rain sensor FORD KUGA 2011 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 456 of 2057

Description

Item

HS CAN

1

DLC2

MS CAN

3

Instrument cluster (gateway)

4

Front windshield wiper motors

5

GEM6

Rear window wiper motors

7

Indicator/heated windshield

8

Indicator/heated rear window

9 Description

Item

Mini-liftgate latch motor

10

Liftgate latch motor

11

Electric booster Heater

12

Front wiper windscreen washer pump

13

Rear wiper windscreen washer pump

14

Headlamp

15

Courtesy Lighting

16

Alarm horn

17

System Operation

GEM.

The following functions are controlled or performed

by the GEM at a battery voltage of between 9 and

16 volts:

• Current distribution

• Battery charging (Smart Charge)

• Ignition overload protection

• Headlamp switch-off delay

• Turn signals

• Interior lighting

• Heated windscreen

• Heated rear window and heated external mirrors

• Ambient air temperature

• Brake fluid level

• Automatic headlamps

• Combined rain sensor/light sensor

• Windshield wash/wipe system

• Speed control – reads the speed control switches andtransmits signals on the CAN data bus

• central door locking – transmits signals on the CAN data bus

• Anti-theft

• Electric booster Heater

• Climate control

• Parking brake –(monitors the switch and transmits the signal

on the CAN data bus

• Communication via the medium-speed CAN data bus Component Description

Battery charging (Smart Charge)

In addition to the familiar functions, the Smart

Charge system also performs the following

functions:

•

Automatic deactivation of non-critical high power

electrical consumers when the battery voltage

is low in order to reduce the level of current

drawn.

• Automatic activation of non-critical high power electrical consumers when the battery voltage

is excessively high in order to protect

components which are sensitive to increased

voltages.

The battery charging current is optimized through

continuous calculation of the battery temperature

and monitoring of the alternator output voltage.

The alternator load is signaled to the PCM

(powertrain control module) in order to provide it

with an early indication when an electric component

is to be switched on or off, thereby also providing

information about imminent changes to the amount

of torque demanded by the alternator. By

evaluating this information the PCM is capable of

increasing the stability of the engine under idling.

The two remaining functions of the Smart Charge

system are controlled by the GEM. G1030788en

2008.50 Kuga 8/2011 419-10-6

Multifunction Electronic Modules

419-10-6

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 459 of 2057

• 4 minutes have elapsed since the button for the

heated windshield was pressed.

• The ignition switch is turned to the "I" or "0" position.

• The "Defrost" function is deactivated or the switch for the heated windscreen is pressed

again while the heated windscreen is still

switched on.

• The charging system warning indicator is switched on.

• The battery voltage falls below the threshold value for low battery voltage for more than 20

seconds (power management strategy). Manual

requests for switching on the heated windshield

by pressing the switch are ignored at this time.

• More than 4 minutes have passed since starting

the engine.

Heated rear window and heated external

mirrors

The GEM transmits a request signal via the CAN

bus to the door modules to switch on the heated

exterior mirrors.

The heated rear window and the heated exterior

mirrors are switched on by the GEM under the

following conditions:

• The switch for the heated rear window is pressed and the ignition switch is in the "II"

position.

• The "defrost" function of the air conditioning is activated and the ignition switch is in the position

"II".

• The battery voltage has exceeded 16 V for more

than 20 seconds (power management strategy).

Manual requests to switch off the heated rear

window by pressing the button are ignored at

this time.

• The engine was started at an outside air temperature below 4°C and an engine

temperature below 65°. Manual requests for

switching off the heated rear window by pressing

the switch are accepted.

NOTE: If the battery voltage returns to the normal

range then the disabling of the heated rear window

is cancelled - the heated rear window is then in a

switched-off state.

The GEM transmits a request signal via the CAN

bus to the door modules to switch off the heated

exterior mirrors. The heated rear window and the heated exterior

mirrors are switched off by the GEM under the

following conditions

• 14 minutes have elapsed since the button for

the heated rear window was pressed.

• The ignition switch is turned to the position "0", "I" or "III".

• The switch for the heated rear window is pressed or the "defrost" function of the air

conditioning is deactivated while the heated rear

window is switched on.

• The battery voltage has dropped below 10.3 V for more than 20 seconds (power management

strategy). Manual requests for switching on the

heated rear window by pressing the switch are

ignored at this time.

• More than 14 minutes have passed since starting the engine.

Ambient air temperature

The ambient air temperature sensor is connected

via a cable to the GEM. It measures the outside

air temperature to an accuracy of around ±0.5 °C.

The GEM broadcasts the ambient air temperature

on the medium speed CAN bus, where it can be

evaluated by various systems.

Brake fluid level

The brake fluid level switch is connected via a

cable to the GEM.

The GEM transmits a message on the medium

speed CAN bus. The instrument cluster then

transfers this message to the high speed CAN bus

where it is made available for various other

functions.

Automatic headlamps

Refer to: Exterior Lighting (417-01 Exterior Lighting,

Description and Operation).

Combined rain sensor/light sensor

Refer to: Exterior Lighting (417-01 Exterior Lighting,

Description and Operation). G1030788en

2008.50 Kuga 8/2011 419-10-9

Multifunction Electronic Modules

419-10-9

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1428 of 2057

Description

Item

Battery

1

Battery junction box (BJB) in the engine

compartment

2

Generic electronic module (GEM)

3

Powertrain Control Module (PCM)

4

Instrument cluster

5

Data link connector (DLC)

6

Steering Wheel Rotation Sensor

7

ABS/ESP module or hydraulic control unit

(HCU)

8Description

Item

Combined yaw rate sensor and lateral

acceleration sensor / longitudinal

acceleration sensor

9

Front wheel sensor

10

Rear wheel sensor

11

Rear wheel sensor

12

Front wheel sensor

13

ESP switch

14

Rear brakes

15

Front brake

16

The ABS monitors the different wheel speeds of

the vehicle with the aid of wheel speed sensors.

Using the data from all of the wheel speed sensors,

the ABS module calculates the so-called reference

speed, which is a measure of the actual road

speed. The ABS module compares the individual

circumferential wheel speeds with this reference

speed when the driver initiates braking. If one or

more of the circumferential wheel speeds deviates

too far from the reference speed, this means that

slip at the affected wheels is so great that steering

stability of the vehicle is no longer ensured. The

ABS module actuates electro-mechanical valves

which influence the brake pressure at the relevant

wheels.

Like the traction control system (TCS), the ESP

system uses a large proportion of the ABS

components. In addition, there are sensors which

pick up the steering angle, the acceleration forces

acting on the vehicle and the yaw rate or yaw

moment. The sensors transmit these signals to the

combined ABS/ESP module. Using the wheel

speed and steering angle data, the ABS/ESP

module calculates the direction of travel planned

by the driver and determines the corresponding

speed-dependent lateral acceleration and yaw

moment. These values are compared with those

actual measured. If the actual lateral acceleration

and the yaw moment deviate excessively from the

target values (unstable driving characteristics), the

ABS/ESP module actuates individual brakes

selectively via the HCU (hydraulic control unit). In

addition, the engine speed is reduced by

intervention in the engine management system.

How the system works for understeer: In the

event of understeer, brake intervention occurs at

the wheels on the inside of the curve. The rear

wheel is braked heavily, so that a high amount of slip is caused. In this way, the cornering force of

the rear axle is heavily reduced and the centrifugal

force that now becomes effective turns the rear of

the vehicle back into the curve. The front wheel is

not braked as hard. The braking force that is

transmitted via the front wheel to the road surface

generates a torque with the aid of the lever arm

(vertical tire force to the vehicle's centre of gravity),

which supports the yaw moment of the vehicle.

Both measures together result in the vehicle

reverting back to the curved path intended by the

driver.

How the system works for oversteer:

In the

event of oversteer the wheels on the outside of the

curve are braked. This time, the front wheel is

subjected to a high level of slip so that the

cornering force at the front axle is reduced. The

rear wheel is not braked as heavily and, together

with the effective lever arm, results in a reduction

in the vehicle yaw moment. Both measures

together result in the vehicle being stabilized and

reverting back to the curved path intended by the

driver.

If ESP control occurs, possible ABS interventions

will be overridden as the ESP works at higher slip

rates than the ABS.

Emergency brake assist (EBA): The emergency

brake assist helps drivers in emergency braking

situations by automatically applying the brakes with

the maximum possible braking force.

If the brake pedal is pressed very suddenly, the

ABS module increases the hydraulic pressure to

all of the brakes until the threshold for ABS

intervention is reached. This applies the maximum

braking effort for the available traction. The ABS

control unit monitors inputs from the brake pedal

switch and from the pressure sensor within the

G1001304en2008.50 Kuga8/2011

206-09B- 10

Anti-Lock Control - Stability Assist

206-09B- 10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1433 of 2057

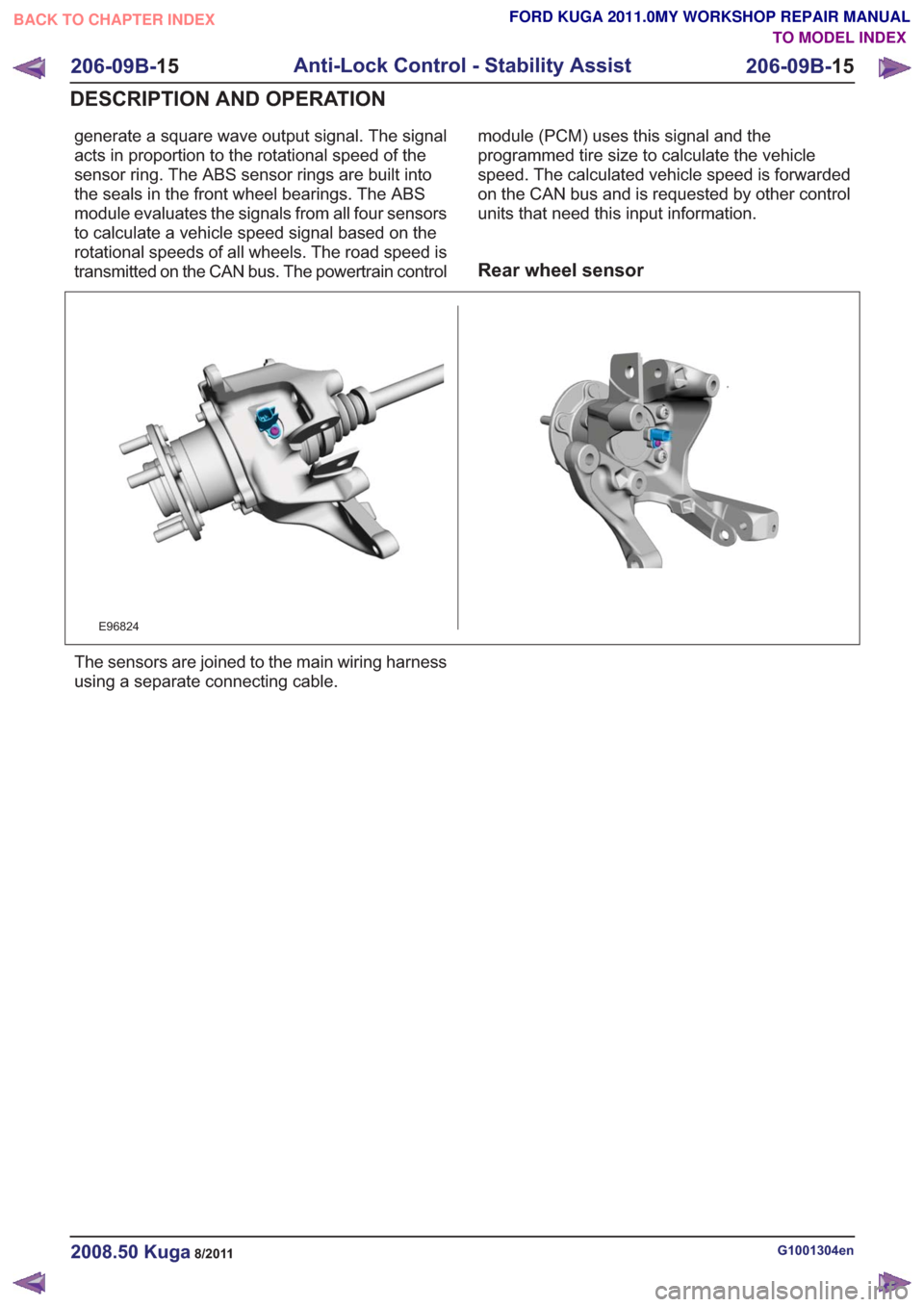

generate a square wave output signal. The signal

acts in proportion to the rotational speed of the

sensor ring. The ABS sensor rings are built into

the seals in the front wheel bearings. The ABS

module evaluates the signals from all four sensors

to calculate a vehicle speed signal based on the

rotational speeds of all wheels. The road speed is

transmitted on the CAN bus. The powertrain controlmodule (PCM) uses this signal and the

programmed tire size to calculate the vehicle

speed. The calculated vehicle speed is forwarded

on the CAN bus and is requested by other control

units that need this input information.

Rear wheel sensor

E96824

The sensors are joined to the main wiring harness

using a separate connecting cable.

G1001304en2008.50 Kuga8/2011

206-09B-

15

Anti-Lock Control - Stability Assist

206-09B- 15

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1465 of 2057

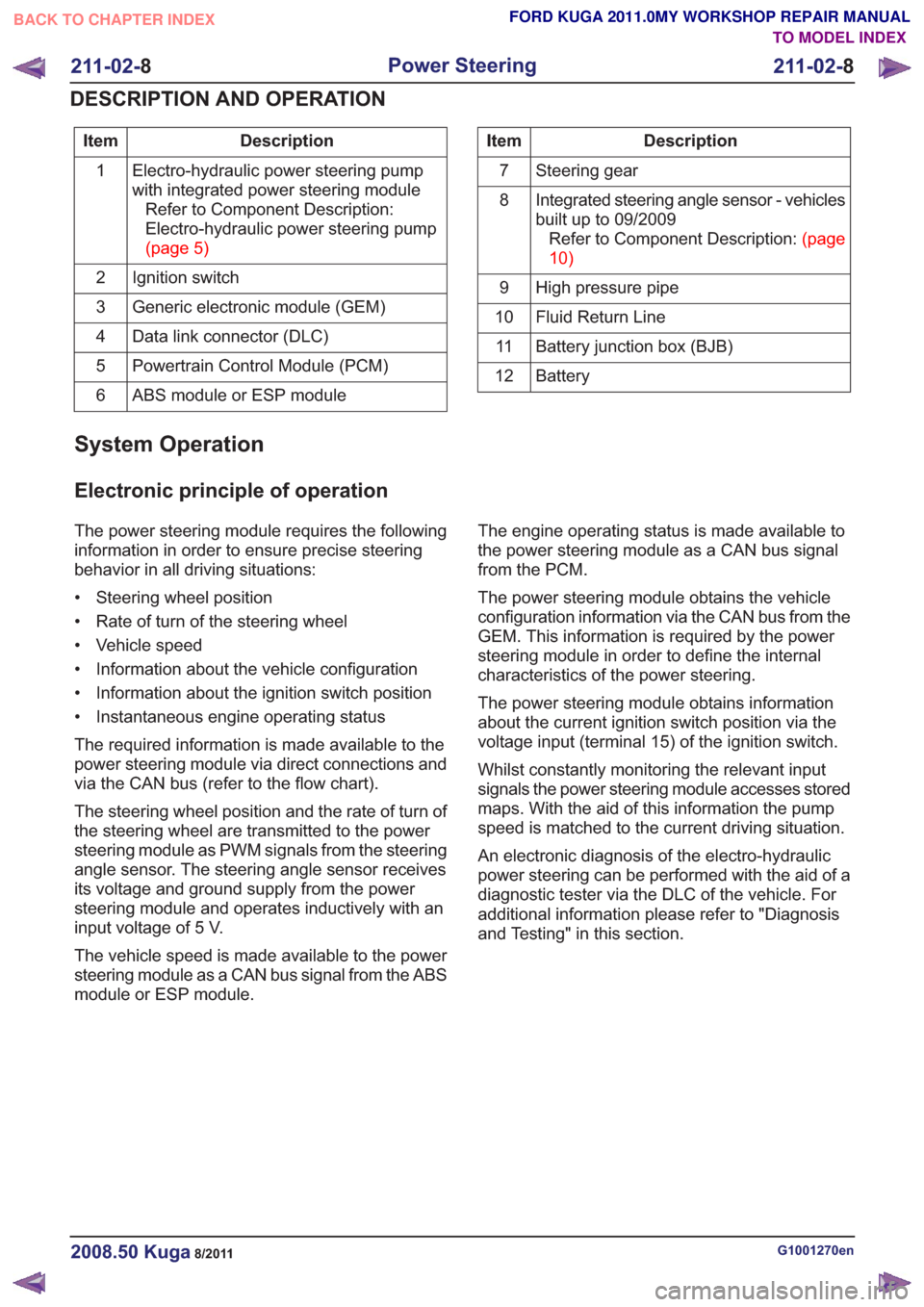

Description

Item

Electro-hydraulic power steering pump

with integrated power steering moduleRefer to Component Description:

Electro-hydraulic power steering pump

(page5)

1

Ignition switch

2

Generic electronic module (GEM)

3

Data link connector (DLC)

4

Powertrain Control Module (PCM)

5

ABS module or ESP module

6Description

Item

Steering gear

7

Integrated steering angle sensor - vehicles

built up to 09/2009RefertoComponentDescription:(page

10)

8

High pressure pipe

9

Fluid Return Line

10

Battery junction box (BJB)

11

Battery

12

System Operation

Electronic principle of operation

The power steering module requires the following

information in order to ensure precise steering

behavior in all driving situations:

• Steering wheel position

• Rate of turn of the steering wheel

• Vehicle speed

• Information about the vehicle configuration

• Information about the ignition switch position

• Instantaneous engine operating status

The required information is made available to the

power steering module via direct connections and

via the CAN bus (refer to the flow chart).

The steering wheel position and the rate of turn of

the steering wheel are transmitted to the power

steering module as PWM signals from the steering

angle sensor. The steering angle sensor receives

its voltage and ground supply from the power

steering module and operates inductively with an

input voltage of 5 V.

The vehicle speed is made available to the power

steering module as a CAN bus signal from the ABS

module or ESP module. The engine operating status is made available to

the power steering module as a CAN bus signal

from the PCM.

The power steering module obtains the vehicle

configuration information via the CAN bus from the

GEM. This information is required by the power

steering module in order to define the internal

characteristics of the power steering.

The power steering module obtains information

about the current ignition switch position via the

voltage input (terminal 15) of the ignition switch.

Whilst constantly monitoring the relevant input

signals the power steering module accesses stored

maps. With the aid of this information the pump

speed is matched to the current driving situation.

An electronic diagnosis of the electro-hydraulic

power steering can be performed with the aid of a

diagnostic tester via the DLC of the vehicle. For

additional information please refer to "Diagnosis

and Testing" in this section.

G1001270en2008.50 Kuga8/2011

211-02-

8

Power Steering

211-02- 8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1675 of 2057

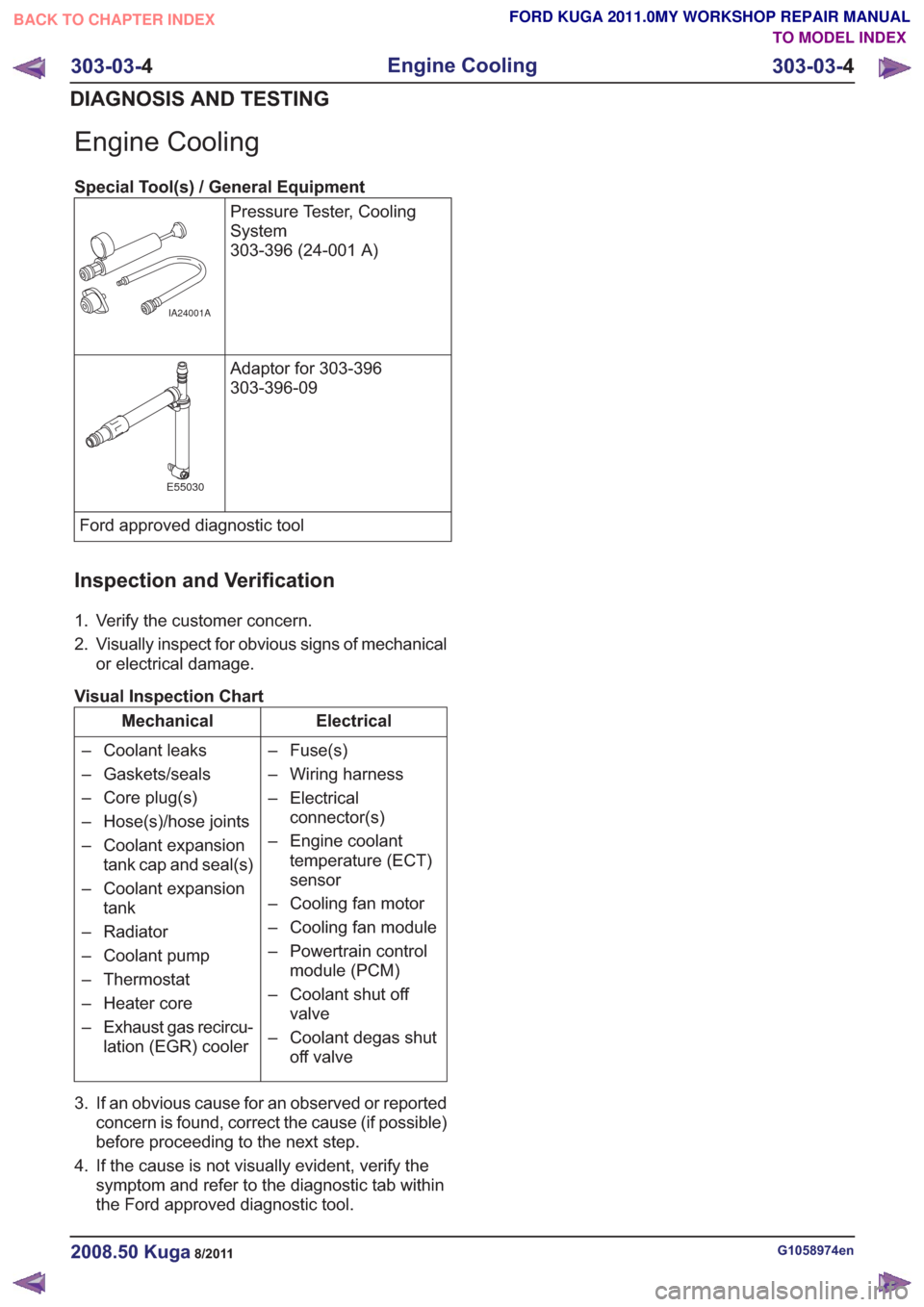

Engine Cooling

Special Tool(s) / General EquipmentPressure Tester, Cooling

System

303-396 (24-001 A)

IA24001A

Adaptor for 303-396

303-396-09

E55030

Ford approved diagnostic tool

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicalor electrical damage.

Visual Inspection Chart

Electrical

Mechanical

– Fuse(s)

– Wiring harness

– Electricalconnector(s)

– Engine coolant temperature (ECT)

sensor

– Cooling fan motor

– Cooling fan module

– Powertrain control module (PCM)

– Coolant shut off valve

– Coolant degas shut off valve

– Coolant leaks

– Gaskets/seals

– Core plug(s)

– Hose(s)/hose joints

– Coolant expansion

tank cap and seal(s)

– Coolant expansion tank

– Radiator

– Coolant pump

– Thermostat

– Heater core

– Exhaust gas recircu- lation (EGR) cooler

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool.

G1058974en2008.50 Kuga8/2011

303-03- 4

Engine Cooling

303-03- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1695 of 2057

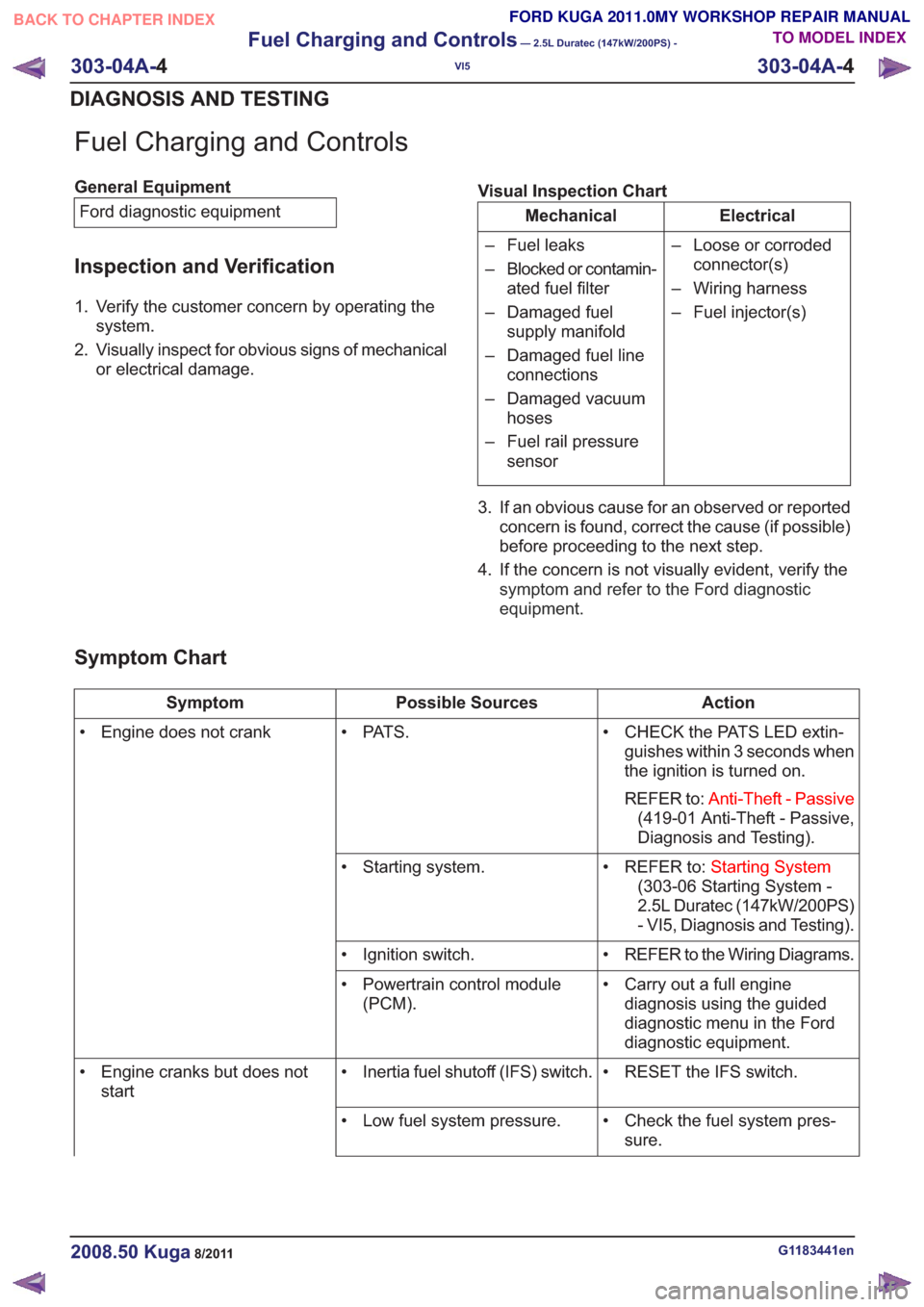

Fuel Charging and Controls

General EquipmentFord diagnostic equipment

Inspection and Verification

1. Verify the customer concern by operating the system.

2. Visually inspect for obvious signs of mechanical or electrical damage. Visual Inspection Chart

Electrical

Mechanical

– Loose or corrodedconnector(s)

– Wiring harness

– Fuel injector(s)

– Fuel leaks

– Blocked or contamin-

ated fuel filter

– Damaged fuel supply manifold

– Damaged fuel line connections

– Damaged vacuum hoses

– Fuel rail pressure sensor

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the concern is not visually evident, verify the symptom and refer to the Ford diagnostic

equipment .

Symptom Chart

Action

Possible Sources

Symptom

• CHECK the PATS LED extin-guishes within 3 seconds when

the ignition is turned on.

REFER to: Anti-Theft - Passive

(419-01 Anti-Theft - Passive,

Diagnosis and Testing).

• PAT S .

• Engine does not crank

• REFER to:Starting System

(303-06 Starting System -

2.5L Duratec (147kW/200PS)

- VI5, Diagnosis and Testing).

• Starting system.

• REFER to the Wiring Diagrams.

• Ignition switch.

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• Powertrain control module

(PCM).

• RESET the IFS switch.

• Inertia fuel shutoff (IFS) switch.

• Engine cranks but does not

start

• Check the fuel system pres-sure.

• Low fuel system pressure.

G1183441en2008.50 Kuga8/2011

303-04A-

4

Fuel Charging and Controls

— 2.5L Duratec (147kW/200PS) -

VI5

303-04A- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1697 of 2057

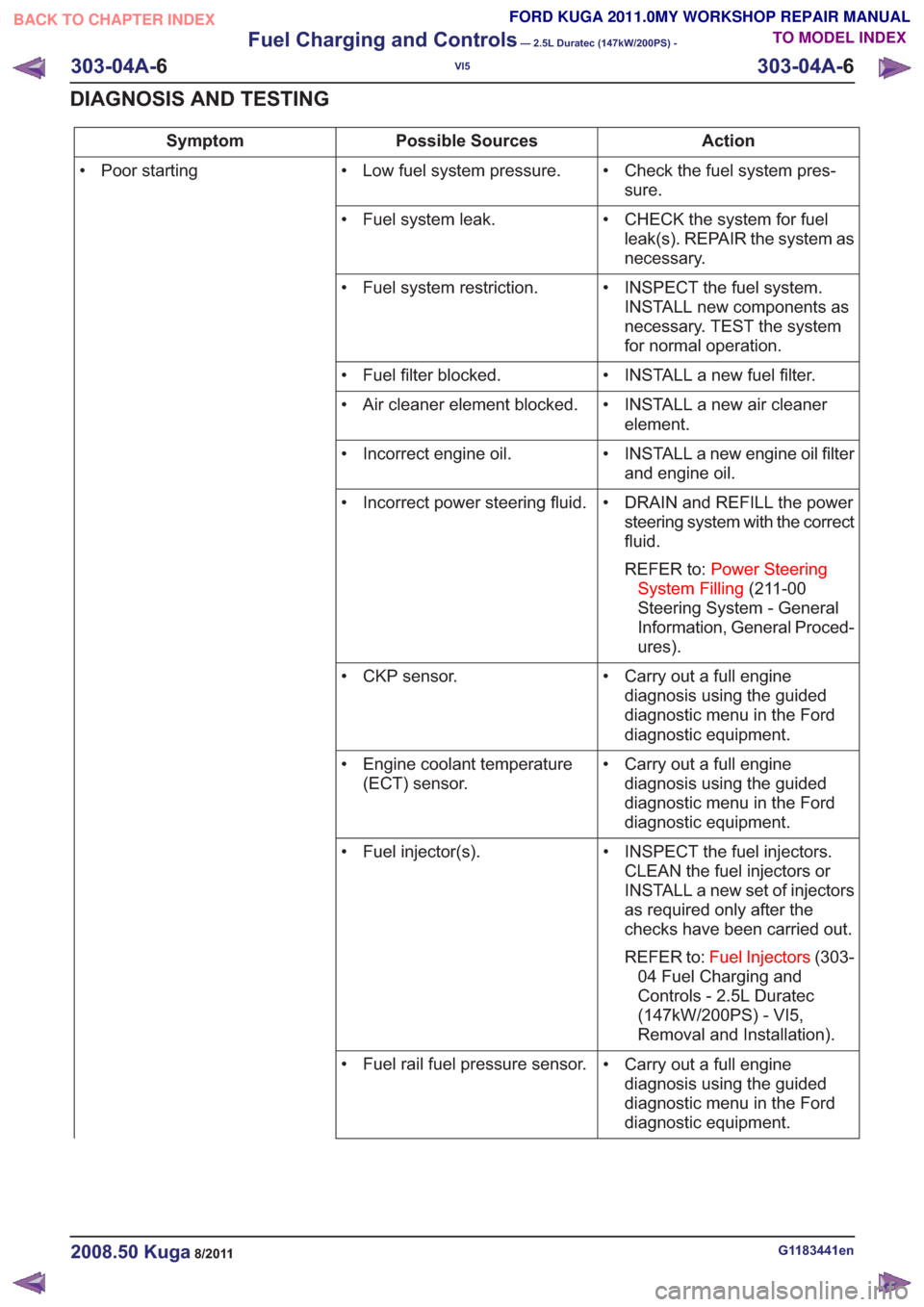

Action

Possible Sources

Symptom

• Check the fuel system pres-sure.

• Low fuel system pressure.

• Poor starting

• CHECK the system for fuelleak(s). REPAIR the system as

necessary.

• Fuel system leak.

• INSPECT the fuel system.INSTALL new components as

necessary. TEST the system

for normal operation.

• Fuel system restriction.

• INSTALL a new fuel filter.

• Fuel filter blocked.

• INSTALL a new air cleanerelement.

• Air cleaner element blocked.

• INSTALL a new engine oil filterand engine oil.

• Incorrect engine oil.

• DRAIN and REFILL the powersteering system with the correct

fluid.

REFER to: Power Steering

System Filling (211-00

Steering System - General

Information, General Proced-

ures).

• Incorrect power steering fluid.

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• CKP sensor.

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• Engine coolant temperature

(ECT) sensor.

• INSPECT the fuel injectors.CLEAN the fuel injectors or

INSTALL a new set of injectors

as required only after the

checks have been carried out.

REFER to: Fuel Injectors (303-

04 Fuel Charging and

Controls - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Fuel injector(s).

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• Fuel rail fuel pressure sensor.

G1183441en2008.50 Kuga8/2011

303-04A-

6

Fuel Charging and Controls

— 2.5L Duratec (147kW/200PS) -

VI5

303-04A- 6

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1699 of 2057

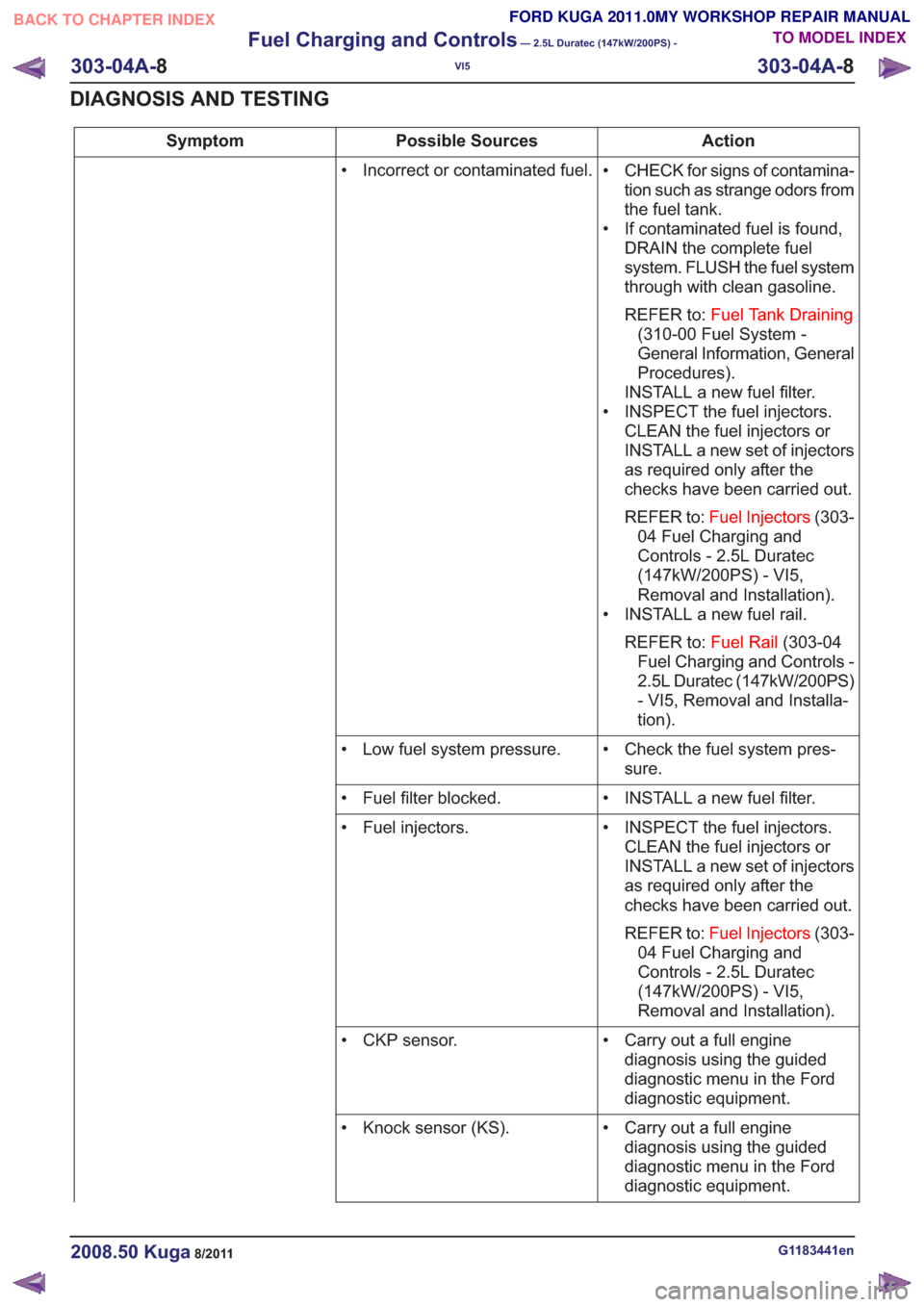

Action

Possible Sources

Symptom

• CHECK for signs of contamina-tion such as strange odors from

the fuel tank.

• If contaminated fuel is found, DRAIN the complete fuel

system. FLUSH the fuel system

through with clean gasoline.

REFER to: Fuel Tank Draining

(310-00 Fuel System -

General Information, General

Procedures).

INSTALL a new fuel filter.

• INSPECT the fuel injectors. CLEAN the fuel injectors or

INSTALL a new set of injectors

as required only after the

checks have been carried out.

REFER to: Fuel Injectors (303-

04 Fuel Charging and

Controls - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• INSTALL a new fuel rail.

REFER to: Fuel Rail(303-04

Fuel Charging and Controls -

2.5L Duratec (147kW/200PS)

- VI5, Removal and Installa-

tion).

• Incorrect or contaminated fuel.

• Check the fuel system pres-sure.

• Low fuel system pressure.

• INSTALL a new fuel filter.

• Fuel filter blocked.

• INSPECT the fuel injectors.CLEAN the fuel injectors or

INSTALL a new set of injectors

as required only after the

checks have been carried out.

REFER to: Fuel Injectors (303-

04 Fuel Charging and

Controls - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Fuel injectors.

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• CKP sensor.

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• Knock sensor (KS).

G1183441en2008.50 Kuga8/2011

303-04A-

8

Fuel Charging and Controls

— 2.5L Duratec (147kW/200PS) -

VI5

303-04A- 8

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1701 of 2057

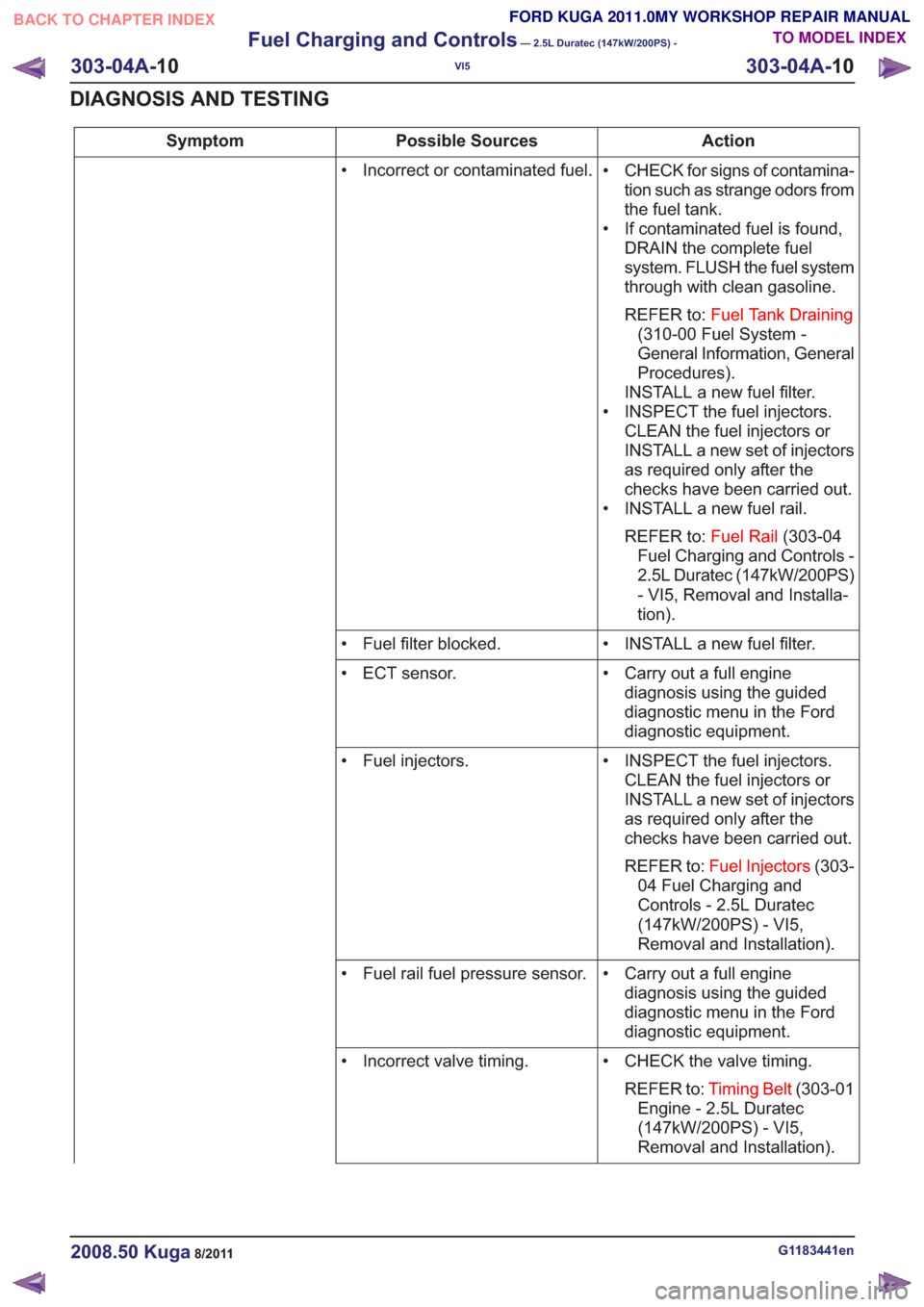

Action

Possible Sources

Symptom

• CHECK for signs of contamina-tion such as strange odors from

the fuel tank.

• If contaminated fuel is found, DRAIN the complete fuel

system. FLUSH the fuel system

through with clean gasoline.

REFER to: Fuel Tank Draining

(310-00 Fuel System -

General Information, General

Procedures).

INSTALL a new fuel filter.

• INSPECT the fuel injectors. CLEAN the fuel injectors or

INSTALL a new set of injectors

as required only after the

checks have been carried out.

• INSTALL a new fuel rail.

REFER to: Fuel Rail(303-04

Fuel Charging and Controls -

2.5L Duratec (147kW/200PS)

- VI5, Removal and Installa-

tion).

• Incorrect or contaminated fuel.

• INSTALL a new fuel filter.

• Fuel filter blocked.

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• ECT sensor.

• INSPECT the fuel injectors.CLEAN the fuel injectors or

INSTALL a new set of injectors

as required only after the

checks have been carried out.

REFER to: Fuel Injectors (303-

04 Fuel Charging and

Controls - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Fuel injectors.

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• Fuel rail fuel pressure sensor.

• CHECK the valve timing.REFER to: Timing Belt (303-01

Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Incorrect valve timing.

G1183441en2008.50 Kuga8/2011

303-04A-

10

Fuel Charging and Controls

— 2.5L Duratec (147kW/200PS) -

VI5

303-04A- 10

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL