Engine FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1847 of 2057

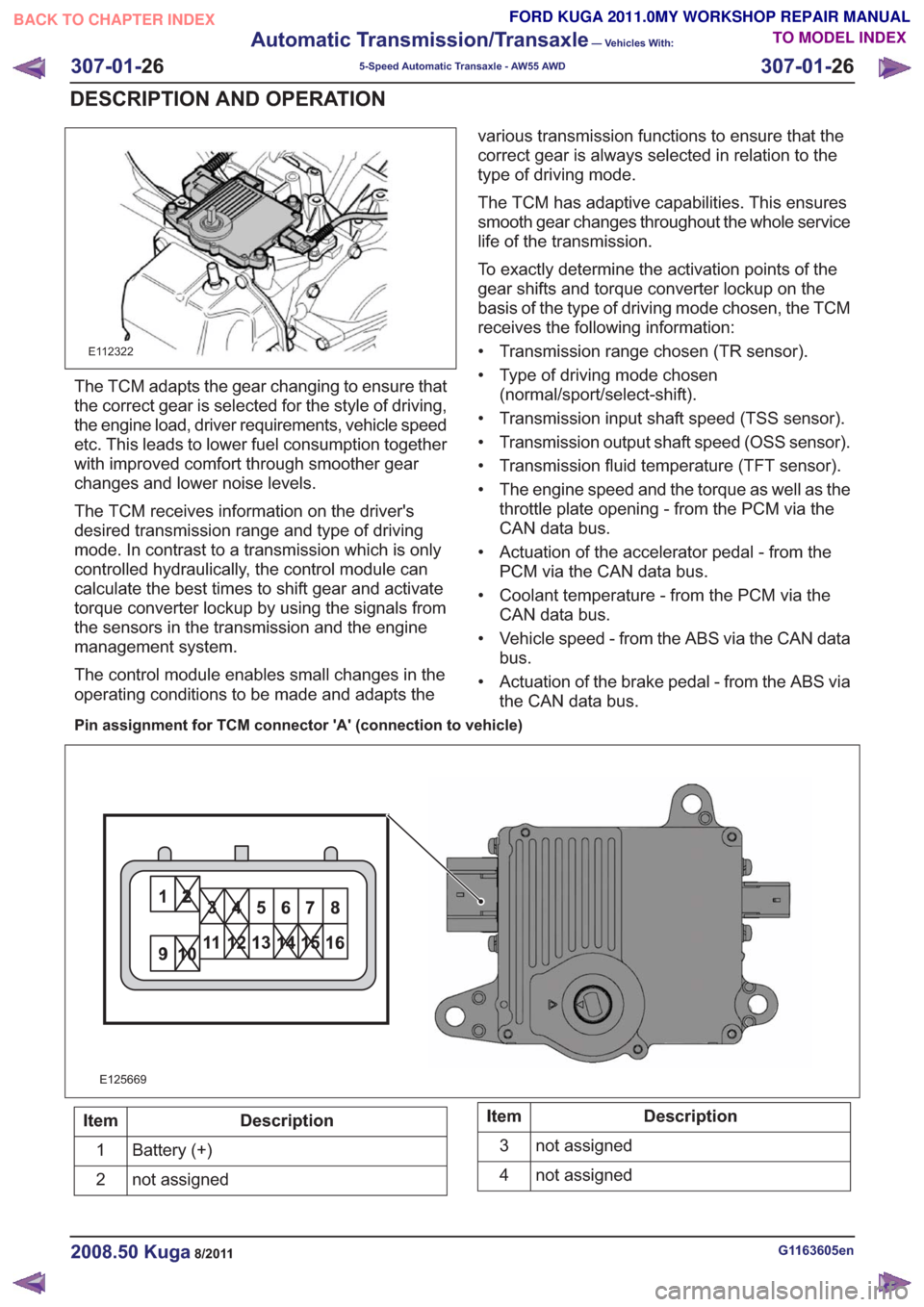

E112322

The TCM adapts the gear changing to ensure that

the correct gear is selected for the style of driving,

the engine load, driver requirements, vehicle speed

etc. This leads to lower fuel consumption together

with improved comfort through smoother gear

changes and lower noise levels.

The TCM receives information on the driver's

desired transmission range and type of driving

mode. In contrast to a transmission which is only

controlled hydraulically, the control module can

calculate the best times to shift gear and activate

torque converter lockup by using the signals from

the sensors in the transmission and the engine

management system.

The control module enables small changes in the

operating conditions to be made and adapts thevarious transmission functions to ensure that the

correct gear is always selected in relation to the

type of driving mode.

The TCM has adaptive capabilities. This ensures

smooth gear changes throughout the whole service

life of the transmission.

To exactly determine the activation points of the

gear shifts and torque converter lockup on the

basis of the type of driving mode chosen, the TCM

receives the following information:

• Transmission range chosen (TR sensor).

• Type of driving mode chosen

(normal/sport/select-shift).

• Transmission input shaft speed (TSS sensor).

• Transmission output shaft speed (OSS sensor).

• Transmission fluid temperature (TFT sensor).

• The engine speed and the torque as well as the throttle plate opening - from the PCM via the

CAN data bus.

• Actuation of the accelerator pedal - from the PCM via the CAN data bus.

• Coolant temperature - from the PCM via the CAN data bus.

• Vehicle speed - from the ABS via the CAN data bus.

• Actuation of the brake pedal - from the ABS via the CAN data bus.

Pin assignment for TCM connector 'A' (connection to vehicle)

11

E125669

Description

Item

Battery (+)

1

not assigned

2Description

Item

not assigned

3

not assigned

4

G1163605en2008.50 Kuga8/2011

307-01- 26

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 26

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1849 of 2057

21

22 20 19

15 14 13

161718 12

876

9

10

11 5

3

42121

22 20 19

15 14 13

161718 12

876

9

10

11 5

3

421

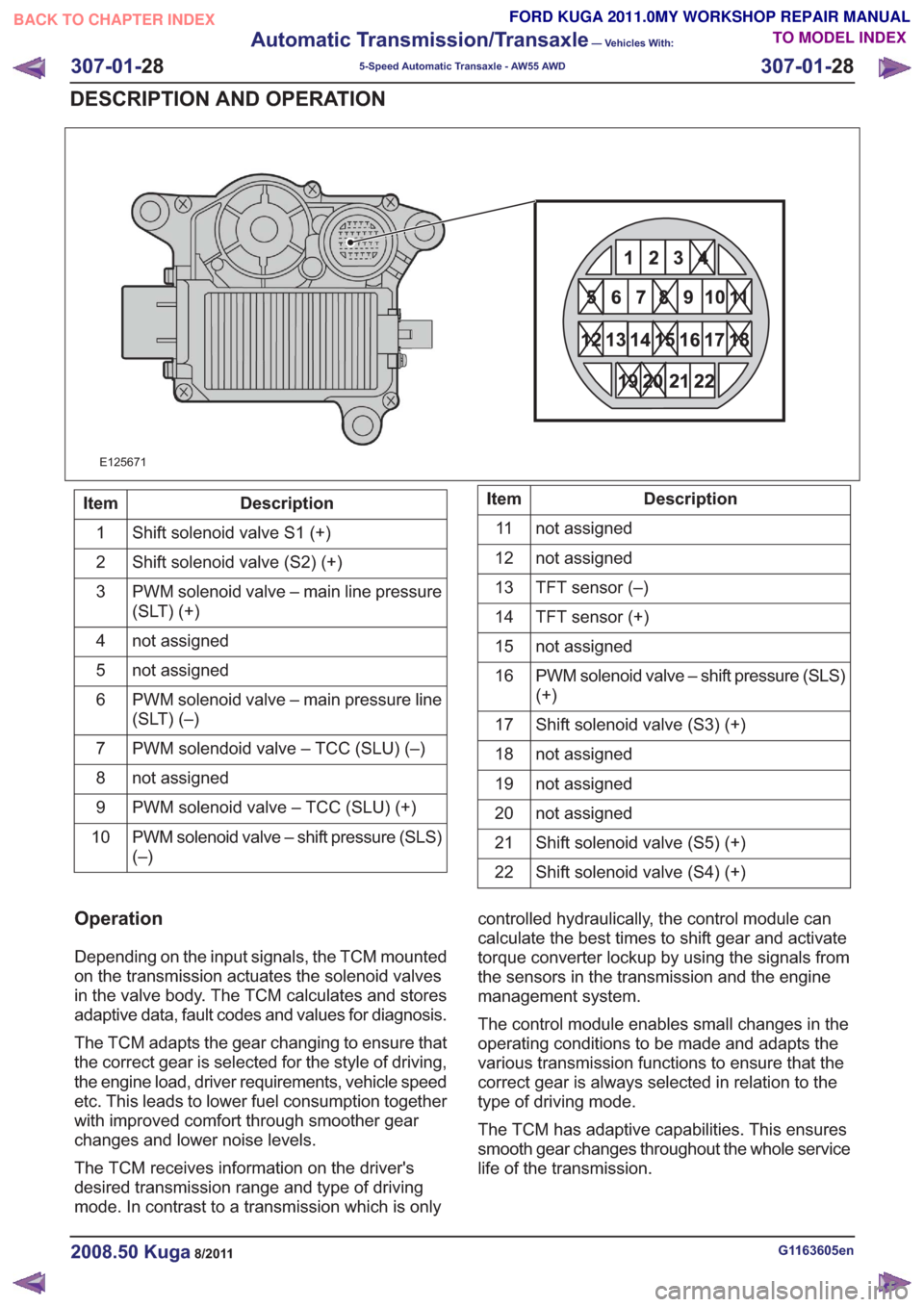

E125671

Description

Item

Shift solenoid valve S1 (+)

1

Shift solenoid valve (S2) (+)

2

PWM solenoid valve – main line pressure

(SLT) (+)

3

not assigned

4

not assigned

5

PWM solenoid valve – main pressure line

(SLT) (–)

6

PWM solendoid valve – TCC (SLU) (–)

7

not assigned

8

PWM solenoid valve – TCC (SLU) (+)

9

PWM solenoid valve – shift pressure (SLS)

(–)

10Description

Item

not assigned

11

not assigned

12

TFT sensor (–)

13

TFT sensor (+)

14

not assigned

15

PWM solenoid valve – shift pressure (SLS)

(+)

16

Shift solenoid valve (S3) (+)

17

not assigned

18

not assigned

19

not assigned

20

Shift solenoid valve (S5) (+)

21

Shift solenoid valve (S4) (+)

22

Operation

Depending on the input signals, the TCM mounted

on the transmission actuates the solenoid valves

in the valve body. The TCM calculates and stores

adaptive data, fault codes and values for diagnosis.

The TCM adapts the gear changing to ensure that

the correct gear is selected for the style of driving,

the engine load, driver requirements, vehicle speed

etc. This leads to lower fuel consumption together

with improved comfort through smoother gear

changes and lower noise levels.

The TCM receives information on the driver's

desired transmission range and type of driving

mode. In contrast to a transmission which is only controlled hydraulically, the control module can

calculate the best times to shift gear and activate

torque converter lockup by using the signals from

the sensors in the transmission and the engine

management system.

The control module enables small changes in the

operating conditions to be made and adapts the

various transmission functions to ensure that the

correct gear is always selected in relation to the

type of driving mode.

The TCM has adaptive capabilities. This ensures

smooth gear changes throughout the whole service

life of the transmission.

G1163605en2008.50 Kuga8/2011

307-01-

28

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 28

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1850 of 2057

To exactly determine the activation points of the

gear shifts and torque converter lockup on the

basis of the type of driving mode chosen, the TCM

receives the following information:

• Selected transmission range (TR sensor)

• Selected driving mode (normal/sport/select-shift)

• Transmission input shaft speed (TSS sensor)

• Transmission output shaft speed (OSS sensor)

• Transmission fluid temperature (TFT sensor)

• The engine speed and the torque as well as thethrottle plate opening - from the PCM via the

CAN databus

• Actuation of accelerator – from the PCM via the CAN databus

• The coolant temperature – from the PCM via the CAN databus

• Road speed – from the ABS module via the CAN databus

• Actuation of brake pedal – from the PCM via the CAN databus

Gearshift control

Adaptation

The TCM monitors every shift operation in all

driving conditions to make even and smooth gear

shifts possible. This is done by the control module,

which either lowers or increases the hydraulic line

pressure during gearshifts.

The changed pressure values are stored in the

control module memory after the engine is switched

off and retrieved during engine starting. This

improves the shift comfort and extends the service

life.

Full adaptability occurs when the following criteria

are met:

• Throttle plate opening is constant.

• Transmission fluid temperature between 65 °Cand 110 °C.

Shifting from 'P' to another transmission

range

To be able to move the selector lever from 'P' into

another transmission range, the ignition must be

switched on and the brake pedal pressed (stoplamp

switch on). The TCM detects the position of the

brake pedal via the CAN data bus and the engaged

transmission range from the TR sensor. Based on this information, the TCM transmits a

signal to the select-shift switch module. This

activates the brake shift interlock actuator in the

selector lever assembly.

When the brake shift interlock actuator is activated,

the locking pin is retracted so that another

transmission range can be selected.

The brake shift interlock actuator is deactivated

when the ignition is switched off. It is mechanically

locked when the gear selector lever is in 'P'.

Automatic transmission, selector lever in

position "D".

The TCM adapts the shift points to match the

driving conditions. Normally the TCM is in adaptive

mode and gear changes take place adapted to the

driving conditions. If special driving conditions are

detected, the TCM switches to predefined

characteristics.

When driving with normal acceleration, the TCM

uses a preset shift program which is optimized for

economical driving.

This shift program is suitable for "normal" driving

and delivers early upward changes and torque

converter lockup. Furthermore, the transmission

fluid pressure is adapted to make smooth

engagement of the gears possible.

Sport mode, selector lever in position "S"

The transmission switches from automatic

operation into sport mode. In this mode the TCM

switches to another set of characteristic curves.

These characteristic curves for control of the gear

changes are adapted to sporting calculations (e.g.

gear change at higher engine speed).

In the sport mode shift program the shift points are

set so that good performance is offered. Changing

down occurs at lower engine speeds.

Manual gear changes (select-shift mode) can be

made in sport mode by moving the selector lever

in the (+) or (-) direction.

Changing gear in select-shift mode

If you move the selector lever to 'S', the automatic

transaxle remains hydraulically in 'D' position. If

you move the gear selector lever forwards (-), the

G1163605en2008.50 Kuga8/2011

307-01-

29

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 29

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1851 of 2057

select-shift switch module transmits a downshift

signal to the TCM.

If you move the gear selector lever backwards (+),

an upshift signal is transmitted to the TCM. In the

instrument cluster, the symbol when the selector

lever is in the 'S' position changes from 'D' to the

current gear, for example 3.

The TCM transmits a signal to the select-shift

switch module to switch on the light emitting diode

for 'S' and to switch off all other light emitting

diodes. The TCM decides whether the shift process

is possible.

If the shift process is permitted, then the various

valves are activated according to the intended

combination for each gear.

In certain situations however, the TCM determines

the gear shifting. The following applies:

• If the vehicle is stationary, only 1st, 2nd and 3rdgears can be selected. 4th gear can be selected

at speeds over 30 km/h and 5th gear at speeds

over 40 km/h.

• The kickdown function is only available in the automatic transmission range 'D'

• Automatic gear changes into the next higher or next lower gear occur at fixed vehicle speeds

and fixed engine speeds

• The permitted engine speed for manual change down agree with that for the kickdown change

up, i.e. an engine speed of approximately 6000

rpm.

• If the temperature inside the transmission rises too high, the TCM takes control of the shift

decisions in order to select a gear in which

activation of torque converter lockup at the

current speed is possible

• Torque converter lockup is possible in 3rd, 4th and 5th gear. (1st and 2nd gears do not have

torque converter lockup)

The signal that specifies the position of the lever

to the select-shift switch module is generated as

follows in the selector lever position 'S': there is a

Hall sensor at the printed circuit board for the

module for each of the three selector lever

positions. A permanent magnet on the cover in the

selector lever affects the output signals to the

control module from the sensors. The control

module recognizes the position of the lever by the

differences in the signal properties.Selector lever from 'N' to 'R' position

The TCM only permits shifting to reverse gear if

the vehicle speed is less than 4.35 mph.

If the vehicle speed is greater than 7 km/h (approx.

4.35 mph), the clutch (C2) and the multi-plate brake

(B3) are not activated and the gearshift is thus

prevented.

Self-test and Diagnosis

The TCM monitors all the transaxle sensors and

electronic components including the PCM. If a fault

occurs, the driver is informed via a warning

indicator and a text message in the instrument

cluster. Faults are stored as DTCs in the fault

memory of the TCM and can be read out and

cleared using the IDS.

Temperature controlled torque converter

lockup

If heavy load and high ambient temperatures cause

an abnormal rise in the transmission temperature,

torque converter lockup is activated as often as

possible (temperature controlled lockup).

This reduces the slip and the heat developed in

the transmission. When the temperature drops

below +20 °C, torque converter lockup is not used.

Slip locking

When changing gear this function makes it possible

for the gears to engage more smoothly with

reduced vibration and less noise. In this mode, the

torque converter clutch is activated but not fully

locked.

The following conditions must be met for the

function to activate:

• Gear selector lever in position D or S.

• Gear 3, 4 or 5.

• The transmission input speed is 1100 rpm or more and the throttle plate opening 20 - 35%.

• The transmission fluid temperature is 40 - 120 °C.

Hill climbing

The TCM can change the shift pattern slightly when

driving uphill to avoid changing gear too often.

G1163605en2008.50 Kuga8/2011

307-01- 30

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 30

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1852 of 2057

The TCM detects uphill driving by comparing the

engine load transmitted by the PCM with the engine

speed. If the engine load increases and the engine

speed falls, then the TCM causes the transaxle to

shift to a lower transmission range in order to

increase the traction force.

Downhill driving

The TCM detects downhill driving by comparing

the engine load and engine speed values

transmitted by the PCM with the OSS sensor

signal. In order to prevent overloading of the

vehicle brakes, the TCM causes the transaxle to

shift to a lower transmission range.

Hill-hold function

If the vehicle is stopped on an uphill incline, the

TCM detects this through the faster drop in engine

speed compared with the drop in engine speed

when stopping on the flat. In this situation, the

hydraulics are actuated by the TCM in such a way

that the vehicle is prevented from rolling back. This

function is not used on steep inclines.

If the vehicle is parked on an uphill incline (ignition

switched off), the hill-hold function is not active

when pulling away.

Altitude correction

Lower air density results in reduced engine

performance. In order to compensate for this

operating situation, the TCM changes the shift

points.

Selector lever lock

To prevent the selector lever being accidentally

moved from the P or N position, the vehicle also

has an electrically operated selector lever lock.

This blocks the locking pin in the locking segment

and thus locks the selector lever in the P or N

position.

Shifting from P into another transmission

range

To be able to move the selector lever from P into

another transmission range, the ignition must be

switched on and the brake pedal must be

depressed (stop light switch on). The TCM detects

the position of the brake pedal via the CAN data

bus and the engaged transmission range from the

TR sensor.

The signal is then transferred from the TCM to the

select-shift switch module in order to activate the

solenoid valve in the selector mechanism

assembly.

In position P, the solenoid valve is activated and

the locking pin is pulled in so that the lock button

on the selector lever can be pressed as usual to

engage another transmission range.

In the selector mechanism assembly there is a Hall

sensor which is affected by a permanent magnet

on the gate of the selector mechanism assembly.

If the selector lever is moved from the P position,

both the Hall sensor and the selector lever lock

solenoid are simultaneously deactivated, to prevent

the selector from being kept in the N position.

If the ignition is set to "I" or "0" the solenoid valve

is deactivated. When the selector lever is in the P

position, it is mechanically locked because it has

no voltage.

Shifting from N into another transmission

range

The conditions are the same as for shifting from P

into another transmission range.

However, the lock button on the selector lever must

be pressed to be able to select R or P.

Power flow through the transmission

Clutches and brakes

G1163605en2008.50 Kuga8/2011

307-01-31

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 31

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1857 of 2057

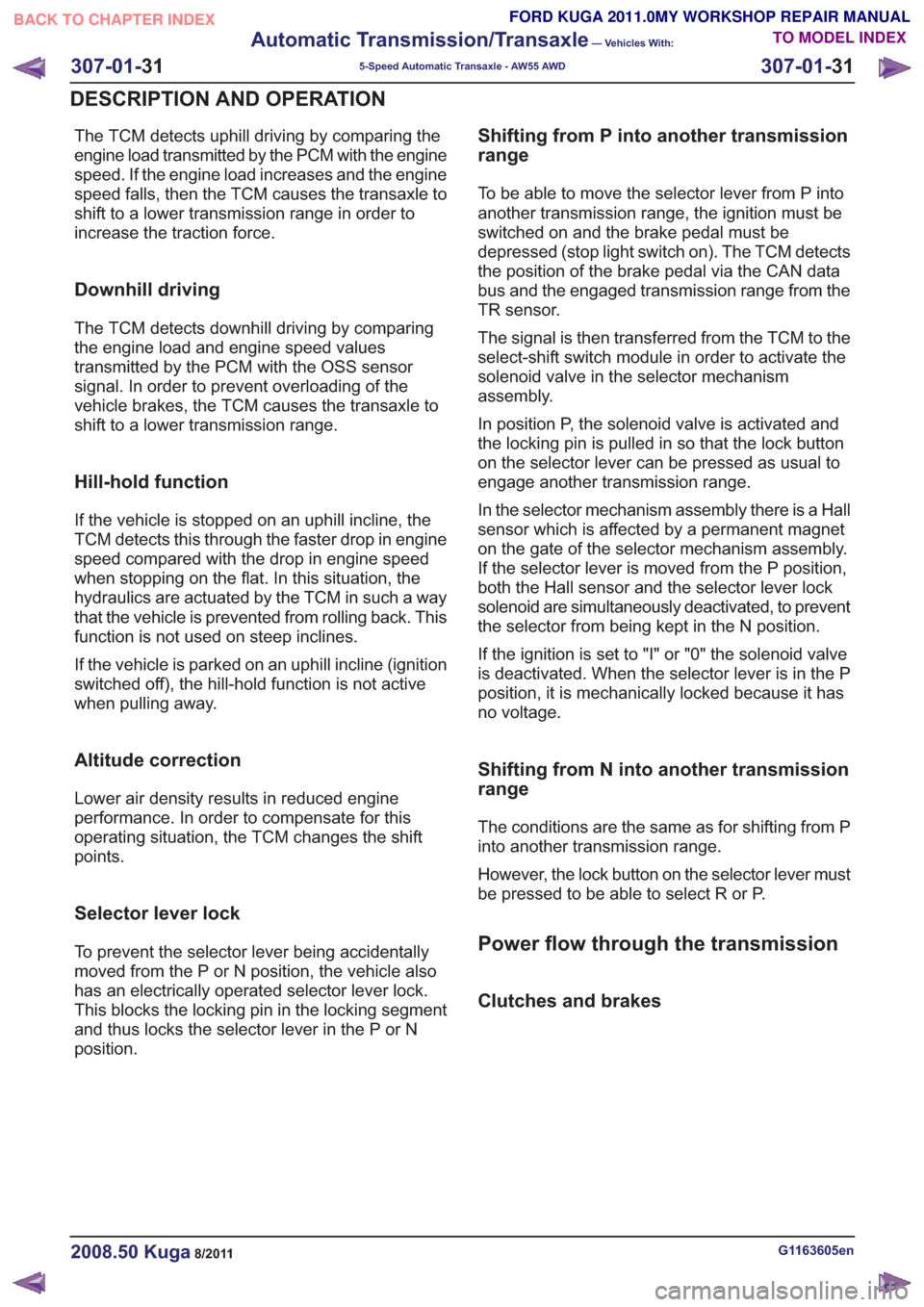

E127358

21

3

Input shaft:

The transmission input shaft rotates in the

clockwise direction. Clutch C1 (1) joins the

transaxle input shaft with the ring gear, which

rotates in clockwise direction. The rear planetary

gear set rotates in the clockwise direction. The

front larger planetary gear set rotates clockwise

with the rear planetary gear set as a single unit.

The front smaller planetary gear set rotates in the

clockwise direction. The front annular gear rotates

counterclockwise. One-way clutch F2 (2) blocks

the front annular gear clockwise rotation.

The front and rear planetary gear carriers are

turned clockwise because of the reactive forces

from the small gear. The primary idler gear rotates

clockwise with the front and rear planetary gear

carriers as one unit.

Output shaft:

The secondary idler gear rotates counterclockwise.

The front annular gear rotates counterclockwise

with the secondary idler gear as a single unit.The front planetary gear set rotates in the clockwise

direction. The sun gear rotates clockwise.

The rear planetary gear set rotates

counterclockwise. Brake B5 (3) prevents rotation

of the rear planetary gear carrier. The rear annular

gear rotates counterclockwise. The front planetary

gear carrier and the final drive pinion rotate

counterclockwise with the rear annular gear as one

unit. The final drive rotates in the clockwise

direction.

Engine braking:

The 1st gear has no engine braking function

because the power flow is interrupted by the

one-way clutch F2 rotating against the locking

direction.

The brake B3 is additionally activated in select-shift

mode to guarantee engine braking.

Position D, 2nd gear

G1163605en2008.50 Kuga8/2011

307-01-

36

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 36

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1858 of 2057

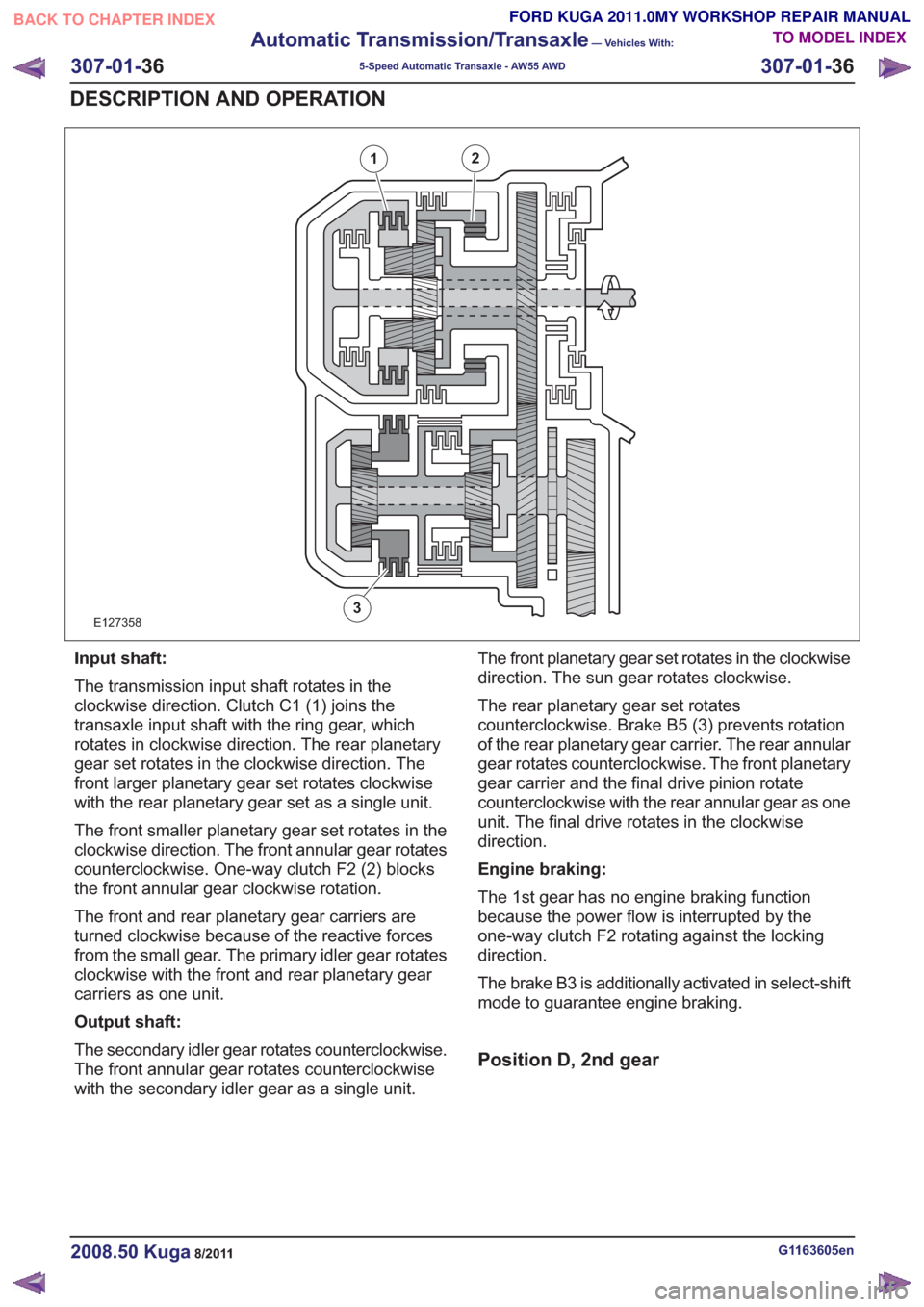

E127359

1

2

3

4

5

Input shaft:

The transmission input shaft rotates in the

clockwise direction. The clutch C1 (1) joins the

transaxle input shaft and the ring gear. The ring

gear rotates in clockwise direction. The planetary

gear set rotates in clockwise direction.

The front larger planet gear rotates clockwise with

the rear planet gear as a single unit. Brakes B2

(2), brake B1 (3) and the one-way clutch F1 (4)

prevent rotation of the sun gear.

The front and rear planetary gear carriers are

turned clockwise by the front larger gear. The

primary idler gear rotates clockwise with the front

and rear planetary gear carriers as one unit.

Output shaft:

The secondary idler gear rotates counterclockwise.

The front annular gear rotates counterclockwisewith the secondary idler gear as a single unit. The

front planetary gear set rotates in the clockwise

direction.

The sun gear rotates clockwise. The rear planetary

gear set rotates counterclockwise. Brake B5 (5)

prevents rotation of the rear planetary gear carrier.

The rear annular gear rotates counterclockwise.

The front planetary gear carrier and the shaft drive

pinion rotate in counterclockwise direction with the

rear ring gear as one unit. The final drive rotates

in the clockwise direction.

Engine braking:

The power is transferred directly to the

transmission input shaft without one-way clutch

involvement. Engine braking is thus applied.

Position D, 3rd gear

G1163605en2008.50 Kuga8/2011

307-01-

37

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 37

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1859 of 2057

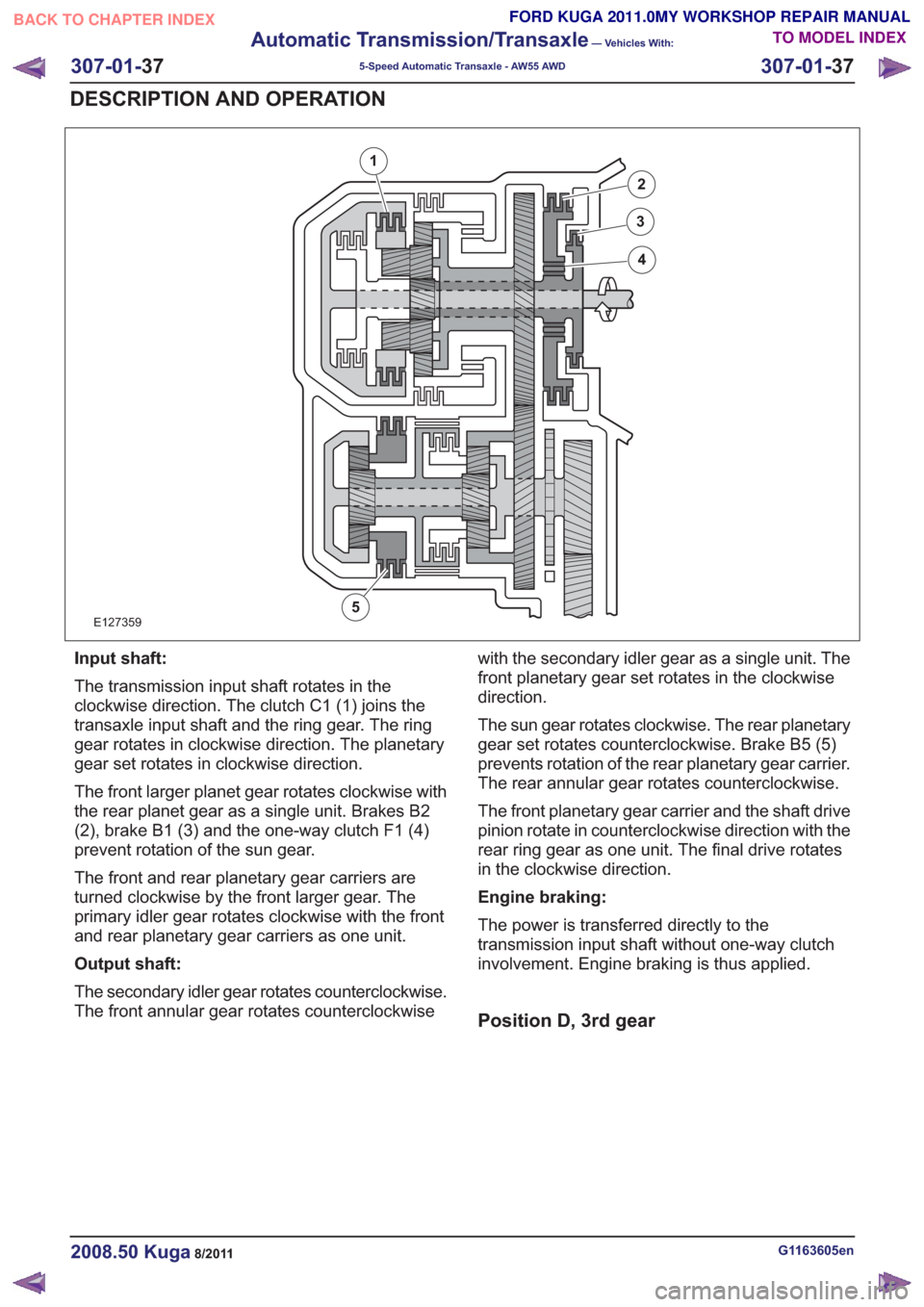

E127360

1

2

3

4

5

Input shaft:

The transmission input shaft rotates in the

clockwise direction. The clutch C1 (5) joins the

transaxle input shaft and the ring gear. The ring

gear rotates in clockwise direction. The rear

planetary gear set rotates in the clockwise

direction.

The front larger planet gear rotates clockwise with

the rear planet gear as a single unit. Brakes B2 (1)

and B1 (2) and also the one-way clutch F1 (3)

prevent rotation of the sun gear.

The front and rear planetary gear carriers are

turned clockwise because of the reactive forces

from the front larger gear. The primary idler gear

rotates clockwise with the front and rear planetary

gear carriers as one unit.

Output shaft:The secondary idler gear rotates counterclockwise.

The front annular gear rotates counterclockwise

with the secondary idler gear as a single unit. The

front planetary gear set rotates in counterclockwise

direction. The brake band B4 (4) locks the

rotational movement of the sun gear.

The front planetary gear carrier rotates in

counterclockwise direction. The front planetary

gear carrier and the shaft drive pinion rotate in

counterclockwise direction with the rear ring gear

as one unit. The final drive rotates in the clockwise

direction.

Engine braking:

The power is transferred directly to the

transmission input shaft without one-way clutch

involvement. Engine braking is thus applied.

Position D, 4th gear

G1163605en2008.50 Kuga8/2011

307-01-

38

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 38

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1860 of 2057

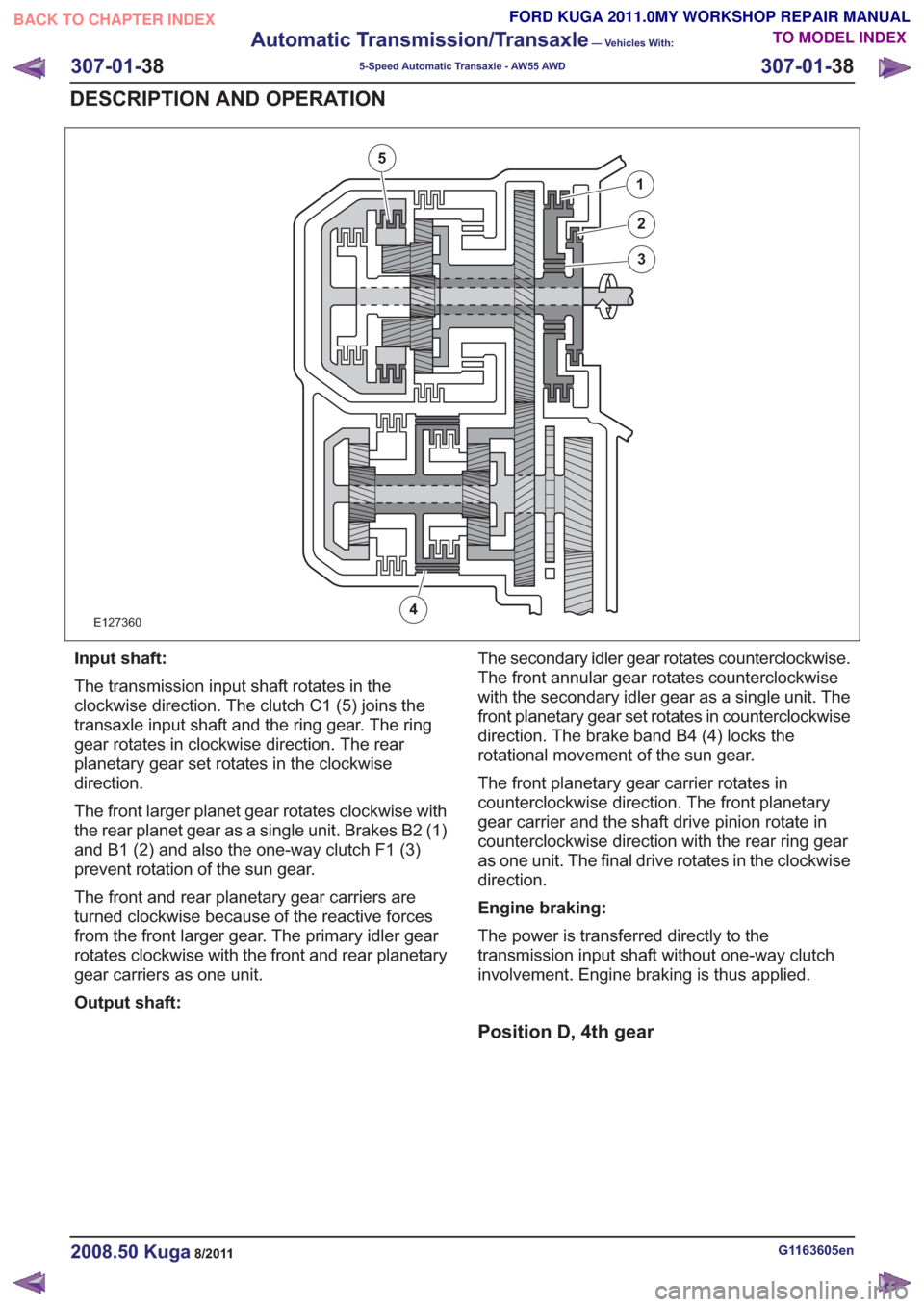

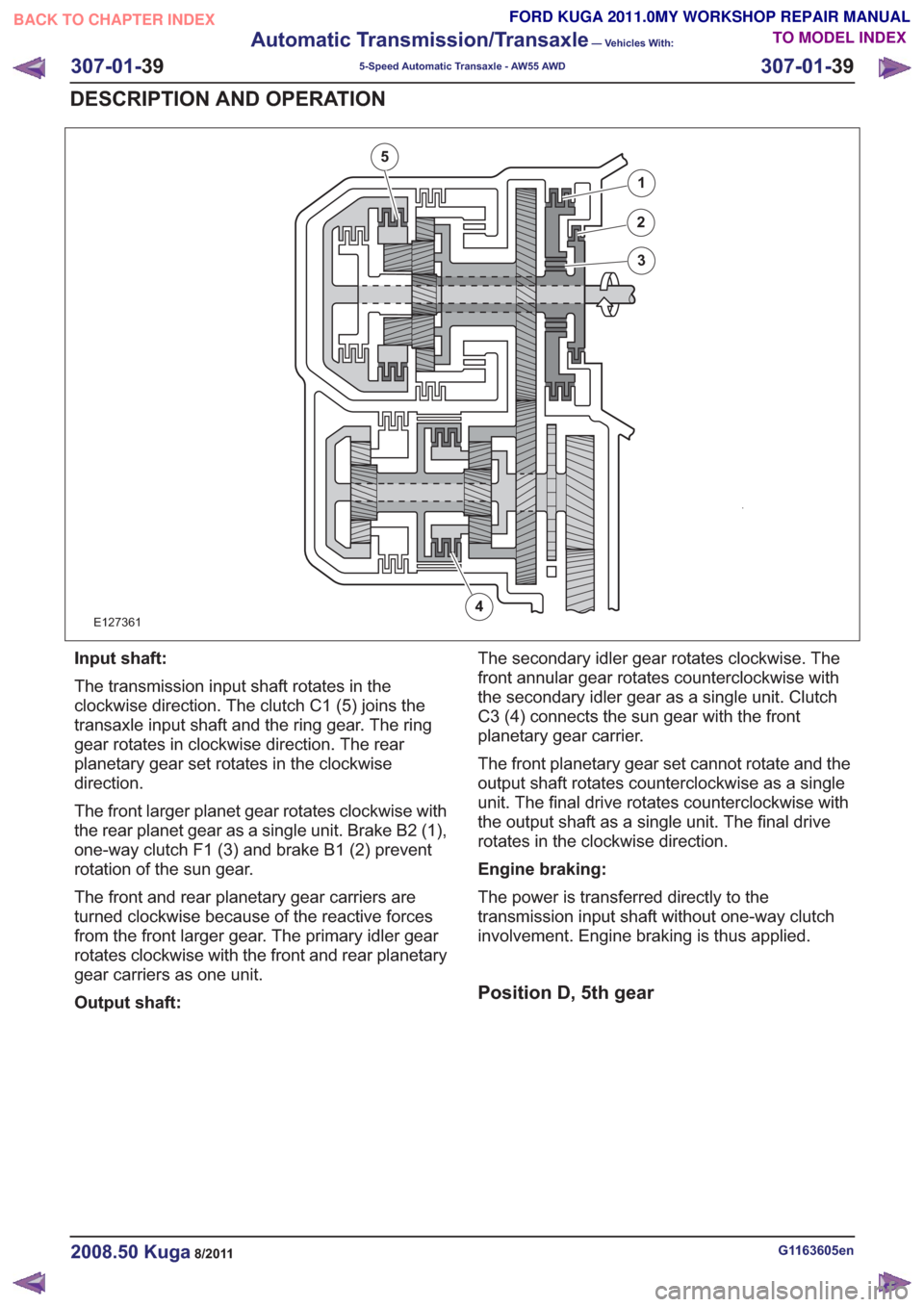

E127361

1

2

3

4

5

Input shaft:

The transmission input shaft rotates in the

clockwise direction. The clutch C1 (5) joins the

transaxle input shaft and the ring gear. The ring

gear rotates in clockwise direction. The rear

planetary gear set rotates in the clockwise

direction.

The front larger planet gear rotates clockwise with

the rear planet gear as a single unit. Brake B2 (1),

one-way clutch F1 (3) and brake B1 (2) prevent

rotation of the sun gear.

The front and rear planetary gear carriers are

turned clockwise because of the reactive forces

from the front larger gear. The primary idler gear

rotates clockwise with the front and rear planetary

gear carriers as one unit.

Output shaft:The secondary idler gear rotates clockwise. The

front annular gear rotates counterclockwise with

the secondary idler gear as a single unit. Clutch

C3 (4) connects the sun gear with the front

planetary gear carrier.

The front planetary gear set cannot rotate and the

output shaft rotates counterclockwise as a single

unit. The final drive rotates counterclockwise with

the output shaft as a single unit. The final drive

rotates in the clockwise direction.

Engine braking:

The power is transferred directly to the

transmission input shaft without one-way clutch

involvement. Engine braking is thus applied.

Position D, 5th gear

G1163605en2008.50 Kuga8/2011

307-01-

39

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 39

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1861 of 2057

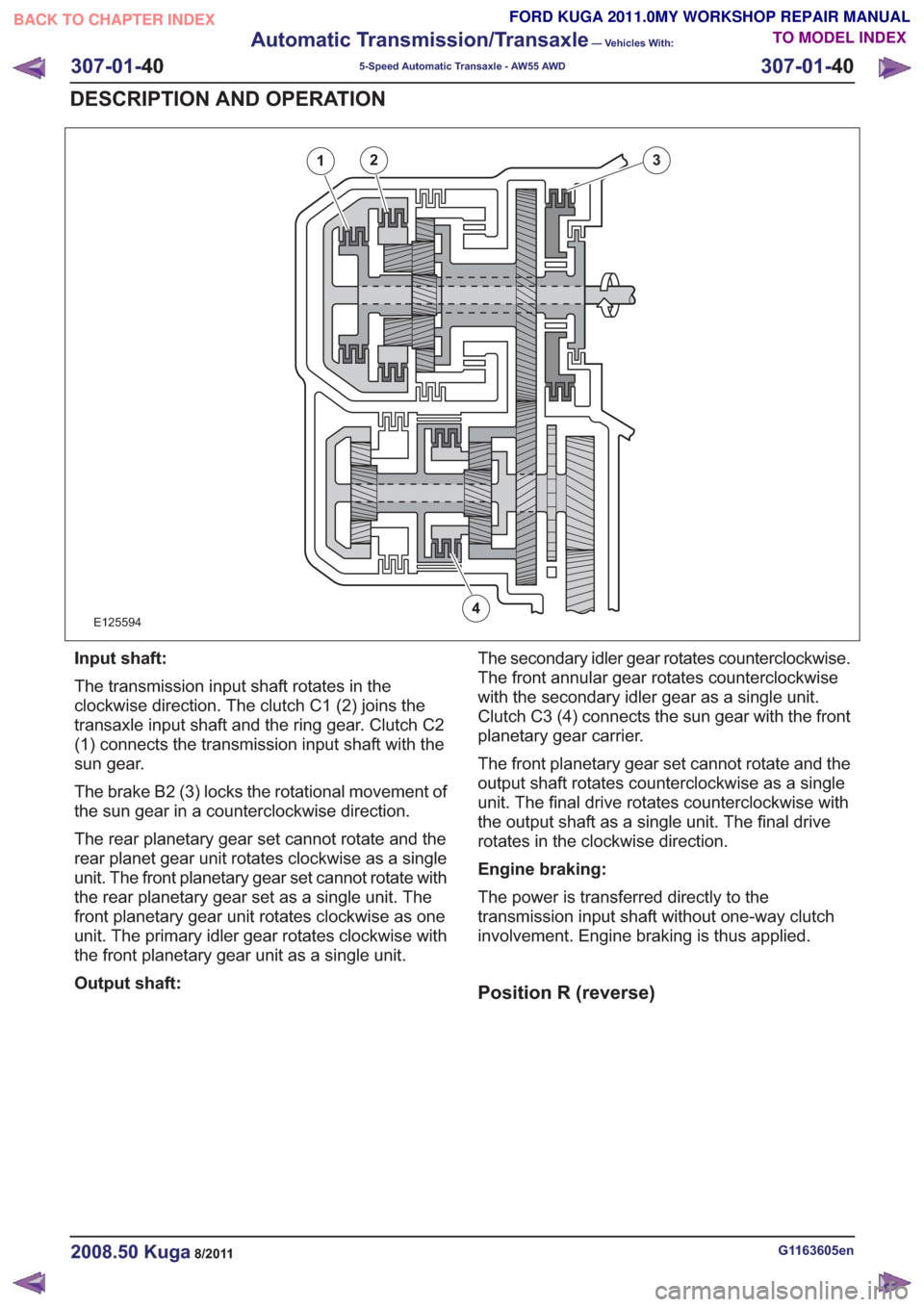

E125594

12

4

3

Input shaft:

The transmission input shaft rotates in the

clockwise direction. The clutch C1 (2) joins the

transaxle input shaft and the ring gear. Clutch C2

(1) connects the transmission input shaft with the

sun gear.

The brake B2 (3) locks the rotational movement of

the sun gear in a counterclockwise direction.

The rear planetary gear set cannot rotate and the

rear planet gear unit rotates clockwise as a single

unit. The front planetary gear set cannot rotate with

the rear planetary gear set as a single unit. The

front planetary gear unit rotates clockwise as one

unit. The primary idler gear rotates clockwise with

the front planetary gear unit as a single unit.

Output shaft:The secondary idler gear rotates counterclockwise.

The front annular gear rotates counterclockwise

with the secondary idler gear as a single unit.

Clutch C3 (4) connects the sun gear with the front

planetary gear carrier.

The front planetary gear set cannot rotate and the

output shaft rotates counterclockwise as a single

unit. The final drive rotates counterclockwise with

the output shaft as a single unit. The final drive

rotates in the clockwise direction.

Engine braking:

The power is transferred directly to the

transmission input shaft without one-way clutch

involvement. Engine braking is thus applied.

Position R (reverse)

G1163605en2008.50 Kuga8/2011

307-01-

40

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 40

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL