case FORD KUGA 2011 1.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1519 of 2057

Action

Possible Sources

Symptom

• CHECK if the PCV system isoperating correctly and repair

as necessary. Engine - 2.5L

Duratec-ST (VI5) -

REFER to: Engine Emission

Control (303-08 Engine

Emission Control - 2.5L

Duratec (147kW/200PS) -

VI5, Diagnosis and Testing).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Faulty positive crankcase vent-

ilation (PCV) system.

- Hoses or ventilation orbreather valves are blocked.

This causes excessive

pressure in the crankcase

which causes more oil to

enter the combustion

chamber.

- PCV oil separator is faulty and engine oil can enter the

combustion chamber

through the intake manifold.

• INSTALL a new turbocharger.Engine - 2.5L Duratec-ST (VI5)

-

REFER to: Turbocharger (303-

04 Fuel Charging and

Controls - Turbocharger -

2.5L Duratec (147kW/200PS)

- VI5, Removal and Installa-

tion).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Turbocharger seals.

• CHECK the gaskets and matingsurfaces for damage.

Remove the cylinder head.

CHECK the mating faces, cylinder

head gasket and the evenness of

the cylinder head and engine block

mating faces.

INSTALL new valve seals. Engine

- 2.5L Duratec-ST (VI5) -

REFER to: Valve Stem Seals

(303-01 Engine - 2.5L Duratec

(147kW/200PS) - VI5, Removal

and Installation).

Engine - 2.0L Duratorq-TDCi (DW)

Diesel -

• Damaged gaskets or mating

surfaces.

- Cylinder head gasket isdamaged or mating face are

warped.

- Valve stem seals are worn and engine oil can enter the

combustion chamber

between the valve stem and

the valve stem guide.

• INSTALL new components asnecessary.

• Piston ring or cylinder liner

wear.

• CHECK the running surfacesand clearances of the individual

engine components. INSTALL

new components as necessary.

INSTALL a new cylinder block

if necessary.

• Check the pistons and piston rings.

• Damaged cylinder liners or

excessive clearance of engine

components.

- Pistons.

- Piston rings (clearance ingroove and end gap).

- Cylinder liners.

G1055128en2008.50 Kuga8/2011

303-00- 3

Engine System - General Information

303-00- 3

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1547 of 2057

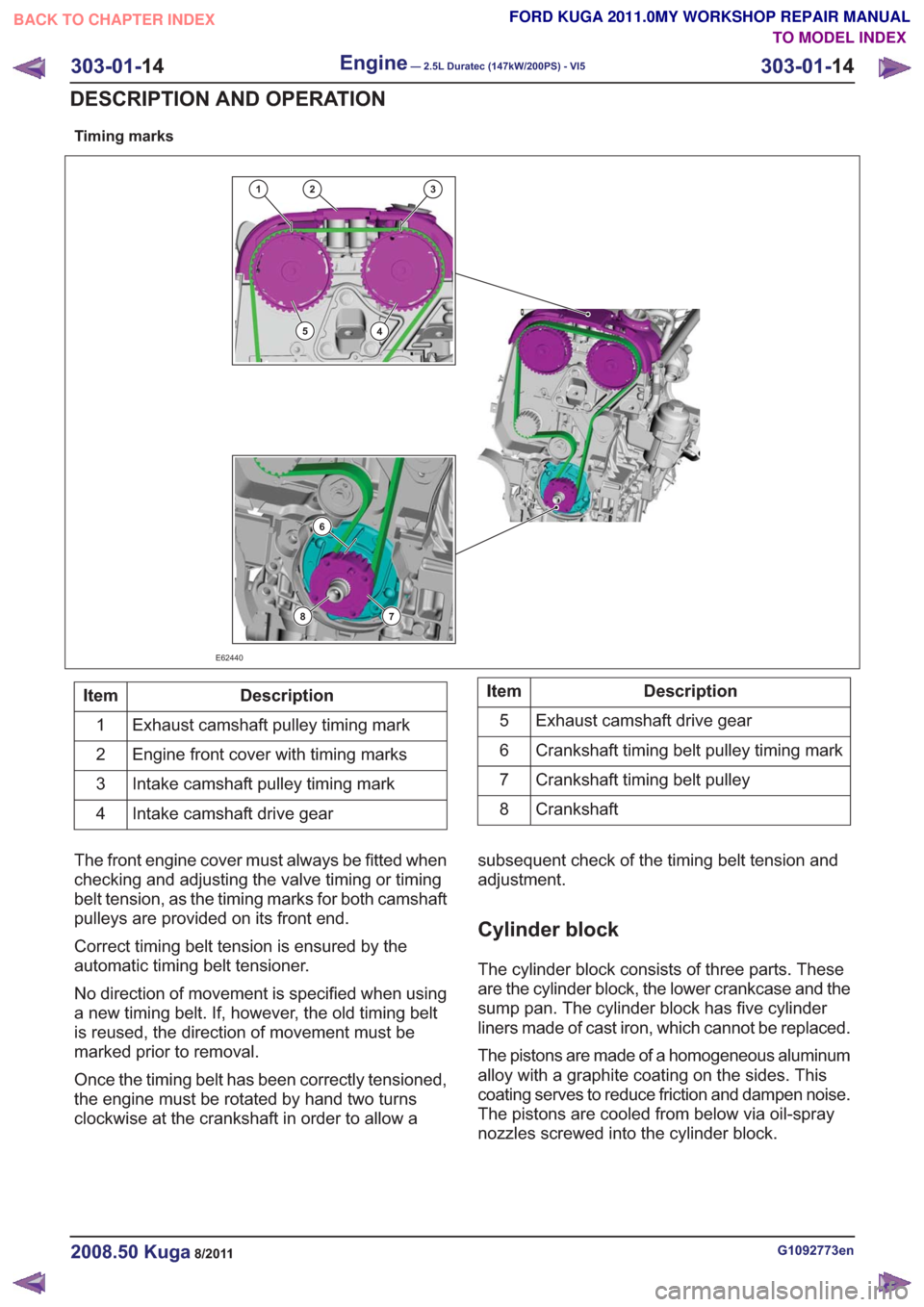

Timing marks

132

45

6

78

E62440

Description

Item

Exhaust camshaft pulley timing mark

1

Engine front cover with timing marks

2

Intake camshaft pulley timing mark

3

Intake camshaft drive gear

4Description

Item

Exhaust camshaft drive gear

5

Crankshaft timing belt pulley timing mark

6

Crankshaft timing belt pulley

7

Crankshaft

8

The front engine cover must always be fitted when

checking and adjusting the valve timing or timing

belt tension, as the timing marks for both camshaft

pulleys are provided on its front end.

Correct timing belt tension is ensured by the

automatic timing belt tensioner.

No direction of movement is specified when using

a new timing belt. If, however, the old timing belt

is reused, the direction of movement must be

marked prior to removal.

Once the timing belt has been correctly tensioned,

the engine must be rotated by hand two turns

clockwise at the crankshaft in order to allow a subsequent check of the timing belt tension and

adjustment.

Cylinder block

The cylinder block consists of three parts. These

are the cylinder block, the lower crankcase and the

sump pan. The cylinder block has five cylinder

liners made of cast iron, which cannot be replaced.

The pistons are made of a homogeneous aluminum

alloy with a graphite coating on the sides. This

coating serves to reduce friction and dampen noise.

The pistons are cooled from below via oil-spray

nozzles screwed into the cylinder block.

G1092773en2008.50 Kuga8/2011

303-01-

14

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

14

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1606 of 2057

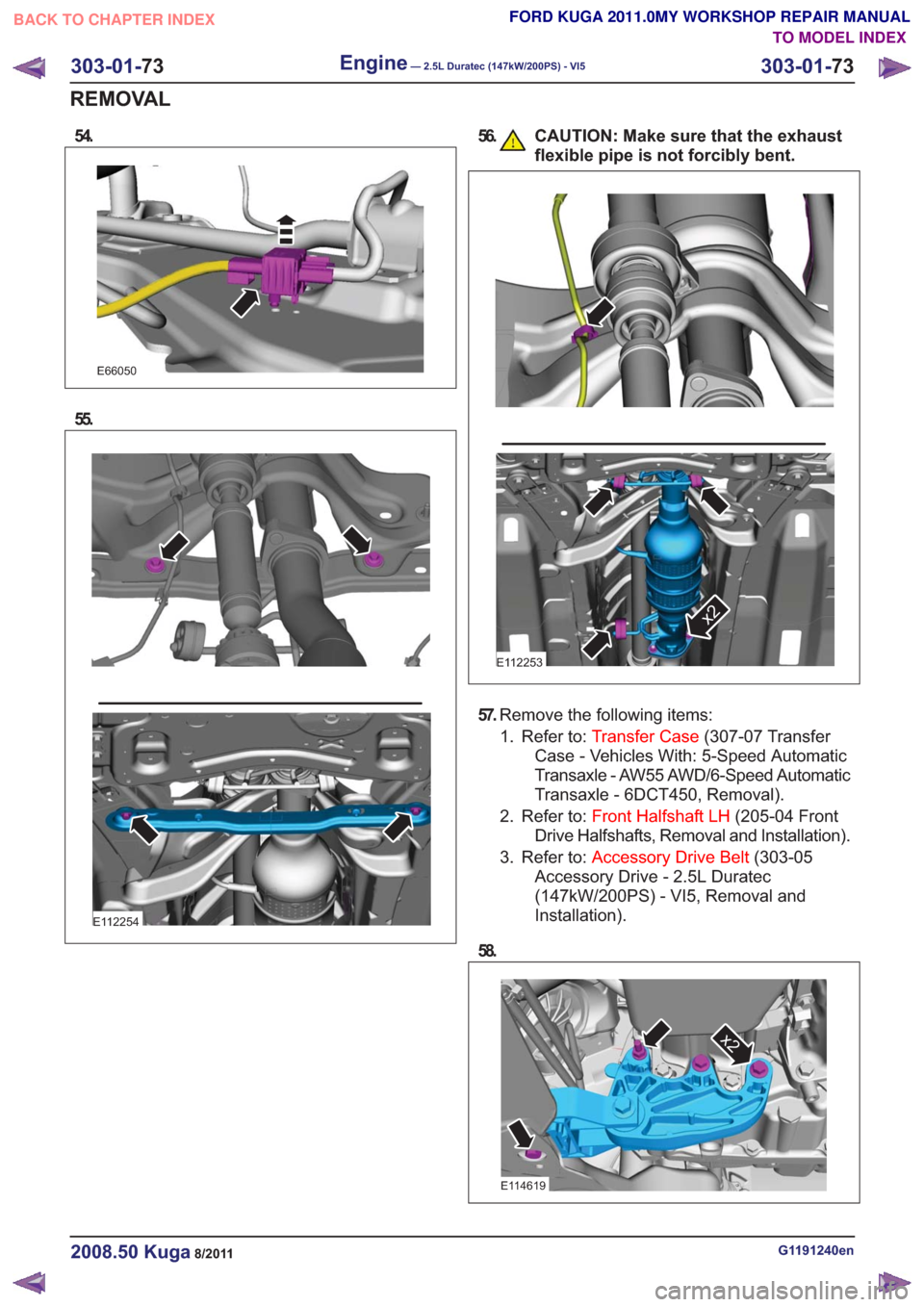

54.

E66050

55.

E112254

56. CAUTION: Make sure that the exhaustflexible pipe is not forcibly bent.

E112253

x2

57.Remove the following items:

1. Refer to: Transfer Case (307-07 Transfer

Case - Vehicles With: 5-Speed Automatic

Transaxle - AW55 AWD/6-Speed Automatic

Transaxle - 6DCT450, Removal).

2. Refer to: Front Halfshaft LH (205-04 Front

Drive Halfshafts, Removal and Installation).

3. Refer to: Accessory Drive Belt (303-05

Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

58.

x2x2

E114619

G1191240en2008.50 Kuga8/2011

303-01- 73

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

73

REMOVAL

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1657 of 2057

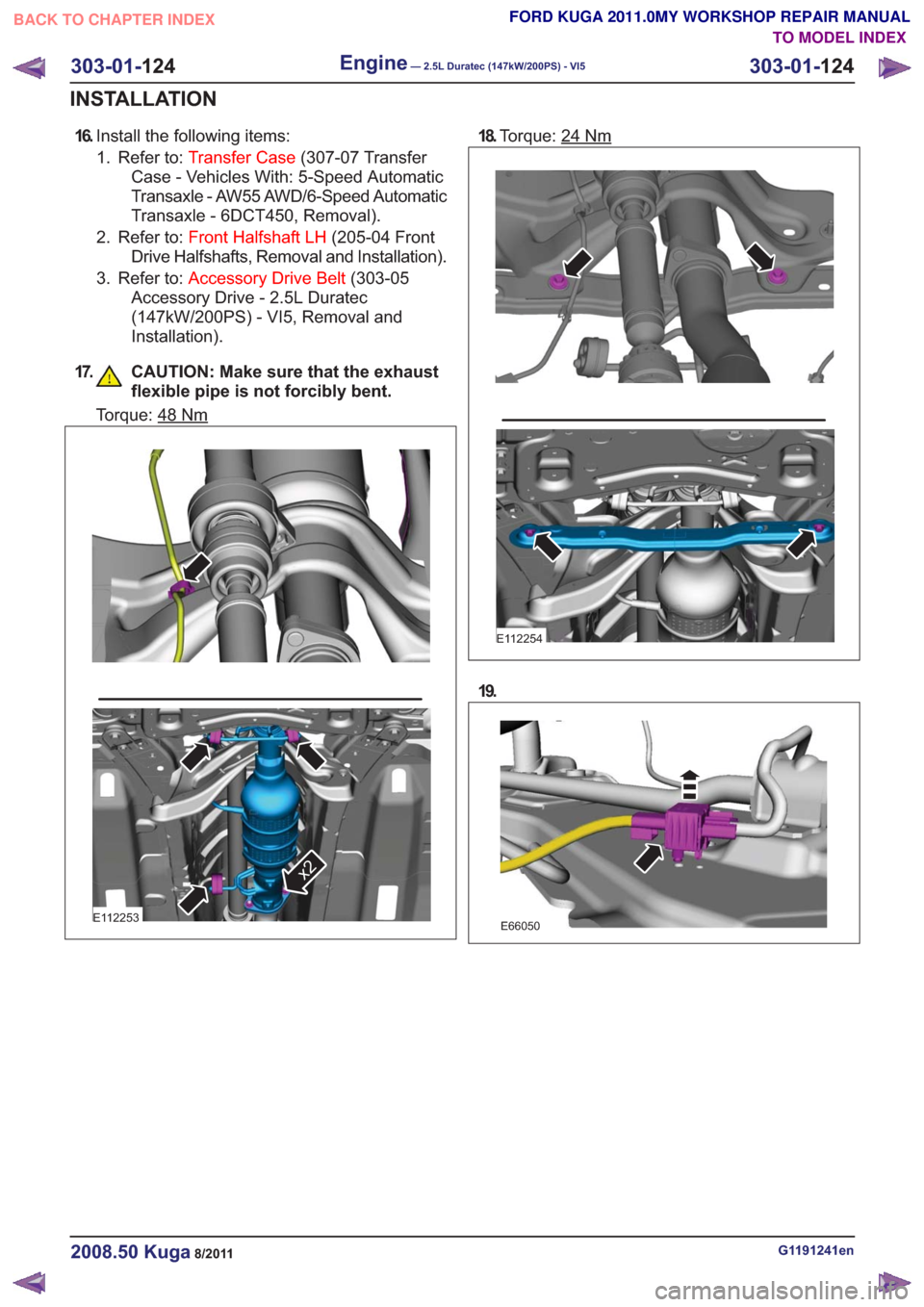

16.Install the following items:

1. Refer to: Transfer Case (307-07 Transfer

Case - Vehicles With: 5-Speed Automatic

Transaxle - AW55 AWD/6-Speed Automatic

Transaxle - 6DCT450, Removal).

2. Refer to: Front Halfshaft LH (205-04 Front

Drive Halfshafts, Removal and Installation).

3. Refer to: Accessory Drive Belt (303-05

Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

17. CAUTION: Make sure that the exhaust flexible pipe is not forcibly bent.

Torque: 48Nm

E112253

x2

18.Torque: 24Nm

E112254

19.

E66050

G1191241en2008.50 Kuga8/2011

303-01- 124

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

124

INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1705 of 2057

Action

Possible Sources

Symptom

• CHECK for signs of contamina-tion such as strange odors from

the fuel tank.

• If contaminated fuel is found, DRAIN the complete fuel

system. FLUSH the fuel system

through with clean gasoline.

REFER to: Fuel Tank Draining

(310-00 Fuel System -

General Information, General

Procedures).

INSTALL a new fuel filter.

• INSPECT the fuel injectors. CLEAN the fuel injectors or

INSTALL a new set of injectors

as required only after the

checks have been carried out.

REFER to: Fuel Injectors (303-

04 Fuel Charging and

Controls - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• INSTALL a new fuel rail.

REFER to: Fuel Rail(303-04

Fuel Charging and Controls -

2.5L Duratec (147kW/200PS)

- VI5, Removal and Installa-

tion).

• Incorrect or contaminated fuel.

• INSPECT for visible signs ofdamage or blockage. CLEAN,

REPAIR or INSTALL new parts

as necessary.

• Positive crankcase ventilation

(PCV) system.

• REMOVE the cylinder head.INSPECT the cylinder head,

pistons and cylinder bores for

signs of wear or damage.

REFER to: Cylinder Head (303-

01 Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Worn or damaged valve

guide(s), piston ring(s), cylinder

bore(s), cylinder head or

gasket.

G1183441en2008.50 Kuga8/2011

303-04A- 14

Fuel Charging and Controls

— 2.5L Duratec (147kW/200PS) -

VI5

303-04A- 14

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1719 of 2057

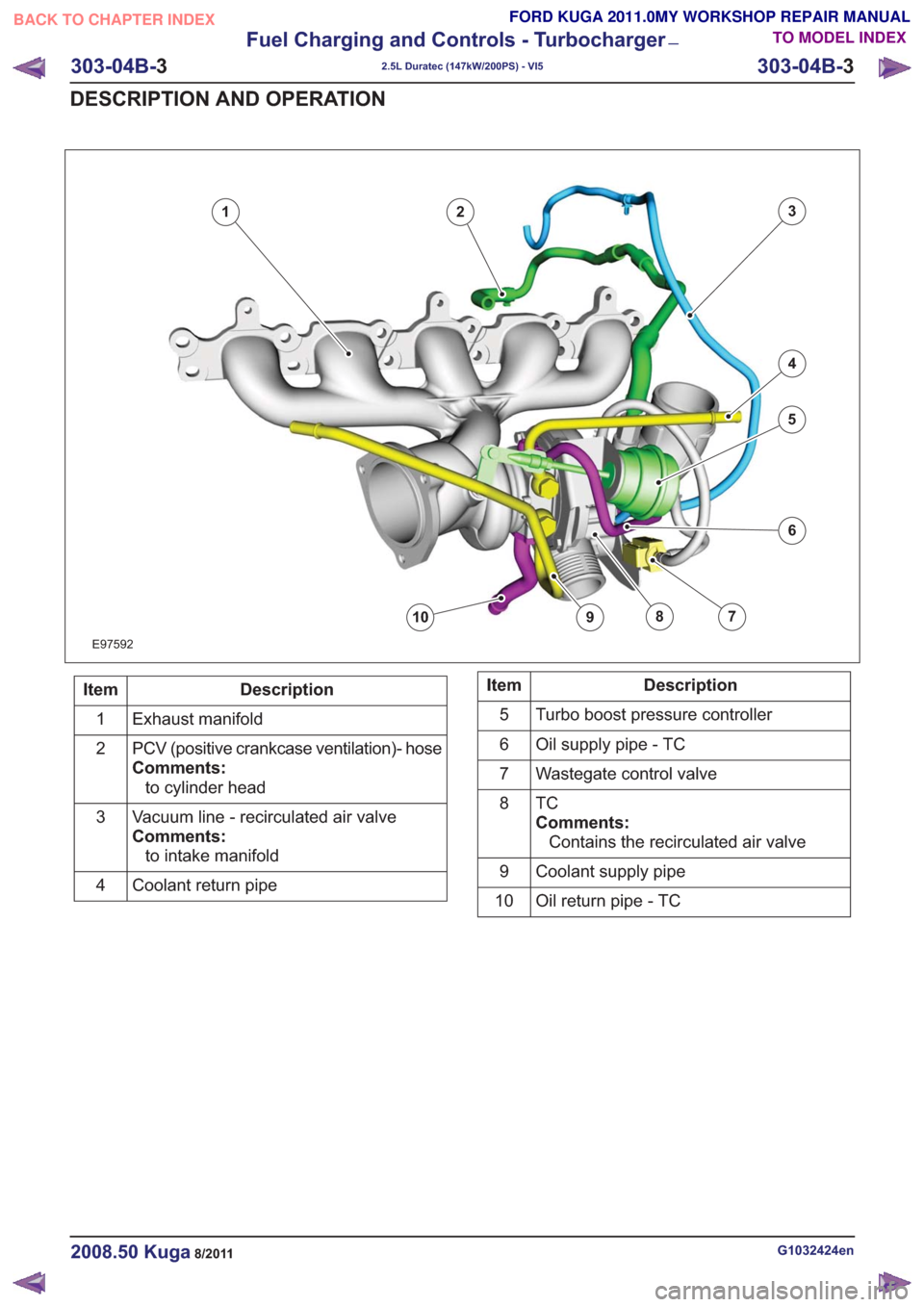

6

79108

123

4

5

6

79108

E97592

Description

Item

Exhaust manifold

1

PCV (positive crankcase ventilation)- hose

Comments:to cylinder head

2

Vacuum line - recirculated air valve

Comments:to intake manifold

3

Coolant return pipe

4Description

Item

Turbo boost pressure controller

5

Oil supply pipe - TC

6

Wastegate control valve

7

TC

Comments:Contains the recirculated air valve

8

Coolant supply pipe

9

Oil return pipe - TC

10

G1032424en2008.50 Kuga8/2011

303-04B- 3

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1725 of 2057

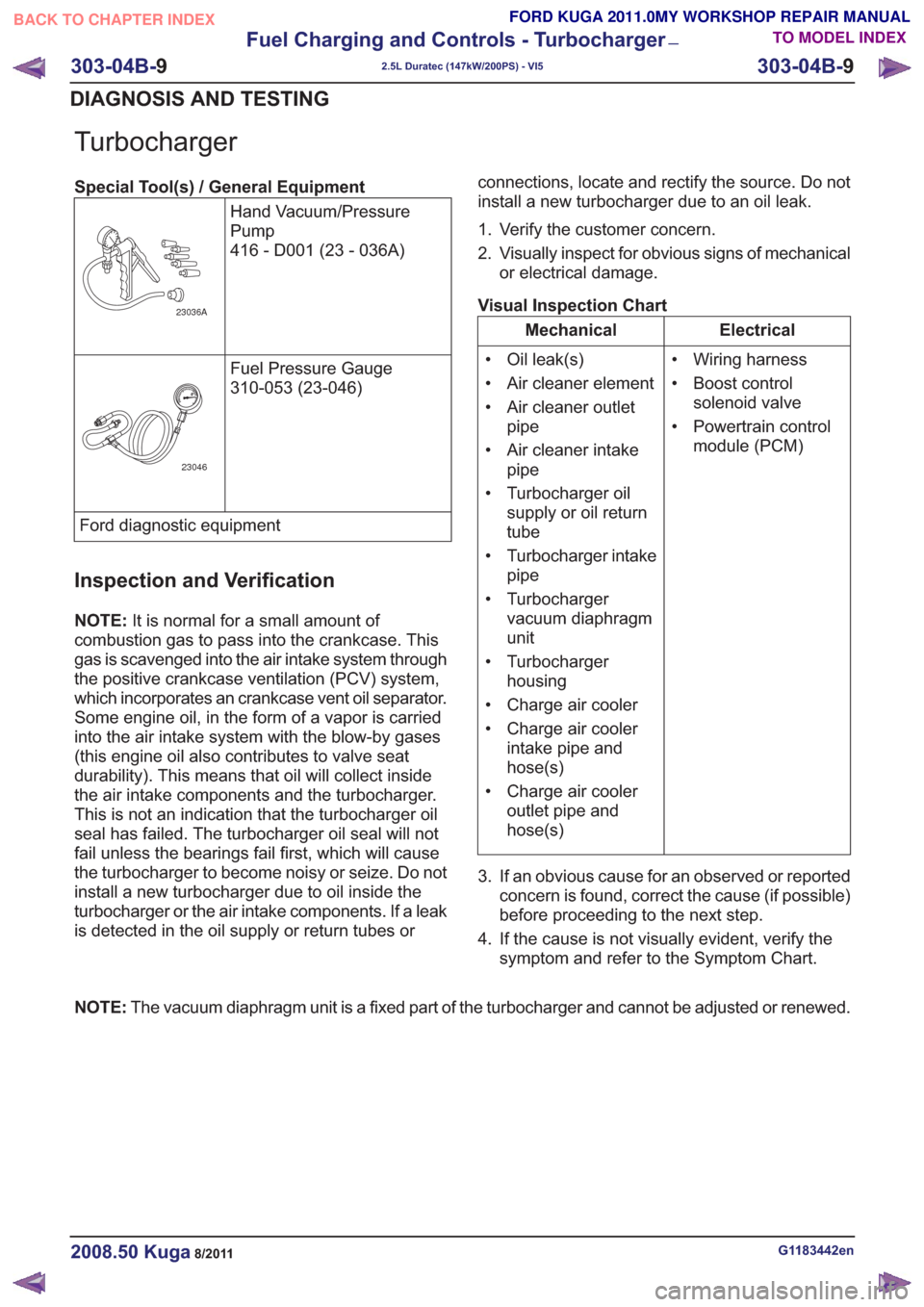

Turbocharger

Special Tool(s) / General EquipmentHand Vacuum/Pressure

Pump

416 - D001 (23 - 036A)

23036A

Fuel Pressure Gauge

310-053 (23-046)

23046

Ford diagnostic equipment

Inspection and Verification

NOTE:It is normal for a small amount of

combustion gas to pass into the crankcase. This

gas is scavenged into the air intake system through

the positive crankcase ventilation (PCV) system,

which incorporates an crankcase vent oil separator.

Some engine oil, in the form of a vapor is carried

into the air intake system with the blow-by gases

(this engine oil also contributes to valve seat

durability). This means that oil will collect inside

the air intake components and the turbocharger.

This is not an indication that the turbocharger oil

seal has failed. The turbocharger oil seal will not

fail unless the bearings fail first, which will cause

the turbocharger to become noisy or seize. Do not

install a new turbocharger due to oil inside the

turbocharger or the air intake components. If a leak

is detected in the oil supply or return tubes or connections, locate and rectify the source. Do not

install a new turbocharger due to an oil leak.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Wiring harness

• Boost controlsolenoid valve

• Powertrain control module (PCM)

• Oil leak(s)

• Air cleaner element

• Air cleaner outlet

pipe

• Air cleaner intake pipe

• Turbocharger oil supply or oil return

tube

• Turbocharger intake pipe

• Turbocharger vacuum diaphragm

unit

• Turbocharger housing

• Charge air cooler

• Charge air cooler intake pipe and

hose(s)

• Charge air cooler outlet pipe and

hose(s)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

NOTE: The vacuum diaphragm unit is a fixed part of the turbocharger and cannot be adjusted or renewed.

G1183442en2008.50 Kuga8/2011

303-04B- 9

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1752 of 2057

Description

Item

Start/stop button

1

Keyless vehicle module

2

Electronic steering lock with mount -

passive key and PATS transmitter/receiver

unit

Comments:for emergency start function

3

Radio frequency receiver

Comments:Signal is only executed in GEM

4Description

Item

GEM

5

Stoplight Switch

6

TCM7

Starting deactivation relay

8

PCM

9

Starter relay

10

Starter motor

11

Battery

12

System Operation

Smart Start

The PCM enables the starting process when a key

providing a valid code is read via the PATS. This

code is then verified in the GEM and compared

with the saved code. If this code is recognized as

correct, synchronization with other modules is

carried out. After successful synchronization, the

engine is cleared to start in the PCM. The PCM

connects earth to the starter relay, which then

connects power to the starter solenoid. As soon

as the engine reaches a certain speed, the PCM

disconnects the starter relay and so turns off the

starter. This protects the starter.

If the engine does not turn or turns only slowly, the

starting process is aborted by the PCM.

The starter is notactivated if:

• the engine is running (i.e. the engine speed is above a particular value),

• the PATS does not permit the engine to be started,

• the clutch pedal is not operated (vehicles with manual transmission),

• the gear selector level is not set to P or N (vehicles with automatic transmission),

• the brake pedal is not operated (vehicles with automatic transmission).

Emergency starting function

If the keyless vehicle system is unable to recognize

the passive key, the vehicle can be started via the

emergency starting function. In this case, there is a passive key mount on the

steering wheel. A PATS transmission/reception

unit is attached to this.

To start the engine, the passive key must be

inserted into the passive key mount. The Start/Stop

button can then be used to turn on the ignition and

start the engine as normal. To deactivate the

PATS, a transponder is fitted in the passive key,

which is read by the transmission/reception unit.

G1032961en2008.50 Kuga8/2011

303-06-

8

Starting System— 2.5L Duratec (147kW/200PS) - VI5303-06-

8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1762 of 2057

Description

Item

Intake manifold to turbocharger breather

hose

1

Crankcase vent oil separator to valve

cover hose

2

Crankcase vent oil separator to intake

manifold hose

3

Crankcase vent oil separator

4

G510285en2008.50 Kuga8/2011

303-08- 3

Engine Emission Control— 2.5L Duratec (147kW/200PS) - VI5303-08-

3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1763 of 2057

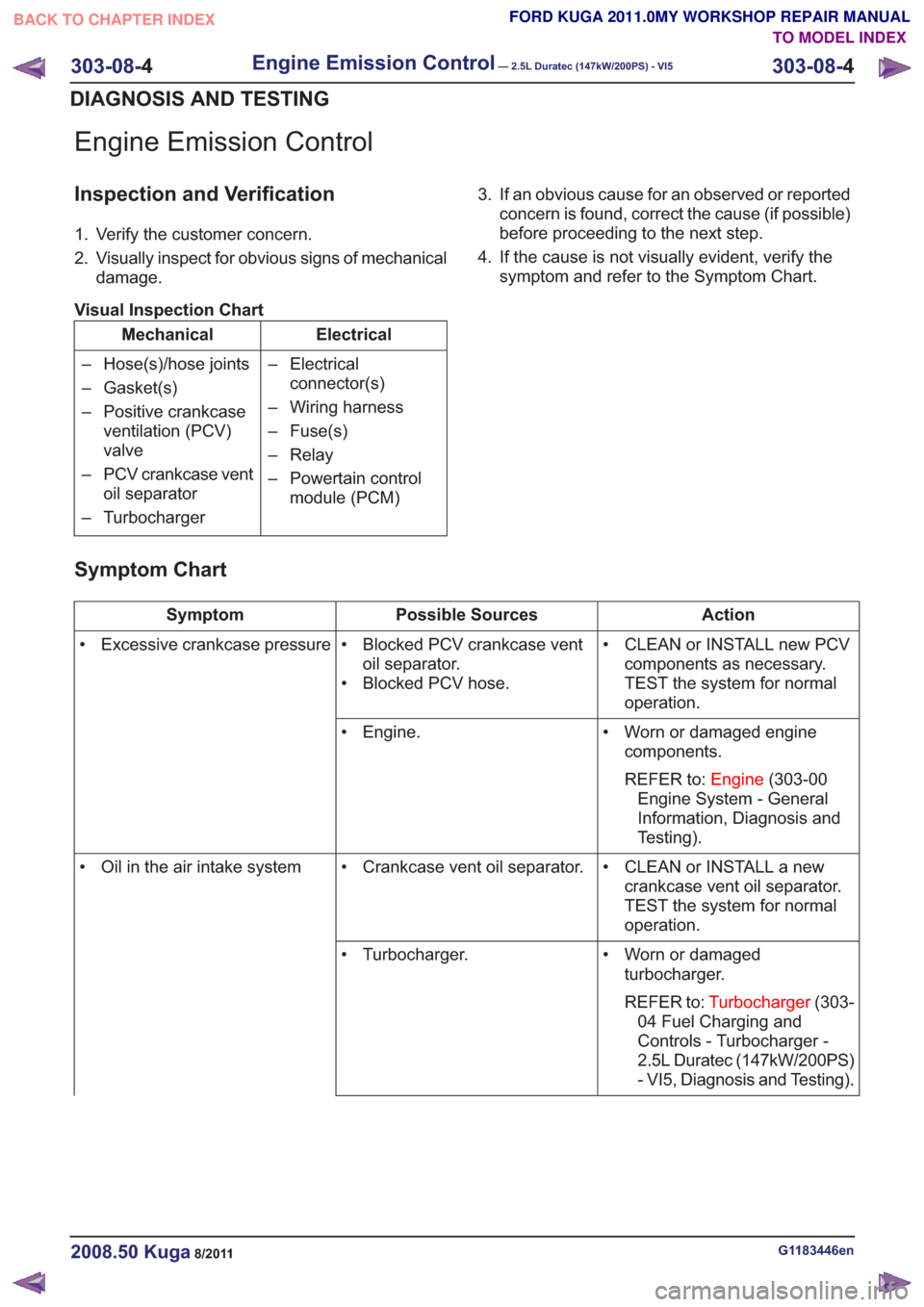

Engine Emission Control

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicaldamage.

Visual Inspection Chart

Electrical

Mechanical

– Electricalconnector(s)

– Wiring harness

– Fuse(s)

– Relay

– Powertain control module (PCM)

– Hose(s)/hose joints

– Gasket(s)

– Positive crankcase

ventilation (PCV)

valve

– PCV crankcase vent oil separator

– Turbocharger 3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

Symptom Chart

Action

Possible Sources

Symptom

• CLEAN or INSTALL new PCVcomponents as necessary.

TEST the system for normal

operation.

• Blocked PCV crankcase vent

oil separator.

• Blocked PCV hose.

• Excessive crankcase pressure

• Worn or damaged enginecomponents.

REFER to: Engine(303-00

Engine System - General

Information, Diagnosis and

Testing).

• Engine.

• CLEAN or INSTALL a newcrankcase vent oil separator.

TEST the system for normal

operation.

• Crankcase vent oil separator.

• Oil in the air intake system

• Worn or damagedturbocharger.

REFER to: Turbocharger (303-

04 Fuel Charging and

Controls - Turbocharger -

2.5L Duratec (147kW/200PS)

- VI5, Diagnosis and Testing).

• Turbocharger.

G1183446en2008.50 Kuga8/2011

303-08-

4

Engine Emission Control— 2.5L Duratec (147kW/200PS) - VI5303-08-

4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL