remove pcm FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1525 of 2057

Action

Possible Sources

Symptom

• CHECK the engine compon-ents for wear or damage. Make

sure that all components are

within specification. INSTALL

new components as necessary.

Engine - 2.5L Duratec-ST (VI5)

-

REFER to: Specifications (303-

01 Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Specifications).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Engine components

- Pistons.

- Piston rings.

- Connecting rod big end,main bearing or thrust

bearing journals.

- Connecting rods bent or damaged.

• Noisy running or engine noise

Engine - Oil Leaks

NOTE:

Before installing new gaskets or oil seals,

make sure that the fault is clearly established.

If the oil leak cannot be identified clearly by a visual

inspection, carry out an ultraviolet (UV) test:

Ultraviolet (UV) Testing

1. Clean the engine and transmission with a suitable cleaning fluid.

2. Pour the UV-test fluid in accordance with the quantity specified by the manufacturer through

the oil filler neck into the engine and install the

oil filler cap.

WARNING: Vehicles with manual transaxle,

shift the transaxle into Neutral. Failure to

follow this instruction may result in

personal injury.

3. Start the engine and let it run for about five minutes.

4. Switch off the engine.

NOTE: If no leak can be found, road test the

vehicle under various loads and check the engine

for leaks again.

5. Check the engine for oil leaks using a suitable UV lamp.

6. Rectify any leaks found and check the engine for oil leaks.

Measure the compression pressure

NOTE: The powertrain control module (PCM)

receives an error message when the fuel pump

relay is removed or electrical components are disconnected. This error message must be deleted

from the fault memory using the Ford diagnostic

equipment after completing the compression test.

NOTE:

Valve clearance must be set correctly

before performing a compression test. Make sure

the engine is at the normal operating temperature.

NOTE: The varying design of compression

checking devices and fluctuating starter motor

speeds normally only allows for a comparison to

be made of the compression pressures in all

cylinders.

G1055128en2008.50 Kuga8/2011

303-00- 9

Engine System - General Information

303-00- 9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1530 of 2057

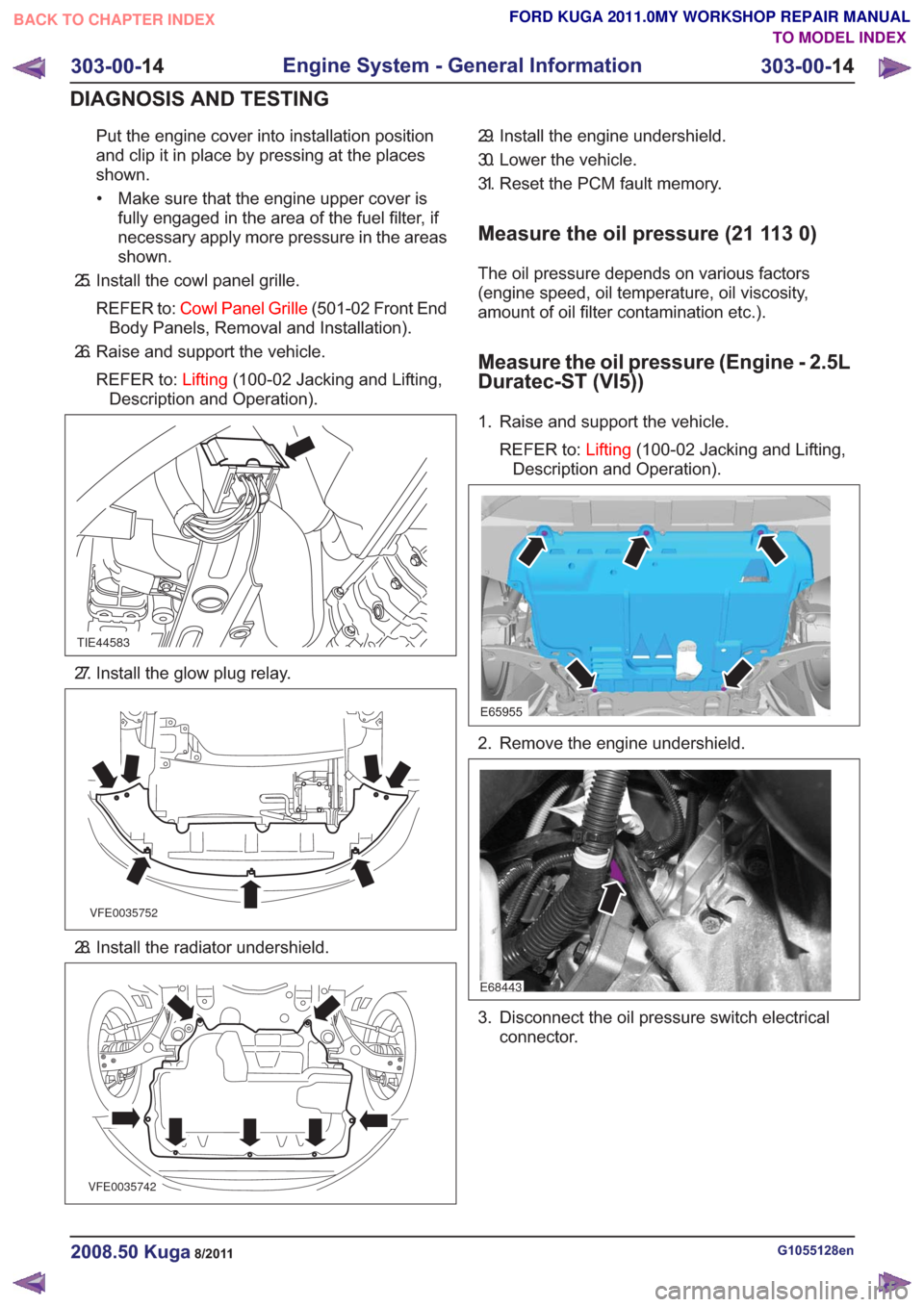

Put the engine cover into installation position

and clip it in place by pressing at the places

shown.• Make sure that the engine upper cover is fully engaged in the area of the fuel filter, if

necessary apply more pressure in the areas

shown.

25. Install the cowl panel grille.

REFER to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

26. Raise and support the vehicle.

REFER to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

TIE44583

27. Install the glow plug relay.

VFE0035752

28. Install the radiator undershield.

VFE0035742

29. Install the engine undershield.

30. Lower the vehicle.

31. Reset the PCM fault memory.

Measure the oil pressure (21 113 0)

The oil pressure depends on various factors

(engine speed, oil temperature, oil viscosity,

amount of oil filter contamination etc.).

Measure the oil pressure (Engine - 2.5L

Duratec-ST (VI5))

1. Raise and support the vehicle.

REFER to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

E65955

2. Remove the engine undershield.

E68443

3. Disconnect the oil pressure switch electrical connector.

G1055128en2008.50 Kuga8/2011

303-00- 14

Engine System - General Information

303-00- 14

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1595 of 2057

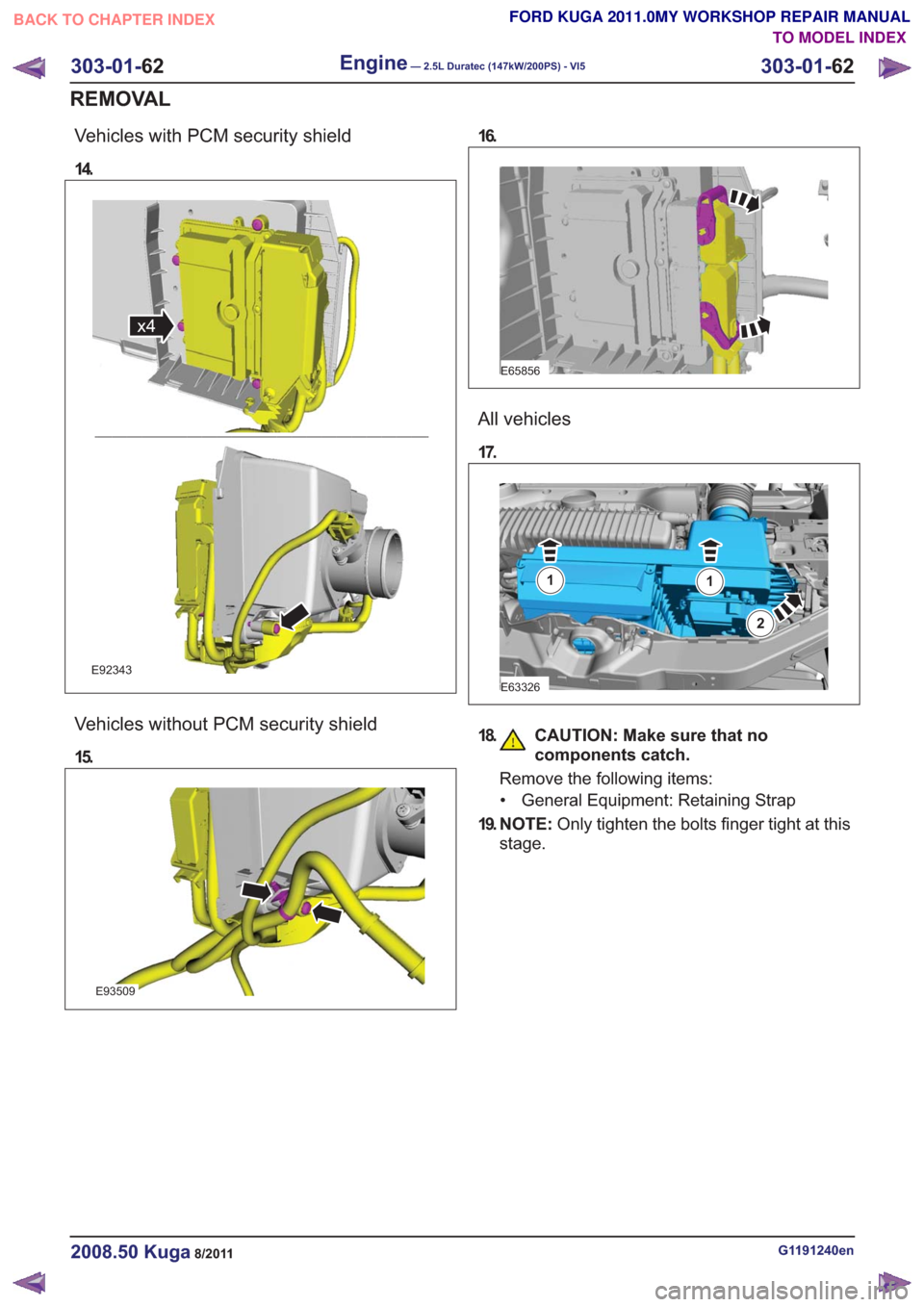

Vehicles with PCM security shield

14.

x4x4

E92343

Vehicles without PCM security shield

15.

E93509

16.

E65856

All vehicles

17.

E63326

11

2

18. CAUTION: Make sure that nocomponents catch.

Remove the following items:

• General Equipment: Retaining Strap

19. N O T E : Only tighten the bolts finger tight at this

stage.

G1191240en2008.50 Kuga8/2011

303-01- 62

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

62

REMOVAL

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1668 of 2057

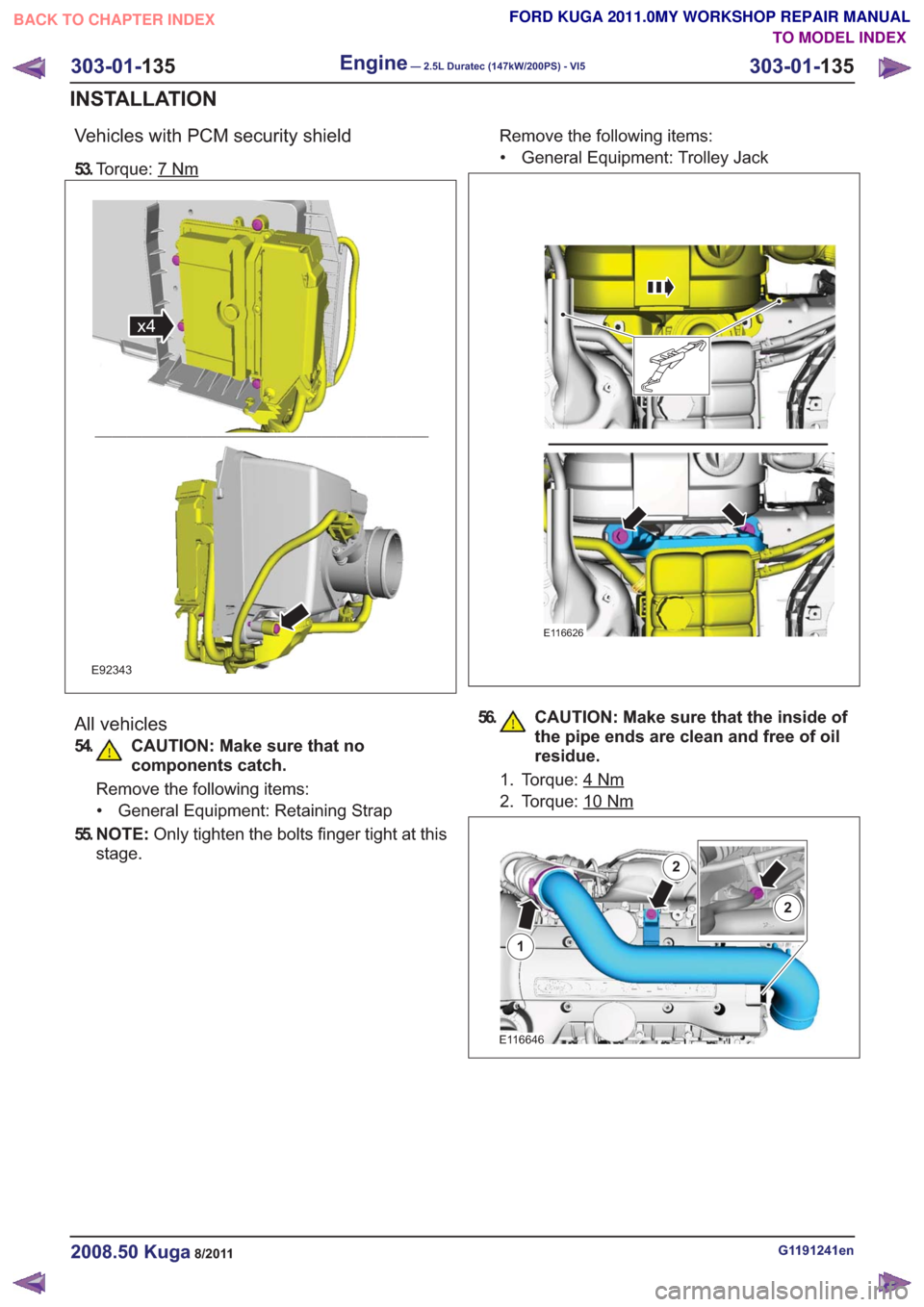

Vehicles with PCM security shield

53.Torque: 7Nm

x4x4

E92343

All vehicles

54. CAUTION: Make sure that no

components catch.

Remove the following items:

• General Equipment: Retaining Strap

55. N O T E : Only tighten the bolts finger tight at this

stage. Remove the following items:

• General Equipment: Trolley Jack

E116626

56. CAUTION: Make sure that the inside of the pipe ends are clean and free of oil

residue.

1. Torque: 4Nm

2. Torque: 10Nm

E116646

1

2

2

G1191241en2008.50 Kuga8/2011

303-01- 135

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

135

INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1698 of 2057

Action

Possible Sources

Symptom

• REMOVE and visuallyINSPECT the catalytic

converter as necessary.

REFER to: Catalytic Converter

(309-00 Exhaust System -

2.5L Duratec (147kW/200PS)

- VI5, Removal and Installa-

tion).

• Catalytic converter blocked.

• TEST the engine cylindercompression.

REFER to: Engine(303-00

Engine System - General

Information, Diagnosis and

Testing).

• Low cylinder compression.

• INSTALL a new air cleanerelement.

• Air cleaner element blocked.

• Engine starts but immediately

stops

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• CKP sensor.

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• CMP sensor.

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

•PCM.

• Check the fuel system pres-sure.

• Low fuel system pressure.

• INSPECT the fuel system.INSTALL new components as

necessary. TEST the system

for normal operation.

• Fuel system restriction.

• INSTALL a new fuel filter.

• Fuel filter blocked.

• INSTALL a new air cleanerelement.

• Air cleaner element blocked.

• Poor idling

G1183441en2008.50 Kuga8/2011

303-04A- 7

Fuel Charging and Controls

— 2.5L Duratec (147kW/200PS) -

VI5

303-04A- 7

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1782 of 2057

Powertrain Control Module (PCM)

E65160

The PCM communicates with all engine sensors

and the other modules. Communication of the PCM

with the other modules and the system diagnostics

takes place via the CAN (controller area network)

data bus.

The following functions are regulated or controlled

by the PCM:

• Fuel supply to the engine including lambdacontrol

• Ignition setting including knock control

• Idle speed control

• Control of optimum valve timing via the camshaft adjustment for intake and exhaust camshafts

• The refrigerant compressor is controlled by the air conditioning clutch relay and the delivery of

the refrigerant compressor is controlled by a

PWM (pulse width modulation) signal.

• Control of EVAP purge valve

• Boost pressure control

• Control of the cooling fan

• Charging system (Smart Charge)

• Starting system (Smart Start)

If the PCM is isolated from the vehicle electrical

system or the battery is disconnected, the throttle

control unit mustbe initialized.

The PCM is fitted in the engine compartment in the

air filter housing. On right hand drive vehicles a

protective metal plate is also installed to prevent

the plug connector from being pulled off, or make

it harder to pull off, in case of theft. The protective

plate is secured with a shear bolt. The shear bolt

needs to be drilled out in order to remove the

protective plate.

Knock Sensor

E96986

Two KSs are fitted. They are on the cylinder block,

one close to the 2nd cylinder and one close to the

4th cylinder.

When fitting, adhere strictly to the specified

tightening torque, otherwise the KS will not work

properly.

If the signal from one or both KS is implausible or

absent, knock control is deactivated. The PCM

switches to an ignition map that is further away

from the knock limit. As a result, engine damage

caused by combustion knock is avoided. If a fault

occurs, a fault code is stored in the error memory

of the PCM.

Camshaft Position (CMP) Sensor

E89993

If one or both CMP sensors fail, a fault is saved in

the error memory of the PCM and the camshaft

adjustment and knock control are deactivated.

G1021907en2008.50 Kuga8/2011

303-14- 8

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1797 of 2057

Calculation of valve timing adjustment

angle

The 2.5L Duratec (VI5) engine has two camshaft

adjustment units which work independently of each

other.

One camshaft adjustment solenoid is installed for

each intake camshaft and exhaust camshaft.

This allows the PCM to continuously adjust the

intake and exhaust-side camshaft adjustments

independently of one another. The timing is

adjusted by the PCM using curves; adjustment is

primarily done as a function of engine load and

engine speed.

In this way the engine performance is increased

and internal exhaust gas recirculation is realized.

The advantages of camshaft adjustment are as

follows:

• Higher torque and improved torquecharacteristics

• Reduced fuel consumption

• Improved emissions performance

The camshaft adjustment solenoids are actuated

by the PWM by means of a PCM signal.

Continuous adjustment of the camshafts by the

PCM is achieved by means of the camshaft

adjustment solenoids, the camshaft adjustment

units and two CMP sensors. A defined quantity of

engine is oil is supplied to or drained from the

adjustment units via the camshaft adjustment

solenoids. The existing EOP (engine oil pressure)

is taken into account in the process. In this way

the valve timings are adjusted according to the

operating condition of the engine. The camshaft

adjusters work according to the vane-cell principle.

On starting the engine, both camshafts are

mechanically locked in their starting positions. The

intake camshaft is in the maximum late position

and the exhaust camshaft in the maximum early

position.

Control is divided into four main areas:

• Low engine speed and low load

• Partial load

• Low engine speed and high load

• High engine speed and high load

At low engine speed and low load, the exhaust

valves open early and the intake valves open late.

The result is reduced fuel consumption and more

uniform idling. In the partial load range, the exhaust valves and

the intake valves open late. The late opening of

the exhaust valves results in a good utilization of

the expanding gases in the cylinder. Closing the

exhaust valves after Top Dead Center allows

internal exhaust gas recirculation through aspiration

of exhaust gases into the combustion chamber.

Moreover, the intake valves close after Bottom

Dead Centre, allowing the fresh air/fuel mixture

and exhaust gases to flow back into the intake

tract. The result is reduced fuel consumption and

low emissions.

At low engine speed and high engine load, the

exhaust valves open late and the intake valves

open early. Due to the resulting valve opening

overlap at Top Dead Centre, the pulsating gas

column within the combustion chamber is utilized

to achieve better charging of the combustion

chamber. The result is increased torque at lower

RPM.

At high engine speeds and high engine load, the

exhaust valves open early and the intake valves

close late. Because a rapid gas exchange must be

achieved at high engine speeds, the early opening

of the exhaust valves achieves better expulsion of

the exhaust gas and the late closing of the intake

valves improves cylinder charge efficiency.

Optimum power output is achieved.

Many other camshaft positions are possible in

addition to these settings.

In order to avoid a malfunction in the camshaft

adjustment units at excessively low ambient or

engine-oil temperatures, they are activated by the

PCM with a time delay via the camshaft adjustment

solenoids. The PCM receives the information

required for this from the ECT sensor and the

outside air temperature sensor.

When idling and during deceleration, the camshaft

adjustment solenoids are activated repeatedly by

the PCM in order to remove any dirt which may be

on the bore holes and ring grooves.

Boost pressure control

Optimum regulation is achieved by means of an

electronically-controlled solenoid valve, the boost

control solenoid valve.

Refer to:

Turbocharger (303-04 Fuel Charging and

Controls - Turbocharger - 2.5L Duratec

(147kW/200PS) - VI5, Description and

Operation).

G1021908en2008.50 Kuga8/2011

303-14- 23

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

23

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2005 of 2057

Speed Control – Overview

Speed Control

The cruise control system keeps the vehicle to a

target speed selected by the driver. The cruise

control system is controlled by the PCM (powertrain

control module)

WARNING: The cruise control system may

not be used in heavy traffic, on winding

roads or on a slippery road surface.

To remove the buttons for the cruise control

system, the airbag must be removed. The buttons

for the two control switch units cannot be replaced

individually.

G1015505en2008.50 Kuga8/2011

310-03- 2

Speed Control

310-03- 2

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2015 of 2057

• The refrigerant line between the fixed orificetube and the evaporator must be cold from the

point where the fixed orifice tube is installed.

Depending on the weather, the refrigerant line

may also have ice on its surface.

• The refrigerant line between the evaporator and the A/C compressor including the dehydrator

must be cold.

Evaporator outlet line temperature test

To test the power of the A/C system, the

temperature at the evaporator outlet line must be

measured. To do this, the following preconditions

must be met:

• Open all windows.

• Set the air distribution to the defrost/dashboardposition and open all the ventilation nozzles.

• DO NOT switch on recirculated air.

• Select lowest blower switch setting.

• Select lowest temperature setting.

NOTE: The temperature measurement cannot be

done with a thermometer which makes no contact.

The surface reflection from the metal line may

cause incorrect readings.

Connect the temperature sensor (Fluke 80 PK-8)

to the outlet line of the evaporator. Locate the

temperature sensor as close as possible to the

evaporator. Connect the temperature sensor to the

multimeter.

Start the engine and allow it to run at idle speed

for several minutes.

Switch on the A/C.

After three minutes, measure the surface

temperature of the evaporator outlet line.

If the temperature measured is 4° C or lower, the

A/C system is OK. If the temperature is higher, the

A/C system may be under-filled. For further

information, refer to

REFER to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging (412-00

Climate Control System - General Information,

General Procedures).

Frequent faults and their causes

If the cooling power of the A/C system is not

adequate, make certain that the temperature

control flap(s) is/are operating correctly. • No or poor cooling performance:

– Blockage or narrowing of a refrigerant line orin the dehydrator. The location of the

blockage or narrowing can easily be located

by temperature comparisons at the

refrigerant lines and the dehydrator. The

blockage or restriction is located at the point

where the temperature difference is

identified. Note: A temperature difference

in the area of the fixed orifice tube is

normal. If the location of the blockage or

narrowing is found, check the corresponding

component and renew as applicable.

• Sudden drop in cooling performance (after the air conditioning has been switched off for

approx. 5 minutes, the cooling performance

returns to normal):

– The cause is an iced-up fixed orifice tubebecause of moisture in the refrigerant circuit.

In order to ensure that moisture is completely

removed from the refrigerant circuit, the

dehydrator should be renewed and the

evacuation time should be extended to 2-3

hours. For further information

REFER to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging

(412-00 Climate Control System - General

Information, General Procedures).

Sequence of A/C Request Signal

NOTE: The electronic automatic temperature

control (EATC) module is integrated into the air

conditioning control assembly.

NOTE: The generic electronic module (GEM) is

an integral part of the central junction box (CJB).

After actuating the A/C ON/OFF switch integrated

into the A/C control assembly, an A/C request

signal is sent from the A/C control assembly

(vehicles with EATC: EATC module) to the GEM.

From there, the signal is sent to the instrument

cluster via the MS-CAN bus. A gateway is installed

in the instrument cluster, which establishes the

connection between the MS-CAN bus and the

HS-CAN bus.

After the signal has been converted in the gateway,

it is relayed to the powertrain control module (PCM)

via the HS-CAN bus. Once all the required

parameters have been met, the PCM switches on

the refrigerant compressor and thus the A/C system

via the A/C clutch relay.

G1055878en2008.50 Kuga8/2011

412-00- 4

Climate Control System - General Information

412-00- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL