refrigerant type FORD GRANADA 1985 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 3 of 255

1•2

Every 12 000 miles (20 000 km) or

12 months – whichever comes sooner

m mCheck operation of latches, check straps and locks; lubricate if

necessary (Section 19)

m mCheck condition and tension of auxiliary drivebelt(s); adjust or

renew as necessary (Section 21)

m mCheck tightness of battery terminals, clean and neutralise

corrosion if necessary (Section 22)

m mCheck engine valve clearances (Section 23) m

mCheck tightness of inlet manifold bolts (V6 only) (Section 24) m

mRenew spark plugs (Section 20) m

mClean air conditioning condenser fins (when applicable)

(Section 25)

m mCheck air conditioning refrigerant charge (when applicable)

(Section 26)

m mCheck manual gearbox oil level (Section 18) m

mCheck final drive oil level (Section 27) m

mLubricate automatic transmission selector/kickdown linkage

(Section 28)

m mCheck security and condition of steering and suspension

components, gaiters and boots (Section 29)

m mCheck condition and security of driveshaft joints (Section 30) m

mInspect underbody and panels for corrosion or other damage

(Section 31)

m mInspect brake pipes and hoses (Section 32) m

mClean idle speed control linkage at throttle (when applicable)

(Section 33)

m mRoad test and check operation of ABS (Section 34)m

mCheck automatic transmission fluid level (engine hot)

(Section 17)

m mCheck engine for satisfactory hot starting (Section 37)m

mCheck that automatic choke is fully off with engine hot (not fuel-

injection models) (Section 36)

m mCheck power steering fluid level (when applicable) (Section 35)

Every 24 000 miles (40 000 km) or

2 years - whichever comes sooner

m

mRenew air cleaner element (Section 38) m

mClean and inspect distributor cap, rotor arm, HT leads and coil

tower (Section 39)

m mAdjust automatic transmission brake bands (Section 40)m

mRenew fuel filter (fuel-injection models only) (Section 41) m

mRenew crankcase ventilation vent valve (carburettor models)

(Section 42)

Every 36 000 miles (60 000 km) or

3 years - whichever comes sooner

m

mRenew brake hydraulic system seals and hoses if necessary

(Section 43)

m mRenew brake hydraulic fluid (Section 44) m

mRenew camshaft drivebelt on SOHC models - recommended as

a precautionary measure (Section 45)

Every 2 years - regardless of mileage

m

mRenew coolant (Section 46)

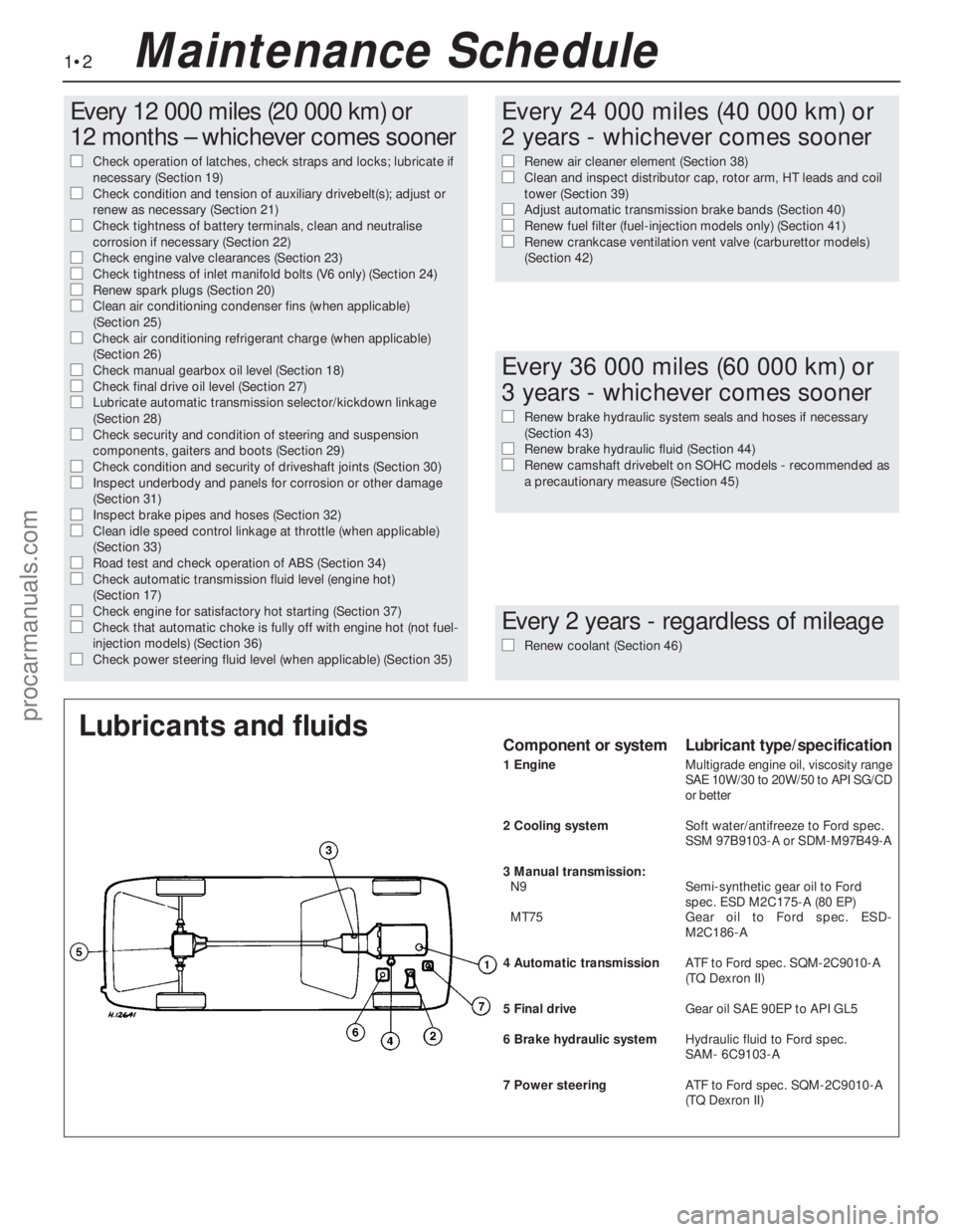

Lubricants and fluidsComponent or systemLubricant type/specification

1 EngineMultigrade engine oil, viscosity range

SAE 10W/30 to 20W/50 to API SG/CD

or better

2 Cooling systemSoft water/antifreeze to Ford spec.

SSM 97B9103-A or SDM-M97B49-A

3 Manual transmission:

N9Semi-synthetic gear oil to Ford

spec. ESD M2C175-A (80 EP)

MT75Gear oil to Ford spec. ESD-

M2C186-A

4 Automatic transmissionATF to Ford spec. SQM-2C9010-A

(TQ Dexron II)

5 Final driveGear oil SAE 90EP to APIGL5

6 Brake hydraulic systemHydraulic fluid to Ford spec.

SAM- 6C9103-A

7 Power steeringATFto Ford spec. SQM-2C9010-A

(TQDexron II)

Maintenance Schedule

procarmanuals.com

Page 16 of 255

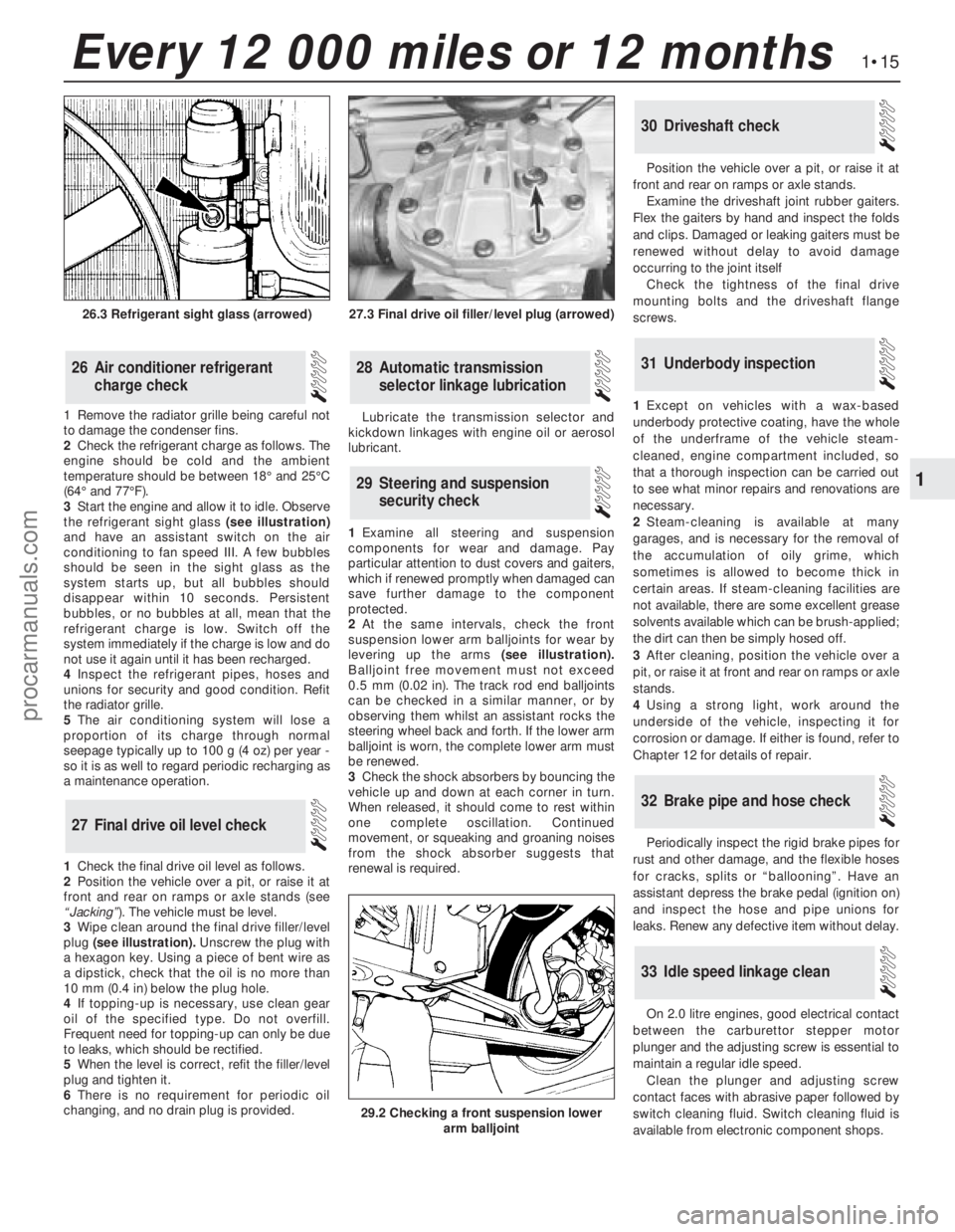

1Remove the radiator grille being careful not

to damage the condenser fins.

2Check the refrigerant charge as follows. The

engine should be cold and the ambient

temperature should be between 18°and 25°C

(64°and 77°F).

3Start the engine and allow it to idle. Observe

the refrigerant sight glass(see illustration)

and have an assistant switch on the air

conditioning to fan speed III. A few bubbles

should be seen in the sight glass as the

system starts up, but all bubbles should

disappear within 10 seconds. Persistent

bubbles, or no bubbles at all, mean that the

refrigerant charge is low. Switch off the

system immediately if the charge is low and do

not use it again until it has been recharged.

4Inspect the refrigerant pipes, hoses and

unions for security and good condition. Refit

the radiator grille.

5The air conditioning system will lose a

proportion of its charge through normal

seepage typically up to 100 g (4 oz) per year -

so it is as well to regard periodic recharging as

a maintenance operation.

1Check the final drive oil level as follows.

2Position the vehicle over a pit, or raise it at

front and rear on ramps or axle stands (see

“Jacking”). The vehicle must be level.

3Wipe clean around the final drive filler/level

plug (see illustration).Unscrew the plug with

a hexagon key. Using a piece of bent wire as

a dipstick, check that the oil is no more than

10 mm (0.4 in) below the plug hole.

4If topping-up is necessary, use clean gear

oil of the specified type. Do not overfill.

Frequent need for topping-up can only be due

to leaks, which should be rectified.

5When the level is correct, refit the filler/level

plug and tighten it.

6There is no requirement for periodic oil

changing, and no drain plug is provided. Lubricate the transmission selector and

kickdown linkages with engine oil or aerosol

lubricant.

1Examine all steering and suspension

components for wear and damage. Pay

particular attention to dust covers and gaiters,

which if renewed promptly when damaged can

save further damage to the component

protected.

2At the same intervals, check the front

suspension lower arm balljoints for wear by

levering up the arms(see illustration).

Balljoint free movement must not exceed

0.5 mm (0.02 in). The track rod end balljoints

can be checked in a similar manner, or by

observing them whilst an assistant rocks the

steering wheel back and forth. If the lower arm

balljoint is worn, the complete lower arm must

be renewed.

3Check the shock absorbers by bouncing the

vehicle up and down at each corner in turn.

When released, it should come to rest within

one complete oscillation. Continued

movement, or squeaking and groaning noises

from the shock absorber suggests that

renewal is required.Position the vehicle over a pit, or raise it at

front and rear on ramps or axle stands.

Examine the driveshaft joint rubber gaiters.

Flex the gaiters by hand and inspect the folds

and clips. Damaged or leaking gaiters must be

renewed without delay to avoid damage

occurring to the joint itself

Check the tightness of the final drive

mounting bolts and the driveshaft flange

screws.

1Except on vehicles with a wax-based

underbody protective coating, have the whole

of the underframe of the vehicle steam-

cleaned, engine compartment included, so

that a thorough inspection can be carried out

to see what minor repairs and renovations are

necessary.

2Steam-cleaning is available at many

garages, and is necessary for the removal of

the accumulation of oily grime, which

sometimes is allowed to become thick in

certain areas. If steam-cleaning facilities are

not available, there are some excellent grease

solvents available which can be brush-applied;

the dirt can then be simply hosed off.

3After cleaning, position the vehicle over a

pit, or raise it at front and rear on ramps or axle

stands.

4Using a strong light, work around the

underside of the vehicle, inspecting it for

corrosion or damage. If either is found, refer to

Chapter 12 for details of repair.

Periodically inspect the rigid brake pipes for

rust and other damage, and the flexible hoses

for cracks, splits or “ballooning”. Have an

assistant depress the brake pedal (ignition on)

and inspect the hose and pipe unions for

leaks. Renew any defective item without delay.

On 2.0 litre engines, good electrical contact

between the carburettor stepper motor

plunger and the adjusting screw is essential to

maintain a regular idle speed.

Clean the plunger and adjusting screw

contact faces with abrasive paper followed by

switch cleaning fluid. Switch cleaning fluid is

available from electronic component shops.

33Idle speed linkage clean

32Brake pipe and hose check

31Underbody inspection

30Driveshaft check

29Steering and suspension

security check

28Automatic transmission

selector linkage lubrication

27Final drive oil level check

26Air conditioner refrigerant

charge check

1•15

1

Every 12 000 miles or 12 months

27.3 Final drive oil filler/level plug (arrowed)

29.2 Checking a front suspension lower

arm balljoint

26.3 Refrigerant sight glass (arrowed)

procarmanuals.com

Page 85 of 255

Cooling system

The cooling system is of pressurised type

and includes a front mounted crossflow

radiator, belt-driven water pump, temperature-

sensitive thermo-viscous fan (on DOHC

models, an electrically-operated cooling fan is

fitted, operated by a switch in the thermostat

housing), wax type thermostat, and an

expansion and degas tank.

The radiator matrix is of copper and brass

construction and the end tanks are of plastic.

On automatic transmission models the right-

hand side end tank incorporates the

transmission oil cooler.

The thermostat is located behind the water

outlet elbow at the front of the cylinder head

on OHCmodels, and on the front of the water

pump on V6 models. Its purpose is to ensure

rapid engine warm-up by restricting the flow of

coolant in the engine when cold, and also to

assist in regulating the normal operating

temperature of the engine.

The expansion tank incorporates a pressure

cap which effectively pressurises the cooling

system as the coolant temperature rises,

thereby increasing the boiling point of the

coolant. The tank also has a further degas

function. Any accumulation of air bubbles in

the coolant, in particular in the thermostat

housing and the radiator, is returned to the

tank and released in the air space thus

maintaining the efficiency of the coolant.

On models fitted with the auxiliary warning

system, the expansion tank contains a level

sensor which operates a warning light if the

coolant level falls significantly.

When the engine is started from cold, the

water pump circulates coolant around the

cylinder block, cylinder head(s) and inlet

manifold. The warm coolant passes through

the automatic choke housing (when

applicable) and through the heater matrix

before returning to the engine. As the coolant

expands, the level in the expansion tank rises.

Circulation of coolant through the radiator is

prevented while the thermostat is shut. When

the coolant reaches the predeterminedtemperature the thermostat opens and hot

water passes through the top hose to the top

of the radiator. As the water circulates down

through the radiator, it is cooled by the

passage of air past the radiator when the car is

in forward motion, supplemented by the action

of the thermo-viscous fan when necessary.

Having reached the bottom of the radiator, the

water is now cool and the cycle is repeated.

Circulation of water continues through the

expansion tank, inlet manifold and heater at all

times; the heater temperature control being by

an air flap.

The thermo-viscous fan is controlled by the

temperature of air behind the radiator. When

the air temperature reaches a predetermined

level, a bi-metallic coil commences to open a

valve within the unit and silicon fluid is fed

through a system of vanes. Half of the vanes

are driven directly by the water pump and the

remaining half are connected to the fan blades.

The vanes are arranged so that drive is

transmitted to the fan blades in relation to the

drag or viscosity of the fluid, and this in turn

depends on ambient temperature and engine

speed. The fan is therefore only operated when

required, and compared with direct drive type

fan represents a considerable improvement in

fuel economy, drivebelt wear and fan noise.

Air conditioning

Air conditioning is fitted as standard on

Scorpio models and is optionally available on

some other models. In conjunction with the

heater, the system enables any reasonable air

temperature to be achieved inside the car, it

also reduces the humidity of the incoming air,

aiding demisting even when cooling is not

required.

The refrigeration side of the air conditioning

system functions in a similar way to a

domestic refrigerator. A compressor, belt-

driven from the crankshaft pulley, draws

refrigerant in its gaseous phase from an

evaporator. The compressed refrigerant

passes through a condenser where it loses

heat and enters its liquid phase. After

dehydration the refrigerant returns to the

evaporator where it absorbs heat from air

passing over the evaporator fins. The

refrigerant becomes a gas again and the cycle

is repeated.Various subsidiary controls and sensors

protect the system against excessive

temperature and pressures. Additionally,

engine idle speed is increased when the

system is in use to compensate for the

additional load imposed by the compressor.

Precautions

Antifreeze mixture

Antifreeze mixture is poisonous. Keep it out

of reach of children and pets. Wash splashes

off skin and clothing with plenty of water.

Wash splashes off vehicle paintwork to avoid

discolouration.

Antifreeze/water mixture must be renewed

every two years to preserve its anti-corrosive

properties. In climates where antifreeze

protection is unnecessary, a corrosion

inhibitor may be used instead - consult a Ford

dealer. Never run the engine for long periods

with plain water as coolant. Only use the

specified antifreeze, as inferior brands may not

contain the necessary corrosion inhibitors, or

may break down at high temperatures.

Antifreeze containing methanol is particularly

to be avoided, as the methanol evaporates.

The specified mixture is 45 to 50%

antifreeze and 50 to 55% clean soft water (by

volume). Mix the required quantity in a clean

container.

Air conditioning refrigerant

Although the refrigerant is not itself toxic, in

the presence of a naked flame (or a lighted

cigarette) it forms a highly toxic gas. Liquid

refrigerant spilled on the skin will cause

frostbite. If refrigerant enters the eyes, rinse

them with a dilute solution of boric acid and

seek medical advice immediately.

In view of the above points, and of the need

for specialised equipment for evacuating and

recharging the system, any work which

requires the disconnection of a refrigerant line

must be left to a specialist.

Do not allow refrigerant lines to be exposed

to temperatures above 110°C (230°F) - eg

during welding or paint drying operations and

do not operate the air conditioning system if it

is known to be short of refrigerant, or further

damage may result.

1General information and

precautions

3•2Cooling, heating and ventilation systems

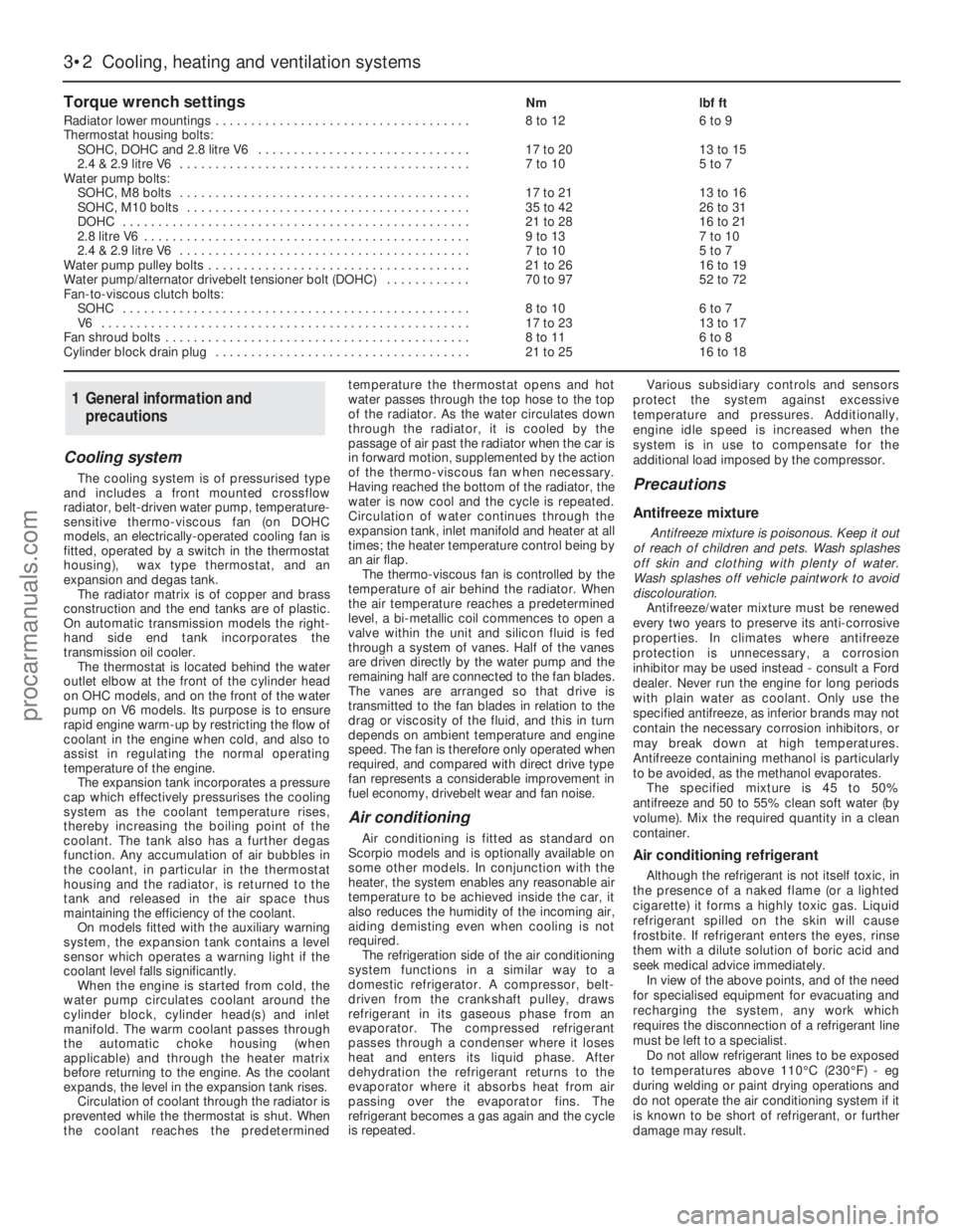

Torque wrench settingsNmlbf ft

Radiator lower mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 126 to 9

Thermostat housing bolts:

SOHC, DOHC and 2.8 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2013 to 15

2.4 & 2.9 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 105 to 7

Water pump bolts:

SOHC, M8 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 16

SOHC, M10 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4226 to 31

DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2816 to 21

2.8 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

2.4 & 2.9 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 105 to 7

Water pump pulley bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2616 to 19

Water pump/alternator drivebelt tensioner bolt (DOHC) . . . . . . . . . . . .70 to 9752 to 72

Fan-to-viscous clutch bolts:

SOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 106 to 7

V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2313 to 17

Fan shroud bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Cylinder block drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2516 to 18

procarmanuals.com

Page 249 of 255

REF•14Glossary of Technical Terms

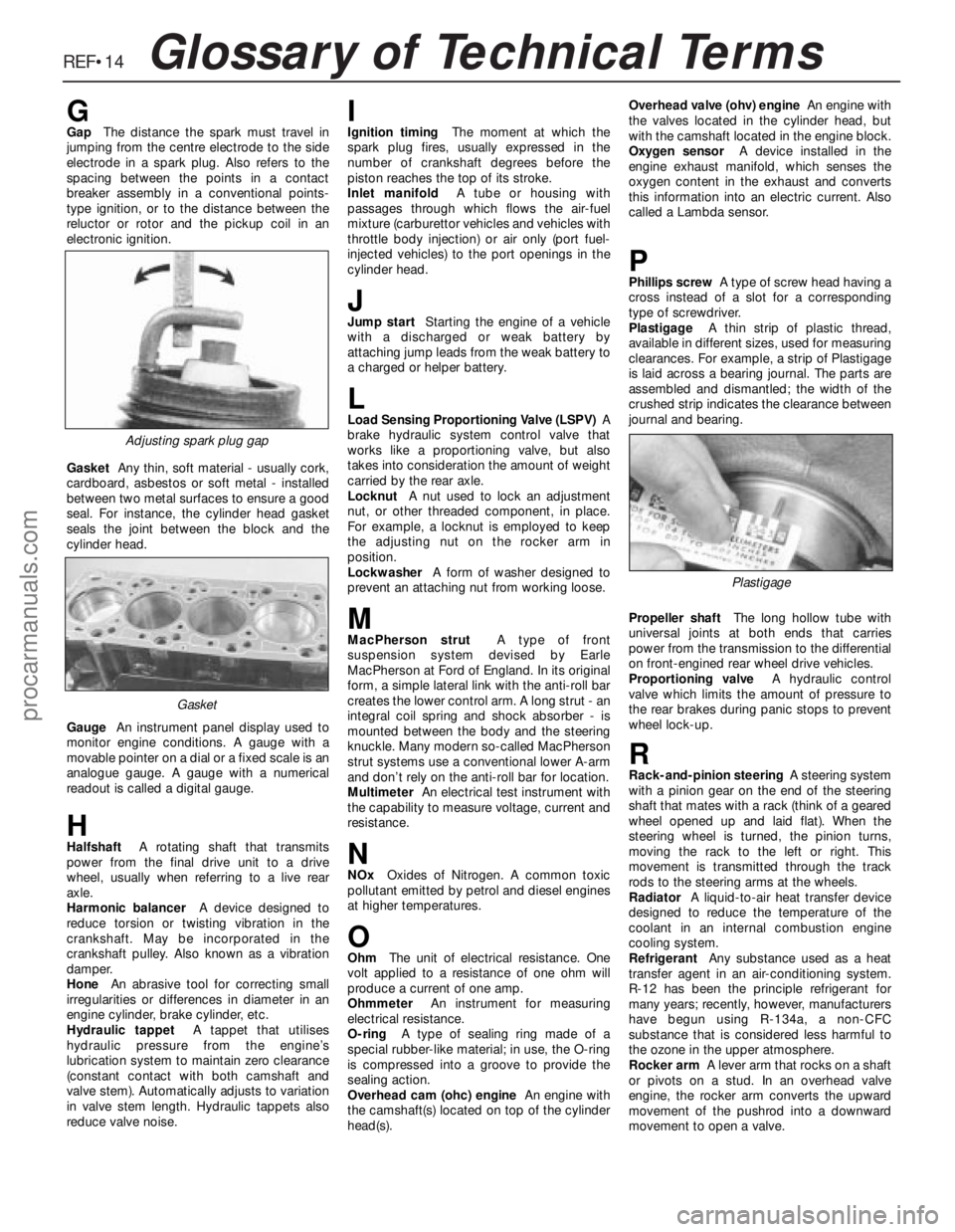

GGapThe distance the spark must travel in

jumping from the centre electrode to the side

electrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.

Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful to

the ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

Adjusting spark plug gap

Plastigage

Gasket

procarmanuals.com