sensor FORD MONDEO 1993 Service Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 100 of 279

This Chapter is concerned with those

features of the engine management system

that supply clean fuel and air to the engine,

meter it in the required proportions, and

dispose of the results. Since the emission

control sub-systems modify the functions of

both the fuel and exhaust sub-systems, all of

which are integral parts of the whole engine

management system, there are many cross-

references to Chapters 5 and 6. Information

on the electronic control system, its fault

diagnosis, sensors and actuators, is given in

Chapter 6.

The air intake system consists of several

plastics components designed to eliminate

induction roar as much as possible. The air

intake tube (opening behind the direction

indicator/headlight assembly) is connected,

via small and large resonators located under

the front left-hand wing, to the air cleaner

assembly in the engine compartment. Once it

has passed through the filter element and the

air mass meter, the air enters the plenum

chamber mounted above the throttle housing

and inlet manifold; the resonator mounted in

the engine compartment further reduces noise

levels.

The fuel system consists of a plastic tank

(mounted under the body, beneath the rear

seats), combined metal and plastic fuel hoses,

an electric fuel pump mounted in the fuel tank,

and an electronic fuel injection system.

The exhaust system consists of an exhaust

manifold, the front downpipe and catalytic

converter and, on production-fit systems, a

rear section incorporating two or three

silencers and the tailpipe assembly. The

service replacement exhaust system consists

of three or four sections: the front

downpipe/catalytic converter, the

intermediate pipe and front silencer, and the

tailpipe and rear silencer. On some versions,

the tailpipe is in two pieces, with two rear

silencers. The system is suspended

throughout its entire length by rubber

mountings.

Extreme caution should be exercised when

dealing with either the fuel or exhaust

systems. Fuel is a primary element for

combustion. Be very careful! The exhaust

system is an area for exercising caution, as it

operates at very high temperatures. Serious

burns can result from even momentary

contact with any part of the exhaust system,

and the fire risk is ever-present. The catalytic

converter in particular runs at very high

temperatures - refer to the information in

Chapter 6.

Warning: Many of the procedures

in this Chapter require the

removal of fuel lines and

connections, which may result in

some fuel spillage. Petrol is extremely

flammable, so take extra precautionswhen you work on any part of the fuel

system. Don’t smoke, or allow open flames

or bare light bulbs, near the work area.

Don’t work in a garage where a natural

gas-type appliance (such as a water

heater or clothes dryer) with a pilot light is

present. If you spill any fuel on your skin,

rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a Class B type fire extinguisher

on hand. Before carrying out any operation

on the fuel system, refer also to the

precautions given in “Safety first!” at the

beginning of this manual, and follow them

implicitly. Petrol is a highly-dangerous and

volatile liquid, and the precautions

necessary when handling it cannot be

overstressed.

Warning: The fuel system will

remain pressurised for long

periods of time after the engine is

switched off - this pressure must

be released before any part of the system

is disturbed. Petrol is extremely

flammable, so take extra precautions

when you work on any part of the fuel

system. Don’t smoke, or allow open flames

or bare light bulbs, near the work area.

Don’t work in a garage where a natural

gas-type appliance (such as a water

heater or clothes dryer) with a pilot light is

present. If you spill any fuel on your skin,

rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a Class B type fire extinguisher

on hand.

1The fuel system referred to in this Chapter

is defined as the fuel tank and tank-mounted

fuel pump/fuel gauge sender unit, the fuel

filter, the fuel injectors and the pressure

regulator in the injector rail, and the metal

pipes and flexible hoses of the fuel lines

between these components. All these contain

fuel, which will be under pressure while the

engine is running and/or while the ignition is

switched on.

2The pressure will remain for some time after

the ignition has been switched off, and must

be relieved before any of these components is

disturbed for servicing work.

3The simplest method is simply to

disconnect the fuel pump’s electrical supply

while the engine is running - either by

removing the fuel pump fuse (number 14), or

by lifting the red button on the fuel cut-off

switch (see Section 13) - and to allow the

engine to idle until it dies through lack of fuel

pressure. Turn the engine over once or twice

on the starter to ensure that all pressure is

released, then switch off the ignition; do not

forget to refit the fuse (or depress the redbutton, as appropriate) when work is

complete.

4The Ford method of depressurisation is to

use service tool 29-033 fitted to the fuel rail

pressure test/release fitting - a Schrader-type

valve with a blue plastic cap, located on the

union of the fuel feed line and the fuel rail - to

release the pressure, using a suitable

container and wads of rag to catch the spilt

fuel. Do notsimply depress the valve core to

release fuel pressure - droplets of fuel will

spray out, with a consequent risk of fire, and

of personal injury through fuel getting into

your eyes.

Warning: Either procedure will

merely relieve the increased

pressure necessary for the

engine to run. Remember that

fuel will still be present in the system

components, and take precautions

accordingly before disconnecting any of

them.

5Note that, once the fuel system has been

depressurised and drained (even partially), it

will take significantly longer to restart the

engine - perhaps several seconds of cranking

- before the system is refilled and pressure

restored.

Warning: The fuel system

pressure must be released before

any part of the system is

disturbed - see Section 2. Petrol

is extremely flammable, so take extra

precautions when you work on any part of

the fuel system. Don’t smoke, or allow

open flames or bare light bulbs, near the

work area. Don’t work in a garage where a

natural gas-type appliance (such as a

water heater or clothes dryer) with a pilot

light is present. If you spill any fuel on your

skin, rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a Class B type fire extinguisher

on hand.

Disconnecting and connecting

quick-release couplings

1Quick-release couplings are employed at all

unions in the fuel feed and return lines.

2Before disconnecting any fuel system

component, relieve the residual pressure in

the system (see Section 2), and equalise tank

pressure by removing the fuel filler cap.

Warning: This procedure will

merely relieve the increased

pressure necessary for the

engine to run - remember that

fuel will still be present in the system

components, and take precautions

accordingly before disconnecting any of

them.

3 Fuel lines and fittings-

general information

2 Fuel system - depressurisation

1 General information and

precautions

4•2 Fuel and exhaust systems

procarmanuals.com

Page 101 of 279

3Release the protruding locking lugs on each

union, by squeezing them together and

carefully pulling the coupling apart. Use rag to

soak up any spilt fuel. Where the unions are

colour-coded, the pipes cannot be confused.

Where both unions are the same colour, note

carefully which pipe is connected to which,

and ensure that they are correctly

reconnected on refitting (see illustration).

4To reconnect one of these couplings, press

them together until the locking lugs snap into

their groove. Switch the ignition on and off

five times to pressurise the system, and check

for any sign of fuel leakage around the

disturbed coupling before attempting to start

the engine.

Checking

5Checking procedures for the fuel lines are

included in Chapter 1.

Component renewal

6If you must renew any damaged sections,

use original-equipment replacement hoses or

pipes, constructed from exactly the same

material as the section you are replacing. Do

not install substitutes constructed from

inferior or inappropriate material, or you could

cause a fuel leak or a fire.

7Before detaching or disconnecting any part

of the fuel system, note the routing of all

hoses and pipes, and the orientation of all

clamps and clips. Replacement sections must

be installed in exactly the same manner.8Before disconnecting any part of the fuel

system, be sure to relieve the fuel system

pressure (see Section 2), and equalise tank

pressure by removing the fuel filler cap. Also

disconnect the battery negative (earth) lead -

see Chapter 5, Section 1. Cover the fitting

being disconnected with a rag, to absorb any

fuel that may spray out.

Air cleaner assembly

1Disconnect the battery negative (earth) lead

- see Chapter 5, Section 1.

2Unclip the air mass meter from the air

cleaner cover (see Chapter 6).

3Disconnect the crankcase breather hose,

either from the air cleaner housing or from the

cylinder head cover union (see illustration).

4Remove the rubber retaining band (see

illustration). Withdraw the air cleaner

assembly, lifting it upwards out of its

grommets, and releasing it from the rubber

connector sleeve in the inner wing panel.

5Refitting is the reverse of the removal

procedure. Ensure that the housing pegs seat

correctly in their grommets, and that the

intake mouth is fully engaged inside the

connector sleeve (see illustration).

Air intake components

Note:Depending on the reason for removal,

these components can be removed either

individually, or as one assembly. For example,

unplugging the two electrical connectors and

disconnecting the vacuum hose (where fitted),

will allow the air cleaner assembly cover to be

removed with the air mass meter, the

resonator and the plenum chamber.

Air mass meter

6Refer to Section 4 of Chapter 6.

Resonator (engine compartment)

7Unbolt the resonator support bracket from

the engine compartment front crossmember.

Slacken the two clamp screws securing the

resonator to the air mass meter and plenum

chamber hoses. Swing the resonator clear of

the thermostat housing, and unplug the intake

air temperature sensor’s electrical connector

(see illustration). Withdraw the resonator.

8Refitting is the reverse of the removal

procedure.

Plenum chamber

9Prising out the rubber plugs covering them,

undo the chamber’s fasteners (see

illustration). Slacken the clamp screw

securing the chamber to the resonator hose.

10Lift the chamber and (where fitted)

disconnect the vacuum hose from its

underside. Withdraw the chamber - note the

two rubber spacers (one on each throttle

4 Air cleaner assembly and air

intake components -

removal and refitting

Fuel and exhaust systems 4•3

4

4.5 Ensure air filter housing intake mouth

is fully engaged inside connector sleeve4.7 Unplugging intake air temperature

sensor’s electrical connector4.9 Plenum chamber fasteners (arrowed) -

four shown here, some vehicles may only

have three

3.3 Disconnect fuel line quick-release

couplings by squeezing together protruding

locking lugs and pulling coupling apart4.3 Disconnecting the crankcase breather

hose from the cylinder head union4.4 Remove rubber retaining band to

withdraw air cleaner assembly

procarmanuals.com

Page 107 of 279

into the inlet ports, just above the inlet valves,

by four fuel injectors. The system also

includes features such as the flushing of fresh

(ie, cold) fuel around each injector on start-up,

thus improving hot starts.

The amount of fuel supplied by the injectors

is precisely controlled by an Electronic

Control Unit (ECU). The ECU uses the signals

derived from the engine speed/crankshaft

position sensor and the camshaft position

sensor, to trigger each injector separately in

cylinder firing order (sequential injection), with

benefits in terms of better fuel economy and

lower exhaust emissions.

Air induction system

The air system consists of an air filter

housing, an air mass meter, an intake

resonator and plenum chamber, and a throttle

housing. The air mass meter is an information-

gathering device for the ECU; it uses a “hot-

wire” system to send the ECU a constantly-

varying (analogue) voltage signal

corresponding to the volume of air passing

into the engine. Another sensor in the air mass

meter measures intake air temperature. The

ECU uses these signals to calculate the mass

of air entering the engine.

The throttle valve inside the throttle housing

is controlled by the driver, through the

accelerator pedal. As the valve opens, the

amount of air that can pass through the

system increases. The throttle potentiometer

opens further, the air mass meter’s signal

alters, and the ECU opens each injector for a

longer duration, to increase the amount of fuel

delivered to the inlet ports.

Electronic control system

The ECU controls the fuel injection system,

as well as the other sub-systems which make

up the entire engine management system. It

receives signals from a number of information

sensors, which monitor such variables as

intake air mass and temperature, coolant

temperature, engine speed and position,

acceleration/deceleration, and exhaust gas

oxygen content. These signals help the ECU

determine the injection duration necessary for

the optimum air/fuel ratio. These sensors and

associated ECU-controlled relays are located

throughout the engine compartment. For

further information regarding the ECU and its

control of the engine management system,

see Chapter 6.

Idle speed and mixture

adjustment - general

Both the idle speed and mixture are under

the control of the ECU, and cannot be

adjusted. Not only can they not be adjusted,

they cannot even be checked, except with the

use of special diagnostic equipment (see

Chapter 6) - this makes it a task for a Ford

dealer service department. Do notattempt to

“adjust” these settings in any way without

such equipment.

If the idle speed and mixture are thought tobe incorrect, take the vehicle to a Ford dealer

for the complete system to be tested.

On models equipped with a heated

windscreen, an idle-increase solenoid valve is

fitted, which raises the idle speed to

compensate for the increased load on the

engine when the heated windscreen is

switched on. When the valve is open, air from

the plenum chamber bypasses the throttle

housing and idle speed control valve, passing

directly into the inlet manifold through the

union on its left-hand end. The system is

active only for the four minutes that the

heated windscreen circuit is live, and is

supplementary to the main (ECU-controlled)

idle speed regulation.

Warning: Petrol is extremely

flammable, so extra precautions

must be taken when working on

any part of the fuel system. Do

not smoke, or allow open flames or bare

light bulbs, near the work area. Don’t work

in a garage if a natural gas-type appliance

with a pilot light is present. While

performing any work on the fuel system,

wear safety glasses, and have a dry

chemical (Class B) fire extinguisher on

hand. If you spill any fuel on your skin,

rinse it off immediately with soap and

water.

Note: This is an initial check of the fuel delivery

and air induction sub-systems of the engine

management system, to be carried out in

conjunction with the operational check of the

fuel pump (see Section 8), and as part of the

preliminary checks of the complete engine

management system (see Section 3 of

Chapter 6).

1Check the earth wire connections for

tightness. Check all wiring and electrical

connectors that are related to the system.

Loose electrical connectors and poor earths

can cause many problems that resemble

more serious malfunctions.

2Check to see that the battery is fully-

charged. The ECU and sensors depend on an

accurate supply voltage to properly meter the

fuel.

3Check the air filter element - a dirty or

partially-blocked filter will severely impede

performance and economy (see Chapter 1).

4If a blown fuse is found, renew it and see if

it blows again. If it does, search for a short-

circuited wire in the harness related to the

system (see Chapter 6).

5Check the air intake duct from the intake to

the inlet manifold for leaks, which will result in

an excessively-lean mixture. Also check the

condition of the vacuum hoses connected to

the inlet manifold.

6Remove the plenum chamber from the

throttle housing. Check the throttle valve for

dirt, carbon or other residue build-up. If it’sdirty, seek the advice of a Ford dealer - since

the electronic control system is designed to

compensate for factors such as the build-up

of dirt in the throttle housing, it may well be

best to leave it dirty, unless the deposits are

extensive. Note: A warning label on the

housing states specifically that the housing

bore and the throttle valve have a special

coating, and must not be cleaned using

carburettor cleaner, as this may damage it.

7With the engine running, place a

screwdriver or a stethoscope against each

injector, one at a time. Listen through the

screwdriver handle or stethoscope for a

clicking sound, indicating operation.

8If an injector isn’t operating (or sounds

different from the others), turn off the engine,

and unplug the electrical connector from the

injector. Check the resistance across the

terminals of the injector, and compare your

reading with the resistance value listed in this

Chapter’s Specifications. If the resistance

isn’t as specified, renew the injector.

9A rough idle, diminished performance

and/or increased fuel consumption could also

be caused by clogged or fouled fuel injectors.

Fuel additives that can sometimes clean

fouled injectors are available at car accessory

shops.

10The remainder of the system checks

should be left to a dealer service department

or other qualified repair specialist, as there is

a chance that the ECU may be damaged if

tests are not performed properly.

Warning: The fuel system

pressure must be released before

any part of the system is

disturbed - see Section 2. Petrol

is extremely flammable, so take extra

precautions when you work on any part of

the fuel system. Don’t smoke, or allow

open flames or bare light bulbs, near the

work area. Don’t work in a garage where a

natural gas-type appliance (such as a

water heater or clothes dryer) with a pilot

light is present. If you spill any fuel on your

skin, rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a Class B type fire extinguisher

on hand.

Throttle housing

Check

1Remove the plenum chamber (see Sec-

tion 4), and verify that the throttle linkage

operates smoothly.

2If the housing bore and valve are dirty

enough for you to think that this might be the

cause of a fault, seek the advice of a Ford

dealer. Do notclean the housing (see the

notes in the checking procedure given in

Section 15).

16 Fuel system components-

check and renewal

15 Fuel injection system/engine

management system - check

Fuel and exhaust systems 4•9

4

procarmanuals.com

Page 111 of 279

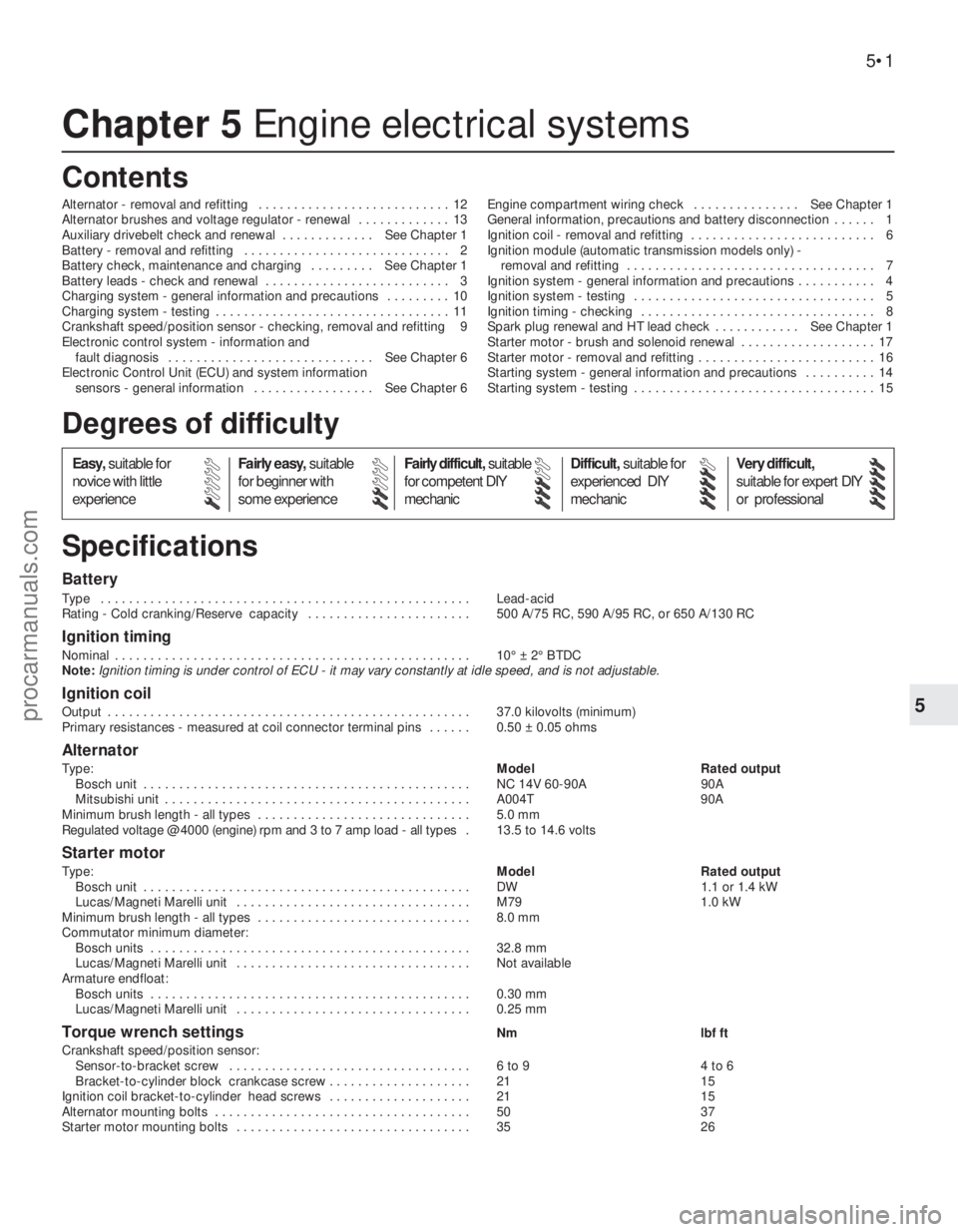

Chapter 5 Engine electrical systems

Alternator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Alternator brushes and voltage regulator - renewal . . . . . . . . . . . . . 13

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . See Chapter 1

Battery - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Battery check, maintenance and charging . . . . . . . . . See Chapter 1

Battery leads - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Charging system - general information and precautions . . . . . . . . . 10

Charging system - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Crankshaft speed/position sensor - checking, removal and refitting 9

Electronic control system - information and

fault diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 6

Electronic Control Unit (ECU) and system information

sensors - general information . . . . . . . . . . . . . . . . . See Chapter 6Engine compartment wiring check . . . . . . . . . . . . . . . See Chapter 1

General information, precautions and battery disconnection . . . . . . 1

Ignition coil - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ignition module (automatic transmission models only) -

removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ignition system - general information and precautions . . . . . . . . . . . 4

Ignition system - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ignition timing - checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Spark plug renewal and HT lead check . . . . . . . . . . . . See Chapter 1

Starter motor - brush and solenoid renewal . . . . . . . . . . . . . . . . . . . 17

Starter motor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 16

Starting system - general information and precautions . . . . . . . . . . 14

Starting system - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Battery

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Lead-acid

Rating - Cold cranking/Reserve capacity . . . . . . . . . . . . . . . . . . . . . . . 500 A/75 RC, 590 A/95 RC, or 650 A/130 RC

Ignition timing

Nominal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10° ± 2° BTDC

Note:Ignition timing is under control of ECU - it may vary constantly at idle speed, and is not adjustable.

Ignition coil

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37.0 kilovolts (minimum)

Primary resistances - measured at coil connector terminal pins . . . . . . 0.50 ± 0.05 ohms

Alternator

Type:Model Rated output

Bosch unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NC 14V 60-90A 90A

Mitsubishi unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A004T 90A

Minimum brush length - all types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.0 mm

Regulated voltage @ 4000 (engine) rpm and 3 to 7 amp load - all types .13.5 to 14.6 volts

Starter motor

Type:Model Rated output

Bosch unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DW 1.1 or 1.4 kW

Lucas/Magneti Marelli unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M79 1.0 kW

Minimum brush length - all types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.0 mm

Commutator minimum diameter:

Bosch units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.8 mm

Lucas/Magneti Marelli unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Not available

Armature endfloat:

Bosch units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30 mm

Lucas/Magneti Marelli unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 mm

Torque wrench settingsNm lbf ft

Crankshaft speed/position sensor:

Sensor-to-bracket screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 to 9 4 to 6

Bracket-to-cylinder block crankcase screw . . . . . . . . . . . . . . . . . . . . 21 15

Ignition coil bracket-to-cylinder head screws . . . . . . . . . . . . . . . . . . . . 21 15

Alternator mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 37

Starter motor mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 26

5•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,suitable

for competent DIY

mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Specifications Contents

5

procarmanuals.com

Page 113 of 279

5If you are renewing the battery, make sure

that you get one that’s identical, with the

same dimensions, amperage rating, cold

cranking rating, etc. Dispose of the old battery

in a responsible fashion. Most local authorities

have facilities for the collection and disposal

of such items - batteries contain sulphuric

acid and lead, and should not be simply

thrown out with the household rubbish!

6Refitting is the reverse of the removal

procedure.

Note:See also the relevant Sections of

Chapter 1.

1Periodically inspect the entire length of

each battery lead for damage, cracked or

burned insulation, and corrosion. Poor battery

lead connections can cause starting problems

and decreased engine performance.

2Check the lead-to-terminal connections at

the ends of the leads for cracks, loose wire

strands and corrosion. The presence of white,

fluffy deposits under the insulation at the lead

terminal connection is a sign that the lead is

corroded and should be renewed. Check the

terminals for distortion, missing clamp bolts,

and corrosion.

3When removing the leads, always

disconnect the negative lead first, and

reconnect it last (see Section 1). Even if only

the positive lead is being renewed, be sure to

disconnect the negative lead from the battery

first (see Chapter 1 for further information

regarding battery lead removal).

4Disconnect the old leads from the battery,

then trace each of them to their opposite

ends, and detach them from the starter

solenoid and earth terminals. Note the routing

of each lead, to ensure correct installation.

5If you are renewing either or both of the old

leads, take them with you when buying new

leads. It is vitally important that you replace

the leads with identical parts. Leads have

characteristics that make them easy to

identify: positive leads are usually red, larger

in cross-section, and have a larger-diameter

battery post clamp; earth leads are usually

black, smaller in cross-section and have a

slightly smaller-diameter clamp for the

negative post.

6Clean the threads of the solenoid or earth

connection with a wire brush to remove rust

and corrosion.

7Attach the lead to the solenoid or earth

connection, and tighten the mounting nut/bolt

securely.

8Before connecting a new lead to thebattery, make sure that it reaches the battery

post without having to be stretched.

9Connect the positive lead first, followed by

the negative lead.

General

The ignition system includes the ignition

switch, the battery, the crankshaft speed/

position sensor, the coil, the primary (low

tension/LT) and secondary (high tension/HT)

wiring circuits, and the spark plugs. On models

with automatic transmission, a separate

ignition module is also fitted, its functions

being incorporated in the ECU on models with

manual transmission. The ignition system is

controlled by the engine management

system’s Electronic Control Unit (ECU). Using

data provided by information sensors which

monitor various engine functions (such as

engine speed and piston position, intake air

mass and temperature, engine coolant

temperature, etc.), the ECU ensures a

perfectly-timed spark under all conditions (see

Chapter 6). Note:The ignition timing is under

the full control of the ECU, and cannot be

adjusted - see Section 8 for further details.

Precautions

When working on the ignition system, take

the following precautions:

(a) Do not keep the ignition switch on for more

than 10 seconds if the engine will not start.

(b) If a separate tachometer is ever required

for servicing work, consult a dealer

service department before buying a

tachometer for use with this vehicle -

some tachometers may be incompatible

with this ignition system - and always

connect it in accordance with the

equipment manufacturer’s instructions.

(c) Never connect the ignition coil terminals

to earth. This could result in damage to

the coil and/or the ECU or ignition module

(whichever is fitted).

(d) Do not disconnect the battery when the

engine is running.

(e) Make sure that the ignition module (where

fitted) is properly earthed.

(f) Refer to the warning at the beginning of

the next Section concerning HT voltage.

Warning: Because of the high

voltage generated by the ignition

system, extreme care should be

taken whenever an operation is performed

involving ignition components. This not

only includes the ignition module/ECU, coil

and spark plug (HT) leads, but related

components such as electrical connectors,

tachometer and other test equipment also.Note: This is an initial check of the “ignition

part” of the main engine management system,

to be carried out as part of the preliminary

checks of the complete engine management

system (see Chapter 6).

1If the engine turns over but won’t start,

disconnect the (HT) lead from any spark plug,

and attach it to a calibrated tester (available at

most automotive accessory shops). Connect

the clip on the tester to a good earth - a bolt

or metal bracket on the engine. If you’re

unable to obtain a calibrated ignition tester,

have the check carried out by a Ford dealer

service department or similar. Any other form

of testing (such as jumping a spark from the

end of an HT lead to earth) is not

recommended, because of the risk of

personal injury, or of damage to the

ECU/ignition module (see notes above and in

Section 4).

2Crank the engine and watch the end of the

tester to see if bright blue, well-defined sparks

occur.

3If sparks occur, sufficient voltage is

reaching the plug to fire it. Repeat the check

at the remaining plugs, to ensure that all leads

are sound and that the coil is serviceable.

However, the plugs themselves may be fouled

or faulty, so remove and check them as

described in Chapter 1.

4If no sparks or intermittent sparks occur,

the spark plug lead(s) may be defective -

check them as described in Chapter 1.

5If there’s still no spark, check the coil’s

electrical connector, to make sure it’s clean

and tight. Check for full battery voltage to the

coil at the connector’s centre terminal. The

coil is earthed through the ECU - do not

attempt to check this. Check the coil itself

(see Section 6). Make any necessary repairs,

then repeat the check again.

6The remainder of the system checks should

be left to a dealer service department or other

qualified repair facility, as there is a chance

that the ECU may be damaged if tests are not

performed properly.

Warning: Because of the high

voltage generated by the ignition

system, extreme care should be

taken whenever an operation is performed

involving ignition components. This not

only includes the ignition module/ECU, coil

and spark plug (HT) leads, but related

components such as electrical connectors,

tachometer and other test equipment also.

Check

1Having checked that full battery voltage is

available at the centre terminal of the coil’s

electrical connector (see Section 5),

disconnect the battery negative (earth) lead -

see Section 1.

2Unplug the coil’s electrical connector, if not

already disconnected.

6 Ignition coil -

removal and refitting

5 Ignition system - testing

4 Ignition system - general

information and precautions

3 Battery leads -

check and renewal

Engine electrical systems 5•3

5

Apply a light coat of battery

terminal corrosion inhibitor,

or petroleum jelly, to the

threads, to prevent future

corrosion.

procarmanuals.com

Page 114 of 279

3Using an ohmmeter, measure the

resistance of the coil’s primary windings,

connecting the meter between the coil’s

terminal pins as follows. Measure first from

one outer pin to the centre pin, then from the

other outer pin to the centre. Compare your

readings with the coil primary resistance listed

in the Specifications Section at the beginning

of this Chapter.

4Disconnect the spark plug (HT) leads - note

their connections or label them carefully, as

described in Chapter 1. Use the meter to

check that there is continuity (ie, a resistance

corresponding to that of the coil secondary

winding) between each pair of (HT) lead

terminals; Nos 1 and 4 terminals are

connected by their secondary winding, as are

Nos 2 and 3. Now switch to the highest

resistance scale, and check that there is no

continuity between either pair of terminals and

the other - ie, there should be infinite

resistance between terminals 1 and 2, or 4

and 3 - and between any terminal and earth.

5If either of the above tests yield resistance

values outside the specified amount, or

results other than those described, renew the

coil. Any further testing should be left to a

dealer service department or other qualified

repair facility.

Removal and refitting

6Disconnect the battery negative (earth) lead

- see Section 1.

7Remove the air mass meter and resonator -

refer to Chapter 4.

8Unplug the electrical connector from each

side of the coil, then disconnect the spark

plug (HT) leads - note their connections or

label them carefully, as described in Chapter

1.

9Undo the two screws securing the EGR

pipe to the coil bracket, then remove the coil

mounting (Torx-type) screws. Withdraw the

coil assembly from the cylinder head (see

illustration).

10The suppressor can be unbolted from the

mounting bracket, if required; note that the

coil and bracket are only available as a single

unit.

11Refitting is the reverse of the removalprocedure. Ensure that the spark plug (HT)

leads are correctly reconnected, and tighten

the coil screws securely.

Note:See Chapter 6 for component location

illustrations.

1Disconnect the battery negative (earth) lead

- see Section 1.

2If better access is required, remove the

resonator (see Chapter 4).

3Unplug the electrical connector from the

module (see illustration).

4Remove the retaining screws, and detach

the module from the bulkhead mounting

bracket.

5Refitting is the reverse of the removal

procedure.

As noted in Section 4, the ignition timing is

controlled entirely by the ECU (acting with the

ignition module, on models with automatic

transmission), and cannot be adjusted. The

value quoted in the Specifications Section of

this Chapter is for reference only, and mayvary significantly if “checked” by simply

connecting a timing light to the system and

running the engine at idle speed.

Not only can the ignition timing not be

adjusted, it cannot be checked either, except

with the use of special diagnostic equipment

(see Chapter 6) - this makes it a task for a

Ford dealer service department.

Owners who are taking their vehicles

abroad should note that the ignition system is

set for the engine to use petrol of 95 RON

octane rating by fitting a “plug-in bridge” to

the service connector on the engine

compartment bulkhead (see illustration).

Removing the “plug-in bridge” retards the

ignition timing - by an unspecified value - to

allow the engine to run on 91 RON fuel. This

grade of fuel is the “Regular” or “Normal”

widely used abroad, but not at present

available in the UK. If you are taking the

vehicle abroad, seek the advice of a Ford

dealer (or of one of the motoring

organisations). This will ensure that you are

familiar with the grades of fuel you are likely to

find (and the sometimes confusing names for

those grades), and that the vehicle is set

correctly at all times for the fuel used. Note:

The octane ratings mentioned above are both,

of course, for unleadedpetrol. Do not use

leaded petrol at any time in a vehicle equipped

with a catalytic converter.

Checking

1See Section 4 of Chapter 6.

Removal and refitting

2Disconnect the battery negative (earth) lead

- see Section 1.

3Raise the front of the vehicle, and support it

securely on axle stands.

Warning: Do not place any part of

your body under a vehicle when

it’s supported only by a jack!

4Unplug the sensor’s electrical connector

(see illustration).

9 Crankshaft speed/position

sensor-

checking, removal and refitting

8 Ignition timing - checking

7 Ignition module (automatic

transmission models only) -

removal and refitting

5•4 Engine electrical systems

6.9 Unplug coil electrical connector (A),

suppressor connector (B), and spark

plug/HT leads (C), remove screws (D), then

undo Torx-type screws (E) to release

ignition coil assembly7.3 Separate ignition module is fitted to

automatic transmission models only - note

electrical connector (A) and retaining

screws (B)

8.3 Service connector (A) mounted on

engine compartment bulkhead is fitted with

“plug-in bridge” (B) to set engine to use

(unleaded) petrol of 95 RON octane rating9.4 Location of crankshaft speed/position

sensor - connector arrowed - in front of

cylinder block/crankcase

procarmanuals.com

Page 115 of 279

5Undo the sensor’s retaining screw and

withdraw the sensor. The sensor’s bracket

cannot be unbolted from the cylinder

block/crankcase unless the transmission and

flywheel/driveplate have been removed (see

Chapter 2).

6Refitting is the reverse of the removal

procedure.

General information

The charging system includes the

alternator, an internal voltage regulator, a no-

charge (or “ignition”) warning light, the

battery, and the wiring between all the

components. The charging system supplies

electrical power for the ignition system, the

lights, the radio, etc. The alternator is driven

by the auxiliary drivebelt at the front (right-

hand end) of the engine.

The purpose of the voltage regulator is to

limit the alternator’s voltage to a preset value.

This prevents power surges, circuit overloads,

etc., during peak voltage output.

The charging system doesn’t ordinarily

require periodic maintenance. However, the

drivebelt, battery and wires and connections

should be inspected at the intervals outlined

in Chapter 1.

The dashboard warning light should come

on when the ignition key is turned to positions

“II” or “III”, then should go off immediately the

engine starts. If it remains on, or if it comes on

while the engine is running, there is a

malfunction in the charging system (see

Section 11). If the light does not come on

when the ignition key is turned, and the bulb is

sound (see Chapter 12), there is a fault in the

alternator.

Precautions

Be very careful when making electrical

circuit connections to a vehicle equipped with

an alternator, and note the following:

(a) When reconnecting wires to the alternator

from the battery, be sure to note the

polarity.

(b) Before using arc-welding equipment to

repair any part of the vehicle, disconnect

the wires from the alternator and the

battery terminals.

(c) Never start the engine with a battery

charger connected.

(d) Always disconnect both battery leads

before using a battery charger.

(e) The alternator is driven by an engine

drivebelt which could cause serious injury

if your hand, hair or clothes become

entangled in it with the engine running.

(f) Because the alternator is connected

directly to the battery, it could arc or

cause a fire if overloaded or shorted-out.

(g) Wrap a plastic bag over the alternator,

and secure it with rubber bands, beforesteam-cleaning or pressure-washing the

engine.

(h) Never disconnect the alternator terminals

while the engine is running.

1If a malfunction occurs in the charging

circuit, don’t automatically assume that the

alternator is causing the problem. First check

the following items:

(a) Check the tension and condition of the

auxiliary drivebelt - renew it if it is worn or

deteriorated (see Chapter 1).

(b) Ensure the alternator mounting bolts and

nuts are tight.

(c) Inspect the alternator wiring harness and

the electrical connections at the

alternator; they must be in good

condition, and tight.

(d) Check the large main fuses in the engine

compartment (see Chapter 12). If any is

blown, determine the cause, repair the

circuit and renew the fuse (the vehicle

won’t start and/or the accessories won’t

work if the fuse is blown).

(e) Start the engine and check the alternator

for abnormal noises - for example, a

shrieking or squealing sound may indicate

a badly-worn bearing or brush.

(f) Make sure that the battery is fully-charged

- one bad cell in a battery can cause

overcharging by the alternator.

(g) Disconnect the battery leads (negative

first, then positive). Inspect the battery

posts and the lead clamps for corrosion.

Clean them thoroughly if necessary (see

Section 3 and Chapter 1). Reconnect the

lead to the negative terminal.

(h) With the ignition and all accessories

switched off, insert a test light between

the battery negative post and the

disconnected negative lead clamp:

(1) If the test light does not come on, re-

attach the clamp and proceed to the next

step.

(2) If the test light comes on, there is a short

in the electrical system of the vehicle. The

short must be repaired before the

charging system can be checked.

(3) To find the short, disconnect the

alternator wiring harness:

(a) If the light goes out, the alternator is

at fault.

(b) If the light stays on, remove each fuse

until it goes out - this will tell you

which component is short-circuited.

2Using a voltmeter, check the battery

voltage with the engine off. It should be

approximately 12 volts.

3Start the engine and check the battery

voltage again. Increase engine speed until the

voltmeter reading remains steady; it should

now be approximately 13.5 to 14.6 volts.

4Switch on as many electrical accessories

(eg the headlights, heated rear window andheater blower) as possible, and check that the

alternator maintains the regulated voltage at

around 13 to 14 volts. The voltage may drop

and then come back up; it may also be

necessary to increase engine speed slightly,

even if the charging system is working

properly.

5If the voltage reading is greater than the

specified charging voltage, renew the voltage

regulator (see Section 13).

6If the voltmeter reading is less than that

specified, the fault may be due to worn

brushes, weak brush springs, a faulty voltage

regulator, a faulty diode, a severed phase

winding, or worn or damaged slip rings. The

brushes and slip rings may be checked (see

Section 13), but if the fault persists, the

alternator should be renewed or taken to an

auto-electrician for testing and repair.

1Disconnect the battery negative (earth) lead

- see Section 1.

2Remove the plenum chamber (see Chap-

ter 4).

3Unscrew the nuts to disconnect the wiring

from the alternator (see illustration). If

additional working clearance is required, undo

the right-hand of the three screws securing

the wiring “rail” to the rear of the inlet

manifold.

4Jack up and support the front right-hand

corner of the vehicle. Remove the auxiliary

drivebelt and the engine oil filter - place a wad

of rag to soak up the spilled oil (see Chap-

ter 1). Rather than refit a used filter, you are

advised to drain the engine oil, and then to fit

a new filter and refill the engine with clean oil

on reassembly. Where an engine oil cooler is

fitted, it may prove necessary to remove this

as well, to provide the clearance necessary to

remove the alternator (see Chapter 2, Part A).

5Unscrew the two bolts securing the power

steering system pipes to the right-hand side

of the front suspension subframe. With the

front wheels in the straight-ahead position,

disconnect the right-hand track rod end from

the steering knuckle (see Chapter 10).

6Remove the mounting bolts and nuts (one

12 Alternator-

removal and refitting

11 Charging system- testing

10 Charging system - general

information and precautions

Engine electrical systems 5•5

5

12.3 Disconnecting alternator wiring

procarmanuals.com

Page 117 of 279

starter motor must be overhauled or renewed.

(Other possibilities are that the starter motor

mounting bolts are very loose, or that teeth

are missing from the flywheel/driveplate ring

gear.)

4If, when the switch is actuated, the starter

motor does not operate at all but the solenoid

clicks, then the problem lies with either the

battery, the main solenoid contacts, or the

starter motor itself (or the engine is seized).

5If the solenoid plunger cannot be heard to

click when the switch is actuated, the battery

is faulty, there is a fault in the circuit, or the

solenoid itself is defective.

6To check the solenoid, connect a fused

jumper lead between the battery (+) and the

ignition switch terminal (the small terminal) on

the solenoid. If the starter motor now

operates, the solenoid is OK, and the problem

is in the ignition switch, selector lever position

sensor (automatic transmission) or in the

wiring.

7If the starter motor still does not operate,

remove it (see Section 16). The brushes and

commutator may be checked (see Sec-

tion 17), but if the fault persists, the motor

should be renewed, or taken to an auto-

electrician for testing and repair.

8If the starter motor cranks the engine at anabnormally-slow speed, first make sure that

the battery is charged, and that all terminal

connections are tight. If the engine is partially

seized, or has the wrong viscosity oil in it, it

will crank slowly.

9Run the engine until normal operating

temperature is reached, then switch off and

disable the ignition system by unplugging the

ignition coil’s electrical connector; remove

fuse 14 to disconnect the fuel pump.

10Connect a voltmeter positive lead to the

battery positive terminal, and connect the

negative lead to the negative terminal.

11Crank the engine, and take the voltmeter

readings as soon as a steady figure is

indicated. Do not allow the starter motor to

turn for more than 15 seconds at a time. A

reading of 10.5 volts or more, with the starter

motor turning at normal cranking speed, is

normal. If the reading is 10.5 volts or more but

the cranking speed is slow, the solenoid

contacts are burned, the motor is faulty, or

there is a bad connection. If the reading is less

than 10.5 volts and the cranking speed is

slow, the starter motor is faulty or there is a

problem with the battery.1Disconnect the battery negative (earth) lead

- see Section 1.

2Remove the air mass meter and resonator -

refer to Chapter 4.

3Unscrew the upper two starter motor

mounting bolts, noting that one also secures

an engine/transmission earth lead (see

illustration).

4Raise the front of the vehicle, and support it

securely on axle stands.

Warning: Do not place any part of

your body under a vehicle when

it’s supported only by a jack!

5Unscrew the nuts to disconnect the wiring

from the starter/solenoid terminals.

6Remove the remaining starter motor

mounting bolt (see illustration). Remove the

starter.

7Refitting is the reverse of the removal

procedure. Tighten the bolts to the specified

torque wrench settings.

Note:This procedure assumes that

replacement brushes of the correct type have

been obtained - at the time of writing, no

individual starter motor components were

available as separate replacement Ford parts.

An auto electrical specialist should be able to

supply parts such as brushes.

The following procedures are for the

Lucas/Magneti Marelli unit fitted to the project

vehicle - the procedure is essentially the same

for the Bosch unit that may be found on other

models.

1Remove the starter motor from the vehicle

(Section 16) (see illustration).

17 Starter motor- brush and

solenoid renewal

16 Starter motor -

removal and refitting

Engine electrical systems 5•7

5

16.3 Unscrew upper two starter motor

mounting bolts (arrowed) from above16.6 Disconnect starter motor wiring (A),

then unscrew remaining mounting bolt (B),

and remove starter motor from beneath

vehicle

17.1 Exploded view of the Bosch DW starter

motor

1 Solenoid

2 Spring

3 Plunger

4 Engaging lever

5 Drive end housing

6 Drive pinion and

clutch

7 Spacer

8 Ring gear and carrier

9 Output shaft and

planet gear unit

10 Circlip11 Screw

12 End cap

13 C-clip

14 Shim

15 Commutator end

housing

16 Brushplate

17 Yoke

18 Rubber block

19 Armature

20 Retaining plate

procarmanuals.com

Page 119 of 279

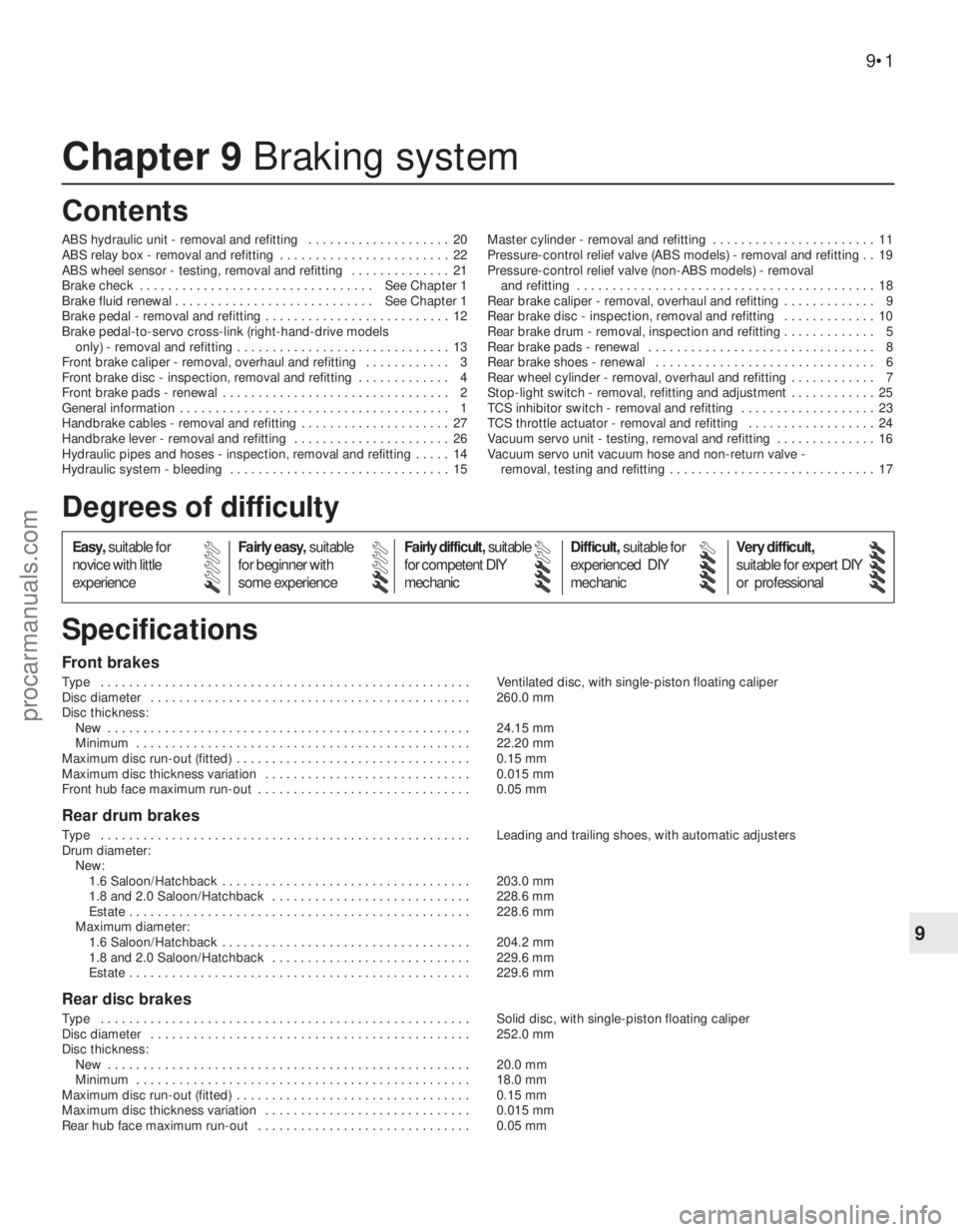

Chapter 9 Braking system

ABS hydraulic unit - removal and refitting . . . . . . . . . . . . . . . . . . . . 20

ABS relay box - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 22

ABS wheel sensor - testing, removal and refitting . . . . . . . . . . . . . . 21

Brake check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Brake fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Brake pedal - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Brake pedal-to-servo cross-link (right-hand-drive models

only) - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Front brake caliper - removal, overhaul and refitting . . . . . . . . . . . . 3

Front brake disc - inspection, removal and refitting . . . . . . . . . . . . . 4

Front brake pads - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Handbrake cables - removal and refitting . . . . . . . . . . . . . . . . . . . . . 27

Handbrake lever - removal and refitting . . . . . . . . . . . . . . . . . . . . . . 26

Hydraulic pipes and hoses - inspection, removal and refitting . . . . . 14

Hydraulic system - bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Master cylinder - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure-control relief valve (ABS models) - removal and refitting . . 19

Pressure-control relief valve (non-ABS models) - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Rear brake caliper - removal, overhaul and refitting . . . . . . . . . . . . . 9

Rear brake disc - inspection, removal and refitting . . . . . . . . . . . . . 10

Rear brake drum - removal, inspection and refitting . . . . . . . . . . . . . 5

Rear brake pads - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Rear brake shoes - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Rear wheel cylinder - removal, overhaul and refitting . . . . . . . . . . . . 7

Stop-light switch - removal, refitting and adjustment . . . . . . . . . . . . 25

TCS inhibitor switch - removal and refitting . . . . . . . . . . . . . . . . . . . 23

TCS throttle actuator - removal and refitting . . . . . . . . . . . . . . . . . . 24

Vacuum servo unit - testing, removal and refitting . . . . . . . . . . . . . . 16

Vacuum servo unit vacuum hose and non-return valve -

removal, testing and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Front brakes

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ventilated disc, with single-piston floating caliper

Disc diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260.0 mm

Disc thickness:

New . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.15 mm

Minimum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22.20 mm

Maximum disc run-out (fitted) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15 mm

Maximum disc thickness variation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.015 mm

Front hub face maximum run-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 mm

Rear drum brakes

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Leading and trailing shoes, with automatic adjusters

Drum diameter:

New:

1.6 Saloon/Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203.0 mm

1.8 and 2.0 Saloon/Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228.6 mm

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228.6 mm

Maximum diameter:

1.6 Saloon/Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204.2 mm

1.8 and 2.0 Saloon/Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229.6 mm

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229.6 mm

Rear disc brakes

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Solid disc, with single-piston floating caliper

Disc diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252.0 mm

Disc thickness:

New . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.0 mm

Minimum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18.0 mm

Maximum disc run-out (fitted) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15 mm

Maximum disc thickness variation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.015 mm

Rear hub face maximum run-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 mm

9•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,suitable

for competent DIY

mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Specifications Contents

9

procarmanuals.com

Page 121 of 279

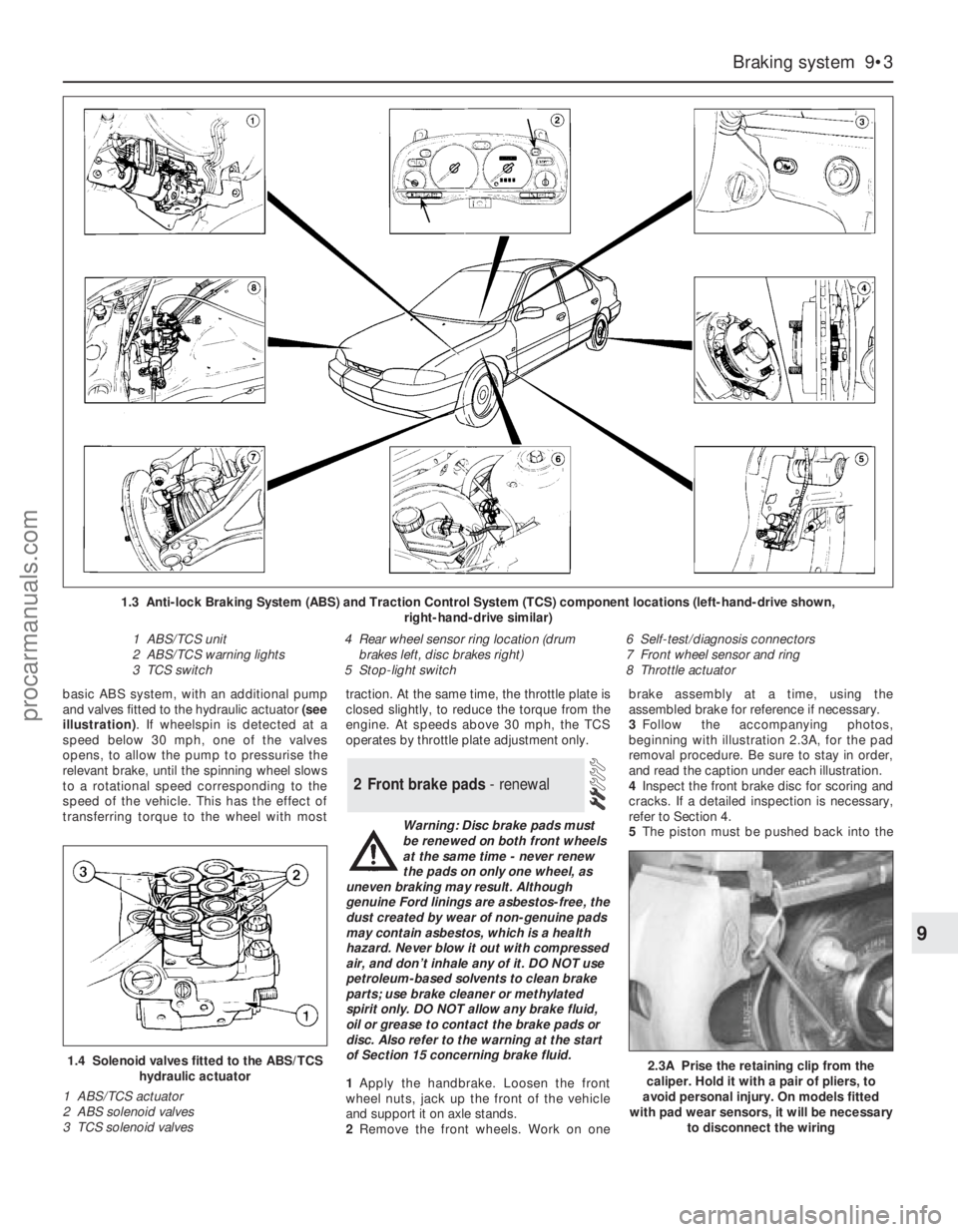

basic ABS system, with an additional pump

and valves fitted to the hydraulic actuator (see

illustration). If wheelspin is detected at a

speed below 30 mph, one of the valves

opens, to allow the pump to pressurise the

relevant brake, until the spinning wheel slows

to a rotational speed corresponding to the

speed of the vehicle. This has the effect of

transferring torque to the wheel with mosttraction. At the same time, the throttle plate is

closed slightly, to reduce the torque from the

engine. At speeds above 30 mph, the TCS

operates by throttle plate adjustment only.

Warning: Disc brake pads must

be renewed on both front wheels

at the same time - never renew

the pads on only one wheel, as

uneven braking may result. Although

genuine Ford linings are asbestos-free, the

dust created by wear of non-genuine pads

may contain asbestos, which is a health

hazard. Never blow it out with compressed

air, and don’t inhale any of it. DO NOT use

petroleum-based solvents to clean brake

parts; use brake cleaner or methylated

spirit only. DO NOT allow any brake fluid,

oil or grease to contact the brake pads or

disc. Also refer to the warning at the start

of Section 15 concerning brake fluid.

1Apply the handbrake. Loosen the front

wheel nuts, jack up the front of the vehicle

and support it on axle stands.

2Remove the front wheels. Work on onebrake assembly at a time, using the

assembled brake for reference if necessary.

3Follow the accompanying photos,

beginning with illustration 2.3A, for the pad

removal procedure. Be sure to stay in order,

and read the caption under each illustration.

4Inspect the front brake disc for scoring and

cracks. If a detailed inspection is necessary,

refer to Section 4.

5The piston must be pushed back into the

2 Front brake pads - renewal

Braking system 9•3

9

1.4 Solenoid valves fitted to the ABS/TCS

hydraulic actuator

1 ABS/TCS actuator

2 ABS solenoid valves

3 TCS solenoid valves

1.3 Anti-lock Braking System (ABS) and Traction Control System (TCS) component locations (left-hand-drive shown,

right-hand-drive similar)

1 ABS/TCS unit

2 ABS/TCS warning lights

3 TCS switch4 Rear wheel sensor ring location (drum

brakes left, disc brakes right)

5 Stop-light switch6 Self-test/diagnosis connectors

7 Front wheel sensor and ring

8 Throttle actuator

2.3A Prise the retaining clip from the

caliper. Hold it with a pair of pliers, to

avoid personal injury. On models fitted

with pad wear sensors, it will be necessary

to disconnect the wiring

procarmanuals.com