body FORD KUGA 2011 1.G Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1714 of 2057

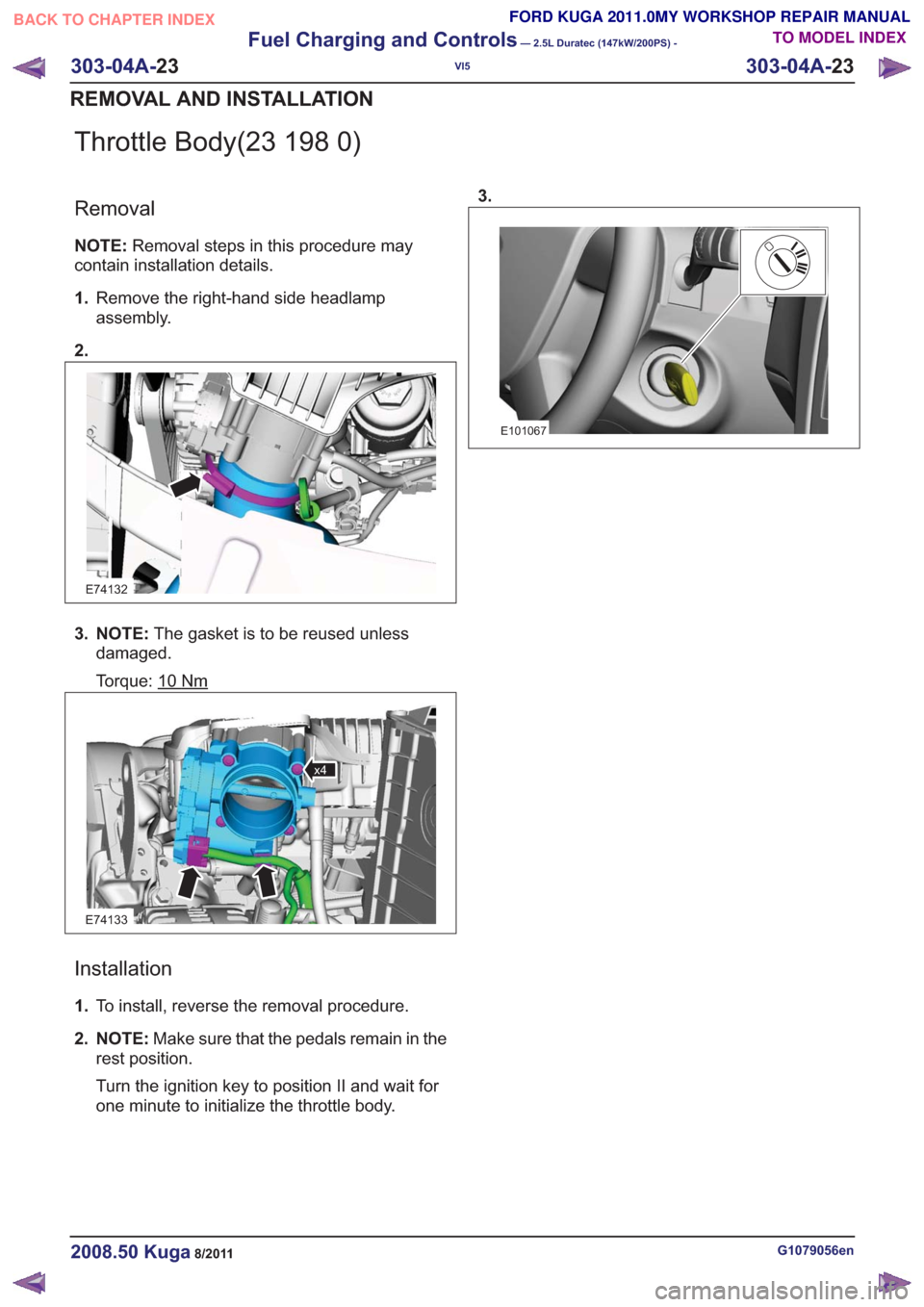

Throttle Body(23 198 0)

Removal

NOTE:Removal steps in this procedure may

contain installation details.

1. Remove the right-hand side headlamp

assembly.

2.

E74132

3. NOTE: The gasket is to be reused unless

damaged.

Torque: 10

Nm

E74133

x4

Installation

1. To install, reverse the removal procedure.

2. NOTE: Make sure that the pedals remain in the

rest position.

Turn the ignition key to position II and wait for

one minute to initialize the throttle body. 3.

E101067

G1079056en2008.50 Kuga8/2011

303-04A-

23

Fuel Charging and Controls

— 2.5L Duratec (147kW/200PS) -

VI5

303-04A- 23

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1727 of 2057

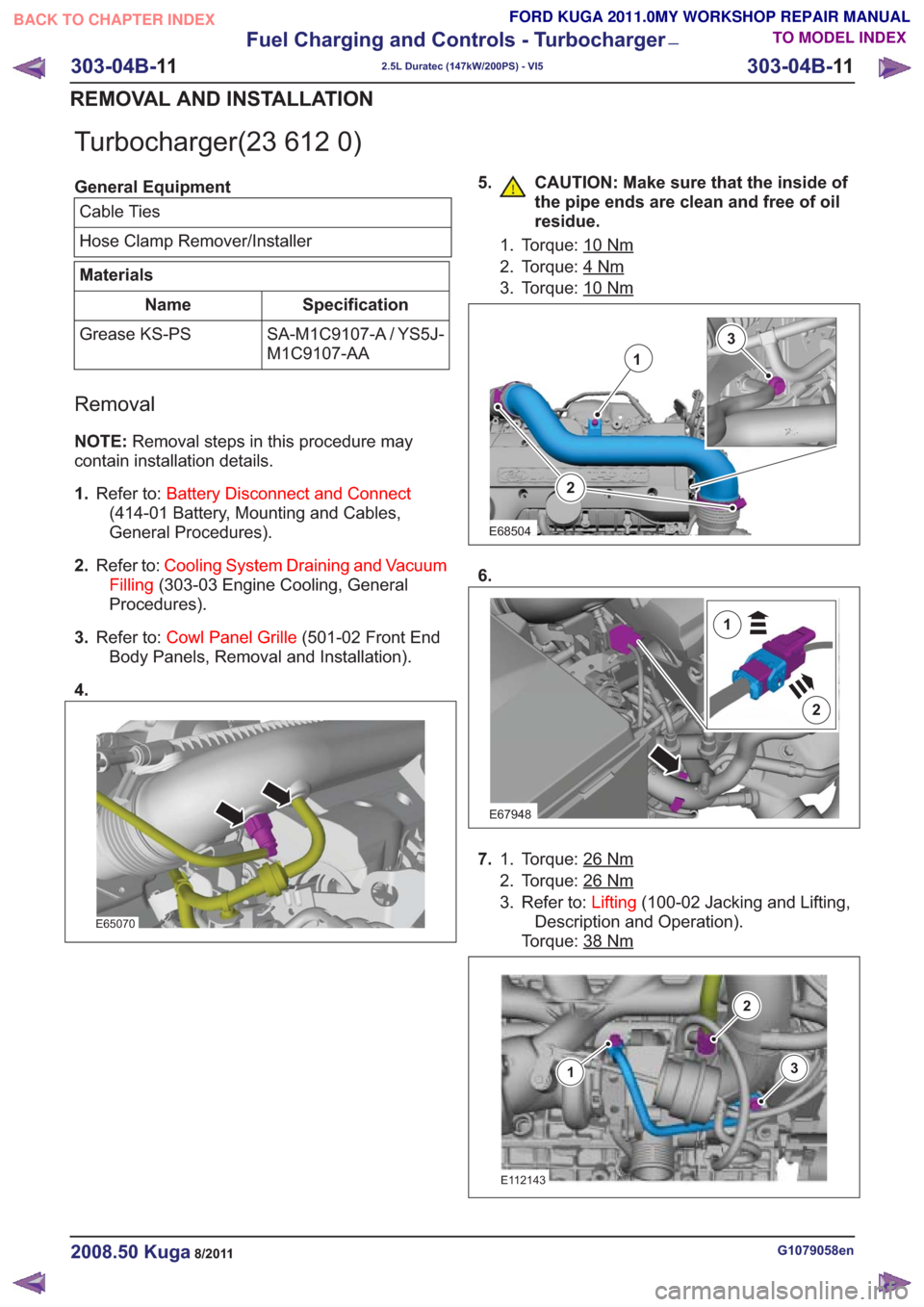

Turbocharger(23 612 0)

General EquipmentCable Ties

Hose Clamp Remover/Installer

Materials

Specification

Name

SA-M1C9107-A / YS5J-

M1C9107-AA

Grease KS-PS

Removal

NOTE:

Removal steps in this procedure may

contain installation details.

1. Refer to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

General Procedures).

2. Refer to: Cooling System Draining and Vacuum

Filling (303-03 Engine Cooling, General

Procedures).

3. Refer to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

4.

E65070

5. CAUTION: Make sure that the inside of the pipe ends are clean and free of oil

residue.

1. Torque: 10Nm

2. Torque: 4Nm

3. Torque: 10Nm

2

1

3

E68504

6.

E67948

2

1

7.Torque: 26Nm1.

2. Torque: 26

Nm

3. Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

Torque: 38

Nm

E112143

3

2

1

G1079058en2008.50 Kuga8/2011

303-04B- 11

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 11

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

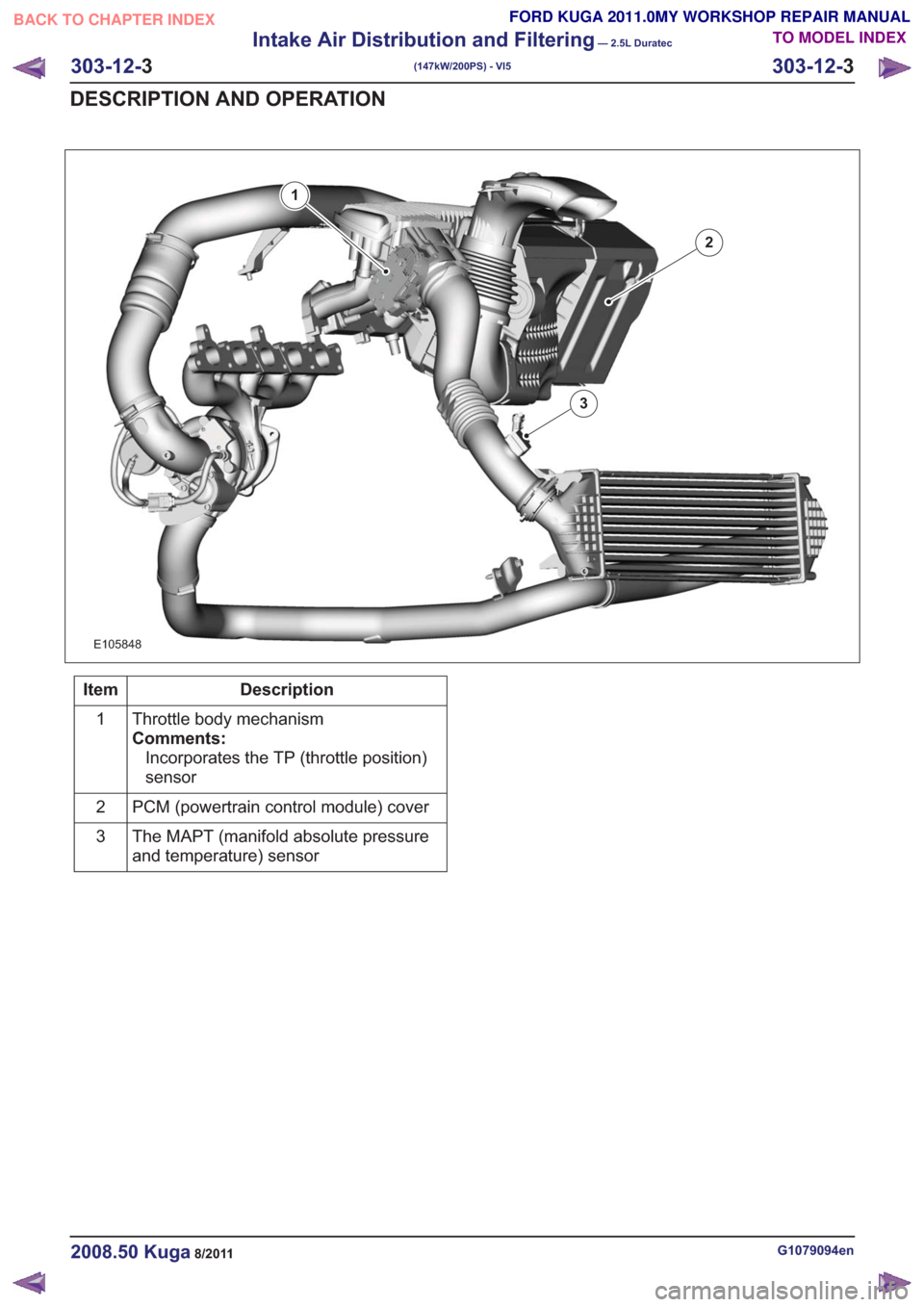

Page 1767 of 2057

E105848

1

2

3

Description

Item

Throttle body mechanism

Comments:Incorporates the TP (throttle position)

sensor

1

PCM (powertrain control module) cover

2

The MAPT (manifold absolute pressure

and temperature) sensor

3

G1079094en2008.50 Kuga8/2011

303-12-

3

Intake Air Distribution and Filtering

— 2.5L Duratec

(147kW/200PS) - VI5

303-12- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1817 of 2057

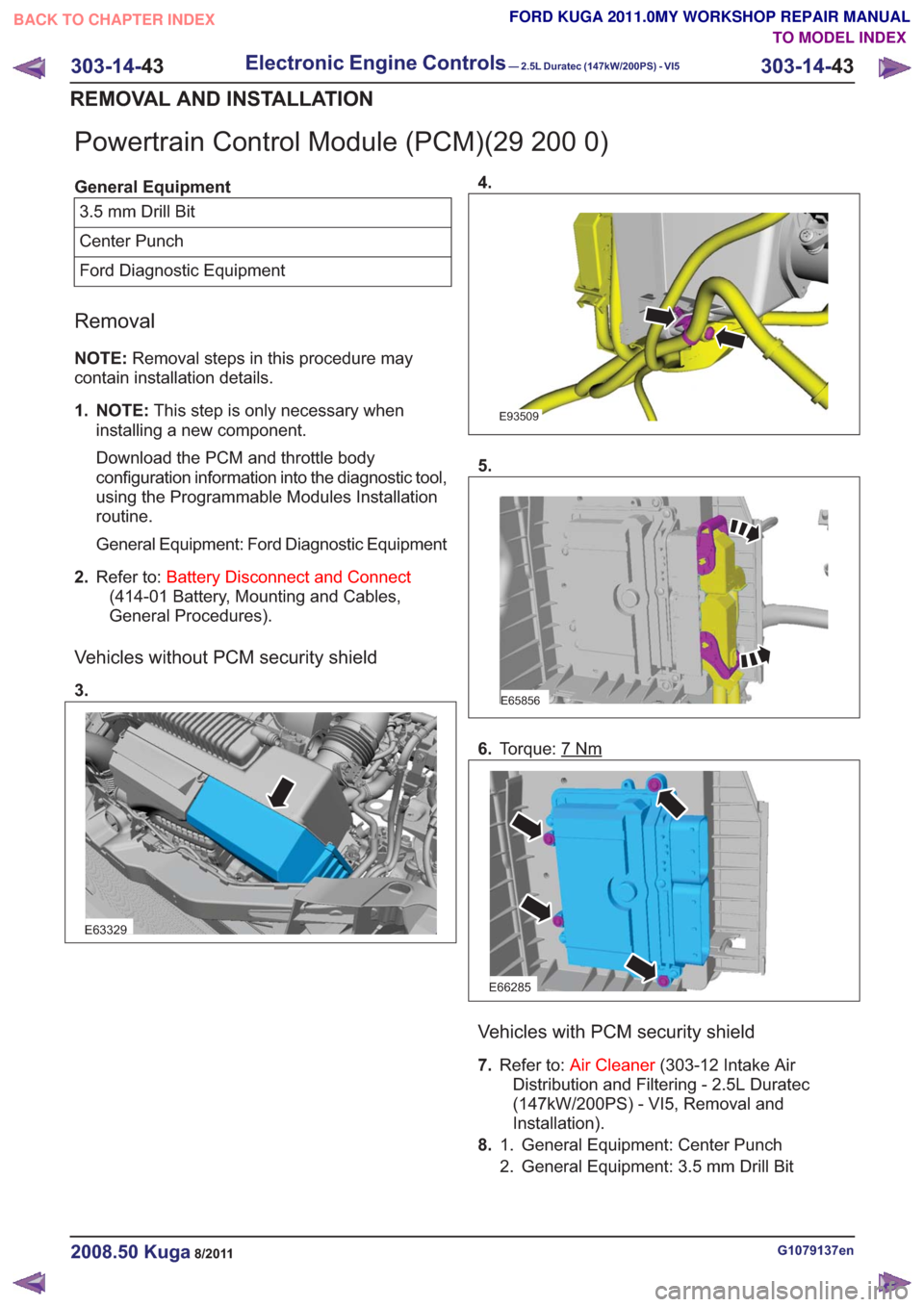

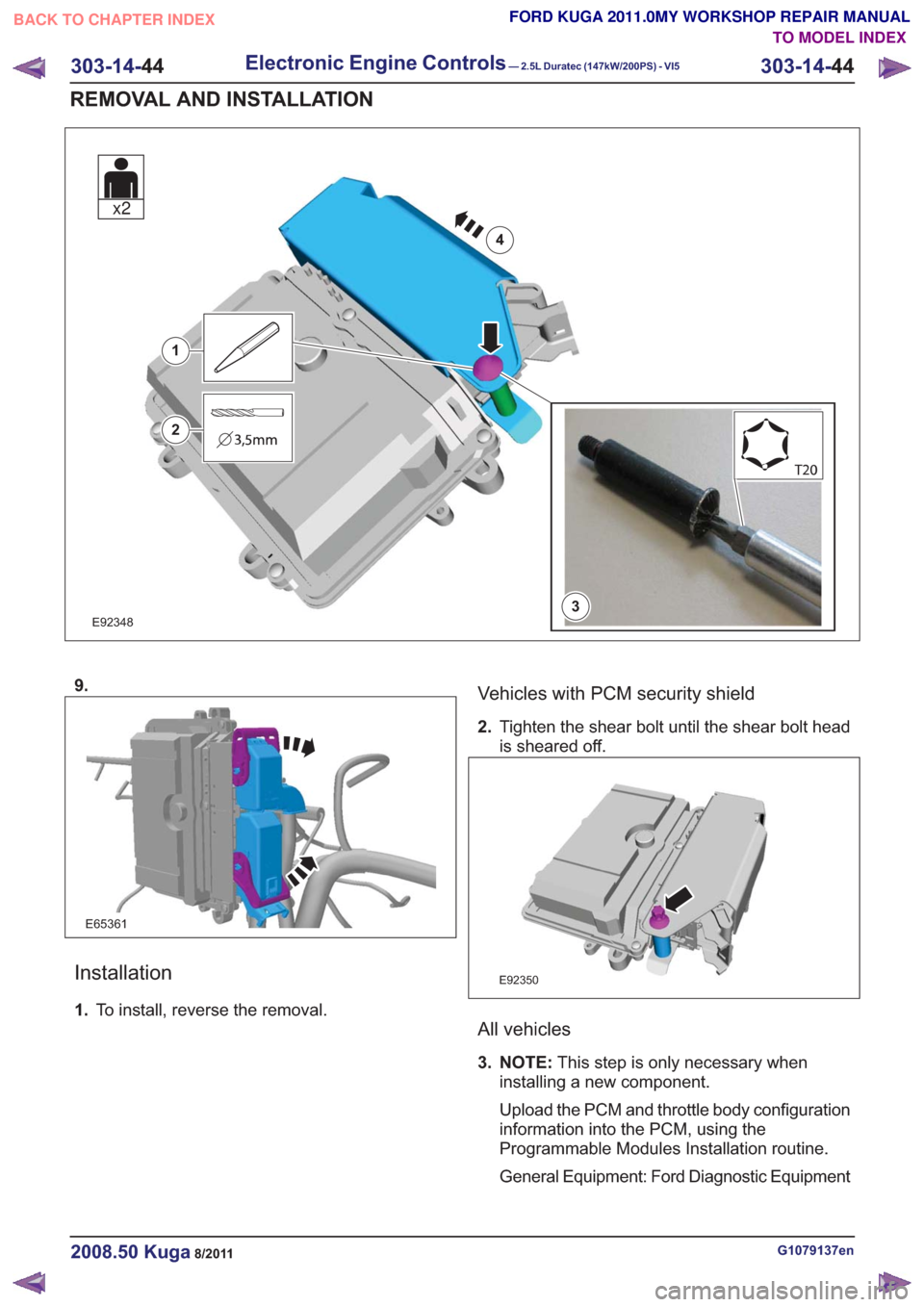

Powertrain Control Module (PCM)(29 200 0)

General Equipment3.5 mm Drill Bit

Center Punch

Ford Diagnostic Equipment

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. NOTE: This step is only necessary when

installing a new component.

Download the PCM and throttle body

configuration information into the diagnostic tool,

using the Programmable Modules Installation

routine.

General Equipment: Ford Diagnostic Equipment

2. Refer to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

General Procedures).

Vehicles without PCM security shield

3.

E63329

4.

E93509

5.

E65856

6. Torque: 7Nm

E66285

Vehicles with PCM security shield

7.Refer to: Air Cleaner (303-12 Intake Air

Distribution and Filtering - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

8. General Equipment: Center Punch

1.

2. General Equipment: 3.5 mm Drill Bit

G1079137en2008.50 Kuga8/2011

303-14- 43

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

43

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1818 of 2057

E923483

1

2

4

x2

9.

E65361

Installation

1.To install, reverse the removal.

Vehicles with PCM security shield

2.Tighten the shear bolt until the shear bolt head

is sheared off.

E92350

All vehicles

3. NOTE: This step is only necessary when

installing a new component.

Upload the PCM and throttle body configuration

information into the PCM, using the

Programmable Modules Installation routine.

General Equipment: Ford Diagnostic Equipment

G1079137en2008.50 Kuga8/2011

303-14- 44

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

44

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1823 of 2057

307-01-29

Automatic transmission, selector lever in position "D". ...................................................

307-01-29

Sport mode, selector lever in position "S" .......................................................................

307-01-29

Changing gear in select-shift mode........................................................................\

........

307-01-30

Selector lever from 'N' to 'R' position ........................................................................\

......

307-01-30

Self-test and Diagnosis ........................................................................\

...........................

307-01-30

Temperature controlled torque converter lockup ............................................................

307-01-30

Slip locking ........................................................................\

..............................................

307-01-30

Hill climbing ........................................................................\

.............................................

307-01-31

Downhill driving ........................................................................\

.......................................

307-01-31

Hill-hold function ........................................................................\

.....................................

307-01-31

Altitude correction ........................................................................\

...................................

307-01-31

Selector lever lock ........................................................................\

..................................

307-01-31

Shifting from P into another transmission range .............................................................

307-01-31

Shifting from N into another transmission range .............................................................

307-01-31

Power flow through the transmission ........................................................................\

......

307-01-31

Clutches and brakes ........................................................................\

...............................

307-01-33

Position P (park) ........................................................................\

.....................................

307-01-34

Position N (neutral) ........................................................................\

.................................

307-01-35

Position D, 1st gear........................................................................\

................................

307-01-36

Position D, 2nd gear ........................................................................\

...............................

307-01-37

Position D, 3rd gear ........................................................................\

................................

307-01-38

Position D, 4th gear ........................................................................\

................................

307-01-39

Position D, 5th gear ........................................................................\

................................

307-01-40

Position R (reverse) ........................................................................\

................................

307-01-41

Service instructions ........................................................................\

.................................

307-01-41

Towing procedure ........................................................................\

...................................

307-01-42

Reset adaptation data ........................................................................\

.............................

307-01-42

Limp home mode ........................................................................\

....................................

307-01-42

Component Description ........................................................................\

..............................

Tasks of the electronic components ........................................................................\

........

307-01-44

Input signals ........................................................................\

............................................

307-01-45

Output signals ........................................................................\

.........................................

Control valve assembly ........................................................................\

...........................

Shift solenoids S1 - S5 ........................................................................\

...........................

PWM-

solenoid valve – TCC (SLU) ........................................................................\

........

PWM solenoid valve – shift pressure (SLS) ...................................................................

PWM solenoid valve for main line pressure (SLT) ..........................................................

307-01-52

Installation position ........................................................................\

.................................

Operation ........................................................................\

................................................

Selector lever with integrated select-shift switch module ...............................................

Oil pump ........................................................................\

..................................................

Torque converter with TCC ........................................................................\

.....................

The TSS sensor ........................................................................\

......................................

The OSS sensor ........................................................................\

.....................................

The TFT sensor ........................................................................\

......................................

The TR sensor ........................................................................\

........................................

GENERAL PROCEDURES

T ransmission Fluid Level Check ........................................................................\

.................

307-01-63

T ransmission Fluid Drain and Refill ........................................................................\

............

REMOVAL AND INSTALLATION 307-01-67

Halfshaft Seal LH ........................................................................\

........................................

307-01-68

Halfshaft Seal RH........................................................................\

.......................................

307-01-69

Main Control Valve Body ........................................................................\

............................

307-01-2

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 2

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

307-01-42

307-01-49

307-01-52 307-01-47

307-01-45

307-01-50

307-01-51

307-01-53

307-01-55

307-01-54

307-01-56

307-01-57

307-01-58

307-01-61 307-01-60

PAGE 2 OF 3 FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1831 of 2057

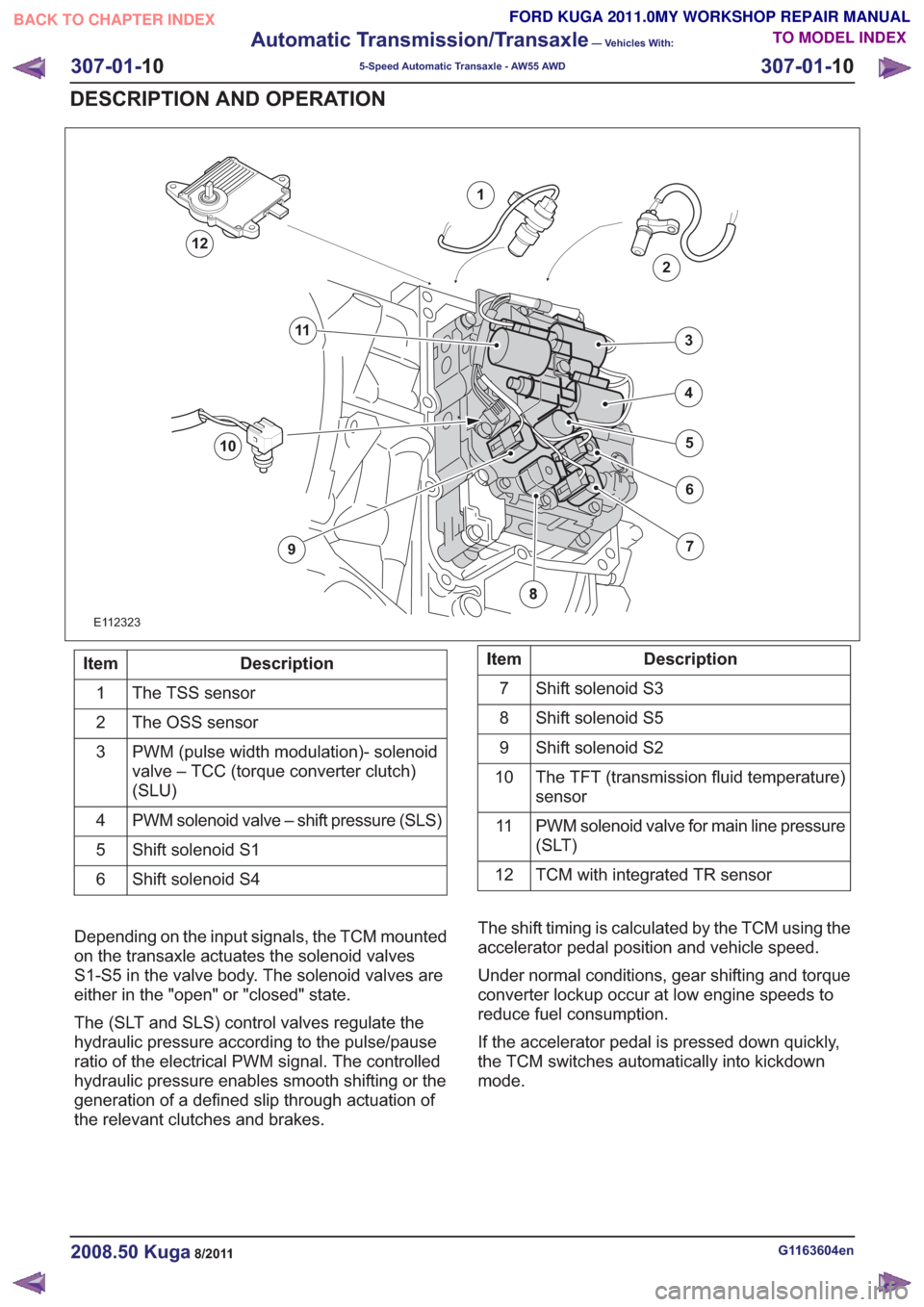

E112323

1

2

7

6

4

5

3

10

9

11

12

Description

Item

The TSS sensor

1

The OSS sensor

2

PWM (pulse width modulation)- solenoid

valve – TCC (torque converter clutch)

(SLU)

3

PWM solenoid valve – shift pressure (SLS)

4

Shift solenoid S1

5

Shift solenoid S4

6Description

Item

Shift solenoid S3

7

Shift solenoid S5

8

Shift solenoid S2

9

The TFT (transmission fluid temperature)

sensor

10

PWM solenoid valve for main line pressure

(SLT)

11

TCM with integrated TR sensor

12

Depending on the input signals, the TCM mounted

on the transaxle actuates the solenoid valves

S1-S5 in the valve body. The solenoid valves are

either in the "open" or "closed" state.

The (SLT and SLS) control valves regulate the

hydraulic pressure according to the pulse/pause

ratio of the electrical PWM signal. The controlled

hydraulic pressure enables smooth shifting or the

generation of a defined slip through actuation of

the relevant clutches and brakes. The shift timing is calculated by the TCM using the

accelerator pedal position and vehicle speed.

Under normal conditions, gear shifting and torque

converter lockup occur at low engine speeds to

reduce fuel consumption.

If the accelerator pedal is pressed down quickly,

the TCM switches automatically into kickdown

mode.

G1163604en2008.50 Kuga8/2011

307-01-

10

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1845 of 2057

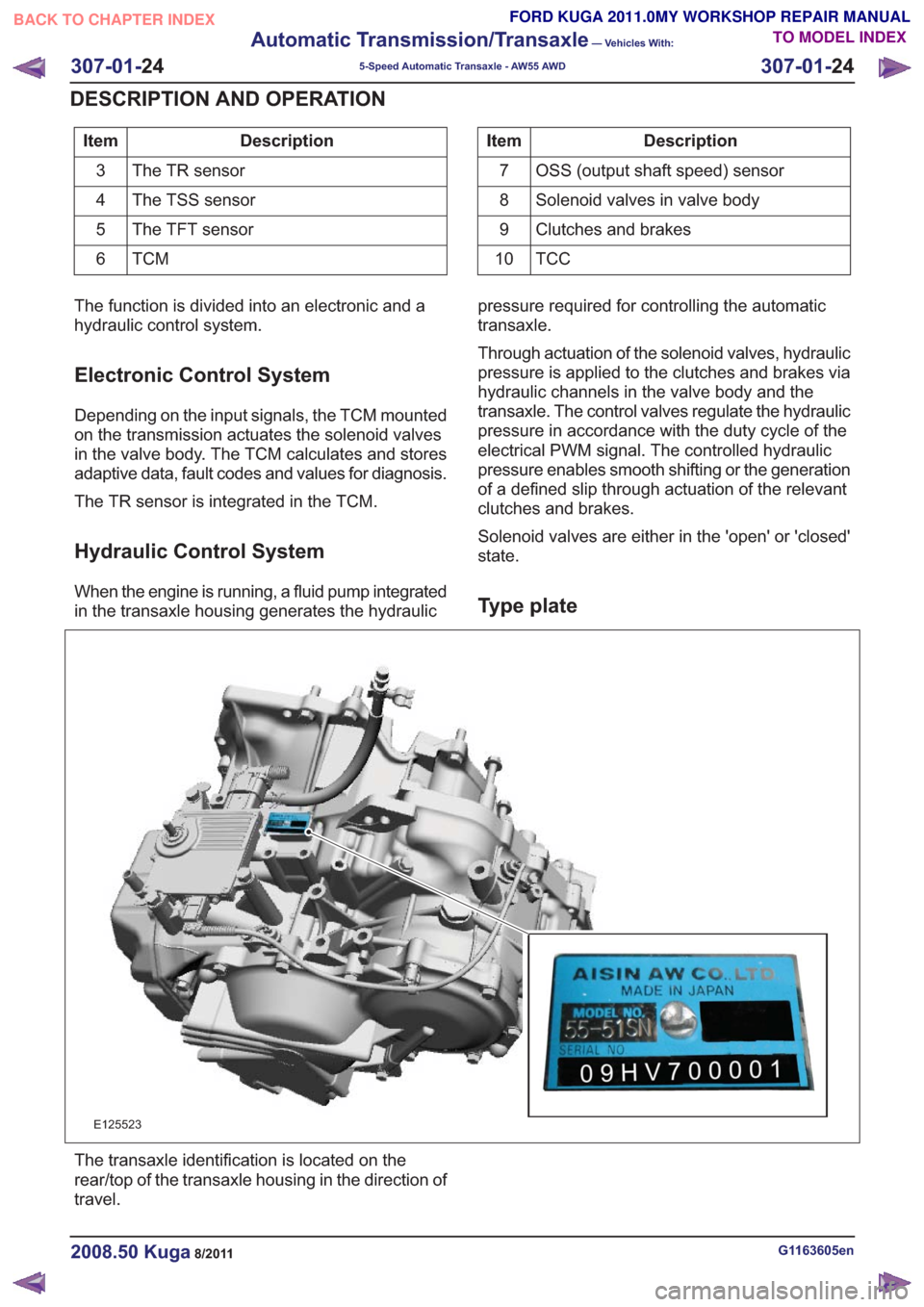

Description

Item

The TR sensor

3

The TSS sensor

4

The TFT sensor

5

TCM6Description

Item

OSS (output shaft speed) sensor

7

Solenoid valves in valve body

8

Clutches and brakes

9

TCC

10

The function is divided into an electronic and a

hydraulic control system.

Electronic Control System

Depending on the input signals, the TCM mounted

on the transmission actuates the solenoid valves

in the valve body. The TCM calculates and stores

adaptive data, fault codes and values for diagnosis.

The TR sensor is integrated in the TCM.

Hydraulic Control System

When the engine is running, a fluid pump integrated

in the transaxle housing generates the hydraulic pressure required for controlling the automatic

transaxle.

Through actuation of the solenoid valves, hydraulic

pressure is applied to the clutches and brakes via

hydraulic channels in the valve body and the

transaxle. The control valves regulate the hydraulic

pressure in accordance with the duty cycle of the

electrical PWM signal. The controlled hydraulic

pressure enables smooth shifting or the generation

of a defined slip through actuation of the relevant

clutches and brakes.

Solenoid valves are either in the 'open' or 'closed'

state.Type plate

E125523

The transaxle identification is located on the

rear/top of the transaxle housing in the direction of

travel.

G1163605en2008.50 Kuga8/2011

307-01-

24

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 24

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1846 of 2057

Serial number of the transmission

Example:09HV70001

• 09: year of manufacture, 2009 •

H: code letter for the month of manufacture,

August

• V7: automatic transaxle type 55-51SN

• 00001 : Production number for the specified

month

Identification letter coding

January

A

February

B

March

C

April

D

May

E

June

F

July

G

August

H.

September

J

October

K

November

left-hand

December

Ground

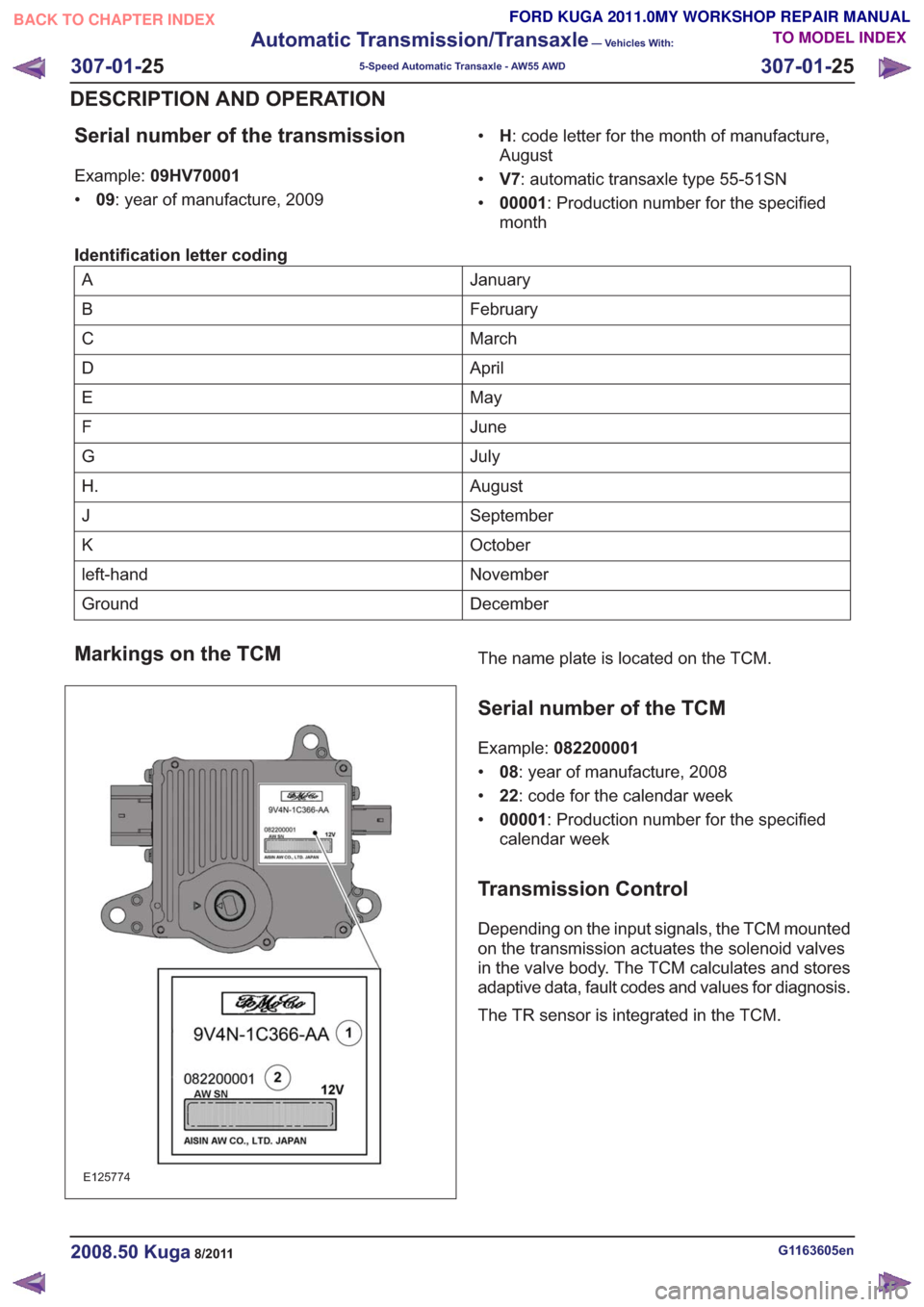

Markings on the TCM

E125774

The name plate is located on the TCM.

Serial number of the TCM

Example: 082200001

• 08: year of manufacture, 2008

• 22: code for the calendar week

• 00001 : Production number for the specified

calendar week

Transmission Control

Depending on the input signals, the TCM mounted

on the transmission actuates the solenoid valves

in the valve body. The TCM calculates and stores

adaptive data, fault codes and values for diagnosis.

The TR sensor is integrated in the TCM.

G1163605en2008.50 Kuga8/2011

307-01- 25

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 25

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1849 of 2057

21

22 20 19

15 14 13

161718 12

876

9

10

11 5

3

42121

22 20 19

15 14 13

161718 12

876

9

10

11 5

3

421

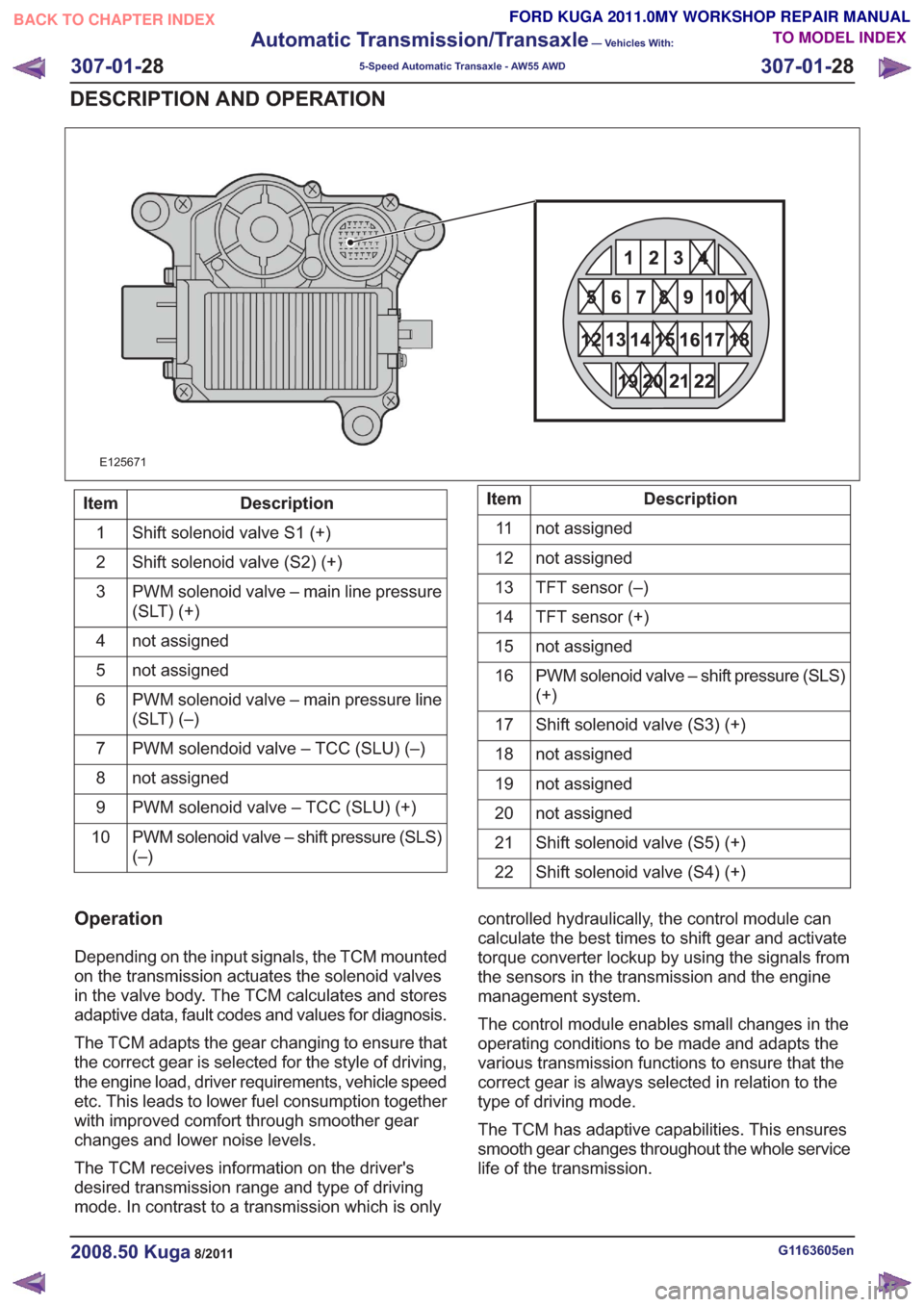

E125671

Description

Item

Shift solenoid valve S1 (+)

1

Shift solenoid valve (S2) (+)

2

PWM solenoid valve – main line pressure

(SLT) (+)

3

not assigned

4

not assigned

5

PWM solenoid valve – main pressure line

(SLT) (–)

6

PWM solendoid valve – TCC (SLU) (–)

7

not assigned

8

PWM solenoid valve – TCC (SLU) (+)

9

PWM solenoid valve – shift pressure (SLS)

(–)

10Description

Item

not assigned

11

not assigned

12

TFT sensor (–)

13

TFT sensor (+)

14

not assigned

15

PWM solenoid valve – shift pressure (SLS)

(+)

16

Shift solenoid valve (S3) (+)

17

not assigned

18

not assigned

19

not assigned

20

Shift solenoid valve (S5) (+)

21

Shift solenoid valve (S4) (+)

22

Operation

Depending on the input signals, the TCM mounted

on the transmission actuates the solenoid valves

in the valve body. The TCM calculates and stores

adaptive data, fault codes and values for diagnosis.

The TCM adapts the gear changing to ensure that

the correct gear is selected for the style of driving,

the engine load, driver requirements, vehicle speed

etc. This leads to lower fuel consumption together

with improved comfort through smoother gear

changes and lower noise levels.

The TCM receives information on the driver's

desired transmission range and type of driving

mode. In contrast to a transmission which is only controlled hydraulically, the control module can

calculate the best times to shift gear and activate

torque converter lockup by using the signals from

the sensors in the transmission and the engine

management system.

The control module enables small changes in the

operating conditions to be made and adapts the

various transmission functions to ensure that the

correct gear is always selected in relation to the

type of driving mode.

The TCM has adaptive capabilities. This ensures

smooth gear changes throughout the whole service

life of the transmission.

G1163605en2008.50 Kuga8/2011

307-01-

28

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 28

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL