parking FORD KUGA 2011 1.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 452 of 2057

Module Controlled Functions – Overview

Generic electronics module (GEM)

CAUTIONS:

Never swap the GEM (generic electronic

module) between two vehicles.

Compare the number of relays and fuses

in the defective GEM and the new GEM.

Transfer from the defective GEM any relays

and fuses which are not in the new GEM.

In doing so, pay attention that fuses with

the correct Ampere rating are used, by

referring to the wiring diagrams.

NOTE: The GEM is integrated in the CJB (central

junction box) and cannot be replaced as a separate

unit.

For repair work during a service, vehicle-specific

configuration is necessary if a new GEM is

installed.

Emergency function

The GEM is equipped with restricted emergency

running functions on vehicles with mid or high-end

equipment levels.

The microcontroller sends a control signal to a

monitoring function within the GEM at regular

intervals. If the battery voltage falls below a value

of approx. 7.5 volts, this check signal is not present

and the GEM switches to emergency function after

a predetermined time.

In this case, the low beam is permanently switched

on, regardless of the light switch position. The

windshield wiper can only be operated in stage 1;

the wiper switch must however be in the stage I or

II position. The wiper park position is not

recognized. Intermittent wiping is not available.

When the control signal recurs, the GEM switches

back to normal operation.

Service mode

Description of operation

Diagnosis of the GEM can be carried out using the

Ford diagnostic unit. Furthermore, an integrated

service mode enables testing of the input and

output signals without the need for further tools.

To enable activation of service mode: • switch off the ignition,

• switch off all other electrical consumers,

• apply the handbrake,

• Shift to neutral

• and close the doors.

Activating the service mode

NOTE:

If the alarm is activated (in vehicles fitted

with an anti-theft alarm system), service mode

cannot be activated.

Proceed as follows to activate the service mode:

• OPERATE the switch of the heated rear window

and HOLD IT THERE

• SWITCH ON the ignition.

• RELEASE the switch of the heated rear window

A signal sounds and the turn signal lamps come

on to indicate that service mode has been

successfully activated.

Inputs

SWITCH the windshield wiper switch to the "OFF"

position to test the input signals. The following is

a list of the switch signals to be tested, in no

particular order:

• Windshield wiper stage I

• Windshield wiper stage II

• Windshield washer system

• Rear window wiper

• Rear window washer system

• Doors open/closed

• Remote control for central locking with double locking

• Hood open/closed (in vehicles equipped with an anti-theft alarm system)

• Tailgate open/closed

• A/C request signal

• Heated windscreen (if fitted)

• Parking brake

• Brake fluid level

• Cruise control system

• Autolamps

• Dipped beam

• Main beam

• Headlamp flasher

• Side lights

• Turn signals (right, left, hazard warning lights) G1030787en

2008.50 Kuga 8/2011 419-10-2

Multifunction Electronic Modules

419-10-2

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 456 of 2057

Description

Item

HS CAN

1

DLC2

MS CAN

3

Instrument cluster (gateway)

4

Front windshield wiper motors

5

GEM6

Rear window wiper motors

7

Indicator/heated windshield

8

Indicator/heated rear window

9 Description

Item

Mini-liftgate latch motor

10

Liftgate latch motor

11

Electric booster Heater

12

Front wiper windscreen washer pump

13

Rear wiper windscreen washer pump

14

Headlamp

15

Courtesy Lighting

16

Alarm horn

17

System Operation

GEM.

The following functions are controlled or performed

by the GEM at a battery voltage of between 9 and

16 volts:

• Current distribution

• Battery charging (Smart Charge)

• Ignition overload protection

• Headlamp switch-off delay

• Turn signals

• Interior lighting

• Heated windscreen

• Heated rear window and heated external mirrors

• Ambient air temperature

• Brake fluid level

• Automatic headlamps

• Combined rain sensor/light sensor

• Windshield wash/wipe system

• Speed control – reads the speed control switches andtransmits signals on the CAN data bus

• central door locking – transmits signals on the CAN data bus

• Anti-theft

• Electric booster Heater

• Climate control

• Parking brake –(monitors the switch and transmits the signal

on the CAN data bus

• Communication via the medium-speed CAN data bus Component Description

Battery charging (Smart Charge)

In addition to the familiar functions, the Smart

Charge system also performs the following

functions:

•

Automatic deactivation of non-critical high power

electrical consumers when the battery voltage

is low in order to reduce the level of current

drawn.

• Automatic activation of non-critical high power electrical consumers when the battery voltage

is excessively high in order to protect

components which are sensitive to increased

voltages.

The battery charging current is optimized through

continuous calculation of the battery temperature

and monitoring of the alternator output voltage.

The alternator load is signaled to the PCM

(powertrain control module) in order to provide it

with an early indication when an electric component

is to be switched on or off, thereby also providing

information about imminent changes to the amount

of torque demanded by the alternator. By

evaluating this information the PCM is capable of

increasing the stability of the engine under idling.

The two remaining functions of the Smart Charge

system are controlled by the GEM. G1030788en

2008.50 Kuga 8/2011 419-10-6

Multifunction Electronic Modules

419-10-6

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 461 of 2057

Generic Electronic Module (GEM)

Refer to Wiring Diagrams Section 419-10, for

schematic and connector information.

Special Tool(s) / General Equipment

Terminal Probe Kit

418-S035Digital multimeter

Ford approved diagnostic tool

Description of operation

A diagnosis of the generic electronic module (GEM)

can be performed with the Ford approved

diagnostic tool. Furthermore, an integrated service

mode enables testing of the input and output

signals without the need for further tools. To enable

activation of service mode:

• Switch off the ignition

• Switch off all other electrical consumers

• Apply the handbrake

• Shift to neutral

• Close the doors.

Activate service mode

Proceed as follows to activate service mode:

• PRESS and HOLD the switch of the heated rear

window

• SWITCH ON the ignition.

• RELEASE the switch of the heated rear window

A signal sounds and the turn signal lamps

illuminate to indicate that service mode has been

successfully activated.

NOTE: If the alarm is armed (in vehicles fitted with

an anti-theft alarm system), service mode cannot

be activated.

Input signals

SWITCH the windshield wiper switch to the "Off"

position to test the input signals. The following is

a list of the switch signals to be tested, in no

particular order: • Turn signals (right, left, hazard warning lights)

• Windshield wiper stage I

• Windshield wiper stage II

• Windshield washer system

• Rear window wiper

• Rear window washer system

• Doors open/closed

• Door key cylinder set/reset switch

• Remote control for central locking with double

locking

• Hood up/down (in vehicles fitted with anti-theft alarm system)

• Tailgate open/closed

• Mini liftgate open/closed

• Manual A/C request signal

• Manual AUX heater request signal

• Heated windshield (if fitted)

• Parking brake

• Brake fluid level

• Cruise control system

• Autolamps

• Dipped beam

• Main beam

• Headlamp flasher

• Side lights

• Reversing lamp

• Tailgate release

• Mini liftgate release

• Interior scanning system

• Ignition switch, terminal 15 (turn key to 0 position, then turn key to II position.)

An acoustic signal sounds and the turn signal

lamps flash to indicate receipt of each input signal

by the generic electronic module.

Test the windshield wiper "intermittent mode" stage

input signal (only vehicles with adjustable

intermittent mode)

The windshield wiper switch must be switched to

"intermittent mode" in order to test the input signal.

The delay times of the input signals can then be

tested by operating the rotary switch. Each change

of the rotary switch position is indicated by an

acoustic signal and illumination of the turn signals. G1055084en

2008.50 Kuga 8/2011 419-10-11

Multifunction Electronic Modules

419-10-11

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL29011A

Page 1252 of 2057

General overview

Haldex clutches of the 3rd and 4th generations are

used in the Ford Kuga.

The development of the third generation Haldex

clutch represents a big step forward in modern

all-wheel technology. The Haldex clutch is

electro-hydraulically controlled. Additional

information is taken into consideration during

control tasks via the all-wheel drive control unit.

Slip alone is no longer decisive for the distribution

of the propulsive forces; the vehicle's driving

dynamics are also taken into consideration. The

control unit accesses the driving-related data via

the data bus. With this data, the control unit has

all the essential information about speed, cornering,

coasting or traction operation, and can optimally

react to every driving situation.

Compared with the previous generation, the 4th

generation Haldex clutches operate with higher

pressure and achieve shorter response times when

distributing the drive forces.

Advantages of the Haldex clutch:

• Permanent all-wheel drive withelectronically-controlled multi-plate clutch

• Fast response

• No straining when parking and manoeuvring

• Compatible with different tyres (e.g. emergency spare wheel)

• Fully combinable with driving dynamic control systems

The driveshaft is connected to the input shaft of

the Haldex clutch. Within the Haldex clutch, the

input shaft is separated from the output shaft to

the rear axle differential by means of a multi-plate

clutch. Torque is only transmitted to the rear axle

differential when the plate assembly of the Haldex

clutch is closed.

The multi-plate clutch is electro-hydraulically

controlled via the all-wheel drive control unit. For

ecological driving, the torque to the rear axle is reduced to a minimum up to a throttle position of

approx. 50%. A prerequisite for this is that there is

no difference in speed in the Haldex clutch between

the input and output shafts.

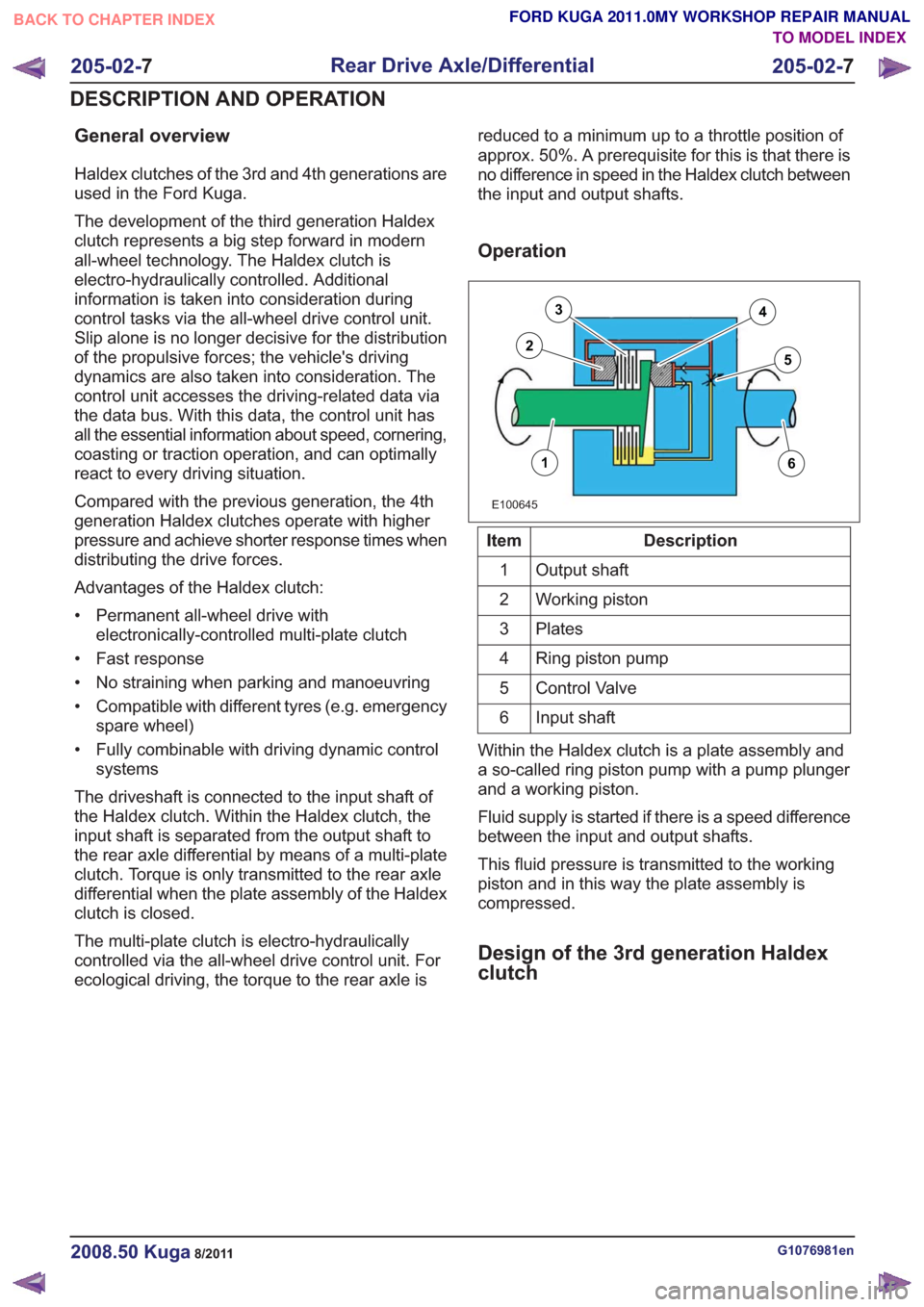

Operation

E100645

16

3

25

4

Description

Item

Output shaft

1

Working piston

2

Plates

3

Ring piston pump

4

Control Valve

5

Input shaft

6

Within the Haldex clutch is a plate assembly and

a so-called ring piston pump with a pump plunger

and a working piston.

Fluid supply is started if there is a speed difference

between the input and output shafts.

This fluid pressure is transmitted to the working

piston and in this way the plate assembly is

compressed.

Design of the 3rd generation Haldex

clutch

G1076981en2008.50 Kuga8/2011

205-02- 7

Rear Drive Axle/Differential

205-02- 7

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1340 of 2057

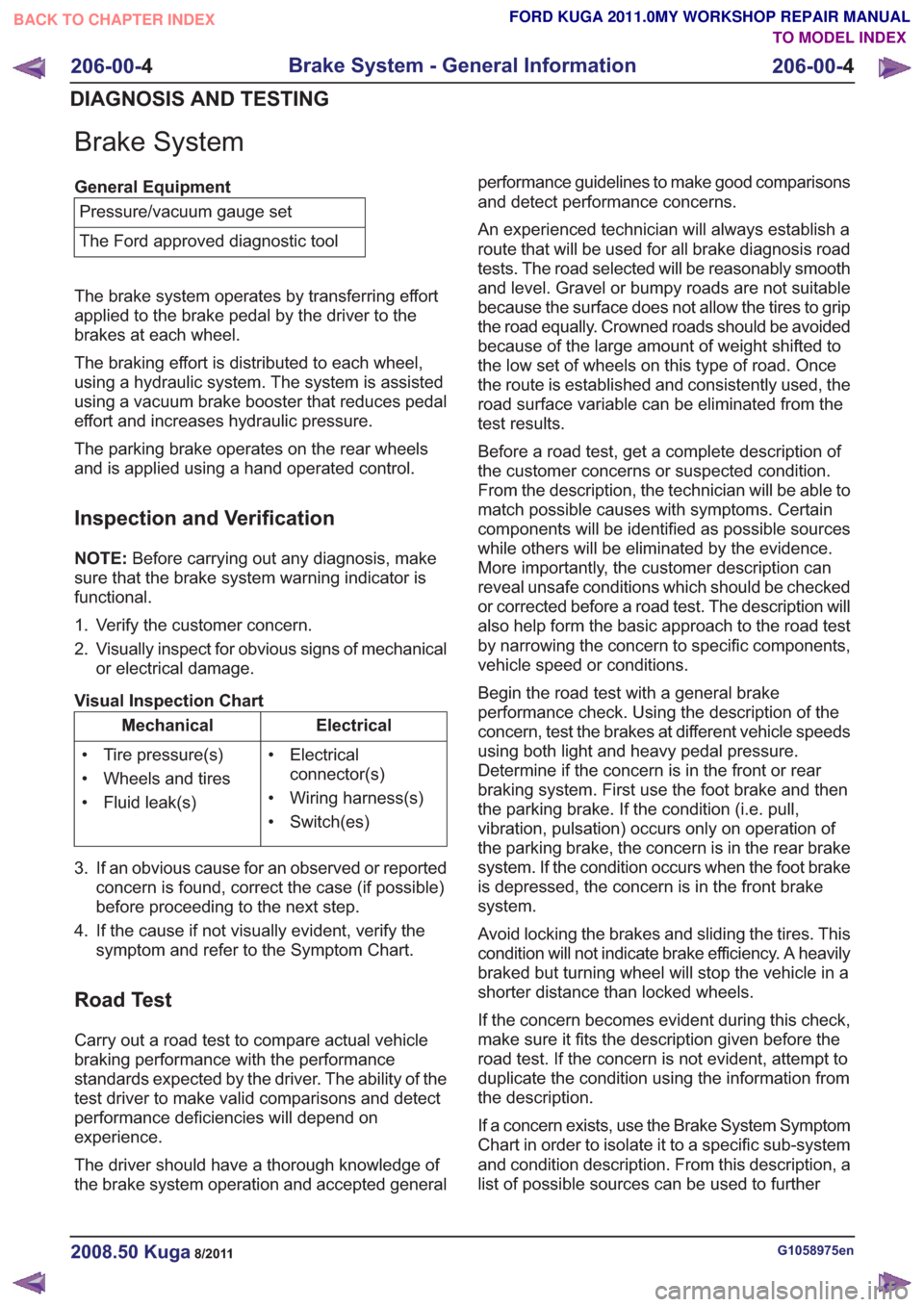

Brake System

General EquipmentPressure/vacuum gauge set

The Ford approved diagnostic tool

The brake system operates by transferring effort

applied to the brake pedal by the driver to the

brakes at each wheel.

The braking effort is distributed to each wheel,

using a hydraulic system. The system is assisted

using a vacuum brake booster that reduces pedal

effort and increases hydraulic pressure.

The parking brake operates on the rear wheels

and is applied using a hand operated control.

Inspection and Verification

NOTE: Before carrying out any diagnosis, make

sure that the brake system warning indicator is

functional.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Electricalconnector(s)

• Wiring harness(s)

• Switch(es)

• Tire pressure(s)

• Wheels and tires

• Fluid leak(s)

3. If an obvious cause for an observed or reported concern is found, correct the case (if possible)

before proceeding to the next step.

4. If the cause if not visually evident, verify the symptom and refer to the Symptom Chart.

Road Test

Carry out a road test to compare actual vehicle

braking performance with the performance

standards expected by the driver. The ability of the

test driver to make valid comparisons and detect

performance deficiencies will depend on

experience.

The driver should have a thorough knowledge of

the brake system operation and accepted general performance guidelines to make good comparisons

and detect performance concerns.

An experienced technician will always establish a

route that will be used for all brake diagnosis road

tests. The road selected will be reasonably smooth

and level. Gravel or bumpy roads are not suitable

because the surface does not allow the tires to grip

the road equally. Crowned roads should be avoided

because of the large amount of weight shifted to

the low set of wheels on this type of road. Once

the route is established and consistently used, the

road surface variable can be eliminated from the

test results.

Before a road test, get a complete description of

the customer concerns or suspected condition.

From the description, the technician will be able to

match possible causes with symptoms. Certain

components will be identified as possible sources

while others will be eliminated by the evidence.

More importantly, the customer description can

reveal unsafe conditions which should be checked

or corrected before a road test. The description will

also help form the basic approach to the road test

by narrowing the concern to specific components,

vehicle speed or conditions.

Begin the road test with a general brake

performance check. Using the description of the

concern, test the brakes at different vehicle speeds

using both light and heavy pedal pressure.

Determine if the concern is in the front or rear

braking system. First use the foot brake and then

the parking brake. If the condition (i.e. pull,

vibration, pulsation) occurs only on operation of

the parking brake, the concern is in the rear brake

system. If the condition occurs when the foot brake

is depressed, the concern is in the front brake

system.

Avoid locking the brakes and sliding the tires. This

condition will not indicate brake efficiency. A heavily

braked but turning wheel will stop the vehicle in a

shorter distance than locked wheels.

If the concern becomes evident during this check,

make sure it fits the description given before the

road test. If the concern is not evident, attempt to

duplicate the condition using the information from

the description.

If a concern exists, use the Brake System Symptom

Chart in order to isolate it to a specific sub-system

and condition description. From this description, a

list of possible sources can be used to further

G1058975en2008.50 Kuga8/2011

206-00-

4

Brake System - General Information

206-00- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1341 of 2057

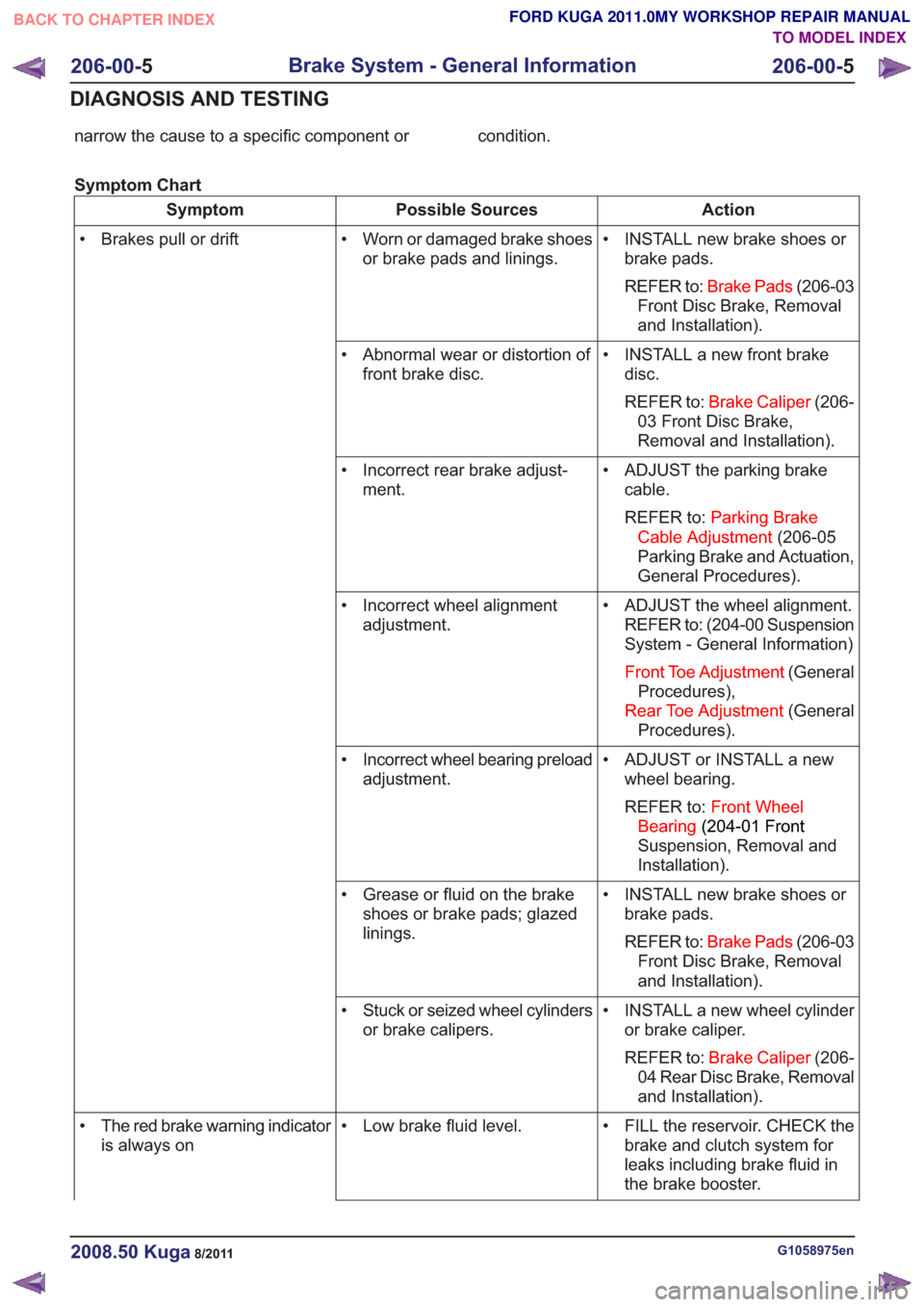

narrow the cause to a specific component or condition.

Symptom Chart

Action

Possible Sources

Symptom

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Worn or damaged brake shoes

or brake pads and linings.

• Brakes pull or drift

• INSTALL a new front brakedisc.

REFER to: Brake Caliper (206-

03 Front Disc Brake,

Removal and Installation).

• Abnormal wear or distortion of

front brake disc.

• ADJUST the parking brakecable.

REFER to: Parking Brake

Cable Adjustment (206-05

Parking Brake and Actuation,

General Procedures).

• Incorrect rear brake adjust-

ment.

• ADJUST the wheel alignment.REFER to: (204-00 Suspension

System - General Information)

Front Toe Adjustment (General

Procedures),

Rear Toe Adjustment (General

Procedures).

• Incorrect wheel alignment

adjustment.

• ADJUST or INSTALL a newwheel bearing.

REFER to: Front Wheel

Bearing (204-01 Front

Suspension, Removal and

Installation).

• Incorrect wheel bearing preload

adjustment.

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Grease or fluid on the brake

shoes or brake pads; glazed

linings.

• INSTALL a new wheel cylinderor brake caliper.

REFER to: Brake Caliper (206-

04 Rear Disc Brake, Removal

and Installation).

• Stuck or seized wheel cylinders

or brake calipers.

• FILL the reservoir. CHECK thebrake and clutch system for

leaks including brake fluid in

the brake booster.

• Low brake fluid level.

• The red brake warning indicator

is always on

G1058975en2008.50 Kuga8/2011

206-00- 5

Brake System - General Information

206-00- 5

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1342 of 2057

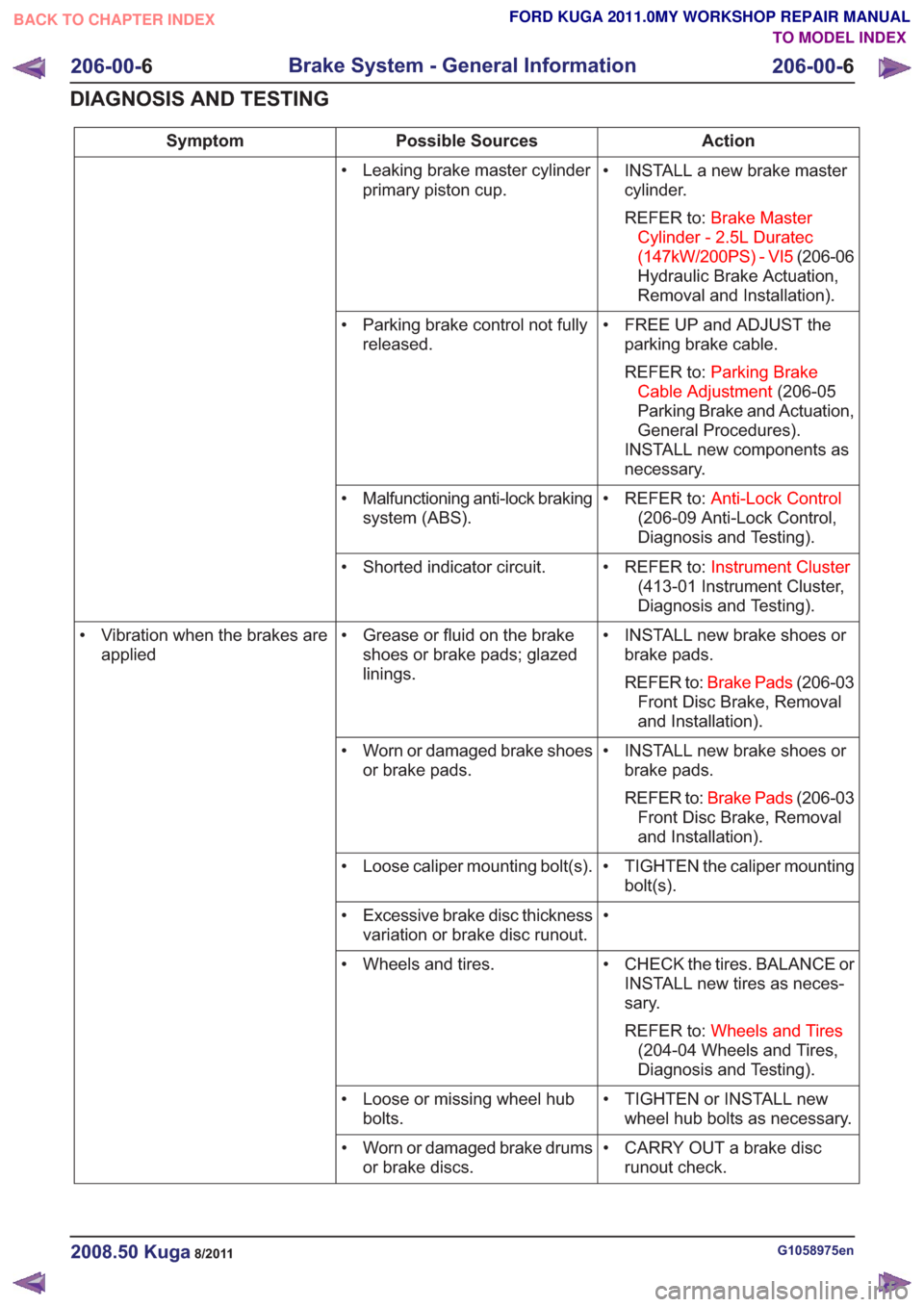

Action

Possible Sources

Symptom

• INSTALL a new brake mastercylinder.

REFER to: Brake Master

Cylinder - 2.5L Duratec

(147kW/200PS) - VI5 (206-06

Hydraulic Brake Actuation,

Removal and Installation).

• Leaking brake master cylinder

primary piston cup.

• FREE UP and ADJUST theparking brake cable.

REFER to: Parking Brake

Cable Adjustment (206-05

Parking Brake and Actuation,

General Procedures).

INSTALL new components as

necessary.

• Parking brake control not fully

released.

• REFER to:Anti-Lock Control

(206-09 Anti-Lock Control,

Diagnosis and Testing).

• Malfunctioning anti-lock braking

system (ABS).

• REFER to:Instrument Cluster

(413-01 Instrument Cluster,

Diagnosis and Testing).

• Shorted indicator circuit.

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Grease or fluid on the brake

shoes or brake pads; glazed

linings.

• Vibration when the brakes are

applied

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Worn or damaged brake shoes

or brake pads.

• TIGHTEN the caliper mountingbolt(s).

• Loose caliper mounting bolt(s).

•

• Excessive brake disc thickness

variation or brake disc runout.

• CHECK the tires. BALANCE orINSTALL new tires as neces-

sary.

REFER to: Wheels and Tires

(204-04 Wheels and Tires,

Diagnosis and Testing).

• Wheels and tires.

• TIGHTEN or INSTALL newwheel hub bolts as necessary.

• Loose or missing wheel hub

bolts.

• CARRY OUT a brake discrunout check.

• Worn or damaged brake drums

or brake discs.

G1058975en2008.50 Kuga8/2011

206-00- 6

Brake System - General Information

206-00- 6

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1345 of 2057

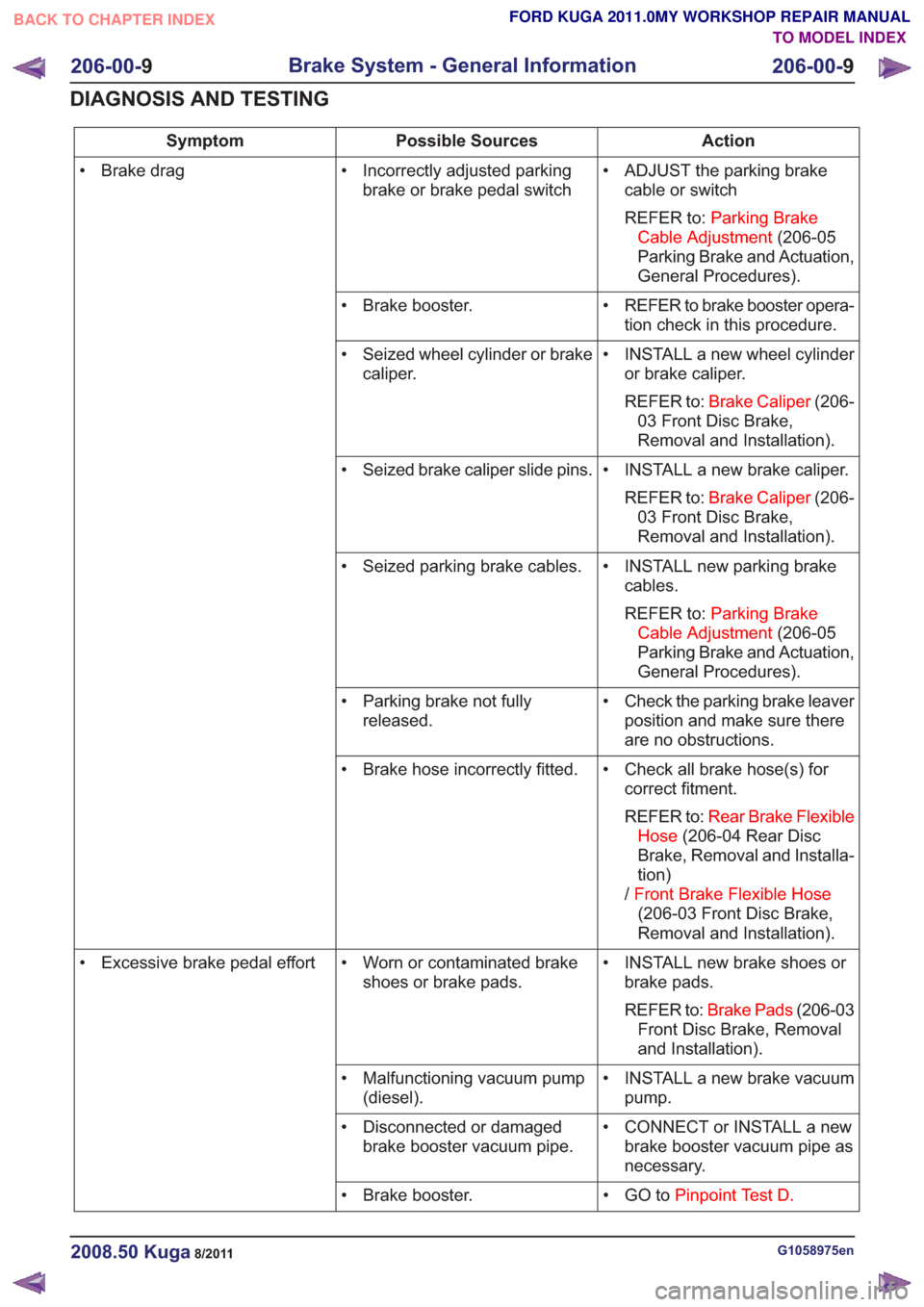

Action

Possible Sources

Symptom

• ADJUST the parking brakecable or switch

REFER to: Parking Brake

Cable Adjustment (206-05

Parking Brake and Actuation,

General Procedures).

• Incorrectly adjusted parking

brake or brake pedal switch

• Brake drag

• REFER to brake booster opera-tion check in this procedure.

• Brake booster.

• INSTALL a new wheel cylinderor brake caliper.

REFER to: Brake Caliper (206-

03 Front Disc Brake,

Removal and Installation).

• Seized wheel cylinder or brake

caliper.

• INSTALL a new brake caliper.REFER to: Brake Caliper (206-

03 Front Disc Brake,

Removal and Installation).

• Seized brake caliper slide pins.

• INSTALL new parking brakecables.

REFER to: Parking Brake

Cable Adjustment (206-05

Parking Brake and Actuation,

General Procedures).

• Seized parking brake cables.

• Check the parking brake leaverposition and make sure there

are no obstructions.

• Parking brake not fully

released.

• Check all brake hose(s) forcorrect fitment.

REFER to: Rear Brake Flexible

Hose (206-04 Rear Disc

Brake, Removal and Installa-

tion)

/ Front Brake Flexible Hose

(206-03 Front Disc Brake,

Removal and Installation).

• Brake hose incorrectly fitted.

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Worn or contaminated brake

shoes or brake pads.

• Excessive brake pedal effort

• INSTALL a new brake vacuumpump.

• Malfunctioning vacuum pump

(diesel).

• CONNECT or INSTALL a newbrake booster vacuum pipe as

necessary.

• Disconnected or damaged

brake booster vacuum pipe.

• GO toPinpoint Test D.

• Brake booster.

G1058975en2008.50 Kuga8/2011

206-00- 9

Brake System - General Information

206-00- 9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1346 of 2057

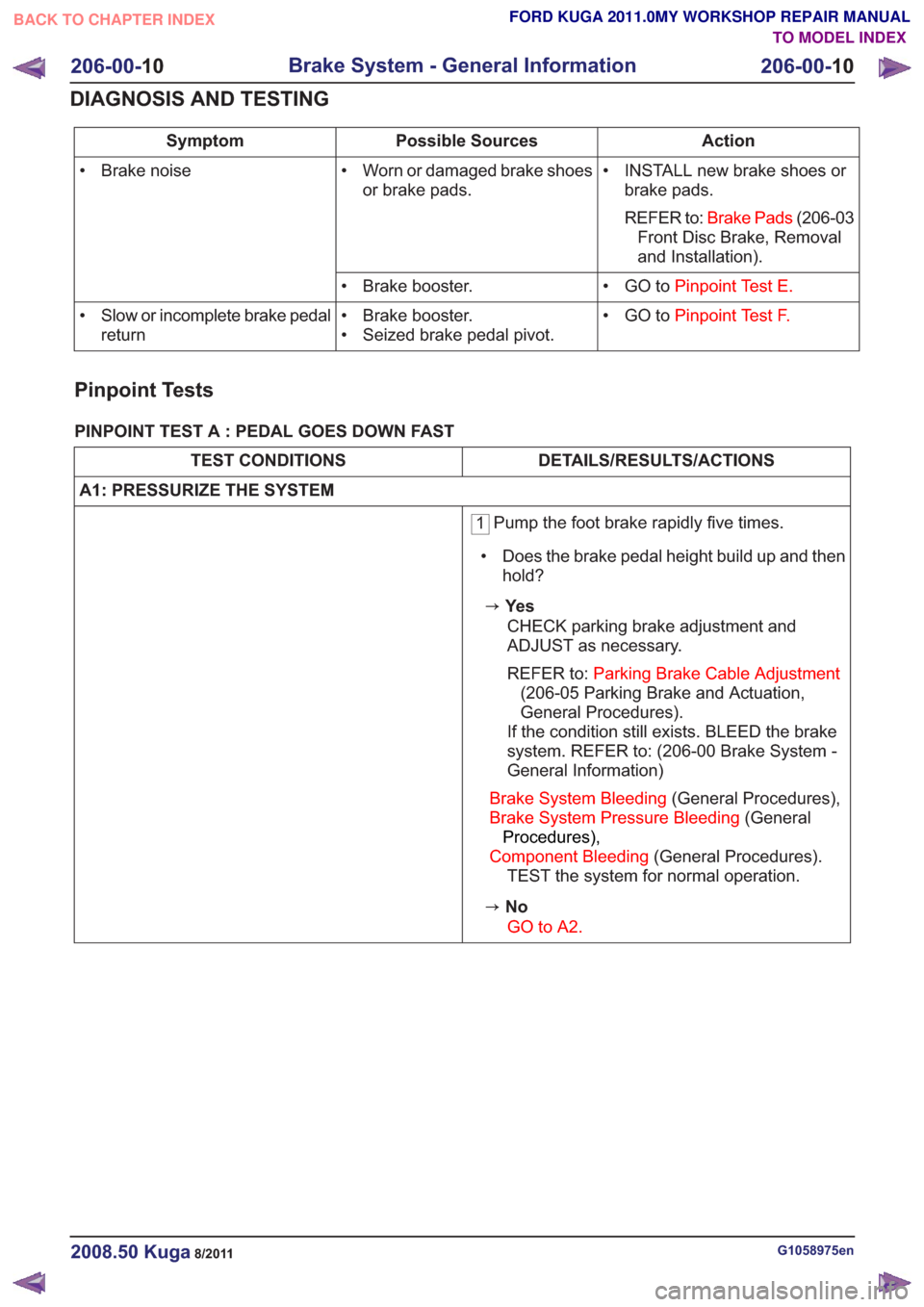

Action

Possible Sources

Symptom

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Worn or damaged brake shoes

or brake pads.

• Brake noise

• GO toPinpoint Test E.

• Brake booster.

• GO toPinpoint Test F.

• Brake booster.

• Seized brake pedal pivot.

• Slow or incomplete brake pedal

return

Pinpoint Tests

PINPOINT TEST A : PEDAL GOES DOWN FAST

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

A1: PRESSURIZE THE SYSTEM

1 Pump the foot brake rapidly five times.

• Does the brake pedal height build up and then hold?

zYe s

CHECK parking brake adjustment and

ADJUST as necessary.

REFER to: Parking Brake Cable Adjustment

(206-05 Parking Brake and Actuation,

General Procedures).

If the condition still exists. BLEED the brake

system. REFER to: (206-00 Brake System -

General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General

Procedures),

Component Bleeding (General Procedures).

TEST the system for normal operation.

zNo

GO to A2.

G1058975en2008.50 Kuga8/2011

206-00- 10

Brake System - General Information

206-00- 10

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1353 of 2057

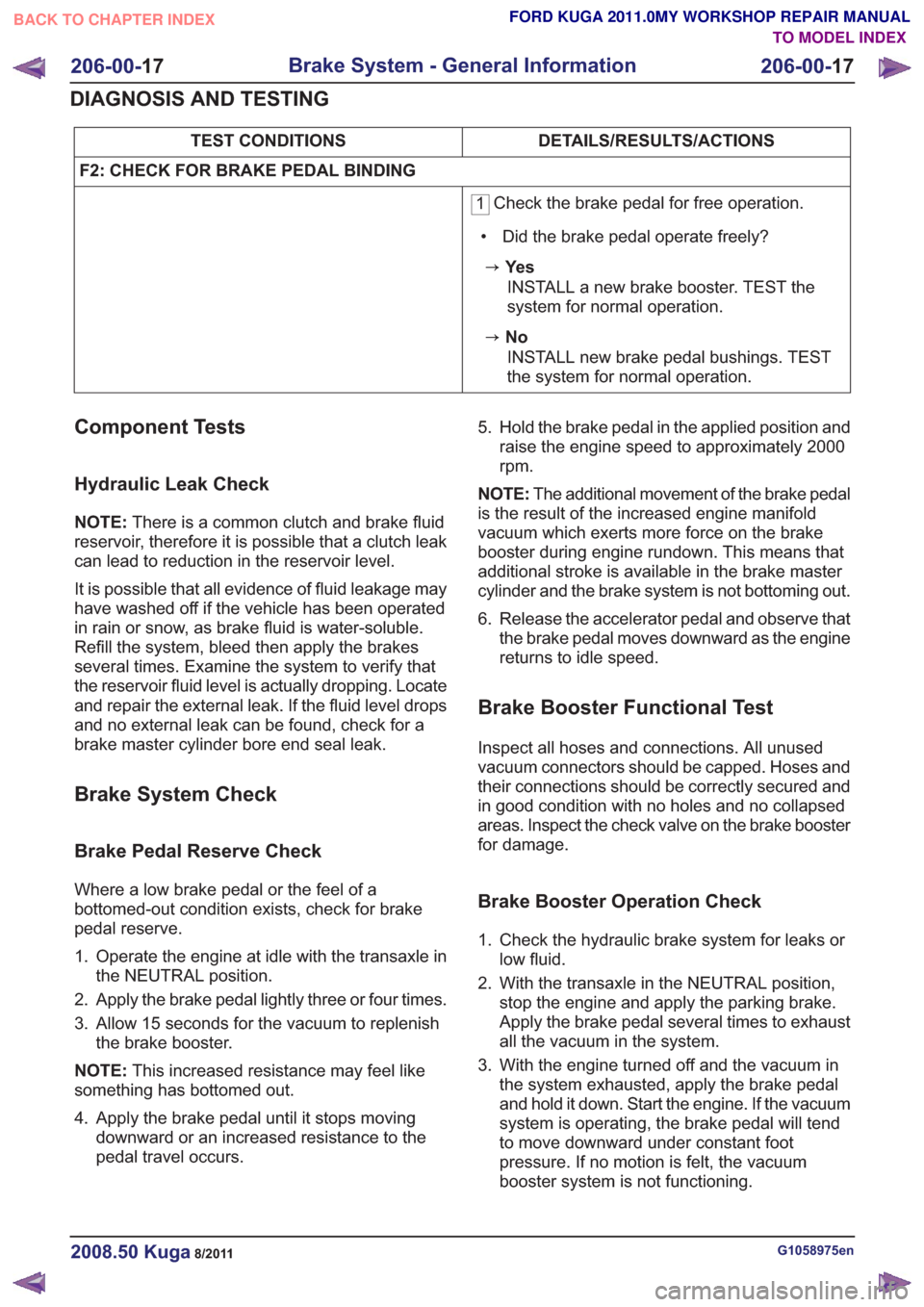

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

F2: CHECK FOR BRAKE PEDAL BINDING

1 Check the brake pedal for free operation.

• Did the brake pedal operate freely?

zYe s INSTALL a new brake booster. TEST the

system for normal operation.

zNoINSTALL new brake pedal bushings. TEST

the system for normal operation.

Component Tests

Hydraulic Leak Check

NOTE: There is a common clutch and brake fluid

reservoir, therefore it is possible that a clutch leak

can lead to reduction in the reservoir level.

It is possible that all evidence of fluid leakage may

have washed off if the vehicle has been operated

in rain or snow, as brake fluid is water-soluble.

Refill the system, bleed then apply the brakes

several times. Examine the system to verify that

the reservoir fluid level is actually dropping. Locate

and repair the external leak. If the fluid level drops

and no external leak can be found, check for a

brake master cylinder bore end seal leak.

Brake System Check

Brake Pedal Reserve Check

Where a low brake pedal or the feel of a

bottomed-out condition exists, check for brake

pedal reserve.

1. Operate the engine at idle with the transaxle in the NEUTRAL position.

2. Apply the brake pedal lightly three or four times.

3. Allow 15 seconds for the vacuum to replenish the brake booster.

NOTE: This increased resistance may feel like

something has bottomed out.

4. Apply the brake pedal until it stops moving downward or an increased resistance to the

pedal travel occurs. 5. Hold the brake pedal in the applied position and

raise the engine speed to approximately 2000

rpm.

NOTE: The additional movement of the brake pedal

is the result of the increased engine manifold

vacuum which exerts more force on the brake

booster during engine rundown. This means that

additional stroke is available in the brake master

cylinder and the brake system is not bottoming out.

6. Release the accelerator pedal and observe that the brake pedal moves downward as the engine

returns to idle speed.

Brake Booster Functional Test

Inspect all hoses and connections. All unused

vacuum connectors should be capped. Hoses and

their connections should be correctly secured and

in good condition with no holes and no collapsed

areas. Inspect the check valve on the brake booster

for damage.

Brake Booster Operation Check

1. Check the hydraulic brake system for leaks orlow fluid.

2. With the transaxle in the NEUTRAL position, stop the engine and apply the parking brake.

Apply the brake pedal several times to exhaust

all the vacuum in the system.

3. With the engine turned off and the vacuum in the system exhausted, apply the brake pedal

and hold it down. Start the engine. If the vacuum

system is operating, the brake pedal will tend

to move downward under constant foot

pressure. If no motion is felt, the vacuum

booster system is not functioning.

G1058975en2008.50 Kuga8/2011

206-00- 17

Brake System - General Information

206-00- 17

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL