sensor FORD MONDEO 1993 Service Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 179 of 279

models (see illustration). In other countries, it

is available on certain models only. Where

double-locking is fitted, the lock mechanism

is disconnected (when the system is in use)

from the interior door handles, making it

impossible to open any of the doors or the

tailgate/bootlid from inside the vehicle. This

means that, even if a thief should break a side

window, he will not be able to open the door

using the interior handle. Models with the

double-locking system are fitted with a

control module located beneath the facia on

the right-hand side. In the event of a serious

accident, a crash sensor unlocks all doors if

they were previously locked.

Many of the procedures in this Chapter

require the battery to be disconnected. Refer

to Chapter 5, Section 1 first.

The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy, but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

important also to keep watch on those parts

of the vehicle not immediately visible, for

instance the underside, inside all the wheel

arches, and the lower part of the engine

compartment.

The basic maintenance routine for the

bodywork is washing - preferably with a lot of

water, from a hose. This will remove all the

loose solids which may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way, to remove any

accumulated mud, which will retain moisture

and tend to encourage rust. Paradoxically

enough, the best time to clean the underframe

and wheel arches is in wet weather, when the

mud is thoroughly wet and soft. In very wet

weather, the underframe is usually cleaned of

large accumulations automatically, and this is

a good time for inspection.

Periodically, except on vehicles with a wax-

based underbody protective coating, it is a

good idea to have the whole of the

underframe of the vehicle steam-cleaned,

engine compartment included, so that a

thorough inspection can be carried out to see

what minor repairs and renovations are

necessary. Steam-cleaning is available at

many garages, and is necessary for the

removal of the accumulation of oily grime,

which sometimes is allowed to become thick

in certain areas. If steam-cleaning facilities are

not available, there are some excellent grease

solvents available which can be brush-

applied; the dirt can then be simply hosed off.

Note that these methods should not be used

on vehicles with wax-based underbodyprotective coating, or the coating will be

removed. Such vehicles should be inspected

annually, preferably just prior to Winter, when

the underbody should be washed down, and

any damage to the wax coating repaired.

Ideally, a completely fresh coat should be

applied. It would also be worth considering

the use of such wax-based protection for

injection into door panels, sills, box sections,

etc, as an additional safeguard against rust

damage, where such protection is not

provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish

will give added protection against chemical

pollutants in the air. If the paintwork sheenhas dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to

be taken with metallic paintwork, as special

non-abrasive cleaner/polisher is required to

avoid damage to the finish. Always check that

the door and ventilator opening drain holes

and pipes are completely clear, so that water

can be drained out. Brightwork should be

treated in the same way as paintwork.

Windscreens and windows can be kept clear

of the smeary film which often appears, by the

use of proprietary glass cleaner. Never use

any form of wax or other body or chromium

polish on glass.

2 Maintenance -

bodywork and underframe

11•2 Bodywork and fittings

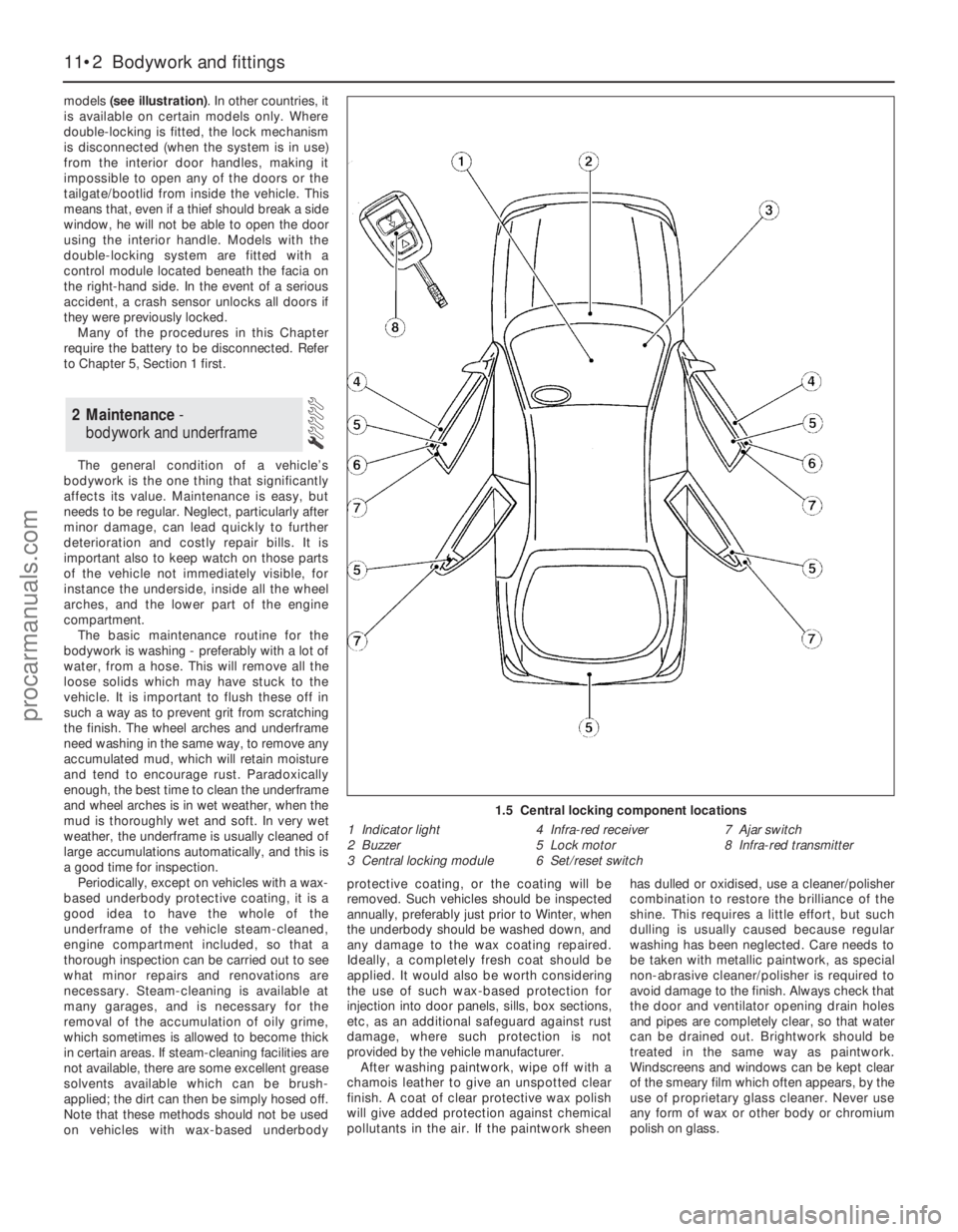

1.5 Central locking component locations

1 Indicator light

2 Buzzer

3 Central locking module4 Infra-red receiver

5 Lock motor

6 Set/reset switch7 Ajar switch

8 Infra-red transmitter

procarmanuals.com

Page 188 of 279

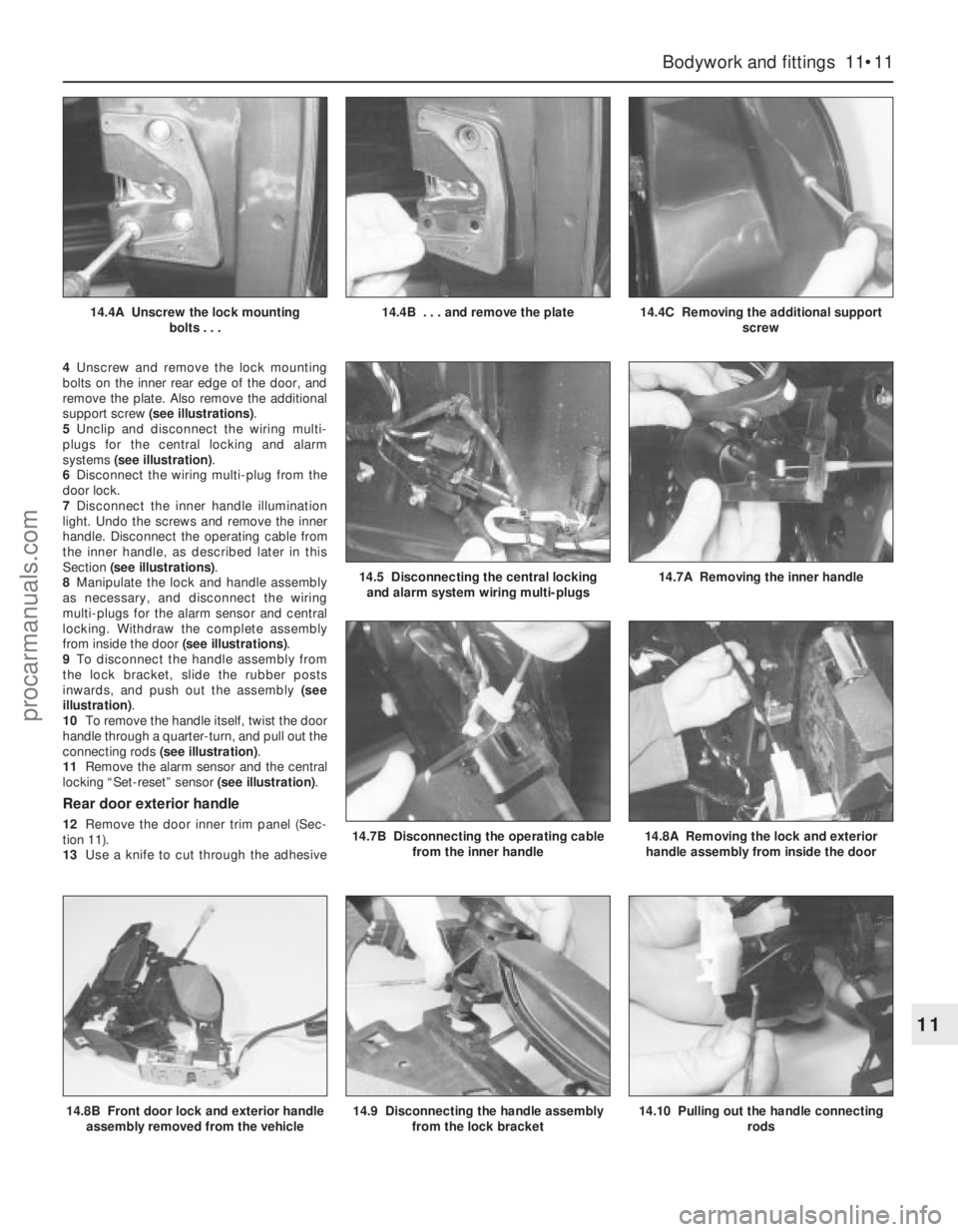

4Unscrew and remove the lock mounting

bolts on the inner rear edge of the door, and

remove the plate. Also remove the additional

support screw (see illustrations).

5Unclip and disconnect the wiring multi-

plugs for the central locking and alarm

systems (see illustration).

6Disconnect the wiring multi-plug from the

door lock.

7Disconnect the inner handle illumination

light. Undo the screws and remove the inner

handle. Disconnect the operating cable from

the inner handle, as described later in this

Section (see illustrations).

8Manipulate the lock and handle assembly

as necessary, and disconnect the wiring

multi-plugs for the alarm sensor and central

locking. Withdraw the complete assembly

from inside the door (see illustrations).

9To disconnect the handle assembly from

the lock bracket, slide the rubber posts

inwards, and push out the assembly (see

illustration).

10To remove the handle itself, twist the door

handle through a quarter-turn, and pull out the

connecting rods (see illustration).

11Remove the alarm sensor and the central

locking “Set-reset” sensor (see illustration).

Rear door exterior handle

12Remove the door inner trim panel (Sec-

tion 11).

13Use a knife to cut through the adhesive

Bodywork and fittings 11•11

11

14.8B Front door lock and exterior handle

assembly removed from the vehicle14.9 Disconnecting the handle assembly

from the lock bracket14.10 Pulling out the handle connecting

rods

14.4A Unscrew the lock mounting

bolts . . .14.4B . . . and remove the plate14.4C Removing the additional support

screw

14.5 Disconnecting the central locking

and alarm system wiring multi-plugs14.7A Removing the inner handle

14.7B Disconnecting the operating cable

from the inner handle14.8A Removing the lock and exterior

handle assembly from inside the door

procarmanuals.com

Page 189 of 279

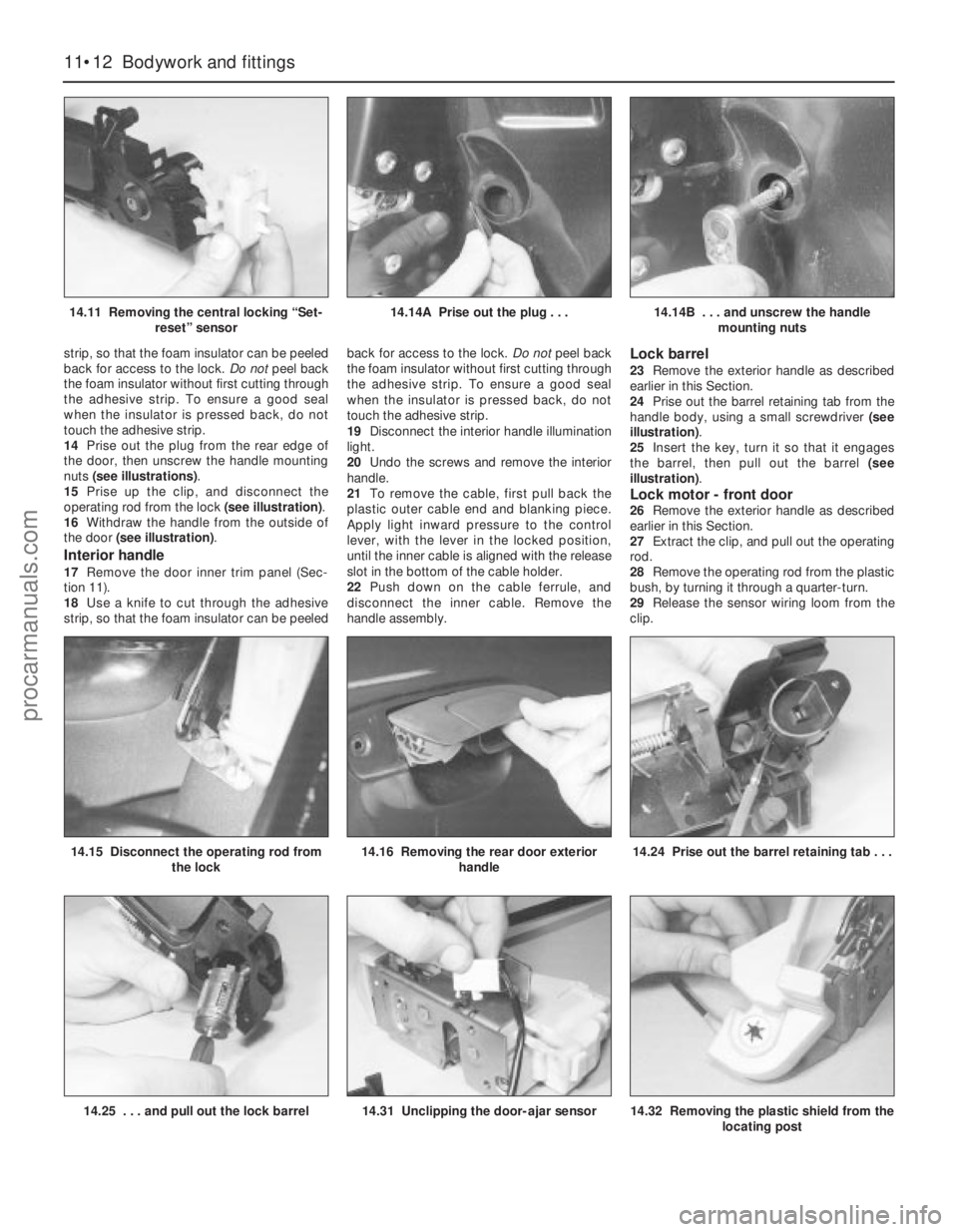

strip, so that the foam insulator can be peeled

back for access to the lock. Do notpeel back

the foam insulator without first cutting through

the adhesive strip. To ensure a good seal

when the insulator is pressed back, do not

touch the adhesive strip.

14Prise out the plug from the rear edge of

the door, then unscrew the handle mounting

nuts (see illustrations).

15Prise up the clip, and disconnect the

operating rod from the lock (see illustration).

16Withdraw the handle from the outside of

the door (see illustration).

Interior handle

17Remove the door inner trim panel (Sec-

tion 11).

18Use a knife to cut through the adhesive

strip, so that the foam insulator can be peeledback for access to the lock. Do notpeel back

the foam insulator without first cutting through

the adhesive strip. To ensure a good seal

when the insulator is pressed back, do not

touch the adhesive strip.

19Disconnect the interior handle illumination

light.

20Undo the screws and remove the interior

handle.

21To remove the cable, first pull back the

plastic outer cable end and blanking piece.

Apply light inward pressure to the control

lever, with the lever in the locked position,

until the inner cable is aligned with the release

slot in the bottom of the cable holder.

22Push down on the cable ferrule, and

disconnect the inner cable. Remove the

handle assembly.

Lock barrel

23Remove the exterior handle as described

earlier in this Section.

24Prise out the barrel retaining tab from the

handle body, using a small screwdriver (see

illustration).

25Insert the key, turn it so that it engages

the barrel, then pull out the barrel (see

illustration).

Lock motor - front door26Remove the exterior handle as described

earlier in this Section.

27Extract the clip, and pull out the operating

rod.

28Remove the operating rod from the plastic

bush, by turning it through a quarter-turn.

29Release the sensor wiring loom from the

clip.

11•12 Bodywork and fittings

14.11 Removing the central locking “Set-

reset” sensor14.14A Prise out the plug . . .14.14B . . . and unscrew the handle

mounting nuts

14.25 . . . and pull out the lock barrel14.31 Unclipping the door-ajar sensor14.32 Removing the plastic shield from the

locating post

14.15 Disconnect the operating rod from

the lock14.16 Removing the rear door exterior

handle14.24 Prise out the barrel retaining tab . . .

procarmanuals.com

Page 190 of 279

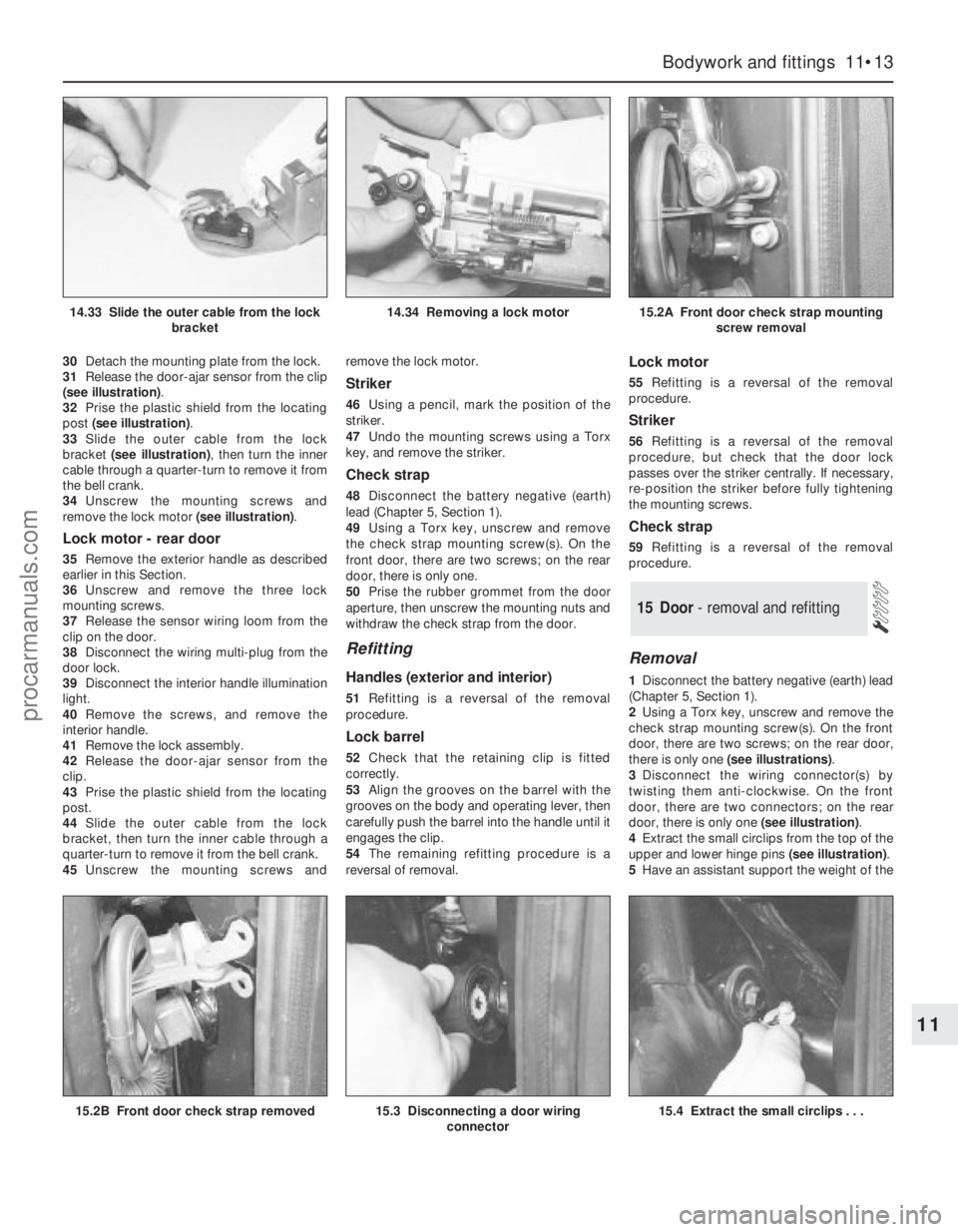

30Detach the mounting plate from the lock.

31Release the door-ajar sensor from the clip

(see illustration).

32Prise the plastic shield from the locating

post (see illustration).

33Slide the outer cable from the lock

bracket (see illustration), then turn the inner

cable through a quarter-turn to remove it from

the bell crank.

34Unscrew the mounting screws and

remove the lock motor (see illustration).

Lock motor - rear door

35Remove the exterior handle as described

earlier in this Section.

36Unscrew and remove the three lock

mounting screws.

37Release the sensor wiring loom from the

clip on the door.

38Disconnect the wiring multi-plug from the

door lock.

39Disconnect the interior handle illumination

light.

40Remove the screws, and remove the

interior handle.

41Remove the lock assembly.

42Release the door-ajar sensor from the

clip.

43Prise the plastic shield from the locating

post.

44Slide the outer cable from the lock

bracket, then turn the inner cable through a

quarter-turn to remove it from the bell crank.

45Unscrew the mounting screws andremove the lock motor.

Striker

46Using a pencil, mark the position of the

striker.

47Undo the mounting screws using a Torx

key, and remove the striker.

Check strap

48Disconnect the battery negative (earth)

lead (Chapter 5, Section 1).

49Using a Torx key, unscrew and remove

the check strap mounting screw(s). On the

front door, there are two screws; on the rear

door, there is only one.

50Prise the rubber grommet from the door

aperture, then unscrew the mounting nuts and

withdraw the check strap from the door.

Refitting

Handles (exterior and interior)

51Refitting is a reversal of the removal

procedure.

Lock barrel

52Check that the retaining clip is fitted

correctly.

53Align the grooves on the barrel with the

grooves on the body and operating lever, then

carefully push the barrel into the handle until it

engages the clip.

54The remaining refitting procedure is a

reversal of removal.

Lock motor

55Refitting is a reversal of the removal

procedure.

Striker

56Refitting is a reversal of the removal

procedure, but check that the door lock

passes over the striker centrally. If necessary,

re-position the striker before fully tightening

the mounting screws.

Check strap

59Refitting is a reversal of the removal

procedure.

Removal

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2Using a Torx key, unscrew and remove the

check strap mounting screw(s). On the front

door, there are two screws; on the rear door,

there is only one (see illustrations).

3Disconnect the wiring connector(s) by

twisting them anti-clockwise. On the front

door, there are two connectors; on the rear

door, there is only one (see illustration).

4Extract the small circlips from the top of the

upper and lower hinge pins (see illustration).

5Have an assistant support the weight of the

15 Door - removal and refitting

Bodywork and fittings 11•13

11

15.2B Front door check strap removed15.3 Disconnecting a door wiring

connector15.4 Extract the small circlips . . .

14.33 Slide the outer cable from the lock

bracket14.34 Removing a lock motor15.2A Front door check strap mounting

screw removal

procarmanuals.com

Page 192 of 279

Removal

Lock barrel

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2With the boot lid open, remove the luggage

space trim from the right-hand rear corner.

3Remove the screws, and prise out the rear

light trim cover from the guides.

4Release the door-ajar sensor from the clip

near the lock.

5Slide the outer cable from the lock bracket.

Raise the inner cable until it is aligned with the

slot in the barrel lever, and disconnect it.

6Pull out the lock locating spring clip.

7Detach the cable mounting bracket from

the barrel, and remove the barrel.

Lock

8Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

9With the boot lid open, prise out the clips

and remove the trim from inside the boot lid.

10Release the door-ajar sensor from the clip

near the lock.

11Using a Torx key, unscrew the lock

mounting screws, and withdraw the lock for

access to the cables.

12Disconnect both the inner and outer

cables from the lock bracket.13Prise open the plastic lip, and remove the

central locking control rod.

14Withdraw the lock assembly.

Refitting

Lock barrel and lock

15Refitting is a reversal of the removal

procedure.

Removal

Hatchback

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1). Open the tailgate.

2The tailgate may be unbolted from the

hinges and the hinges left in position, or the

hinges may be detached from the roof panel

by unscrewing the mounting nuts. In the latter

case, carefully pull down the rear edge of the

headlining for access to the nuts. Take care

not to damage the headlining.

3Remove the parcel shelf left-hand support

bracket as follows. Fold the rear seat

forwards, and disconnect the left-hand seat

pull cable from the bracket and clips.

Unscrew the screws and remove the bracket.

4Pull up the rear seat side bolster, then

carefully remove the side trim from the left-

hand side of the luggage area. On low-series

models, the bolster is retained with a screw.5Separate the tailgate wiring loom multi-

plugs, located on the left-hand side of the

luggage compartment, on top of the wheel

arch.

6Unclip and remove the upper trim panel

from the inside of the tailgate. Also remove

the rear shelf cord plastic post (see

illustrations).

7Prise out the rubber grommet from the top

of the tailgate aperture, and pull the wiring

loom out through the hole in the body (see

illustration).

8Disconnect the rear window washer tube

from the jet.

9Prise out the rubber grommet from the

right-hand side of the tailgate aperture, and

pull out the washer tube.

10Have an assistant support the tailgate in

its open position.

11Using a small screwdriver, prise off the

clips securing the struts to the tailgate. Pull

the sockets from the ball-studs, and move the

struts downwards.

12If the headlining has been pulled back,

unscrew and remove the hinge nuts from the

roof panel. Otherwise, unscrew the bolts

securing the tailgate to the hinges (see

illustration).

13Withdraw the tailgate from the body

aperture, taking care not to damage the

paintwork.

Estate

14Disconnect the battery negative (earth)

lead (Chapter 5, Section 1).

15The tailgate may be unbolted from the

hinges and the hinges left in position, or the

hinges may be detached from the rear roof

panel by unscrewing the mounting nuts. In the

latter case, carefully pull down the rear edge

of the headlining for access to the nuts. Take

care not to damage the headlining.

16Unscrew the retaining screws, then unclip

the “D” pillar trim panels from both sides (see

illustration).

17Unclip and remove the upper trim panel

from inside the tailgate.

18Carefully remove the side trim from the

left-hand side of the luggage area, and

separate the tailgate wiring loom multi-plugs

in the rear light cluster housing.

20 Tailgate -

removal and refitting

19 Boot lid lock components-

removal and refitting

Bodywork and fittings 11•15

11

20.12 Unscrewing the bolts securing the

tailgate to the hinges20.16 “D” pillar trim panel retaining

screws (arrowed) - Estate models

20.6A Unclipping the upper trim panel

from the tailgate20.6B Shelf cord post removal20.7 Removing the wiring loom rubber

grommet

procarmanuals.com

Page 193 of 279

19Attach a strong fine cord to the end of the

wiring loom, to act as an aid to guiding the

wiring through the tailgate when it is refitted.

20Prise the rubber grommet from the top

left-hand side of the tailgate aperture, and pull

out the wiring loom. Untie the cord, leaving it

in position in the “D” pillar.

21Disconnect the rear window washer tube

from the jet. Pull out the rubber grommet, and

remove the tube.

22Have an assistant support the tailgate in

its open position.

23Using a small screwdriver, prise off the

clip securing the struts to the tailgate. Pull the

sockets from the ball-studs, and move the

struts downwards.

24Unscrew and remove the hinge nuts from

the roof panel, or the hinge bolts from thehinge, as desired (see illustration). Withdraw

the tailgate from the body aperture, taking

care not to damage the paintwork.

Refitting

Hatchback and Estate

25Refitting is a reversal of the removal

procedure, but check that the tailgate is

located centrally in the body aperture, and

that the striker enters the lock centrally. If

necessary, loosen the mounting nuts and re-

position the tailgate as required.

Removal

1Support the tailgate in its open position.

2Prise off the upper spring clip securing the

strut to the tailgate, then pull the socket from

the ball-stud (see illustration).

3Similarly prise off the bottom clip (see

illustration), and pull the socket from the ball-

stud. Withdraw the strut.

Refitting

4Refitting is a reversal of the removal

procedure, but make sure that the piston end

of the strut is fitted on the body (ie

downwards).

Removal

Lock barrel (Hatchback)

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2With the tailgate open, pull up the

weatherstrip for access to the lock. Remove

the screws and clips, and remove the trim

panel from the rear of the luggage

compartment.

3Unhook the parcel net, then remove the

screws and clips, and remove the rear

crossmember trim.

4Remove the screws, and prise out the rear

light trim cover from the guides.

5Release the door-ajar sensor from the clip

near the lock.

6Slide the outer cable from the lock bracket.

Raise the inner cable until it is aligned with the

slot in the barrel lever, and disconnect it (see

illustration).

7Pull out the lock barrel locating spring clip.

8Detach the cable mounting bracket from

the barrel, and remove the barrel and cylinder

(see illustrations).

Lock barrel (Estate)

9Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

10Unclip and remove the tailgate trim panel.

Undo the three screws and remove the lock

shield, then unclip the door-ajar sensor.

11Working through the aperture in the

tailgate inner panel, pull out the lock barrel

locating spring clip. Unhook the operating rod

and withdraw the lock barrel.

Lock (Hatchback)

12Disconnect the battery negative (earth)

lead (Chapter 5, Section 1).

13With the tailgate open, pull up the

weatherstrip for access to the lock. Remove

the screws and clips, and remove the trim

panel from the rear of the luggage

compartment.

22 Tailgate lock components -

removal and refitting

21 Tailgate support strut-

removal and refitting

11•16 Bodywork and fittings

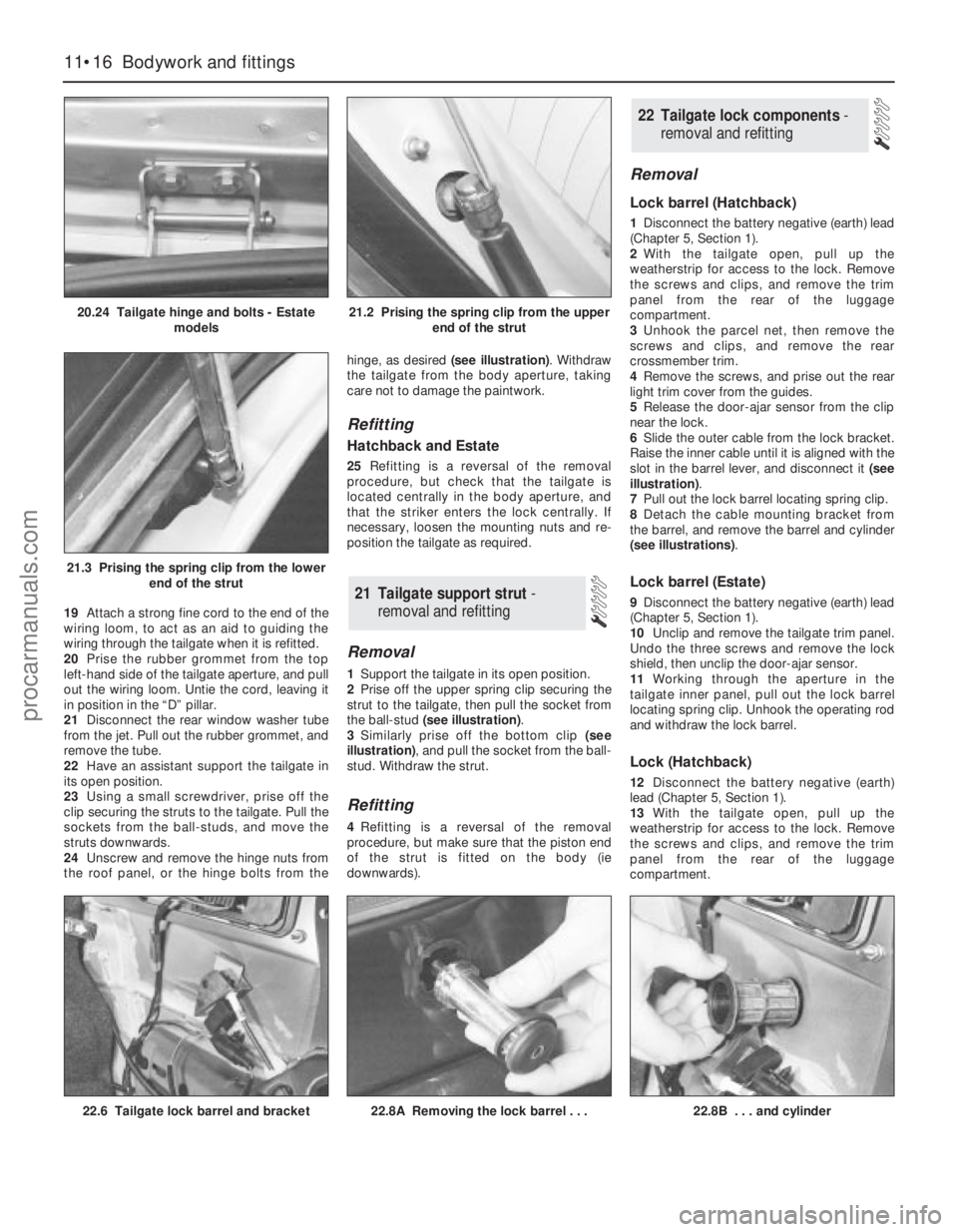

20.24 Tailgate hinge and bolts - Estate

models21.2 Prising the spring clip from the upper

end of the strut

21.3 Prising the spring clip from the lower

end of the strut

22.6 Tailgate lock barrel and bracket22.8A Removing the lock barrel . . .22.8B . . . and cylinder

procarmanuals.com

Page 194 of 279

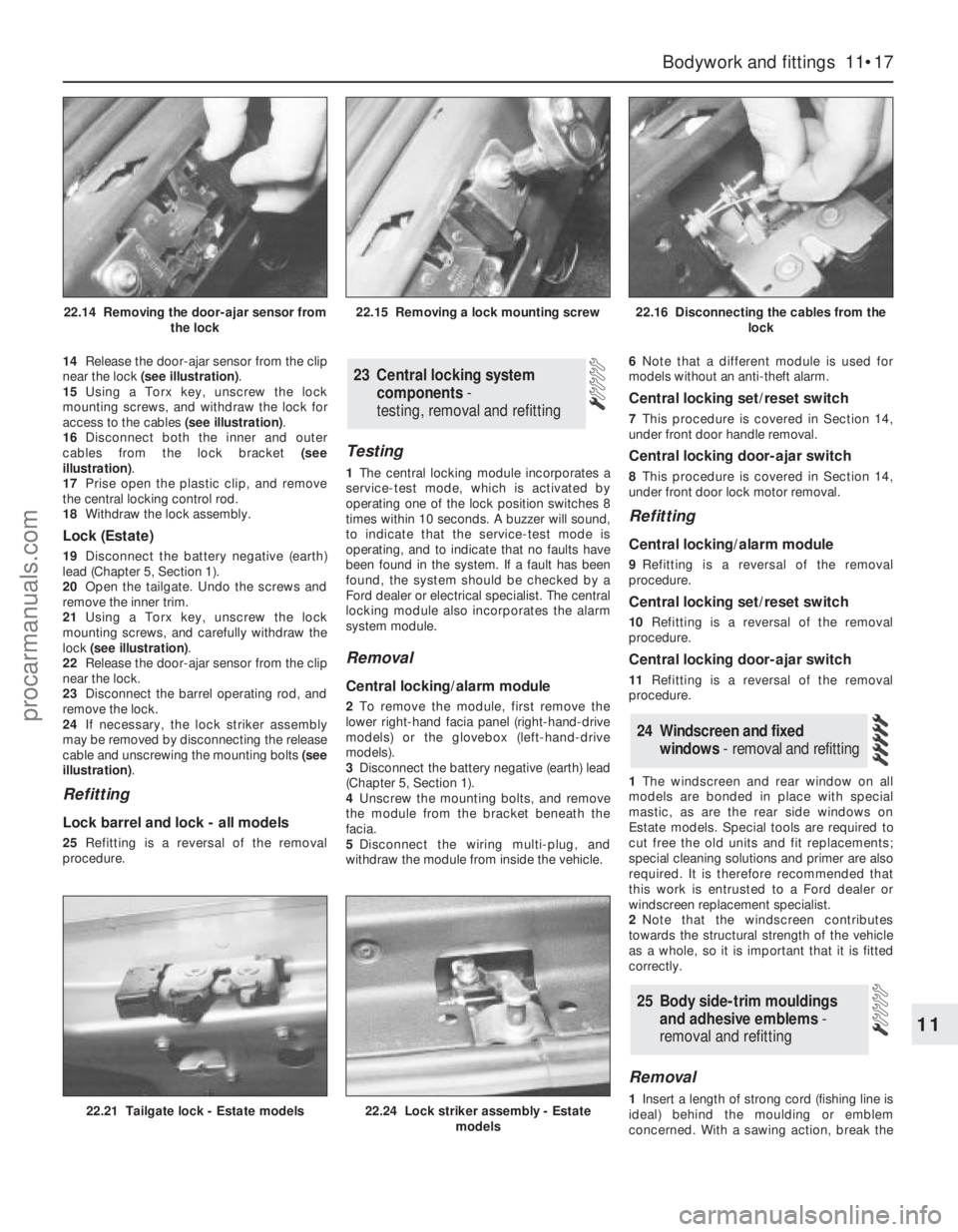

14Release the door-ajar sensor from the clip

near the lock (see illustration).

15Using a Torx key, unscrew the lock

mounting screws, and withdraw the lock for

access to the cables (see illustration).

16Disconnect both the inner and outer

cables from the lock bracket (see

illustration).

17Prise open the plastic clip, and remove

the central locking control rod.

18Withdraw the lock assembly.

Lock (Estate)

19Disconnect the battery negative (earth)

lead (Chapter 5, Section 1).

20Open the tailgate. Undo the screws and

remove the inner trim.

21Using a Torx key, unscrew the lock

mounting screws, and carefully withdraw the

lock (see illustration).

22Release the door-ajar sensor from the clip

near the lock.

23Disconnect the barrel operating rod, and

remove the lock.

24If necessary, the lock striker assembly

may be removed by disconnecting the release

cable and unscrewing the mounting bolts (see

illustration).

Refitting

Lock barrel and lock - all models

25Refitting is a reversal of the removal

procedure.

Testing

1The central locking module incorporates a

service-test mode, which is activated by

operating one of the lock position switches 8

times within 10 seconds. A buzzer will sound,

to indicate that the service-test mode is

operating, and to indicate that no faults have

been found in the system. If a fault has been

found, the system should be checked by a

Ford dealer or electrical specialist. The central

locking module also incorporates the alarm

system module.

Removal

Central locking/alarm module

2To remove the module, first remove the

lower right-hand facia panel (right-hand-drive

models) or the glovebox (left-hand-drive

models).

3Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

4Unscrew the mounting bolts, and remove

the module from the bracket beneath the

facia.

5Disconnect the wiring multi-plug, and

withdraw the module from inside the vehicle.6Note that a different module is used for

models without an anti-theft alarm.

Central locking set/reset switch

7This procedure is covered in Section 14,

under front door handle removal.

Central locking door-ajar switch

8This procedure is covered in Section 14,

under front door lock motor removal.

Refitting

Central locking/alarm module

9Refitting is a reversal of the removal

procedure.

Central locking set/reset switch

10Refitting is a reversal of the removal

procedure.

Central locking door-ajar switch

11Refitting is a reversal of the removal

procedure.

1The windscreen and rear window on all

models are bonded in place with special

mastic, as are the rear side windows on

Estate models. Special tools are required to

cut free the old units and fit replacements;

special cleaning solutions and primer are also

required. It is therefore recommended that

this work is entrusted to a Ford dealer or

windscreen replacement specialist.

2Note that the windscreen contributes

towards the structural strength of the vehicle

as a whole, so it is important that it is fitted

correctly.

Removal

1Insert a length of strong cord (fishing line is

ideal) behind the moulding or emblem

concerned. With a sawing action, break the

25 Body side-trim mouldings

and adhesive emblems -

removal and refitting

24 Windscreen and fixed

windows - removal and refitting

23 Central locking system

components-

testing, removal and refitting

Bodywork and fittings 11•17

11

22.21 Tailgate lock - Estate models22.24 Lock striker assembly - Estate

models

22.14 Removing the door-ajar sensor from

the lock22.15 Removing a lock mounting screw22.16 Disconnecting the cables from the

lock

procarmanuals.com

Page 202 of 279

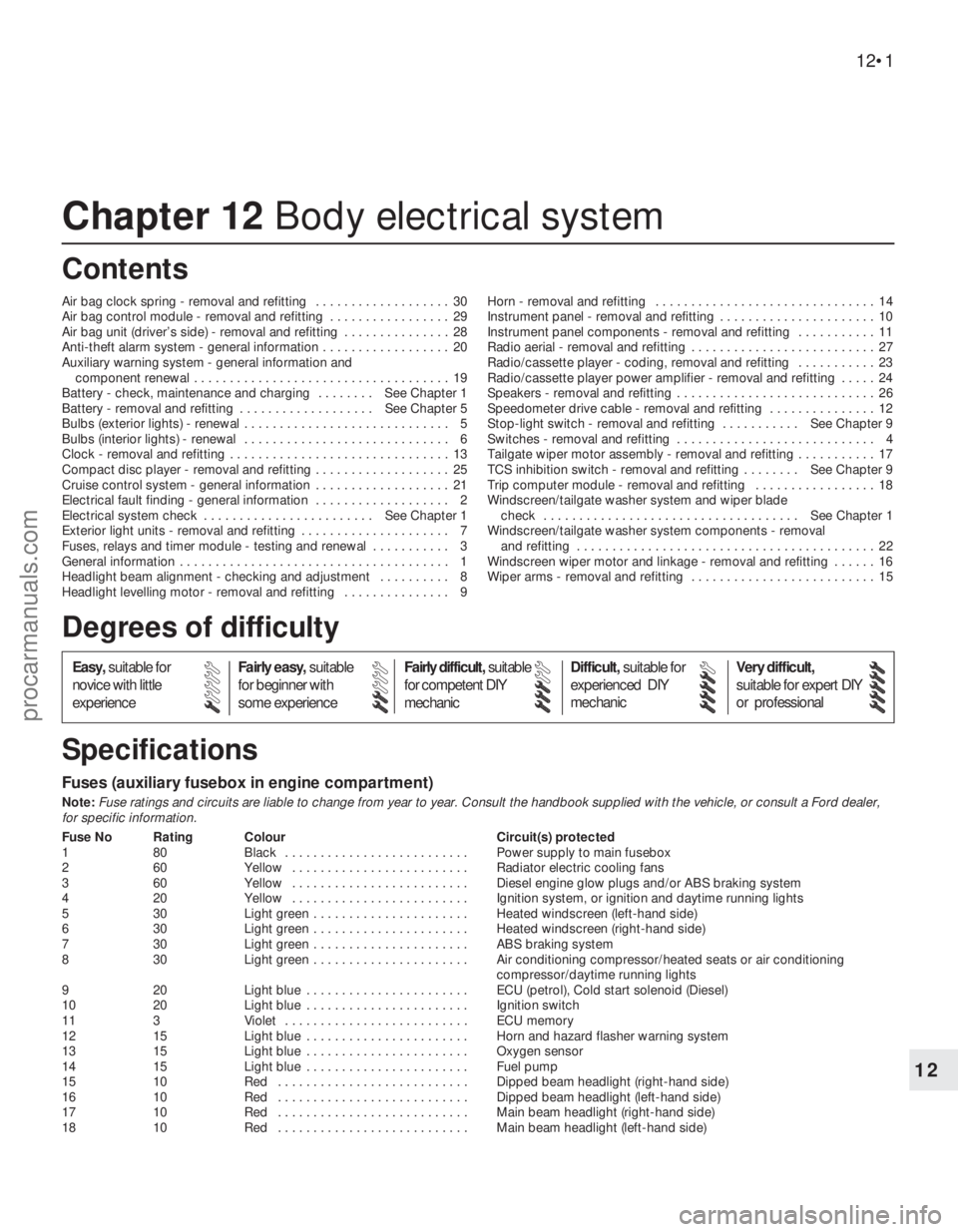

Chapter 12 Body electrical system

Air bag clock spring - removal and refitting . . . . . . . . . . . . . . . . . . . 30

Air bag control module - removal and refitting . . . . . . . . . . . . . . . . . 29

Air bag unit (driver’s side) - removal and refitting . . . . . . . . . . . . . . . 28

Anti-theft alarm system - general information . . . . . . . . . . . . . . . . . . 20

Auxiliary warning system - general information and

component renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Battery - check, maintenance and charging . . . . . . . . See Chapter 1

Battery - removal and refitting . . . . . . . . . . . . . . . . . . . See Chapter 5

Bulbs (exterior lights) - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bulbs (interior lights) - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Clock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Compact disc player - removal and refitting . . . . . . . . . . . . . . . . . . . 25

Cruise control system - general information . . . . . . . . . . . . . . . . . . . 21

Electrical fault finding - general information . . . . . . . . . . . . . . . . . . . 2

Electrical system check . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Exterior light units - removal and refitting . . . . . . . . . . . . . . . . . . . . . 7

Fuses, relays and timer module - testing and renewal . . . . . . . . . . . 3

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Headlight beam alignment - checking and adjustment . . . . . . . . . . 8

Headlight levelling motor - removal and refitting . . . . . . . . . . . . . . . 9Horn - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Instrument panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . 10

Instrument panel components - removal and refitting . . . . . . . . . . . 11

Radio aerial - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Radio/cassette player - coding, removal and refitting . . . . . . . . . . . 23

Radio/cassette player power amplifier - removal and refitting . . . . . 24

Speakers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Speedometer drive cable - removal and refitting . . . . . . . . . . . . . . . 12

Stop-light switch - removal and refitting . . . . . . . . . . . See Chapter 9

Switches - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Tailgate wiper motor assembly - removal and refitting . . . . . . . . . . . 17

TCS inhibition switch - removal and refitting . . . . . . . . See Chapter 9

Trip computer module - removal and refitting . . . . . . . . . . . . . . . . . 18

Windscreen/tailgate washer system and wiper blade

check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Windscreen/tailgate washer system components - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Windscreen wiper motor and linkage - removal and refitting . . . . . . 16

Wiper arms - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fuses (auxiliary fusebox in engine compartment)

Note:Fuse ratings and circuits are liable to change from year to year. Consult the handbook supplied with the vehicle, or consult a Ford dealer,

for specific information.

Fuse No Rating Colour Circuit(s) protected

1 80 Black . . . . . . . . . . . . . . . . . . . . . . . . . . Power supply to main fusebox

2 60 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . Radiator electric cooling fans

3 60 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . Diesel engine glow plugs and/or ABS braking system

4 20 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . Ignition system, or ignition and daytime running lights

5 30 Light green . . . . . . . . . . . . . . . . . . . . . . Heated windscreen (left-hand side)

6 30 Light green . . . . . . . . . . . . . . . . . . . . . . Heated windscreen (right-hand side)

7 30 Light green . . . . . . . . . . . . . . . . . . . . . . ABS braking system

8 30 Light green . . . . . . . . . . . . . . . . . . . . . . Air conditioning compressor/heated seats or air conditioning

compressor/daytime running lights

9 20 Light blue . . . . . . . . . . . . . . . . . . . . . . . ECU (petrol), Cold start solenoid (Diesel)

10 20 Light blue . . . . . . . . . . . . . . . . . . . . . . . Ignition switch

11 3 Violet . . . . . . . . . . . . . . . . . . . . . . . . . . ECU memory

12 15 Light blue . . . . . . . . . . . . . . . . . . . . . . . Horn and hazard flasher warning system

13 15 Light blue . . . . . . . . . . . . . . . . . . . . . . . Oxygen sensor

14 15 Light blue . . . . . . . . . . . . . . . . . . . . . . . Fuel pump

15 10 Red . . . . . . . . . . . . . . . . . . . . . . . . . . . Dipped beam headlight (right-hand side)

16 10 Red . . . . . . . . . . . . . . . . . . . . . . . . . . . Dipped beam headlight (left-hand side)

17 10 Red . . . . . . . . . . . . . . . . . . . . . . . . . . . Main beam headlight (right-hand side)

18 10 Red . . . . . . . . . . . . . . . . . . . . . . . . . . . Main beam headlight (left-hand side)

12•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,suitable

for competent DIY

mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Specifications Contents

12

procarmanuals.com

Page 204 of 279

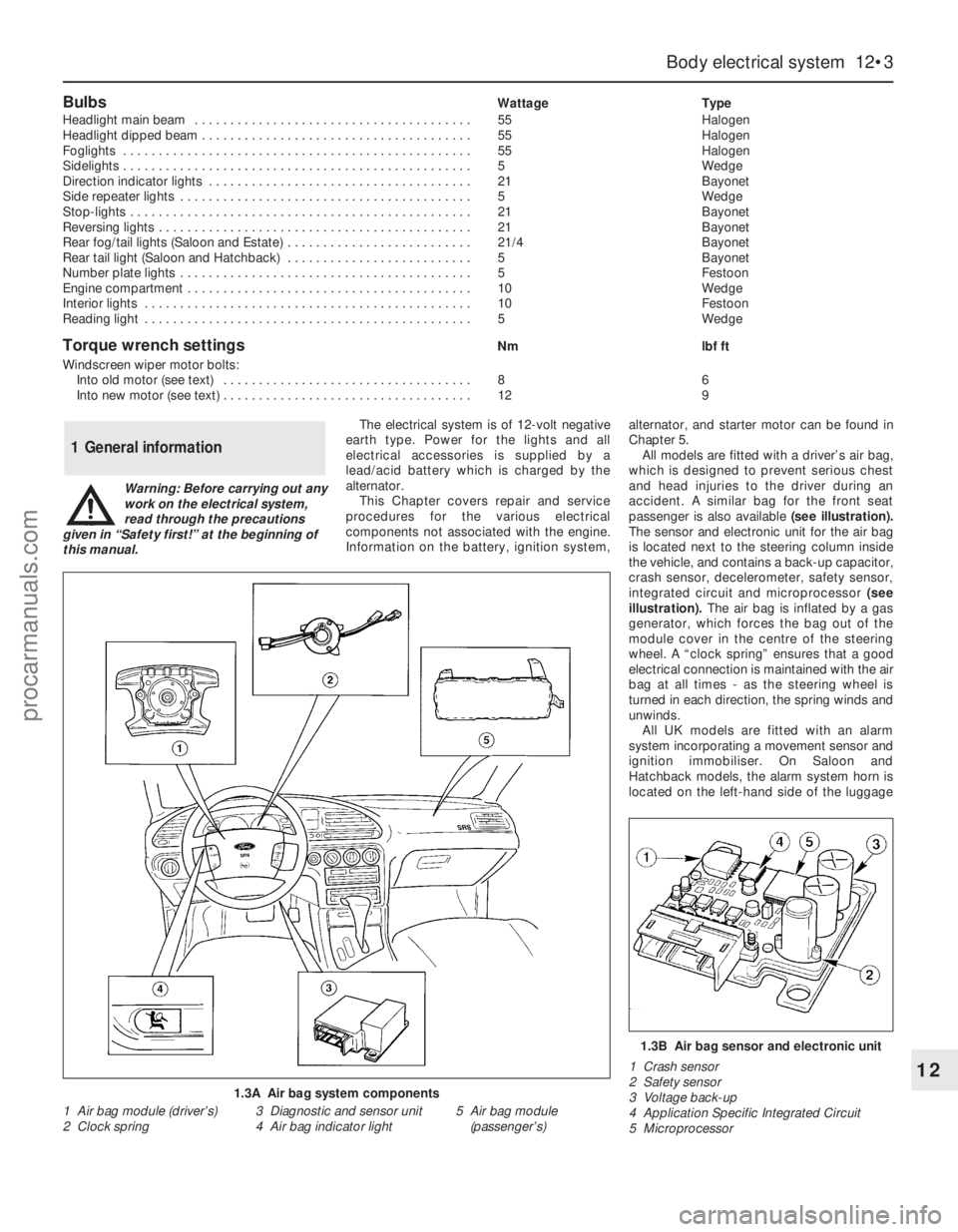

BulbsWattage Type

Headlight main beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Halogen

Headlight dipped beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Halogen

Foglights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Halogen

Sidelights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Wedge

Direction indicator lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Bayonet

Side repeater lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Wedge

Stop-lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Bayonet

Reversing lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Bayonet

Rear fog/tail lights (Saloon and Estate) . . . . . . . . . . . . . . . . . . . . . . . . . . 21/4 Bayonet

Rear tail light (Saloon and Hatchback) . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Bayonet

Number plate lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Festoon

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Wedge

Interior lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Festoon

Reading light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Wedge

Torque wrench settingsNm lbf ft

Windscreen wiper motor bolts:

Into old motor (see text) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Into new motor (see text) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 9

Body electrical system 12•3

12

Warning: Before carrying out any

work on the electrical system,

read through the precautions

given in “Safety first!” at the beginning of

this manual.The electrical system is of 12-volt negative

earth type. Power for the lights and all

electrical accessories is supplied by a

lead/acid battery which is charged by the

alternator.

This Chapter covers repair and service

procedures for the various electrical

components not associated with the engine.

Information on the battery, ignition system,alternator, and starter motor can be found in

Chapter 5.

All models are fitted with a driver’s air bag,

which is designed to prevent serious chest

and head injuries to the driver during an

accident. A similar bag for the front seat

passenger is also available (see illustration).

The sensor and electronic unit for the air bag

is located next to the steering column inside

the vehicle, and contains a back-up capacitor,

crash sensor, decelerometer, safety sensor,

integrated circuit and microprocessor (see

illustration). The air bag is inflated by a gas

generator, which forces the bag out of the

module cover in the centre of the steering

wheel. A “clock spring” ensures that a good

electrical connection is maintained with the air

bag at all times - as the steering wheel is

turned in each direction, the spring winds and

unwinds.

All UK models are fitted with an alarm

system incorporating a movement sensor and

ignition immobiliser. On Saloon and

Hatchback models, the alarm system horn is

located on the left-hand side of the luggage

1 General information

1.3A Air bag system components

1 Air bag module (driver’s)

2 Clock spring3 Diagnostic and sensor unit

4 Air bag indicator light5 Air bag module

(passenger’s)

1.3B Air bag sensor and electronic unit

1 Crash sensor

2 Safety sensor

3 Voltage back-up

4 Application Specific Integrated Circuit

5 Microprocessor

procarmanuals.com

Page 216 of 279

6Similarly remove the fuel gauge and

temperature gauge by unscrewing the single

screws.

7Remove all the pin contacts.

8Using a small punch, push in the multi-plug

securing pins, and remove the multi-plugs.

9Carefully lift the printed circuit from the

location dowels on the housing, taking care

not to damage it.

Refitting

10Refitting is a reversal of the removal

procedure.

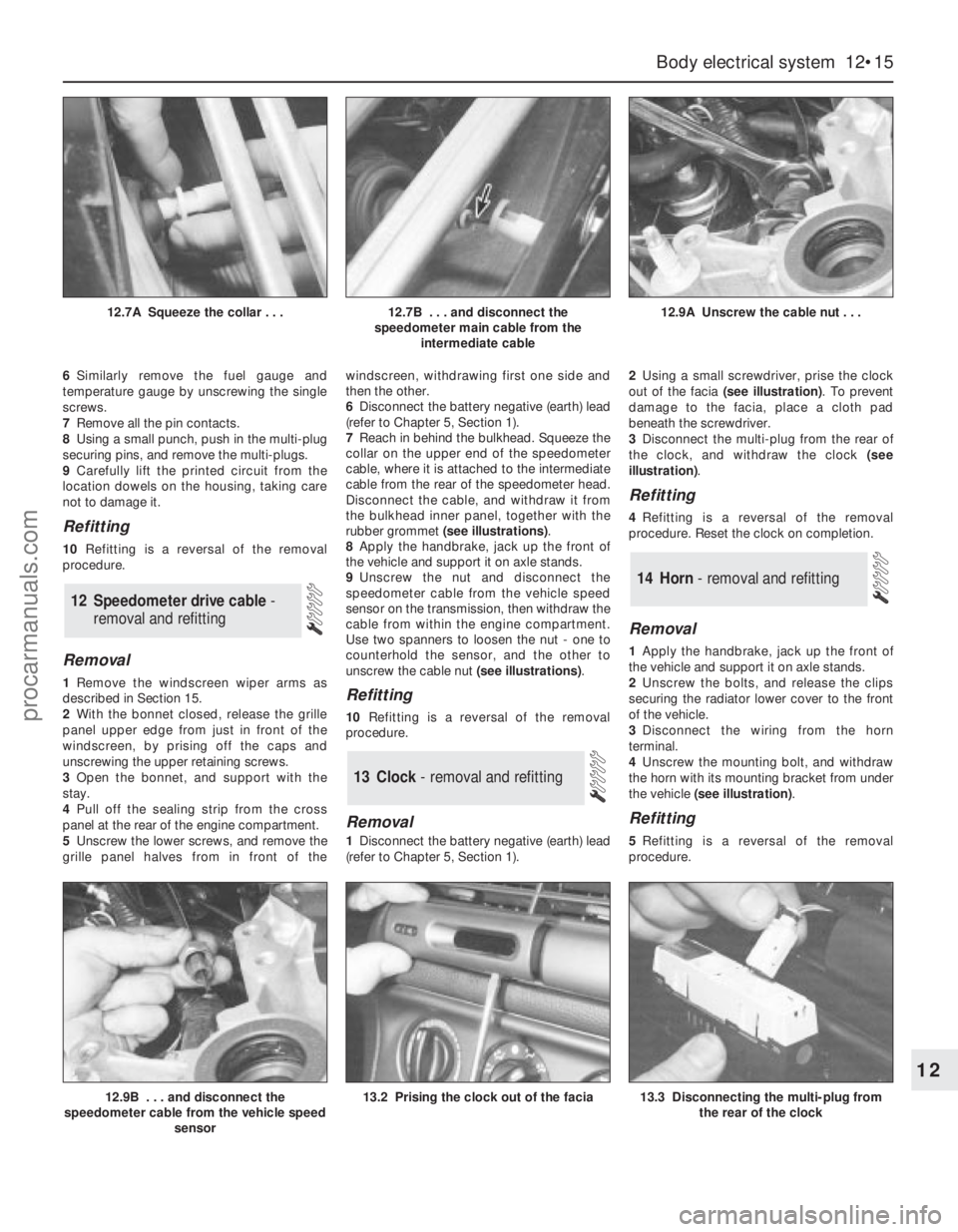

Removal

1Remove the windscreen wiper arms as

described in Section 15.

2With the bonnet closed, release the grille

panel upper edge from just in front of the

windscreen, by prising off the caps and

unscrewing the upper retaining screws.

3Open the bonnet, and support with the

stay.

4Pull off the sealing strip from the cross

panel at the rear of the engine compartment.

5Unscrew the lower screws, and remove the

grille panel halves from in front of thewindscreen, withdrawing first one side and

then the other.

6Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

7Reach in behind the bulkhead. Squeeze the

collar on the upper end of the speedometer

cable, where it is attached to the intermediate

cable from the rear of the speedometer head.

Disconnect the cable, and withdraw it from

the bulkhead inner panel, together with the

rubber grommet (see illustrations).

8Apply the handbrake, jack up the front of

the vehicle and support it on axle stands.

9Unscrew the nut and disconnect the

speedometer cable from the vehicle speed

sensor on the transmission, then withdraw the

cable from within the engine compartment.

Use two spanners to loosen the nut - one to

counterhold the sensor, and the other to

unscrew the cable nut (see illustrations).Refitting

10Refitting is a reversal of the removal

procedure.

Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).2Using a small screwdriver, prise the clock

out of the facia (see illustration). To prevent

damage to the facia, place a cloth pad

beneath the screwdriver.

3Disconnect the multi-plug from the rear of

the clock, and withdraw the clock (see

illustration).

Refitting

4Refitting is a reversal of the removal

procedure. Reset the clock on completion.

Removal

1Apply the handbrake, jack up the front of

the vehicle and support it on axle stands.

2Unscrew the bolts, and release the clips

securing the radiator lower cover to the front

of the vehicle.

3Disconnect the wiring from the horn

terminal.

4Unscrew the mounting bolt, and withdraw

the horn with its mounting bracket from under

the vehicle (see illustration).

Refitting

5Refitting is a reversal of the removal

procedure.

14 Horn - removal and refitting

13 Clock- removal and refitting

12 Speedometer drive cable -

removal and refitting

Body electrical system 12•15

12

12.9B . . . and disconnect the

speedometer cable from the vehicle speed

sensor13.2 Prising the clock out of the facia13.3 Disconnecting the multi-plug from

the rear of the clock

12.7A Squeeze the collar . . .12.7B . . . and disconnect the

speedometer main cable from the

intermediate cable12.9A Unscrew the cable nut . . .

procarmanuals.com