clutch FORD KUGA 2011 1.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1877 of 2057

Full lock-up mode of the TCC is not generated at

engine temperatures below 20 °C (68 °F).

Slip lock-up mode

In slip lock-up mode, slip in the TCC is permitted

in order to improve driving comfort. The hydraulic

pressure acting on the TCM varies in accordance

with the duty signal of the actuation signal

generated by the PWM for the TCC solenoid valve

for the TCC (SLU). The automatic transaxle

temperature increases in slip lock-up mode.

The TSS sensor

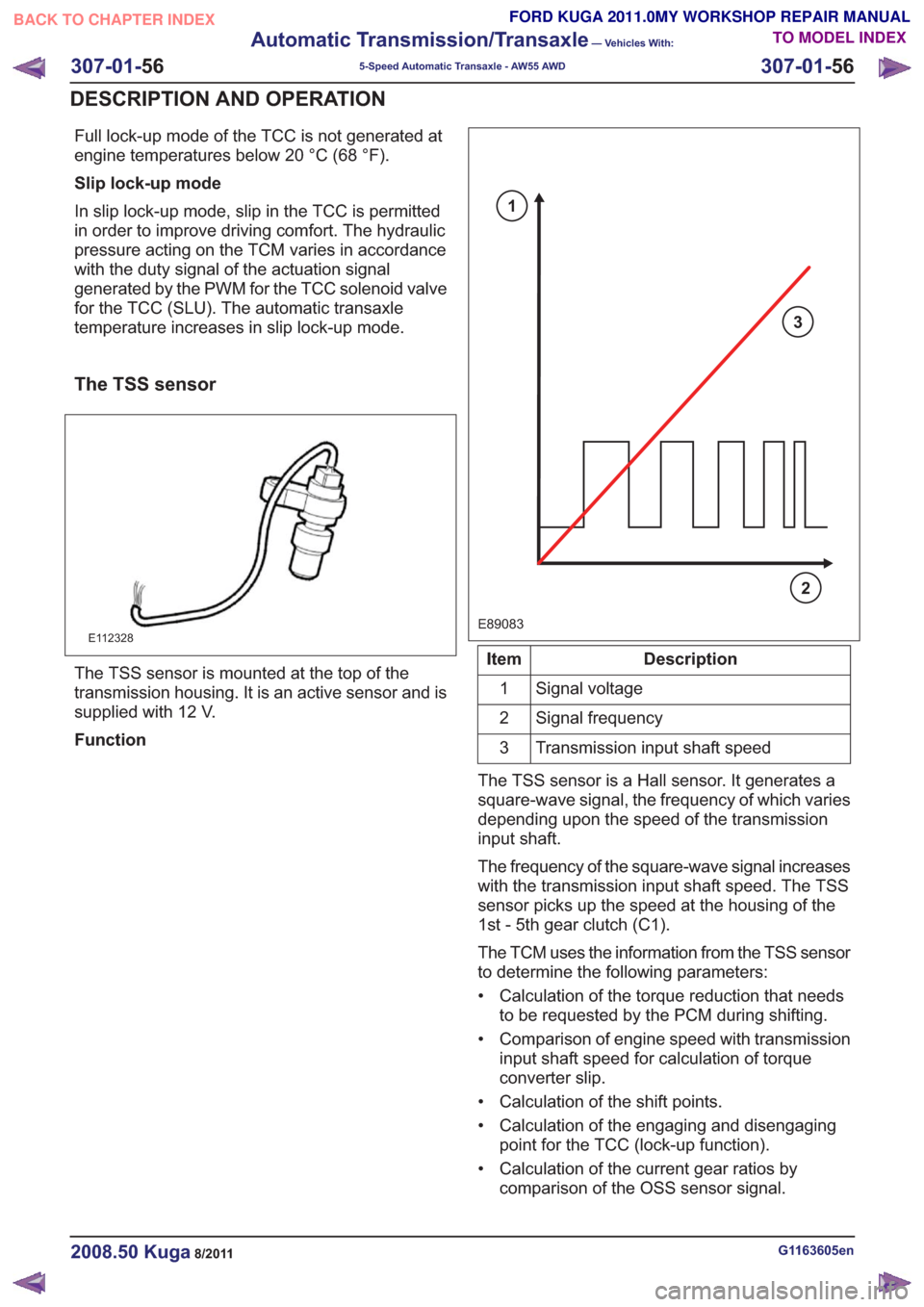

E112328

The TSS sensor is mounted at the top of the

transmission housing. It is an active sensor and is

supplied with 12 V.

Function

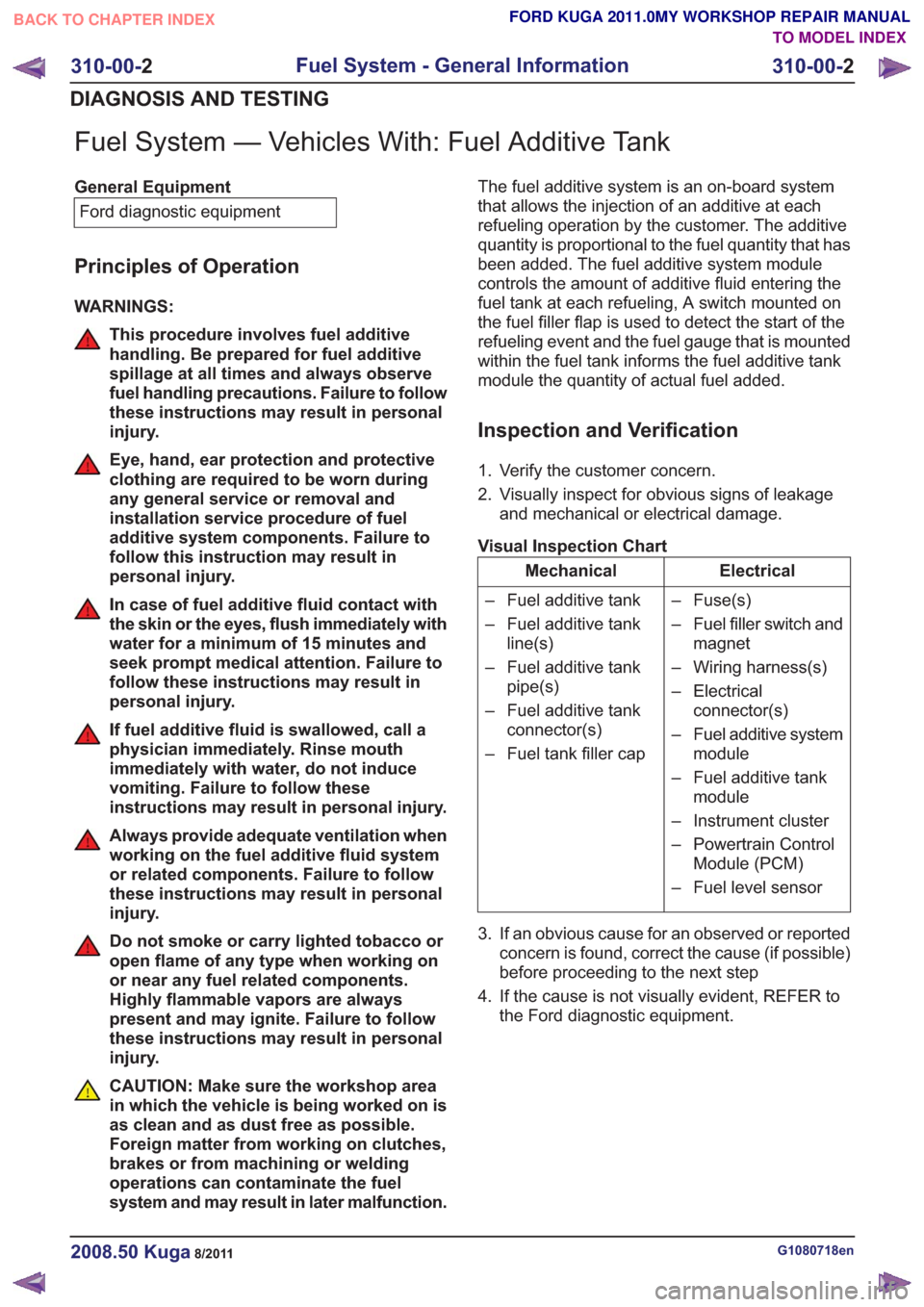

E89083

3

2

1

Description

Item

Signal voltage

1

Signal frequency

2

Transmission input shaft speed

3

The TSS sensor is a Hall sensor. It generates a

square-wave signal, the frequency of which varies

depending upon the speed of the transmission

input shaft.

The frequency of the square-wave signal increases

with the transmission input shaft speed. The TSS

sensor picks up the speed at the housing of the

1st - 5th gear clutch (C1).

The TCM uses the information from the TSS sensor

to determine the following parameters:

• Calculation of the torque reduction that needs to be requested by the PCM during shifting.

• Comparison of engine speed with transmission input shaft speed for calculation of torque

converter slip.

• Calculation of the shift points.

• Calculation of the engaging and disengaging point for the TCC (lock-up function).

• Calculation of the current gear ratios by comparison of the OSS sensor signal.

G1163605en2008.50 Kuga8/2011

307-01- 56

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 56

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1970 of 2057

Fuel System — Vehicles With: Fuel Additive Tank

General EquipmentFord diagnostic equipment

Principles of Operation

WARNINGS:

This procedure involves fuel additive

handling. Be prepared for fuel additive

spillage at all times and always observe

fuel handling precautions. Failure to follow

these instructions may result in personal

injury.

Eye, hand, ear protection and protective

clothing are required to be worn during

any general service or removal and

installation service procedure of fuel

additive system components. Failure to

follow this instruction may result in

personal injury.

In case of fuel additive fluid contact with

the skin or the eyes, flush immediately with

water for a minimum of 15 minutes and

seek prompt medical attention. Failure to

follow these instructions may result in

personal injury.

If fuel additive fluid is swallowed, call a

physician immediately. Rinse mouth

immediately with water, do not induce

vomiting. Failure to follow these

instructions may result in personal injury.

Always provide adequate ventilation when

working on the fuel additive fluid system

or related components. Failure to follow

these instructions may result in personal

injury.

Do not smoke or carry lighted tobacco or

open flame of any type when working on

or near any fuel related components.

Highly flammable vapors are always

present and may ignite. Failure to follow

these instructions may result in personal

injury.

CAUTION: Make sure the workshop area

in which the vehicle is being worked on is

as clean and as dust free as possible.

Foreign matter from working on clutches,

brakes or from machining or welding

operations can contaminate the fuel

system and may result in later malfunction. The fuel additive system is an on-board system

that allows the injection of an additive at each

refueling operation by the customer. The additive

quantity is proportional to the fuel quantity that has

been added. The fuel additive system module

controls the amount of additive fluid entering the

fuel tank at each refueling, A switch mounted on

the fuel filler flap is used to detect the start of the

refueling event and the fuel gauge that is mounted

within the fuel tank informs the fuel additive tank

module the quantity of actual fuel added.

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of leakage

and mechanical or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

– Fuse(s)

– Fuel filler switch andmagnet

– Wiring harness(s)

– Electrical connector(s)

– Fuel additive system module

– Fuel additive tank module

– Instrument cluster

– Powertrain Control Module (PCM)

– Fuel level sensor

– Fuel additive tank

– Fuel additive tank

line(s)

– Fuel additive tank pipe(s)

– Fuel additive tank connector(s)

– Fuel tank filler cap

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step

4. If the cause is not visually evident, REFER to the Ford diagnostic equipment.

G1080718en2008.50 Kuga8/2011

310-00- 2

Fuel System - General Information

310-00- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2007 of 2057

Description

Item

PCM

8

Throttle body

Comments:Contains the TP (throttle position) sensor

9

The APP (accelerator pedal position)

sensor.

10Description

Item

CPP (clutch pedal position) switch

Comments:Vehicles with manual transaxle.

11

BPP (brake pedal position) switch

12

Reverse gear solenoid

Comments:Vehicles with manual transaxle.

13

System Operation

Speed Control

Cruise control is integrated into PCM and

intervenes in engine management to automatically

keep to the target speed selected by the driver.

When the system is active, the vehicle can be

accelerated or decelerated without the accelerator

pedal being pressed. Cruise control is operated

using the control switch units on the steering wheel.

The PCM controls the throttle to achieve this. The

ABS module supplies the VSS signal for this.

On vehicles with automatic transmission, the TCM

receives a notification via the CAN (controller area

network) bus that cruise control is active. The TCM

then controls the transmission based on special

engine maps.

Cruise control recognizes three operating modes:

• "OFF": Control is switched off.

• "STANDBY": Control is switched on but not

active. The speed of the vehicle is not regulated

by the cruise control.

• "ACTIVE": Control is switched on and active. Cruise control adjusts the vehicle speed to the

stored or desired target speed.

Every time the engine is started, cruise control is

in the "OFF" mode. In this mode, only the "ON"

button is operable.

Cruise control is initially set to "STANDBY" mode

when the "ON" button is pressed. The green cruise

control indicator lamp in the instrument cluster

lights up. There is no target speed saved.

Cruise control can only be set to "STANDBY" mode

under the following conditions:

• Engine speed is between idle speed and maximum permissible speed. Cruise control can only be changed into "ACTIVE"

mode under the following conditions:

• 2nd - 6th gear engaged.

• Engine speed between idle speed and maximum

permissible speed.

• Vehicle speed at least 40 km/h.

Pressing the "SET+" or "SET-" button activates

cruise control ("ACTIVE" mode). The green "Cruise

control" indicator lamp in the instrument cluster

lights up. The current vehicle speed is saved as

the target.

In "ACTIVE" mode the "OFF", "SET+", "SET-" and

"RES" buttons are active. If the "RES" button is

pressed again, control is suspended. The "RES"

button has a dual function and is used to resume

and suspend the cruise control.

Tapping the "SET+" button (for less than 640 ms)

increases the target speed by 1 km/h at a time.

Holding down the "SET+" button (for longer than

640 ms) increases the target speed until the button

is released. If the button is not released, cruise

control accelerates the vehicle up to the maximum

permissible vehicle speed (200 km/h) or up to the

vehicle's maximum speed (whichever speed is

lower). Tapping the "SET-" button (for less than

640 ms) reduces the target speed by 1 km/h at a

time. When the the "SET-" button is held down, the

control reduces the target speed until the button is

released. If the "SET-" button is held down until

the minimum speed of 40 km/h is reached, cruise

control switches to "STANDBY" mode.

Cruise control is put into "STANDBY" mode when

the "RES" button is pressed. Control to the stored

target speed can be started again by pressing the

"RES" button again. If the "SET+" or "SET-" button

is pressed while the "RES" function is being

performed (control to saved target speed), cruise

G1044191en2008.50 Kuga8/2011

310-03- 4

Speed Control

310-03- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2008 of 2057

control saves the current speed as the target

speed.

Cruise control goes into STANDBY mode in the

following situations:

• Operation of the brake pedal

• Operation of the clutch pedal

• Operation of the parking brake

• If the driver operates the accelerator pedal andthe saved target speed is subsequently

exceeded for more than 5 minutes.

• Pressing any cruise control button for more than 2 minutes

• Intervention by the traction control or electronic stability program (for longer than 40 ms)

• Shifting of the gear selector lever to the "N" position (vehicles with automatic transmission

only)

• Minimum speed falls below 40 km/h.

• Occurrence of particular DTC (diagnostic trouble code)

• faulty signal from the backup lamp switch

Cruise control is switched off when the "OFF"

button is pressed.

If the accelerator pedal is pressed down, the

vehicle speed increases. As soon as the pedal is

released, the speed falls to the saved target value. The following components supply the signals

needed by the cruise control:

• The APP sensor.

– The APP sensor identifies the currentposition of the accelerator pedal and sends

a PWM (pulse width modulation) signal to

the PCM and an analog DC (direct current)

signal to the GEM.

– If one or both of the APP sensors fails, a fault is stored in the PCM fault memory and cruise

control cannot be activated.

• BPP switch – The BPP switch tells the PCM whether thevehicle is being braked. In its rest state the

switch is closed and sends an earth signal

to the GEM. This signal is sent via the CAN

to the PCM.

– The brake light switch is likewise connected to the GEM and is opened in the rest state.

When the vehicle is braked, the brake light

switch sends a signal to the GEM. This

compares the signals from the BPP switch

and the brake light switch. If a discrepancy

occurs, a fault is stored in the error memory

of the GEM. Cruise control cannot be

activated.

• CPP switch – The CPP switch sends a ground signal to theGEM as soon as the clutch is operated. This

signal is passed on by the GEM via the CAN

bus to the PCM. This then supplies the signal

to the cruise control.

– If the CPP switch is incorrectly installed or set, cruise control cannot be activated.

• Wheel speed sensors – The wheel speed sensors record the speedof all the wheels. The recorded speed values

are sent to the ABS module via a hard-wired

connection. The ABS module calculates a

vehicle speed signal (VS signal) from the

speed values and the wheel diameter. This

vehicle speed signal is transferred via the

CAN bus to the PCM and supplied to the

cruise control. If the vehicle speed signal is

faulty, cruise control cannot be activated.

G1044191en2008.50 Kuga8/2011

310-03- 5

Speed Control

310-03- 5

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2010 of 2057

Speed Control

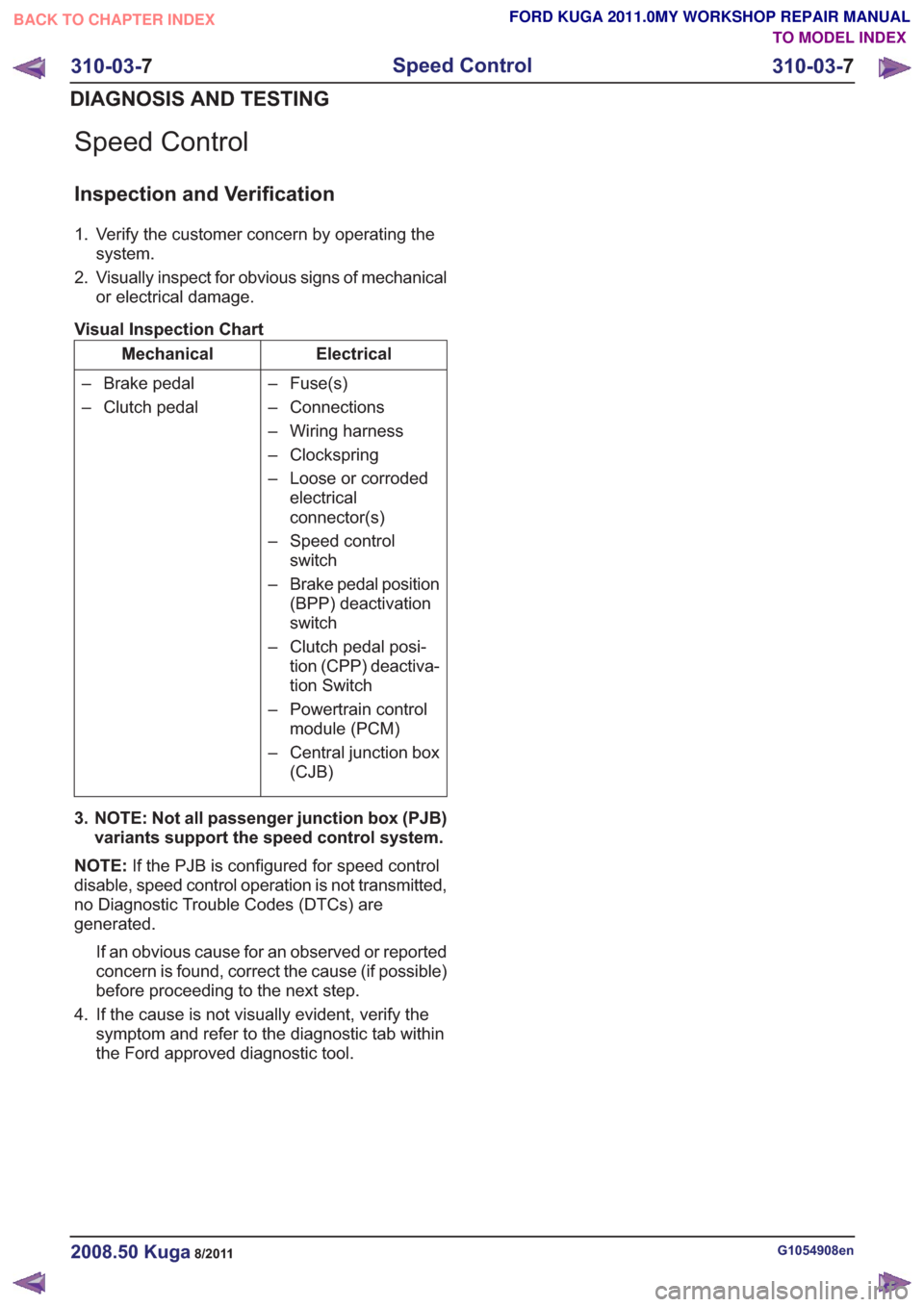

Inspection and Verification

1. Verify the customer concern by operating thesystem.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

– Fuse(s)

– Connections

– Wiring harness

– Clockspring

– Loose or corrodedelectrical

connector(s)

– Speed control switch

– Brake pedal position (BPP) deactivation

switch

– Clutch pedal posi- tion (CPP) deactiva-

tion Switch

– Powertrain control module (PCM)

– Central junction box (CJB)

– Brake pedal

– Clutch pedal

3. NOTE: Not all passenger junction box (PJB) variants support the speed control system.

NOTE: If the PJB is configured for speed control

disable, speed control operation is not transmitted,

no Diagnostic Trouble Codes (DTCs) are

generated.

If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool.

G1054908en2008.50 Kuga8/2011

310-03- 7

Speed Control

310-03- 7

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2012 of 2057

SECTION 412-00 Climate Control System - General

Information

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

SPECIFICATIONS

412-00-2

Specifications ........................................................................\

..............................................

DIAGNOSIS AND TESTING 412-00-3

Climate Control System ........................................................................\

..............................

412-00-3

Inspection and Checking ........................................................................\

............................

412-00-3

Refrigerant Circuit - Quick Check ........................................................................\

...............

412-00-4

Sequence of A/C Request Signal ........................................................................\

...............

GENERAL PROCEDURES 412-00-6

Air Conditioning (A/C) System Flushing ........................................................................\

.....

412-00-7

Air Conditioning (A/C) System Recovery, Evacuation and Charging .................................

412-00-9

Spring Lock Coupling ........................................................................\

..................................

412-00-11

Air Conditioning (A/C) Clutch Air Gap Adjustment .............................................................

412-00-12

Refrigerant Oil Adding ........................................................................\

................................

412-00-13

Contaminated Refrigerant Handling ........................................................................\

...........

412-00-14

Electronic Leak Detection ........................................................................\

...........................

412-00-15

Fluorescent Dye Leak Detection ........................................................................\

................

412-00-16

Vacuum Leak Detection ........................................................................\

..............................

412-00-1

Climate Control System - General Information

412-00- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2013 of 2057

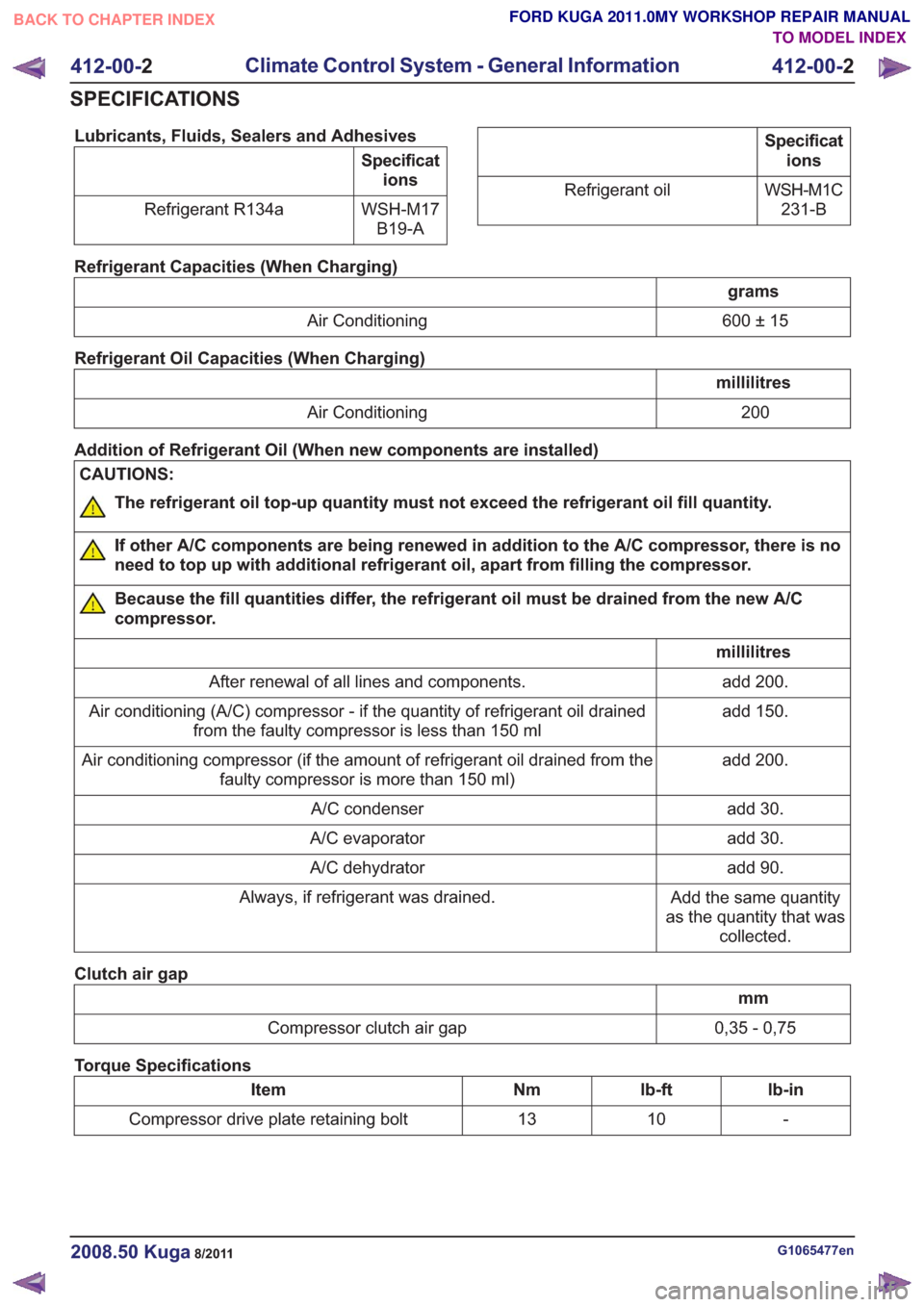

Lubricants, Fluids, Sealers and Adhesives

Specifications

WSH-M17 B19-A

Refrigerant R134a

Specificat

ions

WSH-M1C 231-B

Refrigerant oil

Refrigerant Capacities (When Charging)

grams

600 ± 15

Air Conditioning

Refrigerant Oil Capacities (When Charging)

millilitres 200

Air Conditioning

Addition of Refrigerant Oil (When new components are installed)

CAUTIONS:

The refrigerant oil top-up quantity must not exceed the refrigerant oil fill quantity.

If other A/C components are being renewed in addition to the A/C compressor, there is no

need to top up with additional refrigerant oil, apart from filling the compressor.

Because the fill quantities differ, the refrigerant oil must be drained from the new A/C

compressor.

millilitres add 200.

After renewal of all lines and components.

add 150.

Air conditioning (A/C) compressor - if the quantity of refrigerant oil drained

from the faulty compressor is less than 150 ml

add 200.

Air conditioning compressor (if the amount of refrigerant oil drained from the

faulty compressor is more than 150 ml)

add 30.

A/C condenser

add 30.

A/C evaporator

add 90.

A/C dehydrator

Add the same quantity

as the quantity that was collected.

Always, if refrigerant was drained.

Clutch air gap

mm

0,35 - 0,75

Compressor clutch air gap

Torque Specifications

lb-in

lb-ft

Nm

Item

-

10

13

Compressor drive plate retaining bolt

G1065477en2008.50 Kuga8/2011

412-00- 2

Climate Control System - General Information

412-00- 2

SPECIFICATIONS

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2015 of 2057

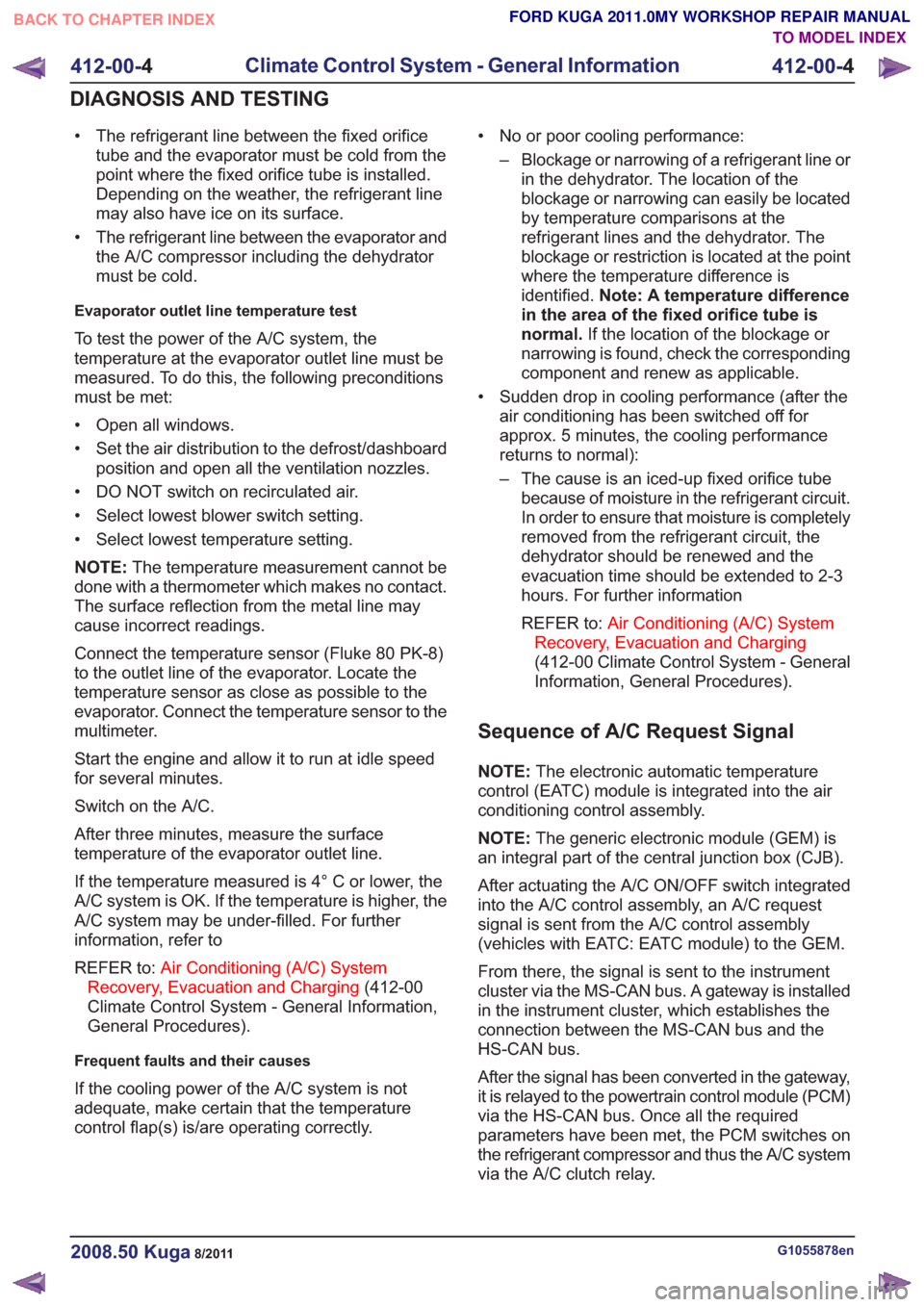

• The refrigerant line between the fixed orificetube and the evaporator must be cold from the

point where the fixed orifice tube is installed.

Depending on the weather, the refrigerant line

may also have ice on its surface.

• The refrigerant line between the evaporator and the A/C compressor including the dehydrator

must be cold.

Evaporator outlet line temperature test

To test the power of the A/C system, the

temperature at the evaporator outlet line must be

measured. To do this, the following preconditions

must be met:

• Open all windows.

• Set the air distribution to the defrost/dashboardposition and open all the ventilation nozzles.

• DO NOT switch on recirculated air.

• Select lowest blower switch setting.

• Select lowest temperature setting.

NOTE: The temperature measurement cannot be

done with a thermometer which makes no contact.

The surface reflection from the metal line may

cause incorrect readings.

Connect the temperature sensor (Fluke 80 PK-8)

to the outlet line of the evaporator. Locate the

temperature sensor as close as possible to the

evaporator. Connect the temperature sensor to the

multimeter.

Start the engine and allow it to run at idle speed

for several minutes.

Switch on the A/C.

After three minutes, measure the surface

temperature of the evaporator outlet line.

If the temperature measured is 4° C or lower, the

A/C system is OK. If the temperature is higher, the

A/C system may be under-filled. For further

information, refer to

REFER to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging (412-00

Climate Control System - General Information,

General Procedures).

Frequent faults and their causes

If the cooling power of the A/C system is not

adequate, make certain that the temperature

control flap(s) is/are operating correctly. • No or poor cooling performance:

– Blockage or narrowing of a refrigerant line orin the dehydrator. The location of the

blockage or narrowing can easily be located

by temperature comparisons at the

refrigerant lines and the dehydrator. The

blockage or restriction is located at the point

where the temperature difference is

identified. Note: A temperature difference

in the area of the fixed orifice tube is

normal. If the location of the blockage or

narrowing is found, check the corresponding

component and renew as applicable.

• Sudden drop in cooling performance (after the air conditioning has been switched off for

approx. 5 minutes, the cooling performance

returns to normal):

– The cause is an iced-up fixed orifice tubebecause of moisture in the refrigerant circuit.

In order to ensure that moisture is completely

removed from the refrigerant circuit, the

dehydrator should be renewed and the

evacuation time should be extended to 2-3

hours. For further information

REFER to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging

(412-00 Climate Control System - General

Information, General Procedures).

Sequence of A/C Request Signal

NOTE: The electronic automatic temperature

control (EATC) module is integrated into the air

conditioning control assembly.

NOTE: The generic electronic module (GEM) is

an integral part of the central junction box (CJB).

After actuating the A/C ON/OFF switch integrated

into the A/C control assembly, an A/C request

signal is sent from the A/C control assembly

(vehicles with EATC: EATC module) to the GEM.

From there, the signal is sent to the instrument

cluster via the MS-CAN bus. A gateway is installed

in the instrument cluster, which establishes the

connection between the MS-CAN bus and the

HS-CAN bus.

After the signal has been converted in the gateway,

it is relayed to the powertrain control module (PCM)

via the HS-CAN bus. Once all the required

parameters have been met, the PCM switches on

the refrigerant compressor and thus the A/C system

via the A/C clutch relay.

G1055878en2008.50 Kuga8/2011

412-00- 4

Climate Control System - General Information

412-00- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2022 of 2057

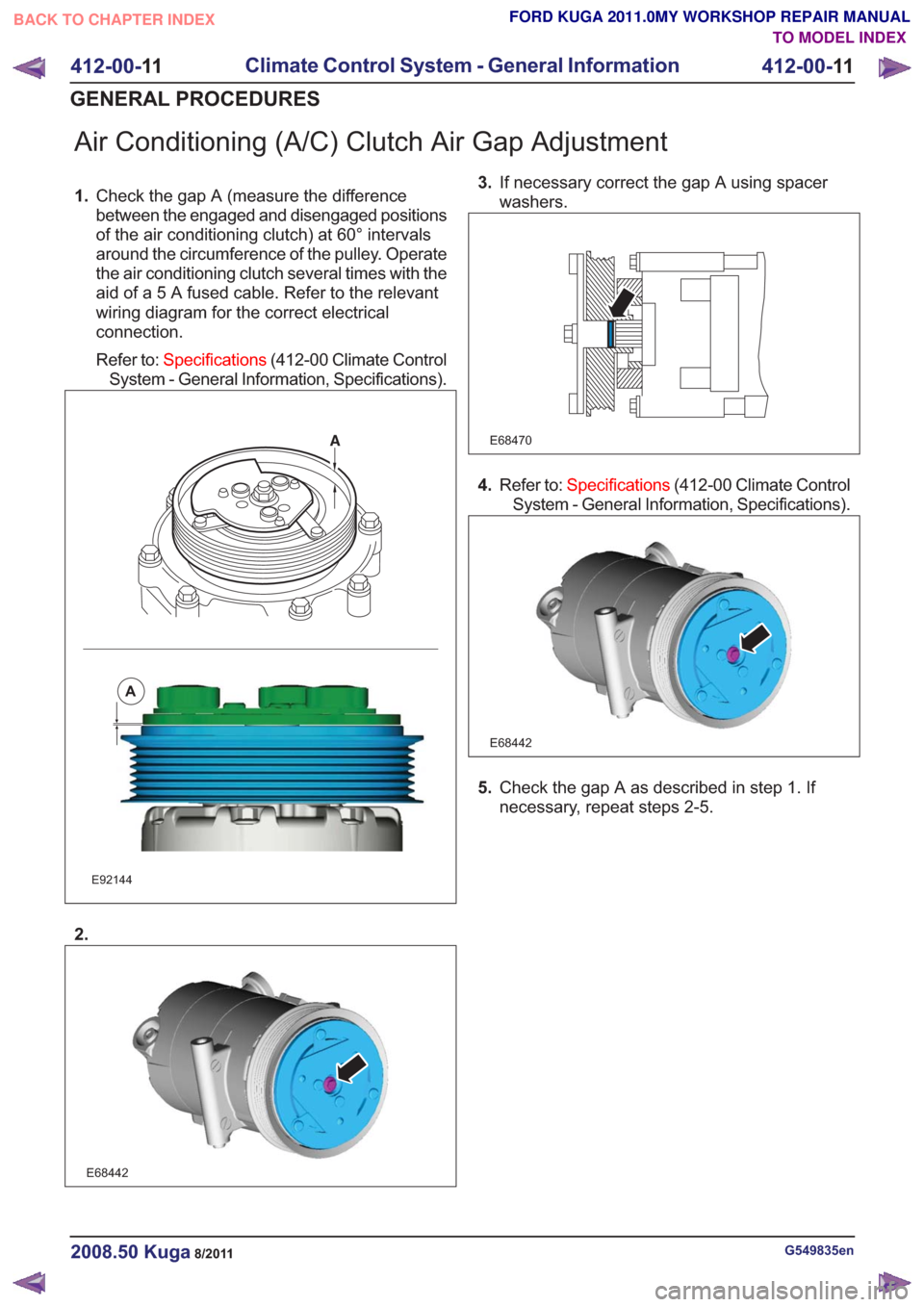

Air Conditioning (A/C) Clutch Air Gap Adjustment

1.Check the gap A (measure the difference

between the engaged and disengaged positions

of the air conditioning clutch) at 60° intervals

around the circumference of the pulley. Operate

the air conditioning clutch several times with the

aid of a 5 A fused cable. Refer to the relevant

wiring diagram for the correct electrical

connection.

Refer to: Specifications (412-00 Climate Control

System - General Information, Specifications).

E92144

A

2.

E68442

3. If necessary correct the gap A using spacer

washers.

E68470

4.Refer to: Specifications (412-00 Climate Control

System - General Information, Specifications).

E68442

5. Check the gap A as described in step 1. If

necessary, repeat steps 2-5.

G549835en2008.50 Kuga8/2011

412-00- 11

Climate Control System - General Information

412-00- 11

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2028 of 2057

SECTION 412-01 Climate Control

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

SPECIFICATIONS

412-01-3

Specifications ........................................................................\

..............................................

DESCRIPTION AND OPERATION 412-01-4

Climate Control (Component Location) ........................................................................\

......

412-01-10

Climate Control (Overview) ........................................................................\

........................

412-01-10

Pollen filter ........................................................................\

..................................................

412-01-10

Heat exchanger ........................................................................\

..........................................

412-01-10

Evaporator assembly ........................................................................\

..................................

412-01-10

Blower motor ........................................................................\

..............................................

412-01-11

Fault Memory Interrogation without diagnostics unit - vehicles with automatic temperature

control ........................................................................\

.......................................................

412-01-11

Switch over from Celsius to Fahrenheit ........................................................................\

......

412-01-12

Climate Control (System Operation and Component Description) .....................................

412-01-12

System Diagram ........................................................................\

.........................................

412-01-19

System Operation ........................................................................\

.......................................

412-01-19

Climate control housing ........................................................................\

..........................

412-01-22

Climate control ........................................................................\

........................................

412-01-24

Component Description ........................................................................\

..............................

412-01-24

Air conditioning compressor ........................................................................\

...................

412-01-24

Pollen filter ........................................................................\

..............................................

412-01-24

Control assembly, climate control - vehicles with manual temperature control ..............

412-01-25

Control assembly, climate control - vehicles with automatic temperature control ...........

412-01-25

Control assembly, climate control - vehicles with DVD navigation system with a touch

screen........................................................................\

................................................... 412-01-25

Climate control module - vehicles with DVD navigation system with a touch screen.....

412-01-25

Sun sensor - vehicles with automatic temperature control .............................................

412-01-26

In-vehicle temperature sensor ........................................................................\

................

412-01-26

Ambient temperature sensor ........................................................................\

..................

412-01-26

Blower motor ........................................................................\

...........................................

412-01-26

Blower control module - vehicles equipped with automatic temperature control ............

REMOVAL AND INSTALLATION 412-01-28

(34 626 4)

Air Conditioning (A/C) Compressor — 2.5L Duratec (147kW/200PS) - VI5 ....

412-01-29

Air Conditioning (A/C) Compressor to Condenser Discharge Line .....................................

412-01-30

Air Conditioning (A/C) Compressor to Condenser Discharge Line — 2.5L Duratec

(147kW/200PS) - VI5 ........................................................................\

................................

412-01-31

Condenser ........................................................................\

..................................................

412-01-35

Clutch and Clutch Field Coil........................................................................\

.......................

412-01-36

Pollen Filter — RHD........................................................................\

...................................

412-01-37

(34

374 0)

Blower Motor — RHD ........................................................................\

.............

412-01-40

(34 382 0)

Blower Motor Resistor — Vehicles With: Manual Temperature Control, RHD .

412-01-41

(34 382 0)

Blower Motor Resistor — Vehicles With: Dual Automatic Temperature

Control ........................................................................\

..................................

412-01- 1

Climate Control

412-01- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

PAGE 1 OF 2 FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL