differential FORD KUGA 2011 1.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1295 of 2057

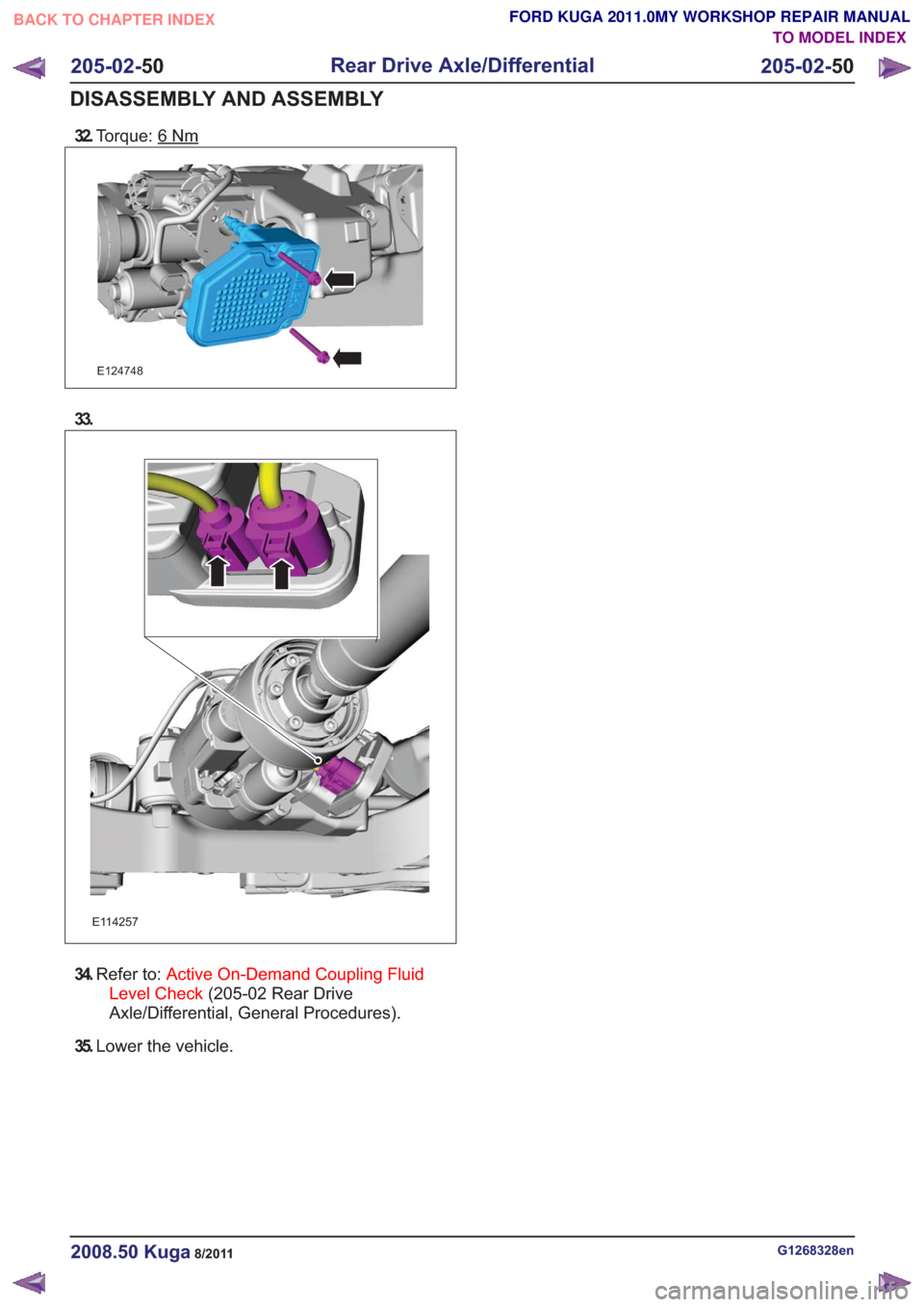

32.Torque: 6Nm

E124748

33.

E114257

34.Refer to: Active On-Demand Coupling Fluid

Level Check (205-02 Rear Drive

Axle/Differential, General Procedures).

35. Lower the vehicle.

G1268328en2008.50 Kuga8/2011

205-02- 50

Rear Drive Axle/Differential

205-02- 50

DISASSEMBLY AND ASSEMBLY

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1299 of 2057

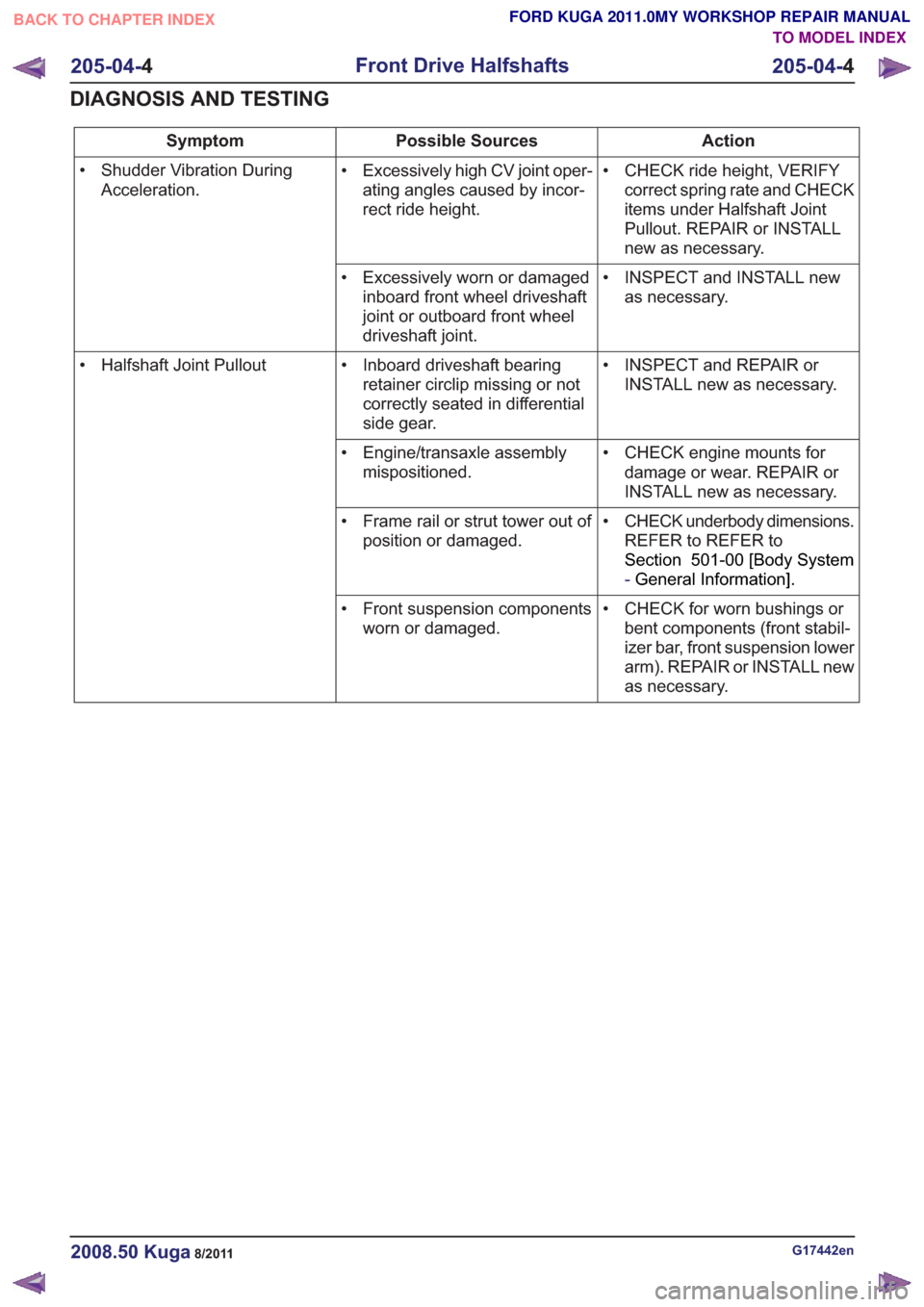

Action

Possible Sources

Symptom

• CHECK ride height, VERIFYcorrect spring rate and CHECK

items under Halfshaft Joint

Pullout. REPAIR or INSTALL

new as necessary.

• Excessively high CV joint oper-

ating angles caused by incor-

rect ride height.

• Shudder Vibration During

Acceleration.

• INSPECT and INSTALL newas necessary.

• Excessively worn or damaged

inboard front wheel driveshaft

joint or outboard front wheel

driveshaft joint.

• INSPECT and REPAIR orINSTALL new as necessary.

• Inboard driveshaft bearing

retainer circlip missing or not

correctly seated in differential

side gear.

• Halfshaft Joint Pullout

• CHECK engine mounts fordamage or wear. REPAIR or

INSTALL new as necessary.

• Engine/transaxle assembly

mispositioned.

• CHECK underbody dimensions.REFER to REFER to

Section 501-00 [Body System

-General Information] .

• Frame rail or strut tower out of

position or damaged.

• CHECK for worn bushings orbent components (front stabil-

izer bar, front suspension lower

arm). REPAIR or INSTALL new

as necessary.

• Front suspension components

worn or damaged.

G17442en2008.50 Kuga8/2011

205-04- 4

Front Drive Halfshafts

205-04- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1326 of 2057

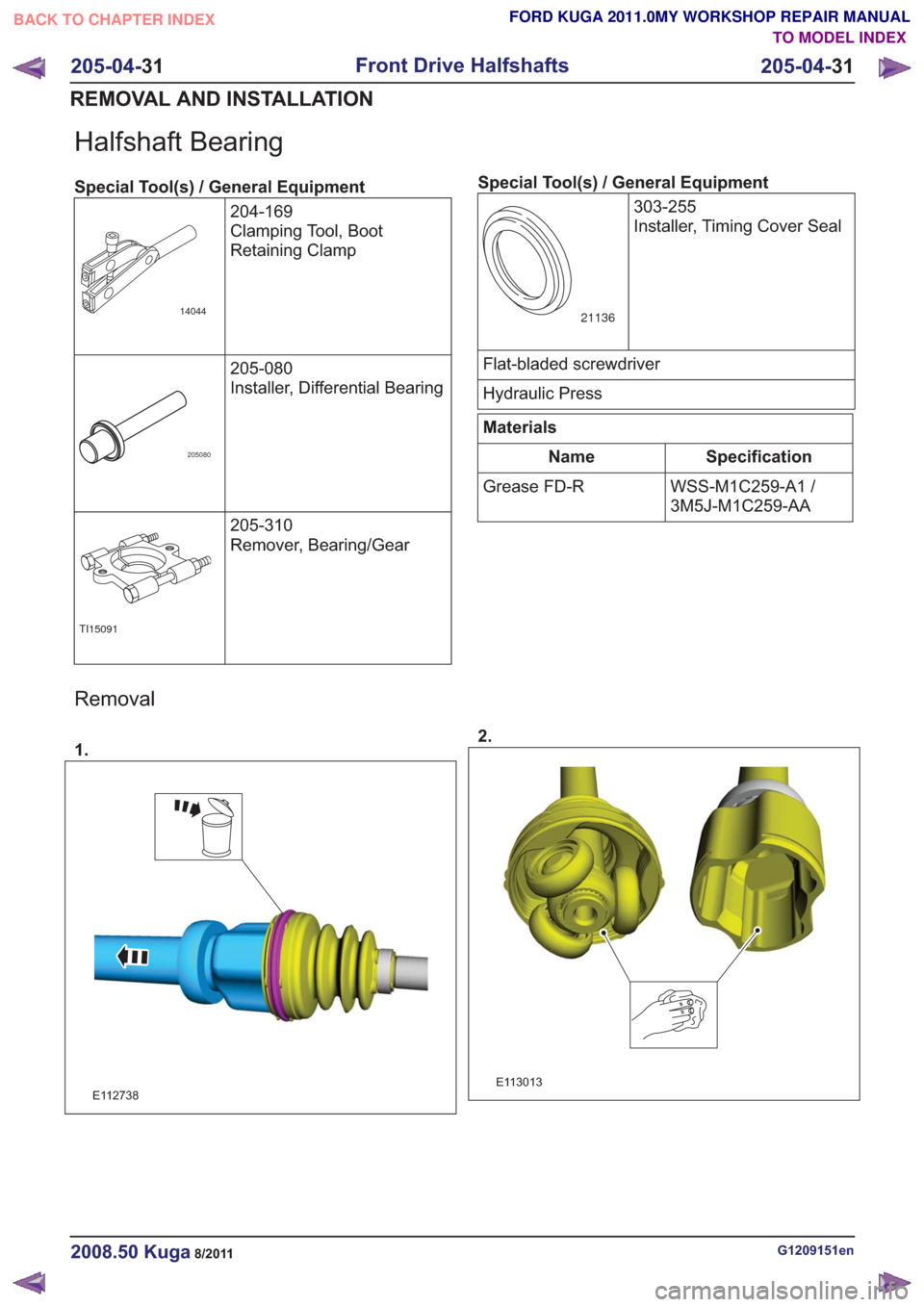

Halfshaft Bearing

Special Tool(s) / General Equipment204-169

Clamping Tool, Boot

Retaining Clamp

14044

205-080

Installer, Differential Bearing

205080

205-310

Remover, Bearing/Gear

TI15091

Special Tool(s) / General Equipment303-255

Installer, Timing Cover Seal

21136

Flat-bladed screwdriver

Hydraulic Press

Materials

Specification

Name

WSS-M1C259-A1 /

3M5J-M1C259-AA

Grease FD-R

Removal

1.

E112738

2.

E113013

G1209151en2008.50 Kuga8/2011

205-04-

31

Front Drive Halfshafts

205-04- 31

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1336 of 2057

15.On both sides.

Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

16. Refer to: Differential Fluid Level Check (205-02

Rear Drive Axle/Differential, General

Procedures).

G1058429en2008.50 Kuga8/2011

205-05- 8

Rear Drive Halfshafts

205-05- 8

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1825 of 2057

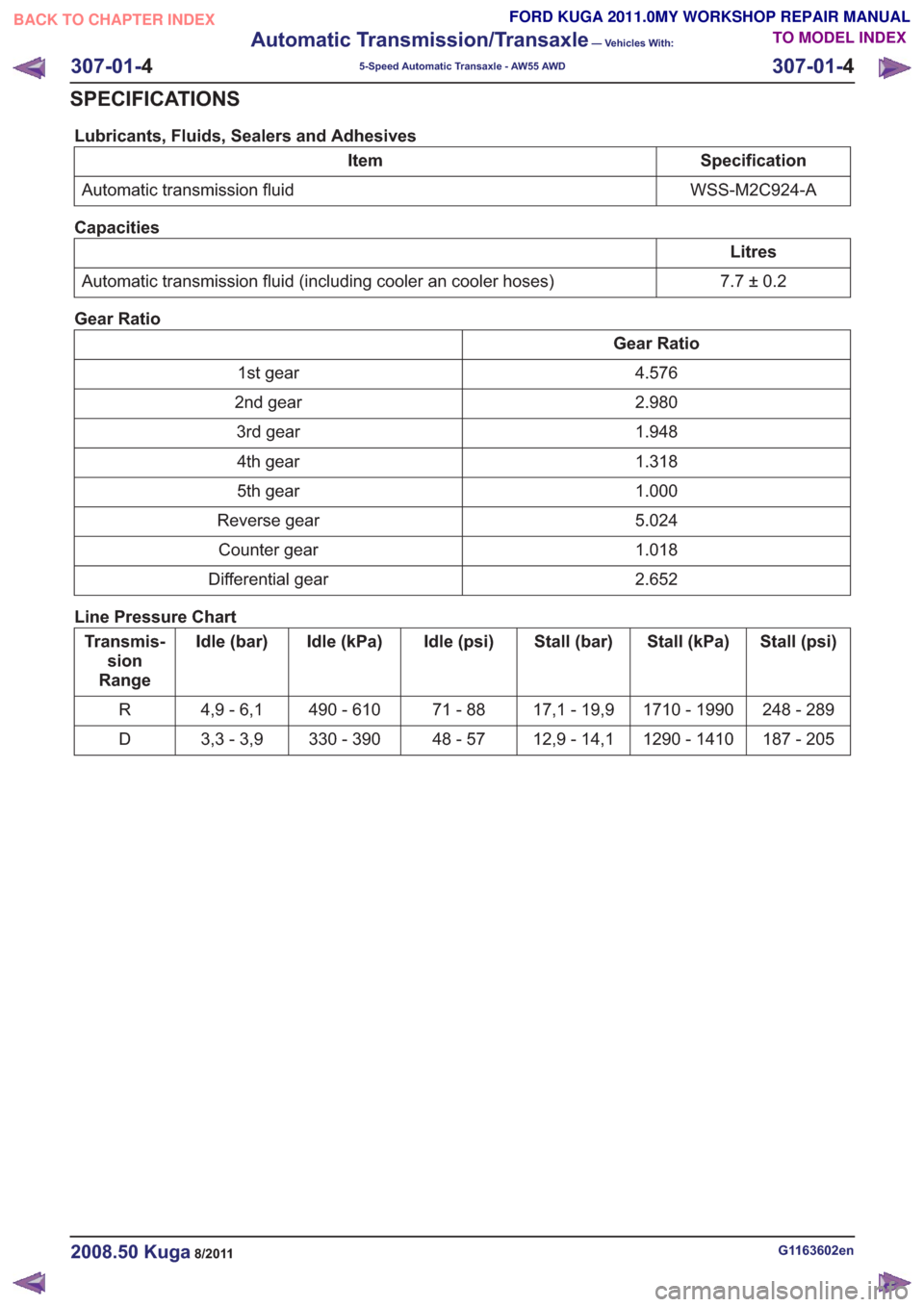

Lubricants, Fluids, Sealers and Adhesives

Specification

Item

WSS-M2C924-A

Automatic transmission fluid

Capacities

Litres

7.7±0.2

Automatic transmission fluid (including cooler an cooler hoses)

Gear Ratio

Gear Ratio 4.576

1st gear

2.980

2nd gear

1.948

3rd gear

1.318

4th gear

1.000

5th gear

5.024

Reverse gear

1.018

Counter gear

2.652

Differential gear

Line Pressure Chart

Stall (psi)

Stall (kPa)

Stall (bar)

Idle (psi)

Idle (kPa)

Idle (bar)

Transmis-

sion

Range

248 - 289

1710 - 1990

17,1 - 19,9

71 - 88

490 - 610

4,9 - 6,1

R

187 - 205

1290 - 1410

12,9 - 14,1

48 - 57

330 - 390

3,3 - 3,9

D

G1163602en2008.50 Kuga8/2011

307-01- 4

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 4

SPECIFICATIONS

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1827 of 2057

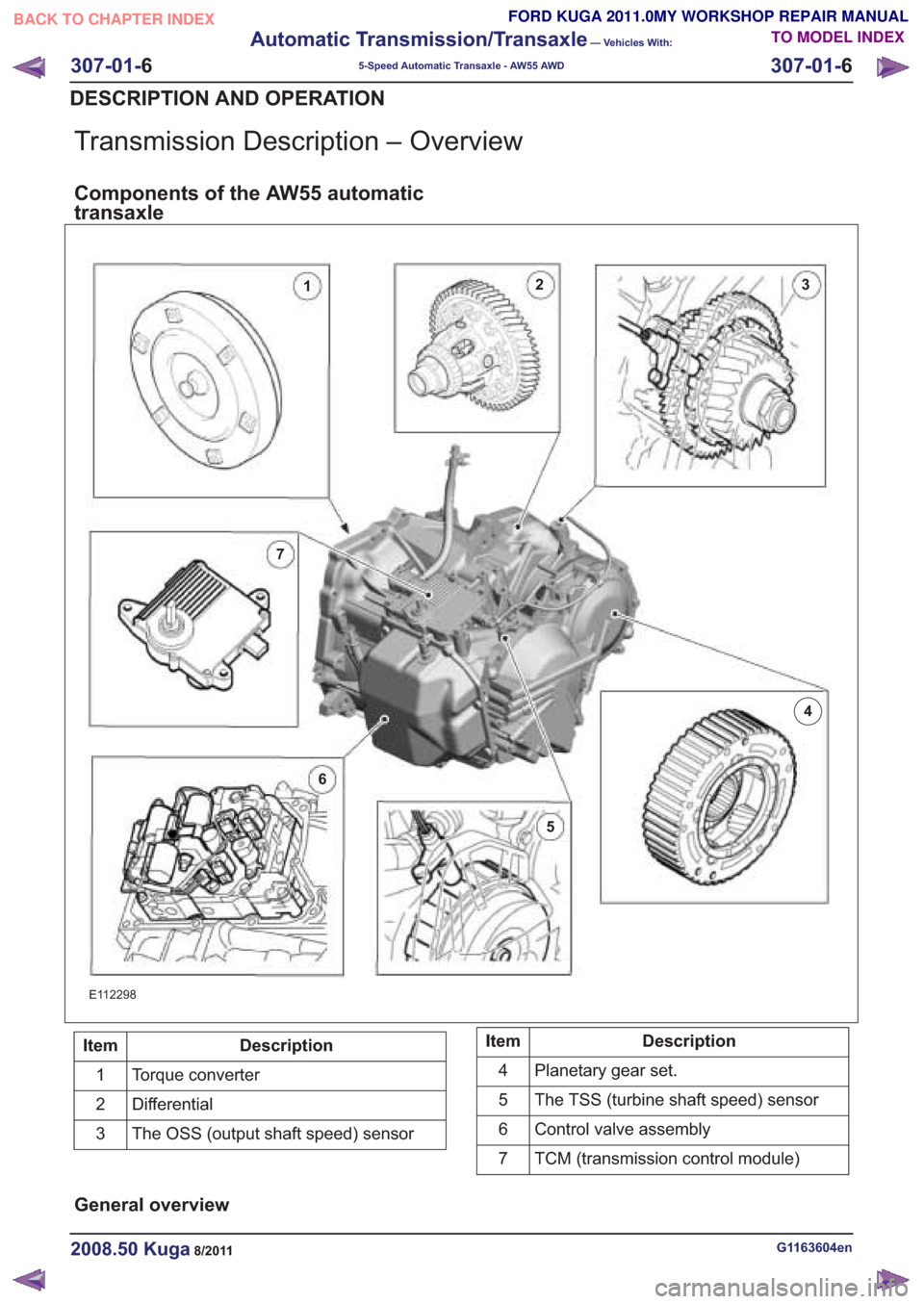

Transmission Description – Overview

Components of the AW55 automatic

transaxle

E112298

Description

Item

Torque converter

1

Differential

2

The OSS (output shaft speed) sensor

3Description

Item

Planetary gear set.

4

The TSS (turbine shaft speed) sensor

5

Control valve assembly

6

TCM (transmission control module)

7

General overview

G1163604en2008.50 Kuga8/2011

307-01- 6

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

23

4

5

6

7

1

Page 1828 of 2057

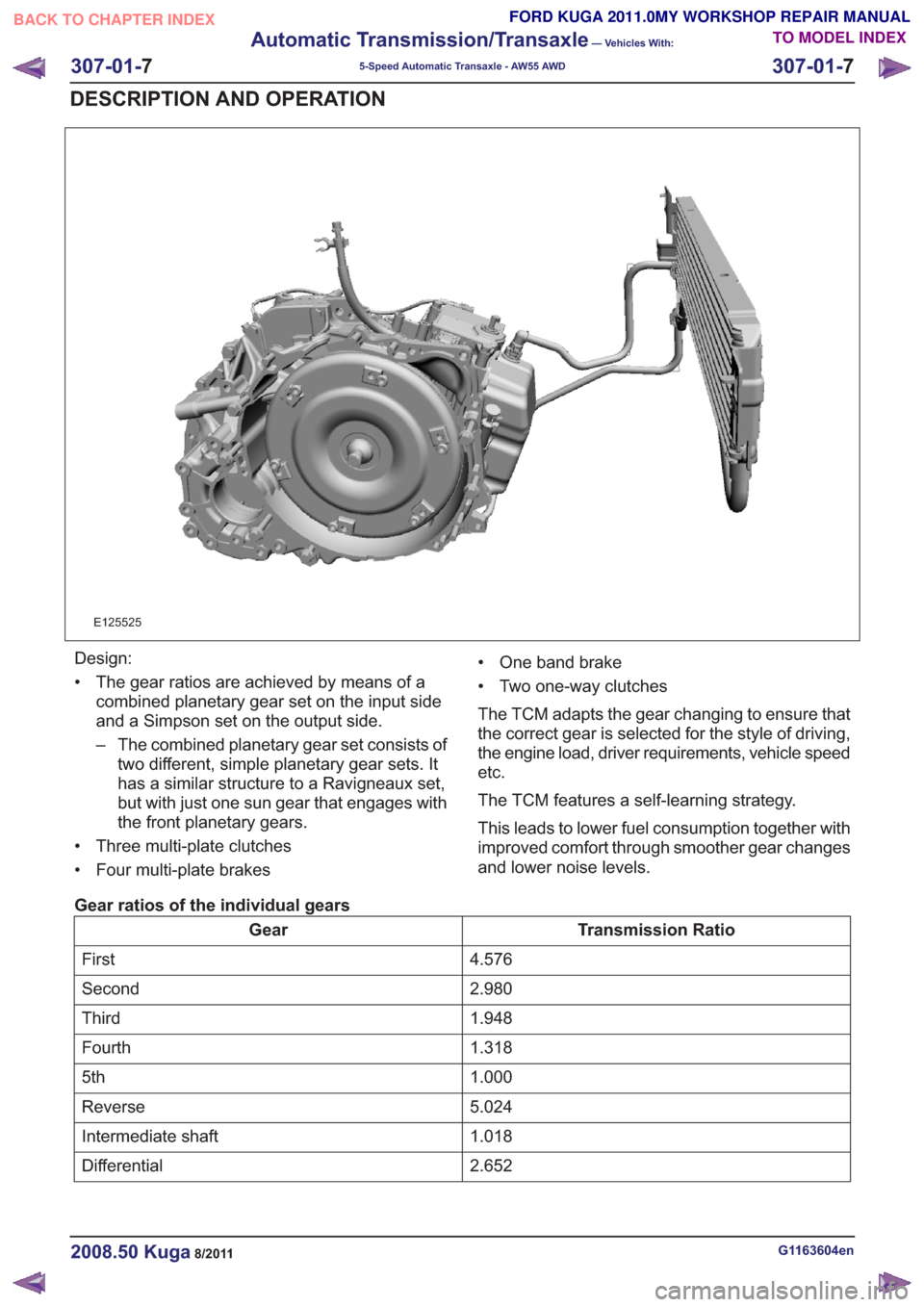

E125525

Design:

• The gear ratios are achieved by means of acombined planetary gear set on the input side

and a Simpson set on the output side.

– The combined planetary gear set consists oftwo different, simple planetary gear sets. It

has a similar structure to a Ravigneaux set,

but with just one sun gear that engages with

the front planetary gears.

• Three multi-plate clutches

• Four multi-plate brakes • One band brake

• Two one-way clutches

The TCM adapts the gear changing to ensure that

the correct gear is selected for the style of driving,

the engine load, driver requirements, vehicle speed

etc.

The TCM features a self-learning strategy.

This leads to lower fuel consumption together with

improved comfort through smoother gear changes

and lower noise levels.

Gear ratios of the individual gears

Transmission Ratio

Gear

4.576

First

2.980

Second

1.948

Third

1.318

Fourth

1.000

5th

5.024

Reverse

1.018

Intermediate shaft

2.652

Differential

G1163604en2008.50 Kuga8/2011

307-01- 7

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 7

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

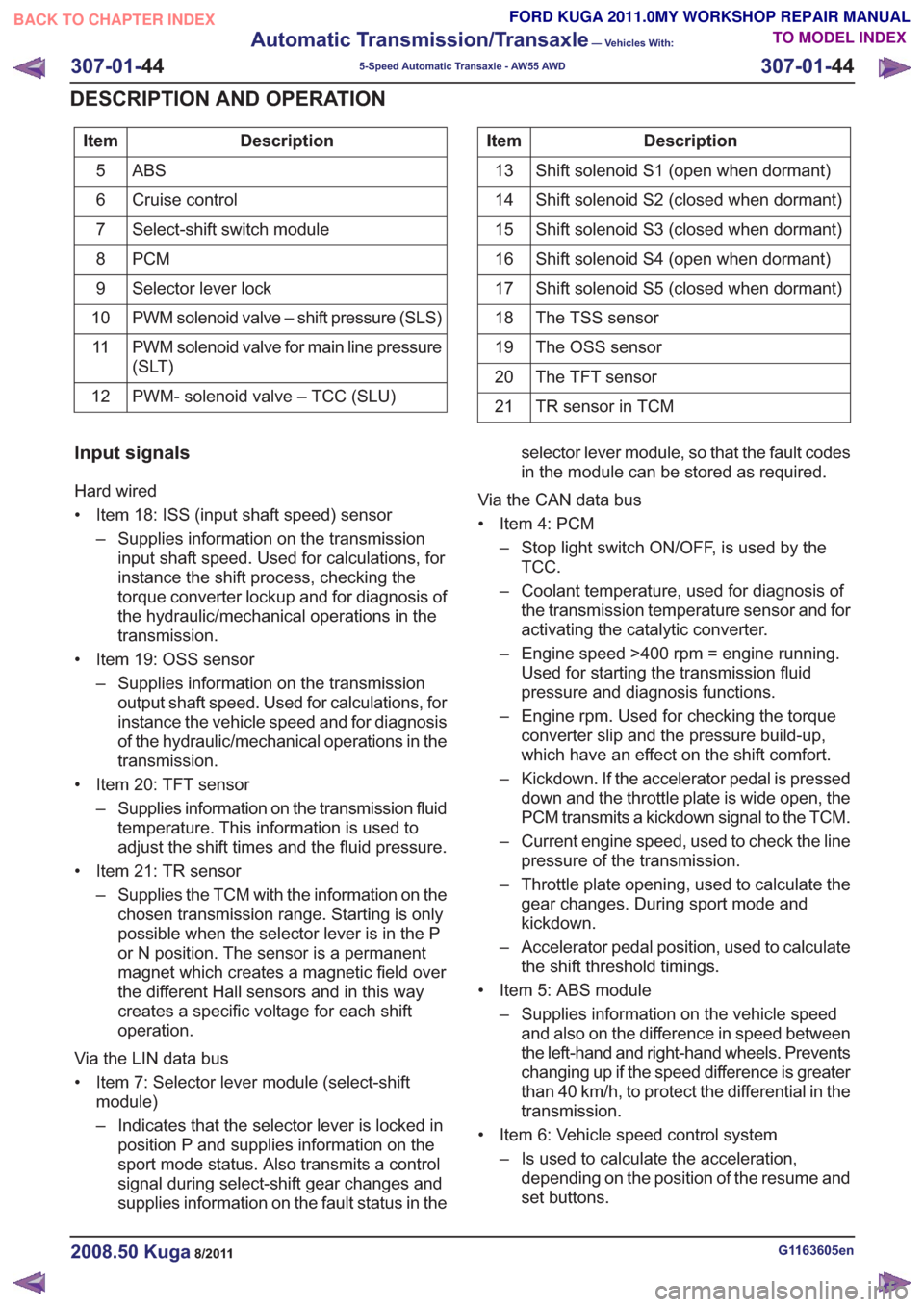

Page 1865 of 2057

Description

Item

ABS5

Cruise control

6

Select-shift switch module

7

PCM

8

Selector lever lock

9

PWM solenoid valve – shift pressure (SLS)

10

PWM solenoid valve for main line pressure

(SLT)

11

PWM- solenoid valve – TCC (SLU)

12Description

Item

Shift solenoid S1 (open when dormant)

13

Shift solenoid S2 (closed when dormant)

14

Shift solenoid S3 (closed when dormant)

15

Shift solenoid S4 (open when dormant)

16

Shift solenoid S5 (closed when dormant)

17

The TSS sensor

18

The OSS sensor

19

The TFT sensor

20

TR sensor in TCM

21

Input signals

Hard wired

• Item 18: ISS (input shaft speed) sensor

– Supplies information on the transmissioninput shaft speed. Used for calculations, for

instance the shift process, checking the

torque converter lockup and for diagnosis of

the hydraulic/mechanical operations in the

transmission.

• Item 19: OSS sensor – Supplies information on the transmissionoutput shaft speed. Used for calculations, for

instance the vehicle speed and for diagnosis

of the hydraulic/mechanical operations in the

transmission.

• Item 20: TFT sensor – Supplies information on the transmission fluidtemperature. This information is used to

adjust the shift times and the fluid pressure.

• Item 21: TR sensor – Supplies the TCM with the information on thechosen transmission range. Starting is only

possible when the selector lever is in the P

or N position. The sensor is a permanent

magnet which creates a magnetic field over

the different Hall sensors and in this way

creates a specific voltage for each shift

operation.

Via the LIN data bus

• Item 7: Selector lever module (select-shift module)

– Indicates that the selector lever is locked inposition P and supplies information on the

sport mode status. Also transmits a control

signal during select-shift gear changes and

supplies information on the fault status in the selector lever module, so that the fault codes

in the module can be stored as required.

Via the CAN data bus

• Item 4: PCM – Stop light switch ON/OFF, is used by theTCC.

– Coolant temperature, used for diagnosis of the transmission temperature sensor and for

activating the catalytic converter.

– Engine speed >400 rpm = engine running. Used for starting the transmission fluid

pressure and diagnosis functions.

– Engine rpm. Used for checking the torque converter slip and the pressure build-up,

which have an effect on the shift comfort.

– Kickdown. If the accelerator pedal is pressed down and the throttle plate is wide open, the

PCM transmits a kickdown signal to the TCM.

– Current engine speed, used to check the line pressure of the transmission.

– Throttle plate opening, used to calculate the gear changes. During sport mode and

kickdown.

– Accelerator pedal position, used to calculate the shift threshold timings.

• Item 5: ABS module – Supplies information on the vehicle speedand also on the difference in speed between

the left-hand and right-hand wheels. Prevents

changing up if the speed difference is greater

than 40 km/h, to protect the differential in the

transmission.

• Item 6: Vehicle speed control system – Is used to calculate the acceleration,depending on the position of the resume and

set buttons.

G1163605en2008.50 Kuga8/2011

307-01- 44

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 44

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1888 of 2057

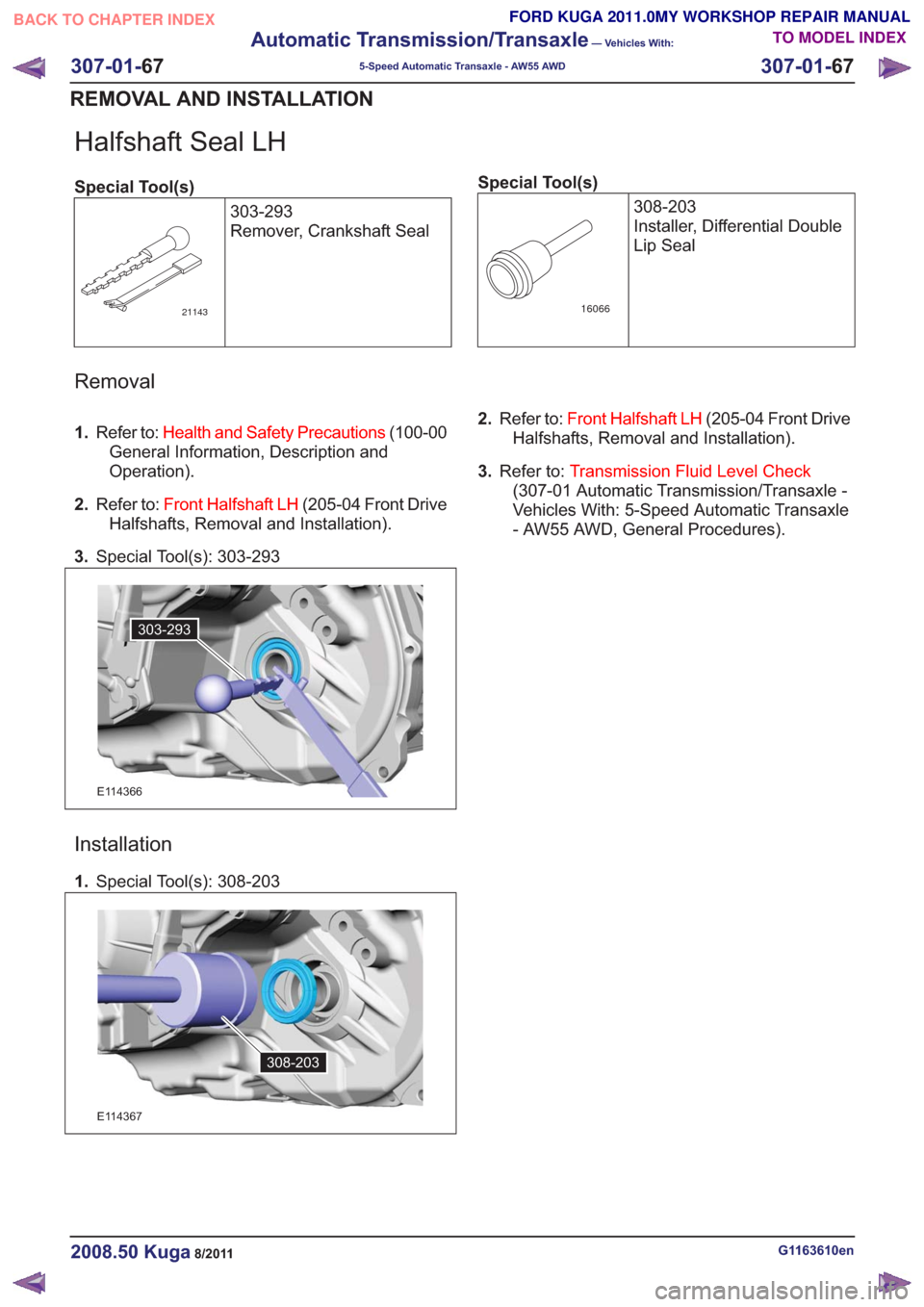

Halfshaft Seal LH

Special Tool(s)303-293

Remover, Crankshaft Seal

21143

Special Tool(s)308-203

Installer, Differential Double

Lip Seal

16066

Removal

1.Refer to: Health and Safety Precautions (100-00

General Information, Description and

Operation).

2. Refer to: Front Halfshaft LH (205-04 Front Drive

Halfshafts, Removal and Installation).

3. Special Tool(s): 303-293

303-293303-293

E114366

Installation

1.Special Tool(s): 308-203

308-203308-203

E114367

2.Refer to: Front Halfshaft LH (205-04 Front Drive

Halfshafts, Removal and Installation).

3. Refer to: Transmission Fluid Level Check

(307-01 Automatic Transmission/Transaxle -

Vehicles With: 5-Speed Automatic Transaxle

- AW55 AWD, General Procedures).

G1163610en2008.50 Kuga8/2011

307-01- 67

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 67

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1945 of 2057

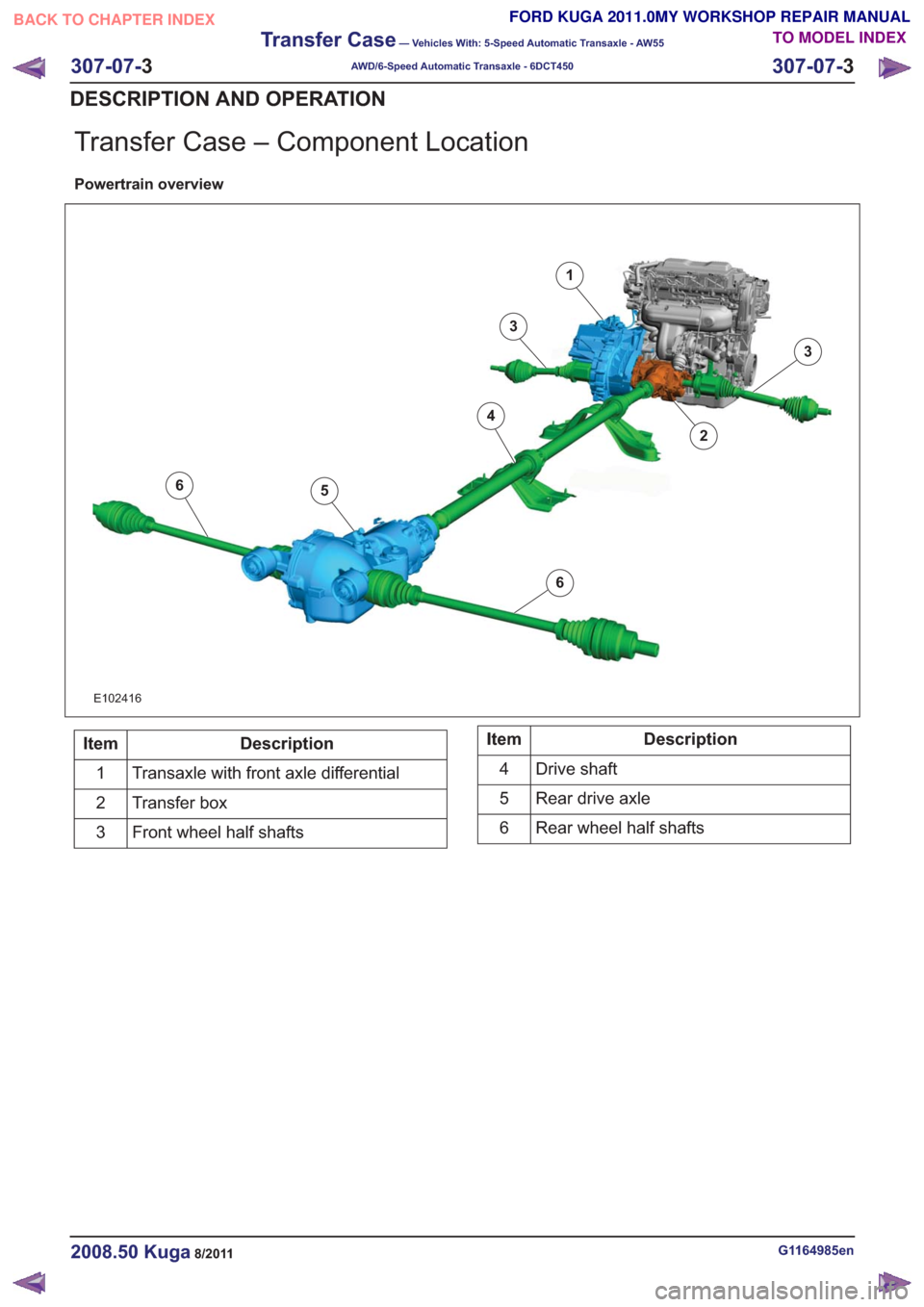

Transfer Case – Component Location

Powertrain overview

6

6

1

2

3

3

4

5

6

6

E102416

Description

Item

Transaxle with front axle differential

1

Transfer box

2

Front wheel half shafts

3Description

Item

Drive shaft

4

Rear drive axle

5

Rear wheel half shafts

6

G1164985en2008.50 Kuga8/2011

307-07- 3

Transfer Case

— Vehicles With: 5-Speed Automatic Transaxle - AW55

AWD/6-Speed Automatic Transaxle - 6DCT450

307-07- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL