case FORD KUGA 2011 1.G Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1764 of 2057

Action

Possible Sources

Symptom

• Worn or damaged enginecomponents.

REFER to: Engine(303-00

Engine System - General

Information, Diagnosis and

Testing).

• Excessive crankcase pressure.

G1183446en2008.50 Kuga8/2011

303-08-

5

Engine Emission Control— 2.5L Duratec (147kW/200PS) - VI5303-08-

5

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1768 of 2057

Intake Air Distribution and Filtering

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicalor electrical damage.

Visual Inspection Chart

Electrical

Mechanical

– Mass air flow (MAF)sensor

– Manifold absolute pressure (MAP)

sensor

– Electrical connector(s)

– Air cleaner element

– Air cleaner intake

pipe

– Air cleaner outlet pipe

– Charge air cooler

– Charge air cooler intake pipe

– Charge air cooler outlet pipe 3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

Symptom Chart

Action

Possible Sources

Symptom

• CHECK the pipe(s) for securityand leaks to atmosphere.

INSTALL new intake air

components as necessary.

TEST the system for normal

operation.

• Detached air cleaner pipe(s).

• Detached turbocharger pipe(s).

• Detached charge air cooler

pipe(s).

• Excessive intake air noise

• REFER to:Engine Emission

Control (303-08 Engine

Emission Control - 2.5L

Duratec (147kW/200PS) -

VI5, Diagnosis and Testing).

• Blocked or damaged PCV

pipe(s)/hose(s).

• Blocked or damaged crankcase vent oil separator.

• Oil in the air intake system

• REFER to:Turbocharger(303-

04 Fuel Charging and

Controls - Turbocharger -

2.5L Duratec (147kW/200PS)

- VI5, Diagnosis and Testing).

• Turbocharger.

• CHECK the air intake pipesplash shield for correct install-

ation and alignment.

REPAIR/INSTALL the air intake

pipe splash shield as neces-

sary. TEST the system for

normal operation.

• Air intake pipe splash shield.

• Water in the air cleaner

G1183447en2008.50 Kuga8/2011

303-12- 4

Intake Air Distribution and Filtering

— 2.5L Duratec

(147kW/200PS) - VI5

303-12- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1782 of 2057

Powertrain Control Module (PCM)

E65160

The PCM communicates with all engine sensors

and the other modules. Communication of the PCM

with the other modules and the system diagnostics

takes place via the CAN (controller area network)

data bus.

The following functions are regulated or controlled

by the PCM:

• Fuel supply to the engine including lambdacontrol

• Ignition setting including knock control

• Idle speed control

• Control of optimum valve timing via the camshaft adjustment for intake and exhaust camshafts

• The refrigerant compressor is controlled by the air conditioning clutch relay and the delivery of

the refrigerant compressor is controlled by a

PWM (pulse width modulation) signal.

• Control of EVAP purge valve

• Boost pressure control

• Control of the cooling fan

• Charging system (Smart Charge)

• Starting system (Smart Start)

If the PCM is isolated from the vehicle electrical

system or the battery is disconnected, the throttle

control unit mustbe initialized.

The PCM is fitted in the engine compartment in the

air filter housing. On right hand drive vehicles a

protective metal plate is also installed to prevent

the plug connector from being pulled off, or make

it harder to pull off, in case of theft. The protective

plate is secured with a shear bolt. The shear bolt

needs to be drilled out in order to remove the

protective plate.

Knock Sensor

E96986

Two KSs are fitted. They are on the cylinder block,

one close to the 2nd cylinder and one close to the

4th cylinder.

When fitting, adhere strictly to the specified

tightening torque, otherwise the KS will not work

properly.

If the signal from one or both KS is implausible or

absent, knock control is deactivated. The PCM

switches to an ignition map that is further away

from the knock limit. As a result, engine damage

caused by combustion knock is avoided. If a fault

occurs, a fault code is stored in the error memory

of the PCM.

Camshaft Position (CMP) Sensor

E89993

If one or both CMP sensors fail, a fault is saved in

the error memory of the PCM and the camshaft

adjustment and knock control are deactivated.

G1021907en2008.50 Kuga8/2011

303-14- 8

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1784 of 2057

If one of the two APP sensors fails, then only a

proportion of the engine's power will be available

when accelerating. Top speed can nevertheless

be achieved.

If both of the APP sensors fail, the engine is

regulated to a defined speed following a plausibility

check after the BPP (brake pedal position) switch

and brake light switch have been actuated once.

The vehicle can then only be accelerated to a

defined speed.

In either case, a fault is saved in the error memory

of the PCM.

Throttle control unit

E74167

1

2

Description

Item

TP (throttle position) sensor

1

Electric motor

2

CAUTION: The throttle control unit must

not be repaired or adjusted. The stop of

the throttle valve must on no account be

adjusted.

After disconnecting the battery or replacing the

throttle control unit or the PCM, initialization is

necessary. • engine off

• Accelerator pedal not pressed

• Battery voltage 11 ... 14 V

• Ignition key in ON position

• Wait approximately 30 seconds until initialization

is complete.

Engine Coolant Temperature (ECT)

sensor

E94804

The ECT (engine coolant temperature) sensor is

designed as an NTC (negative temperature

coefficient) resistor.

If the signal from the ECT sensor fails, the cooling

fan is on all the time and the A/C (air conditioning)

is turned off. When the ignition is switched on, the

value from the IAT (intake air temperature) sensor

is read. When the engine is running, the

temperature is calculated using a temperature map

stored in the PCM according to how long the

engine has been running. This substitute value is

then used as the basis for calculating the injected

fuel quantity and the ignition timing.

Ignition coil-on-plug

E73540

G1021907en2008.50 Kuga8/2011

303-14- 10

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1791 of 2057

• Starting process

• Engine running– Fuel supply to the engine including lambdacontrol

– Ignition setting including knock control

– Idle speed control

– Boost pressure control

– Valve timing via the camshaft adjuster for the intake and exhaust camshafts (including

internal exhaust gas recirculation)

• Refrigerant compressor (activation, deactivation and delivery)

• EVAP purge valve

• Charging system

Fuel is supplied to the engine via a sequential

multi-point injection system. Ignition is performed

by a distributor-less ignition system with one

ignition coil unit for each cylinder.

The PCM optimizes engine power and emissions

at all times by processing the sensor signals and

information received via the CAN databus and

using these for open or closed loop control of the

different variables.

The PCM contains part of the PATS (passive

anti-theft system).

The PCM is supplied with battery voltage via a fuse

in the BJB (battery junction box). This power supply

is needed to ensure that saved data is not lost

when the engine is switched off.

For other power supply requirements, the PCM

switches on a relay in the BJB which is responsible

for supplying power to the PCM and to some

sensors and actuators. Each of these are protected

by fuses in the BJB.

To guarantee optimum engine running at all times,

the PCM has several adaptive (self-learning)

functions. These adapt the output signals to

changing circumstances, such as wear or system

faults.

In some cases a faulty signal is replaced with a

substitute value or limited. A substitute value can

be calculated from other signals or it can be

predefined by the PCM. The substitute value allows

the vehicle to keep on running without the emission

values changing unduly. Depending on the signal

failure, the PCM operates in emergency mode. In

this mode, the engine power and/or the engine

speed is reduced to prevent further damage.

Depending on the faulty signal, a fault code is

stored in the error memory of the PCM. These can be read out using IDS (Integrated Diagnostic

System) via the DLC.

The PCM processes and evaluates the signals

from the sensors. The following sensors send

signals to the PCM:

• CMP sensors

• CKP sensor

• MAF sensor

•KS

• ECT sensor

• TP sensor

• APP sensor

• Broadband HO2S

• Catalyst monitor sensor

• MAPT sensor

• Air conditioning (A/C) pressure sensor

• Alternator

• Fuel temperature and fuel pressure sensor

• Engine oil level, temperature and quality sensor

• Outside air temperature sensor

The following components receive signals from the

PCM:

• Powertrain Control Module relay

• A/C clutch relay

• injectors

• Direct ignition coils

• Cooling fan module

• Throttle control unit

• Camshaft adjuster solenoid valve

• Starter Relay

• EVAP purge valve

• Alternator

• Heating element - broadband HO2S

• Catalyst monitor sensor heating element

• FPDM

• Wastegate control valve

• Air conditioning compressor

The PCM receives the following signals via the

CAN databus:

• APP

•CPP

• BPP

• Vehicle speed.

• Refrigerant compressor request

• PAT S

G1021908en2008.50 Kuga8/2011

303-14-

17

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

17

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1837 of 2057

• Press the gaiter frame to move the emergencyrelease downwards and move the selector lever

out of position P (4).

• Pull the gaiter upwards until the gaiter frame engages in the gaiter frame.

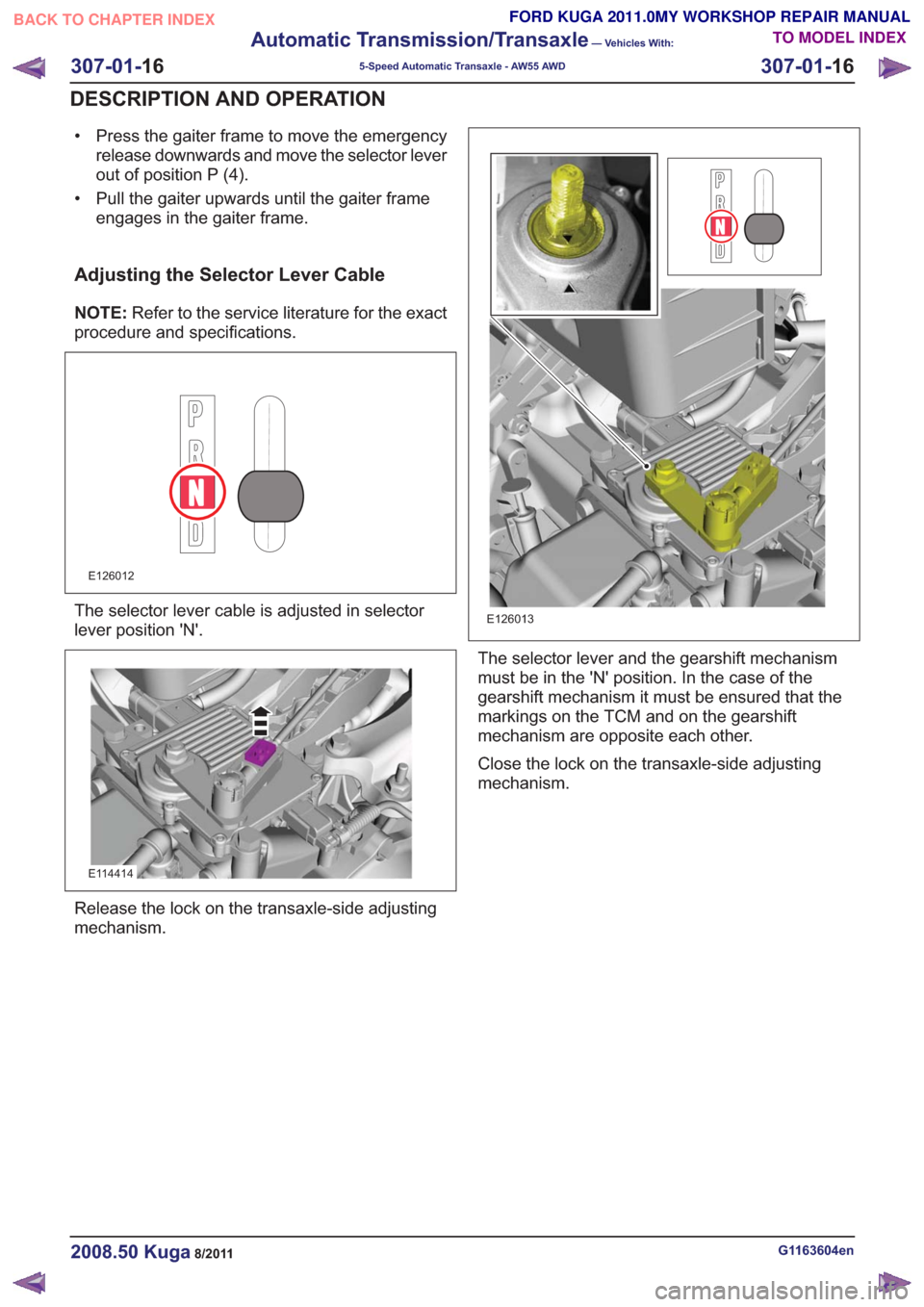

Adjusting the Selector Lever Cable

NOTE: Refer to the service literature for the exact

procedure and specifications.

E126012

The selector lever cable is adjusted in selector

lever position 'N'.

E114414

Release the lock on the transaxle-side adjusting

mechanism.

E126013

The selector lever and the gearshift mechanism

must be in the 'N' position. In the case of the

gearshift mechanism it must be ensured that the

markings on the TCM and on the gearshift

mechanism are opposite each other.

Close the lock on the transaxle-side adjusting

mechanism.

G1163604en2008.50 Kuga8/2011

307-01- 16

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 16

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1838 of 2057

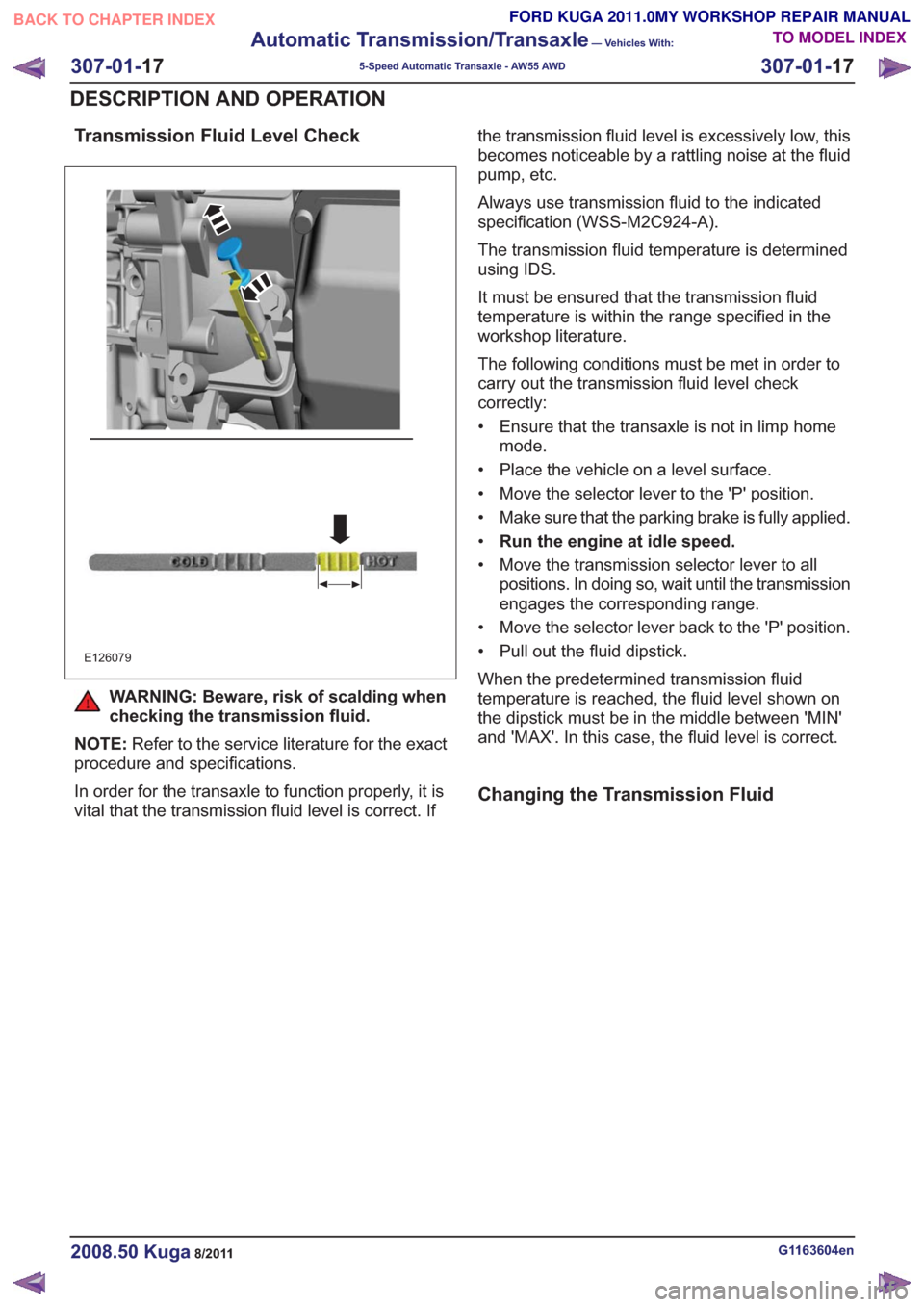

Transmission Fluid Level Check

E126079

WARNING: Beware, risk of scalding when

checking the transmission fluid.

NOTE: Refer to the service literature for the exact

procedure and specifications.

In order for the transaxle to function properly, it is

vital that the transmission fluid level is correct. If the transmission fluid level is excessively low, this

becomes noticeable by a rattling noise at the fluid

pump, etc.

Always use transmission fluid to the indicated

specification (WSS-M2C924-A).

The transmission fluid temperature is determined

using IDS.

It must be ensured that the transmission fluid

temperature is within the range specified in the

workshop literature.

The following conditions must be met in order to

carry out the transmission fluid level check

correctly:

• Ensure that the transaxle is not in limp home

mode.

• Place the vehicle on a level surface.

• Move the selector lever to the 'P' position.

• Make sure that the parking brake is fully applied.

• Run the engine at idle speed.

• Move the transmission selector lever to all positions. In doing so, wait until the transmission

engages the corresponding range.

• Move the selector lever back to the 'P' position.

• Pull out the fluid dipstick.

When the predetermined transmission fluid

temperature is reached, the fluid level shown on

the dipstick must be in the middle between 'MIN'

and 'MAX'. In this case, the fluid level is correct.

Changing the Transmission Fluid

G1163604en2008.50 Kuga8/2011

307-01- 17

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 17

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1863 of 2057

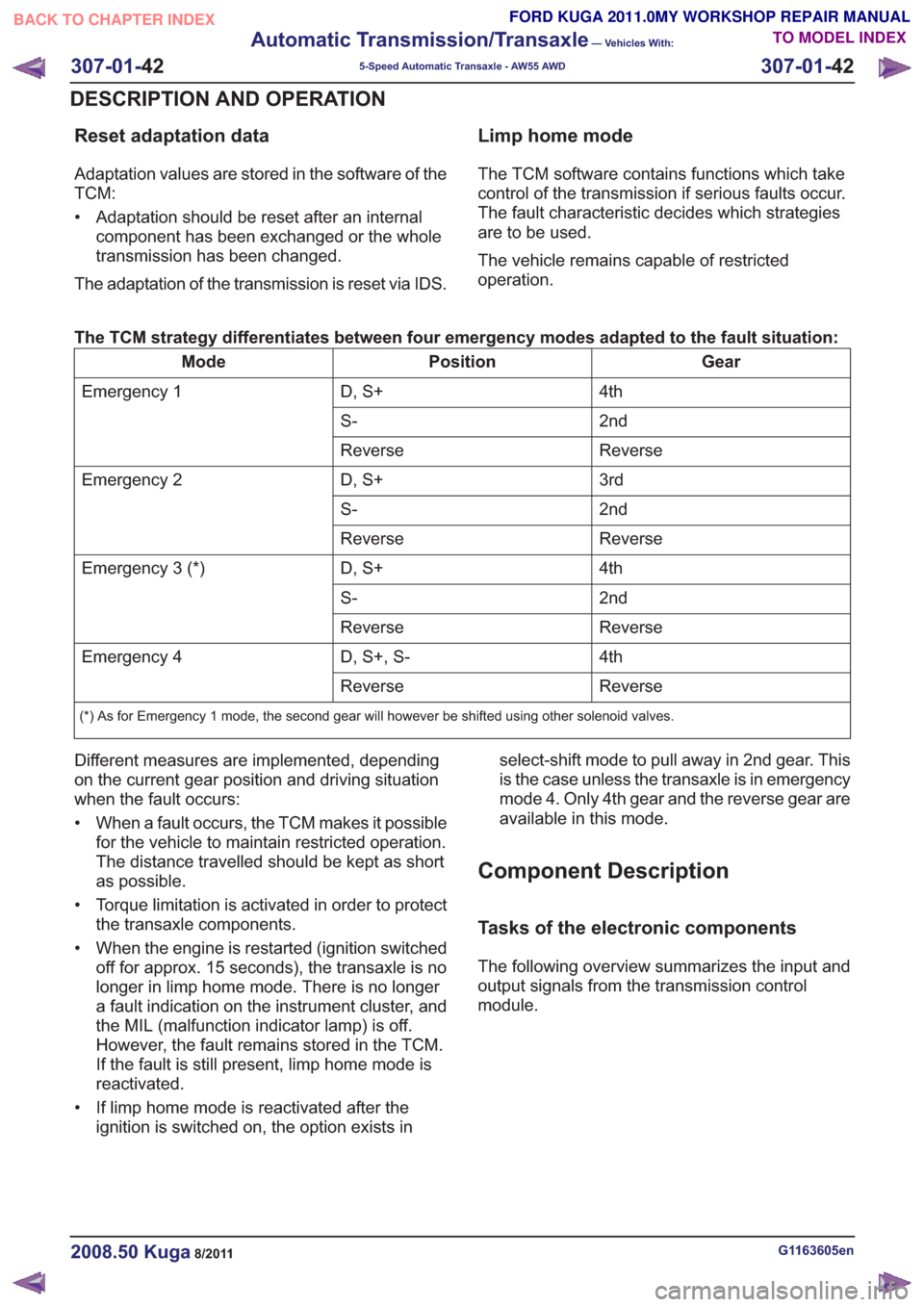

Reset adaptation data

Adaptation values are stored in the software of the

TCM:

• Adaptation should be reset after an internalcomponent has been exchanged or the whole

transmission has been changed.

The adaptation of the transmission is reset via IDS.

Limp home mode

The TCM software contains functions which take

control of the transmission if serious faults occur.

The fault characteristic decides which strategies

are to be used.

The vehicle remains capable of restricted

operation.

The TCM strategy differentiates between four emergency modes adapted to the fault situation:

Gear

Position

Mode

4th

D, S+

Emergency 1

2nd

S-

Reverse

Reverse

3rd

D, S+

Emergency 2

2nd

S-

Reverse

Reverse

4th

D, S+

Emergency 3 (*)

2nd

S-

Reverse

Reverse

4th

D, S+, S-

Emergency 4

Reverse

Reverse

(*) As for Emergency 1 mode, the second gear will however be shifted using other solenoid valves.

Different measures are implemented, depending

on the current gear position and driving situation

when the fault occurs:

• When a fault occurs, the TCM makes it possible

for the vehicle to maintain restricted operation.

The distance travelled should be kept as short

as possible.

• Torque limitation is activated in order to protect the transaxle components.

• When the engine is restarted (ignition switched off for approx. 15 seconds), the transaxle is no

longer in limp home mode. There is no longer

a fault indication on the instrument cluster, and

the MIL (malfunction indicator lamp) is off.

However, the fault remains stored in the TCM.

If the fault is still present, limp home mode is

reactivated.

• If limp home mode is reactivated after the ignition is switched on, the option exists in select-shift mode to pull away in 2nd gear. This

is the case unless the transaxle is in emergency

mode 4. Only 4th gear and the reverse gear are

available in this mode.

Component Description

Tasks of the electronic components

The following overview summarizes the input and

output signals from the transmission control

module.

G1163605en2008.50 Kuga8/2011

307-01-

42

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 42

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1873 of 2057

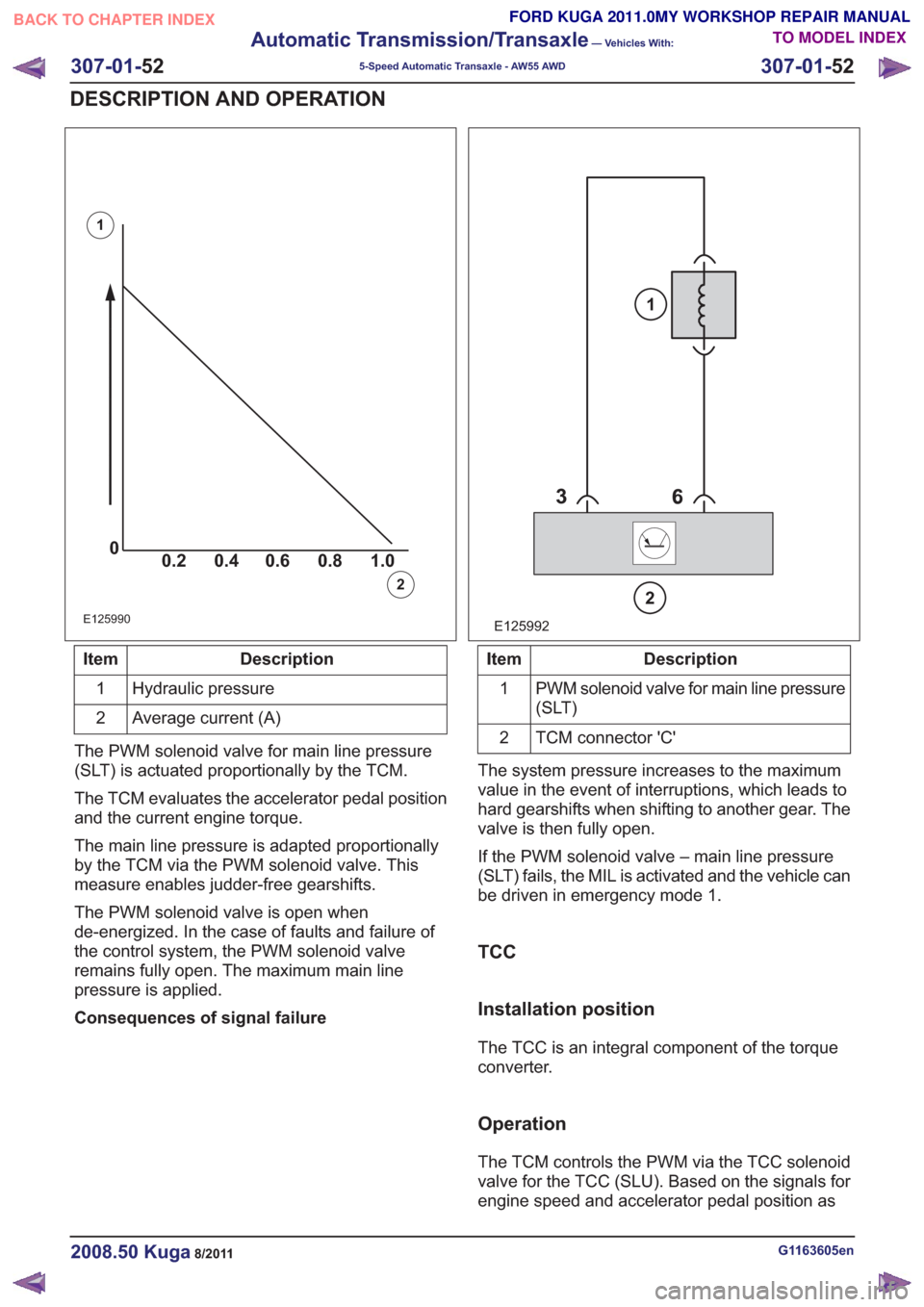

00.2 1.0 0.80.60.4

0

0.2 1.0

0.80.60.40

0.2 1.0 0.80.60.40

0.2 1.0 0.80.60.4

E125990

1

2

Description

Item

Hydraulic pressure

1

Average current (A)

2

The PWM solenoid valve for main line pressure

(SLT) is actuated proportionally by the TCM.

The TCM evaluates the accelerator pedal position

and the current engine torque.

The main line pressure is adapted proportionally

by the TCM via the PWM solenoid valve. This

measure enables judder-free gearshifts.

The PWM solenoid valve is open when

de-energized. In the case of faults and failure of

the control system, the PWM solenoid valve

remains fully open. The maximum main line

pressure is applied.

Consequences of signal failure

E125992

2

1

Description

Item

PWM solenoid valve for main line pressure

(SLT)

1

TCM connector 'C'

2

The system pressure increases to the maximum

value in the event of interruptions, which leads to

hard gearshifts when shifting to another gear. The

valve is then fully open.

If the PWM solenoid valve – main line pressure

(SLT) fails, the MIL is activated and the vehicle can

be driven in emergency mode 1.

TCC

Installation position

The TCC is an integral component of the torque

converter.

Operation

The TCM controls the PWM via the TCC solenoid

valve for the TCC (SLU). Based on the signals for

engine speed and accelerator pedal position as

G1163605en2008.50 Kuga8/2011

307-01- 52

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 52

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1889 of 2057

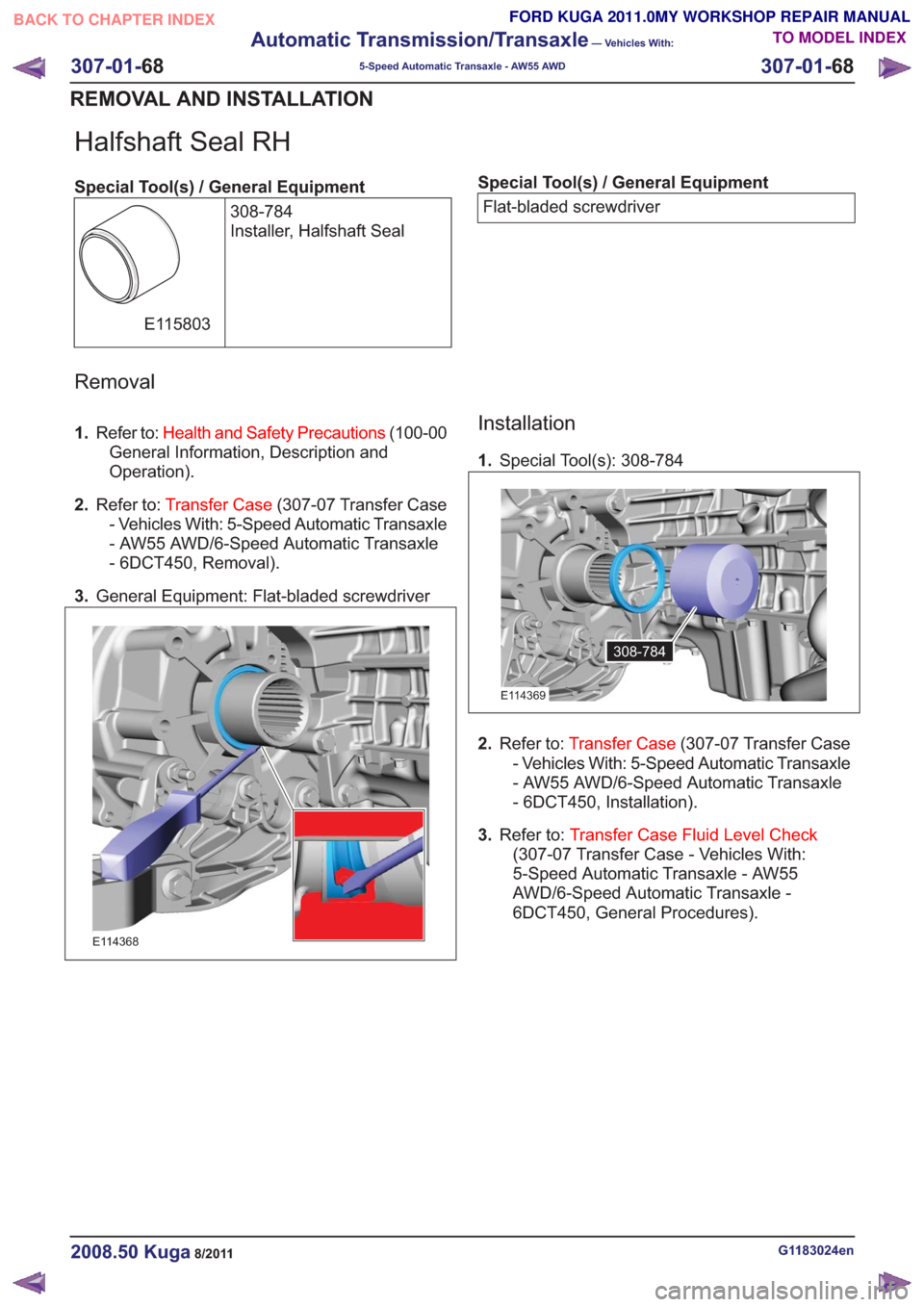

Halfshaft Seal RH

Special Tool(s) / General Equipment308-784

Installer, Halfshaft Seal

E115803

Special Tool(s) / General EquipmentFlat-bladed screwdriver

Removal

1. Refer to: Health and Safety Precautions (100-00

General Information, Description and

Operation).

2. Refer to: Transfer Case (307-07 Transfer Case

- Vehicles With: 5-Speed Automatic Transaxle

- AW55 AWD/6-Speed Automatic Transaxle

- 6DCT450, Removal).

3. General Equipment: Flat-bladed screwdriver

E114368

Installation

1.Special Tool(s): 308-784

308-784308-784

E114369

2.Refer to: Transfer Case (307-07 Transfer Case

- Vehicles With: 5-Speed Automatic Transaxle

- AW55 AWD/6-Speed Automatic Transaxle

- 6DCT450, Installation).

3. Refer to: Transfer Case Fluid Level Check

(307-07 Transfer Case - Vehicles With:

5-Speed Automatic Transaxle - AW55

AWD/6-Speed Automatic Transaxle -

6DCT450, General Procedures).

G1183024en2008.50 Kuga8/2011

307-01- 68

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 68

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL