connector FORD KUGA 2011 1.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1418 of 2057

Anti-Lock Control

schematic

and connector information.

General Equipment

The Ford approved diagnostic tool

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Fuse(s)

• Electricalconnector(s)

• Wiring harness(s).

• Anti-lock brake system (ABS)

module

• Wheel speed

sensor(s)

• Wheel speed sensor ring(s)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool.

G1058976en2008.50 Kuga8/2011

206-09A- 5

Anti-Lock Control

206-09A- 5

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Refer to

Wiring Diagrams Section 206-09A, for

Page 1428 of 2057

Description

Item

Battery

1

Battery junction box (BJB) in the engine

compartment

2

Generic electronic module (GEM)

3

Powertrain Control Module (PCM)

4

Instrument cluster

5

Data link connector (DLC)

6

Steering Wheel Rotation Sensor

7

ABS/ESP module or hydraulic control unit

(HCU)

8Description

Item

Combined yaw rate sensor and lateral

acceleration sensor / longitudinal

acceleration sensor

9

Front wheel sensor

10

Rear wheel sensor

11

Rear wheel sensor

12

Front wheel sensor

13

ESP switch

14

Rear brakes

15

Front brake

16

The ABS monitors the different wheel speeds of

the vehicle with the aid of wheel speed sensors.

Using the data from all of the wheel speed sensors,

the ABS module calculates the so-called reference

speed, which is a measure of the actual road

speed. The ABS module compares the individual

circumferential wheel speeds with this reference

speed when the driver initiates braking. If one or

more of the circumferential wheel speeds deviates

too far from the reference speed, this means that

slip at the affected wheels is so great that steering

stability of the vehicle is no longer ensured. The

ABS module actuates electro-mechanical valves

which influence the brake pressure at the relevant

wheels.

Like the traction control system (TCS), the ESP

system uses a large proportion of the ABS

components. In addition, there are sensors which

pick up the steering angle, the acceleration forces

acting on the vehicle and the yaw rate or yaw

moment. The sensors transmit these signals to the

combined ABS/ESP module. Using the wheel

speed and steering angle data, the ABS/ESP

module calculates the direction of travel planned

by the driver and determines the corresponding

speed-dependent lateral acceleration and yaw

moment. These values are compared with those

actual measured. If the actual lateral acceleration

and the yaw moment deviate excessively from the

target values (unstable driving characteristics), the

ABS/ESP module actuates individual brakes

selectively via the HCU (hydraulic control unit). In

addition, the engine speed is reduced by

intervention in the engine management system.

How the system works for understeer: In the

event of understeer, brake intervention occurs at

the wheels on the inside of the curve. The rear

wheel is braked heavily, so that a high amount of slip is caused. In this way, the cornering force of

the rear axle is heavily reduced and the centrifugal

force that now becomes effective turns the rear of

the vehicle back into the curve. The front wheel is

not braked as hard. The braking force that is

transmitted via the front wheel to the road surface

generates a torque with the aid of the lever arm

(vertical tire force to the vehicle's centre of gravity),

which supports the yaw moment of the vehicle.

Both measures together result in the vehicle

reverting back to the curved path intended by the

driver.

How the system works for oversteer:

In the

event of oversteer the wheels on the outside of the

curve are braked. This time, the front wheel is

subjected to a high level of slip so that the

cornering force at the front axle is reduced. The

rear wheel is not braked as heavily and, together

with the effective lever arm, results in a reduction

in the vehicle yaw moment. Both measures

together result in the vehicle being stabilized and

reverting back to the curved path intended by the

driver.

If ESP control occurs, possible ABS interventions

will be overridden as the ESP works at higher slip

rates than the ABS.

Emergency brake assist (EBA): The emergency

brake assist helps drivers in emergency braking

situations by automatically applying the brakes with

the maximum possible braking force.

If the brake pedal is pressed very suddenly, the

ABS module increases the hydraulic pressure to

all of the brakes until the threshold for ABS

intervention is reached. This applies the maximum

braking effort for the available traction. The ABS

control unit monitors inputs from the brake pedal

switch and from the pressure sensor within the

G1001304en2008.50 Kuga8/2011

206-09B- 10

Anti-Lock Control - Stability Assist

206-09B- 10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1443 of 2057

Steering System

Special Tool(s) / General EquipmentAlignment Pins, Subframe

205-316 (15-097A)

15097

Simulator, Driver and

Passenger Air Bags and Side

Air Curtains

501-073 (40-016)

501073

The Ford approved diagnostic tool

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicalor electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Battery

• Battery cables

• Steering anglesensor electrical

connector

• Power steering pump control

module electrical

connectors

• Power steering pump control

module ground

cable

• Power steering pump control

module ground

cable retaining

screw

• Steering angle sensor warning

indicator

• Fuse(s)

• Tire pressure(s)

• Loose tie-rod end(s)

• Loose strut and

spring assemblies or

ball joints

• Loose pinch bolts on steering column

shaft flexible coup-

ling

• Wheels and tires

• Power steering line fluid leaks

• Steering gear bellows 3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool.

Components Tests

Steering Linkage

1. Grasp the steering wheel firmly and move it upand down and to the left and right without

turning the steering wheel to check the steering

column bearing for wear, steering column shaft

for wear, steering wheel for looseness and

steering column for looseness. If the steering

column bearing or the steering column shaft is

worn install a new steering column. If the

steering wheel or the steering column is loose,

tighten the steering wheel or the steering column

retaining bolts.

2. With the road wheels in the straight ahead position, gently turn the steering wheel to the

left and the right to check for free play in the

steering linkage.

3. There should be no excessive free play at the steering wheel rim. If there is excessive free

play, CHECK the tie-rod inner and outer ball

joints, REFER to Tie-Rod Component Test in

this procedure. CHECK the steering column

universal joint, REFER to Steering Column

Universal Joint Component Test in this

procedure. If there is no free play in the tie-rod

and the steering column, install a new steering

gear.

Tie-Rod

CAUTION: Steering gear boots must be

handled carefully to avoid damage. Use

new steering boot clamps when installing

the steering gear boots.

NOTE: Noises such as knocks, which may appear

to originate from the steering linkage, may also be

generated by front suspension components.

REFER to: Noise, Vibration and Harshness (NVH)

(100-04 Noise, Vibration and Harshness,

Diagnosis and Testing).

G1059437en2008.50 Kuga8/2011

211-00- 2

Steering System - General Information

211-00- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1465 of 2057

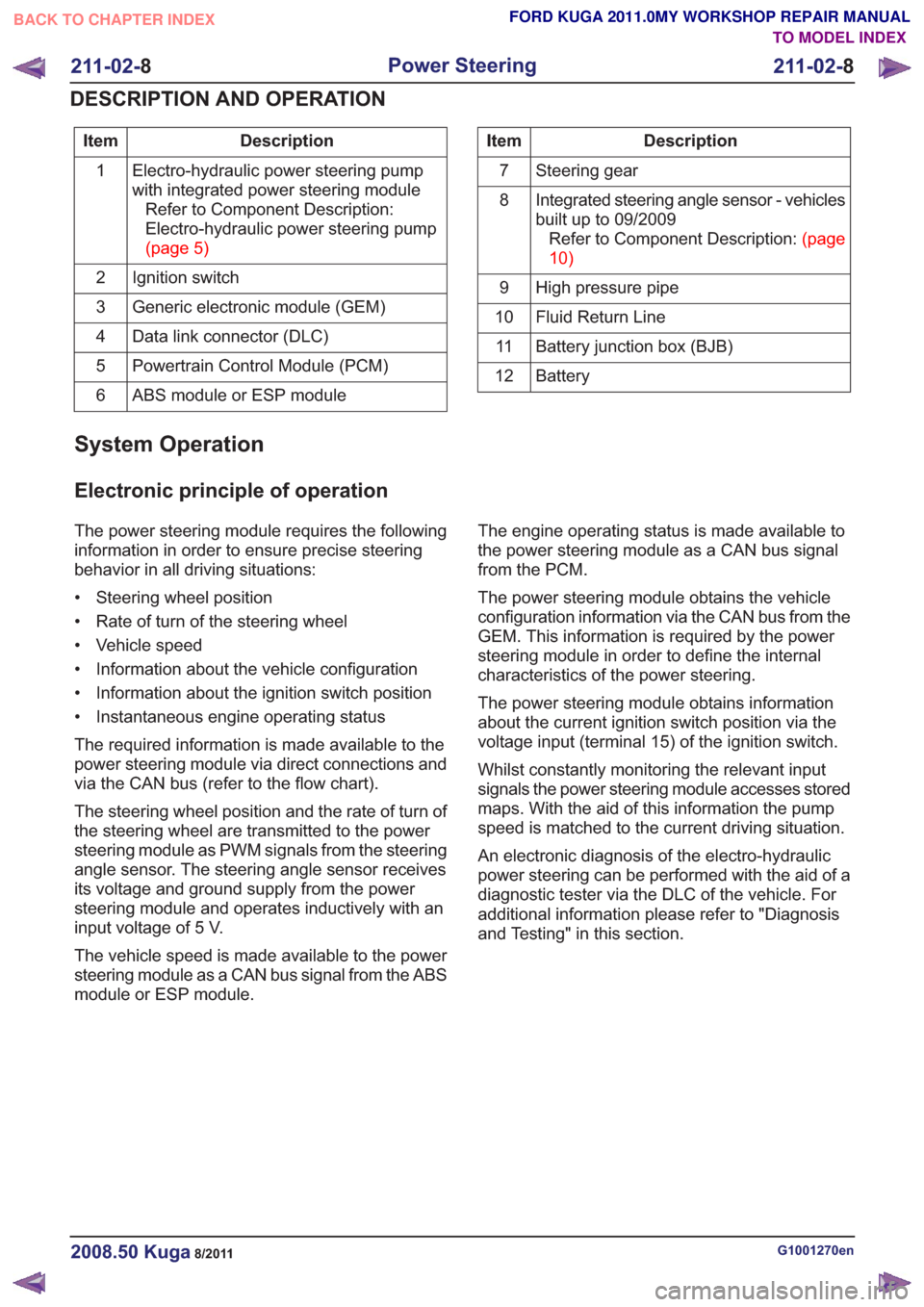

Description

Item

Electro-hydraulic power steering pump

with integrated power steering moduleRefer to Component Description:

Electro-hydraulic power steering pump

(page5)

1

Ignition switch

2

Generic electronic module (GEM)

3

Data link connector (DLC)

4

Powertrain Control Module (PCM)

5

ABS module or ESP module

6Description

Item

Steering gear

7

Integrated steering angle sensor - vehicles

built up to 09/2009RefertoComponentDescription:(page

10)

8

High pressure pipe

9

Fluid Return Line

10

Battery junction box (BJB)

11

Battery

12

System Operation

Electronic principle of operation

The power steering module requires the following

information in order to ensure precise steering

behavior in all driving situations:

• Steering wheel position

• Rate of turn of the steering wheel

• Vehicle speed

• Information about the vehicle configuration

• Information about the ignition switch position

• Instantaneous engine operating status

The required information is made available to the

power steering module via direct connections and

via the CAN bus (refer to the flow chart).

The steering wheel position and the rate of turn of

the steering wheel are transmitted to the power

steering module as PWM signals from the steering

angle sensor. The steering angle sensor receives

its voltage and ground supply from the power

steering module and operates inductively with an

input voltage of 5 V.

The vehicle speed is made available to the power

steering module as a CAN bus signal from the ABS

module or ESP module. The engine operating status is made available to

the power steering module as a CAN bus signal

from the PCM.

The power steering module obtains the vehicle

configuration information via the CAN bus from the

GEM. This information is required by the power

steering module in order to define the internal

characteristics of the power steering.

The power steering module obtains information

about the current ignition switch position via the

voltage input (terminal 15) of the ignition switch.

Whilst constantly monitoring the relevant input

signals the power steering module accesses stored

maps. With the aid of this information the pump

speed is matched to the current driving situation.

An electronic diagnosis of the electro-hydraulic

power steering can be performed with the aid of a

diagnostic tester via the DLC of the vehicle. For

additional information please refer to "Diagnosis

and Testing" in this section.

G1001270en2008.50 Kuga8/2011

211-02-

8

Power Steering

211-02- 8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1469 of 2057

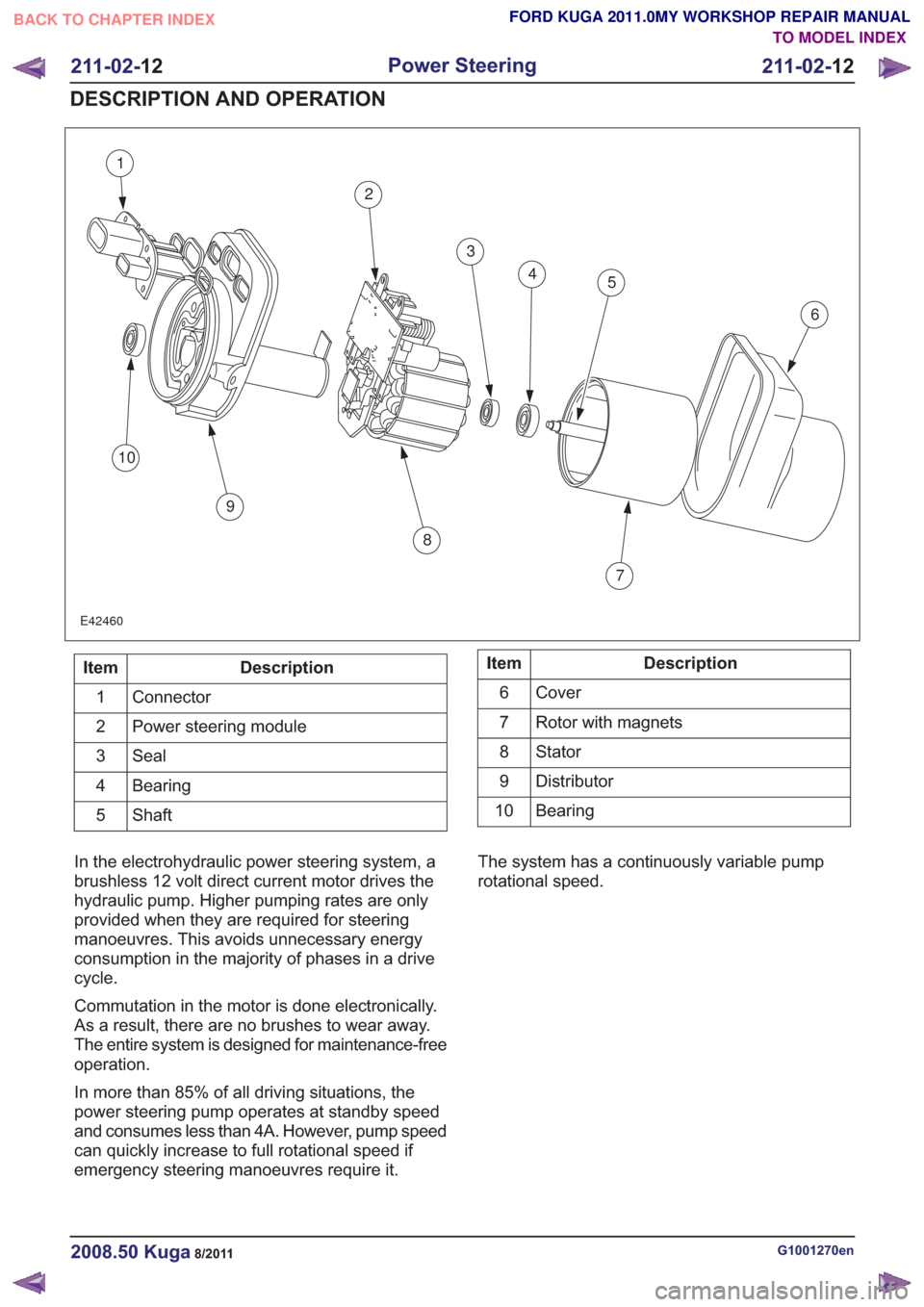

1

2

3

45

6

7

8

9

10

E42460

Description

Item

Connector

1

Power steering module

2

Seal

3

Bearing

4

Shaft

5Description

Item

Cover

6

Rotor with magnets

7

Stator8

Distributor

9

Bearing

10

In the electrohydraulic power steering system, a

brushless 12 volt direct current motor drives the

hydraulic pump. Higher pumping rates are only

provided when they are required for steering

manoeuvres. This avoids unnecessary energy

consumption in the majority of phases in a drive

cycle.

Commutation in the motor is done electronically.

As a result, there are no brushes to wear away.

The entire system is designed for maintenance-free

operation.

In more than 85% of all driving situations, the

power steering pump operates at standby speed

and consumes less than 4A. However, pump speed

can quickly increase to full rotational speed if

emergency steering manoeuvres require it. The system has a continuously variable pump

rotational speed.

G1001270en2008.50 Kuga8/2011

211-02-

12

Power Steering

211-02- 12

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1518 of 2057

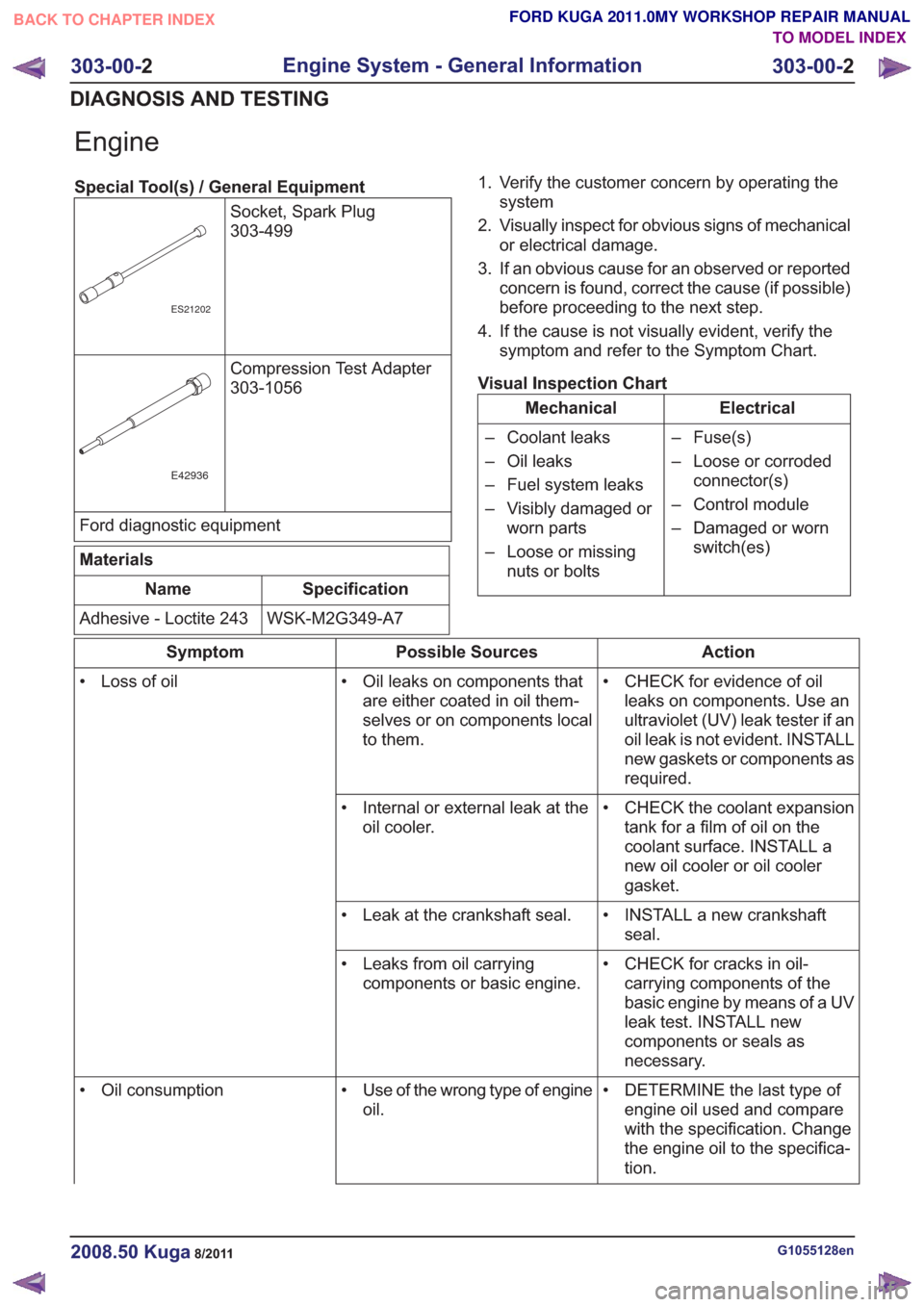

Engine

Special Tool(s) / General EquipmentSocket, Spark Plug

303-499

ES21202

Compression Test Adapter

303-1056

E42936

Ford diagnostic equipment

Materials

Specification

Name

WSK-M2G349-A7

Adhesive - Loctite 243 1. Verify the customer concern by operating the

system

2. Visually inspect for obvious signs of mechanical or electrical damage.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

Visual Inspection Chart

Electrical

Mechanical

– Fuse(s)

– Loose or corrodedconnector(s)

– Control module

– Damaged or worn switch(es)

– Coolant leaks

– Oil leaks

– Fuel system leaks

– Visibly damaged or

worn parts

– Loose or missing nuts or bolts

Action

Possible Sources

Symptom

• CHECK for evidence of oilleaks on components. Use an

ultraviolet (UV) leak tester if an

oil leak is not evident. INSTALL

new gaskets or components as

required.

• Oil leaks on components that

are either coated in oil them-

selves or on components local

to them.

• Loss of oil

• CHECK the coolant expansiontank for a film of oil on the

coolant surface. INSTALL a

new oil cooler or oil cooler

gasket.

• Internal or external leak at the

oil cooler.

• INSTALL a new crankshaftseal.

• Leak at the crankshaft seal.

• CHECK for cracks in oil-carrying components of the

basic engine by means of a UV

leak test. INSTALL new

components or seals as

necessary.

• Leaks from oil carrying

components or basic engine.

• DETERMINE the last type ofengine oil used and compare

with the specification. Change

the engine oil to the specifica-

tion.

• Use of the wrong type of engine

oil.

• Oil consumption

G1055128en2008.50 Kuga8/2011

303-00-

2

Engine System - General Information

303-00- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1528 of 2057

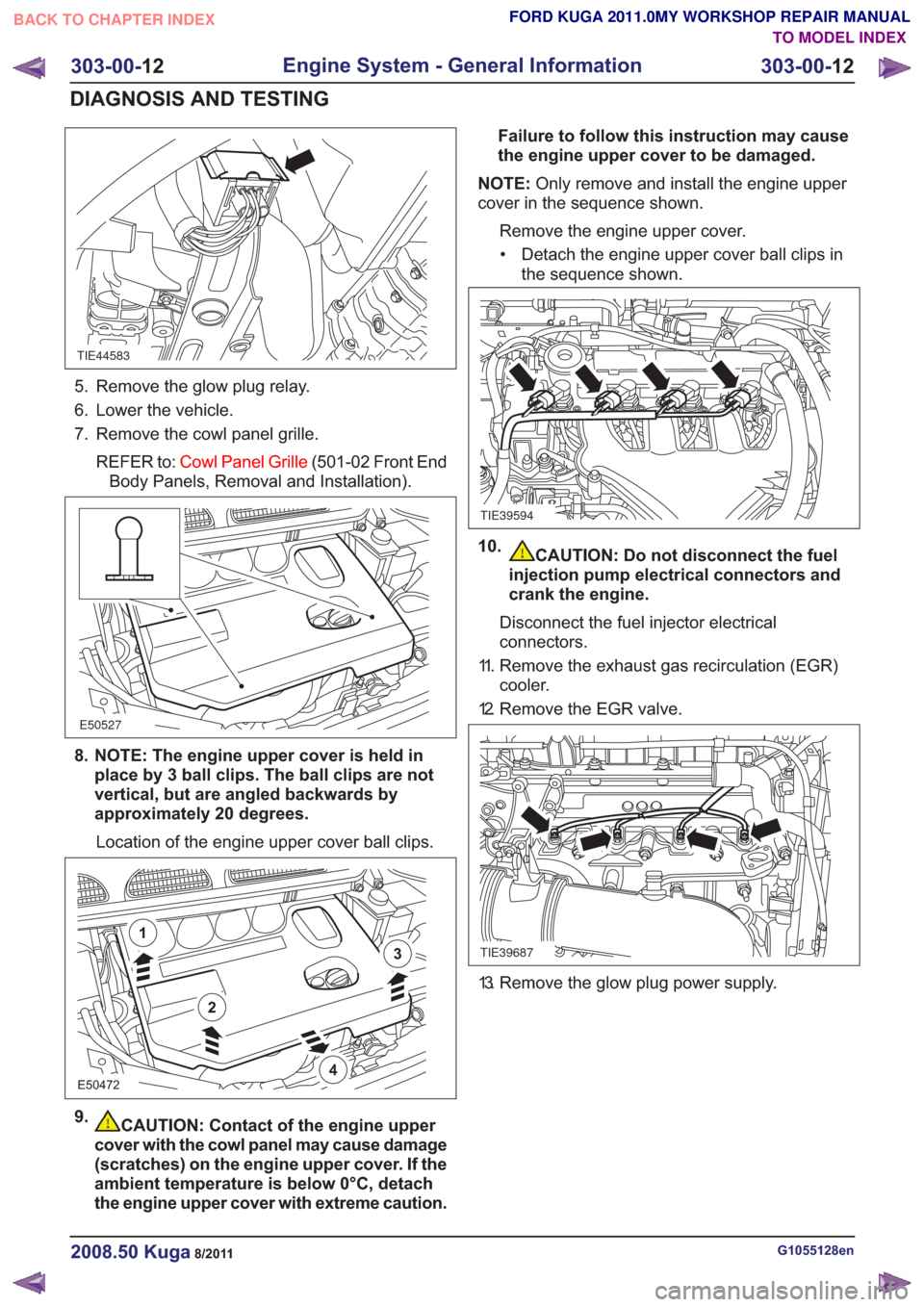

TIE44583

5. Remove the glow plug relay.

6. Lower the vehicle.

7. Remove the cowl panel grille.REFER to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

E50527

8. NOTE: The engine upper cover is held in place by 3 ball clips. The ball clips are not

vertical, but are angled backwards by

approximately 20 degrees.

Location of the engine upper cover ball clips.

E50472

2

1

3

4

9.CAUTION: Contact of the engine upper

cover with the cowl panel may cause damage

(scratches) on the engine upper cover. If the

ambient temperature is below 0°C, detach

the engine upper cover with extreme caution. Failure to follow this instruction may cause

the engine upper cover to be damaged.

NOTE: Only remove and install the engine upper

cover in the sequence shown.

Remove the engine upper cover.• Detach the engine upper cover ball clips in the sequence shown.

TIE39594

10.CAUTION: Do not disconnect the fuel

injection pump electrical connectors and

crank the engine.

Disconnect the fuel injector electrical

connectors.

11. Remove the exhaust gas recirculation (EGR) cooler.

12. Remove the EGR valve.

TIE39687

13. Remove the glow plug power supply.

G1055128en2008.50 Kuga8/2011

303-00- 12

Engine System - General Information

303-00- 12

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1529 of 2057

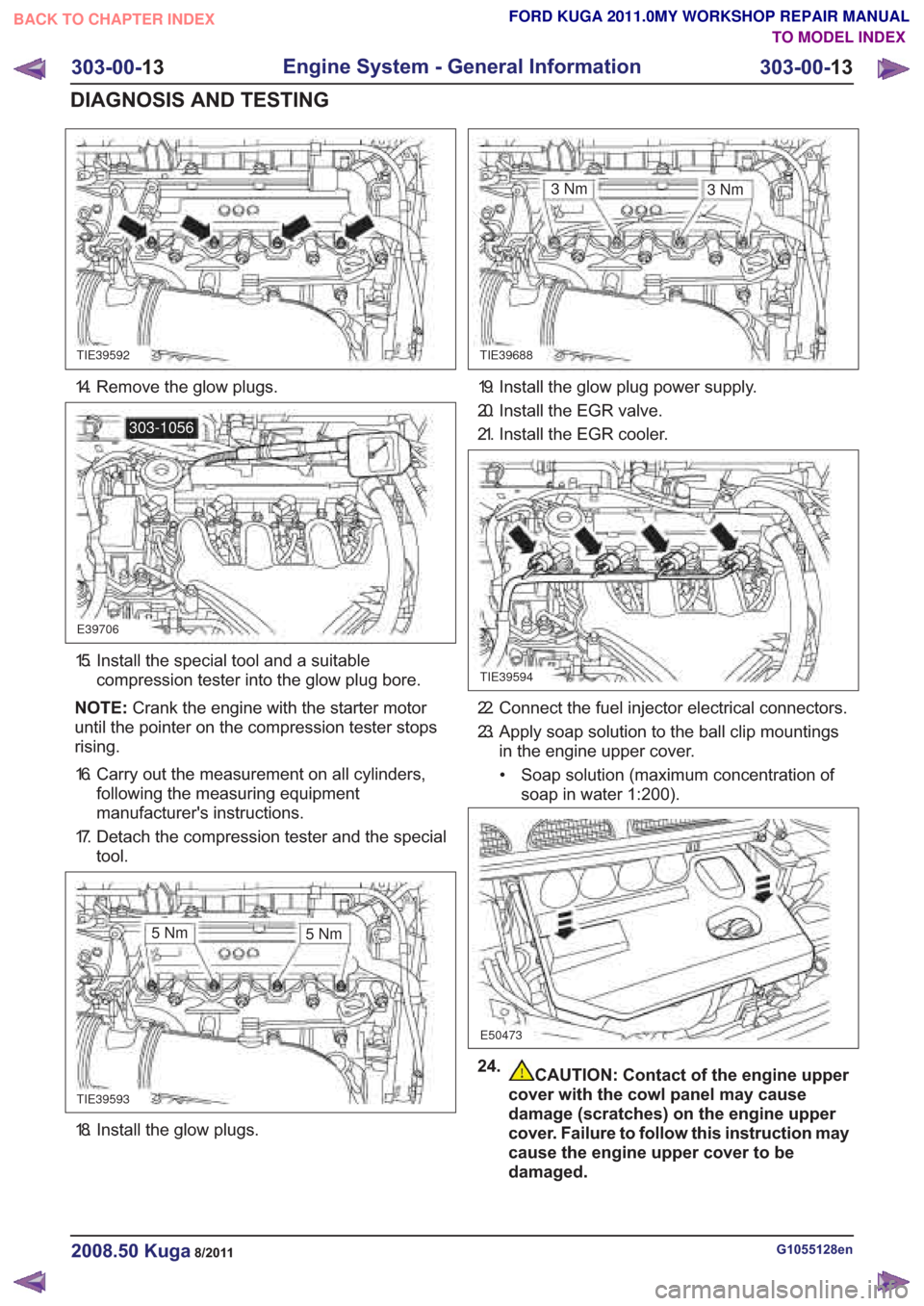

18. Install the glow plugs.

CAUTION: Contact of the engine upper

cover with the cowl panel may cause

damage (scratches) on the engine upper

cover. Failure to follow this instruction may

cause the engine upper cover to be

damaged.

G1055128en2008.50 Kuga8/2011

303-00- 13

Engine System - General Information

303-00- 13

DIAGNOSIS AND TESTING

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

TO MODEL INDEX

BACK TO CHAPTER INDEX

TIE39592TIE39688

E39706

303-1056

TIE39593

3Nm

TIE39594

E50473

3Nm

5Nm 5Nm

14. Remove the glow plugs.

15. Install the special tool and a suitable

compression tester into the glow plug bore.

NOTE: Crank the engine with the starter motor

until the pointer on the compression tester stops

rising.

16. Carry out the measurement on all cylinders, following the measuring equipment

manufacturer's instructions.

17. Detach the compression tester and the special tool.

19. Install the glow plug power supply.

20. Install the EGR valve.

21. Install the EGR cooler.

22. Connect the fuel injector electrical connectors.

23. Apply soap solution to the ball clip mountingsin the engine upper cover.

• Soap solution (maximum concentration of soap in water 1:200).

24.

Page 1530 of 2057

Put the engine cover into installation position

and clip it in place by pressing at the places

shown.• Make sure that the engine upper cover is fully engaged in the area of the fuel filter, if

necessary apply more pressure in the areas

shown.

25. Install the cowl panel grille.

REFER to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

26. Raise and support the vehicle.

REFER to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

TIE44583

27. Install the glow plug relay.

VFE0035752

28. Install the radiator undershield.

VFE0035742

29. Install the engine undershield.

30. Lower the vehicle.

31. Reset the PCM fault memory.

Measure the oil pressure (21 113 0)

The oil pressure depends on various factors

(engine speed, oil temperature, oil viscosity,

amount of oil filter contamination etc.).

Measure the oil pressure (Engine - 2.5L

Duratec-ST (VI5))

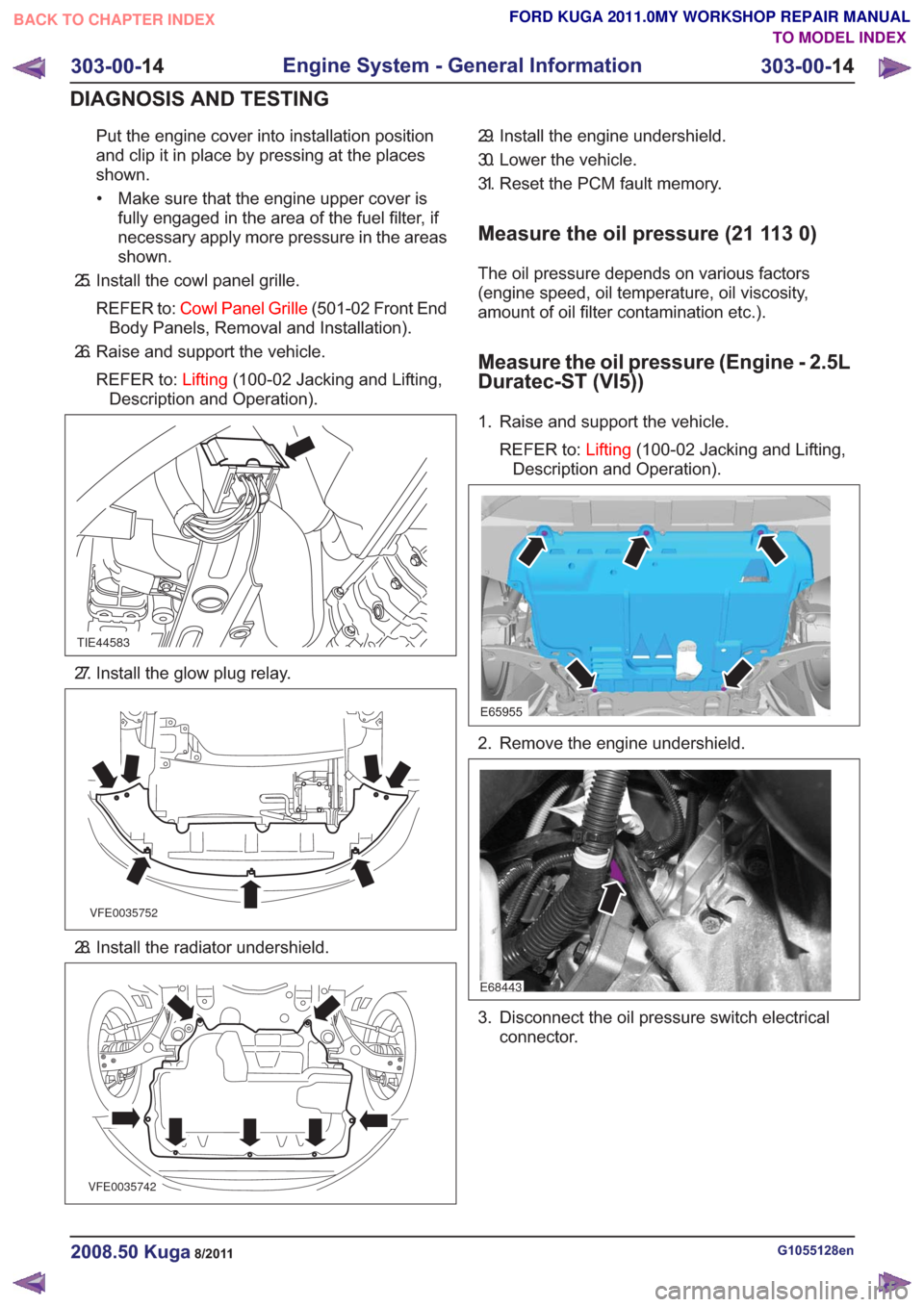

1. Raise and support the vehicle.

REFER to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

E65955

2. Remove the engine undershield.

E68443

3. Disconnect the oil pressure switch electrical connector.

G1055128en2008.50 Kuga8/2011

303-00- 14

Engine System - General Information

303-00- 14

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1531 of 2057

E68435

4. Remove the oil pressure switch.

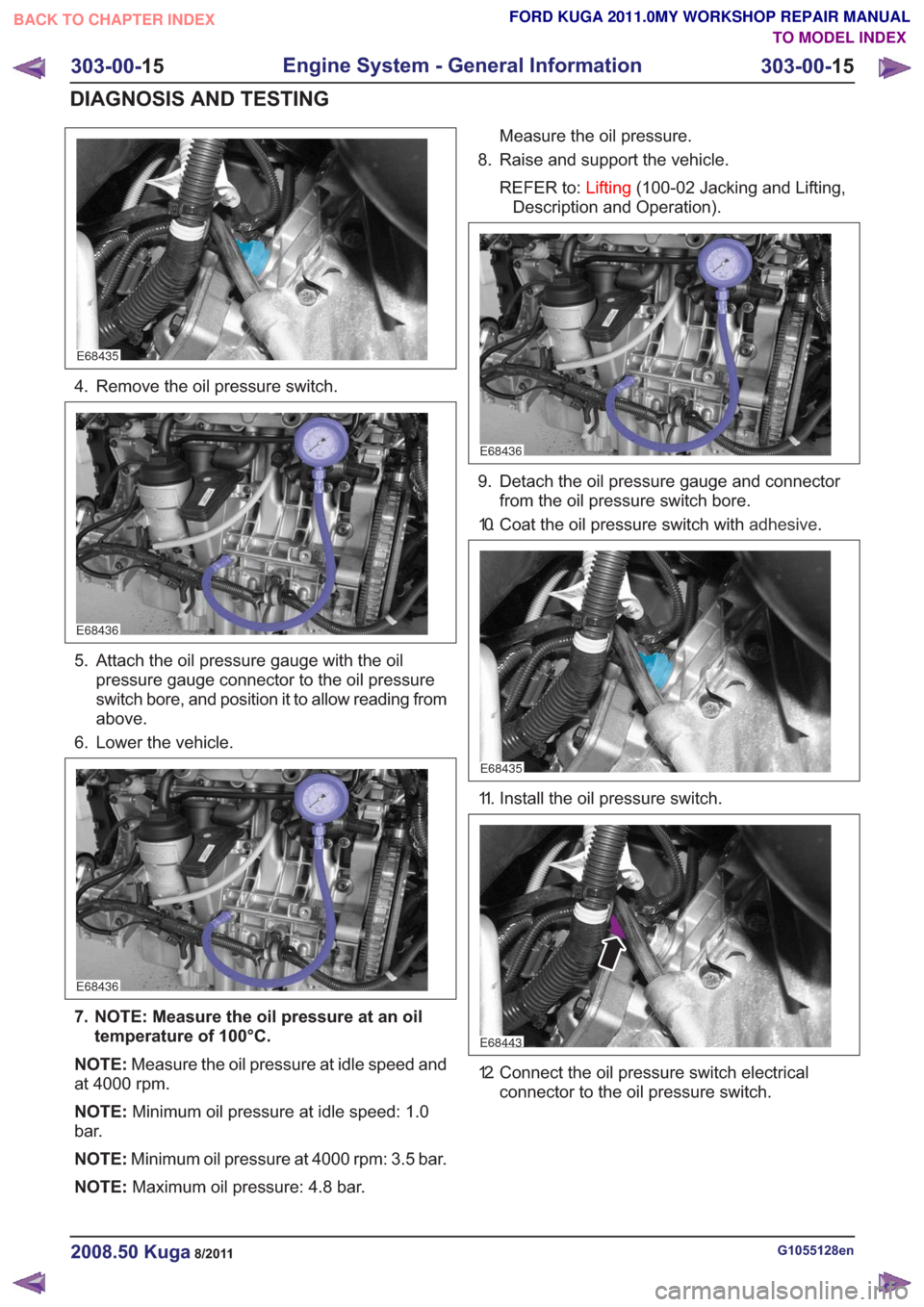

E68436

5. Attach the oil pressure gauge with the oilpressure gauge connector to the oil pressure

switch bore, and position it to allow reading from

above.

6. Lower the vehicle.

E68436

7. NOTE: Measure the oil pressure at an oil temperature of 100°C.

NOTE: Measure the oil pressure at idle speed and

at 4000 rpm.

NOTE: Minimum oil pressure at idle speed: 1.0

bar.

NOTE: Minimum oil pressure at 4000 rpm: 3.5 bar.

NOTE: Maximum oil pressure: 4.8 bar. Measure the oil pressure.

8. Raise and support the vehicle.

REFER to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

E68436

9. Detach the oil pressure gauge and connector from the oil pressure switch bore.

10. Coat the oil pressure switch with adhesive.

E68435

11. Install the oil pressure switch.

E68443

12. Connect the oil pressure switch electrical

connector to the oil pressure switch.

G1055128en2008.50 Kuga8/2011

303-00- 15

Engine System - General Information

303-00- 15

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL