IAT FORD KUGA 2011 1.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 67 of 2057

Brake System Health and Safety Precautions

WARNINGS:

EYE CONTACT: Brake fluid contains

polyglycol ethers and polyglycols. Avoid

contact with the eyes. Wash hands

thoroughly after handling. If brake fluid

comes into contact with the eyes, flush the

eyes with plenty of cold running water for

15 minutes. Seek medical attention for any

persistent eye irritation or abnormality.

SWALLOWED: Brake fluid contains

polyglycol ethers and polyglycols. If

swallowed, drink plenty of water. Seek

immediate medical attention.

INHALED: Dust from friction materials can

be harmful if inhaled.

Only use new specified brake fluid from

airtight containers.

CAUTION: If brake fluid is spilled on the

paintwork, the affected area must be

immediately washed down with cold water.

G565862en2008.50 Kuga8/2011

100-00-62

General Information

100-00- 62

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 68 of 2057

Engine Cooling System Health and Safety Precautions

WARNINGS:

Extreme care must be exercised when

handling hot fluids. Always wash off spilled

fluids from affected areas of skin

immediately.

Vapors may be given off from antifreeze

when heated. Avoid breathing these

vapors.

SKIN CONTACT: Antifreeze may be

absorbed through the skin in toxic or

harmful quantities.

SWALLOWED: If antifreeze is swallowed,

drink plenty of water, induce vomiting.

Seek immediate medical attention.

Antifreeze must not be used in any cooling

or industrial water system that is

connected or linked to general water

supplies.

G548995en2008.50 Kuga8/2011

100-00-63

General Information

100-00- 63

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 69 of 2057

Window Glass Health and Safety Precautions

WARNINGS:

Cured polyurethane (PU) adhesive can

degrade if subjected to high temperatures.

Isocyanide compounds can be released

when grinding or welding in close

proximity to cured PU adhesive.

SKIN CONTACT: Prolonged exposure to

polyurethane (PU) adhesive may cause

skin irritation. If PU adhesive comes into

contact with the skin, remove any

contaminated clothing. Immediately wash

the skin with soap and water. Seek medical

attention for any persistent skin irritation

or abnormality.

EYE CONTACT: Polyurethane (PU)

adhesive may cause severe irritation or

damage. If PU adhesive comes into contact

with the eyes, immediately flush eyes with

plenty of running water for at least 15

minutes. Seek immediate medical attention.

SWALLOWED: If polyurethane (PU)

adhesive is swallowed, flush the mouth

thoroughly. Do not induce vomiting.

Provide rest, warmth and fresh air. Seek

immediate medical attention.

INHALED: Persons having a respiratory

allergy may have an allergic reaction when

handling polyurethane (PU) adhesive.

INHALED: Polyurethane (PU) adhesive can

cause asthma like symptoms. Isocyanate

vapor from primer or PU adhesive can

cause allergies in the respiratory tract.

INHALED: If polyurethane (PU) adhesive

fumes are inhaled, move victim to fresh

air. Provide oxygen if necessary. If

breathing stops, provide artificial

respiration. Keep a victim warm and at rest.

Seek immediate medical attention.

CAUTIONS:

Make sure that the direct glazing for

bonded glass cutting blades are changed

where the cutting depth changes to avoid

damage to the body and trim panels.

During the curing period of the PU

adhesive, the door windows must be left

open to avoid a build up of pressure when

the doors are opened and closed.

G548999en2008.50 Kuga8/2011

100-00- 66

General Information

100-00- 66

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 70 of 2057

Petrol and Petrol-Ethanol Fuel Systems Health and SafetyPrecautions

WARNINGS:

Fuel may not give adequate warning before

toxic or harmful effects arise.

Exposure to fuel can be harmful and can

cause severe health damage or death.

Extreme care must be exercised when

handling hot fluids. Always wash off spilled

fluids from affected areas of skin

immediately.

Highly flammable mixtures are always

present and may ignite when working on

fuel systems. Do not allow naked flames,

sparks or lighted substances to come near

fuel related components.

Fuel must not be used as a cleaning agent.

Keep fuel containers tightly closed, out of

direct sunlight and in a cool area. Keep

away from heat sources, ignition sources

and oxidizing agents.

SKIN CONTACT: Excessive or prolonged

skin contact with diesel fuel may cause

serious skin disorders including skin

cancer.

SKIN CONTACT: Fuel is mildly irritating to

the skin and may cause dermatitis due to

defatting effect. Remove contaminated

clothing. Wash affected areas of skin with

soap and water. Seek medical attention for

any persistent skin irritation or

abnormality. Wash contaminated clothing

before reuse.

EYE CONTACT: Fuel is mildly irritating to

the eyes. Flush with plenty of running

water, blinking as often as possible. Do not

force the eyelid open. Seek medical

attention for any persistent eye irritation

or abnormality.

SWALLOWED: Fuel is moderately toxic

and tends to foam on vomiting. If drawn

into the lungs, inflammation may develop.

Do not induce vomiting. If spontaneous

vomiting occurs place the victim in a

forward position to reduce the risk of fuel

being drawn into the lungs. Give nothing

by mouth. If breathing but unconscious,

place in the recovery position. If breathing has stopped, apply artificial respiration.

Seek immediate medical attention.

INHALED: Fuel is toxic to the respiratory

and other body systems. Exposure may

result in various symptoms including

drowsiness, unconsciousness or severe

health damage. Move a victim to fresh air.

Keep a victim warm and at rest. If

unconscious, place in the recovery

position. If not breathing, apply artificial

respiration. Give cardiac massage if

necessary. Seek immediate medical

attention.

CAUTIONS:

Fuel injection equipment is manufactured

to very precise tolerances and fine

clearances. It is essential that absolute

cleanliness is observed when working with

these components.

Make sure that the workshop area in which

the vehicle is being worked on is as clean

and as dust free as possible.

G548996en2008.50 Kuga8/2011

100-00- 64

General Information

100-00- 64

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 71 of 2057

Supplemental Restraint System (SRS) Health and SafetyPrecautions

WARNINGS:

Only qualified technicians are allowed to

work on pyrotechnic components.

INHALED: Exposure to pyrotechnic residue

may cause low blood pressure, severe

headache, irritation of mucous membranes,

fainting, shortness of breath or rapid pulse.

Move a victim to fresh air. Seek immediate

medical attention.

EYE CONTACT: Exposure to unburned

pyrotechnic residue may cause irritation,

burning and etching of the eyes. Flush

immediately with plenty of cold running

water for at least 15 minutes. Seek

immediate medical attention.

EYE CONTACT: Exposure to burned

pyrotechnic residue may cause irritation,

burning and etching of the eyes. Flush

immediately with diluted boric acid

solution. Seek immediate medical

attention.

SKIN CONTACT: Unburned pyrotechnic

residue may be rapidly absorbed through

the skin in toxic quantities. Wash

immediately with plenty of soap and water.

Seek medical attention.

SKIN CONTACT: Burned pyrotechnic

residue may be rapidly absorbed through

the skin in toxic quantities. Wash with

plenty of water. Do not use soap. Seek

medical attention.

SWALLOWED: Unburned pyrotechnic

residue is extremely toxic. If conscious

drink plenty of water then induce vomiting.

Seek immediate medical attention. If

unconscious, or in convulsions do not

attempt to induce vomiting or give

anything by mouth. Seek immediate

medical attention.

SWALLOWED: Burned pyrotechnic residue

is extremely toxic. Drink plenty of water

and seek immediate medical attention.

The deployment key must only be

accessible to authorized personnel.

Make sure that the deployment key remains

removed from the deployment equipment

except during deployment.

If permenantly disabling or enabling the

passenger air bag a new seat belt for

vehicles without or with a passenger air

bag must be installed.

Undeployed pyrotechnic components must

not be deployed in the vehicle.

Pyrotechnic components must be deployed

following local regulations.

Check thoroughly that no loose objects

can be spread during the deployment of

pyrotechnic components.

Pyrotechnic components must be

transported following local regulations.

Never carry out any electrical measurement

on disconnected, undeployed pyrotechnic

components.

Pyrotechnic components must not be

disassembled.

Pyrotechnic components are not

interchangeable between vehicles.

Always carry a live air bag module away

from the body with the air bag or trim cover

pointing upwards.

Live air bag modules must be placed in a

suitable cage when removed from the

vehicle. The air bag or trim cover must be

facing upwards.

Do not install a rearward facing child safety

seat to the passenger seat with an

activated passenger air bag.

CAUTIONS:

Pyrotechnic components must not be

subjected to temperatures higher than

110°C.

Never install aftermarket accessories to

the vehicle on or adjacent to the

supplemental restraint system module.

G548998en2008.50 Kuga8/2011

100-00- 65

General Information

100-00- 65

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 72 of 2057

Body Repair Health and Safety and General Precautions

General

Appropriate repair methods and carrying out repair

and paint jobs correctly is particularly important to

the operating safety of vehicles and the safety of

people.

WARNING: There is danger of injury

through:

• High voltage when electrical welding. – Do not perform welding work in a dampenvironment or on a wet substrate. Use

suitable insulation underneath.

• Welding spatter and UV radiation. – Wear protective clothing, gloves and weldingmask or welding goggles.

• Fire, explosion and hot surfaces in the work area.

– Always have a suitable fire extinguisheravailable when using welding or heating

equipment.

– Remove flammable substances from the danger area. Remove the fuel tank and fuel

pipes and hoses.

– Welding and grinding near the battery presents the danger of explosion. Remove

the battery before you start working.

– During paint work there is an increased danger of fire or explosion. Prevent any

sparks being created. Fire, open light and

smoking are forbidden.

– Always ventilate the workplace well and use an extraction system.

– Wear protective footwear made from anti-static material.

– Only use tools made of wood, brass or copper to clean stands and extraction ducts.

Do not use tools made of steel.

– Only fill or decant paint materials in a specially marked area. • Inhalation and/or absorption through the skin of

harmful substances.

– Welding fumes grinding dusts and solventvapours can be extremely harmful to the

health.

– Sealants, underbody protection and paint residues must not be burnt down with an

unshielded flame, as this will produce harmful

substances.

– Always ventilate the workplace well and use an extraction system.

– Wear protective clothing.

• Pyrotechnic components. – Disconnect the battery negative clamp andcover the battery terminal.

– Remove any airbag components.

• Noise – Cutting, grinding and alignment work cancause a noise level over 85 dB (A).

– Always wear ear protection.

• High Forces. – The various body areas are subject to veryhigh forces during realignment work. Should

any component suddenly become detached

during this process, there is a very great

danger of injury.

– Pulling chains and pulling shackles must be secured with arrester cables.

As well as these general instructions on the

dangers in body and paint shops, you must

observe:

• All valid local national and international regulations governing Health and Safety at Work

• Safety instructions of material equipment and tool manufacturers

For additional information, refer to: (100-00 General

Information) Solvents, Sealants and Adhesives (Description

and Operation),

Air Conditioning (A/C) System Health and Safety Precautions (Description and Operation),

Supplemental Restraint System (SRS) Health and Safety Precautions (Description and

Operation).

G963390en2008.50 Kuga8/2011

100-00- 67

General Information

100-00- 67

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 73 of 2057

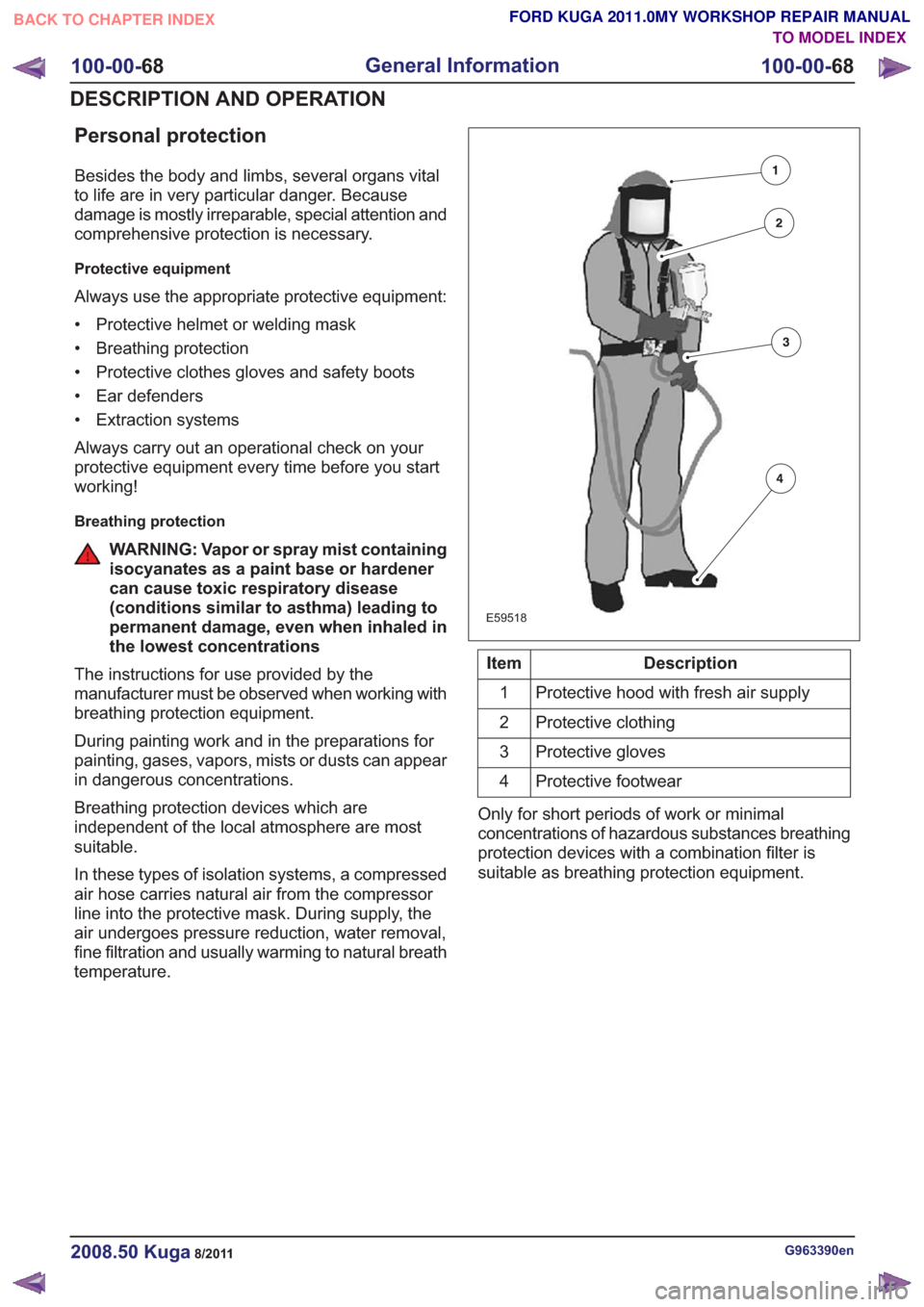

Personal protection

Besides the body and limbs, several organs vital

to life are in very particular danger. Because

damage is mostly irreparable, special attention and

comprehensive protection is necessary.

Protective equipment

Always use the appropriate protective equipment:

• Protective helmet or welding mask

• Breathing protection

• Protective clothes gloves and safety boots

• Ear defenders

• Extraction systems

Always carry out an operational check on your

protective equipment every time before you start

working!

Breathing protection

WARNING: Vapor or spray mist containing

isocyanates as a paint base or hardener

can cause toxic respiratory disease

(conditions similar to asthma) leading to

permanent damage, even when inhaled in

the lowest concentrations

The instructions for use provided by the

manufacturer must be observed when working with

breathing protection equipment.

During painting work and in the preparations for

painting, gases, vapors, mists or dusts can appear

in dangerous concentrations.

Breathing protection devices which are

independent of the local atmosphere are most

suitable.

In these types of isolation systems, a compressed

air hose carries natural air from the compressor

line into the protective mask. During supply, the

air undergoes pressure reduction, water removal,

fine filtration and usually warming to natural breath

temperature.

E59518

Description

Item

Protective hood with fresh air supply

1

Protective clothing

2

Protective gloves

3

Protective footwear

4

Only for short periods of work or minimal

concentrations of hazardous substances breathing

protection devices with a combination filter is

suitable as breathing protection equipment.

G963390en2008.50 Kuga8/2011

100-00- 68

General Information

100-00- 68

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 74 of 2057

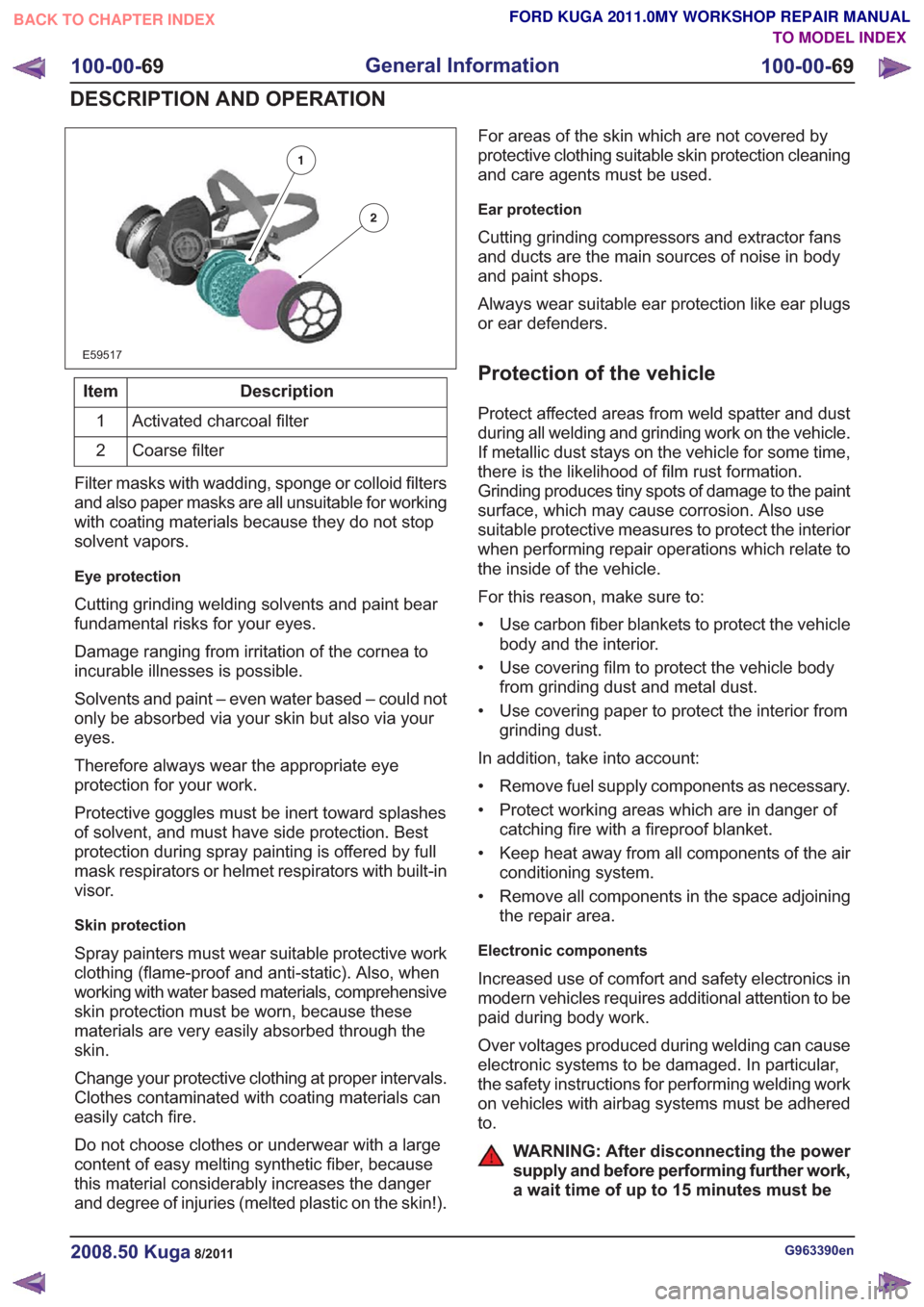

E59517

Description

Item

Activated charcoal filter

1

Coarse filter

2

Filter masks with wadding, sponge or colloid filters

and also paper masks are all unsuitable for working

with coating materials because they do not stop

solvent vapors.

Eye protection

Cutting grinding welding solvents and paint bear

fundamental risks for your eyes.

Damage ranging from irritation of the cornea to

incurable illnesses is possible.

Solvents and paint – even water based – could not

only be absorbed via your skin but also via your

eyes.

Therefore always wear the appropriate eye

protection for your work.

Protective goggles must be inert toward splashes

of solvent, and must have side protection. Best

protection during spray painting is offered by full

mask respirators or helmet respirators with built-in

visor.

Skin protection

Spray painters must wear suitable protective work

clothing (flame-proof and anti-static). Also, when

working with water based materials, comprehensive

skin protection must be worn, because these

materials are very easily absorbed through the

skin.

Change your protective clothing at proper intervals.

Clothes contaminated with coating materials can

easily catch fire.

Do not choose clothes or underwear with a large

content of easy melting synthetic fiber, because

this material considerably increases the danger

and degree of injuries (melted plastic on the skin!). For areas of the skin which are not covered by

protective clothing suitable skin protection cleaning

and care agents must be used.

Ear protection

Cutting grinding compressors and extractor fans

and ducts are the main sources of noise in body

and paint shops.

Always wear suitable ear protection like ear plugs

or ear defenders.

Protection of the vehicle

Protect affected areas from weld spatter and dust

during all welding and grinding work on the vehicle.

If metallic dust stays on the vehicle for some time,

there is the likelihood of film rust formation.

Grinding produces tiny spots of damage to the paint

surface, which may cause corrosion. Also use

suitable protective measures to protect the interior

when performing repair operations which relate to

the inside of the vehicle.

For this reason, make sure to:

• Use carbon fiber blankets to protect the vehicle

body and the interior.

• Use covering film to protect the vehicle body from grinding dust and metal dust.

• Use covering paper to protect the interior from grinding dust.

In addition, take into account:

• Remove fuel supply components as necessary.

• Protect working areas which are in danger of catching fire with a fireproof blanket.

• Keep heat away from all components of the air conditioning system.

• Remove all components in the space adjoining the repair area.

Electronic components

Increased use of comfort and safety electronics in

modern vehicles requires additional attention to be

paid during body work.

Over voltages produced during welding can cause

electronic systems to be damaged. In particular,

the safety instructions for performing welding work

on vehicles with airbag systems must be adhered

to.

WARNING: After disconnecting the power

supply and before performing further work,

a wait time of up to 15 minutes must be

G963390en2008.50 Kuga8/2011

100-00- 69

General Information

100-00- 69

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 81 of 2057

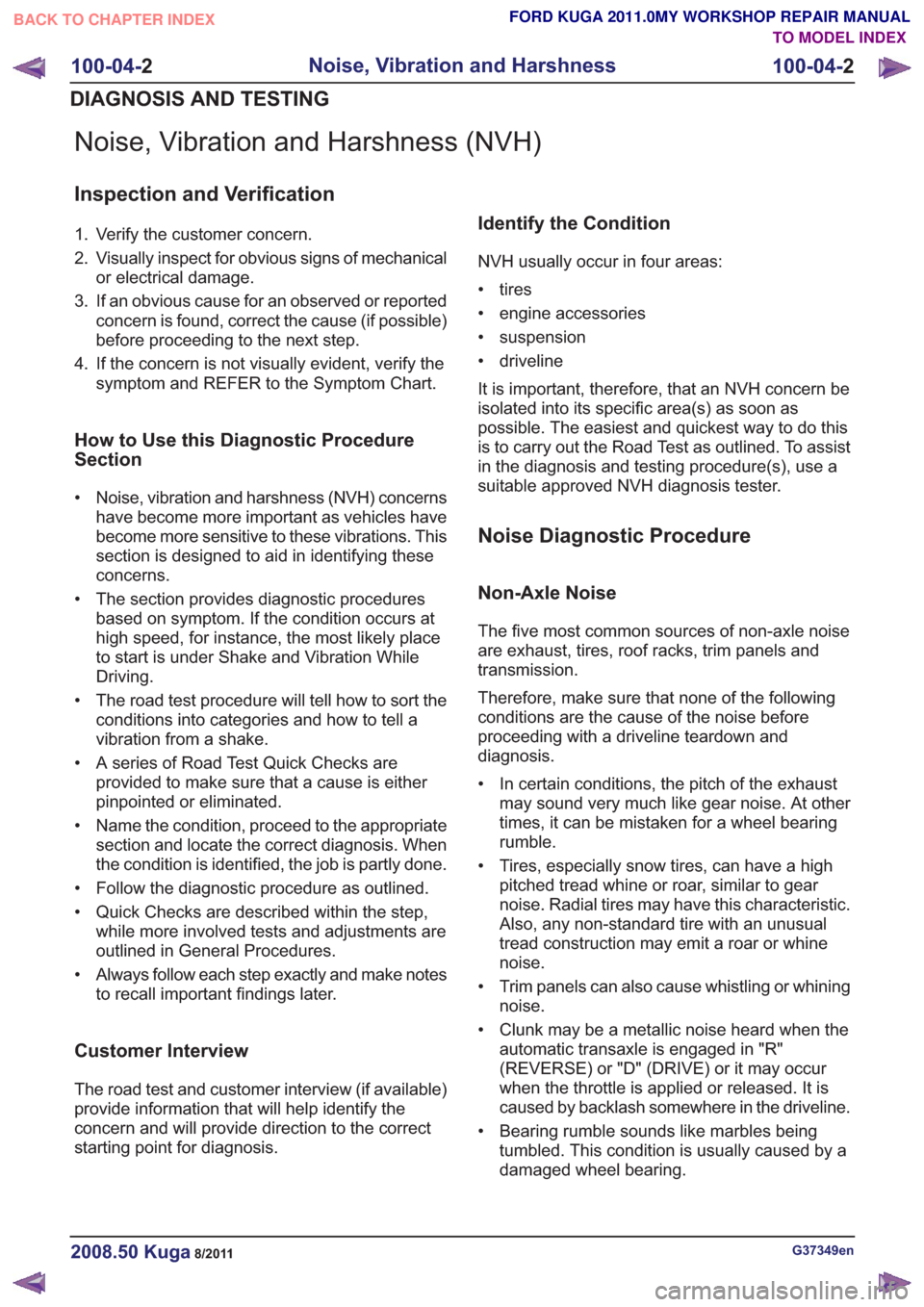

Noise, Vibration and Harshness (NVH)

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicalor electrical damage.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the concern is not visually evident, verify the symptom and REFER to the Symptom Chart.

How to Use this Diagnostic Procedure

Section

• Noise, vibration and harshness (NVH) concernshave become more important as vehicles have

become more sensitive to these vibrations. This

section is designed to aid in identifying these

concerns.

• The section provides diagnostic procedures based on symptom. If the condition occurs at

high speed, for instance, the most likely place

to start is under Shake and Vibration While

Driving.

• The road test procedure will tell how to sort the conditions into categories and how to tell a

vibration from a shake.

• A series of Road Test Quick Checks are provided to make sure that a cause is either

pinpointed or eliminated.

• Name the condition, proceed to the appropriate section and locate the correct diagnosis. When

the condition is identified, the job is partly done.

• Follow the diagnostic procedure as outlined.

• Quick Checks are described within the step, while more involved tests and adjustments are

outlined in General Procedures.

• Always follow each step exactly and make notes to recall important findings later.

Customer Interview

The road test and customer interview (if available)

provide information that will help identify the

concern and will provide direction to the correct

starting point for diagnosis.

Identify the Condition

NVH usually occur in four areas:

• tires

• engine accessories

• suspension

• driveline

It is important, therefore, that an NVH concern be

isolated into its specific area(s) as soon as

possible. The easiest and quickest way to do this

is to carry out the Road Test as outlined. To assist

in the diagnosis and testing procedure(s), use a

suitable approved NVH diagnosis tester.

Noise Diagnostic Procedure

Non-Axle Noise

The five most common sources of non-axle noise

are exhaust, tires, roof racks, trim panels and

transmission.

Therefore, make sure that none of the following

conditions are the cause of the noise before

proceeding with a driveline teardown and

diagnosis.

• In certain conditions, the pitch of the exhaustmay sound very much like gear noise. At other

times, it can be mistaken for a wheel bearing

rumble.

• Tires, especially snow tires, can have a high pitched tread whine or roar, similar to gear

noise. Radial tires may have this characteristic.

Also, any non-standard tire with an unusual

tread construction may emit a roar or whine

noise.

• Trim panels can also cause whistling or whining noise.

• Clunk may be a metallic noise heard when the automatic transaxle is engaged in "R"

(REVERSE) or "D" (DRIVE) or it may occur

when the throttle is applied or released. It is

caused by backlash somewhere in the driveline.

• Bearing rumble sounds like marbles being tumbled. This condition is usually caused by a

damaged wheel bearing.

G37349en2008.50 Kuga8/2011

100-04- 2

Noise, Vibration and Harshness

100-04- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 89 of 2057

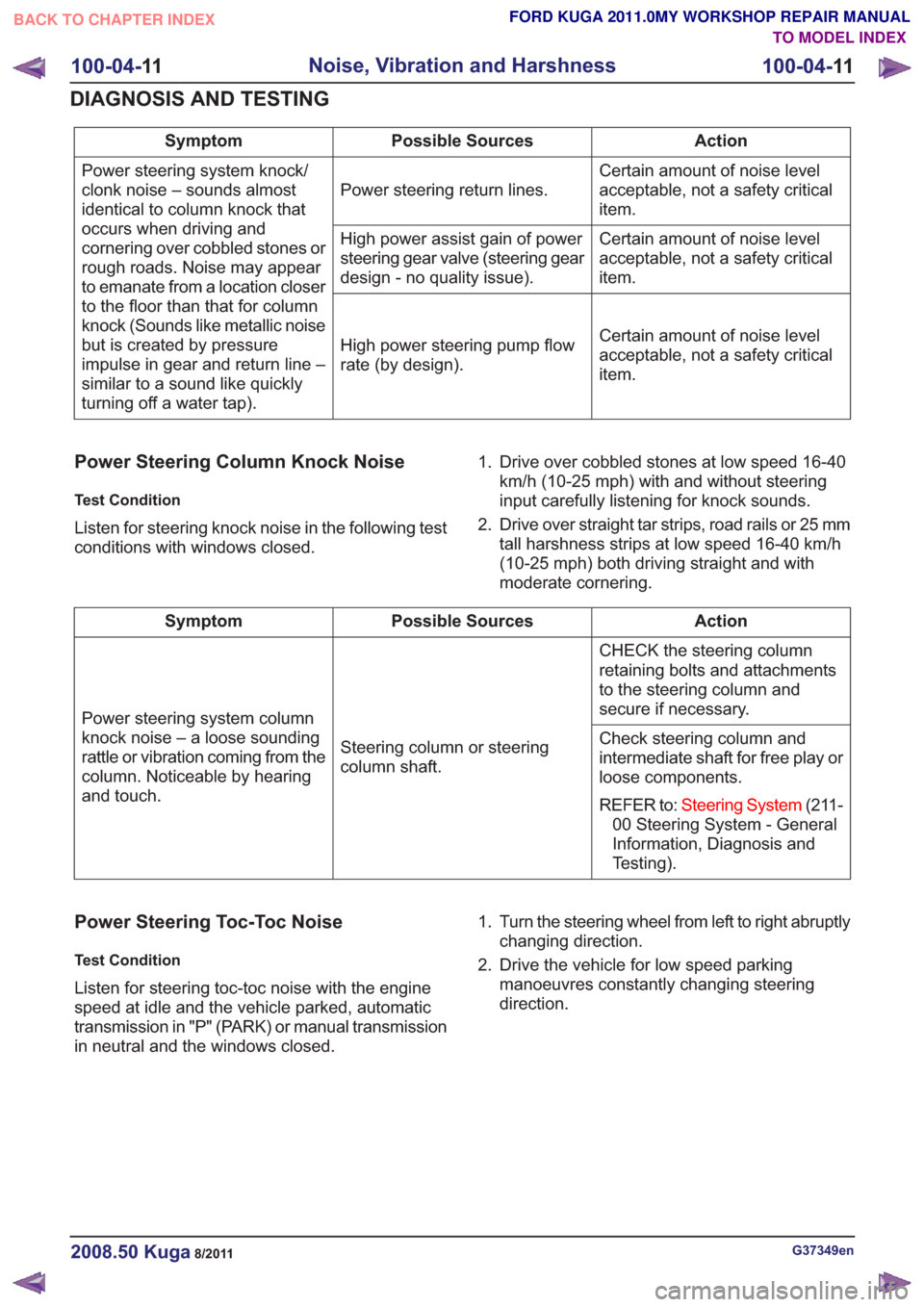

Action

Possible Sources

Symptom

Certain amount of noise level

acceptable, not a safety critical

item.

Power steering return lines.

Power steering system knock/

clonk noise – sounds almost

identical to column knock that

occurs when driving and

cornering over cobbled stones or

rough roads. Noise may appear

to emanate from a location closer

to the floor than that for column

knock (Sounds like metallic noise

but is created by pressure

impulse in gear and return line –

similar to a sound like quickly

turning off a water tap). Certain amount of noise level

acceptable, not a safety critical

item.

High power assist gain of power

steering gear valve (steering gear

design - no quality issue).

Certain amount of noise level

acceptable, not a safety critical

item.

High power steering pump flow

rate (by design).

Power Steering Column Knock Noise

Test Condition

Listen for steering knock noise in the following test

conditions with windows closed. 1. Drive over cobbled stones at low speed 16-40

km/h (10-25 mph) with and without steering

input carefully listening for knock sounds.

2. Drive over straight tar strips, road rails or 25 mm tall harshness strips at low speed 16-40 km/h

(10-25 mph) both driving straight and with

moderate cornering.

Action

Possible Sources

Symptom

CHECK the steering column

retaining bolts and attachments

to the steering column and

secure if necessary.

Steering column or steering

column shaft.

Power steering system column

knock noise – a loose sounding

rattle or vibration coming from the

column. Noticeable by hearing

and touch. Check steering column and

intermediate shaft for free play or

loose components.

REFER to:

Steering System (211-

00 Steering System - General

Information, Diagnosis and

Testing).

Power Steering Toc-Toc Noise

Test Condition

Listen for steering toc-toc noise with the engine

speed at idle and the vehicle parked, automatic

transmission in "P" (PARK) or manual transmission

in neutral and the windows closed. 1. Turn the steering wheel from left to right abruptly

changing direction.

2. Drive the vehicle for low speed parking manoeuvres constantly changing steering

direction.

G37349en2008.50 Kuga8/2011

100-04- 11

Noise, Vibration and Harshness

100-04- 11

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL