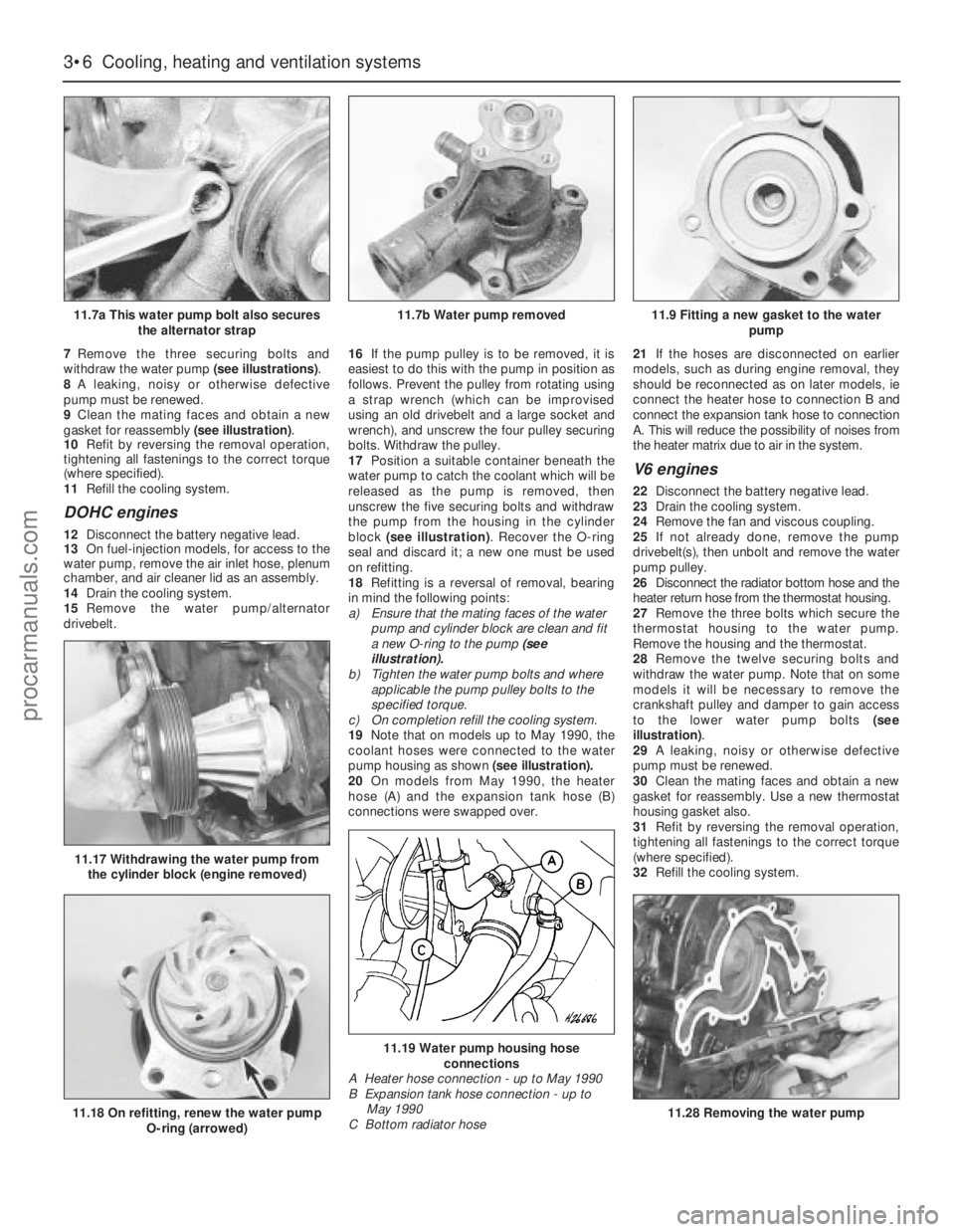

7Remove the three securing bolts and

withdraw the water pump (see illustrations).

8A leaking, noisy or otherwise defective

pump must be renewed.

9Clean the mating faces and obtain a new

gasket for reassembly (see illustration).

10Refit by reversing the removal operation,

tightening all fastenings to the correct torque

(where specified).

11Refill the cooling system.

DOHC engines

12Disconnect the battery negative lead.

13On fuel-injection models, for access to the

water pump, remove the air inlet hose, plenum

chamber, and air cleaner lid as an assembly.

14Drain the cooling system.

15Remove the water pump/alternator

drivebelt.16If the pump pulley is to be removed, it is

easiest to do this with the pump in position as

follows. Prevent the pulley from rotating using

a strap wrench (which can be improvised

using an old drivebelt and a large socket and

wrench), and unscrew the four pulley securing

bolts. Withdraw the pulley.

17Position a suitable container beneath the

water pump to catch the coolant which will be

released as the pump is removed, then

unscrew the five securing bolts and withdraw

the pump from the housing in the cylinder

block (see illustration). Recover the O-ring

seal and discard it; a new one must be used

on refitting.

18Refitting is a reversal of removal, bearing

in mind the following points:

a)Ensure that the mating faces of the water

pump and cylinder block are clean and fit

a new O-ring to the pump (see

illustration).

b)Tighten the water pump bolts and where

applicable the pump pulley bolts to the

specified torque.

c)On completion refill the cooling system.

19Note that on models up to May 1990, the

coolant hoses were connected to the water

pump housing as shown(see illustration).

20On models from May 1990, the heater

hose (A) and the expansion tank hose (B)

connections were swapped over.21If the hoses are disconnected on earlier

models, such as during engine removal, they

should be reconnected as on later models, ie

connect the heater hose to connection B and

connect the expansion tank hose to connection

A. This will reduce the possibility of noises from

the heater matrix due to air in the system.

V6 engines

22Disconnect the battery negative lead.

23Drain the cooling system.

24Remove the fan and viscous coupling.

25If not already done, remove the pump

drivebelt(s), then unbolt and remove the water

pump pulley.

26Disconnect the radiator bottom hose and the

heater return hose from the thermostat housing.

27Remove the three bolts which secure the

thermostat housing to the water pump.

Remove the housing and the thermostat.

28Remove the twelve securing bolts and

withdraw the water pump. Note that on some

models it will be necessary to remove the

crankshaft pulley and damper to gain access

to the lower water pump bolts (see

illustration).

29A leaking, noisy or otherwise defective

pump must be renewed.

30Clean the mating faces and obtain a new

gasket for reassembly. Use a new thermostat

housing gasket also.

31Refit by reversing the removal operation,

tightening all fastenings to the correct torque

(where specified).

32Refill the cooling system.

3•6Cooling, heating and ventilation systems

11.7a This water pump bolt also secures

the alternator strap

11.18 On refitting, renew the water pump

O-ring (arrowed)

11.17 Withdrawing the water pump from

the cylinder block (engine removed)

11.19 Water pump housing hose

connections

A Heater hose connection - up to May 1990

B Expansion tank hose connection - up to

May 1990

C Bottom radiator hose

11.28 Removing the water pump

11.7b Water pump removed11.9 Fitting a new gasket to the water

pump

procarmanuals.com

Page 90 of 255

See Chapter 1, Section 21.

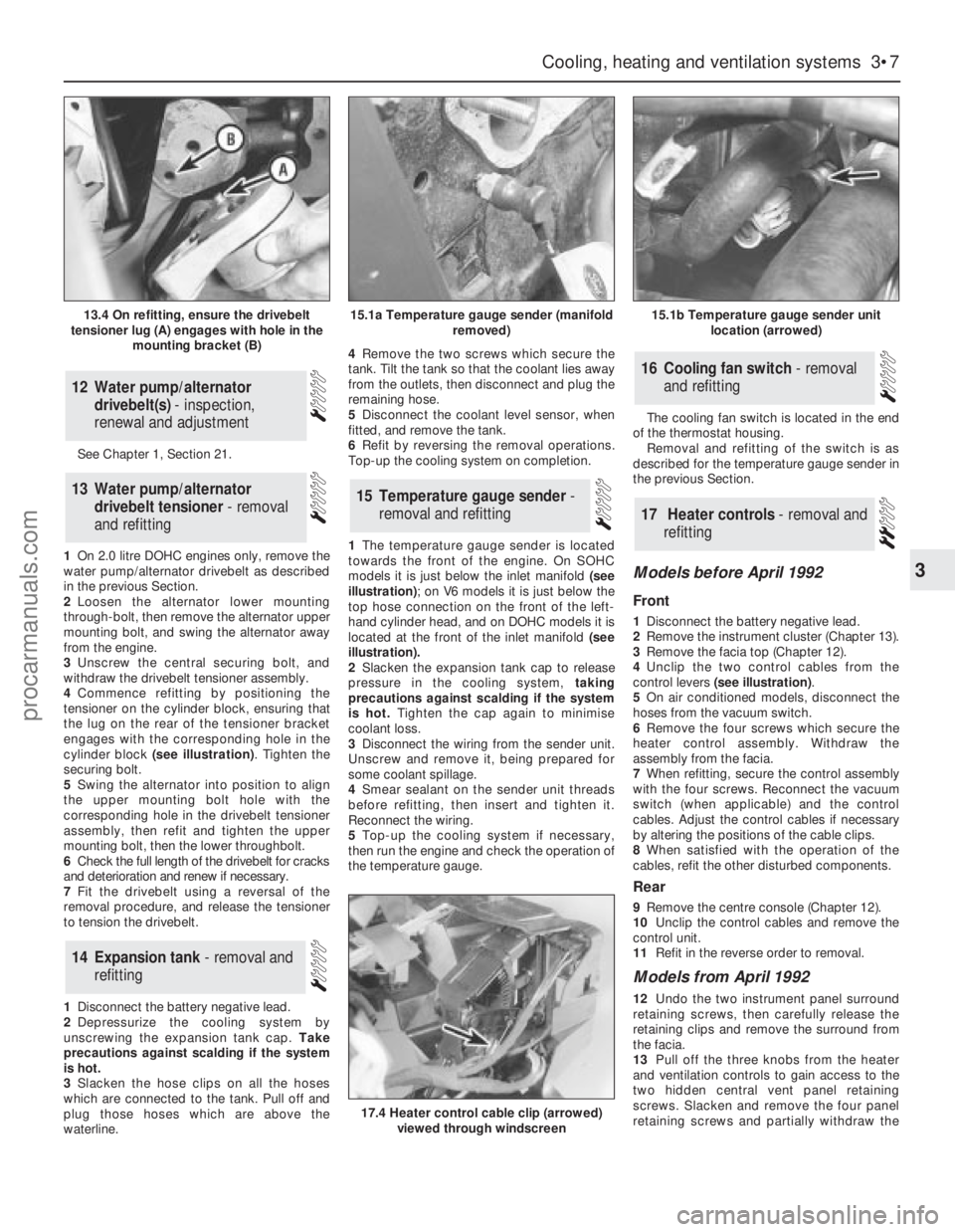

1On 2.0 litre DOHC engines only, remove the

water pump/alternator drivebelt as described

in the previous Section.

2Loosen the alternator lower mounting

through-bolt, then remove the alternator upper

mounting bolt, and swing the alternator away

from the engine.

3Unscrew the central securing bolt, and

withdraw the drivebelt tensioner assembly.

4Commence refitting by positioning the

tensioner on the cylinder block, ensuring that

the lug on the rear of the tensioner bracket

engages with the corresponding hole in the

cylinder block (see illustration). Tighten the

securing bolt.

5Swing the alternator into position to align

the upper mounting bolt hole with the

corresponding hole in the drivebelt tensioner

assembly, then refit and tighten the upper

mounting bolt, then the lower throughbolt.

6Check the full length of the drivebelt for cracks

and deterioration and renew if necessary.

7Fit the drivebelt using a reversal of the

removal procedure, and release the tensioner

to tension the drivebelt.

1Disconnect the battery negative lead.

2Depressurize the cooling system by

unscrewing the expansion tank cap. Take

precautions against scalding if the system

is hot.

3Slacken the hose clips on all the hoses

which are connected to the tank. Pull off and

plug those hoses which are above the

waterline.4Remove the two screws which secure the

tank. Tilt the tank so that the coolant lies away

from the outlets, then disconnect and plug the

remaining hose.

5Disconnect the coolant level sensor, when

fitted, and remove the tank.

6Refit by reversing the removal operations.

Top-up the cooling system on completion.

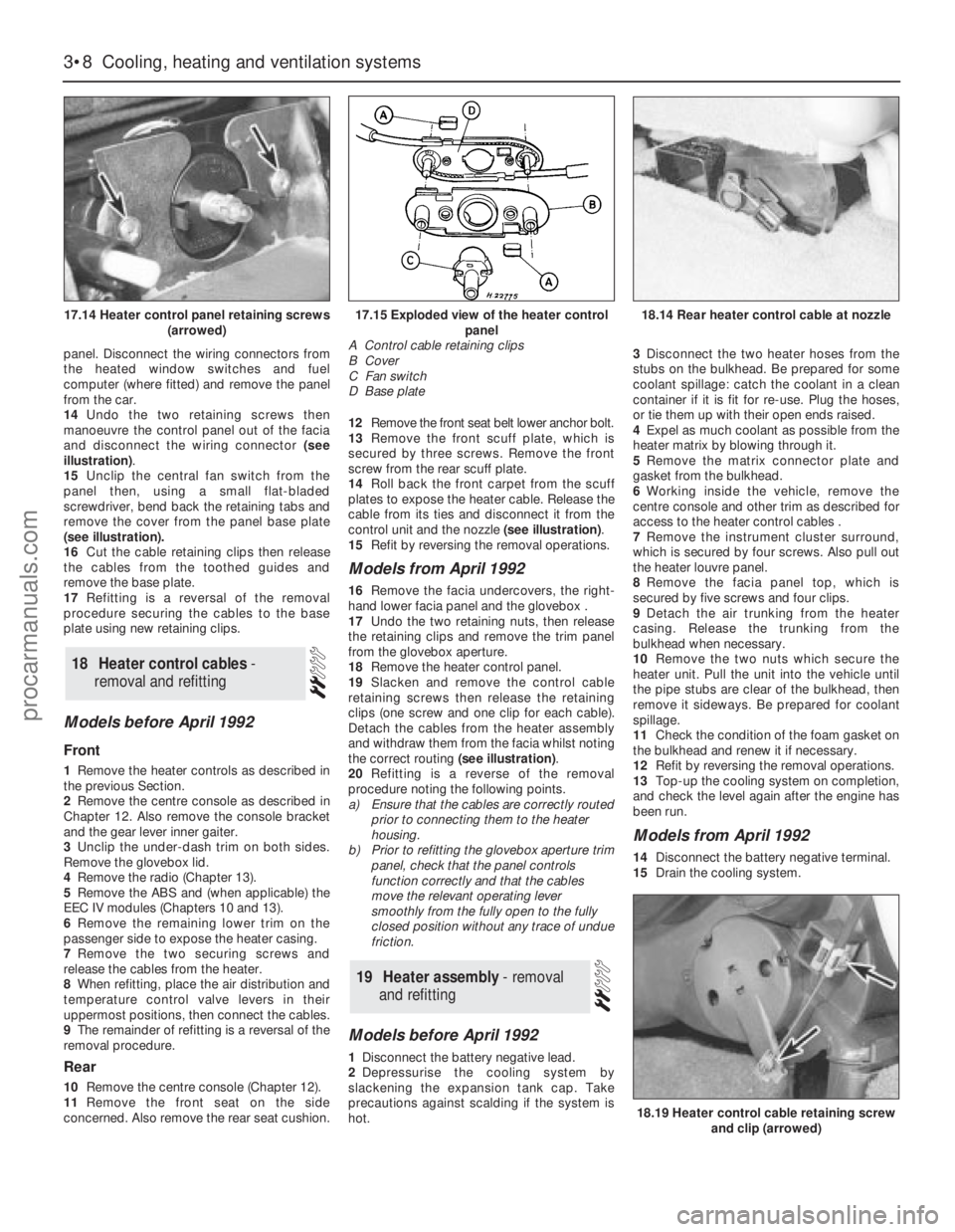

1The temperature gauge sender is located

towards the front of the engine. On SOHC

models it is just below the inlet manifold (see

illustration); on V6 models it is just below the

top hose connection on the front of the left-

hand cylinder head, and on DOHC models it is

located at the front of the inlet manifold (see

illustration).

2Slacken the expansion tank cap to release

pressure in the cooling system, taking

precautions against scalding if the system

is hot.Tighten the cap again to minimise

coolant loss.

3Disconnect the wiring from the sender unit.

Unscrew and remove it, being prepared for

some coolant spillage.

4Smear sealant on the sender unit threads

before refitting, then insert and tighten it.

Reconnect the wiring.

5Top-up the cooling system if necessary,

then run the engine and check the operation of

the temperature gauge.The cooling fan switch is located in the end

of the thermostat housing.

Removal and refitting of the switch is as

described for the temperature gauge sender in

the previous Section.

Models before April 1992

Front

1Disconnect the battery negative lead.

2Remove the instrument cluster (Chapter 13).

3Remove the facia top (Chapter 12).

4Unclip the two control cables from the

control levers (see illustration).

5On air conditioned models, disconnect the

hoses from the vacuum switch.

6Remove the four screws which secure the

heater control assembly. Withdraw the

assembly from the facia.

7When refitting, secure the control assembly

with the four screws. Reconnect the vacuum

switch (when applicable) and the control

cables. Adjust the control cables if necessary

by altering the positions of the cable clips.

8When satisfied with the operation of the

cables, refit the other disturbed components.

Rear

9Remove the centre console (Chapter 12).

10Unclip the control cables and remove the

control unit.

11Refit in the reverse order to removal.

Models from April 1992

12Undo the two instrument panel surround

retaining screws, then carefully release the

retaining clips and remove the surround from

the facia.

13Pull off the three knobs from the heater

and ventilation controls to gain access to the

two hidden central vent panel retaining

screws. Slacken and remove the four panel

retaining screws and partially withdraw the

17Heater controls - removal and

refitting

16Cooling fan switch - removal

and refitting

15Temperature gauge sender -

removal and refitting

14Expansion tank - removal and

refitting

13Water pump/alternator

drivebelt tensioner - removal

and refitting

12Water pump/alternator

drivebelt(s) - inspection,

renewal and adjustment

Cooling, heating and ventilation systems 3•7

3

13.4 On refitting, ensure the drivebelt

tensioner lug (A) engages with hole in the

mounting bracket (B)15.1a Temperature gauge sender (manifold

removed)15.1b Temperature gauge sender unit

location (arrowed)

17.4 Heater control cable clip (arrowed)

viewed through windscreen

procarmanuals.com

Page 91 of 255

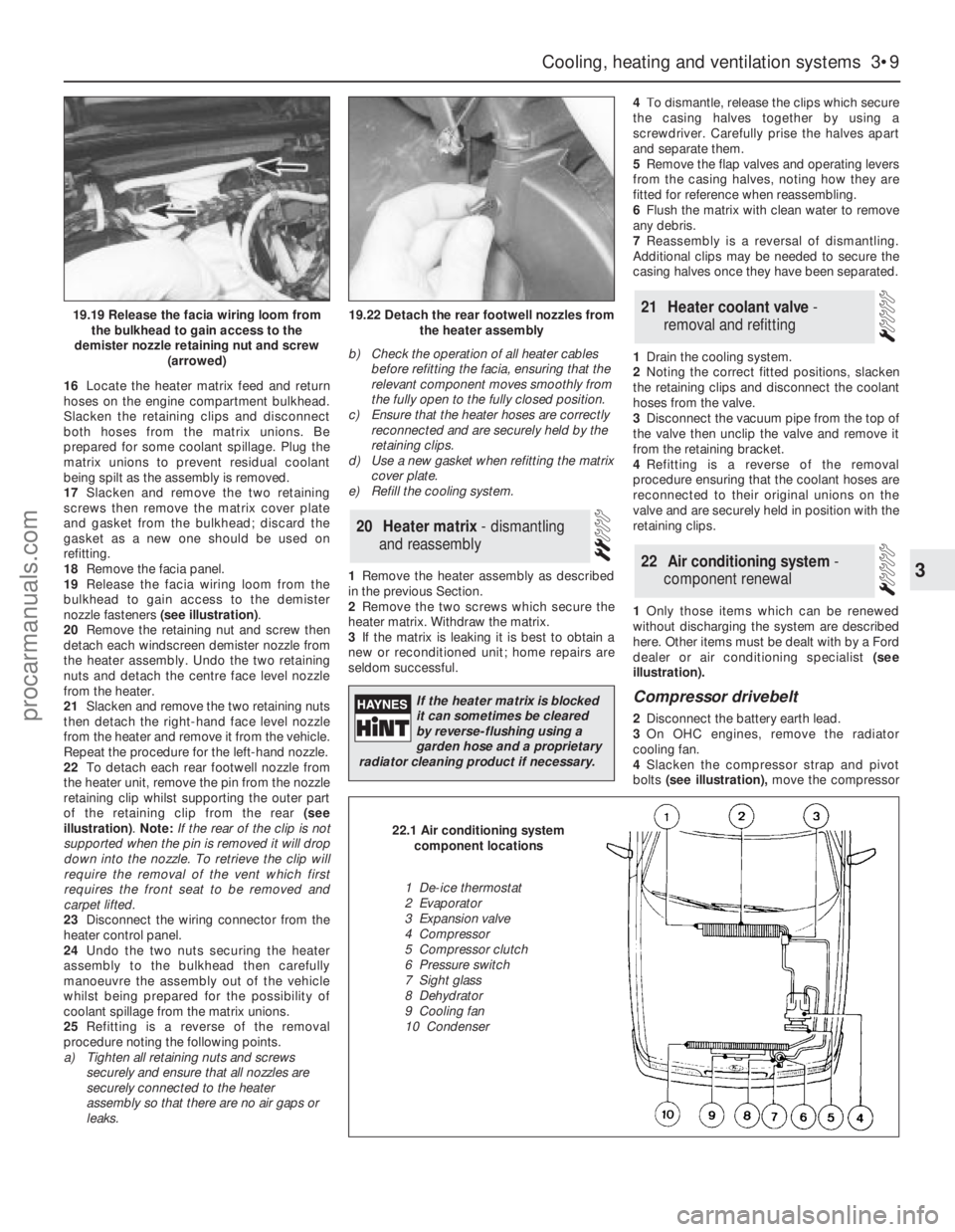

panel. Disconnect the wiring connectors from

the heated window switches and fuel

computer (where fitted) and remove the panel

from the car.

14Undo the two retaining screws then

manoeuvre the control panel out of the facia

and disconnect the wiring connector (see

illustration).

15Unclip the central fan switch from the

panel then, using a small flat-bladed

screwdriver, bend back the retaining tabs and

remove the cover from the panel base plate

(see illustration).

16Cut the cable retaining clips then release

the cables from the toothed guides and

remove the base plate.

17Refitting is a reversal of the removal

procedure securing the cables to the base

plate using new retaining clips.

Models before April 1992

Front

1Remove the heater controls as described in

the previous Section.

2Remove the centre console as described in

Chapter 12. Also remove the console bracket

and the gear lever inner gaiter.

3Unclip the under-dash trim on both sides.

Remove the glovebox lid.

4Remove the radio (Chapter 13).

5Remove the ABS and (when applicable) the

EEC IV modules (Chapters 10 and 13).

6Remove the remaining lower trim on the

passenger side to expose the heater casing.

7Remove the two securing screws and

release the cables from the heater.

8When refitting, place the air distribution and

temperature control valve levers in their

uppermost positions, then connect the cables.

9The remainder of refitting is a reversal of the

removal procedure.

Rear

10Remove the centre console (Chapter 12).

11Remove the front seat on the side

concerned. Also remove the rear seat cushion. 12Remove the front seat belt lower anchor bolt.

13Remove the front scuff plate, which is

secured by three screws. Remove the front

screw from the rear scuff plate.

14Roll back the front carpet from the scuff

plates to expose the heater cable. Release the

cable from its ties and disconnect it from the

control unit and the nozzle (see illustration).

15Refit by reversing the removal operations.

Models from April 1992

16Remove the facia undercovers, the right-

hand lower facia panel and the glovebox .

17Undo the two retaining nuts, then release

the retaining clips and remove the trim panel

from the glovebox aperture.

18Remove the heater control panel.

19Slacken and remove the control cable

retaining screws then release the retaining

clips (one screw and one clip for each cable).

Detach the cables from the heater assembly

and withdraw them from the facia whilst noting

the correct routing (see illustration).

20Refitting is a reverse of the removal

procedure noting the following points.

a)Ensure that the cables are correctly routed

prior to connecting them to the heater

housing.

b)Prior to refitting the glovebox aperture trim

panel, check that the panel controls

function correctly and that the cables

move the relevant operating lever

smoothly from the fully open to the fully

closed position without any trace of undue

friction.

Models before April 1992

1Disconnect the battery negative lead.

2Depressurise the cooling system by

slackening the expansion tank cap. Take

precautions against scalding if the system is

hot.3Disconnect the two heater hoses from the

stubs on the bulkhead. Be prepared for some

coolant spillage: catch the coolant in a clean

container if it is fit for re-use. Plug the hoses,

or tie them up with their open ends raised.

4Expel as much coolant as possible from the

heater matrix by blowing through it.

5Remove the matrix connector plate and

gasket from the bulkhead.

6Working inside the vehicle, remove the

centre console and other trim as described for

access to the heater control cables .

7Remove the instrument cluster surround,

which is secured by four screws. Also pull out

the heater louvre panel.

8Remove the facia panel top, which is

secured by five screws and four clips.

9Detach the air trunking from the heater

casing. Release the trunking from the

bulkhead when necessary.

10Remove the two nuts which secure the

heater unit. Pull the unit into the vehicle until

the pipe stubs are clear of the bulkhead, then

remove it sideways. Be prepared for coolant

spillage.

11Check the condition of the foam gasket on

the bulkhead and renew it if necessary.

12Refit by reversing the removal operations.

13Top-up the cooling system on completion,

and check the level again after the engine has

been run.

Models from April 1992

14Disconnect the battery negative terminal.

15Drain the cooling system.

19Heater assembly - removal

and refitting

18Heater control cables -

removal and refitting

3•8Cooling, heating and ventilation systems

17.14 Heater control panel retaining screws

(arrowed)

18.19 Heater control cable retaining screw

and clip (arrowed)

17.15 Exploded view of the heater control

panel

A Control cable retaining clips

B Cover

C Fan switch

D Base plate18.14 Rear heater control cable at nozzle

procarmanuals.com

Page 92 of 255

16Locate the heater matrix feed and return

hoses on the engine compartment bulkhead.

Slacken the retaining clips and disconnect

both hoses from the matrix unions. Be

prepared for some coolant spillage. Plug the

matrix unions to prevent residual coolant

being spilt as the assembly is removed.

17Slacken and remove the two retaining

screws then remove the matrix cover plate

and gasket from the bulkhead; discard the

gasket as a new one should be used on

refitting.

18Remove the facia panel.

19Release the facia wiring loom from the

bulkhead to gain access to the demister

nozzle fasteners (see illustration).

20Remove the retaining nut and screw then

detach each windscreen demister nozzle from

the heater assembly. Undo the two retaining

nuts and detach the centre face level nozzle

from the heater.

21Slacken and remove the two retaining nuts

then detach the right-hand face level nozzle

from the heater and remove it from the vehicle.

Repeat the procedure for the left-hand nozzle.

22To detach each rear footwell nozzle from

the heater unit, remove the pin from the nozzle

retaining clip whilst supporting the outer part

of the retaining clip from the rear (see

illustration). Note: If the rear of the clip is not

supported when the pin is removed it will drop

down into the nozzle. To retrieve the clip will

require the removal of the vent which first

requires the front seat to be removed and

carpet lifted.

23Disconnect the wiring connector from the

heater control panel.

24Undo the two nuts securing the heater

assembly to the bulkhead then carefully

manoeuvre the assembly out of the vehicle

whilst being prepared for the possibility of

coolant spillage from the matrix unions.

25Refitting is a reverse of the removal

procedure noting the following points.

a)Tighten all retaining nuts and screws

securely and ensure that all nozzles are

securely connected to the heater

assembly so that there are no air gaps or

leaks.b)Check the operation of all heater cables

before refitting the facia, ensuring that the

relevant component moves smoothly from

the fully open to the fully closed position.

c)Ensure that the heater hoses are correctly

reconnected and are securely held by the

retaining clips.

d)Use a new gasket when refitting the matrix

cover plate.

e)Refill the cooling system.

1Remove the heater assembly as described

in the previous Section.

2Remove the two screws which secure the

heater matrix. Withdraw the matrix.

3If the matrix is leaking it is best to obtain a

new or reconditioned unit; home repairs are

seldom successful.4To dismantle, release the clips which secure

the casing halves together by using a

screwdriver. Carefully prise the halves apart

and separate them.

5Remove the flap valves and operating levers

from the casing halves, noting how they are

fitted for reference when reassembling.

6Flush the matrix with clean water to remove

any debris.

7Reassembly is a reversal of dismantling.

Additional clips may be needed to secure the

casing halves once they have been separated.

1Drain the cooling system.

2Noting the correct fitted positions, slacken

the retaining clips and disconnect the coolant

hoses from the valve.

3Disconnect the vacuum pipe from the top of

the valve then unclip the valve and remove it

from the retaining bracket.

4Refitting is a reverse of the removal

procedure ensuring that the coolant hoses are

reconnected to their original unions on the

valve and are securely held in position with the

retaining clips.

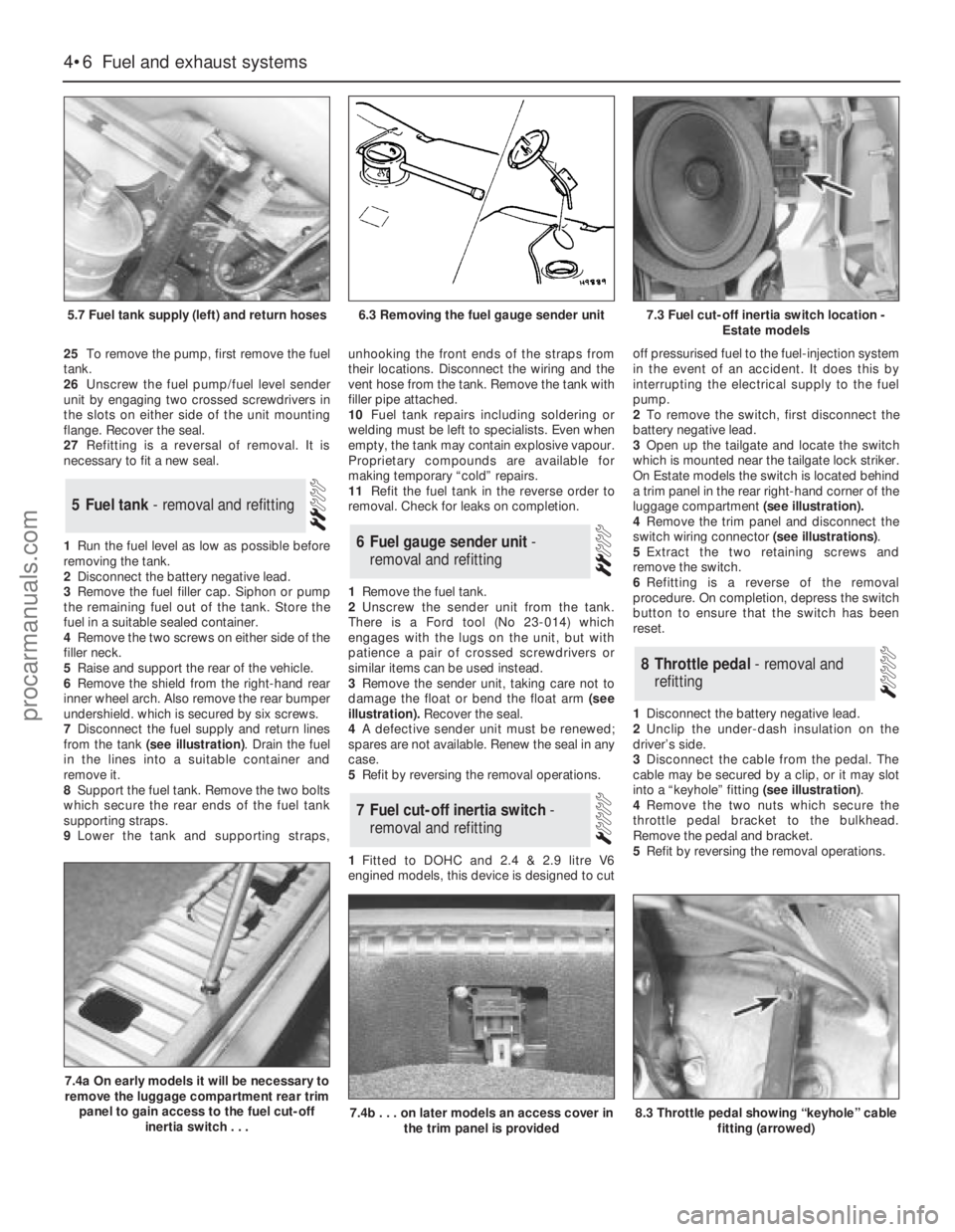

1Only those items which can be renewed

without discharging the system are described

here. Other items must be dealt with by a Ford

dealer or air conditioning specialist (see

illustration).

Compressor drivebelt

2Disconnect the battery earth lead.

3On OHC engines, remove the radiator

cooling fan.

4Slacken the compressor strap and pivot

bolts (see illustration),move the compressor

22Air conditioning system -

component renewal

21Heater coolant valve -

removal and refitting

20Heater matrix - dismantling

and reassembly

Cooling, heating and ventilation systems 3•9

3

19.19 Release the facia wiring loom from

the bulkhead to gain access to the

demister nozzle retaining nut and screw

(arrowed)19.22 Detach the rear footwell nozzles from

the heater assembly

If the heater matrix is blocked

it can sometimes be cleared

by reverse-flushing using a

garden hose and a proprietary

radiator cleaning product if necessary.

22.1 Air conditioning system

component locations

1 De-ice thermostat

2 Evaporator

3 Expansion valve

4 Compressor

5 Compressor clutch

6 Pressure switch

7 Sight glass

8 Dehydrator

9 Cooling fan

10 Condenser

procarmanuals.com

Page 93 of 255

towards the engine and remove the old

drivebelt.

5Fit the new drivebelt, position the

compressor to achieve the correct belt tension

and tighten the strap and pivot bolts.

6Refit and secure the fan, when applicable,

and reconnect the battery.

7Recheck the belt tension after it has run for

at least 10 minutes under load.

Condenser fan and motor

8Disconnect the battery earth lead and

remove the radiator grille.

9Disconnect the fan wiring connector at the

right-hand side of the condenser.

10Remove the three securing bolts andremove the fan and motor(see illustration).

Turn the frame to position the fan wiring on the

dehydrator side to avoid damaging the wiring.

Take care also not to damage the condenser

fins or tube.

11Unclip the fan guard from the top of the

frame.

12To remove the fan blades from the motor,

remove the retaining nut and circlip. The nut

has a left-hand threadie it is undone

clockwise.

13With the blades removed, the motor can

be unscrewed from the frame.

14Reassemble and refit in the reverse order

of dismantling and removal.

De-ice thermostat

15Disconnect the battery negative lead.

16Disconnect the vacuum hoses from the

plenum chamber cover. Pull off the rubber seal

and remove the plenum chamber cover; it is

secured by four screws and one nut.

17Disconnect the thermostat from the

evaporator casing and remove it. Also remove

the thermostat probe.

18Refit by reversing the removal operations.

Heater water valve

19The heater water valve used with air

conditioning is vacuum-operated. It is located

on the right-hand side of the engine bay, near

the bulkhead. 20Drain the cooling system.

21Slacken the hose clips and detach the

coolant hoses from the valve, noting how they

are connected.

22Disconnect the vacuum hose from the top

of the valve.

23Unclip the valve from its bracket and

remove it.

24Refit by reversing the removal operations.

Refill the cooling system.

3•10Cooling, heating and ventilation systems

22.4 Air conditioning compressor adjuster

strap bolts (arrowed)22.10 Condenser fan securing bolts

(arrowed)

procarmanuals.com

Page 99 of 255

25To remove the pump, first remove the fuel

tank.

26Unscrew the fuel pump/fuel level sender

unit by engaging two crossed screwdrivers in

the slots on either side of the unit mounting

flange. Recover the seal.

27Refitting is a reversal of removal. It is

necessary to fit a new seal.

1Run the fuel level as low as possible before

removing the tank.

2Disconnect the battery negative lead.

3Remove the fuel filler cap. Siphon or pump

the remaining fuel out of the tank. Store the

fuel in a suitable sealed container.

4Remove the two screws on either side of the

filler neck.

5Raise and support the rear of the vehicle.

6Remove the shield from the right-hand rear

inner wheel arch. Also remove the rear bumper

undershield. which is secured by six screws.

7Disconnect the fuel supply and return lines

from the tank (see illustration). Drain the fuel

in the lines into a suitable container and

remove it.

8Support the fuel tank. Remove the two bolts

which secure the rear ends of the fuel tank

supporting straps.

9Lower the tank and supporting straps,unhooking the front ends of the straps from

their locations. Disconnect the wiring and the

vent hose from the tank. Remove the tank with

filler pipe attached.

10Fuel tank repairs including soldering or

welding must be left to specialists. Even when

empty, the tank may contain explosive vapour.

Proprietary compounds are available for

making temporary “cold” repairs.

11Refit the fuel tank in the reverse order to

removal. Check for leaks on completion.

1Remove the fuel tank.

2Unscrew the sender unit from the tank.

There is a Ford tool (No 23-014) which

engages with the lugs on the unit, but with

patience a pair of crossed screwdrivers or

similar items can be used instead.

3Remove the sender unit, taking care not to

damage the float or bend the float arm(see

illustration).Recover the seal.

4A defective sender unit must be renewed;

spares are not available. Renew the seal in any

case.

5Refit by reversing the removal operations.

1Fitted to DOHC and 2.4 & 2.9 litre V6

engined models, this device is designed to cutoff pressurised fuel to the fuel-injection system

in the event of an accident. It does this by

interrupting the electrical supply to the fuel

pump.

2To remove the switch, first disconnect the

battery negative lead.

3Open up the tailgate and locate the switch

which is mounted near the tailgate lock striker.

On Estate models the switch is located behind

a trim panel in the rear right-hand corner of the

luggage compartment (see illustration).

4Remove the trim panel and disconnect the

switch wiring connector (see illustrations).

5Extract the two retaining screws and

remove the switch.

6Refitting is a reverse of the removal

procedure. On completion, depress the switch

button to ensure that the switch has been

reset.

1Disconnect the battery negative lead.

2Unclip the under-dash insulation on the

driver’s side.

3Disconnect the cable from the pedal. The

cable may be secured by a clip, or it may slot

into a “keyhole” fitting (see illustration).

4Remove the two nuts which secure the

throttle pedal bracket to the bulkhead.

Remove the pedal and bracket.

5Refit by reversing the removal operations.

8Throttle pedal - removal and

refitting

7Fuel cut-off inertia switch -

removal and refitting

6Fuel gauge sender unit -

removal and refitting

5Fuel tank - removal and refitting

4•6Fuel and exhaust systems

5.7 Fuel tank supply (left) and return hoses

7.4a On early models it will be necessary to

remove the luggage compartment rear trim

panel to gain access to the fuel cut-off

inertia switch . . .

7.4b . . . on later models an access cover in

the trim panel is provided8.3 Throttle pedal showing “keyhole” cable

fitting (arrowed)

6.3 Removing the fuel gauge sender unit7.3 Fuel cut-off inertia switch location -

Estate models

procarmanuals.com

Page 100 of 255

1Disconnect the battery negative lead.

2Disconnect the cable from the pedal.

3Working under the bonnet, free the cable

outer from the bulkhead and pull the cable into

the engine bay.

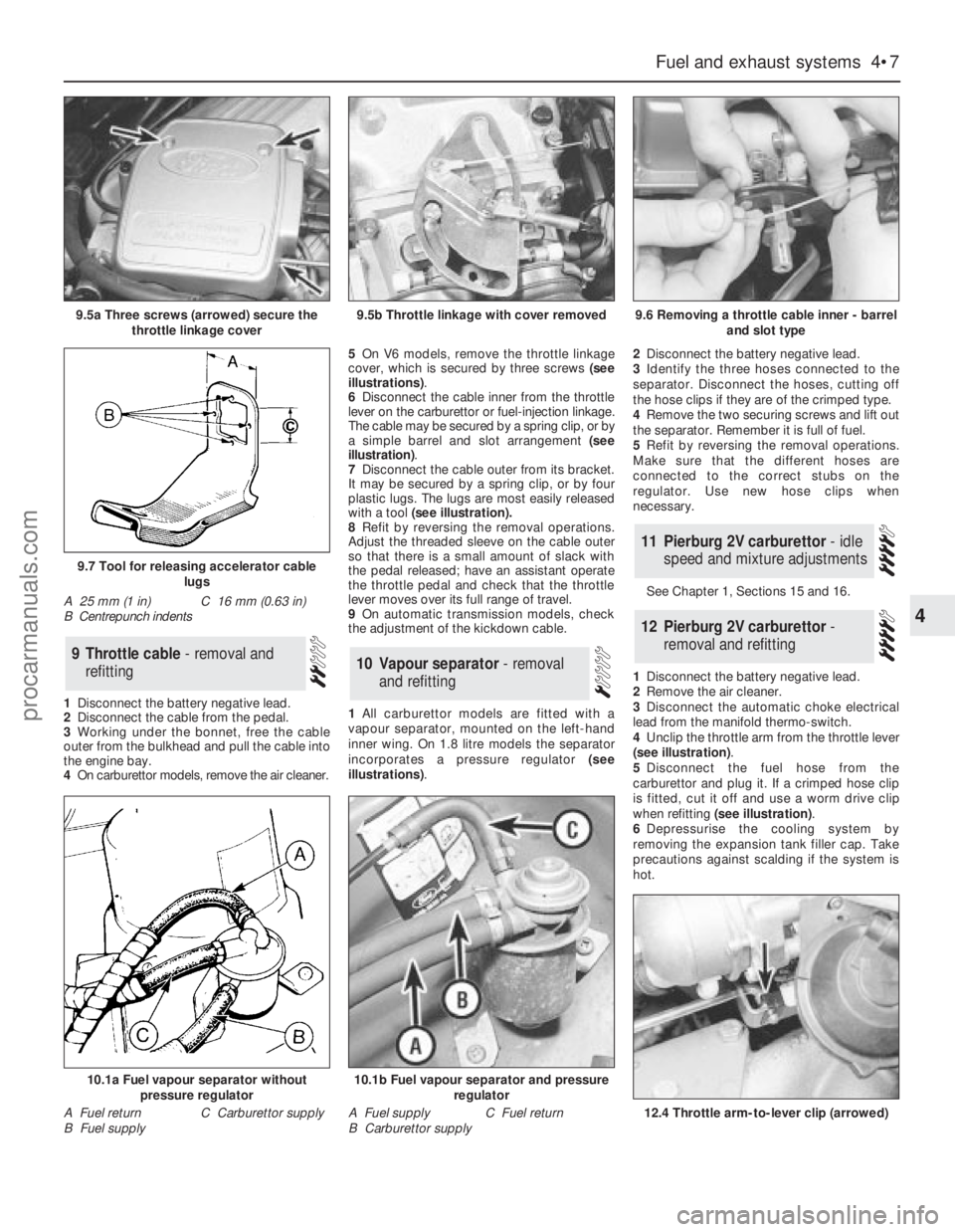

4On carburettor models, remove the air cleaner.5On V6 models, remove the throttle linkage

cover, which is secured by three screws (see

illustrations).

6Disconnect the cable inner from the throttle

lever on the carburettor or fuel-injection linkage.

The cable may be secured by a spring clip, or by

a simple barrel and slot arrangement (see

illustration).

7Disconnect the cable outer from its bracket.

It may be secured by a spring clip, or by four

plastic lugs. The lugs are most easily released

with a tool (see illustration).

8Refit by reversing the removal operations.

Adjust the threaded sleeve on the cable outer

so that there is a small amount of slack with

the pedal released; have an assistant operate

the throttle pedal and check that the throttle

lever moves over its full range of travel.

9On automatic transmission models, check

the adjustment of the kickdown cable.

1All carburettor models are fitted with a

vapour separator, mounted on the left-hand

inner wing. On 1.8 litre models the separator

incorporates a pressure regulator (see

illustrations).2Disconnect the battery negative lead.

3Identify the three hoses connected to the

separator. Disconnect the hoses, cutting off

the hose clips if they are of the crimped type.

4Remove the two securing screws and lift out

the separator. Remember it is full of fuel.

5Refit by reversing the removal operations.

Make sure that the different hoses are

connected to the correct stubs on the

regulator. Use new hose clips when

necessary.

See Chapter 1, Sections 15 and 16.

1Disconnect the battery negative lead.

2Remove the air cleaner.

3Disconnect the automatic choke electrical

lead from the manifold thermo-switch.

4Unclip the throttle arm from the throttle lever

(see illustration).

5Disconnect the fuel hose from the

carburettor and plug it. If a crimped hose clip

is fitted, cut it off and use a worm drive clip

when refitting (see illustration).

6Depressurise the cooling system by

removing the expansion tank filler cap. Take

precautions against scalding if the system is

hot.

12Pierburg 2V carburettor -

removal and refitting

11Pierburg 2V carburettor - idle

speed and mixture adjustments

10Vapour separator - removal

and refitting9Throttle cable - removal and

refitting

Fuel and exhaust systems 4•7

4

9.5a Three screws (arrowed) secure the

throttle linkage cover9.5b Throttle linkage with cover removed9.6 Removing a throttle cable inner - barrel

and slot type

12.4 Throttle arm-to-lever clip (arrowed)

9.7 Tool for releasing accelerator cable

lugs

A 25 mm (1 in)

B Centrepunch indentsC 16 mm (0.63 in)

10.1a Fuel vapour separator without

pressure regulator

A Fuel return

B Fuel supplyC Carburettor supply

10.1b Fuel vapour separator and pressure

regulator

A Fuel supply

B Carburettor supplyC Fuel return

procarmanuals.com