main fuse FORD KUGA 2011 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 462 of 2057

Output signals

SWITCH the wiper switch to the "intermittent""

position to test the output signals. PRESSING the

heated rear window switch activates the output

signals in the following order:

a.

Left-hand turn signal

b. Right-hand turn signal

c. Main beam

d. Dipped beam

e. Windshield wiper stage I

f. Windshield wiper stage II

g. Heated rear windshield

h. Heater blower motor

i. Headlamp washer system (vehicles with HID headlamps)

j. Electric booster heater (if fitted)

k. Autolamps (position lamps only if fitted)

l. Alarm horn (vehicles with alarm system)

m. Rear window wiper

n. Heated front window relay

When the heated rear window switch is pressed

again, the test of the relevant signal is terminated.

When the heated rear window switch is pressed

once more, the test for the next signal in the list is

started.

End service mode

The GEM automatically ends service mode 20

seconds after the last input or at a driving speed

of over 7km/h. However, service mode can be

manually ended at any time by proceeding as

follows:

• PRESS and HOLD the switch of the heated rear

window

• SWITCH OFF the ignition.

• RELEASE the switch of the heated rear window

3 signals sound and the turn signal lamps illuminate

to indicate that service mode has ended.

Reset service mode

If, after completion of service mode, some functions

do not operate or do not operate properly, check

the following functions:

• Instrument cluster illumination, side marker lamps (side lights) and licence plate lamp in

automatic headlamps mode

• Rear wiper

• Headlamp washer assembly

• Electric booster heater • Alarm horn

• Heated windshield

If one or more of the listed functions is not OK, it's

possible that the cause of the fault is due to not

exiting service mode properly. To reactivate the

functions correctly, perform the following steps:

1. Switch off the ignition.

2. SWITCH OFF the switch for the windscreen

wash/wipe system

3. OPERATE the switch of the heated rear window

and HOLD IT THERE

4. SWITCH ON the ignition.

5. RELEASE the heated rear window switch (an acoustic signal will sound if activation has been

performed correctly)

6. SWITCH the windscreen wash/wipe switch to the "Intermittent wipe" position

7. OPERATE the heated rear window switch 6 times (the main beam headlamps switch on and

off automatically)

8. SWITCH OFF the switch for the windscreen wash/wipe system

9. OPERATE the switch of the heated rear window

and HOLD IT THERE

10. Switch off the ignition.

11. RELEASE the heated rear window switch (three

acoustic signals will sound if activation has been

performed correctly)

After completion of the work, check all the

functions.

Inspection and Checking

NOTE: The generic electronic module (GEM) is

integrated into the central junction box (CJB).

1. VERIFY customer concern.

2. Visually CHECK for any obvious mechanical or electrical damage.

NOTE: Ensure correct locking of the wiring harness

connector.

Visual Inspection Electrical

Fuses

Wiring harness Connectors G1055084en

2008.50 Kuga 8/2011 419-10-12

Multifunction Electronic Modules

419-10-12

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1835 of 2057

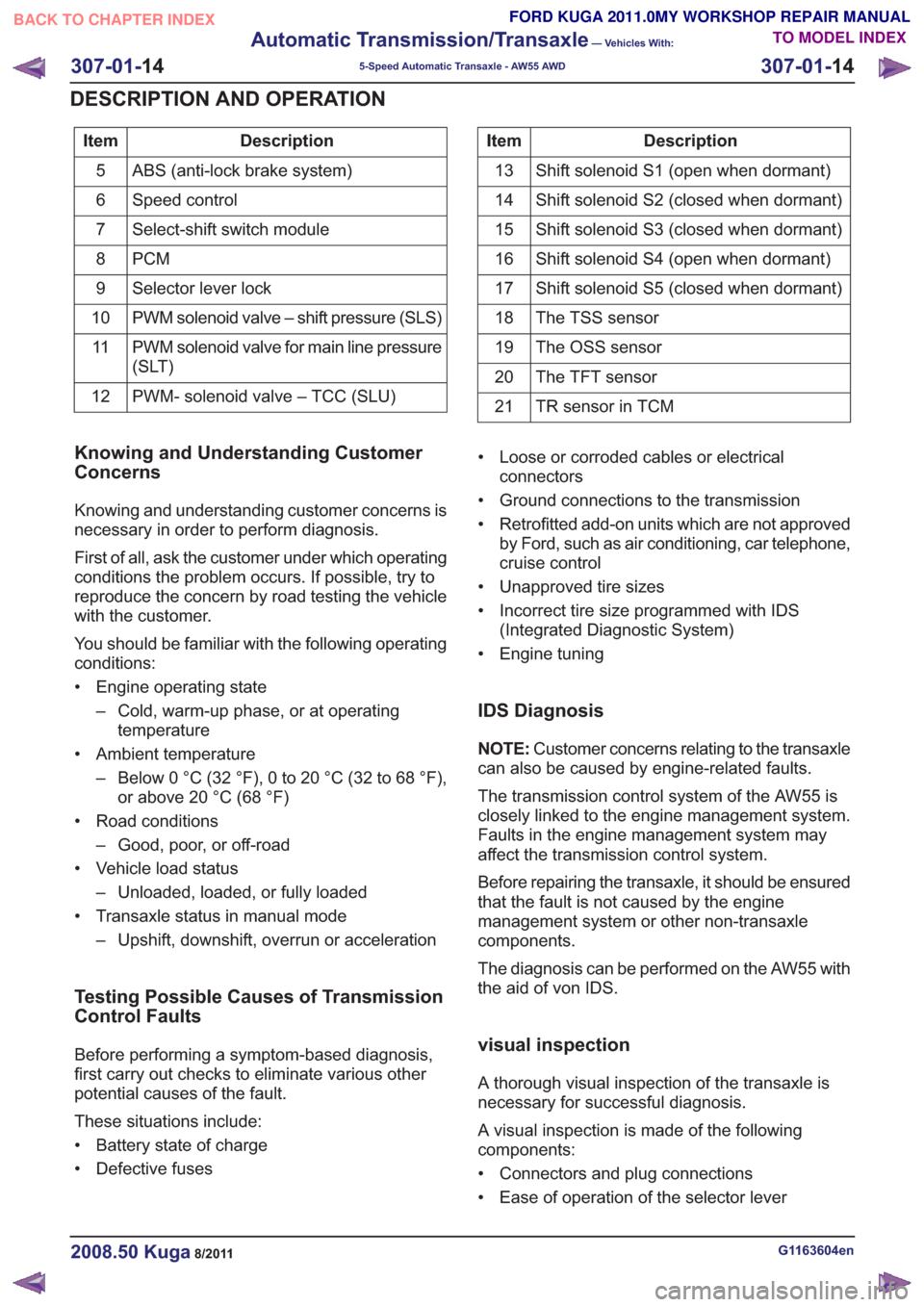

Description

Item

ABS (anti-lock brake system)

5

Speed control

6

Select-shift switch module

7

PCM

8

Selector lever lock

9

PWM solenoid valve – shift pressure (SLS)

10

PWM solenoid valve for main line pressure

(SLT)

11

PWM- solenoid valve – TCC (SLU)

12Description

Item

Shift solenoid S1 (open when dormant)

13

Shift solenoid S2 (closed when dormant)

14

Shift solenoid S3 (closed when dormant)

15

Shift solenoid S4 (open when dormant)

16

Shift solenoid S5 (closed when dormant)

17

The TSS sensor

18

The OSS sensor

19

The TFT sensor

20

TR sensor in TCM

21

Knowing and Understanding Customer

Concerns

Knowing and understanding customer concerns is

necessary in order to perform diagnosis.

First of all, ask the customer under which operating

conditions the problem occurs. If possible, try to

reproduce the concern by road testing the vehicle

with the customer.

You should be familiar with the following operating

conditions:

• Engine operating state

– Cold, warm-up phase, or at operatingtemperature

• Ambient temperature – Below 0 °C (32 °F), 0 to 20 °C (32 to 68 °F),or above 20 °C (68 °F)

• Road conditions – Good, poor, or off-road

• Vehicle load status – Unloaded, loaded, or fully loaded

• Transaxle status in manual mode – Upshift, downshift, overrun or acceleration

Testing Possible Causes of Transmission

Control Faults

Before performing a symptom-based diagnosis,

first carry out checks to eliminate various other

potential causes of the fault.

These situations include:

• Battery state of charge

• Defective fuses • Loose or corroded cables or electrical

connectors

• Ground connections to the transmission

• Retrofitted add-on units which are not approved by Ford, such as air conditioning, car telephone,

cruise control

• Unapproved tire sizes

• Incorrect tire size programmed with IDS (Integrated Diagnostic System)

• Engine tuning

IDS Diagnosis

NOTE: Customer concerns relating to the transaxle

can also be caused by engine-related faults.

The transmission control system of the AW55 is

closely linked to the engine management system.

Faults in the engine management system may

affect the transmission control system.

Before repairing the transaxle, it should be ensured

that the fault is not caused by the engine

management system or other non-transaxle

components.

The diagnosis can be performed on the AW55 with

the aid of von IDS.

visual inspection

A thorough visual inspection of the transaxle is

necessary for successful diagnosis.

A visual inspection is made of the following

components:

• Connectors and plug connections

• Ease of operation of the selector lever

G1163604en2008.50 Kuga8/2011

307-01- 14

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 14

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL