case FORD KUGA 2011 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 280 of 2057

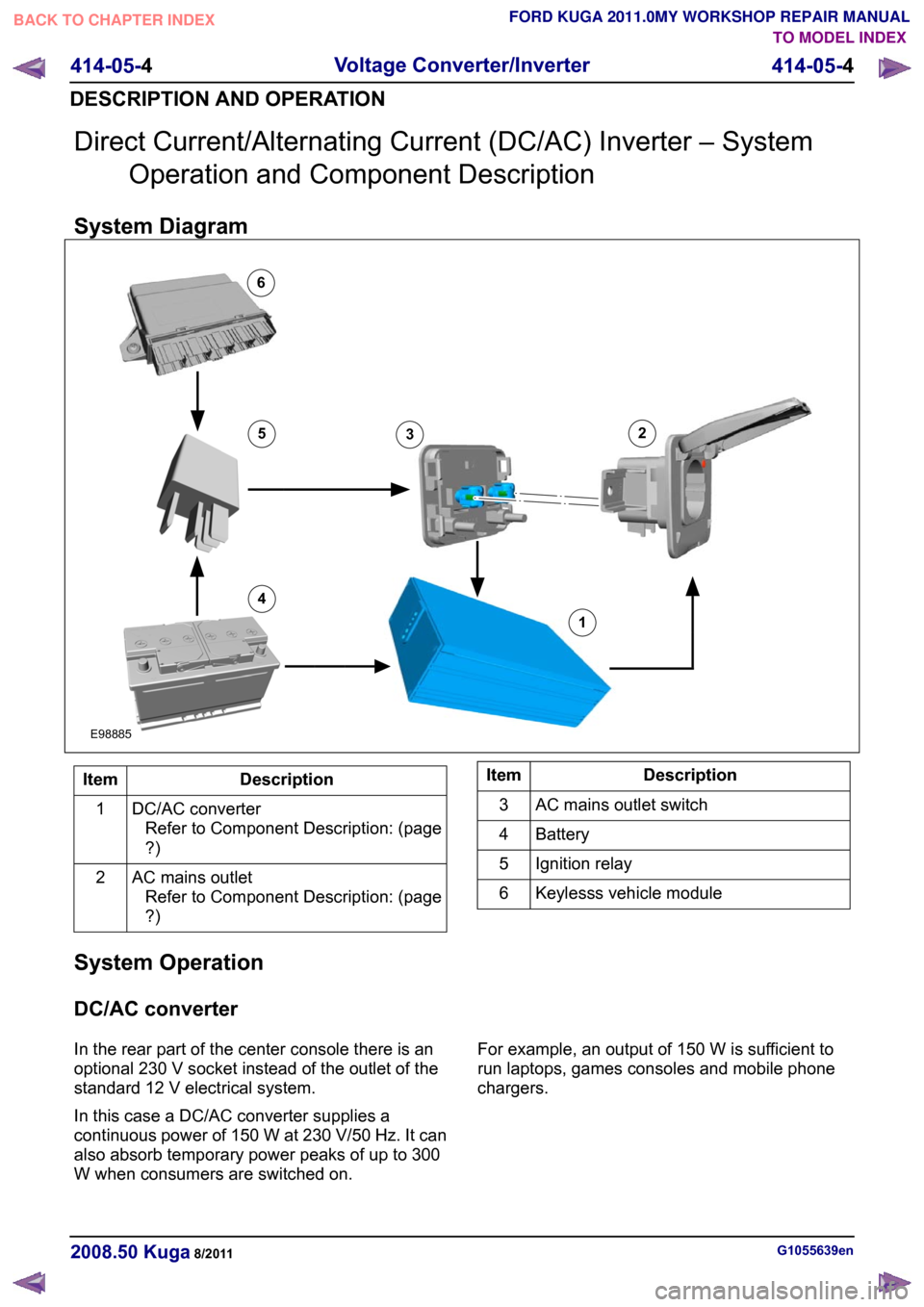

Direct Current/Alternating Current (DC/AC) Inverter – System

Operation and Component Description

System Diagram Description

Item

DC/AC converterRefer to Component Description: (page

?)

1

AC mains outletRefer to Component Description: (page

?)

2 Description

Item

AC mains outlet switch

3

Battery

4

Ignition relay

5

Keylesss vehicle module

6

System Operation

DC/AC converter

In the rear part of the center console there is an

optional 230 V socket instead of the outlet of the

standard 12 V electrical system.

In this case a DC/AC converter supplies a

continuous power of 150 W at 230 V/50 Hz. It can

also absorb temporary power peaks of up to 300

W when consumers are switched on. For example, an output of 150 W is sufficient to

run laptops, games consoles and mobile phone

chargers.

G1055639en

2008.50 Kuga 8/2011 414-05-4

Voltage Converter/Inverter

414-05-4

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL12456E988853

Page 341 of 2057

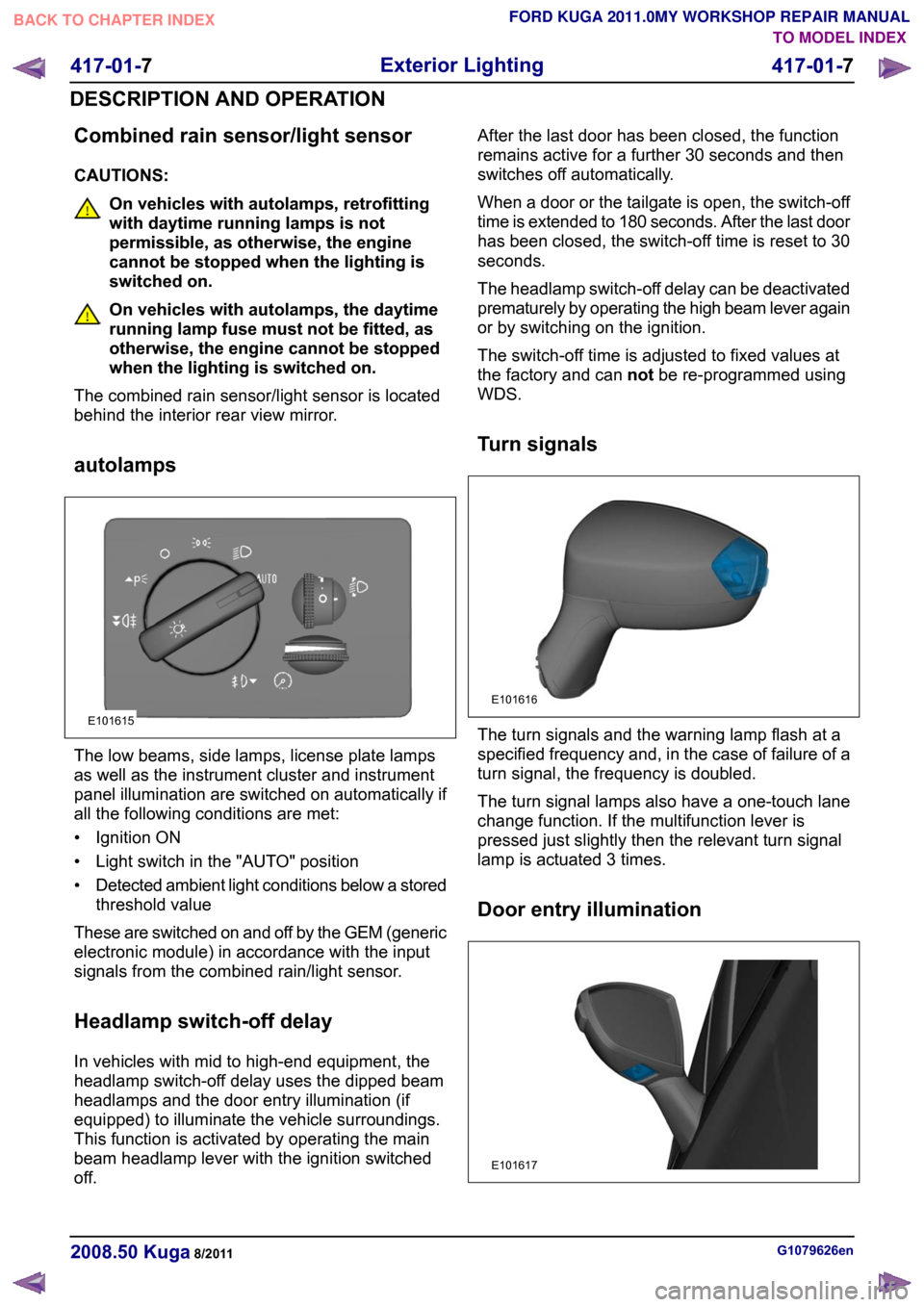

Combined rain sensor/light sensor

CAUTIONS:

On vehicles with autolamps, retrofitting

with daytime running lamps is not

permissible, as otherwise, the engine

cannot be stopped when the lighting is

switched on.

On vehicles with autolamps, the daytime

running lamp fuse must not be fitted, as

otherwise, the engine cannot be stopped

when the lighting is switched on.

The combined rain sensor/light sensor is located

behind the interior rear view mirror.

autolamps The low beams, side lamps, license plate lamps

as well as the instrument cluster and instrument

panel illumination are switched on automatically if

all the following conditions are met:

• Ignition ON

• Light switch in the "AUTO" position

•

Detected ambient light conditions below a stored

threshold value

These are switched on and off by the GEM (generic

electronic module) in accordance with the input

signals from the combined rain/light sensor.

Headlamp switch-off delay

In vehicles with mid to high-end equipment, the

headlamp switch-off delay uses the dipped beam

headlamps and the door entry illumination (if

equipped) to illuminate the vehicle surroundings.

This function is activated by operating the main

beam headlamp lever with the ignition switched

off. After the last door has been closed, the function

remains active for a further 30 seconds and then

switches off automatically.

When a door or the tailgate is open, the switch-off

time is extended to 180 seconds. After the last door

has been closed, the switch-off time is reset to 30

seconds.

The headlamp switch-off delay can be deactivated

prematurely by operating the high beam lever again

or by switching on the ignition.

The switch-off time is adjusted to fixed values at

the factory and can

notbe re-programmed using

WDS.

Turn signals The turn signals and the warning lamp flash at a

specified frequency and, in the case of failure of a

turn signal, the frequency is doubled.

The turn signal lamps also have a one-touch lane

change function. If the multifunction lever is

pressed just slightly then the relevant turn signal

lamp is actuated 3 times.

Door entry illumination

G1079626en

2008.50 Kuga 8/2011 417-01-7

Exterior Lighting

417-01-7

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE101615 E101616 E101617

Page 345 of 2057

The manual headlamp levelling system operates

with an electric motor which is controlled via a

rotary control in the instrument cluster.

Turn signals

The GEM switches the direction indicators and the

direction indicator side repeaters on.

The GEM sends a signal to the instrument cluster

via the CAN (controller area network) bus to switch

on the relevant turn indicator and the acoustic

signal.

The signals from the hazard flasher switch and

from the multifunction switch are transmitted to the

GEM via a wiring connection.

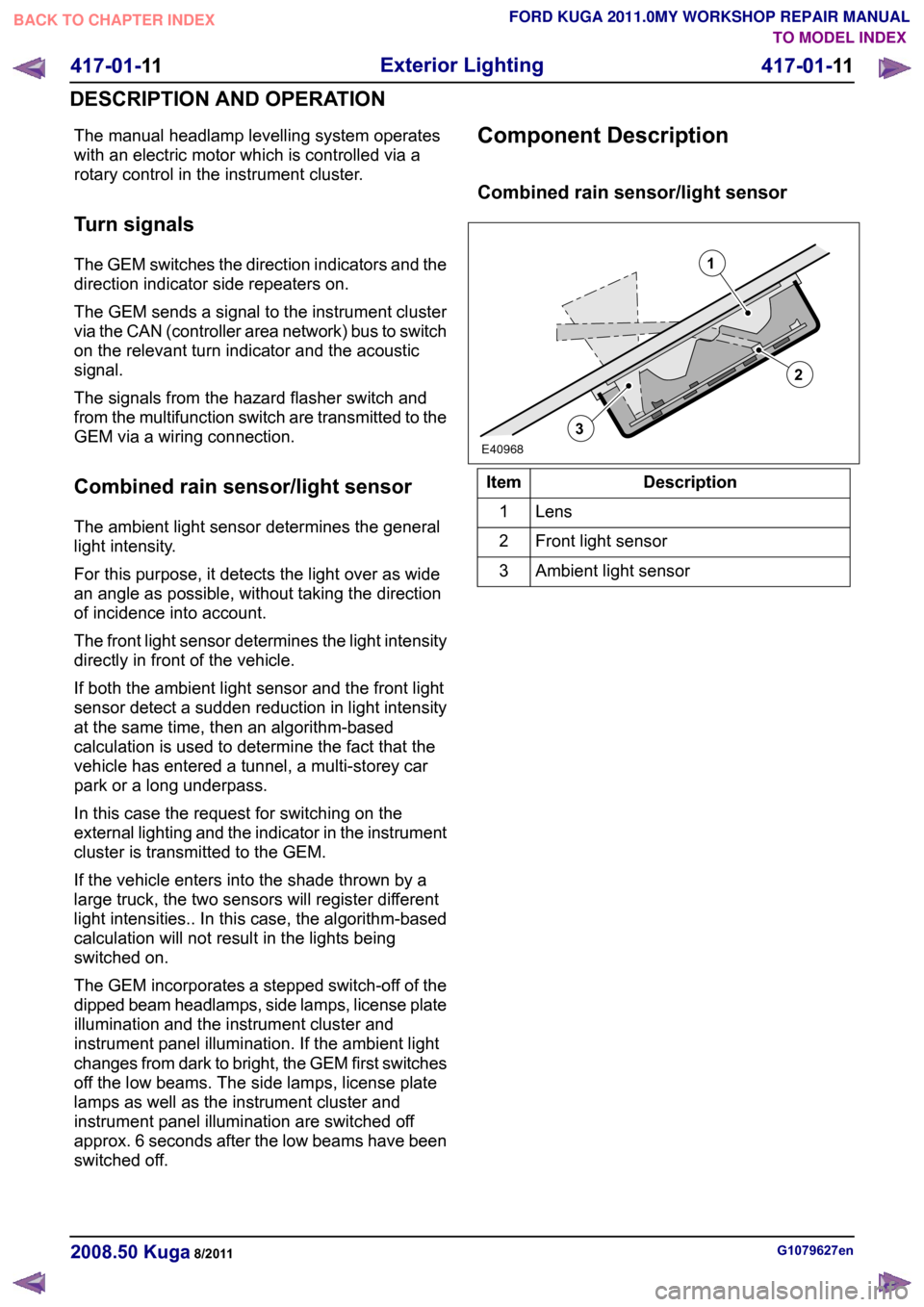

Combined rain sensor/light sensor

The ambient light sensor determines the general

light intensity.

For this purpose, it detects the light over as wide

an angle as possible, without taking the direction

of incidence into account.

The front light sensor determines the light intensity

directly in front of the vehicle.

If both the ambient light sensor and the front light

sensor detect a sudden reduction in light intensity

at the same time, then an algorithm-based

calculation is used to determine the fact that the

vehicle has entered a tunnel, a multi-storey car

park or a long underpass.

In this case the request for switching on the

external lighting and the indicator in the instrument

cluster is transmitted to the GEM.

If the vehicle enters into the shade thrown by a

large truck, the two sensors will register different

light intensities.. In this case, the algorithm-based

calculation will not result in the lights being

switched on.

The GEM incorporates a stepped switch-off of the

dipped beam headlamps, side lamps, license plate

illumination and the instrument cluster and

instrument panel illumination. If the ambient light

changes from dark to bright, the GEM first switches

off the low beams. The side lamps, license plate

lamps as well as the instrument cluster and

instrument panel illumination are switched off

approx. 6 seconds after the low beams have been

switched off.

Component Description

Combined rain sensor/light sensor

Description

Item

Lens1

Front light sensor

2

Ambient light sensor

3 G1079627en

2008.50 Kuga 8/2011 417-01-11

Exterior Lighting

417-01-11

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL213E40968

Page 388 of 2057

Module Configuration

Activation

1.

Install the most up-to-date software version in

the integrated diagnostic system (IDS).

2. In IDS, select the "Module reprogramming"

submenu in the "Module programming" menu

tool box and then follow the instructions.

3. Transfer a new software version (if available)

to the powertrain control module (PCM) using

IDS, if a module-reprogramming of the PCM

may be required in the case of engine running

concerns.

4. Following installation of a wheel/tire

combination, for which the tire-tread

circumference does not correspond to that of

standard tires, the tire size must be changed in

the PCM using IDS. Therefore select the

"Programmable parameters" submenu and enter

the corresponding tire size under the "tire size"

menu item. G1158256en

2008.50 Kuga 8/2011 418-01-2

Module Configuration

418-01-2

GENERAL PROCEDURESTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 452 of 2057

Module Controlled Functions – Overview

Generic electronics module (GEM)

CAUTIONS:

Never swap the GEM (generic electronic

module) between two vehicles.

Compare the number of relays and fuses

in the defective GEM and the new GEM.

Transfer from the defective GEM any relays

and fuses which are not in the new GEM.

In doing so, pay attention that fuses with

the correct Ampere rating are used, by

referring to the wiring diagrams.

NOTE: The GEM is integrated in the CJB (central

junction box) and cannot be replaced as a separate

unit.

For repair work during a service, vehicle-specific

configuration is necessary if a new GEM is

installed.

Emergency function

The GEM is equipped with restricted emergency

running functions on vehicles with mid or high-end

equipment levels.

The microcontroller sends a control signal to a

monitoring function within the GEM at regular

intervals. If the battery voltage falls below a value

of approx. 7.5 volts, this check signal is not present

and the GEM switches to emergency function after

a predetermined time.

In this case, the low beam is permanently switched

on, regardless of the light switch position. The

windshield wiper can only be operated in stage 1;

the wiper switch must however be in the stage I or

II position. The wiper park position is not

recognized. Intermittent wiping is not available.

When the control signal recurs, the GEM switches

back to normal operation.

Service mode

Description of operation

Diagnosis of the GEM can be carried out using the

Ford diagnostic unit. Furthermore, an integrated

service mode enables testing of the input and

output signals without the need for further tools.

To enable activation of service mode: • switch off the ignition,

• switch off all other electrical consumers,

• apply the handbrake,

• Shift to neutral

• and close the doors.

Activating the service mode

NOTE:

If the alarm is activated (in vehicles fitted

with an anti-theft alarm system), service mode

cannot be activated.

Proceed as follows to activate the service mode:

• OPERATE the switch of the heated rear window

and HOLD IT THERE

• SWITCH ON the ignition.

• RELEASE the switch of the heated rear window

A signal sounds and the turn signal lamps come

on to indicate that service mode has been

successfully activated.

Inputs

SWITCH the windshield wiper switch to the "OFF"

position to test the input signals. The following is

a list of the switch signals to be tested, in no

particular order:

• Windshield wiper stage I

• Windshield wiper stage II

• Windshield washer system

• Rear window wiper

• Rear window washer system

• Doors open/closed

• Remote control for central locking with double locking

• Hood open/closed (in vehicles equipped with an anti-theft alarm system)

• Tailgate open/closed

• A/C request signal

• Heated windscreen (if fitted)

• Parking brake

• Brake fluid level

• Cruise control system

• Autolamps

• Dipped beam

• Main beam

• Headlamp flasher

• Side lights

• Turn signals (right, left, hazard warning lights) G1030787en

2008.50 Kuga 8/2011 419-10-2

Multifunction Electronic Modules

419-10-2

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 458 of 2057

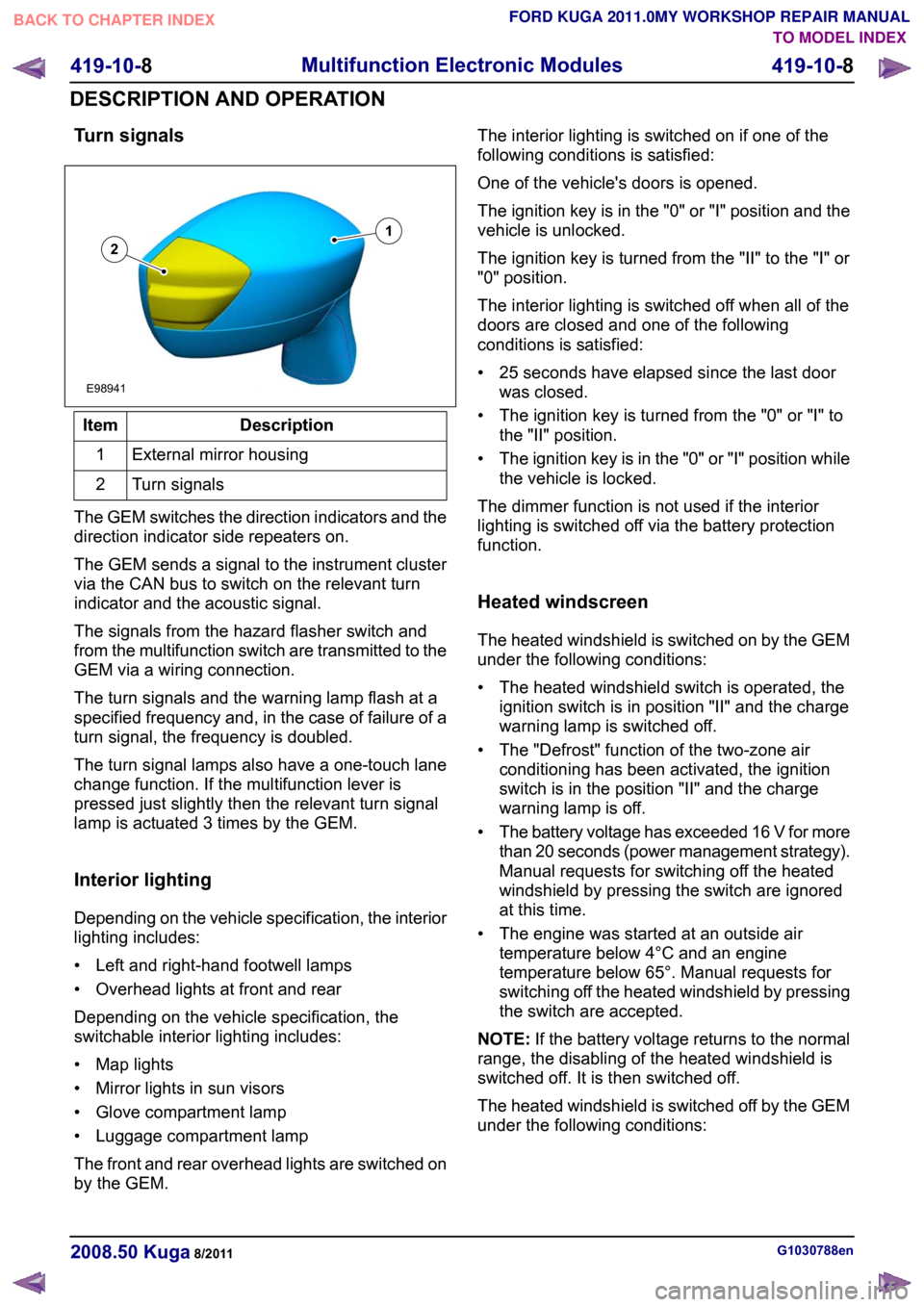

Turn signals

Description

Item

External mirror housing

1

Turn signals

2

The GEM switches the direction indicators and the

direction indicator side repeaters on.

The GEM sends a signal to the instrument cluster

via the CAN bus to switch on the relevant turn

indicator and the acoustic signal.

The signals from the hazard flasher switch and

from the multifunction switch are transmitted to the

GEM via a wiring connection.

The turn signals and the warning lamp flash at a

specified frequency and, in the case of failure of a

turn signal, the frequency is doubled.

The turn signal lamps also have a one-touch lane

change function. If the multifunction lever is

pressed just slightly then the relevant turn signal

lamp is actuated 3 times by the GEM.

Interior lighting

Depending on the vehicle specification, the interior

lighting includes:

• Left and right-hand footwell lamps

• Overhead lights at front and rear

Depending on the vehicle specification, the

switchable interior lighting includes:

• Map lights

• Mirror lights in sun visors

• Glove compartment lamp

• Luggage compartment lamp

The front and rear overhead lights are switched on

by the GEM. The interior lighting is switched on if one of the

following conditions is satisfied:

One of the vehicle's doors is opened.

The ignition key is in the "0" or "I" position and the

vehicle is unlocked.

The ignition key is turned from the "II" to the "I" or

"0" position.

The interior lighting is switched off when all of the

doors are closed and one of the following

conditions is satisfied:

• 25 seconds have elapsed since the last door

was closed.

• The ignition key is turned from the "0" or "I" to the "II" position.

• The ignition key is in the "0" or "I" position while the vehicle is locked.

The dimmer function is not used if the interior

lighting is switched off via the battery protection

function.

Heated windscreen

The heated windshield is switched on by the GEM

under the following conditions:

• The heated windshield switch is operated, the ignition switch is in position "II" and the charge

warning lamp is switched off.

• The "Defrost" function of the two-zone air conditioning has been activated, the ignition

switch is in the position "II" and the charge

warning lamp is off.

• The battery voltage has exceeded 16 V for more

than 20 seconds (power management strategy).

Manual requests for switching off the heated

windshield by pressing the switch are ignored

at this time.

• The engine was started at an outside air temperature below 4°C and an engine

temperature below 65°. Manual requests for

switching off the heated windshield by pressing

the switch are accepted.

NOTE: If the battery voltage returns to the normal

range, the disabling of the heated windshield is

switched off. It is then switched off.

The heated windshield is switched off by the GEM

under the following conditions: G1030788en

2008.50 Kuga 8/2011 419-10-8

Multifunction Electronic Modules

419-10-8

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL12E98941

Page 1246 of 2057

SECTION 205-02 Rear Drive Axle/Differential

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

DESCRIPTION AND OPERATION

205-02-2

Rear Drive Axle and Differential (Component Location) .....................................................

205-02-6

Rear Drive Axle and Differential (System Operation and Component Description) ...........

205-02-6

System Operation ........................................................................\

.......................................

205-02-6

General Information ........................................................................\

................................

205-02-6

Driving situations ........................................................................\

....................................

205-02-6

Haldex clutch ........................................................................\

..........................................

205-02-7

General overview ........................................................................\

....................................

205-02-7

Operation ........................................................................\

................................................

205-02-7

Design of the 3rd generation Haldex clutch ....................................................................

205-02-9

Design of the multi-plate clutch ........................................................................\

...............

205-02-10

All-wheel drive control unit ........................................................................\

......................

205-02-10

Electric feed pump ........................................................................\

..................................

205-02-10

Pressure control - 3rd generation Haldex clutch .............................................................

205-02-11

Base pressure ........................................................................\

.........................................

205-02-12

Increased base pressure (preload) ........................................................................\

.........

205-02-13

Pressure build-up ........................................................................\

....................................

205-02-14

Design of the 4th generation Haldex clutch ...................................................................

205-02-14

General overview ........................................................................\

....................................

205-02-15

Pressure control - 4th generation Haldex clutch .............................................................

GENERAL PROCEDURES 205-02-17

Differential Fluid Level Check ........................................................................\

.....................

205-02-19

Active On-Demand Coupling Fluid Level Check ................................................................

REMOVAL AND INSTALLATION 205-02-21

Differential Case ........................................................................\

.........................................

205-02-25

Active On-Demand Coupling Module ........................................................................\

.........

205-02-32

Differential Input Shaft Seal ........................................................................\

........................

205-02-38

Differential Support Insulator ........................................................................\

......................

205-02-39

Rear Halfshaft Seal ........................................................................\

.....................................

205-02-41

Drive Pinion Seal ........................................................................\

........................................

DISASSEMBLY AND ASSEMBLY

205-02-42

Active On-Demand Coupling — Vehicles With: 5-Speed Automatic Transaxle - AW55

AWD/6-Speed Automatic Transaxle - 6DCT450 ...............................................................

205-02-1

Rear Drive Axle/Differential

205-02- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1266 of 2057

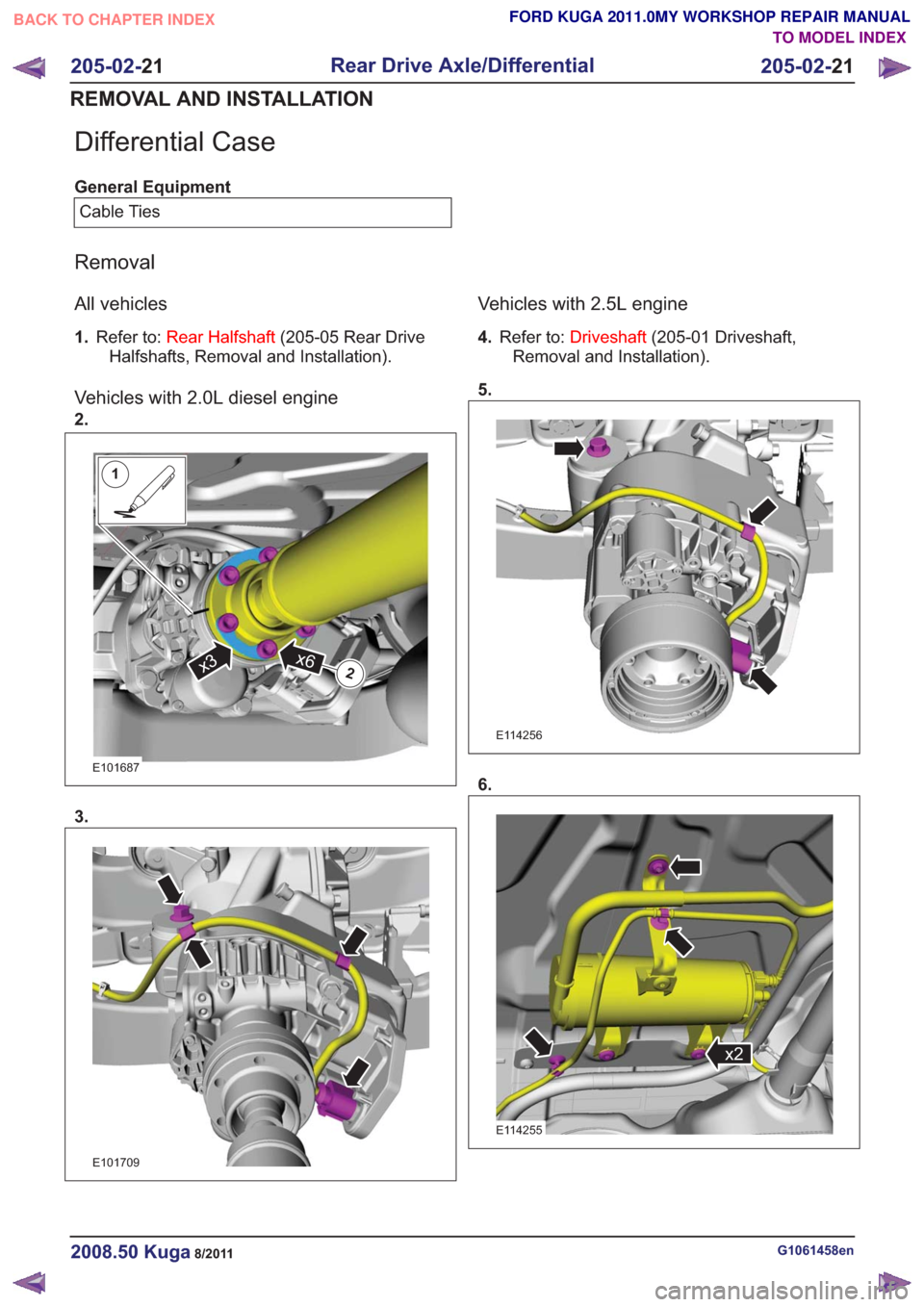

Differential Case

General EquipmentCable Ties

Removal

All vehicles

1. Refer to: Rear Halfshaft (205-05 Rear Drive

Halfshafts, Removal and Installation).

Vehicles with 2.0L diesel engine

2.

1

2x6x3

1

2x6x3

E101687

3.

E101709

Vehicles with 2.5L engine

4. Refer to: Driveshaft (205-01 Driveshaft,

Removal and Installation).

5.

E114256

6.

x2x2

E114255

G1061458en2008.50 Kuga8/2011

205-02- 21

Rear Drive Axle/Differential

205-02- 21

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1283 of 2057

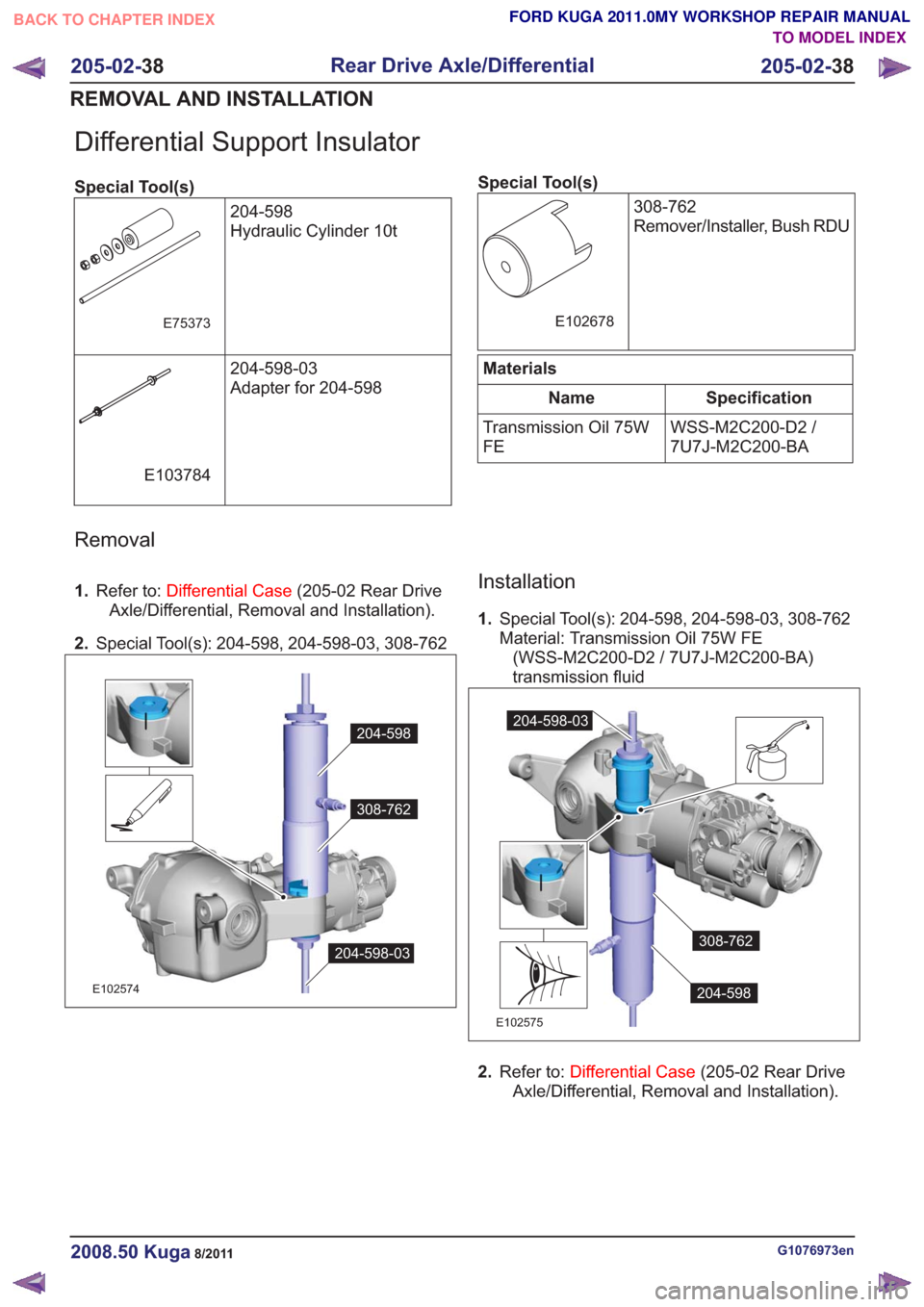

Differential Support Insulator

Special Tool(s)204-598

Hydraulic Cylinder 10t

E75373

204-598-03

Adapter for 204-598

E103784

Special Tool(s)308-762

Remover/Installer, Bush RDU

E102678

Materials

Specification

Name

WSS-M2C200-D2 /

7U7J-M2C200-BA

Transmission Oil 75W

FE

Removal

1.

Refer to: Differential Case (205-02 Rear Drive

Axle/Differential, Removal and Installation).

2. Special Tool(s): 204-598, 204-598-03, 308-762

308-762

204-598

204-598-03

308-762

204-598

204-598-03

E102574

Installation

1.Special Tool(s): 204-598, 204-598-03, 308-762

Material: Transmission Oil 75W FE

(WSS-M2C200-D2 / 7U7J-M2C200-BA)

transmission fluid

308-762

204-598

204-598-03

308-762

204-598

204-598-03

E102575

2. Refer to: Differential Case (205-02 Rear Drive

Axle/Differential, Removal and Installation).

G1076973en2008.50 Kuga8/2011

205-02- 38

Rear Drive Axle/Differential

205-02- 38

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1340 of 2057

Brake System

General EquipmentPressure/vacuum gauge set

The Ford approved diagnostic tool

The brake system operates by transferring effort

applied to the brake pedal by the driver to the

brakes at each wheel.

The braking effort is distributed to each wheel,

using a hydraulic system. The system is assisted

using a vacuum brake booster that reduces pedal

effort and increases hydraulic pressure.

The parking brake operates on the rear wheels

and is applied using a hand operated control.

Inspection and Verification

NOTE: Before carrying out any diagnosis, make

sure that the brake system warning indicator is

functional.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Electricalconnector(s)

• Wiring harness(s)

• Switch(es)

• Tire pressure(s)

• Wheels and tires

• Fluid leak(s)

3. If an obvious cause for an observed or reported concern is found, correct the case (if possible)

before proceeding to the next step.

4. If the cause if not visually evident, verify the symptom and refer to the Symptom Chart.

Road Test

Carry out a road test to compare actual vehicle

braking performance with the performance

standards expected by the driver. The ability of the

test driver to make valid comparisons and detect

performance deficiencies will depend on

experience.

The driver should have a thorough knowledge of

the brake system operation and accepted general performance guidelines to make good comparisons

and detect performance concerns.

An experienced technician will always establish a

route that will be used for all brake diagnosis road

tests. The road selected will be reasonably smooth

and level. Gravel or bumpy roads are not suitable

because the surface does not allow the tires to grip

the road equally. Crowned roads should be avoided

because of the large amount of weight shifted to

the low set of wheels on this type of road. Once

the route is established and consistently used, the

road surface variable can be eliminated from the

test results.

Before a road test, get a complete description of

the customer concerns or suspected condition.

From the description, the technician will be able to

match possible causes with symptoms. Certain

components will be identified as possible sources

while others will be eliminated by the evidence.

More importantly, the customer description can

reveal unsafe conditions which should be checked

or corrected before a road test. The description will

also help form the basic approach to the road test

by narrowing the concern to specific components,

vehicle speed or conditions.

Begin the road test with a general brake

performance check. Using the description of the

concern, test the brakes at different vehicle speeds

using both light and heavy pedal pressure.

Determine if the concern is in the front or rear

braking system. First use the foot brake and then

the parking brake. If the condition (i.e. pull,

vibration, pulsation) occurs only on operation of

the parking brake, the concern is in the rear brake

system. If the condition occurs when the foot brake

is depressed, the concern is in the front brake

system.

Avoid locking the brakes and sliding the tires. This

condition will not indicate brake efficiency. A heavily

braked but turning wheel will stop the vehicle in a

shorter distance than locked wheels.

If the concern becomes evident during this check,

make sure it fits the description given before the

road test. If the concern is not evident, attempt to

duplicate the condition using the information from

the description.

If a concern exists, use the Brake System Symptom

Chart in order to isolate it to a specific sub-system

and condition description. From this description, a

list of possible sources can be used to further

G1058975en2008.50 Kuga8/2011

206-00-

4

Brake System - General Information

206-00- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL