transaxle FORD KUGA 2011 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1354 of 2057

4. Remove the vacuum hose from the brakebooster. Manifold vacuum should be available

at the brake booster end of the hose with the

engine at idle speed and the transaxle in the

NEUTRAL position. Make sure that all unused

vacuum outlets are correctly capped, hose

connectors are correctly secured and vacuum

hoses are in good condition. When it is

established that manifold vacuum is available

to the brake booster, connect the vacuum hose

to the brake booster and repeat Step 3. If no

downward movement of the brake pedal is felt,

install a new brake booster.

5. Operate the engine a minimum of 10 seconds at approximately 1200 rpm. Stop the engine and

let the vehicle stand for 10 minutes. Then, apply

the brake pedal with approximately 89 N (20 lb)

force. The pedal feel (brake application) should

be the same as that noted with the engine

operating. If the brake pedal feels hard (no

power assist), install a new vacuum check valve

and then repeat the test. If the brake pedal still

feels hard, install a new brake booster. If the

brake pedal movement feels spongy, bleed the

brake system. REFER to: (206-00 Brake System

- General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General

Procedures),

Component Bleeding (General Procedures).

Brake Master Cylinder

Usually, the first and strongest indicator of anything

wrong with the braking system is a feeling through

the brake pedal. In diagnosing the condition of the

brake master cylinder, check pedal feel as

evidence of a brake concern. Check for the red

brake warning indicator illumination and the fluid

level in the master cylinder reservoir.

Normal Conditions

The following conditions are considered normal

and are not indications that the brake master

cylinder is in need of service.

– Modern brake systems are not designed to

produce as hard a pedal effort as in the past.

Complaints of light pedal efforts should be compared to pedal efforts of another vehicle, of

the same model and year.

– During normal operation of the brake pedal, the fluid level in the reservoir will rise during brake

pedal application and fall during release. The

net fluid level (i.e., after brake pedal application

and release) will remain unchanged.

– A trace of brake fluid will exists on the brake booster shell below the master cylinder

mounting flange. This results from the normal

lubricating action of the master cylinder bore

end seal.

– The fluid level will fall with brake shoe and lining wear.

Abnormal Conditions

NOTE: Prior to performing any diagnosis, make

sure the brake system warning indicator is

functional.

Changes in brake pedal feel or travel are indicators

that something could be wrong with the braking

system. The diagnostic procedure and techniques

use brake pedal feel, warning indicator illumination

and low brake fluid level as indicators in diagnosing

braking system concerns. The following conditions

are considered abnormal and indicate that the

brake master cylinder is in need of service.

– The brake pedal goes down fast. This could be caused by an external or internal leak.

– The brake pedal eases down slowly. This could be caused by an external or internal leak.

– The brake pedal is low and or feels spongy. This condition may be caused by no fluid in the brake

master cylinder reservoir, reservoir cap vent

holes clogged or air in the hydraulic system.

– The brake pedal effort is excessive. This may be caused by a bind or obstruction in the pedal

or linkage, clogged fluid control valve or

insufficient booster vacuum.

– The rear brakes lock up during light pedal force. This may be caused by incorrect tire pressures,

grease or fluid on the brake shoes and linings,

damaged brake shoes and linings, incorrectly

adjusted parking brake, or damaged or

contaminated brake pressure control valves.

– The brake pedal effort is erratic. This condition could be caused by a brake booster malfunction,

extreme caliper piston knock back or incorrectly

installed brake shoes and linings.

– The red brake warning indicator is ON. This may be caused by low fluid level, ignition wire routing

G1058975en2008.50 Kuga8/2011

206-00- 18

Brake System - General Information

206-00- 18

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1355 of 2057

too close to the fluid level indicator assembly,

or float assembly damage.

Bypass Condition Test

1. Check the fluid in the brake master cylinderreservoir. Fill the brake master cylinder reservoir

if low or empty.

2. Observe the fluid level in the brake master cylinder reservoir. If after several brake

applications, the fluid level remains the same,

measure the wheel turning torque required to

rotate the wheels with the brakes applied as

follows:

Place the transaxle in the NEUTRAL position.

Raise and support the vehicle. REFER to: (100-02

Jacking and Lifting) Jacking (Description and Operation),

Lifting (Description and Operation).

Apply the brakes with a minimum of 445 N (100

lb) and hold for approximately 15 seconds. With

the brakes still applied, exert a torque on the front

wheels of 10.1 Nm (75 lb ft). If either wheel rotates,

install a new brake master cylinder.

REFER to: Brake Master Cylinder - 2.5L Duratec

(147kW/200PS) - VI5 (206-06 Hydraulic Brake

Actuation, Removal and Installation).

Non-Pressure Leaks

Any empty brake master cylinder reservoir

condition may be caused by two types of

non-pressure external leaks.

Type 1: An external leak may occur at the brake

master cylinder reservoir cap because of incorrect

positioning of the gasket and cap. Reposition the

cap and gasket.

Type 2: An external leak may occur at the brake

master cylinder reservoir mounting seals. Service

such a leak by installing new seals.

G1058975en2008.50 Kuga8/2011

206-00- 19

Brake System - General Information

206-00- 19

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1525 of 2057

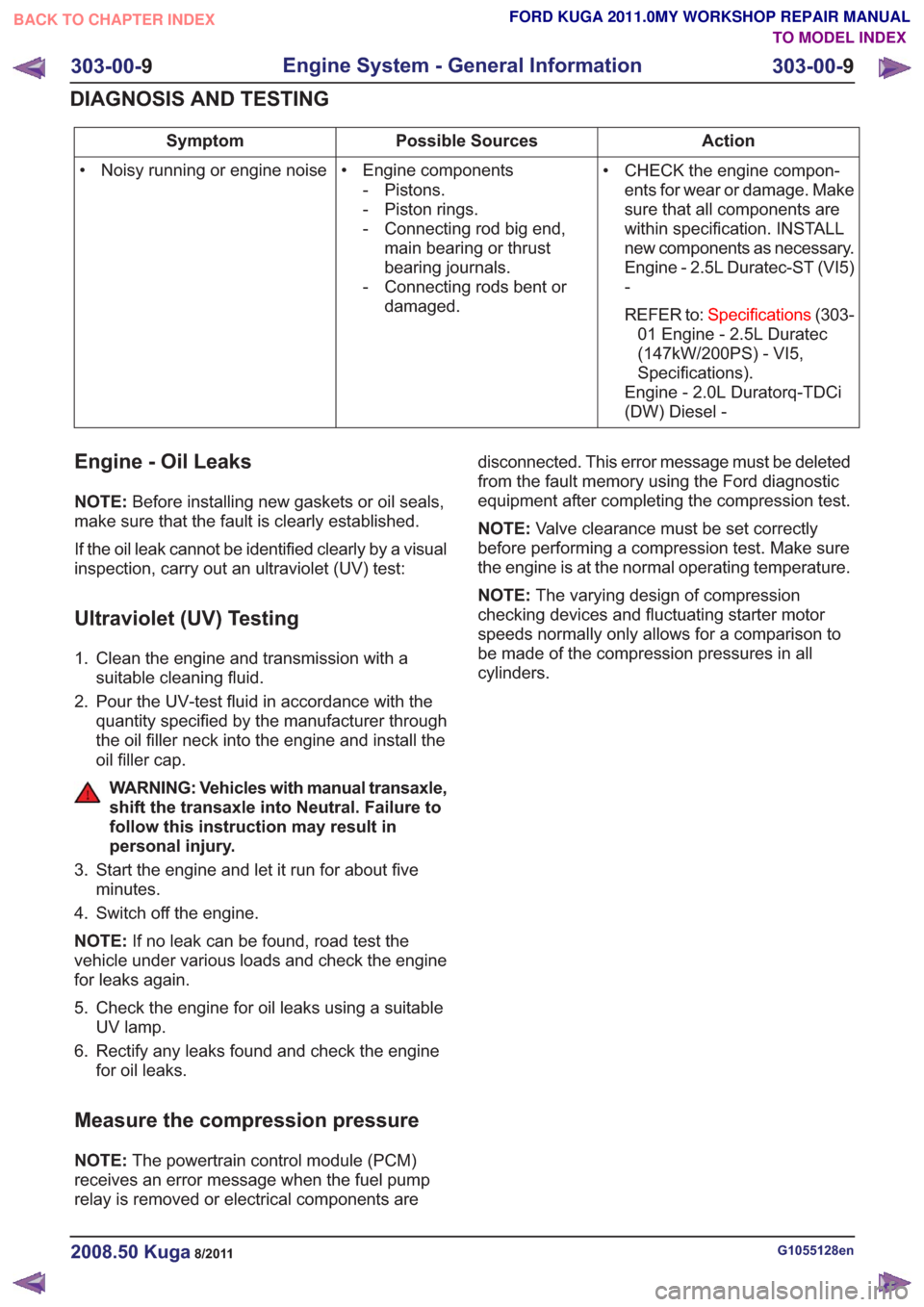

Action

Possible Sources

Symptom

• CHECK the engine compon-ents for wear or damage. Make

sure that all components are

within specification. INSTALL

new components as necessary.

Engine - 2.5L Duratec-ST (VI5)

-

REFER to: Specifications (303-

01 Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Specifications).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Engine components

- Pistons.

- Piston rings.

- Connecting rod big end,main bearing or thrust

bearing journals.

- Connecting rods bent or damaged.

• Noisy running or engine noise

Engine - Oil Leaks

NOTE:

Before installing new gaskets or oil seals,

make sure that the fault is clearly established.

If the oil leak cannot be identified clearly by a visual

inspection, carry out an ultraviolet (UV) test:

Ultraviolet (UV) Testing

1. Clean the engine and transmission with a suitable cleaning fluid.

2. Pour the UV-test fluid in accordance with the quantity specified by the manufacturer through

the oil filler neck into the engine and install the

oil filler cap.

WARNING: Vehicles with manual transaxle,

shift the transaxle into Neutral. Failure to

follow this instruction may result in

personal injury.

3. Start the engine and let it run for about five minutes.

4. Switch off the engine.

NOTE: If no leak can be found, road test the

vehicle under various loads and check the engine

for leaks again.

5. Check the engine for oil leaks using a suitable UV lamp.

6. Rectify any leaks found and check the engine for oil leaks.

Measure the compression pressure

NOTE: The powertrain control module (PCM)

receives an error message when the fuel pump

relay is removed or electrical components are disconnected. This error message must be deleted

from the fault memory using the Ford diagnostic

equipment after completing the compression test.

NOTE:

Valve clearance must be set correctly

before performing a compression test. Make sure

the engine is at the normal operating temperature.

NOTE: The varying design of compression

checking devices and fluctuating starter motor

speeds normally only allows for a comparison to

be made of the compression pressures in all

cylinders.

G1055128en2008.50 Kuga8/2011

303-00- 9

Engine System - General Information

303-00- 9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1534 of 2057

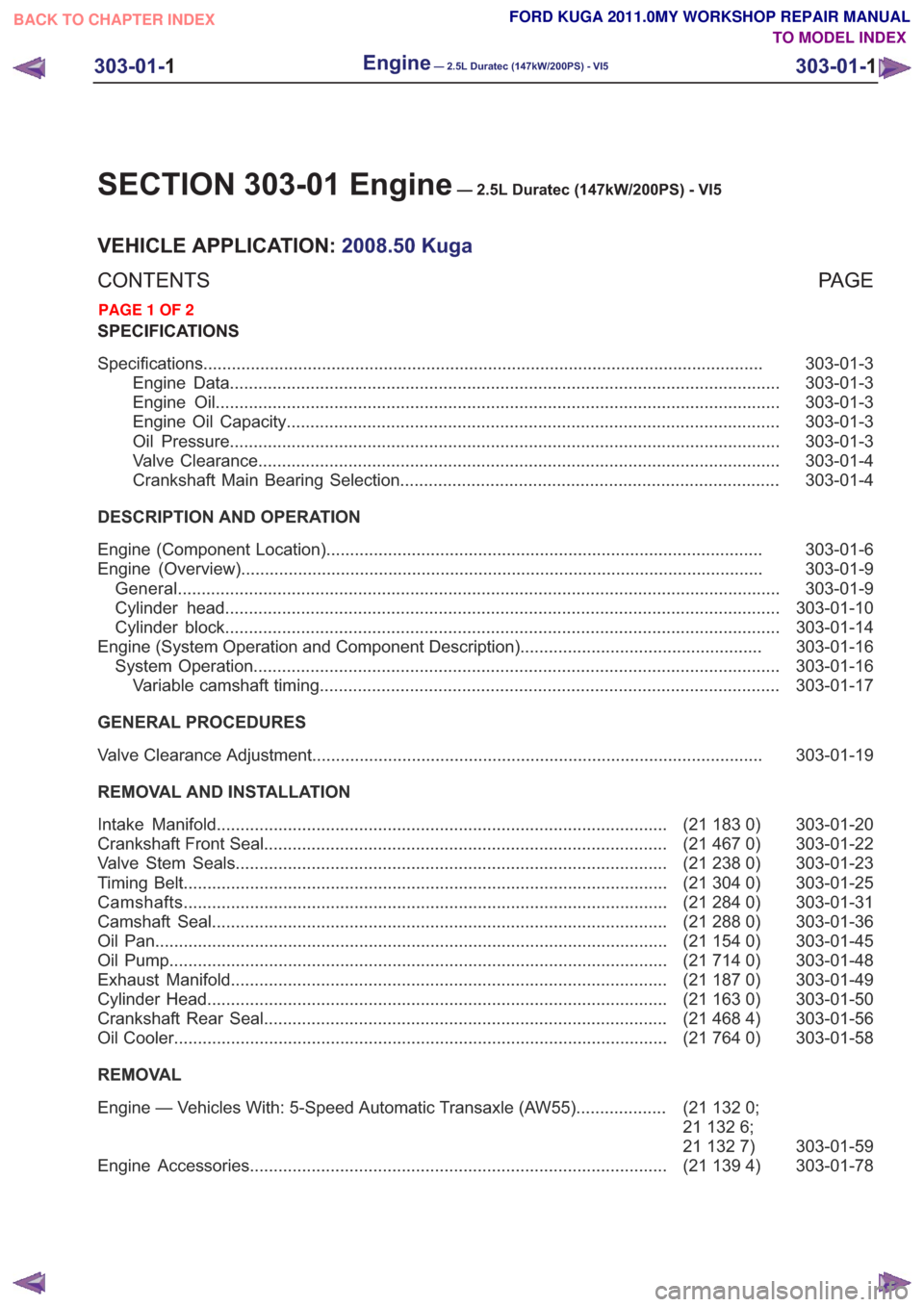

SECTION 303-01 Engine— 2.5L Duratec (147kW/200PS) - VI5

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

SPECIFICATIONS

303-01-3

Specifications ........................................................................\

..............................................

303-01-3

Engine Data ........................................................................\

............................................

303-01-3

Engine Oil ........................................................................\

...............................................

303-01-3

Engine Oil Capacity ........................................................................\

................................

303-01-3

Oil Pressure ........................................................................\

............................................

303-01-4

Valve Clearance ........................................................................\

......................................

303-01-4

Crankshaft Main Bearing Selection ........................................................................\

........

DESCRIPTION AND OPERATION 303-01-6

Engine (Component Location) ........................................................................\

....................

303-01-9

Engine (Overview) ........................................................................\

......................................

303-01-9

General ........................................................................\

.......................................................

303-01-10

Cylinder head ........................................................................\

.............................................

303-01-14

Cylinder block ........................................................................\

.............................................

303-01-16

Engine (System Operation and Component Description) ...................................................

303-01-16

System Operation ........................................................................\

.......................................

303-01-17

Variable camshaft timing ........................................................................\

.........................

GENERAL PROCEDURES 303-01-19

Valve Clearance Adjustment ........................................................................\

.......................

REMOVAL AND INSTALLATION 303-01-20

(21 183 0)

Intake Manifold ........................................................................\

.......................

303-01-22

(21 467 0)

Crankshaft Front Seal ........................................................................\

.............

303-01-23

(21 238 0)

Valve Stem Seals ........................................................................\

...................

303-01-25

(21 304 0)

Timing Belt ........................................................................\

..............................

303-01-31

(21 284 0)

Camshafts ........................................................................\

..............................

303-01-36

(21 288 0)

Camshaft Seal ........................................................................\

........................

303-01-45

(21 154 0)

Oil Pan ........................................................................\

....................................

303-01-48

(21 714 0)

Oil Pump ........................................................................\

.................................

303-01-49

(21 187 0)

Exhaust Manifold ........................................................................\

....................

303-01-50

(21 163 0)

Cylinder Head ........................................................................\

.........................

303-01-56

(21 468 4)

Crankshaft Rear Seal ........................................................................\

.............

303-01-58

(21 764 0)

Oil Cooler ........................................................................\

................................

REMOVAL

303-01-59

(21

132 0;

21 132 6;

21 132 7)

Engine — Vehicles With: 5-Speed Automatic Transaxle (AW55)

...................

303-01-78

(21 139 4)

Engine Accessories ........................................................................\

................

303-01-1

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

PAGE 1 OF 2 FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1535 of 2057

DISASSEMBLY303-01-84

(21 134 8)

Engine ........................................................................\

....................................

DISASSEMBLY AND ASSEMBLY OF SUBASSEMBLIES 303-01-93

(21 165 6)

Cylinder Head ........................................................................\

.........................

ASSEMBLY 303-01-94

(21 134 8)

Engine ........................................................................\

....................................

INSTALLATION 303-01-112

(21 139 4)

Engine Accessories ........................................................................\

................

303-01-119

(21 132 0;

21 132 6;

21 132 7)

Engine — Vehicles With: 5-Speed Automatic Transaxle (AW55)

...................

303-01-2

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

2

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

PAGE 2 OF 2 FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1589 of 2057

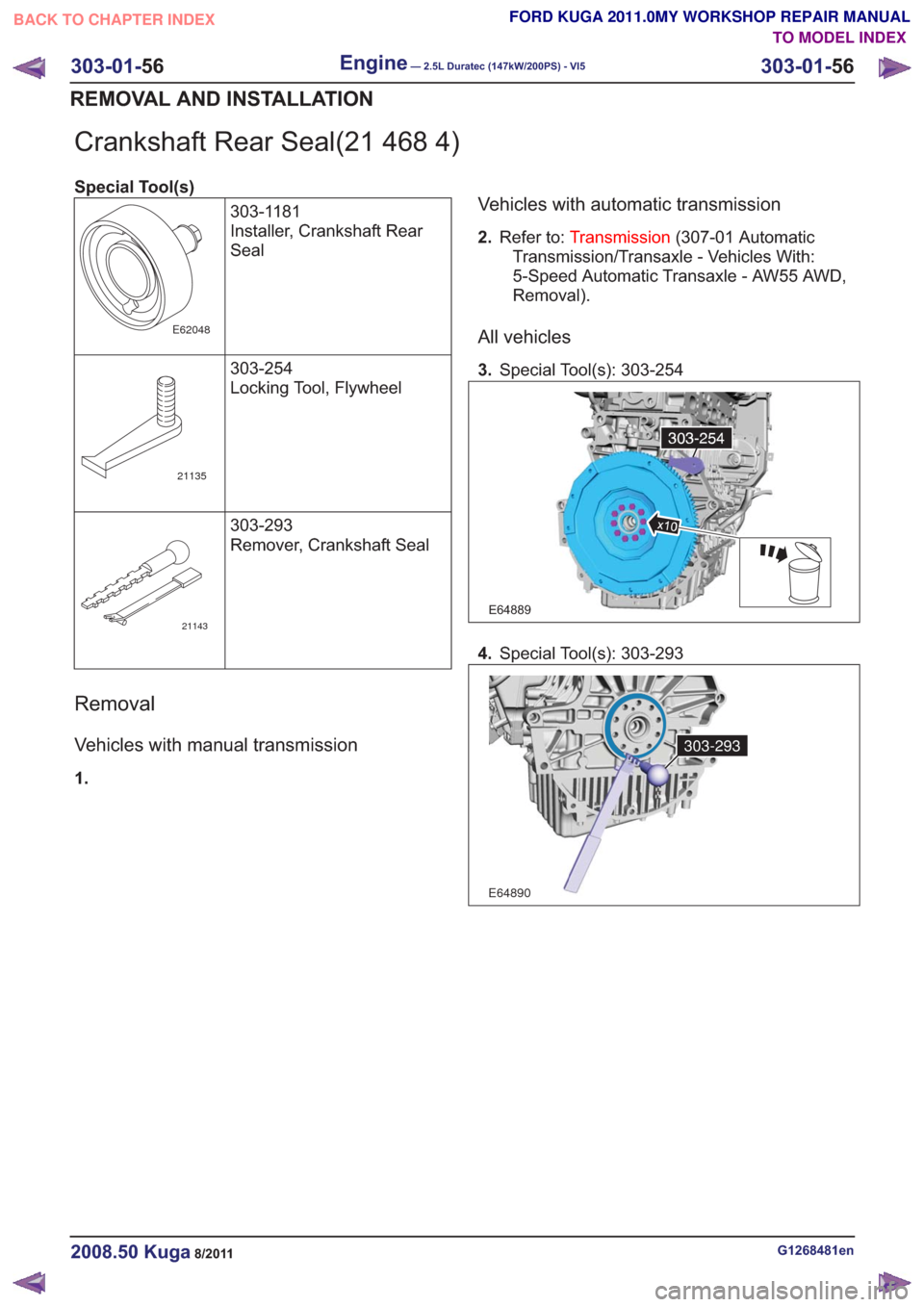

Crankshaft Rear Seal(21 468 4)

Special Tool(s)303-1181

Installer, Crankshaft Rear

Seal

E62048

303-254

Locking Tool, Flywheel

21135

303-293

Remover, Crankshaft Seal

21143

Removal

Vehicles with manual transmission

1.

Vehicles with automatic transmission

2.Refer to: Transmission (307-01 Automatic

Transmission/Transaxle - Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD,

Removal).

All vehicles

3. Special Tool(s): 303-254

E64889

4.Special Tool(s): 303-293

E64890

303-293

G1268481en2008.50 Kuga8/2011

303-01- 56

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

56

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1590 of 2057

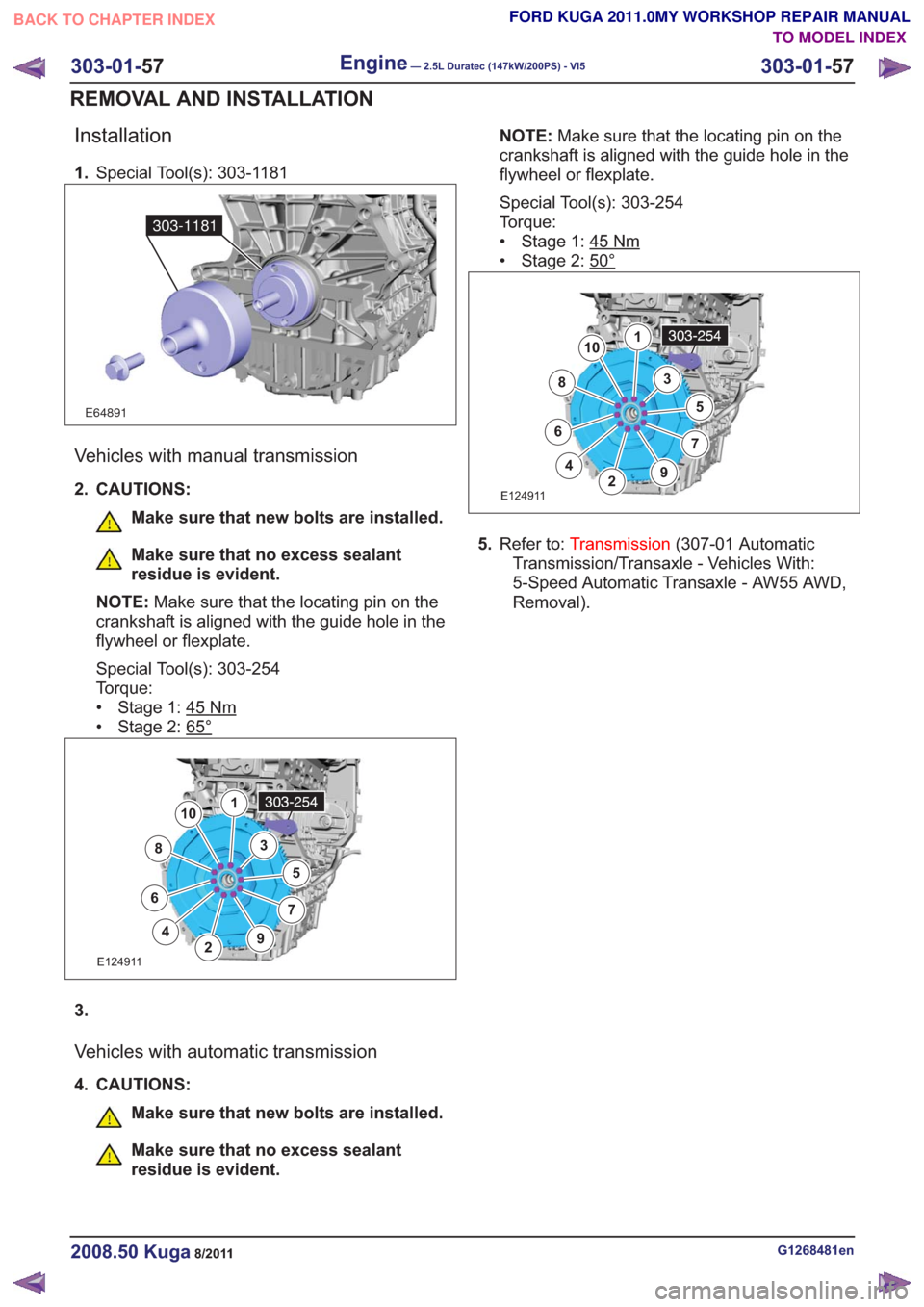

Installation

1.Special Tool(s): 303-1181

E64891

303-1181

Vehicles with manual transmission

2. CAUTIONS:

Make sure that new bolts are installed.

Make sure that no excess sealant

residue is evident.

NOTE: Make sure that the locating pin on the

crankshaft is aligned with the guide hole in the

flywheel or flexplate.

Special Tool(s): 303-254

Torque:

• Stage 1: 45

Nm

• Stage 2: 65°

E124911

1

2

3

4

5

67

8

9

10

3.

Vehicles with automatic transmission

4. CAUTIONS:

Make sure that new bolts are installed.

Make sure that no excess sealant

residue is evident. NOTE:

Make sure that the locating pin on the

crankshaft is aligned with the guide hole in the

flywheel or flexplate.

Special Tool(s): 303-254

Torque:

• Stage 1: 45

Nm

• Stage 2: 50°

E124911

1

2

3

4

5

67

8

9

10

5. Refer to: Transmission (307-01 Automatic

Transmission/Transaxle - Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD,

Removal).

G1268481en2008.50 Kuga8/2011

303-01- 57

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

57

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1592 of 2057

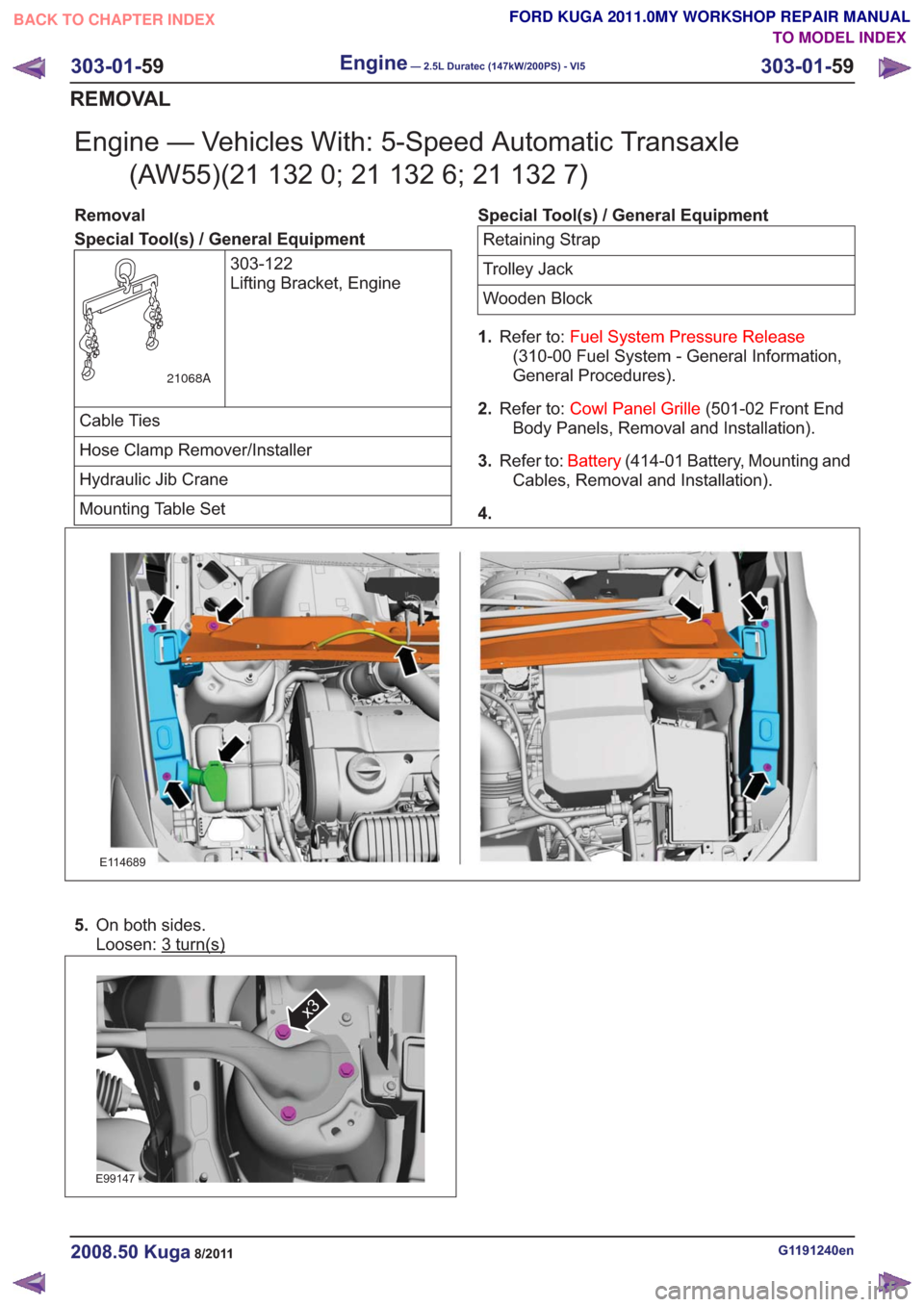

Engine — Vehicles With: 5-Speed Automatic Transaxle(AW55)(21 132 0; 21 132 6; 21 132 7)

Removal

Special Tool(s) / General Equipment

303-122

Lifting Bracket, Engine

21068A

Cable Ties

Hose Clamp Remover/Installer

Hydraulic Jib Crane

Mounting Table Set

Special Tool(s) / General EquipmentRetaining Strap

Trolley Jack

Wooden Block

1. Refer to: Fuel System Pressure Release

(310-00 Fuel System - General Information,

General Procedures).

2. Refer to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

3. Refer to: Battery(414-01 Battery, Mounting and

Cables, Removal and Installation).

4.

E114689

5. On both sides.

Loosen: 3

turn(s)

E99147

x3

G1191240en2008.50 Kuga8/2011

303-01- 59

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

59

REMOVAL

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1606 of 2057

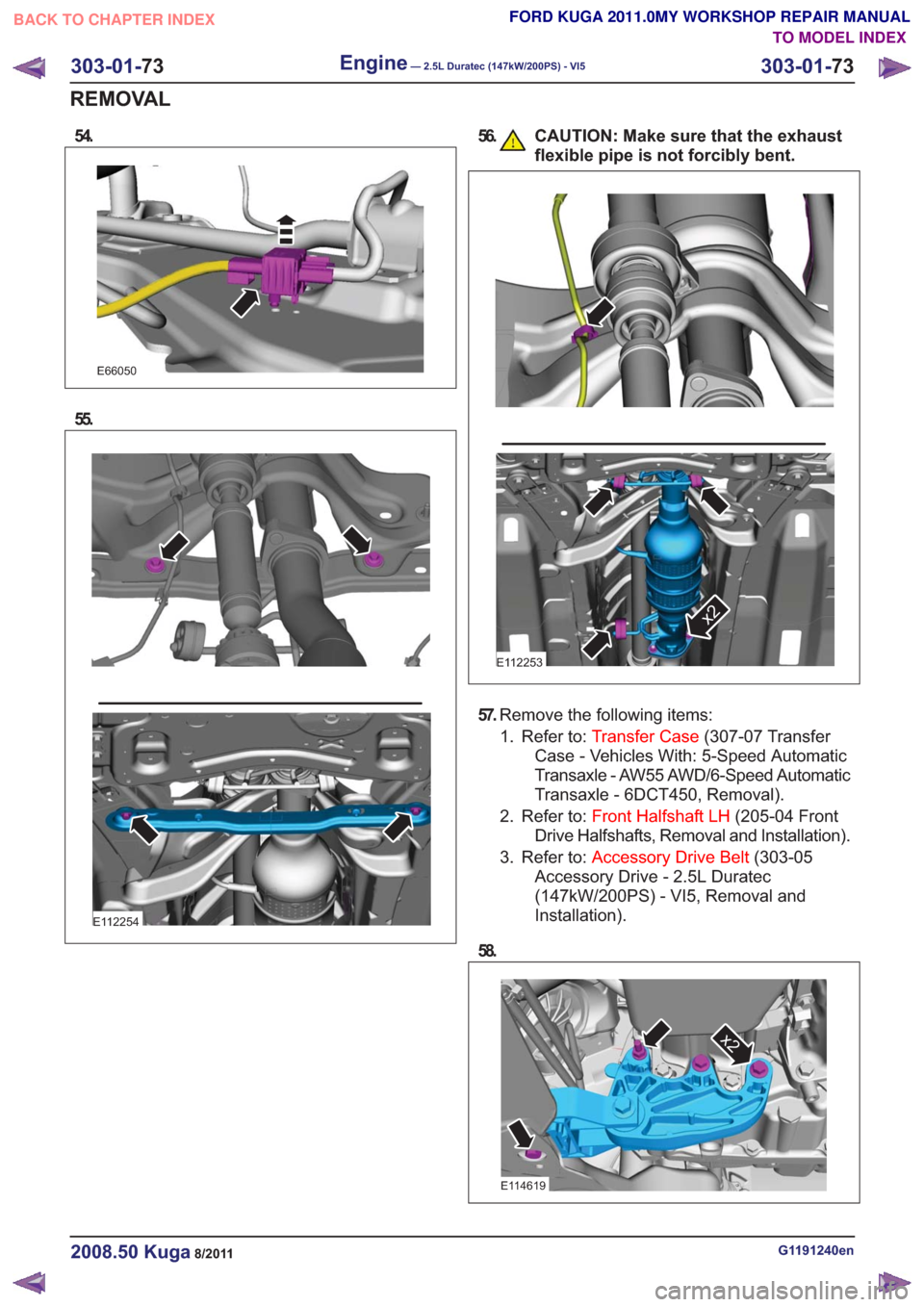

54.

E66050

55.

E112254

56. CAUTION: Make sure that the exhaustflexible pipe is not forcibly bent.

E112253

x2

57.Remove the following items:

1. Refer to: Transfer Case (307-07 Transfer

Case - Vehicles With: 5-Speed Automatic

Transaxle - AW55 AWD/6-Speed Automatic

Transaxle - 6DCT450, Removal).

2. Refer to: Front Halfshaft LH (205-04 Front

Drive Halfshafts, Removal and Installation).

3. Refer to: Accessory Drive Belt (303-05

Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

58.

x2x2

E114619

G1191240en2008.50 Kuga8/2011

303-01- 73

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

73

REMOVAL

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1652 of 2057

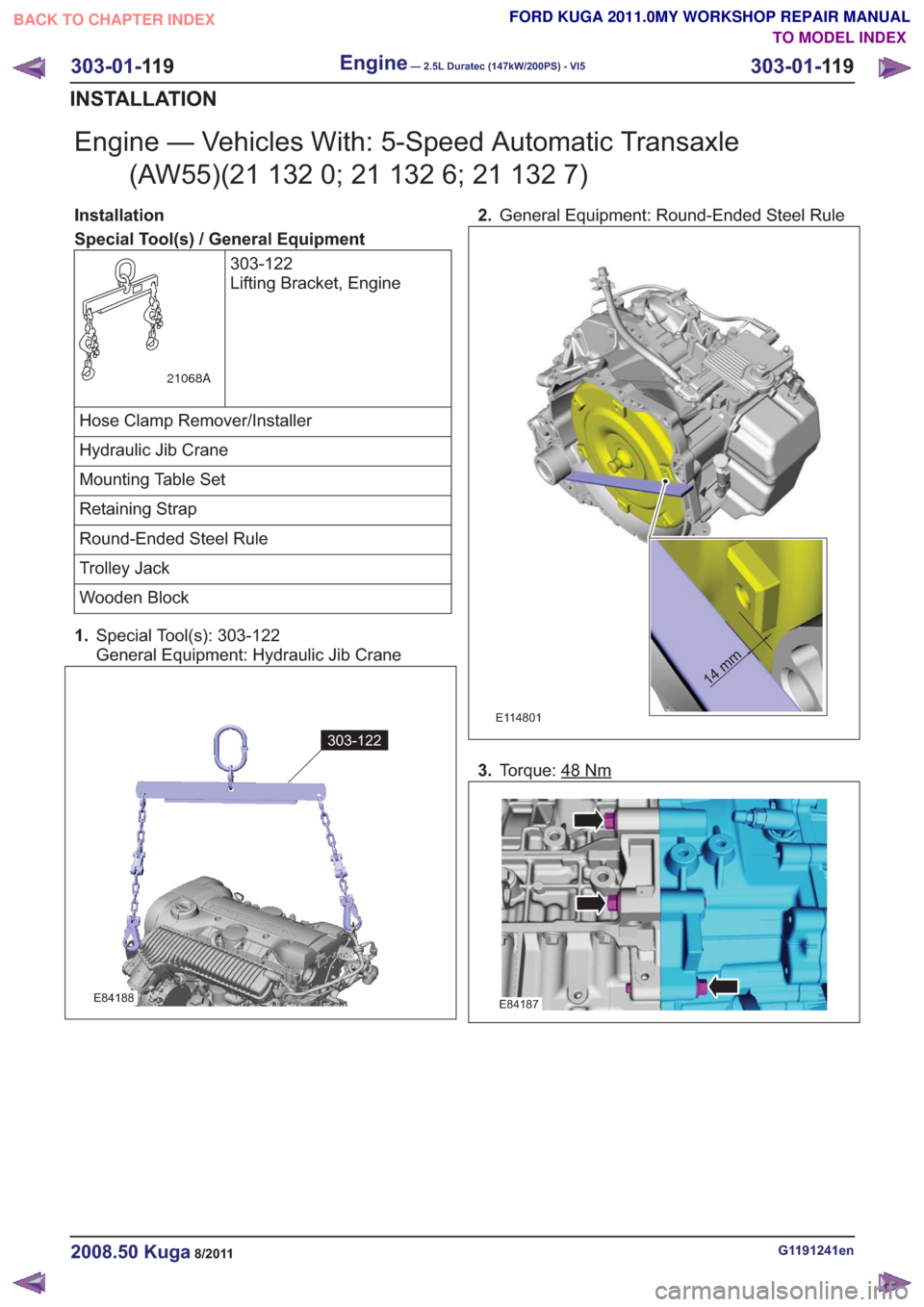

Engine — Vehicles With: 5-Speed Automatic Transaxle(AW55)(21 132 0; 21 132 6; 21 132 7)

Installation

Special Tool(s) / General Equipment

303-122

Lifting Bracket, Engine

21068A

Hose Clamp Remover/Installer

Hydraulic Jib Crane

Mounting Table Set

Retaining Strap

Round-Ended Steel Rule

Trolley Jack

Wooden Block

1. Special Tool(s): 303-122

General Equipment: Hydraulic Jib Crane

E84188

303-122

2.General Equipment: Round-Ended Steel Rule

14 mm14 mm

E114801

3.Torque: 48Nm

E84187

G1191241en2008.50 Kuga8/2011

303-01- 11 9

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

11 9

INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL