rain sensor FORD KUGA 2011 1.G Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1999 of 2057

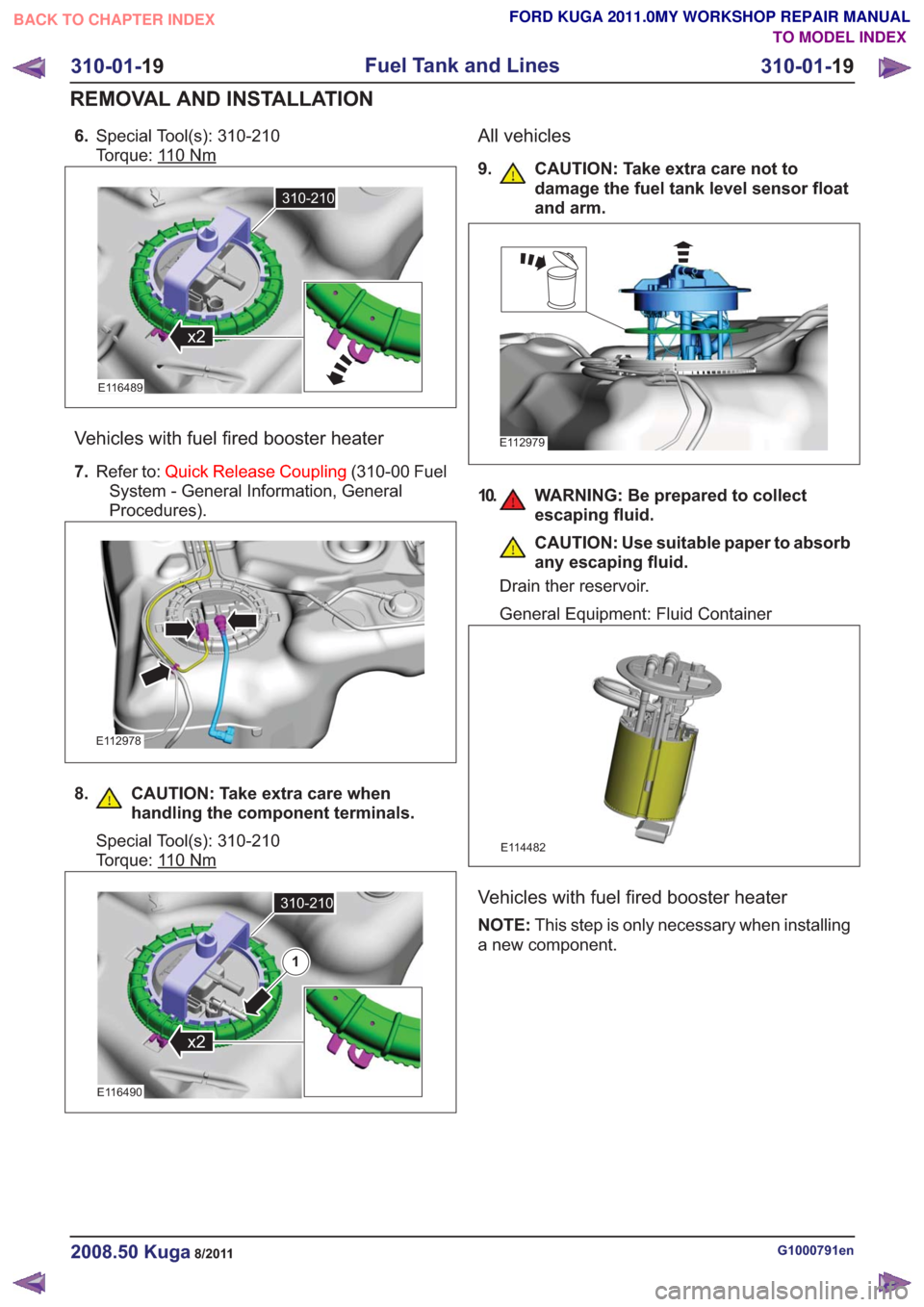

6.Special Tool(s): 310-210

Torque: 1

10Nm

310-210

x2

310-210

x2

E116489

Vehicles with fuel fired booster heater

7.Refer to: Quick Release Coupling (310-00 Fuel

System - General Information, General

Procedures).

E112978

8. CAUTION: Take extra care when handling the component terminals.

Special Tool(s): 310-210

Torque: 1

10Nm

310-210

x2

310-210

x2

E116490

1

All vehicles

9. CAUTION: Take extra care not todamage the fuel tank level sensor float

and arm.

E112979

10. WARNING: Be prepared to collectescaping fluid.

CAUTION: Use suitable paper to absorb

any escaping fluid.

Drain ther reservoir.

General Equipment: Fluid Container

E114482

Vehicles with fuel fired booster heater

NOTE: This step is only necessary when installing

a new component.

G1000791en2008.50 Kuga8/2011

310-01- 19

Fuel Tank and Lines

310-01- 19

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2015 of 2057

• The refrigerant line between the fixed orificetube and the evaporator must be cold from the

point where the fixed orifice tube is installed.

Depending on the weather, the refrigerant line

may also have ice on its surface.

• The refrigerant line between the evaporator and the A/C compressor including the dehydrator

must be cold.

Evaporator outlet line temperature test

To test the power of the A/C system, the

temperature at the evaporator outlet line must be

measured. To do this, the following preconditions

must be met:

• Open all windows.

• Set the air distribution to the defrost/dashboardposition and open all the ventilation nozzles.

• DO NOT switch on recirculated air.

• Select lowest blower switch setting.

• Select lowest temperature setting.

NOTE: The temperature measurement cannot be

done with a thermometer which makes no contact.

The surface reflection from the metal line may

cause incorrect readings.

Connect the temperature sensor (Fluke 80 PK-8)

to the outlet line of the evaporator. Locate the

temperature sensor as close as possible to the

evaporator. Connect the temperature sensor to the

multimeter.

Start the engine and allow it to run at idle speed

for several minutes.

Switch on the A/C.

After three minutes, measure the surface

temperature of the evaporator outlet line.

If the temperature measured is 4° C or lower, the

A/C system is OK. If the temperature is higher, the

A/C system may be under-filled. For further

information, refer to

REFER to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging (412-00

Climate Control System - General Information,

General Procedures).

Frequent faults and their causes

If the cooling power of the A/C system is not

adequate, make certain that the temperature

control flap(s) is/are operating correctly. • No or poor cooling performance:

– Blockage or narrowing of a refrigerant line orin the dehydrator. The location of the

blockage or narrowing can easily be located

by temperature comparisons at the

refrigerant lines and the dehydrator. The

blockage or restriction is located at the point

where the temperature difference is

identified. Note: A temperature difference

in the area of the fixed orifice tube is

normal. If the location of the blockage or

narrowing is found, check the corresponding

component and renew as applicable.

• Sudden drop in cooling performance (after the air conditioning has been switched off for

approx. 5 minutes, the cooling performance

returns to normal):

– The cause is an iced-up fixed orifice tubebecause of moisture in the refrigerant circuit.

In order to ensure that moisture is completely

removed from the refrigerant circuit, the

dehydrator should be renewed and the

evacuation time should be extended to 2-3

hours. For further information

REFER to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging

(412-00 Climate Control System - General

Information, General Procedures).

Sequence of A/C Request Signal

NOTE: The electronic automatic temperature

control (EATC) module is integrated into the air

conditioning control assembly.

NOTE: The generic electronic module (GEM) is

an integral part of the central junction box (CJB).

After actuating the A/C ON/OFF switch integrated

into the A/C control assembly, an A/C request

signal is sent from the A/C control assembly

(vehicles with EATC: EATC module) to the GEM.

From there, the signal is sent to the instrument

cluster via the MS-CAN bus. A gateway is installed

in the instrument cluster, which establishes the

connection between the MS-CAN bus and the

HS-CAN bus.

After the signal has been converted in the gateway,

it is relayed to the powertrain control module (PCM)

via the HS-CAN bus. Once all the required

parameters have been met, the PCM switches on

the refrigerant compressor and thus the A/C system

via the A/C clutch relay.

G1055878en2008.50 Kuga8/2011

412-00- 4

Climate Control System - General Information

412-00- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2045 of 2057

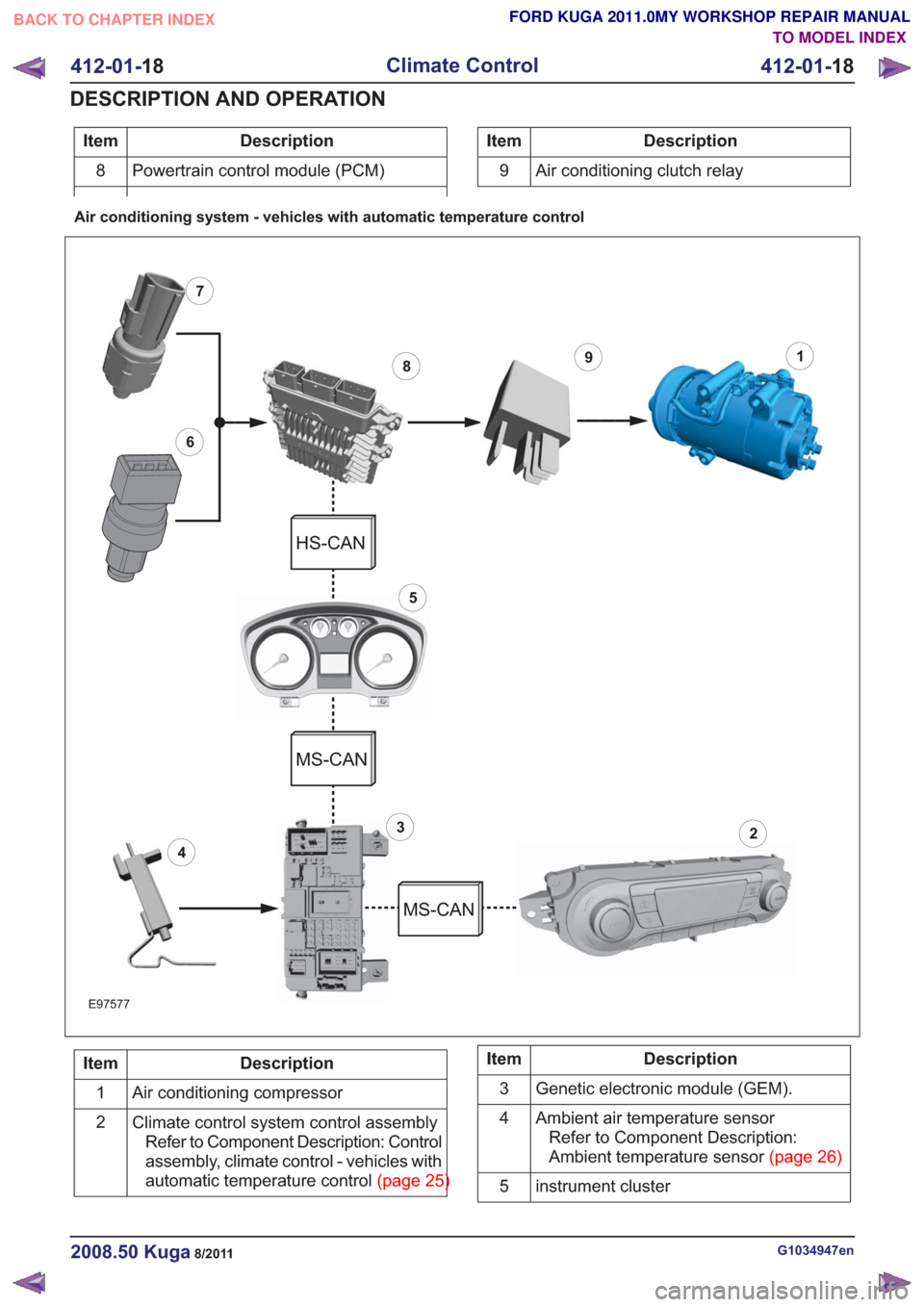

Description

Item

Powertrain control module (PCM)

8Description

Item

9 Air conditioning clutch relay

Air conditioning system - vehicles with automatic temperature control

18

6

7

3

9

5

2

4

E97577

HS-CAN

MS-CAN

MS-CAN

Description

Item

Air conditioning compressor

1

Climate control system control assemblyRefer to Component Description: Control

assembly, climate control - vehicles with

automatictemperaturecontrol(page25)

2Description

Item

Genetic electronic module (GEM).

3

Ambient air temperature sensorRefer to Component Description:

Ambienttemperaturesensor(page26)

4

instrument cluster

5

G1034947en2008.50 Kuga8/2011

412-01- 18

Climate Control

412-01- 18

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL