pressure FORD KUGA 2011 1.G Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1428 of 2057

Description

Item

Battery

1

Battery junction box (BJB) in the engine

compartment

2

Generic electronic module (GEM)

3

Powertrain Control Module (PCM)

4

Instrument cluster

5

Data link connector (DLC)

6

Steering Wheel Rotation Sensor

7

ABS/ESP module or hydraulic control unit

(HCU)

8Description

Item

Combined yaw rate sensor and lateral

acceleration sensor / longitudinal

acceleration sensor

9

Front wheel sensor

10

Rear wheel sensor

11

Rear wheel sensor

12

Front wheel sensor

13

ESP switch

14

Rear brakes

15

Front brake

16

The ABS monitors the different wheel speeds of

the vehicle with the aid of wheel speed sensors.

Using the data from all of the wheel speed sensors,

the ABS module calculates the so-called reference

speed, which is a measure of the actual road

speed. The ABS module compares the individual

circumferential wheel speeds with this reference

speed when the driver initiates braking. If one or

more of the circumferential wheel speeds deviates

too far from the reference speed, this means that

slip at the affected wheels is so great that steering

stability of the vehicle is no longer ensured. The

ABS module actuates electro-mechanical valves

which influence the brake pressure at the relevant

wheels.

Like the traction control system (TCS), the ESP

system uses a large proportion of the ABS

components. In addition, there are sensors which

pick up the steering angle, the acceleration forces

acting on the vehicle and the yaw rate or yaw

moment. The sensors transmit these signals to the

combined ABS/ESP module. Using the wheel

speed and steering angle data, the ABS/ESP

module calculates the direction of travel planned

by the driver and determines the corresponding

speed-dependent lateral acceleration and yaw

moment. These values are compared with those

actual measured. If the actual lateral acceleration

and the yaw moment deviate excessively from the

target values (unstable driving characteristics), the

ABS/ESP module actuates individual brakes

selectively via the HCU (hydraulic control unit). In

addition, the engine speed is reduced by

intervention in the engine management system.

How the system works for understeer: In the

event of understeer, brake intervention occurs at

the wheels on the inside of the curve. The rear

wheel is braked heavily, so that a high amount of slip is caused. In this way, the cornering force of

the rear axle is heavily reduced and the centrifugal

force that now becomes effective turns the rear of

the vehicle back into the curve. The front wheel is

not braked as hard. The braking force that is

transmitted via the front wheel to the road surface

generates a torque with the aid of the lever arm

(vertical tire force to the vehicle's centre of gravity),

which supports the yaw moment of the vehicle.

Both measures together result in the vehicle

reverting back to the curved path intended by the

driver.

How the system works for oversteer:

In the

event of oversteer the wheels on the outside of the

curve are braked. This time, the front wheel is

subjected to a high level of slip so that the

cornering force at the front axle is reduced. The

rear wheel is not braked as heavily and, together

with the effective lever arm, results in a reduction

in the vehicle yaw moment. Both measures

together result in the vehicle being stabilized and

reverting back to the curved path intended by the

driver.

If ESP control occurs, possible ABS interventions

will be overridden as the ESP works at higher slip

rates than the ABS.

Emergency brake assist (EBA): The emergency

brake assist helps drivers in emergency braking

situations by automatically applying the brakes with

the maximum possible braking force.

If the brake pedal is pressed very suddenly, the

ABS module increases the hydraulic pressure to

all of the brakes until the threshold for ABS

intervention is reached. This applies the maximum

braking effort for the available traction. The ABS

control unit monitors inputs from the brake pedal

switch and from the pressure sensor within the

G1001304en2008.50 Kuga8/2011

206-09B- 10

Anti-Lock Control - Stability Assist

206-09B- 10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1429 of 2057

HCU to check for sudden actuation of the brakes.

With the brake pedal pressed, the ABS module

triggers emergency braking if the rate of increase

of hydraulic pressure exceeds the predetermined

limit.

If the brake pedal is pressed so hard that the ABS

becomes active on the front wheels then the ABS

control unit increases the pressure to the rear

wheel brakes up to the ABS intervention threshold.

EBA operation continues until the driver releases

the brake pedal sufficiently for the hydraulic

pressure in the HCU to drop below a threshold

value stored in the ABS module.

Trailer stability control:If the vehicle is ordered

with a trailer coupling then the Trailer Stability

Control function is integrated in the ESP. The ESP

detects snaking when driving with a trailer and

reduces the speed of the vehicle and trailer through

adapted braking and, if necessary, by also reducing

the engine output until the snaking movement of

the trailer is corrected.

Roll-over protection: The ESP dynamically

determines the tipping tendency of the vehicle and

works in conjunction with the EBA system to

prevent the vehicle from tipping over during

dynamic maneuvers like lane changing or while

negotiating bends.

Emergency brake light: The emergency brake

light automatically switches on the hazard flasher

system to warn drivers of other vehicles that

emergency braking is being initiated. Based on a

defined delay value, the ABS/ESP module sends

a signal to the generic electronic module (GEM)

via the CAN data bus. The GEM activates the

hazard flasher system, that then flashes 7 times.

Prerequisites for activation of the emergency brake

light are:

• The speed is higher than 50 km/h.

• The brake pedal is being actuated.

• The deceleration is greater than 9 m/s².

To prevent activation on snow or ice, for example,

the following prerequisites must be met:

• The speed is higher than 50 km/h.

• The brake pedal is being actuated.

• ABS regulation takes place.

• The deceleration is greater than 6 m/s².

Tire pressure monitoring system: The tire

pressure monitoring system used in the Kuga is

able to detect loss of air in a tire at an early stage

and warn the driver. Because it can only compare

the behaviour of the tyres with each other, it is not possible to draw conclusions about the absolute

tyre pressure. It is also not possible to monitor the

spare tyre pressure. In order for the system to

operate correctly, the tyre pressures must be

regularly checked and corrected and the system

subsequently initialised (see below).

The tire pressure monitoring system used here,

depending on the equipment level, is built into the

anti-lock braking system (ABS) as an extra function

and therefore does not have its own sensors.

The ABS module measures the loss of pressure

in the tyres by calculation using the wheel speed

sensors of the ABS system. If a tyre loses

pressure, its diameter decreases and the speed of

the wheel therefore increases. If the ABS module

detects such a loss in pressure, it sends a signal

to the instrument cluster via the CAN bus and a

warning message is displayed in the message

centre. The warning threshold depends among

other things on the dimension of the tyres being

used, the vehicle operating conditions and the

status at the last initialisation. Since neither the

absolute tyre pressure nor the position of the tyre

is known, the pressure of all the tyres must be

checked and the system re-initialised after a tyre

pressure warning. If necessary, the cause of the

loss of pressure must be investigated.

Regular tyre pressure checks are still necessary.

The system must be initialised after a tyre is

changed, winter or summer tyres fitted, the

pressures corrected or adjusted to suit the vehicle

load. This can be done by the driver using the

driver information system. For further information,

see: Owner’s Manual.

Component Description

Opto-electronic steering wheel rotation

sensor

E80158

G1001304en2008.50 Kuga8/2011

206-09B-

11

Anti-Lock Control - Stability Assist

206-09B- 11

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1430 of 2057

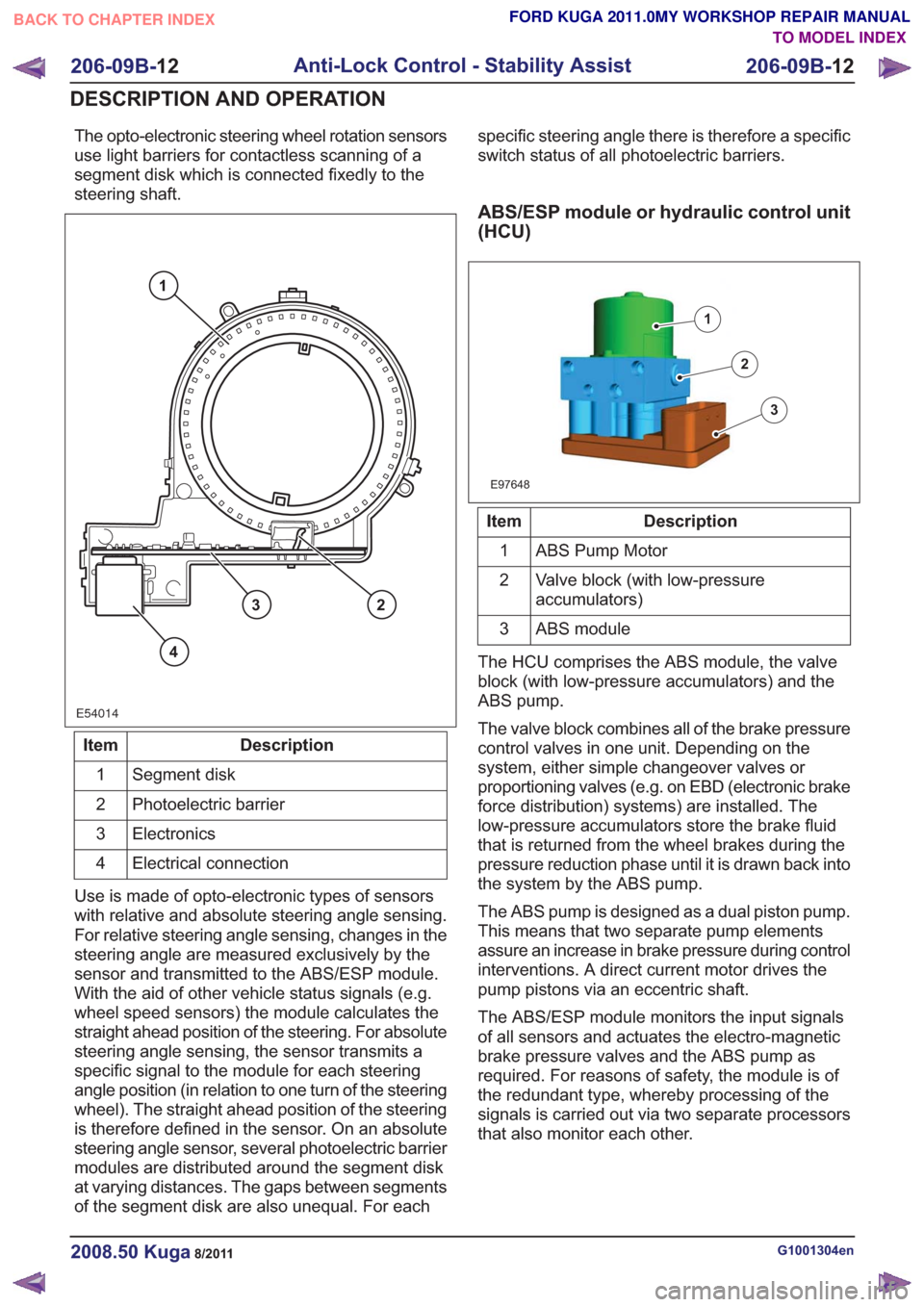

The opto-electronic steering wheel rotation sensors

use light barriers for contactless scanning of a

segment disk which is connected fixedly to the

steering shaft.

E54014

1

23

4

Description

Item

Segment disk

1

Photoelectric barrier

2

Electronics

3

Electrical connection

4

Use is made of opto-electronic types of sensors

with relative and absolute steering angle sensing.

For relative steering angle sensing, changes in the

steering angle are measured exclusively by the

sensor and transmitted to the ABS/ESP module.

With the aid of other vehicle status signals (e.g.

wheel speed sensors) the module calculates the

straight ahead position of the steering. For absolute

steering angle sensing, the sensor transmits a

specific signal to the module for each steering

angle position (in relation to one turn of the steering

wheel). The straight ahead position of the steering

is therefore defined in the sensor. On an absolute

steering angle sensor, several photoelectric barrier

modules are distributed around the segment disk

at varying distances. The gaps between segments

of the segment disk are also unequal. For each specific steering angle there is therefore a specific

switch status of all photoelectric barriers.

ABS/ESP module or hydraulic control unit

(HCU)

E97648

1

2

3

Description

Item

ABS Pump Motor

1

Valve block (with low-pressure

accumulators)

2

ABS module

3

The HCU comprises the ABS module, the valve

block (with low-pressure accumulators) and the

ABS pump.

The valve block combines all of the brake pressure

control valves in one unit. Depending on the

system, either simple changeover valves or

proportioning valves (e.g. on EBD (electronic brake

force distribution) systems) are installed. The

low-pressure accumulators store the brake fluid

that is returned from the wheel brakes during the

pressure reduction phase until it is drawn back into

the system by the ABS pump.

The ABS pump is designed as a dual piston pump.

This means that two separate pump elements

assure an increase in brake pressure during control

interventions. A direct current motor drives the

pump pistons via an eccentric shaft.

The ABS/ESP module monitors the input signals

of all sensors and actuates the electro-magnetic

brake pressure valves and the ABS pump as

required. For reasons of safety, the module is of

the redundant type, whereby processing of the

signals is carried out via two separate processors

that also monitor each other.

G1001304en2008.50 Kuga8/2011

206-09B- 12

Anti-Lock Control - Stability Assist

206-09B- 12

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1436 of 2057

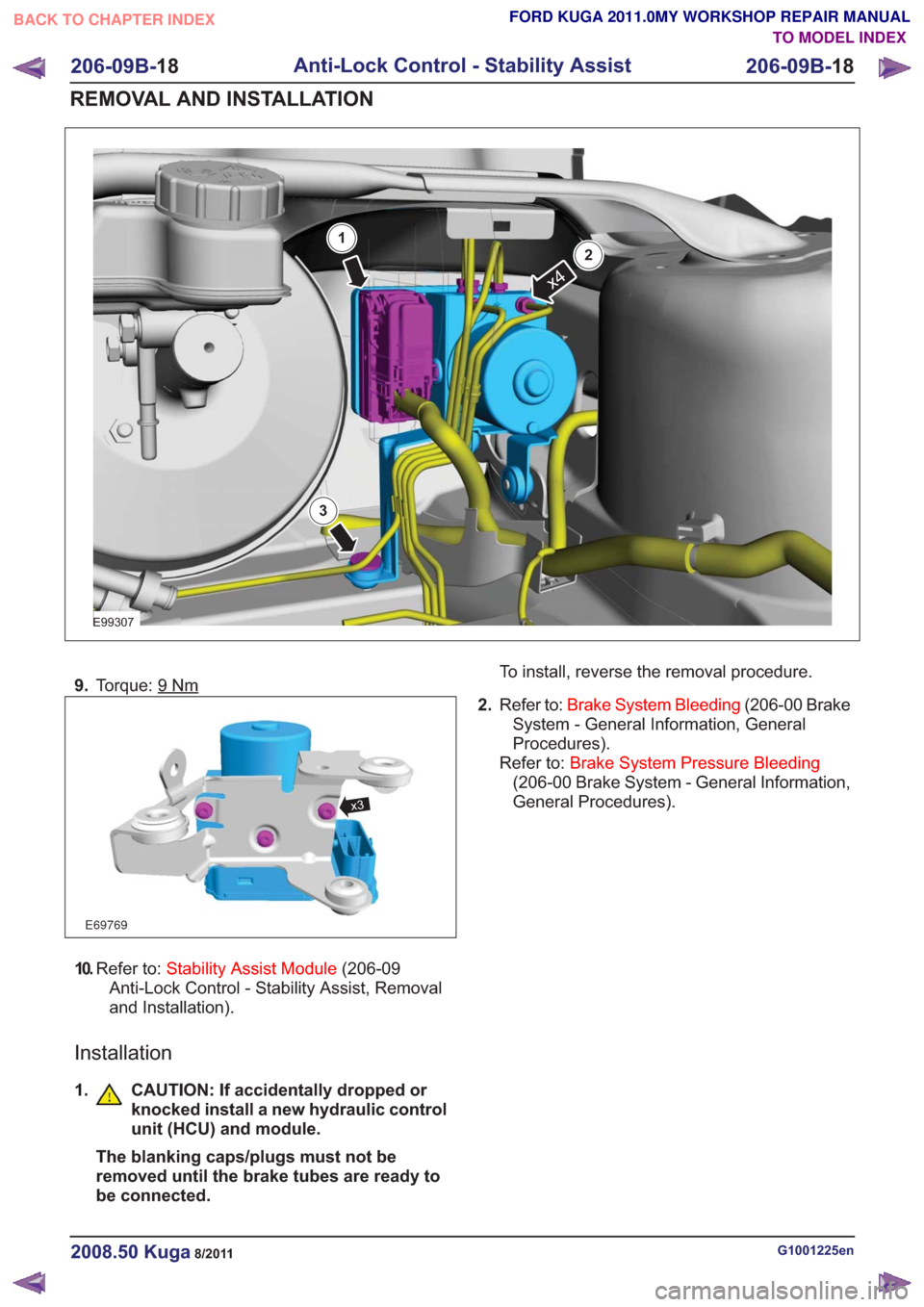

E99307

x4

1

2

3

9.Torque: 9Nm

E69769

x3

10.Refer to: Stability Assist Module (206-09

Anti-Lock Control - Stability Assist, Removal

and Installation).

Installation

1. CAUTION: If accidentally dropped or knocked install a new hydraulic control

unit (HCU) and module.

The blanking caps/plugs must not be

removed until the brake tubes are ready to

be connected. To install, reverse the removal procedure.

2. Refer to: Brake System Bleeding (206-00 Brake

System - General Information, General

Procedures).

Refer to: Brake System Pressure Bleeding

(206-00 Brake System - General Information,

General Procedures).

G1001225en2008.50 Kuga8/2011

206-09B- 18

Anti-Lock Control - Stability Assist

206-09B- 18

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1443 of 2057

Steering System

Special Tool(s) / General EquipmentAlignment Pins, Subframe

205-316 (15-097A)

15097

Simulator, Driver and

Passenger Air Bags and Side

Air Curtains

501-073 (40-016)

501073

The Ford approved diagnostic tool

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicalor electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Battery

• Battery cables

• Steering anglesensor electrical

connector

• Power steering pump control

module electrical

connectors

• Power steering pump control

module ground

cable

• Power steering pump control

module ground

cable retaining

screw

• Steering angle sensor warning

indicator

• Fuse(s)

• Tire pressure(s)

• Loose tie-rod end(s)

• Loose strut and

spring assemblies or

ball joints

• Loose pinch bolts on steering column

shaft flexible coup-

ling

• Wheels and tires

• Power steering line fluid leaks

• Steering gear bellows 3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool.

Components Tests

Steering Linkage

1. Grasp the steering wheel firmly and move it upand down and to the left and right without

turning the steering wheel to check the steering

column bearing for wear, steering column shaft

for wear, steering wheel for looseness and

steering column for looseness. If the steering

column bearing or the steering column shaft is

worn install a new steering column. If the

steering wheel or the steering column is loose,

tighten the steering wheel or the steering column

retaining bolts.

2. With the road wheels in the straight ahead position, gently turn the steering wheel to the

left and the right to check for free play in the

steering linkage.

3. There should be no excessive free play at the steering wheel rim. If there is excessive free

play, CHECK the tie-rod inner and outer ball

joints, REFER to Tie-Rod Component Test in

this procedure. CHECK the steering column

universal joint, REFER to Steering Column

Universal Joint Component Test in this

procedure. If there is no free play in the tie-rod

and the steering column, install a new steering

gear.

Tie-Rod

CAUTION: Steering gear boots must be

handled carefully to avoid damage. Use

new steering boot clamps when installing

the steering gear boots.

NOTE: Noises such as knocks, which may appear

to originate from the steering linkage, may also be

generated by front suspension components.

REFER to: Noise, Vibration and Harshness (NVH)

(100-04 Noise, Vibration and Harshness,

Diagnosis and Testing).

G1059437en2008.50 Kuga8/2011

211-00- 2

Steering System - General Information

211-00- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1445 of 2057

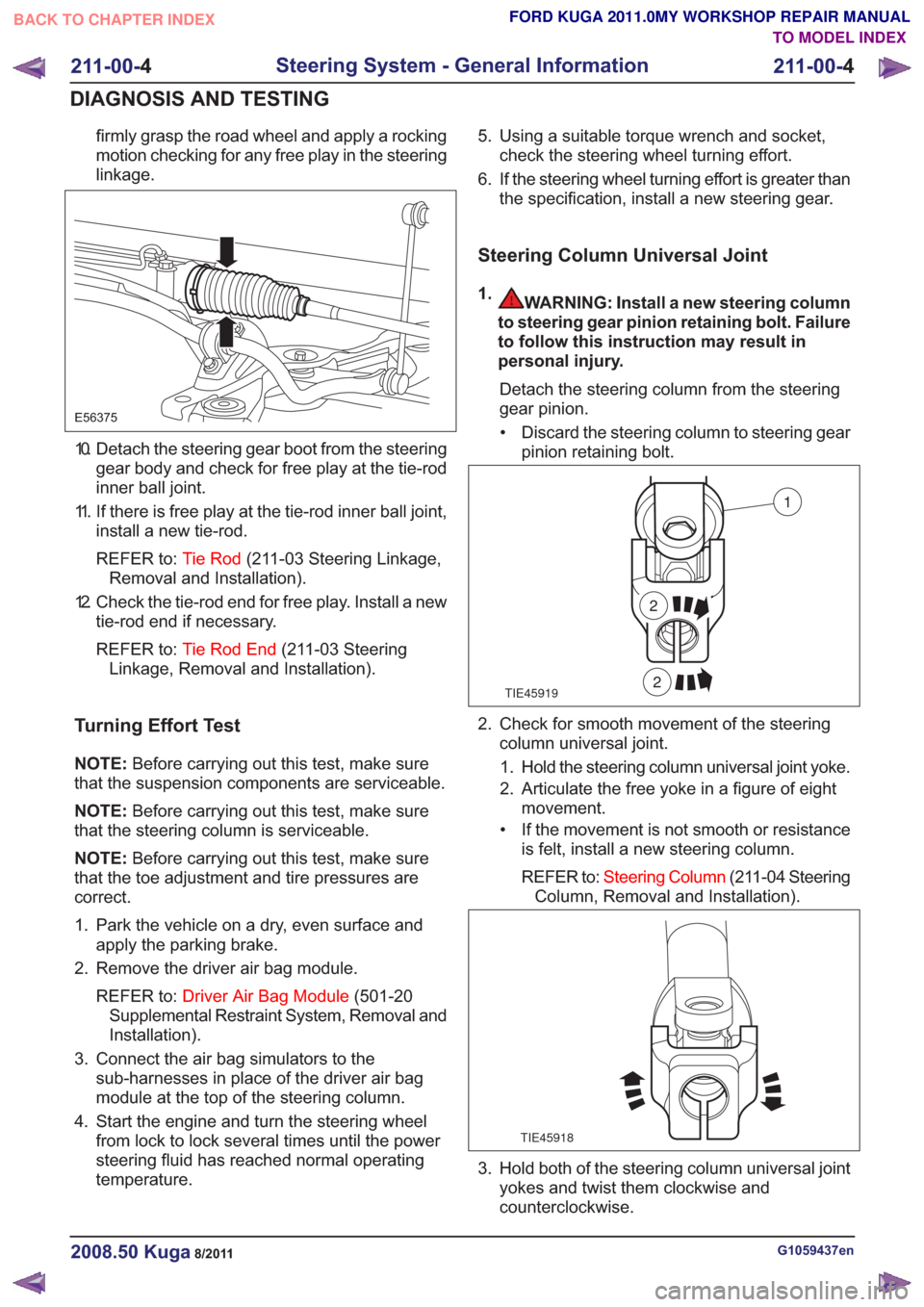

firmly grasp the road wheel and apply a rocking

motion checking for any free play in the steering

linkage.

E56375

10. Detach the steering gear boot from the steeringgear body and check for free play at the tie-rod

inner ball joint.

11. If there is free play at the tie-rod inner ball joint, install a new tie-rod.

REFER to: Tie Rod(211-03 Steering Linkage,

Removal and Installation).

12. Check the tie-rod end for free play. Install a new tie-rod end if necessary.

REFER to: Tie Rod End (211-03 Steering

Linkage, Removal and Installation).

Turning Effort Test

NOTE: Before carrying out this test, make sure

that the suspension components are serviceable.

NOTE: Before carrying out this test, make sure

that the steering column is serviceable.

NOTE: Before carrying out this test, make sure

that the toe adjustment and tire pressures are

correct.

1. Park the vehicle on a dry, even surface and apply the parking brake.

2. Remove the driver air bag module.

REFER to: Driver Air Bag Module (501-20

Supplemental Restraint System, Removal and

Installation).

3. Connect the air bag simulators to the sub-harnesses in place of the driver air bag

module at the top of the steering column.

4. Start the engine and turn the steering wheel from lock to lock several times until the power

steering fluid has reached normal operating

temperature. 5. Using a suitable torque wrench and socket,

check the steering wheel turning effort.

6. If the steering wheel turning effort is greater than the specification, install a new steering gear.

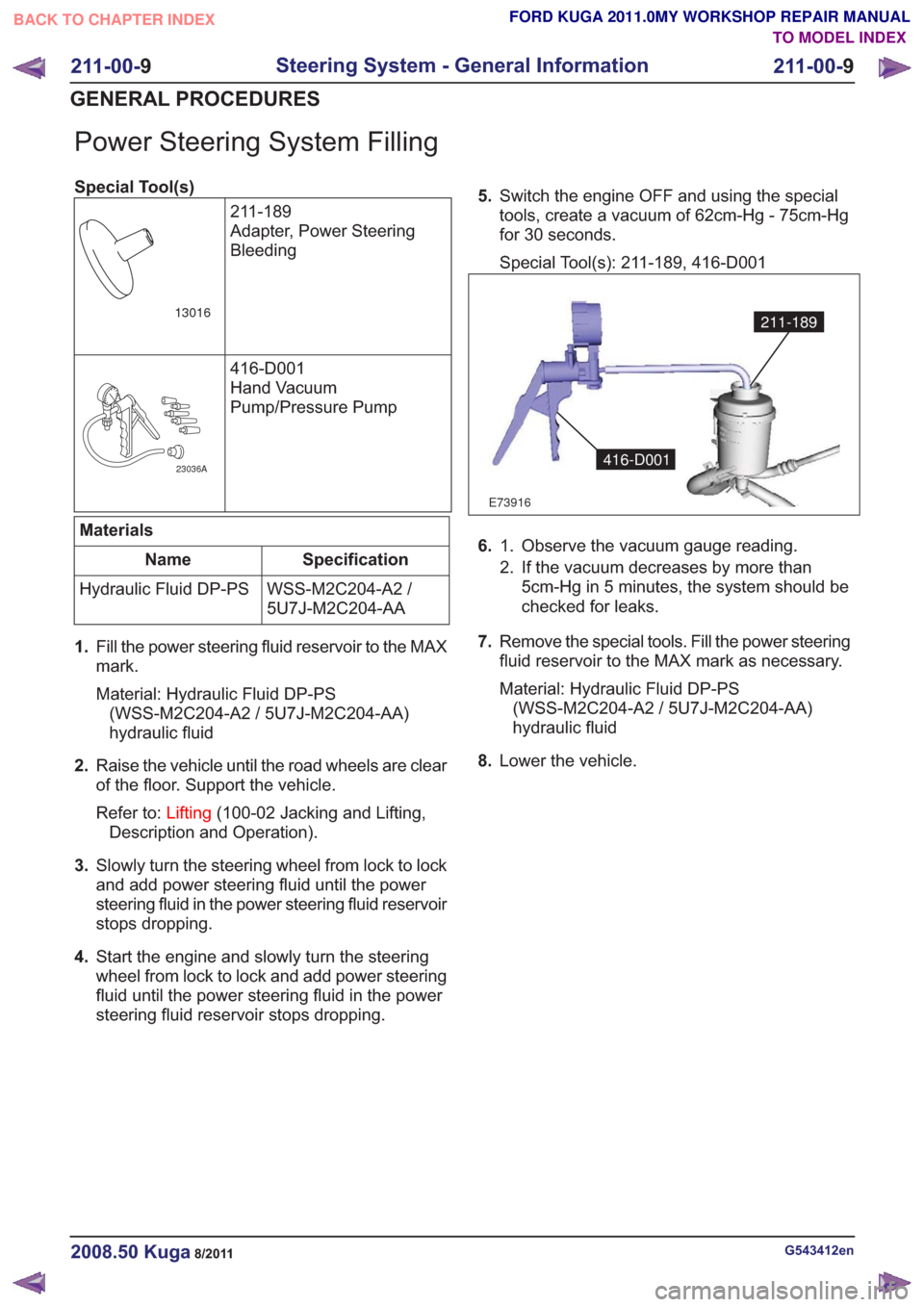

Steering Column Universal Joint

1.WARNING: Install a new steering column

to steering gear pinion retaining bolt. Failure

to follow this instruction may result in

personal injury.

Detach the steering column from the steering

gear pinion.• Discard the steering column to steering gear pinion retaining bolt.

TIE45919

1

2

2

2. Check for smooth movement of the steeringcolumn universal joint.

1. Hold the steering column universal joint yoke.

2. Articulate the free yoke in a figure of eight movement.

• If the movement is not smooth or resistance is felt, install a new steering column.

REFER to: Steering Column (211-04 Steering

Column, Removal and Installation).

TIE45918

3. Hold both of the steering column universal joint yokes and twist them clockwise and

counterclockwise.

G1059437en2008.50 Kuga8/2011

211-00- 4

Steering System - General Information

211-00- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1450 of 2057

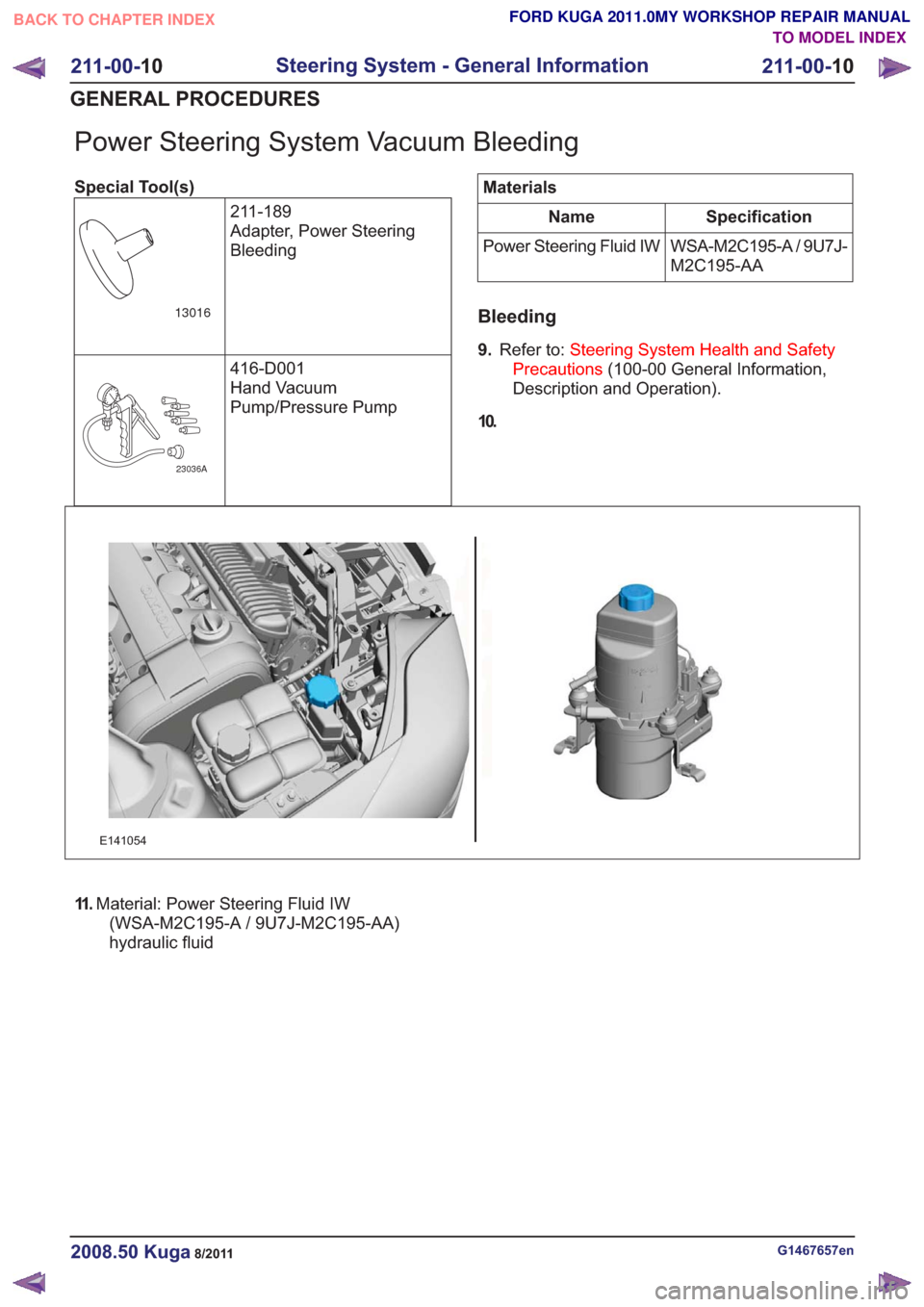

Power Steering System Filling

Special Tool(s)211-189

Adapter, Power Steering

Bleeding

13016

416-D001

Hand Vacuum

Pump/Pressure Pump

23036A

Materials

Specification

Name

WSS-M2C204-A2 /

5U7J-M2C204-AA

Hydraulic Fluid DP-PS

1. Fill the power steering fluid reservoir to the MAX

mark.

Material: Hydraulic Fluid DP-PS

(WSS-M2C204-A2 / 5U7J-M2C204-AA)

hydraulic fluid

2. Raise the vehicle until the road wheels are clear

of the floor. Support the vehicle.

Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

3. Slowly turn the steering wheel from lock to lock

and add power steering fluid until the power

steering fluid in the power steering fluid reservoir

stops dropping.

4. Start the engine and slowly turn the steering

wheel from lock to lock and add power steering

fluid until the power steering fluid in the power

steering fluid reservoir stops dropping. 5.

Switch the engine OFF and using the special

tools, create a vacuum of 62cm-Hg - 75cm-Hg

for 30 seconds.

Special Tool(s): 211-189, 416-D001

E73916

211-189

416-D001

6. Observe the vacuum gauge reading.

1.

2. If the vacuum decreases by more than

5cm-Hg in 5 minutes, the system should be

checked for leaks.

7. Remove the special tools. Fill the power steering

fluid reservoir to the MAX mark as necessary.

Material: Hydraulic Fluid DP-PS

(WSS-M2C204-A2 / 5U7J-M2C204-AA)

hydraulic fluid

8. Lower the vehicle.

G543412en2008.50 Kuga8/2011

211-00- 9

Steering System - General Information

211-00- 9

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1451 of 2057

Power Steering System Vacuum Bleeding

Special Tool(s)211-189

Adapter, Power Steering

Bleeding

13016

416-D001

Hand Vacuum

Pump/Pressure Pump

23036A

Materials

Specification

Name

WSA-M2C195-A / 9U7J-

M2C195-AA

Power Steering Fluid IW

Bleeding

9.

Refer to: Steering System Health and Safety

Precautions (100-00 General Information,

Description and Operation).

10.

E141054

11 . Material: Power Steering Fluid IW

(WSA-M2C195-A / 9U7J-M2C195-AA)

hydraulic fluid

G1467657en2008.50 Kuga8/2011

211-00- 10

Steering System - General Information

211-00- 10

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1458 of 2057

SECTION 211-02 Power Steering

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

DESCRIPTION AND OPERATION

211-02-2

Power Steering (Component Location) ........................................................................\

......

211-02-3

Power Steering (Overview) ........................................................................\

.........................

211-02-3

Power Steering ........................................................................\

...........................................

211-02-4

Steering gear ........................................................................\

..............................................

211-02-5

Electro-hydraulic power steering pump ........................................................................\

......

211-02-6

Pressure and return lines ........................................................................\

...........................

211-02-7

Power Steering (System Operation and Component Description) .....................................

211-02-7

System Diagram ........................................................................\

.........................................

211-02-8

System Operation ........................................................................\

.......................................

211-02-8

Electronic principle of operation ........................................................................\

..............

211-02-9

Hydraulic principle of operation ........................................................................\

..............

211-02-9

Component Description ........................................................................\

..............................

211-02-9

Electro-hydraulic power steering pump ........................................................................\

..

211-02-10

Integrated steering angle sensor - vehicles built up to 09/2009 .....................................

211-02-11

Brushless DC motor with integral power steering module..............................................

REMOVAL AND INSTALLATION

211-02-13

(13 443 0)

Power Steering Pressure Line and Return Line Assembly — 2.5L Duratec

(147kW/200PS) - VI5 ........................................................................\

............

211-02-18

(13 434 0)

Power Steering Pump — 2.5L Duratec (147kW/200PS) - VI5 .......................

211-02-21

(13 440 0;

13 443 0)

Power Steering Pump to Steering Gear Pressure Line — 2.5L Duratec

(147kW/200PS) - VI5 ........................................................................\

............

211-02-25

(13 116 0)

Steering Gear ........................................................................\

.........................

211-02-36

(13 439 0)

Steering Gear to Power Steering Fluid Reservoir Return Line — 2.5L Duratec

(147kW/200PS) - VI5 ........................................................................\

............

211-02-1

Power Steering

211-02- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1460 of 2057

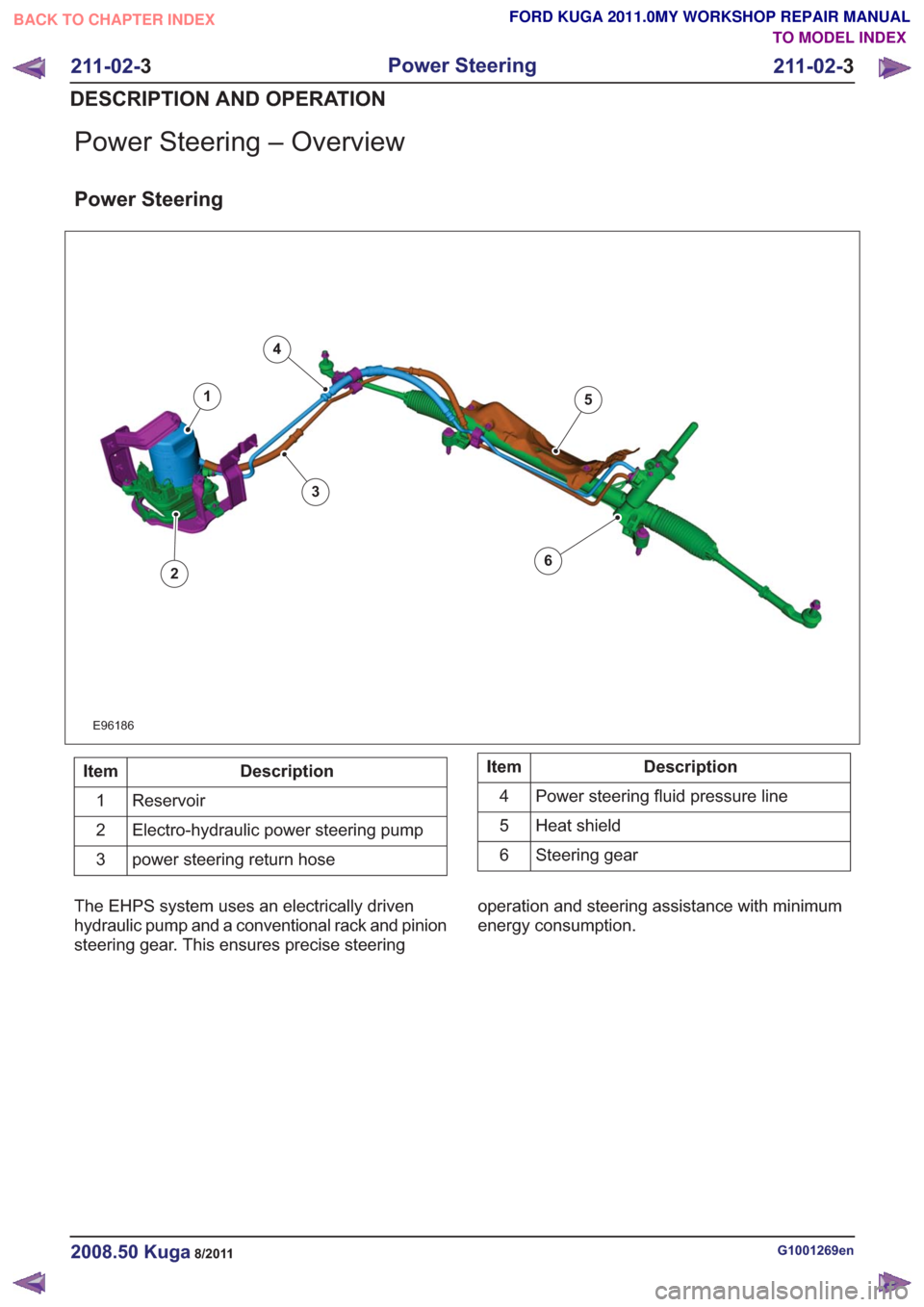

Power Steering – Overview

Power Steering

E96186

1

2

3

4

5

6

Description

Item

Reservoir

1

Electro-hydraulic power steering pump

2

power steering return hose

3Description

Item

Power steering fluid pressure line

4

Heat shield

5

Steering gear

6

The EHPS system uses an electrically driven

hydraulic pump and a conventional rack and pinion

steering gear. This ensures precise steering operation and steering assistance with minimum

energy consumption.

G1001269en2008.50 Kuga8/2011

211-02-

3

Power Steering

211-02- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL