sensor FORD KUGA 2011 1.G Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1432 of 2057

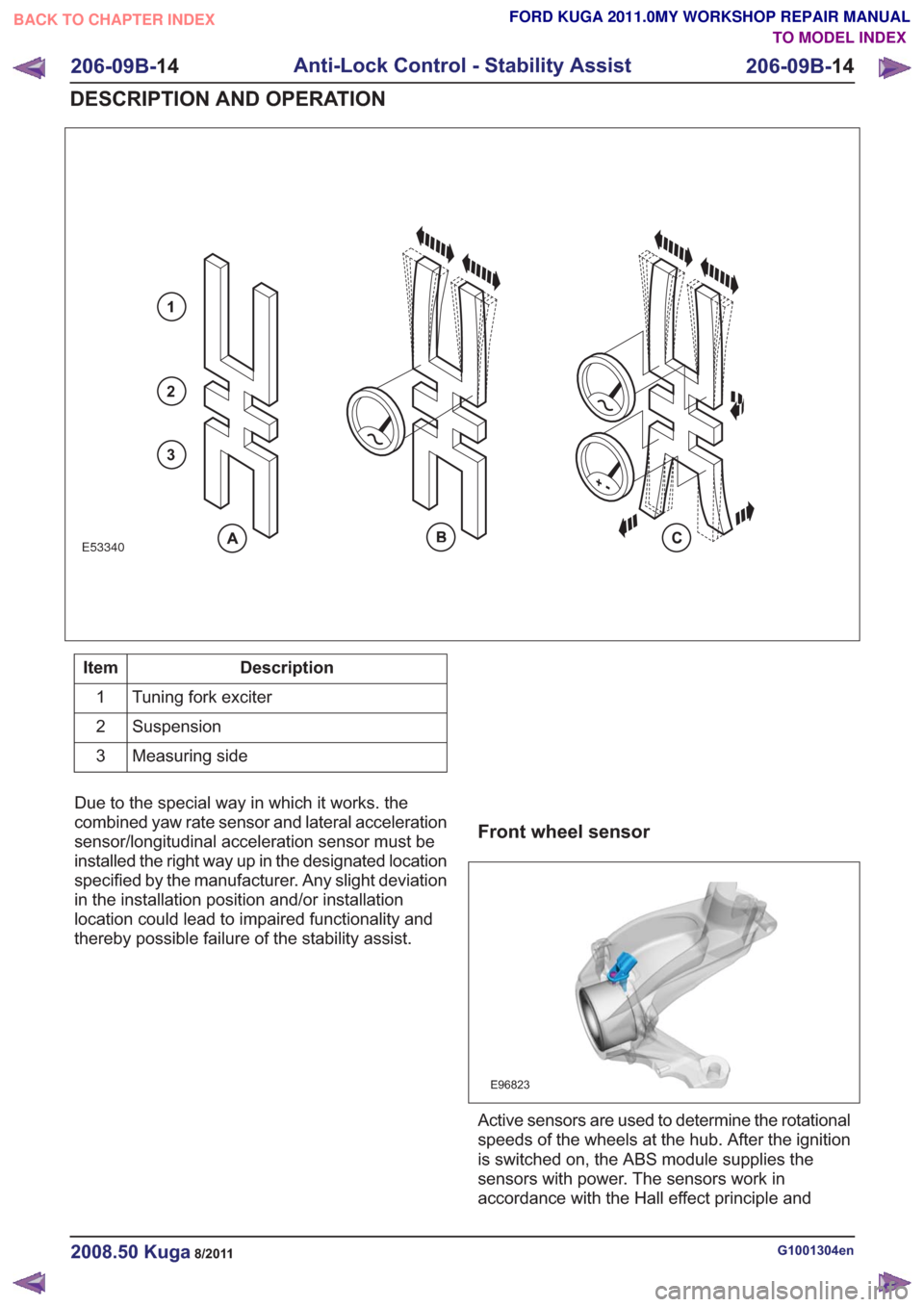

E53340

1

2

3

Description

Item

Tuning fork exciter

1

Suspension

2

Measuring side

3

Due to the special way in which it works. the

combined yaw rate sensor and lateral acceleration

sensor/longitudinal acceleration sensor must be

installed the right way up in the designated location

specified by the manufacturer. Any slight deviation

in the installation position and/or installation

location could lead to impaired functionality and

thereby possible failure of the stability assist.

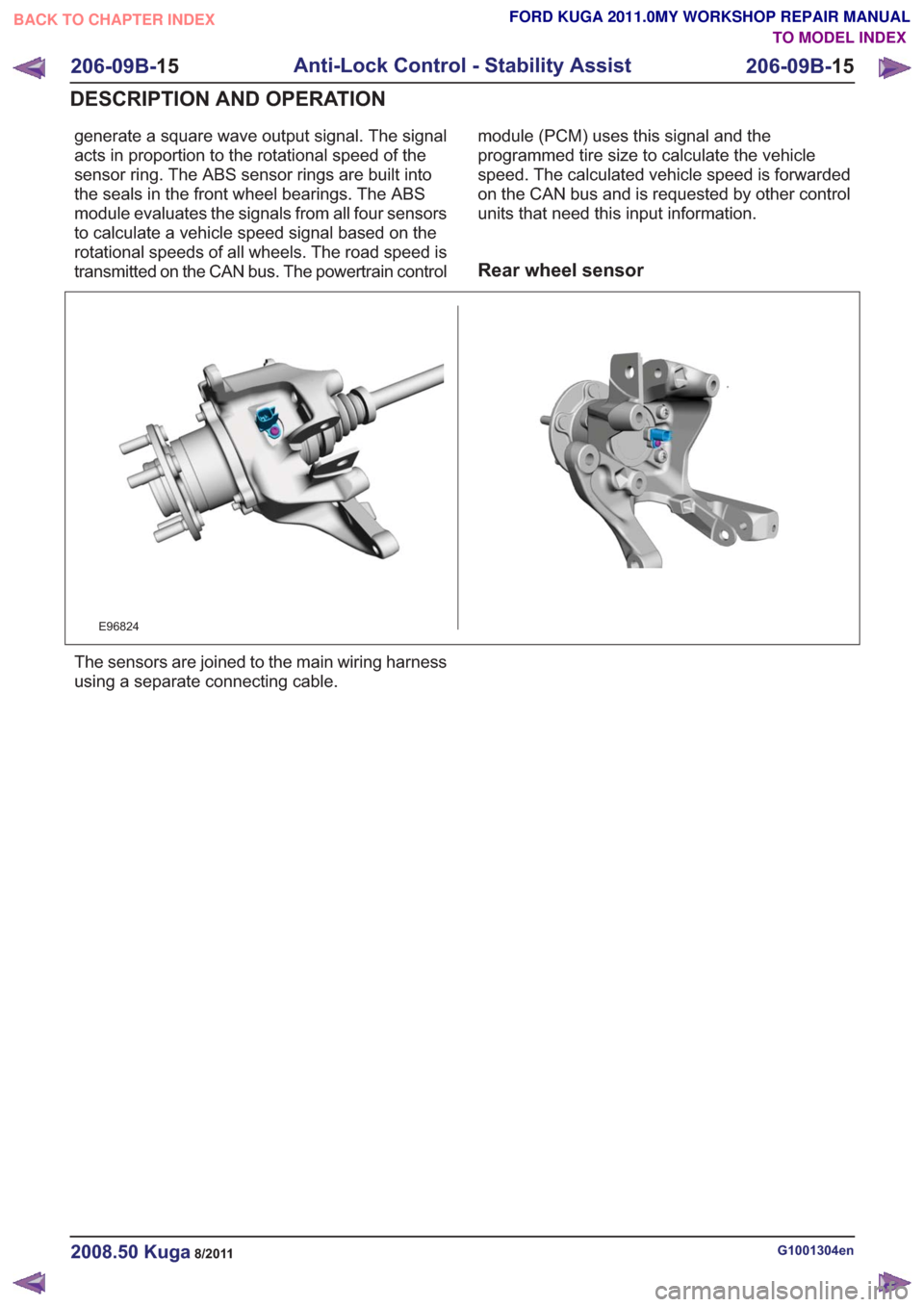

Front wheel sensor

E96823

Active sensors are used to determine the rotational

speeds of the wheels at the hub. After the ignition

is switched on, the ABS module supplies the

sensors with power. The sensors work in

accordance with the Hall effect principle and

G1001304en2008.50 Kuga8/2011

206-09B- 14

Anti-Lock Control - Stability Assist

206-09B- 14

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1433 of 2057

generate a square wave output signal. The signal

acts in proportion to the rotational speed of the

sensor ring. The ABS sensor rings are built into

the seals in the front wheel bearings. The ABS

module evaluates the signals from all four sensors

to calculate a vehicle speed signal based on the

rotational speeds of all wheels. The road speed is

transmitted on the CAN bus. The powertrain controlmodule (PCM) uses this signal and the

programmed tire size to calculate the vehicle

speed. The calculated vehicle speed is forwarded

on the CAN bus and is requested by other control

units that need this input information.

Rear wheel sensor

E96824

The sensors are joined to the main wiring harness

using a separate connecting cable.

G1001304en2008.50 Kuga8/2011

206-09B-

15

Anti-Lock Control - Stability Assist

206-09B- 15

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1439 of 2057

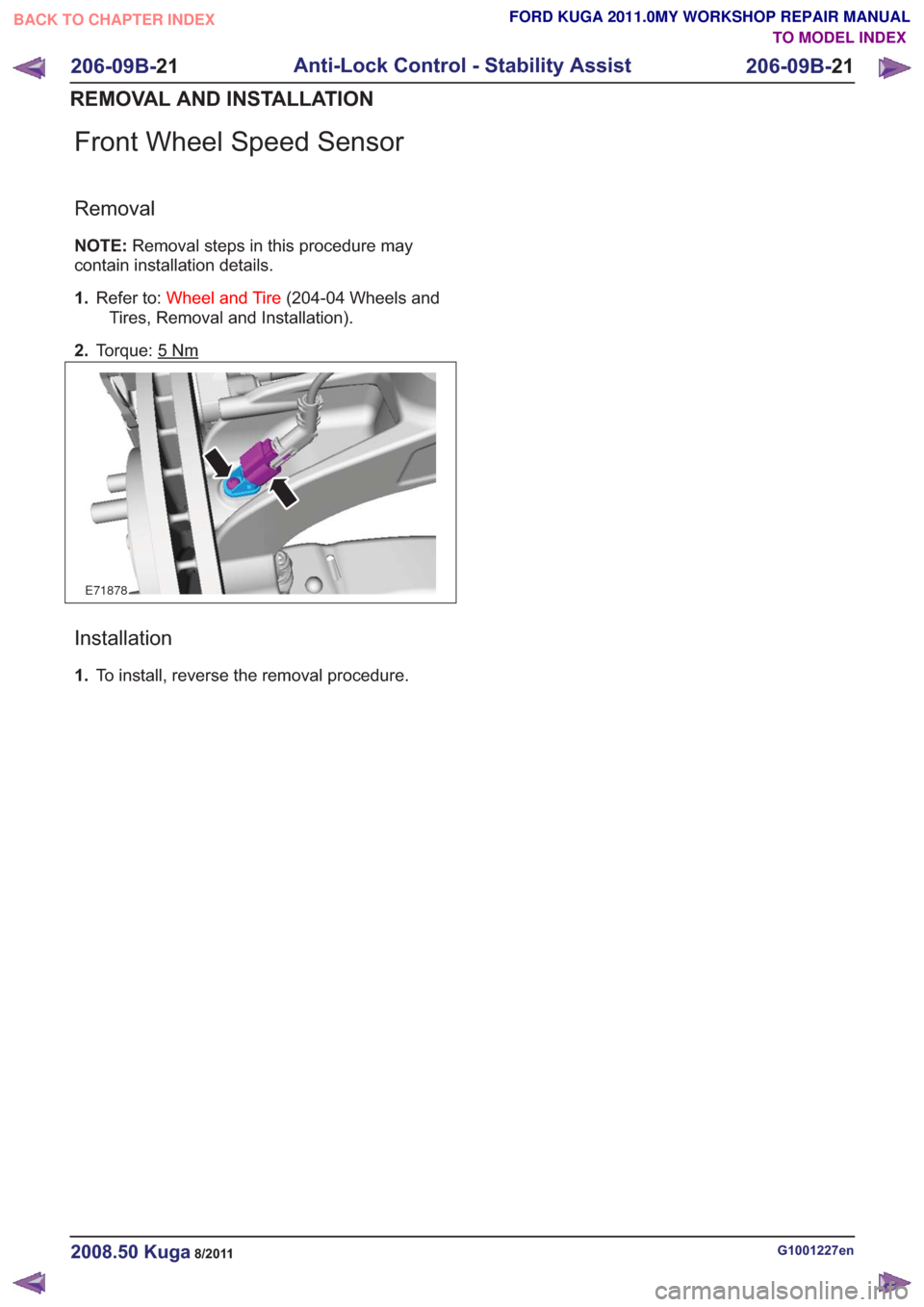

Front Wheel Speed Sensor

Removal

NOTE:Removal steps in this procedure may

contain installation details.

1. Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

2. Torque: 5

Nm

E71878

Installation

1.To install, reverse the removal procedure.

G1001227en2008.50 Kuga8/2011

206-09B- 21

Anti-Lock Control - Stability Assist

206-09B- 21

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1440 of 2057

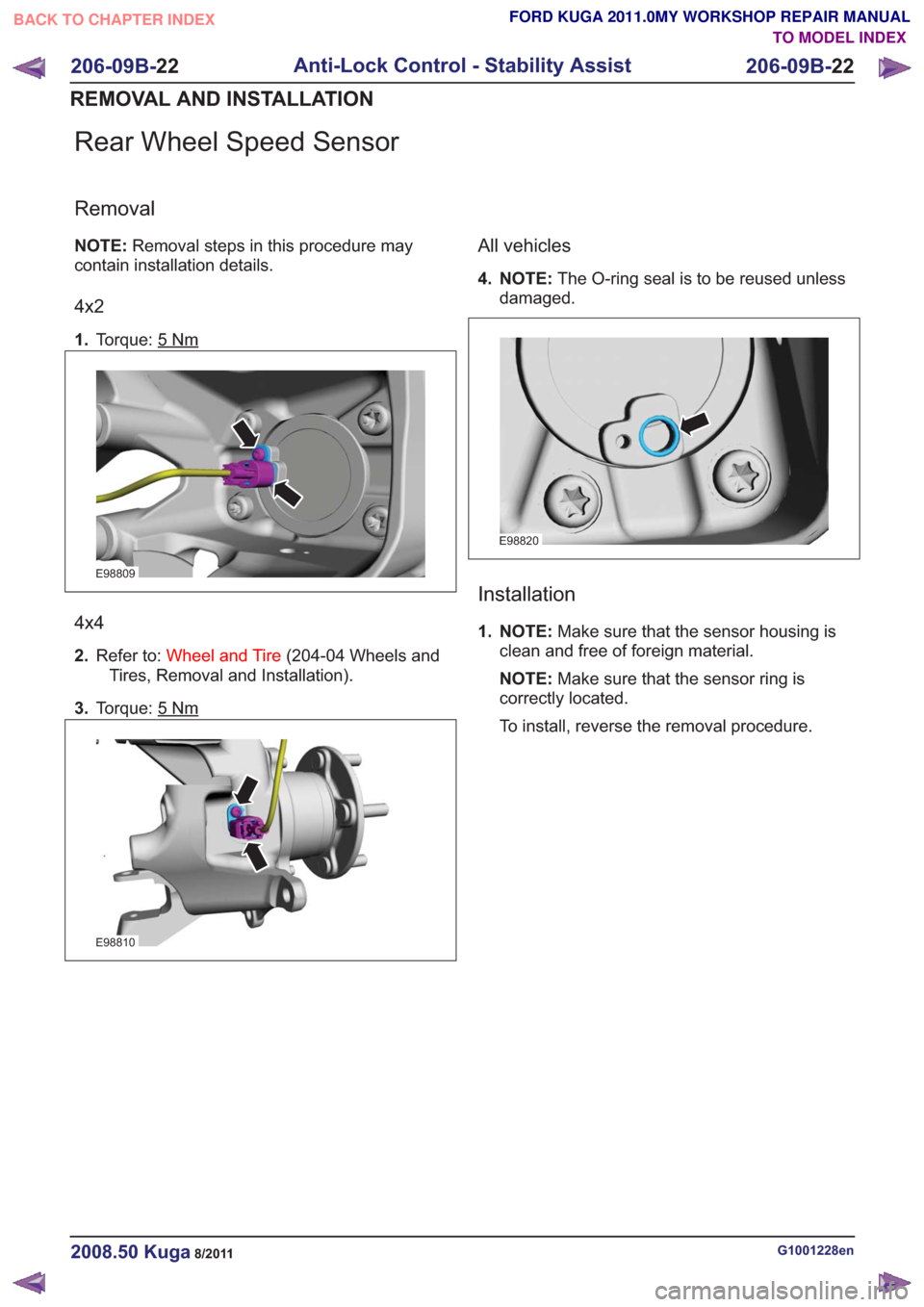

Rear Wheel Speed Sensor

Removal

NOTE:Removal steps in this procedure may

contain installation details.

4x2

1. Torque: 5Nm

E98809

4x4

2.Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

3. Torque: 5

Nm

E98810

All vehicles

4. NOTE: The O-ring seal is to be reused unless

damaged.

E98820

Installation

1. NOTE: Make sure that the sensor housing is

clean and free of foreign material.

NOTE: Make sure that the sensor ring is

correctly located.

To install, reverse the removal procedure.

G1001228en2008.50 Kuga8/2011

206-09B- 22

Anti-Lock Control - Stability Assist

206-09B- 22

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1441 of 2057

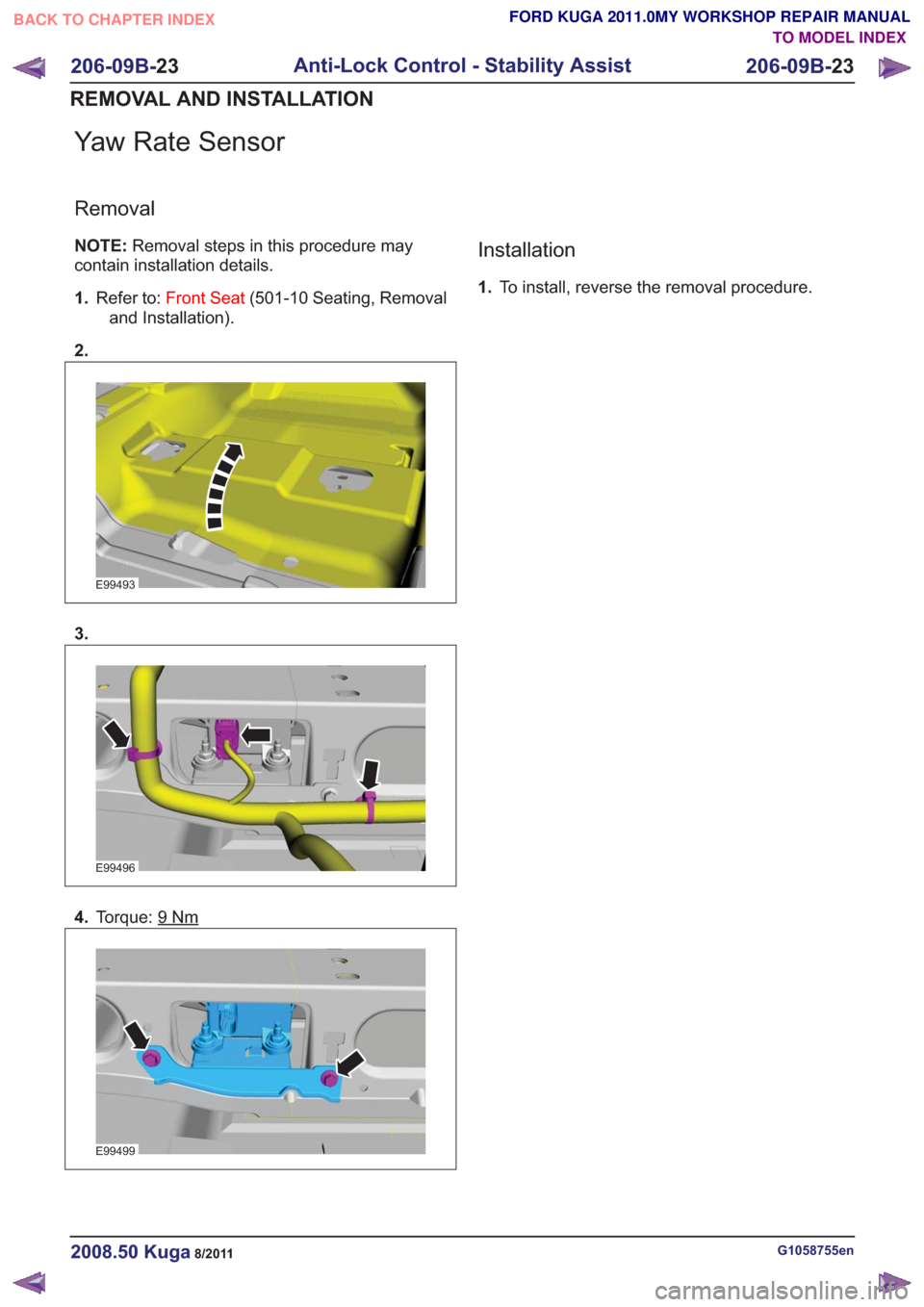

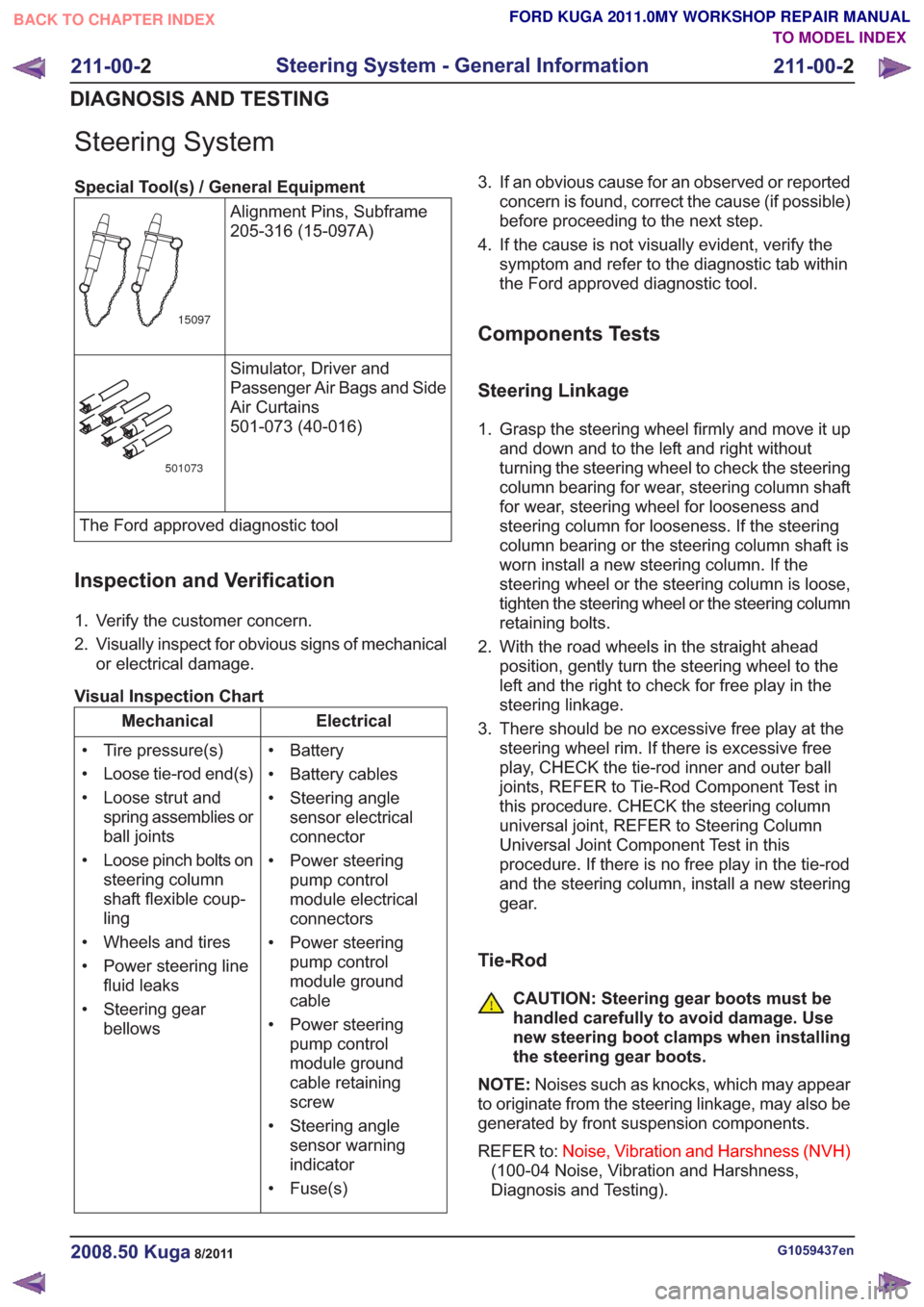

Yaw Rate Sensor

Removal

NOTE:Removal steps in this procedure may

contain installation details.

1. Refer to: Front Seat (501-10 Seating, Removal

and Installation).

2.

E99493

3.

E99496

4. Torque: 9Nm

E99499

Installation

1.To install, reverse the removal procedure.

G1058755en2008.50 Kuga8/2011

206-09B- 23

Anti-Lock Control - Stability Assist

206-09B- 23

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1443 of 2057

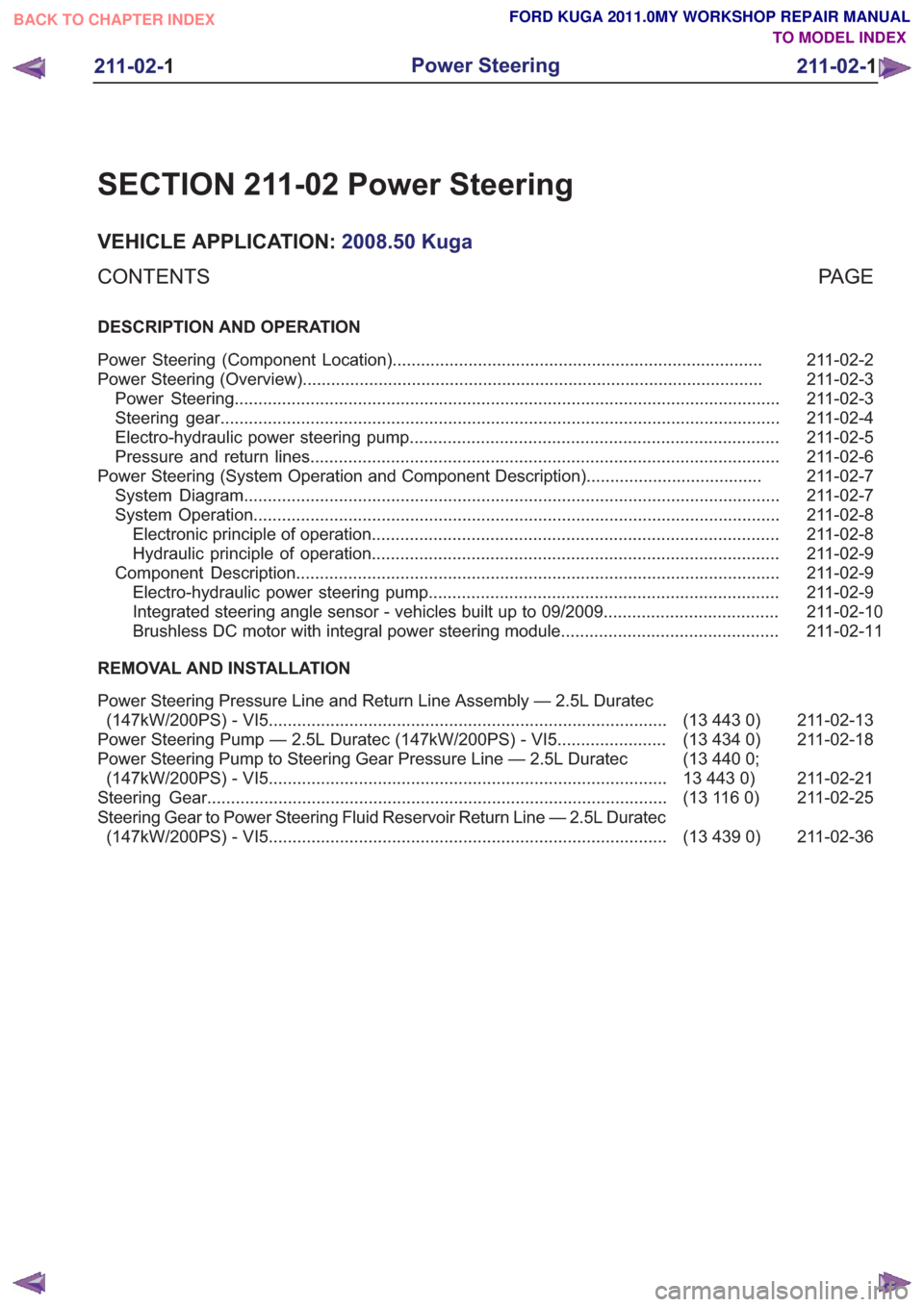

Steering System

Special Tool(s) / General EquipmentAlignment Pins, Subframe

205-316 (15-097A)

15097

Simulator, Driver and

Passenger Air Bags and Side

Air Curtains

501-073 (40-016)

501073

The Ford approved diagnostic tool

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicalor electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Battery

• Battery cables

• Steering anglesensor electrical

connector

• Power steering pump control

module electrical

connectors

• Power steering pump control

module ground

cable

• Power steering pump control

module ground

cable retaining

screw

• Steering angle sensor warning

indicator

• Fuse(s)

• Tire pressure(s)

• Loose tie-rod end(s)

• Loose strut and

spring assemblies or

ball joints

• Loose pinch bolts on steering column

shaft flexible coup-

ling

• Wheels and tires

• Power steering line fluid leaks

• Steering gear bellows 3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool.

Components Tests

Steering Linkage

1. Grasp the steering wheel firmly and move it upand down and to the left and right without

turning the steering wheel to check the steering

column bearing for wear, steering column shaft

for wear, steering wheel for looseness and

steering column for looseness. If the steering

column bearing or the steering column shaft is

worn install a new steering column. If the

steering wheel or the steering column is loose,

tighten the steering wheel or the steering column

retaining bolts.

2. With the road wheels in the straight ahead position, gently turn the steering wheel to the

left and the right to check for free play in the

steering linkage.

3. There should be no excessive free play at the steering wheel rim. If there is excessive free

play, CHECK the tie-rod inner and outer ball

joints, REFER to Tie-Rod Component Test in

this procedure. CHECK the steering column

universal joint, REFER to Steering Column

Universal Joint Component Test in this

procedure. If there is no free play in the tie-rod

and the steering column, install a new steering

gear.

Tie-Rod

CAUTION: Steering gear boots must be

handled carefully to avoid damage. Use

new steering boot clamps when installing

the steering gear boots.

NOTE: Noises such as knocks, which may appear

to originate from the steering linkage, may also be

generated by front suspension components.

REFER to: Noise, Vibration and Harshness (NVH)

(100-04 Noise, Vibration and Harshness,

Diagnosis and Testing).

G1059437en2008.50 Kuga8/2011

211-00- 2

Steering System - General Information

211-00- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1458 of 2057

SECTION 211-02 Power Steering

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

DESCRIPTION AND OPERATION

211-02-2

Power Steering (Component Location) ........................................................................\

......

211-02-3

Power Steering (Overview) ........................................................................\

.........................

211-02-3

Power Steering ........................................................................\

...........................................

211-02-4

Steering gear ........................................................................\

..............................................

211-02-5

Electro-hydraulic power steering pump ........................................................................\

......

211-02-6

Pressure and return lines ........................................................................\

...........................

211-02-7

Power Steering (System Operation and Component Description) .....................................

211-02-7

System Diagram ........................................................................\

.........................................

211-02-8

System Operation ........................................................................\

.......................................

211-02-8

Electronic principle of operation ........................................................................\

..............

211-02-9

Hydraulic principle of operation ........................................................................\

..............

211-02-9

Component Description ........................................................................\

..............................

211-02-9

Electro-hydraulic power steering pump ........................................................................\

..

211-02-10

Integrated steering angle sensor - vehicles built up to 09/2009 .....................................

211-02-11

Brushless DC motor with integral power steering module..............................................

REMOVAL AND INSTALLATION

211-02-13

(13 443 0)

Power Steering Pressure Line and Return Line Assembly — 2.5L Duratec

(147kW/200PS) - VI5 ........................................................................\

............

211-02-18

(13 434 0)

Power Steering Pump — 2.5L Duratec (147kW/200PS) - VI5 .......................

211-02-21

(13 440 0;

13 443 0)

Power Steering Pump to Steering Gear Pressure Line — 2.5L Duratec

(147kW/200PS) - VI5 ........................................................................\

............

211-02-25

(13 116 0)

Steering Gear ........................................................................\

.........................

211-02-36

(13 439 0)

Steering Gear to Power Steering Fluid Reservoir Return Line — 2.5L Duratec

(147kW/200PS) - VI5 ........................................................................\

............

211-02-1

Power Steering

211-02- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1459 of 2057

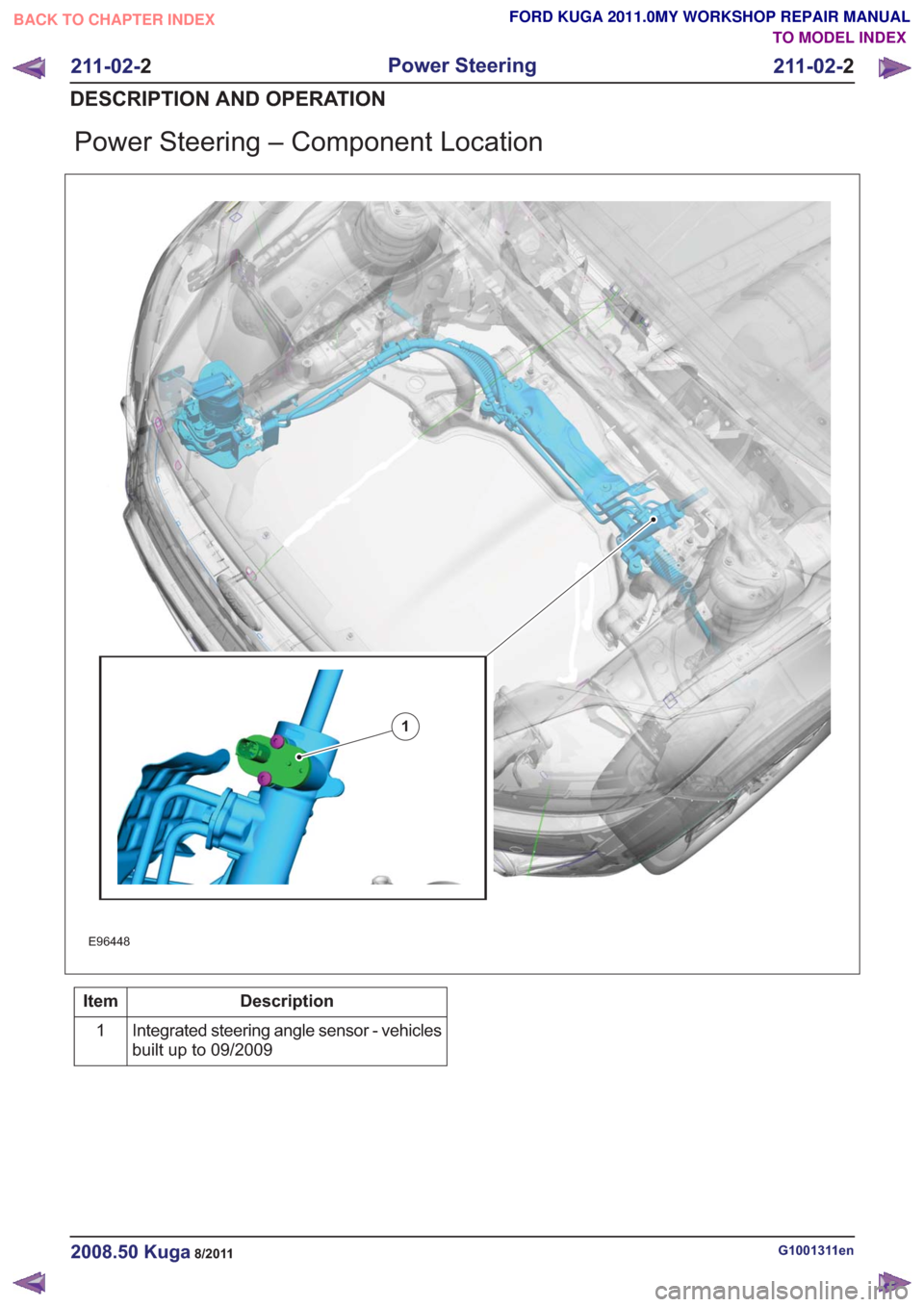

Power Steering – Component Location

E96448

1

Description

Item

Integrated steering angle sensor - vehicles

built up to 09/2009

1

G1001311en2008.50 Kuga8/2011

211-02-

2

Power Steering

211-02- 2

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1461 of 2057

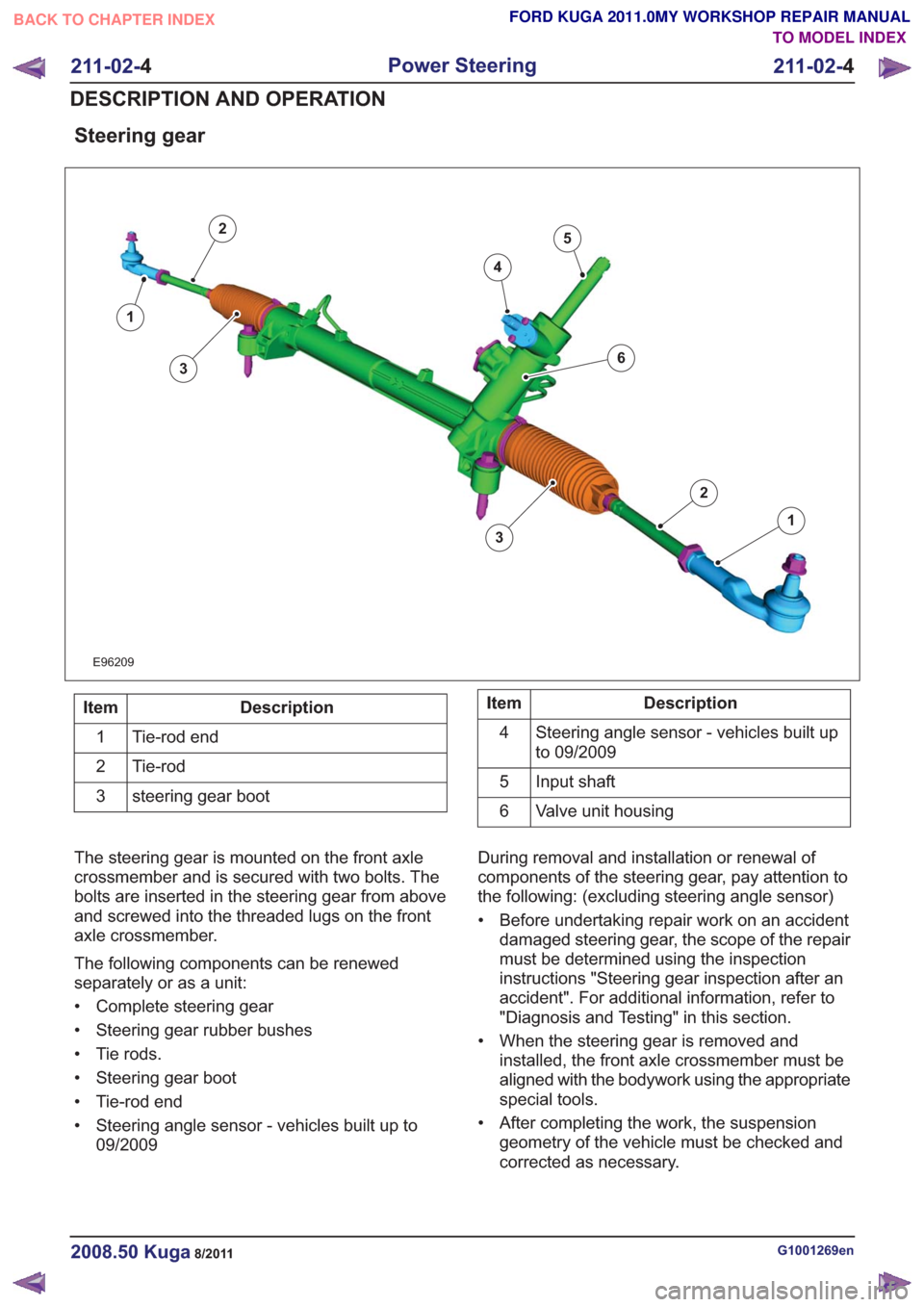

Steering gear

E96209

1

2

3

4

5

1

2

63

Description

Item

Tie-rod end

1

Tie-rod

2

steering gear boot

3Description

Item

Steering angle sensor - vehicles built up

to 09/2009

4

Input shaft

5

Valve unit housing

6

The steering gear is mounted on the front axle

crossmember and is secured with two bolts. The

bolts are inserted in the steering gear from above

and screwed into the threaded lugs on the front

axle crossmember.

The following components can be renewed

separately or as a unit:

• Complete steering gear

• Steering gear rubber bushes

• Tie rods.

• Steering gear boot

• Tie-rod end

• Steering angle sensor - vehicles built up to 09/2009 During removal and installation or renewal of

components of the steering gear, pay attention to

the following: (excluding steering angle sensor)

• Before undertaking repair work on an accident

damaged steering gear, the scope of the repair

must be determined using the inspection

instructions "Steering gear inspection after an

accident". For additional information, refer to

"Diagnosis and Testing" in this section.

• When the steering gear is removed and installed, the front axle crossmember must be

aligned with the bodywork using the appropriate

special tools.

• After completing the work, the suspension geometry of the vehicle must be checked and

corrected as necessary.

G1001269en2008.50 Kuga8/2011

211-02- 4

Power Steering

211-02- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1465 of 2057

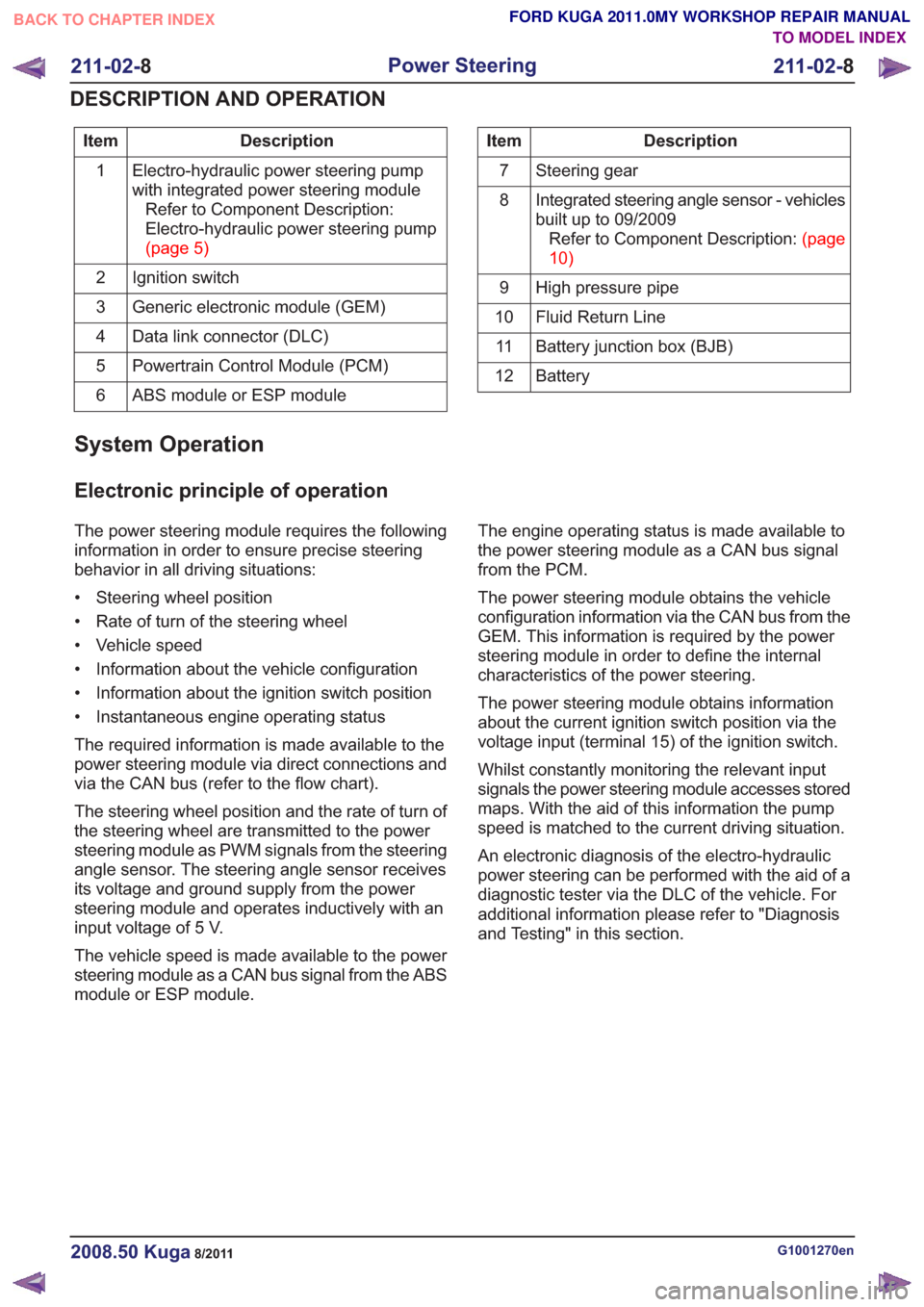

Description

Item

Electro-hydraulic power steering pump

with integrated power steering moduleRefer to Component Description:

Electro-hydraulic power steering pump

(page5)

1

Ignition switch

2

Generic electronic module (GEM)

3

Data link connector (DLC)

4

Powertrain Control Module (PCM)

5

ABS module or ESP module

6Description

Item

Steering gear

7

Integrated steering angle sensor - vehicles

built up to 09/2009RefertoComponentDescription:(page

10)

8

High pressure pipe

9

Fluid Return Line

10

Battery junction box (BJB)

11

Battery

12

System Operation

Electronic principle of operation

The power steering module requires the following

information in order to ensure precise steering

behavior in all driving situations:

• Steering wheel position

• Rate of turn of the steering wheel

• Vehicle speed

• Information about the vehicle configuration

• Information about the ignition switch position

• Instantaneous engine operating status

The required information is made available to the

power steering module via direct connections and

via the CAN bus (refer to the flow chart).

The steering wheel position and the rate of turn of

the steering wheel are transmitted to the power

steering module as PWM signals from the steering

angle sensor. The steering angle sensor receives

its voltage and ground supply from the power

steering module and operates inductively with an

input voltage of 5 V.

The vehicle speed is made available to the power

steering module as a CAN bus signal from the ABS

module or ESP module. The engine operating status is made available to

the power steering module as a CAN bus signal

from the PCM.

The power steering module obtains the vehicle

configuration information via the CAN bus from the

GEM. This information is required by the power

steering module in order to define the internal

characteristics of the power steering.

The power steering module obtains information

about the current ignition switch position via the

voltage input (terminal 15) of the ignition switch.

Whilst constantly monitoring the relevant input

signals the power steering module accesses stored

maps. With the aid of this information the pump

speed is matched to the current driving situation.

An electronic diagnosis of the electro-hydraulic

power steering can be performed with the aid of a

diagnostic tester via the DLC of the vehicle. For

additional information please refer to "Diagnosis

and Testing" in this section.

G1001270en2008.50 Kuga8/2011

211-02-

8

Power Steering

211-02- 8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL