body FORD KUGA 2011 1.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 135 of 2057

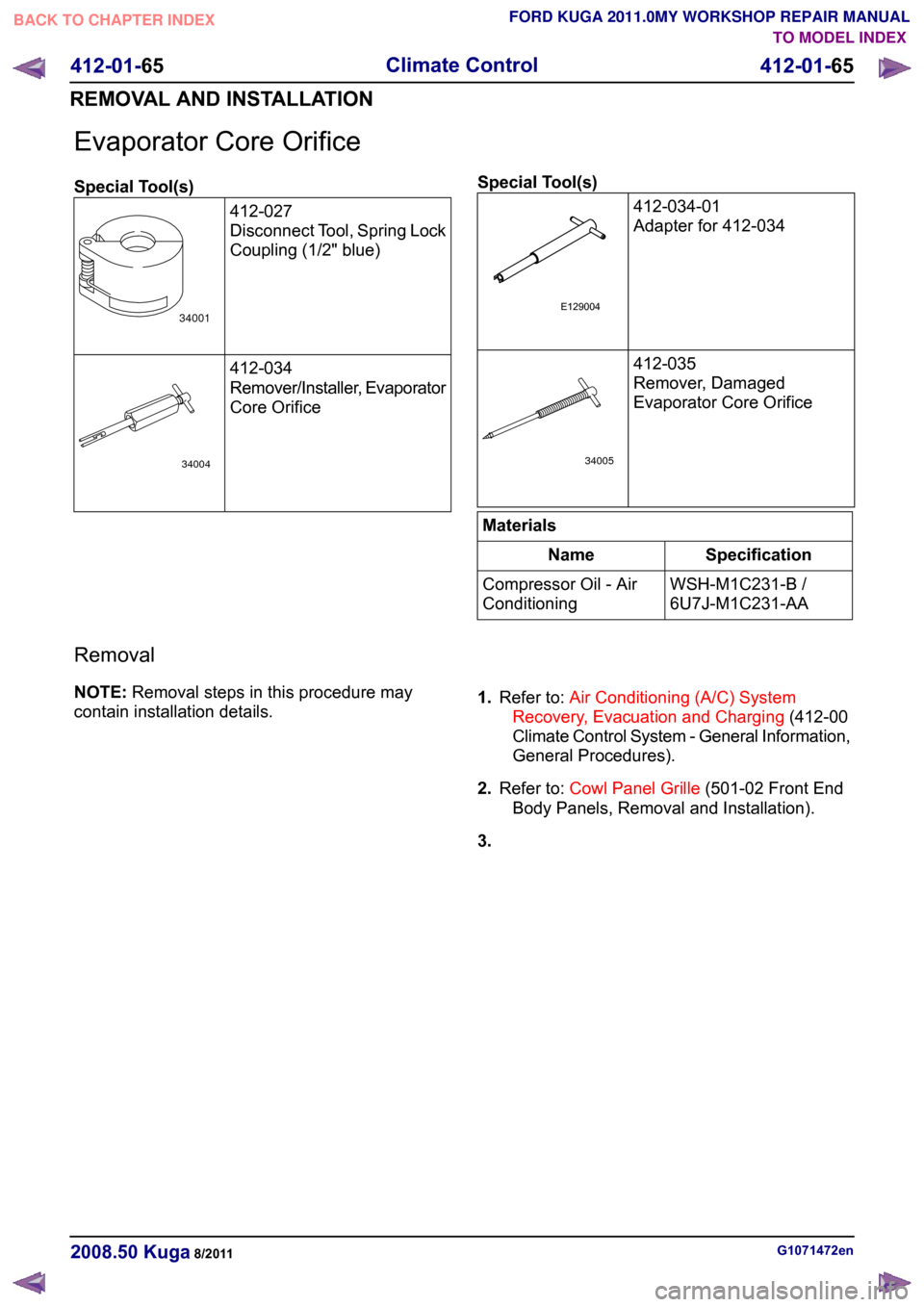

Evaporator Core Orifice

Special Tool(s)

412-027

Disconnect Tool, Spring Lock

Coupling (1/2" blue) 412-034

Remover/Installer, Evaporator

Core Orifice Special Tool(s)

412-034-01

Adapter for 412-034 412-035

Remover, Damaged

Evaporator Core Orifice

Materials

Specification

Name

WSH-M1C231-B /

6U7J-M1C231-AA

Compressor Oil - Air

Conditioning

Removal

NOTE: Removal steps in this procedure may

contain installation details. 1.

Refer to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging (412-00

Climate Control System - General Information,

General Procedures).

2. Refer to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

3. G1071472en

2008.50 Kuga 8/2011 412-01-65

Climate Control

412-01-65

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL34001 34004 E129004 34005

Page 183 of 2057

Instrument Cluster and Panel Illumination

Refer to

Wiring Diagrams Section 413-00, for

schematic and connector information.

Principles of Operation

NOTE: A new instrument cluster must be

configured.

The instrument cluster and panel illumination

consists of dimmable and non-dimmable

illumination. The dimmable panel illumination is

controlled by the panel illumination switch (part of

the headlamp switch), which allows the brightness

level of the backlights to be adjusted dependent

on the customer preference. When the headlamp

switch is in the parking lamps ON or headlamps

ON position, the intensity of the backlighting can

be adjusted using the panel dimmer switch. The

non dimmable illumination allows for full intensity

dependant on the ignition switch position.

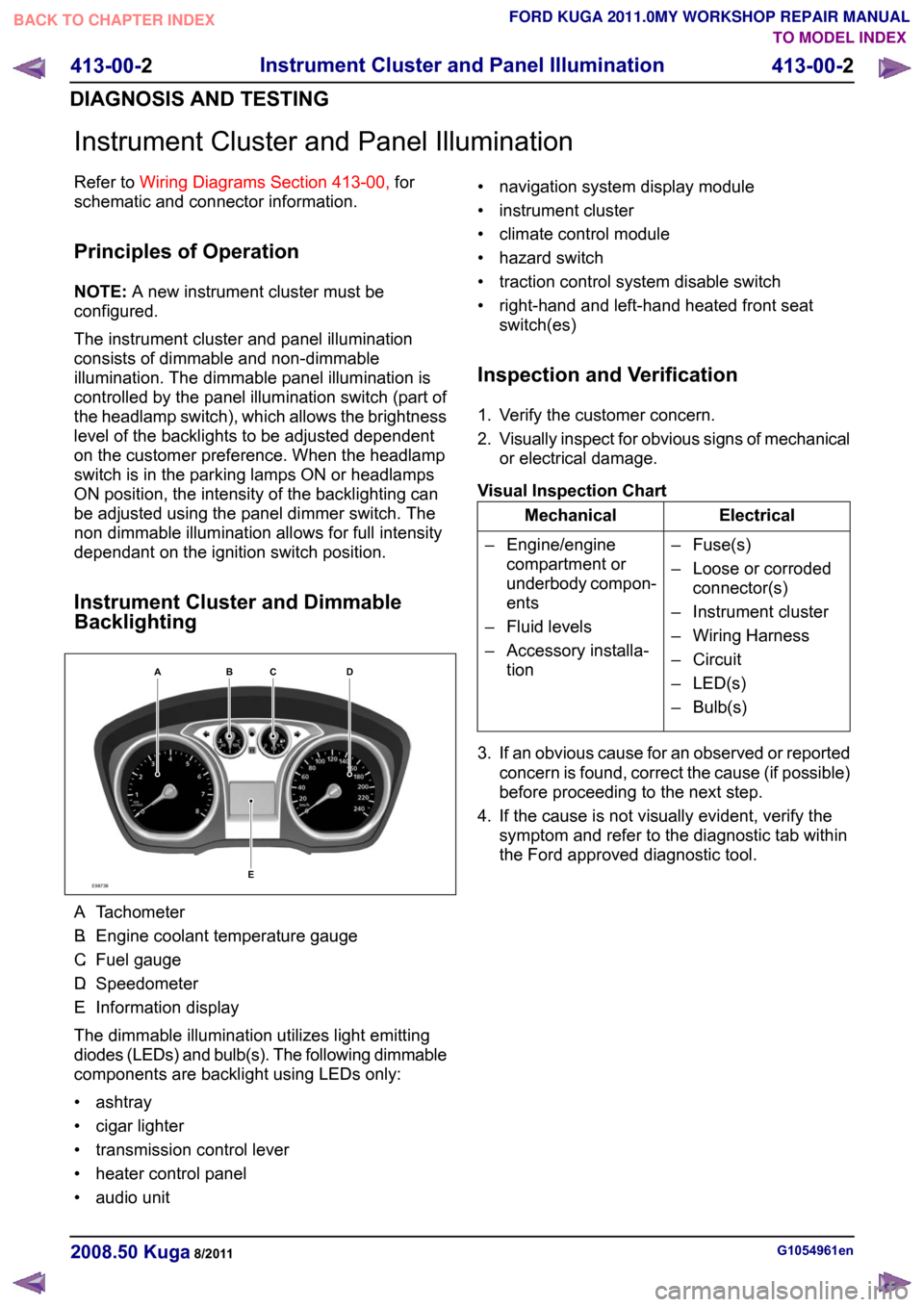

Instrument Cluster and Dimmable

Backlighting A.

Tachometer

B. Engine coolant temperature gauge

C. Fuel gauge

D. Speedometer

E. Information display

The dimmable illumination utilizes light emitting

diodes (LEDs) and bulb(s). The following dimmable

components are backlight using LEDs only:

• ashtray

• cigar lighter

• transmission control lever

• heater control panel

• audio unit • navigation system display module

• instrument cluster

• climate control module

• hazard switch

• traction control system disable switch

• right-hand and left-hand heated front seat

switch(es)

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Visual Inspection Chart Electrical

Mechanical

– Fuse(s)

– Loose or corrodedconnector(s)

– Instrument cluster

– Wiring Harness

– Circuit

– LED(s)

– Bulb(s)

– Engine/engine

compartment or

underbody compon-

ents

– Fluid levels

– Accessory installa- tion

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool. G1054961en

2008.50 Kuga 8/2011 413-00-2

Instrument Cluster and Panel Illumination

413-00-2

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE98738ABCED

Page 214 of 2057

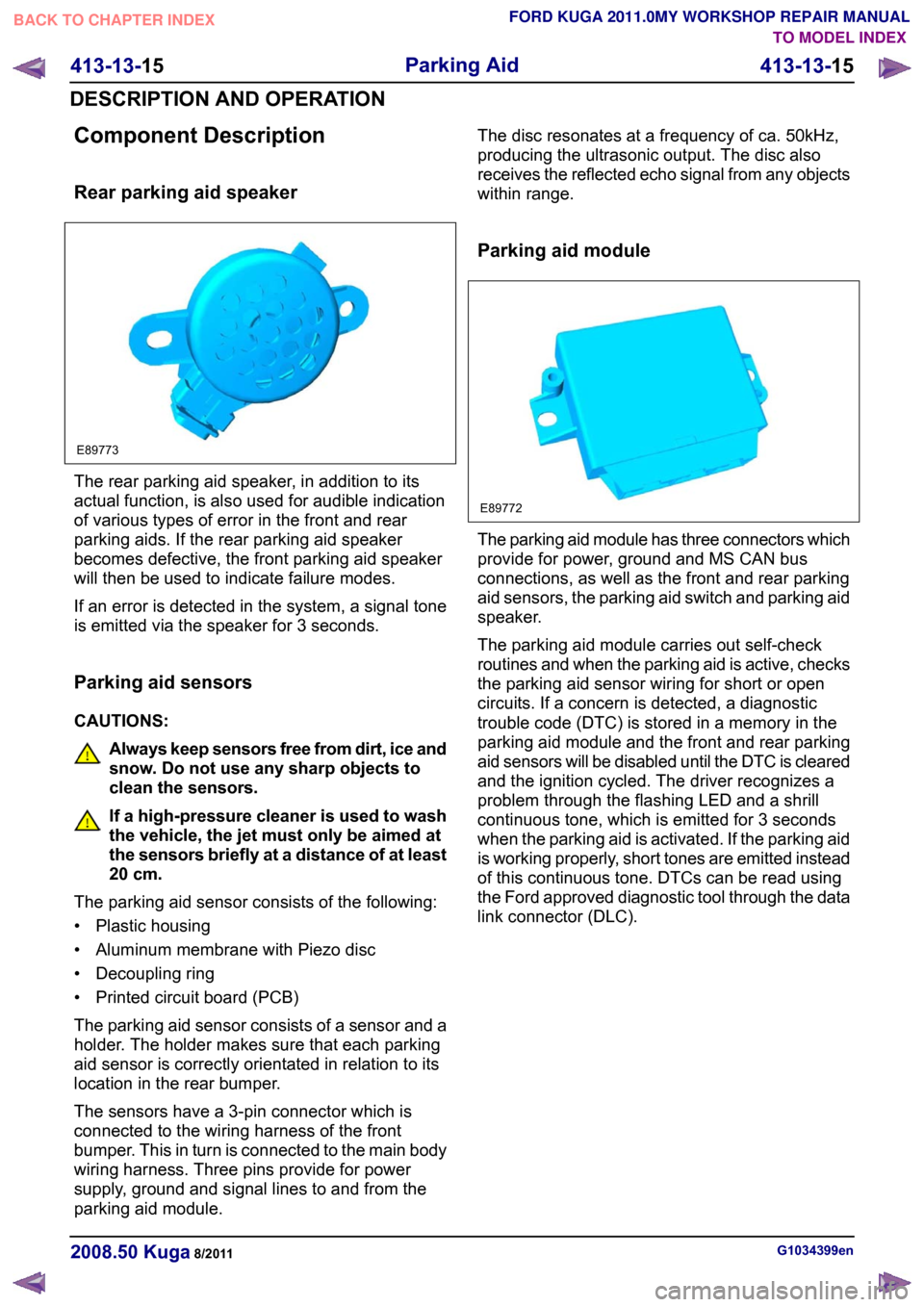

Component Description

Rear parking aid speaker

The rear parking aid speaker, in addition to its

actual function, is also used for audible indication

of various types of error in the front and rear

parking aids. If the rear parking aid speaker

becomes defective, the front parking aid speaker

will then be used to indicate failure modes.

If an error is detected in the system, a signal tone

is emitted via the speaker for 3 seconds.

Parking aid sensors

CAUTIONS:

Always keep sensors free from dirt, ice and

snow. Do not use any sharp objects to

clean the sensors.

If a high-pressure cleaner is used to wash

the vehicle, the jet must only be aimed at

the sensors briefly at a distance of at least

20 cm.

The parking aid sensor consists of the following:

• Plastic housing

• Aluminum membrane with Piezo disc

• Decoupling ring

• Printed circuit board (PCB)

The parking aid sensor consists of a sensor and a

holder. The holder makes sure that each parking

aid sensor is correctly orientated in relation to its

location in the rear bumper.

The sensors have a 3-pin connector which is

connected to the wiring harness of the front

bumper. This in turn is connected to the main body

wiring harness. Three pins provide for power

supply, ground and signal lines to and from the

parking aid module. The disc resonates at a frequency of ca. 50kHz,

producing the ultrasonic output. The disc also

receives the reflected echo signal from any objects

within range.

Parking aid module

The parking aid module has three connectors which

provide for power, ground and MS CAN bus

connections, as well as the front and rear parking

aid sensors, the parking aid switch and parking aid

speaker.

The parking aid module carries out self-check

routines and when the parking aid is active, checks

the parking aid sensor wiring for short or open

circuits. If a concern is detected, a diagnostic

trouble code (DTC) is stored in a memory in the

parking aid module and the front and rear parking

aid sensors will be disabled until the DTC is cleared

and the ignition cycled. The driver recognizes a

problem through the flashing LED and a shrill

continuous tone, which is emitted for 3 seconds

when the parking aid is activated. If the parking aid

is working properly, short tones are emitted instead

of this continuous tone. DTCs can be read using

the Ford approved diagnostic tool through the data

link connector (DLC).

G1034399en

2008.50 Kuga 8/2011 413-13-15

Parking Aid

413-13-15

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE89773 E89772

Page 332 of 2057

Position the spring in the correct position (on

both sides) for the vehicle body style. 2. NOTE:

This step is only necessary when

installing a new component.

Remove the CD changer transportation retaining

clips. 3.

To install, reverse the removal procedure.

4. NOTE: This step is only necessary when

installing a new component.

Configure the CD changer by selecting the

Programmable Module Installation Routine.

General Equipment: Ford Diagnostic Equipment G1065585en

2008.50 Kuga 8/2011 415-01-36

Information and Entertainment System

415-01-36

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL12E91627 E91630

Page 426 of 2057

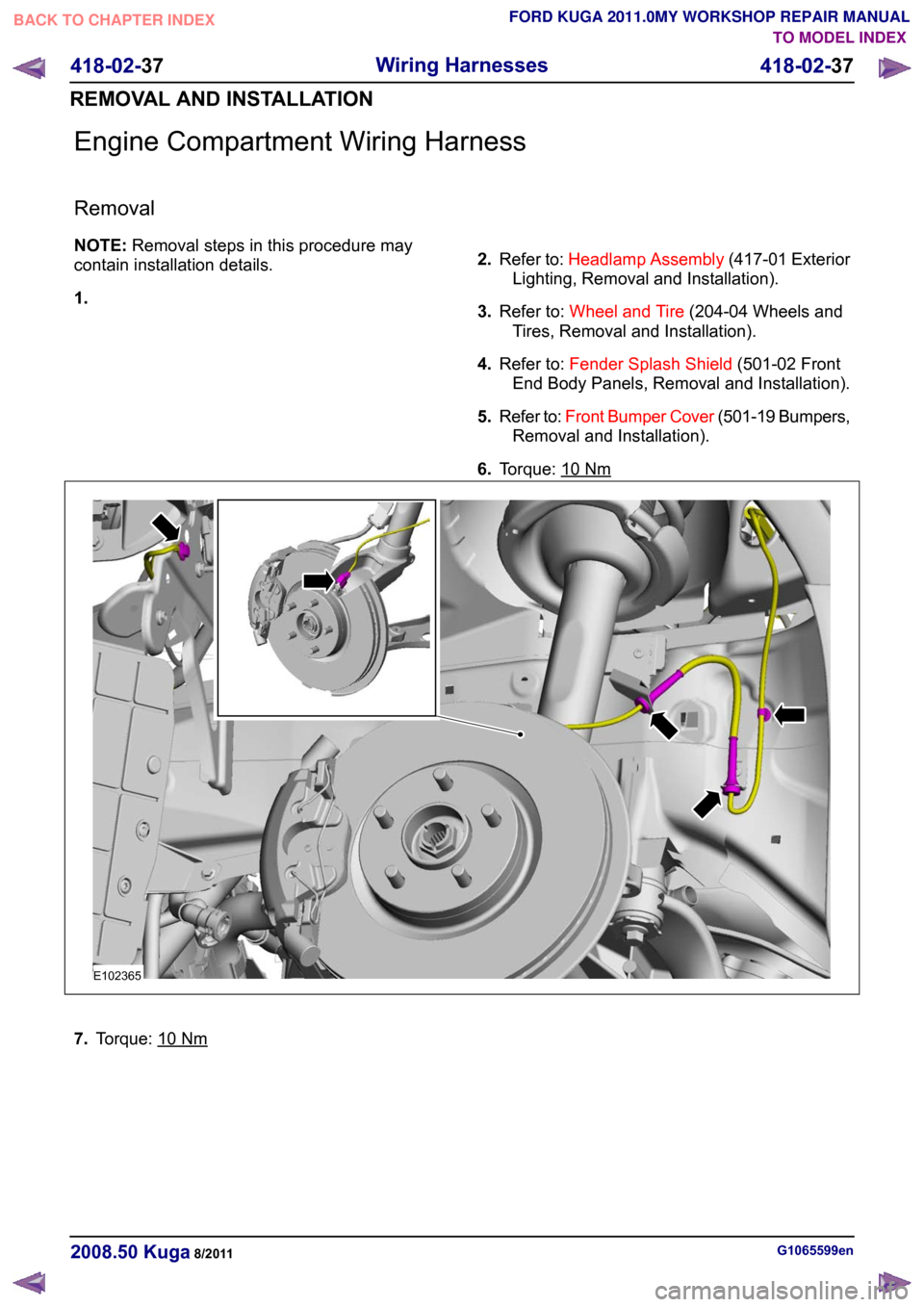

Engine Compartment Wiring Harness

Removal

NOTE:

Removal steps in this procedure may

contain installation details.

1. 2.

Refer to: Headlamp Assembly (417-01 Exterior

Lighting, Removal and Installation).

3. Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

4. Refer to: Fender Splash Shield (501-02 Front

End Body Panels, Removal and Installation).

5. Refer to: Front Bumper Cover (501-19 Bumpers,

Removal and Installation).

6. Torque: 10 Nm

7.

Torque: 10 Nm

G1065599en

2008.50 Kuga 8/2011 418-02-37

Wiring Harnesses

418-02-37

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE102365

Page 443 of 2057

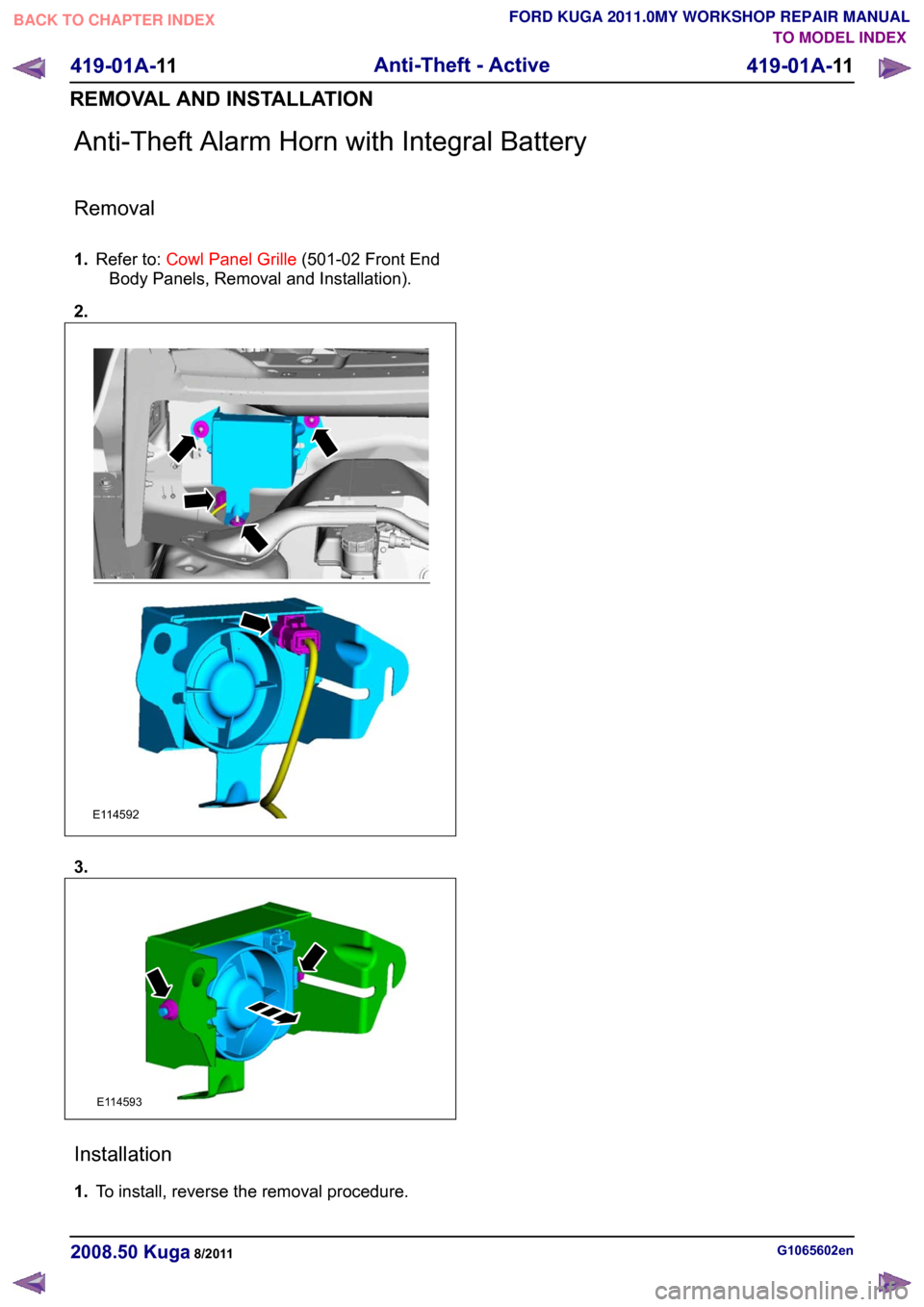

Anti-Theft Alarm Horn with Integral Battery

Removal

1.

Refer to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

2. 3.

Installation

1.

To install, reverse the removal procedure. G1065602en

2008.50 Kuga 8/2011 419-01A-11

Anti-Theft - Active

419-01A-11

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE114592 E114593

Page 1177 of 2057

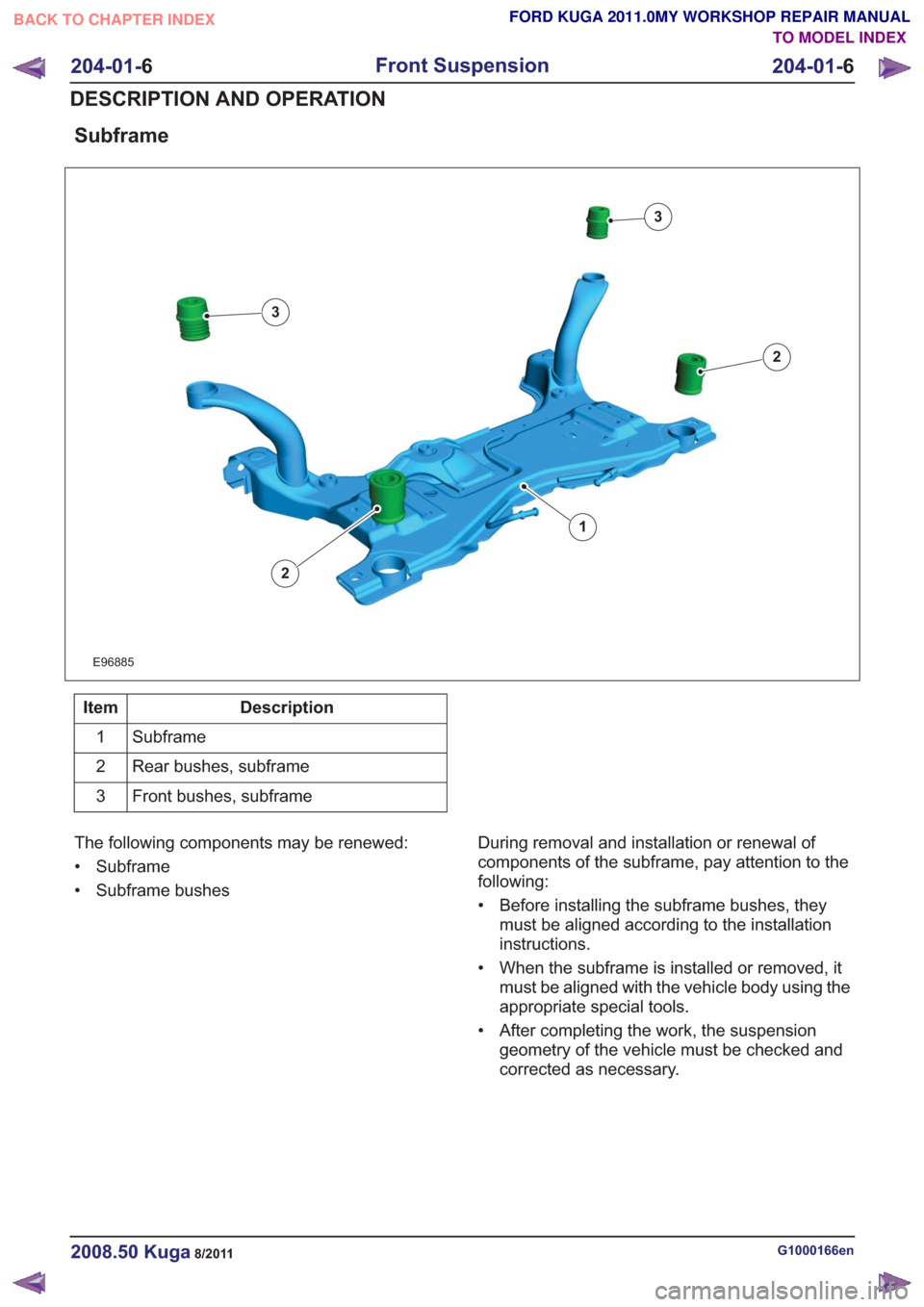

Subframe

E96885

1

2

2

3

3

Description

Item

Subframe

1

Rear bushes, subframe

2

Front bushes, subframe

3

The following components may be renewed:

• Subframe

• Subframe bushes During removal and installation or renewal of

components of the subframe, pay attention to the

following:

• Before installing the subframe bushes, they

must be aligned according to the installation

instructions.

• When the subframe is installed or removed, it must be aligned with the vehicle body using the

appropriate special tools.

• After completing the work, the suspension geometry of the vehicle must be checked and

corrected as necessary.

G1000166en2008.50 Kuga8/2011

204-01- 6

Front Suspension

204-01- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1197 of 2057

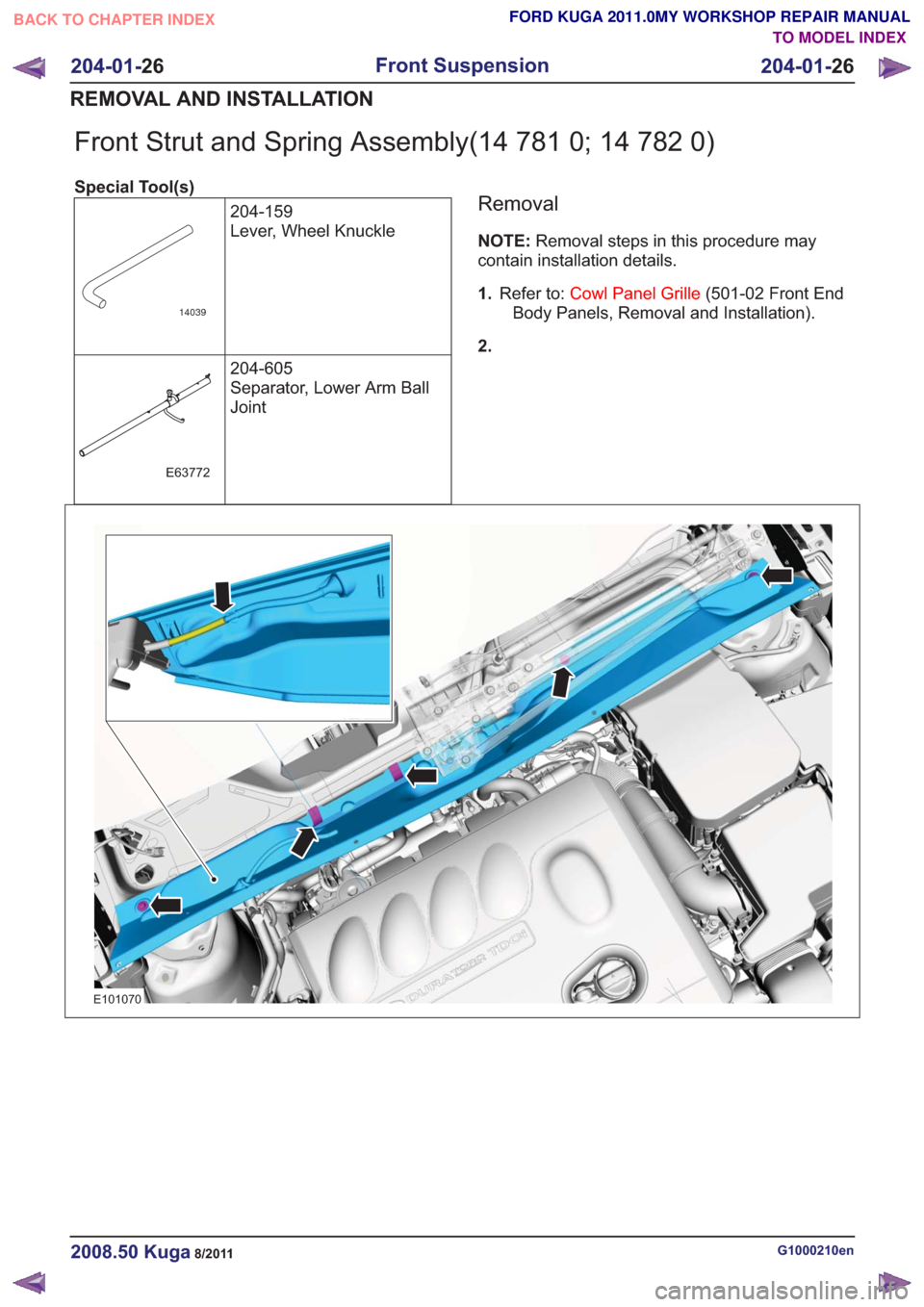

Front Strut and Spring Assembly(14 781 0; 14 782 0)

Special Tool(s)204-159

Lever, Wheel Knuckle

14039

204-605

Separator, Lower Arm Ball

Joint

E63772

Removal

NOTE:Removal steps in this procedure may

contain installation details.

1. Refer to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

2.

E101070

G1000210en2008.50 Kuga8/2011

204-01- 26

Front Suspension

204-01- 26

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1298 of 2057

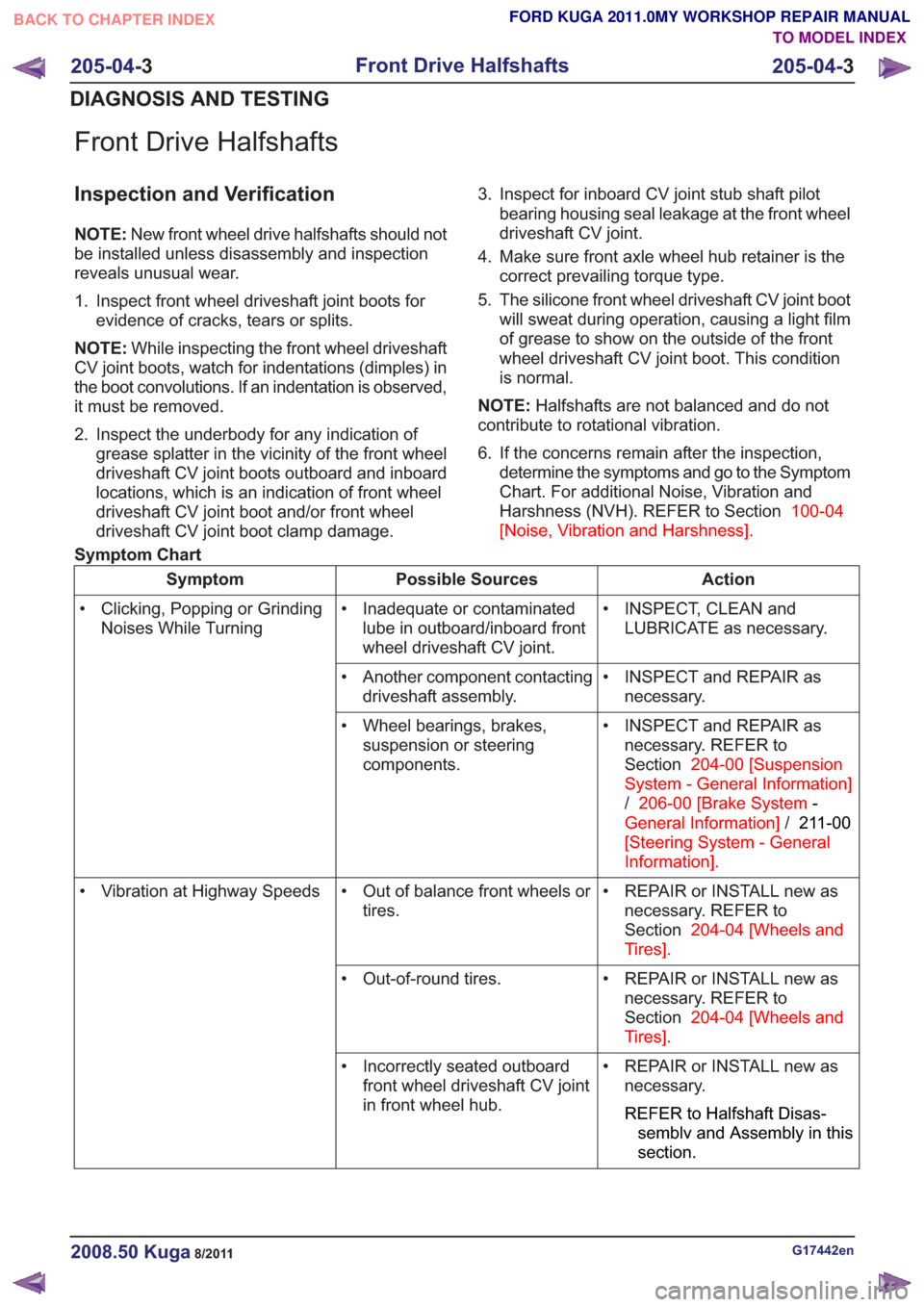

Front Drive Halfshafts

Inspection and Verification

NOTE:New front wheel drive halfshafts should not

be installed unless disassembly and inspection

reveals unusual wear.

1. Inspect front wheel driveshaft joint boots for evidence of cracks, tears or splits.

NOTE: While inspecting the front wheel driveshaft

CV joint boots, watch for indentations (dimples) in

the boot convolutions. If an indentation is observed,

it must be removed.

2. Inspect the underbody for any indication of grease splatter in the vicinity of the front wheel

driveshaft CV joint boots outboard and inboard

locations, which is an indication of front wheel

driveshaft CV joint boot and/or front wheel

driveshaft CV joint boot clamp damage. 3. Inspect for inboard CV joint stub shaft pilot

bearing housing seal leakage at the front wheel

driveshaft CV joint.

4. Make sure front axle wheel hub retainer is the correct prevailing torque type.

5. The silicone front wheel driveshaft CV joint boot will sweat during operation, causing a light film

of grease to show on the outside of the front

wheel driveshaft CV joint boot. This condition

is normal.

NOTE: Halfshafts are not balanced and do not

contribute to rotational vibration.

6. If the concerns remain after the inspection, determine the symptoms and go to the Symptom

Chart. For additional Noise, Vibration and

Harshness (NVH). REFER to Section 100-04

[Noise, Vibration and Harshness] .

Symptom Chart

Action

Possible Sources

Symptom

• INSPECT, CLEAN andLUBRICATE as necessary.

• Inadequate or contaminated

lube in outboard/inboard front

wheel driveshaft CV joint.

• Clicking, Popping or Grinding

Noises While Turning

• INSPECT and REPAIR asnecessary.

• Another component contacting

driveshaft assembly.

• INSPECT and REPAIR asnecessary. REFER to

Section 204-00 [Suspension

System - General Information]

/ 206-00 [Brake System -

General Information] /211-00

[Steering System - General

Information] .

• Wheel bearings, brakes,

suspension or steering

components.

• REPAIR or INSTALL new asnecessary. REFER to

Section 204-04 [Wheels and

Tires] .

• Out of balance front wheels or

tires.

• Vibration at Highway Speeds

• REPAIR or INSTALL new asnecessary. REFER to

Section 204-04 [Wheels and

Tires] .

• Out-of-round tires.

• REPAIR or INSTALL new asnecessary.

REFER to Halfshaft Disas-

semblv and Assembly in this

section.

• Incorrectly seated outboard

front wheel driveshaft CV joint

in front wheel hub.

G17442en2008.50 Kuga8/2011

205-04- 3

Front Drive Halfshafts

205-04- 3

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

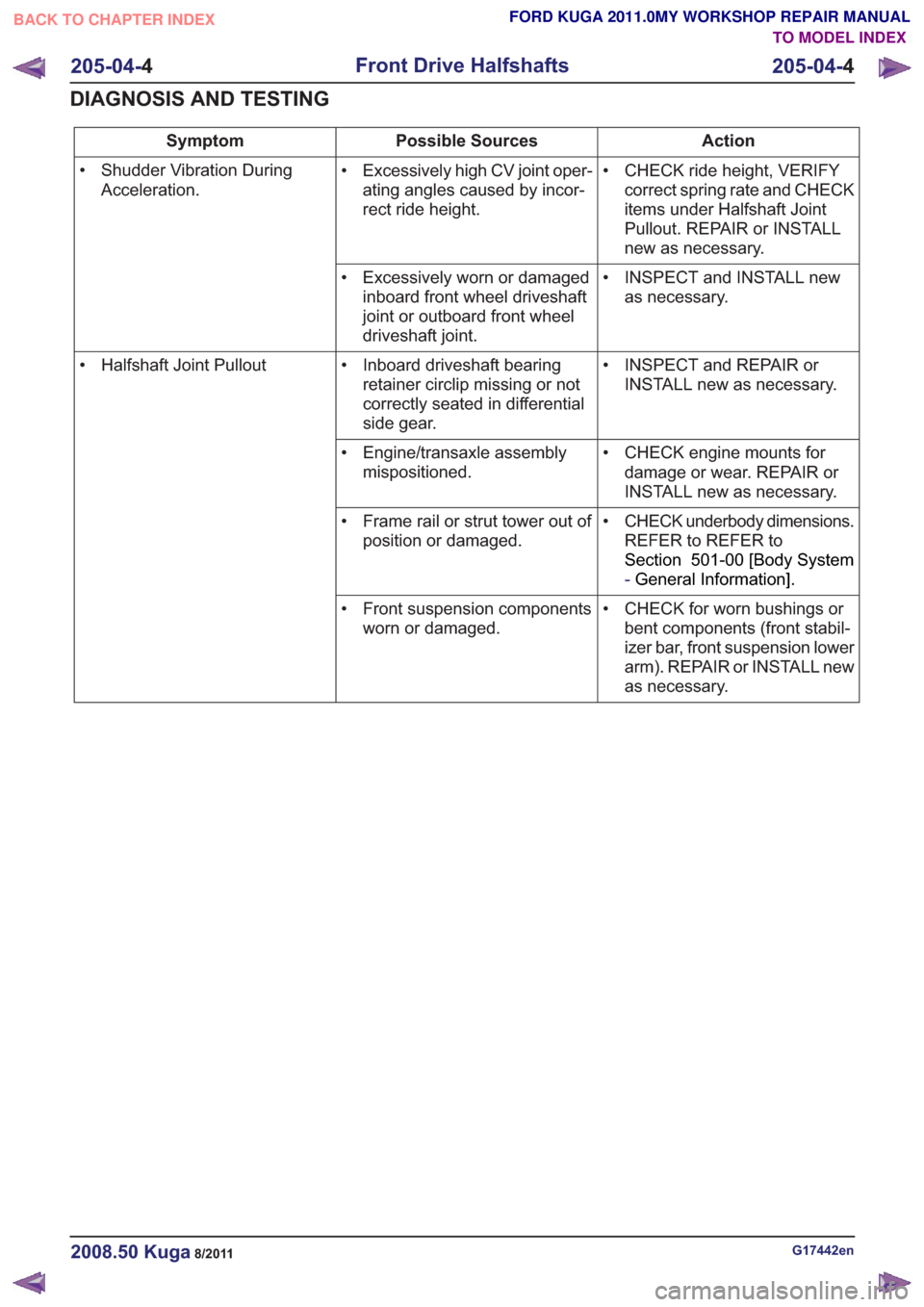

Page 1299 of 2057

Action

Possible Sources

Symptom

• CHECK ride height, VERIFYcorrect spring rate and CHECK

items under Halfshaft Joint

Pullout. REPAIR or INSTALL

new as necessary.

• Excessively high CV joint oper-

ating angles caused by incor-

rect ride height.

• Shudder Vibration During

Acceleration.

• INSPECT and INSTALL newas necessary.

• Excessively worn or damaged

inboard front wheel driveshaft

joint or outboard front wheel

driveshaft joint.

• INSPECT and REPAIR orINSTALL new as necessary.

• Inboard driveshaft bearing

retainer circlip missing or not

correctly seated in differential

side gear.

• Halfshaft Joint Pullout

• CHECK engine mounts fordamage or wear. REPAIR or

INSTALL new as necessary.

• Engine/transaxle assembly

mispositioned.

• CHECK underbody dimensions.REFER to REFER to

Section 501-00 [Body System

-General Information] .

• Frame rail or strut tower out of

position or damaged.

• CHECK for worn bushings orbent components (front stabil-

izer bar, front suspension lower

arm). REPAIR or INSTALL new

as necessary.

• Front suspension components

worn or damaged.

G17442en2008.50 Kuga8/2011

205-04- 4

Front Drive Halfshafts

205-04- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL