warning FORD MONDEO 1993 Service Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 149 of 279

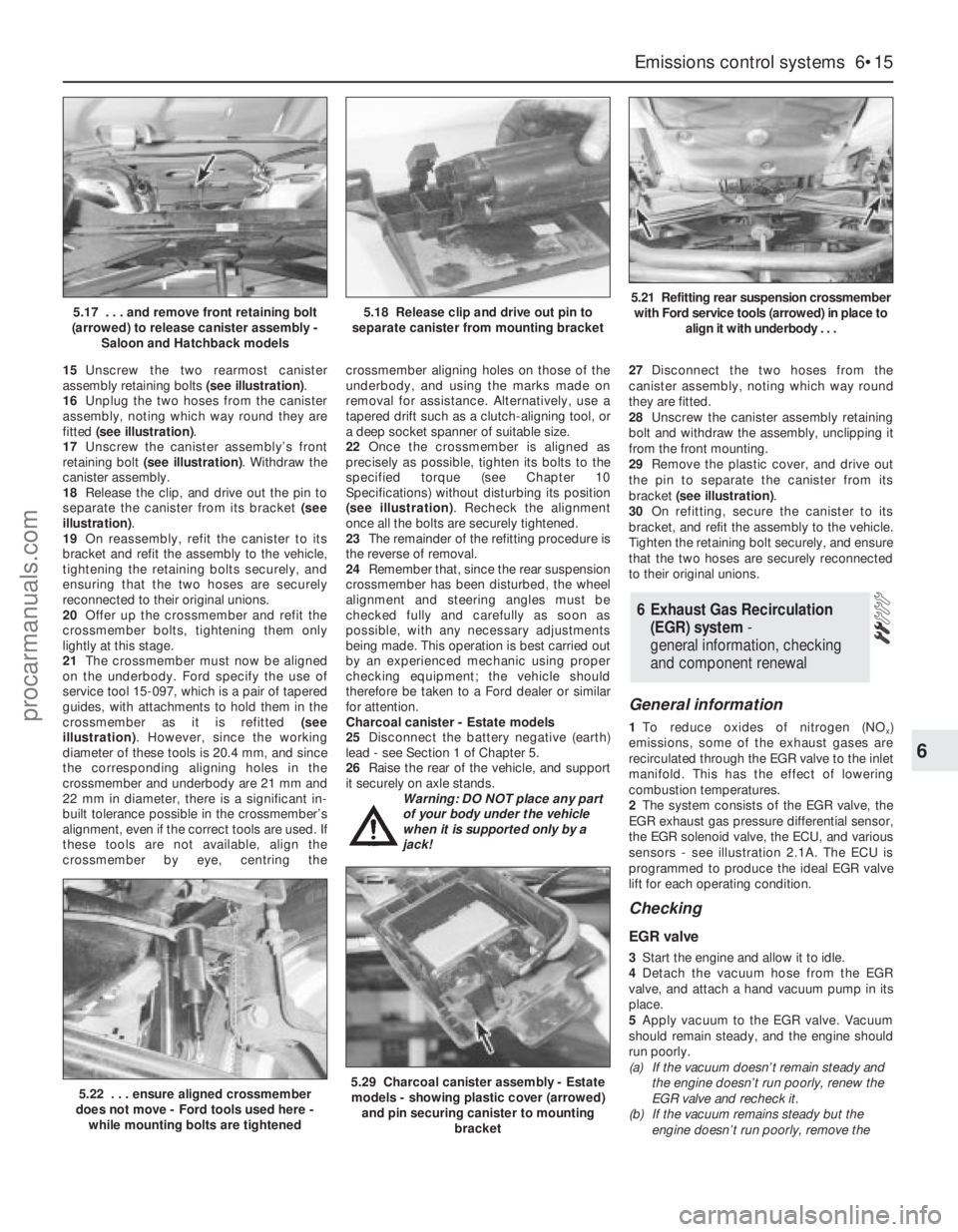

15Unscrew the two rearmost canister

assembly retaining bolts (see illustration).

16Unplug the two hoses from the canister

assembly, noting which way round they are

fitted (see illustration).

17Unscrew the canister assembly’s front

retaining bolt (see illustration). Withdraw the

canister assembly.

18Release the clip, and drive out the pin to

separate the canister from its bracket (see

illustration).

19On reassembly, refit the canister to its

bracket and refit the assembly to the vehicle,

tightening the retaining bolts securely, and

ensuring that the two hoses are securely

reconnected to their original unions.

20Offer up the crossmember and refit the

crossmember bolts, tightening them only

lightly at this stage.

21The crossmember must now be aligned

on the underbody. Ford specify the use of

service tool 15-097, which is a pair of tapered

guides, with attachments to hold them in the

crossmember as it is refitted (see

illustration). However, since the working

diameter of these tools is 20.4 mm, and since

the corresponding aligning holes in the

crossmember and underbody are 21 mm and

22 mm in diameter, there is a significant in-

built tolerance possible in the crossmember’s

alignment, even if the correct tools are used. If

these tools are not available, align the

crossmember by eye, centring thecrossmember aligning holes on those of the

underbody, and using the marks made on

removal for assistance. Alternatively, use a

tapered drift such as a clutch-aligning tool, or

a deep socket spanner of suitable size.

22Once the crossmember is aligned as

precisely as possible, tighten its bolts to the

specified torque (see Chapter 10

Specifications) without disturbing its position

(see illustration). Recheck the alignment

once all the bolts are securely tightened.

23The remainder of the refitting procedure is

the reverse of removal.

24Remember that, since the rear suspension

crossmember has been disturbed, the wheel

alignment and steering angles must be

checked fully and carefully as soon as

possible, with any necessary adjustments

being made. This operation is best carried out

by an experienced mechanic using proper

checking equipment; the vehicle should

therefore be taken to a Ford dealer or similar

for attention.

Charcoal canister - Estate models

25Disconnect the battery negative (earth)

lead - see Section 1 of Chapter 5.

26Raise the rear of the vehicle, and support

it securely on axle stands.

Warning: DO NOT place any part

of your body under the vehicle

when it is supported only by a

jack!27Disconnect the two hoses from the

canister assembly, noting which way round

they are fitted.

28Unscrew the canister assembly retaining

bolt and withdraw the assembly, unclipping it

from the front mounting.

29Remove the plastic cover, and drive out

the pin to separate the canister from its

bracket (see illustration).

30On refitting, secure the canister to its

bracket, and refit the assembly to the vehicle.

Tighten the retaining bolt securely, and ensure

that the two hoses are securely reconnected

to their original unions.

General information

1To reduce oxides of nitrogen (NOx)

emissions, some of the exhaust gases are

recirculated through the EGR valve to the inlet

manifold. This has the effect of lowering

combustion temperatures.

2The system consists of the EGR valve, the

EGR exhaust gas pressure differential sensor,

the EGR solenoid valve, the ECU, and various

sensors - see illustration 2.1A. The ECU is

programmed to produce the ideal EGR valve

lift for each operating condition.

Checking

EGR valve

3Start the engine and allow it to idle.

4Detach the vacuum hose from the EGR

valve, and attach a hand vacuum pump in its

place.

5Apply vacuum to the EGR valve. Vacuum

should remain steady, and the engine should

run poorly.

(a) If the vacuum doesn’t remain steady and

the engine doesn’t run poorly, renew the

EGR valve and recheck it.

(b) If the vacuum remains steady but the

engine doesn’t run poorly, remove the

6 Exhaust Gas Recirculation

(EGR) system-

general information, checking

and component renewal

Emissions control systems 6•15

6

5.22 . . . ensure aligned crossmember

does not move - Ford tools used here -

while mounting bolts are tightened5.29 Charcoal canister assembly - Estate

models - showing plastic cover (arrowed)

and pin securing canister to mounting

bracket

5.17 . . . and remove front retaining bolt

(arrowed) to release canister assembly -

Saloon and Hatchback models5.18 Release clip and drive out pin to

separate canister from mounting bracket5.21 Refitting rear suspension crossmember

with Ford service tools (arrowed) in place to

align it with underbody . . .

procarmanuals.com

Page 159 of 279

Since most of the procedures dealt with in

this Chapter involve jacking up the vehicle

and working underneath it, a good pair of axle

stands will be needed. A hydraulic trolley jack

is the preferred type of jack to lift the vehicle,

and it can also be used to support certain

components during removal and refitting

operations.

Warning: Never, under any

circumstances, rely on a jack to

support the vehicle while working

beneath it. When jacking up the vehicle, do

not lift or support it beneath the front or

rear subframes.

Removal

1Apply the handbrake. Remove the wheel

cover from the relevant front wheel, and

loosen (but do not remove) the driveshaft/hub

nut. This nut is very tight.

2Loosen the front wheel nuts, jack up the

front of the vehicle and support it on axle

stands. Remove the front wheel.

3Extract the split pin from the track rod end

balljoint nut. Unscrew the nut, and detach the

rod from the arm on the steering knuckle

using a conventional balljoint removal tool.

Take care not to damage the balljoint seal.

4Remove the ABS sensor (when fitted) as

described in Chapter 9.

5Remove the brake caliper and brake disc as

described in Chapter 9, but do not disconnect

the flexible hose from the caliper. Suspend

the caliper from a suitable point under the

wheel arch, taking care not to strain the hose.

6Unscrew and remove the driveshaft/hub

nut. Note that the nut is of special laminated

design, and should only be re-used a

maximum of 5 times. (It is a good idea to file a

small notch on the nut every time it is

removed.) Obtain a new nut if necessary.

7Note which way round the lower arm

balljoint clamp bolt is fitted, then unscrew and

remove it from the knuckle assembly. Lever

the balljoint down from the knuckle; if it is

tight, prise the clamp open using a large flat-

bladed tool. Take care not to damage the

balljoint seal during the separation procedure.

8Unscrew and remove the pinch-bolt

securing the steering knuckle assembly to the

front suspension strut, noting which way

round it is fitted. Prise open the clamp using a

wedge-shaped tool, and release the knuckle

from the strut. If necessary, tap the knuckle

downwards with a soft-headed mallet to

separate the two components. Support the

knuckle on an axle stand.

9Pull the steering knuckle and hub assembly

from the driveshaft splines. If it is tight,

connect a universal puller to the hub flange,

and withdraw it from the driveshaft. When the

driveshaft is free, support it on an axle stand,

or suspend it from a suitable point under thewheel arch, making sure that the inner

constant velocity joint is not turned through

more than 18°. (Damage may occur if the joint

is turned through too great an angle.)

Refitting

10Lift the steering knuckle and hub

assembly onto the driveshaft splines, and

support the assembly on an axle stand.

11Locate the assembly on the front

suspension strut. Insert the pinch-bolt with its

head facing forwards. Fit the nut and tighten it

to the specified torque.

12Refit the lower arm balljoint to the knuckle

assembly, and insert the clamp bolt with its

head facing forwards. Refit the nut and tighten

it to the specified torque.

13Refit the driveshaft/hub nut, and tighten it

moderately at this stage. Final tightening of

the nut is made with the vehicle lowered to the

ground.

14Refit the brake caliper and brake disc as

described in Chapter 9.

15Where fitted, refit the ABS sensor as

described in Chapter 9.

16Reconnect the track rod end balljoint to

the steering arm, and tighten the nut to the

specified torque. Check that the split pin

holes are aligned; if necessary, turn the nut to

the nearest alignment, making sure that the

torque wrench setting is still within the

specified range. Insert a new split pin, and

bend it back to secure.

17Refit the front wheel, and lower the

vehicle to the ground. Tighten the wheel nuts

to the specified torque.

18Tighten the driveshaft/hub nut to the

specified torque, and refit the wheel cover.

Inspection

1The front hub bearings are non-adjustable,

and are supplied already greased.

2To check the bearings for excessive wear,

apply the handbrake, jack up the front of the

vehicle and support it on axle stands.

3Grip the front wheel at top and bottom, and

attempt to rock it. If excessive movement is

noted, it may be that the hub bearings are

worn. Do not confuse wear in the driveshaft

outer joint or front suspension lower arm

balljoint with wear in the bearings. Hub

bearing wear will show up as roughness or

vibration when the wheel is spun; it will also

be noticeable as a rumbling or growling noise

when driving.

Renewal

4Remove the steering knuckle and hub

assembly as described in Section 2.

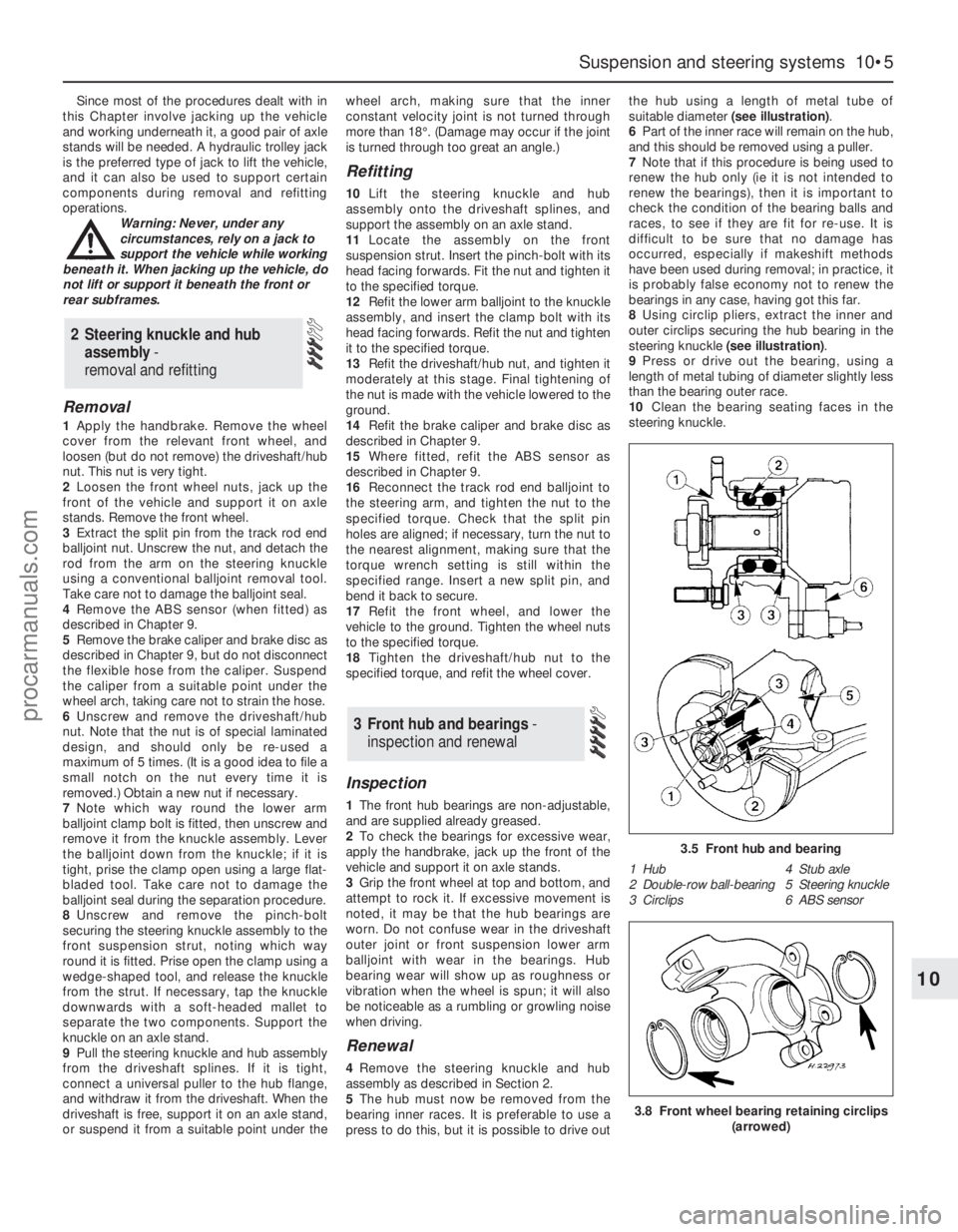

5The hub must now be removed from the

bearing inner races. It is preferable to use a

press to do this, but it is possible to drive outthe hub using a length of metal tube of

suitable diameter (see illustration).

6Part of the inner race will remain on the hub,

and this should be removed using a puller.

7Note that if this procedure is being used to

renew the hub only (ie it is not intended to

renew the bearings), then it is important to

check the condition of the bearing balls and

races, to see if they are fit for re-use. It is

difficult to be sure that no damage has

occurred, especially if makeshift methods

have been used during removal; in practice, it

is probably false economy not to renew the

bearings in any case, having got this far.

8Using circlip pliers, extract the inner and

outer circlips securing the hub bearing in the

steering knuckle (see illustration).

9Press or drive out the bearing, using a

length of metal tubing of diameter slightly less

than the bearing outer race.

10Clean the bearing seating faces in the

steering knuckle.

3 Front hub and bearings -

inspection and renewal

2 Steering knuckle and hub

assembly -

removal and refitting

Suspension and steering systems 10•5

10

3.5 Front hub and bearing

1 Hub 4 Stub axle

2 Double-row ball-bearing 5 Steering knuckle

3 Circlips 6 ABS sensor

3.8 Front wheel bearing retaining circlips

(arrowed)

procarmanuals.com

Page 161 of 279

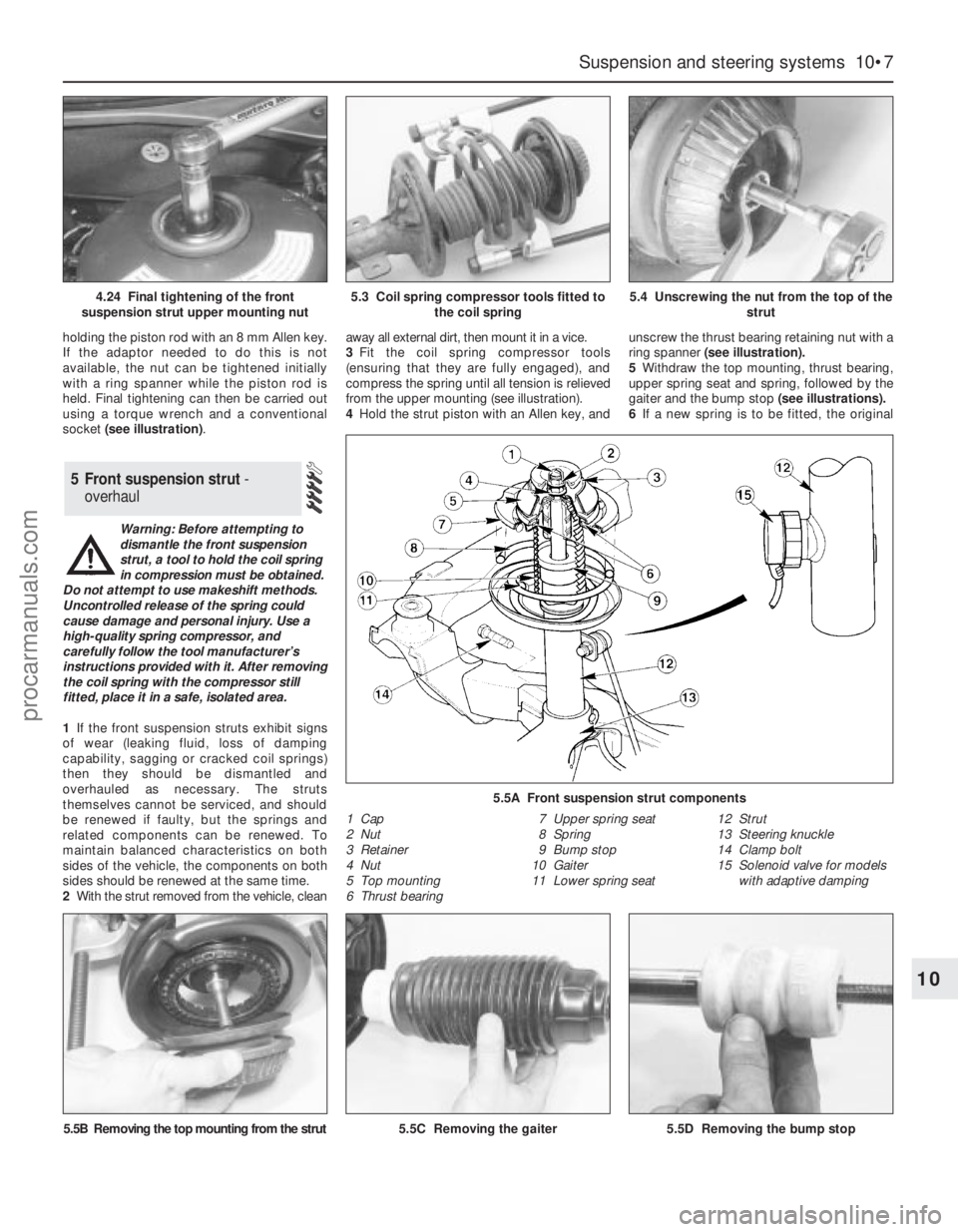

holding the piston rod with an 8 mm Allen key.

If the adaptor needed to do this is not

available, the nut can be tightened initially

with a ring spanner while the piston rod is

held. Final tightening can then be carried out

using a torque wrench and a conventional

socket (see illustration).

Warning: Before attempting to

dismantle the front suspension

strut, a tool to hold the coil spring

in compression must be obtained.

Do not attempt to use makeshift methods.

Uncontrolled release of the spring could

cause damage and personal injury. Use a

high-quality spring compressor, and

carefully follow the tool manufacturer’s

instructions provided with it. After removing

the coil spring with the compressor still

fitted, place it in a safe, isolated area.

1If the front suspension struts exhibit signs

of wear (leaking fluid, loss of damping

capability, sagging or cracked coil springs)

then they should be dismantled and

overhauled as necessary. The struts

themselves cannot be serviced, and should

be renewed if faulty, but the springs and

related components can be renewed. To

maintain balanced characteristics on both

sides of the vehicle, the components on both

sides should be renewed at the same time.

2With the strut removed from the vehicle, cleanaway all external dirt, then mount it in a vice.

3Fit the coil spring compressor tools

(ensuring that they are fully engaged), and

compress the spring until all tension is relieved

from the upper mounting (see illustration).

4Hold the strut piston with an Allen key, andunscrew the thrust bearing retaining nut with a

ring spanner (see illustration).

5Withdraw the top mounting, thrust bearing,

upper spring seat and spring, followed by the

gaiter and the bump stop (see illustrations).

6If a new spring is to be fitted, the original

5 Front suspension strut -

overhaul

Suspension and steering systems 10•7

10

5.5A Front suspension strut components

1 Cap

2 Nut

3 Retainer

4 Nut

5 Top mounting

6 Thrust bearing7 Upper spring seat

8 Spring

9 Bump stop

10 Gaiter

11 Lower spring seat12 Strut

13 Steering knuckle

14 Clamp bolt

15 Solenoid valve for models

with adaptive damping

4.24 Final tightening of the front

suspension strut upper mounting nut5.3 Coil spring compressor tools fitted to

the coil spring5.4 Unscrewing the nut from the top of the

strut

5.5B Removing the top mounting from the strut5.5C Removing the gaiter5.5D Removing the bump stop

procarmanuals.com

Page 164 of 279

Note:Removal of the rear hub from the

knuckle damages the bearings, and renders

them unserviceable for future use. The hub

and bearing assembly mustalways be

renewed if it is removed.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate rear wheel.

2When applicable, remove the ABS sensor

from the knuckle as described in Chapter 9.

3Remove the rear hub and bearing assembly

as described in Section 9.

Drum brake models

4Fit a brake hose clamp to the flexible brake

hose, then release the clip and detach the

flexible hose from the strut. Unscrew the

union nut, and detach the rigid brake pipe

from the wheel cylinder. If preferred (to

eliminate any bleeding procedure during

refitting) the rigid brake pipe may remain

attached to the wheel cylinder, provided that

care is taken to prevent damage to both the

rigid and flexible brake pipes.

5Unbolt the backplate from the rear

suspension knuckle (see illustration), and

support it to one side on an axle stand. The

brake shoes and handbrake cable can remain

attached.

Disc brake models

6Unbolt the splash shield from the rear

suspension knuckle.

All models

7Unscrew and remove the bolt securing the

tie-bar to the bottom of the knuckle, and

move the tie-bar downwards.

8Unscrew and remove the bolts securing the

front and rear lower arms to the knuckle, and

move the arms to one side.

9Support the knuckle on an axle stand, then

unscrew and remove the clamp bolt securing

the knuckle to the strut.

10Prise the top of the knuckle apart carefully

using a large flat-bladed tool, and withdrawthe knuckle downwards from the strut.

Withdraw the knuckle from under the rear

wheel arch.

Refitting

11Locate the knuckle fully on the strut, then

insert the clamp bolt and tighten to the

specified torque.

12Refit the front and rear lower arms to the

knuckle, and insert the bolts finger-tight at

this stage.

13Refit the tie-bar to the bottom of the

knuckle, and insert the bolt finger-tight at this

stage.

14Refit the backplate (or splash shield, as

applicable) to the rear suspension knuckle,

and tighten the bolts to the specified torque.

Drum brake models

15Reconnect the rigid brake pipe to the

wheel cylinder (if disconnected), and tighten

the union nut.

16Attach the flexible hose to the strut, refit

the clip, and remove the hose clamp.

All models

17Fit a new rear hub and bearing assembly

as described in Section 9.

18Where applicable, refit the ABS sensor as

described in Chapter 9.

19Refit the wheel, and lower the vehicle to

the ground.

20With the weight of the vehicle on the

suspension, fully tighten the mounting bolts

for the tie-bar and lower arms.

21Where applicable, bleed the hydraulic

brake circuit as described in Chapter 9.

Note:Before attempting to remove the rear

suspension strut, a tool to hold the coil spring

in compression must be obtained. Careful use

of conventional coil spring compressors will

prove satisfactory.

Removal

1In order to remove the rear suspension

strut, the coil spring must be temporarily

compressed. This will enable the piston rod tobe retracted into the strut, and will provide

additional room for releasing the strut from

the bump stop on top of the rear suspension

crossmember.

Warning: It is important to only

use a high-quality spring

compressor; carefully follow the

tool manufacturer’s instructions

provided with it.

2Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate wheel.

3Where fitted, unclip the ABS sensor wiring

from the strut, and remove the sensor from

the knuckle as described in Chapter 9 (see

illustration).

4On models fitted with adaptive damping,

unclip the wiring from the strut and

disconnect the multi-plug (see illustration).

5On drum brake models, fit a brake hose

clamp to the rear flexible brake hose, then

unscrew the union nut securing the rigid brake

pipe to the flexible hose on the strut. Extract

the clip, and disconnect the flexible hose from

the strut.

6On models fitted with rear disc brakes,

unbolt the caliper from the knuckle as

described in Chapter 9, but leave the

hydraulic hose attached. Support the caliper

on an axle stand, making sure that the flexible

hose is not strained.

7Unscrew the nut securing the rear anti-roll

bar link to the front lower arm on the

appropriate side. Hold the actual link with an

adjustable spanner or grips while unscrewing

the nut, to prevent damage to the link joint.

8Unscrew and remove the bolt securing the

tie-bar to the bottom of the knuckle. Move the

tie-bar downwards (see illustrations).

9Unscrew and remove the bolts securing the

front and rear lower arms to the knuckle, and

move the arms to one side (see illustrations).

10Support the knuckle on a trolley jack, then

unscrew and remove the clamp bolt securing

the knuckle to the strut (see illustrations).

11Prise the clamp on the knuckle apart

using a large flat-bladed tool. Disconnect the

knuckle from the strut, and lower it on the

trolley jack as far as possible, taking care not

to damage the handbrake cable (see

illustration).

11 Rear suspension strut

(Saloon/Hatchback models) -

removal and refitting

10 Rear suspension knuckle

(Saloon/Hatchback models)-

removal and refitting

10•10 Suspension and steering systems

10.5 Two of the bolts securing the brake

backplate to the rear suspension knuckle11.3 Unclipping the ABS sensor wiring

from the strut11.4 Location of the adaptive damping

lead (1) and multi-plug (2)

procarmanuals.com

Page 168 of 279

actual links stationary while the nuts are being

unscrewed, to prevent damage to the joints.

Swivel the anti-roll bar upwards, and recover

the rubber bushes.

5Where applicable, remove the ABS wheel

sensor from the rear suspension knuckle as

described in Chapter 9.

6Unscrew and remove the bolts, and

disconnect both lower arms from the rear

suspension knuckle.

7To allow the rear suspension struts to be

released from the rubber stops on the top of

the crossmember, it is necessary to fit coil

spring compressor tools to both of the rear

coil springs, and compress them until all

tension is removed from the upper and lower

mountings.

Warning: It is important to only

use high-quality spring

compressors, and to carefully

follow the tool manufacturer’s

instructions provided with them. With the

compressor tools fitted, support the struts

to one side.

8Support the rear suspension crossmember

on a trolley jack, then unscrew the four

mounting bolts from the underbody (see

illustration).

9Lower the crossmember to the ground.

10Unscrew the bolts securing the anti-roll

bar clamps to the crossmember, then remove

the clamps and withdraw the anti-roll bar.

11Remove the lower arms from the

crossmember as described in Section 14.

Refitting

12Refitting is a reversal of the removal

procedure. Ford specify the use of a special

tool (tool number 15-097) to accurately align

the crossmember onto the underbody before

tightening the mounting bolts. This tool

should be obtained if possible, since

inaccurate alignment would result in bad

handling and excessive tyre wear. The tie-bar

and arm mounting bolts should be finger-

tightened initially, and only fully tightened

after the vehicle is lowered to the ground, so

that its weight is on the rear suspension. The

rear toe setting should be checked, and if

necessary adjusted, at the earliest

opportunity.

Inspection

1The rear hub bearings are non-adjustable,

and are supplied complete with the hub. It is

not possible to renew the bearings separately

from the hub.

2To check the bearings for excessive wear,

chock the front wheels, then jack up the rear

of the vehicle and support it on axle stands.

Fully release the handbrake.

3Grip the rear wheel at the top and bottom,

and attempt to rock it. If excessive movement

is noted, or if there is any roughness or

vibration felt when the wheel is spun, it is

indicative that the hub bearings are worn.

Renewal

4Remove the rear wheel.

5On drum brake models, remove the rear

brake drum as described in Chapter 9.

6On disc brake models, remove the rear

brake disc as described in Chapter 9.

7Turning the hub as necessary, line up the

hole in the flange with the each of the bolts

securing the hub assembly to the rear

suspension knuckle; unscrew and remove the

bolts (see illustration).

8Withdraw the hub and bearing assembly.

Refit two of the hub mounting bolts, to hold

the backplate/splash shield in place.

9If necessary, the stub shaft may be

removed from the hub for inspection of the

bearing, by unscrewing the hub nut. Note that

the hub nut is of special laminated design,

and may only be re-used a maximum of five

times. (It is a good idea to file a small notch on

the nut every time it is removed; obtain a new

nut if necessary.) Tighten the nut on

reassembly.

10Fit the new hub and bearing assembly

using a reversal of the removal procedure.

Tighten all nuts and bolts to the specified

torque.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate rear wheel,

and release the handbrake.

2Position a trolley jack or axle stand beneath

the rear suspension lower arm, to keep the

coil spring in compression.

3Where applicable, remove the ABS sensor

as described in Chapter 9.

Drum brake models

4Remove the rear brake drum as described

in Chapter 9.

5Disconnect the flexible hydraulic brake

hose at the bracket on the rear suspension

crossmember as described in Chapter 9.

Disc brake models

6Remove the rear brake disc as described in

Chapter 9.

All models

7Remove the rear hub as described in

Section 17.

8Remove the backplate or splash shield, as

applicable. On drum brake models, support

the backplate assembly on an axle stand, to

prevent damage to the handbrake cable.

9Unscrew and remove the shock absorber

lower mounting bolt.

10Unscrew and remove the three bolts

securing the tie-bar to the knuckle.

11Unscrew and remove the bolt securing

the front lower arm to the knuckle.

12Unscrew and remove the bolt securing

the upper arm to the knuckle.

13Support the knuckle, then unscrew and

remove the bolt securing the rear lower arm to

the knuckle, and withdraw the knuckle.

Refitting

14Refitting is a reversal of the removal

procedure, but delay fully tightening the

rubber bush mounting bolts until the weight of

the vehicle is on the suspension. Tighten all

bolts to the specified torque. Where the

flexible rear brake hose was disconnected,

bleed the hydraulic system as described in

Chapter 9. Finally check, and if necessary

adjust, the rear wheel toe setting as described

in Section 36.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate wheel.

19 Rear shock absorber

(Estate models) -

removal, testing and refitting

18 Rear suspension knuckle

(Estate models) -

removal and refitting

17 Rear hub and bearings

(Estate models) -

inspection and renewal

10•14 Suspension and steering systems

16.8 One of the rear suspension

crossmember mounting bolts

17.7 Mounting bolts (arrowed) for the rear

hub on Estate models

procarmanuals.com

Page 171 of 279

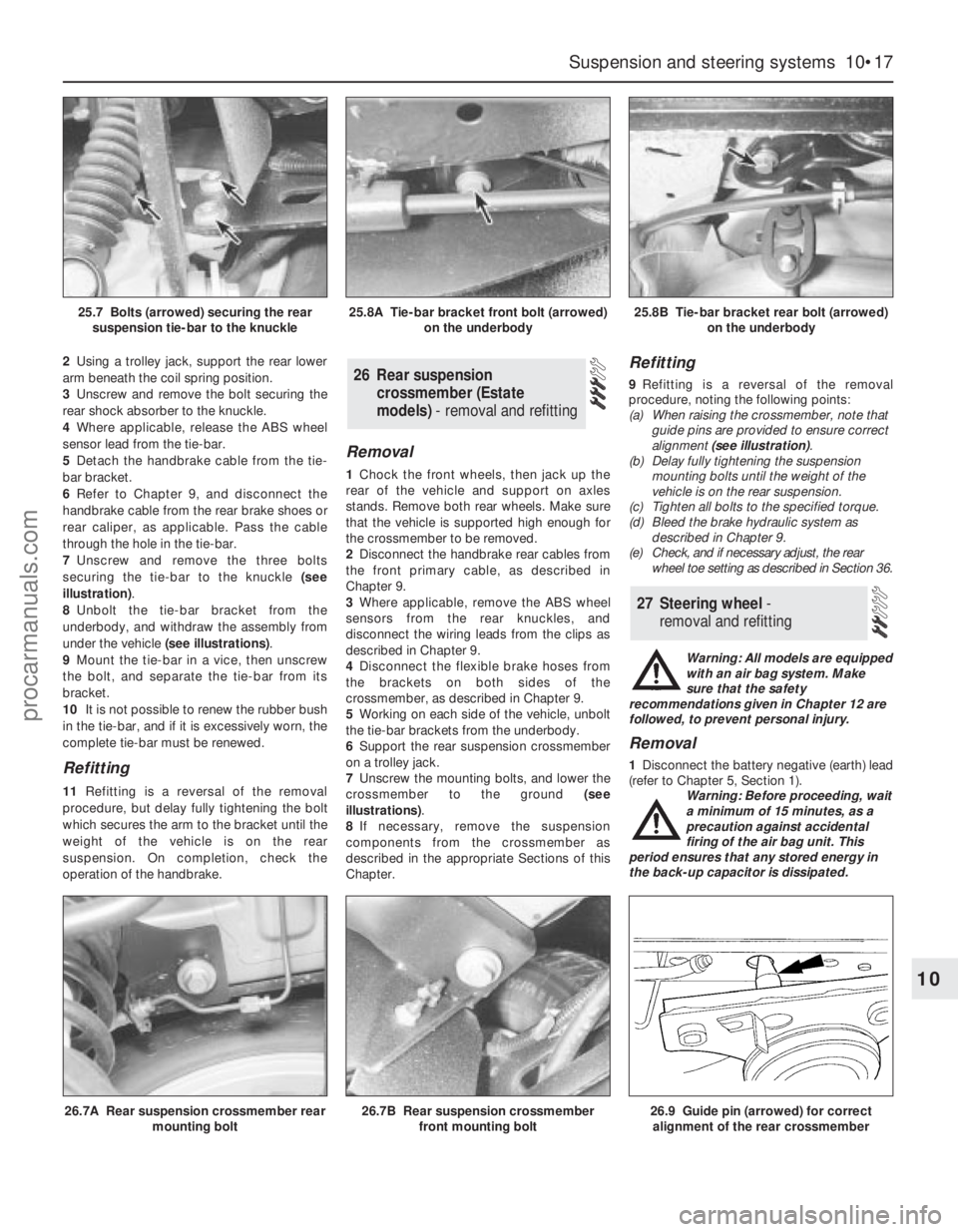

2Using a trolley jack, support the rear lower

arm beneath the coil spring position.

3Unscrew and remove the bolt securing the

rear shock absorber to the knuckle.

4Where applicable, release the ABS wheel

sensor lead from the tie-bar.

5Detach the handbrake cable from the tie-

bar bracket.

6Refer to Chapter 9, and disconnect the

handbrake cable from the rear brake shoes or

rear caliper, as applicable. Pass the cable

through the hole in the tie-bar.

7Unscrew and remove the three bolts

securing the tie-bar to the knuckle (see

illustration).

8Unbolt the tie-bar bracket from the

underbody, and withdraw the assembly from

under the vehicle (see illustrations).

9Mount the tie-bar in a vice, then unscrew

the bolt, and separate the tie-bar from its

bracket.

10It is not possible to renew the rubber bush

in the tie-bar, and if it is excessively worn, the

complete tie-bar must be renewed.

Refitting

11Refitting is a reversal of the removal

procedure, but delay fully tightening the bolt

which secures the arm to the bracket until the

weight of the vehicle is on the rear

suspension. On completion, check the

operation of the handbrake.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support on axles

stands. Remove both rear wheels. Make sure

that the vehicle is supported high enough for

the crossmember to be removed.

2Disconnect the handbrake rear cables from

the front primary cable, as described in

Chapter 9.

3Where applicable, remove the ABS wheel

sensors from the rear knuckles, and

disconnect the wiring leads from the clips as

described in Chapter 9.

4Disconnect the flexible brake hoses from

the brackets on both sides of the

crossmember, as described in Chapter 9.

5Working on each side of the vehicle, unbolt

the tie-bar brackets from the underbody.

6Support the rear suspension crossmember

on a trolley jack.

7Unscrew the mounting bolts, and lower the

crossmember to the ground (see

illustrations).

8If necessary, remove the suspension

components from the crossmember as

described in the appropriate Sections of this

Chapter.

Refitting

9Refitting is a reversal of the removal

procedure, noting the following points:

(a) When raising the crossmember, note that

guide pins are provided to ensure correct

alignment (see illustration).

(b) Delay fully tightening the suspension

mounting bolts until the weight of the

vehicle is on the rear suspension.

(c) Tighten all bolts to the specified torque.

(d) Bleed the brake hydraulic system as

described in Chapter 9.

(e) Check, and if necessary adjust, the rear

wheel toe setting as described in Section 36.

Warning: All models are equipped

with an air bag system. Make

sure that the safety

recommendations given in Chapter 12 are

followed, to prevent personal injury.

Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

Warning: Before proceeding, wait

a minimum of 15 minutes, as a

precaution against accidental

firing of the air bag unit. This

period ensures that any stored energy in

the back-up capacitor is dissipated.

27 Steering wheel -

removal and refitting

26 Rear suspension

crossmember (Estate

models) - removal and refitting

Suspension and steering systems 10•17

10

26.7A Rear suspension crossmember rear

mounting bolt26.7B Rear suspension crossmember

front mounting bolt26.9 Guide pin (arrowed) for correct

alignment of the rear crossmember

25.7 Bolts (arrowed) securing the rear

suspension tie-bar to the knuckle25.8A Tie-bar bracket front bolt (arrowed)

on the underbody25.8B Tie-bar bracket rear bolt (arrowed)

on the underbody

procarmanuals.com

Page 172 of 279

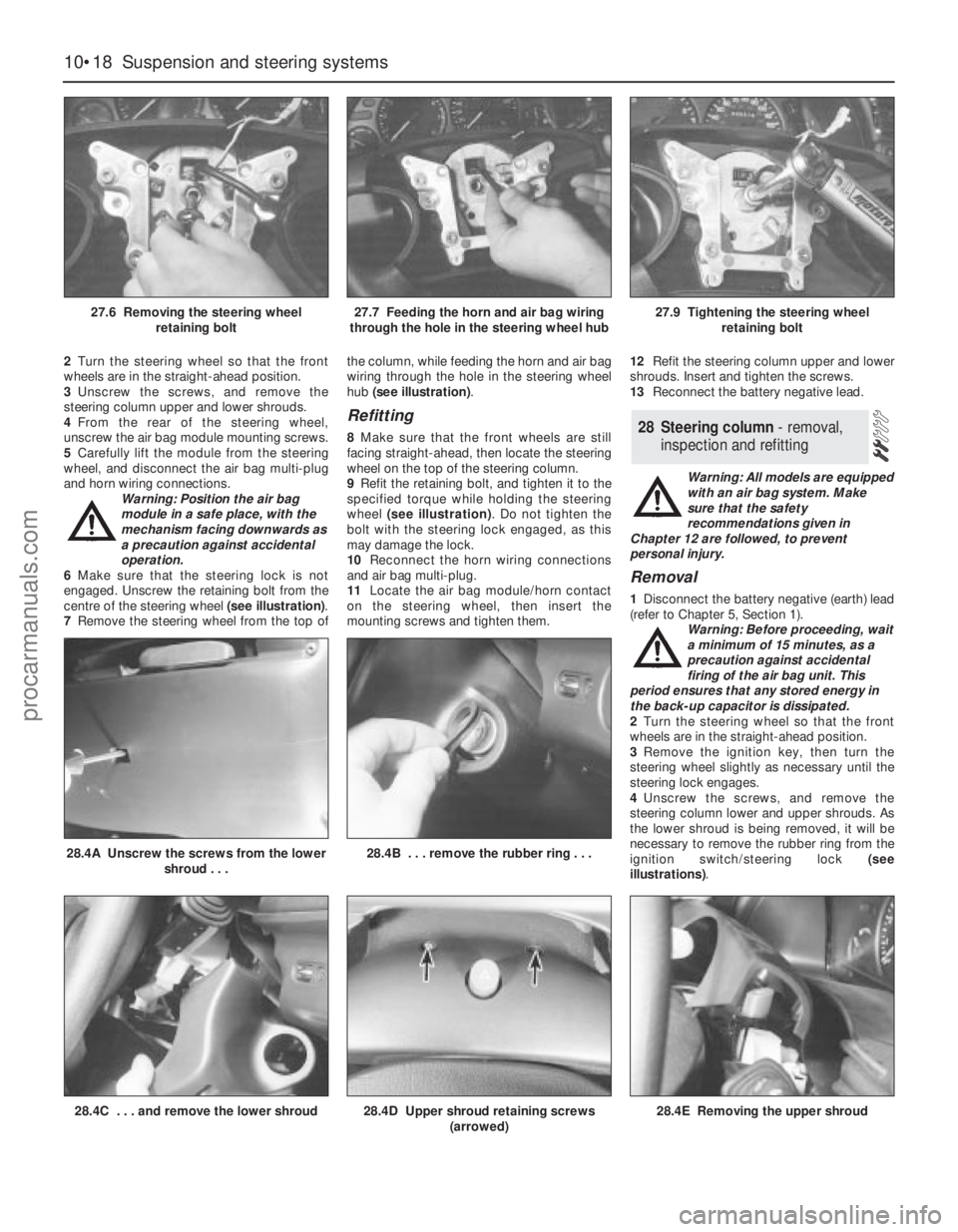

2Turn the steering wheel so that the front

wheels are in the straight-ahead position.

3Unscrew the screws, and remove the

steering column upper and lower shrouds.

4From the rear of the steering wheel,

unscrew the air bag module mounting screws.

5Carefully lift the module from the steering

wheel, and disconnect the air bag multi-plug

and horn wiring connections.

Warning: Position the air bag

module in a safe place, with the

mechanism facing downwards as

a precaution against accidental

operation.

6Make sure that the steering lock is not

engaged. Unscrew the retaining bolt from the

centre of the steering wheel (see illustration).

7Remove the steering wheel from the top ofthe column, while feeding the horn and air bag

wiring through the hole in the steering wheel

hub (see illustration).

Refitting

8Make sure that the front wheels are still

facing straight-ahead, then locate the steering

wheel on the top of the steering column.

9Refit the retaining bolt, and tighten it to the

specified torque while holding the steering

wheel (see illustration). Do not tighten the

bolt with the steering lock engaged, as this

may damage the lock.

10Reconnect the horn wiring connections

and air bag multi-plug.

11Locate the air bag module/horn contact

on the steering wheel, then insert the

mounting screws and tighten them.12Refit the steering column upper and lower

shrouds. Insert and tighten the screws.

13Reconnect the battery negative lead.

Warning: All models are equipped

with an air bag system. Make

sure that the safety

recommendations given in

Chapter 12 are followed, to prevent

personal injury.

Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

Warning: Before proceeding, wait

a minimum of 15 minutes, as a

precaution against accidental

firing of the air bag unit. This

period ensures that any stored energy in

the back-up capacitor is dissipated.

2Turn the steering wheel so that the front

wheels are in the straight-ahead position.

3Remove the ignition key, then turn the

steering wheel slightly as necessary until the

steering lock engages.

4Unscrew the screws, and remove the

steering column lower and upper shrouds. As

the lower shroud is being removed, it will be

necessary to remove the rubber ring from the

ignition switch/steering lock (see

illustrations).

28 Steering column - removal,

inspection and refitting

10•18 Suspension and steering systems

27.6 Removing the steering wheel

retaining bolt27.7 Feeding the horn and air bag wiring

through the hole in the steering wheel hub27.9 Tightening the steering wheel

retaining bolt

28.4C . . . and remove the lower shroud28.4D Upper shroud retaining screws

(arrowed)

28.4A Unscrew the screws from the lower

shroud . . .28.4B . . . remove the rubber ring . . .

28.4E Removing the upper shroud

procarmanuals.com

Page 196 of 279

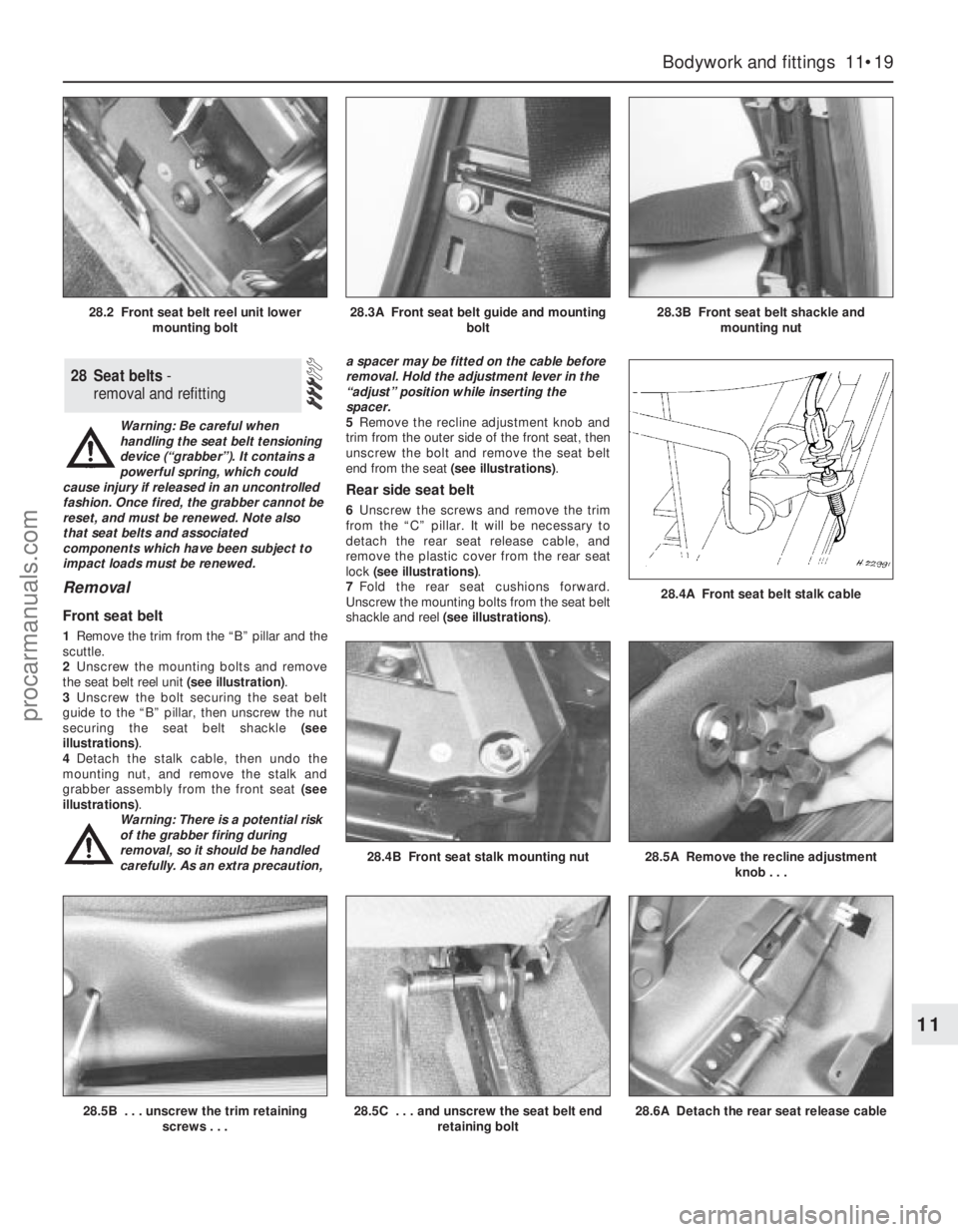

Warning: Be careful when

handling the seat belt tensioning

device (“grabber”). It contains a

powerful spring, which could

cause injury if released in an uncontrolled

fashion. Once fired, the grabber cannot be

reset, and must be renewed. Note also

that seat belts and associated

components which have been subject to

impact loads must be renewed.

Removal

Front seat belt

1Remove the trim from the “B” pillar and the

scuttle.

2Unscrew the mounting bolts and remove

the seat belt reel unit (see illustration).

3Unscrew the bolt securing the seat belt

guide to the “B” pillar, then unscrew the nut

securing the seat belt shackle (see

illustrations).

4Detach the stalk cable, then undo the

mounting nut, and remove the stalk and

grabber assembly from the front seat (see

illustrations).

Warning: There is a potential risk

of the grabber firing during

removal, so it should be handled

carefully. As an extra precaution,a spacer may be fitted on the cable before

removal. Hold the adjustment lever in the

“adjust” position while inserting the

spacer.

5Remove the recline adjustment knob and

trim from the outer side of the front seat, then

unscrew the bolt and remove the seat belt

end from the seat (see illustrations).

Rear side seat belt

6Unscrew the screws and remove the trim

from the “C” pillar. It will be necessary to

detach the rear seat release cable, and

remove the plastic cover from the rear seat

lock (see illustrations).

7Fold the rear seat cushions forward.

Unscrew the mounting bolts from the seat belt

shackle and reel (see illustrations).

28 Seat belts -

removal and refitting

Bodywork and fittings 11•19

11

28.5B . . . unscrew the trim retaining

screws . . .28.5C . . . and unscrew the seat belt end

retaining bolt28.6A Detach the rear seat release cable

28.4A Front seat belt stalk cable

28.4B Front seat stalk mounting nut28.5A Remove the recline adjustment

knob . . .

28.2 Front seat belt reel unit lower

mounting bolt28.3A Front seat belt guide and mounting

bolt28.3B Front seat belt shackle and

mounting nut

procarmanuals.com

Page 200 of 279

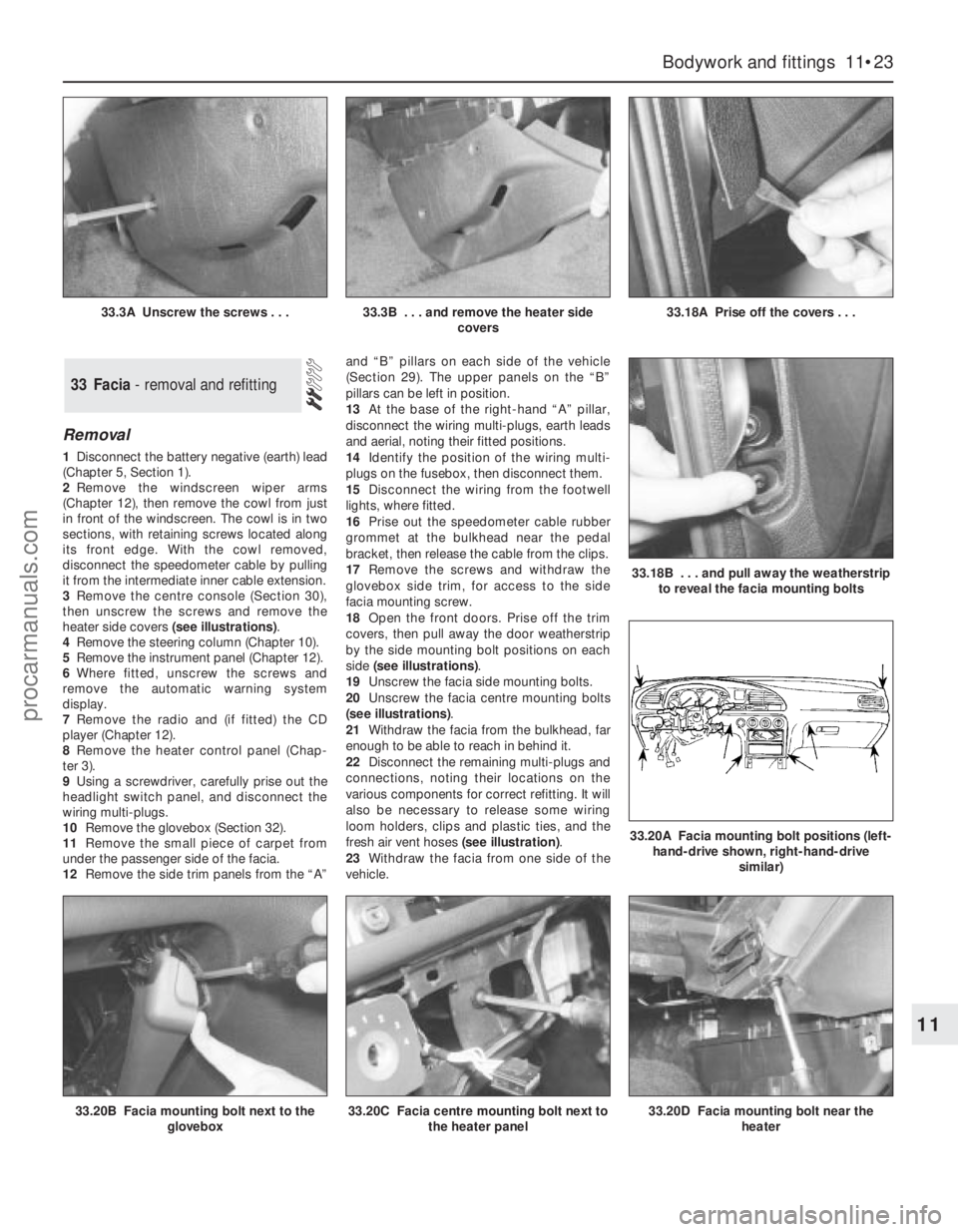

Removal

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2Remove the windscreen wiper arms

(Chapter 12), then remove the cowl from just

in front of the windscreen. The cowl is in two

sections, with retaining screws located along

its front edge. With the cowl removed,

disconnect the speedometer cable by pulling

it from the intermediate inner cable extension.

3Remove the centre console (Section 30),

then unscrew the screws and remove the

heater side covers (see illustrations).

4Remove the steering column (Chapter 10).

5Remove the instrument panel (Chapter 12).

6Where fitted, unscrew the screws and

remove the automatic warning system

display.

7Remove the radio and (if fitted) the CD

player (Chapter 12).

8Remove the heater control panel (Chap-

ter 3).

9Using a screwdriver, carefully prise out the

headlight switch panel, and disconnect the

wiring multi-plugs.

10Remove the glovebox (Section 32).

11Remove the small piece of carpet from

under the passenger side of the facia.

12Remove the side trim panels from the “A”and “B” pillars on each side of the vehicle

(Section 29). The upper panels on the “B”

pillars can be left in position.

13At the base of the right-hand “A” pillar,

disconnect the wiring multi-plugs, earth leads

and aerial, noting their fitted positions.

14Identify the position of the wiring multi-

plugs on the fusebox, then disconnect them.

15Disconnect the wiring from the footwell

lights, where fitted.

16Prise out the speedometer cable rubber

grommet at the bulkhead near the pedal

bracket, then release the cable from the clips.

17Remove the screws and withdraw the

glovebox side trim, for access to the side

facia mounting screw.

18Open the front doors. Prise off the trim

covers, then pull away the door weatherstrip

by the side mounting bolt positions on each

side (see illustrations).

19Unscrew the facia side mounting bolts.

20Unscrew the facia centre mounting bolts

(see illustrations).

21Withdraw the facia from the bulkhead, far

enough to be able to reach in behind it.

22Disconnect the remaining multi-plugs and

connections, noting their locations on the

various components for correct refitting. It will

also be necessary to release some wiring

loom holders, clips and plastic ties, and the

fresh air vent hoses (see illustration).

23Withdraw the facia from one side of the

vehicle.

33 Facia - removal and refitting

Bodywork and fittings 11•23

11

33.20B Facia mounting bolt next to the

glovebox33.20C Facia centre mounting bolt next to

the heater panel33.20D Facia mounting bolt near the

heater

33.3A Unscrew the screws . . .33.3B . . . and remove the heater side

covers33.18A Prise off the covers . . .

33.18B . . . and pull away the weatherstrip

to reveal the facia mounting bolts

33.20A Facia mounting bolt positions (left-

hand-drive shown, right-hand-drive

similar)

procarmanuals.com

Page 202 of 279

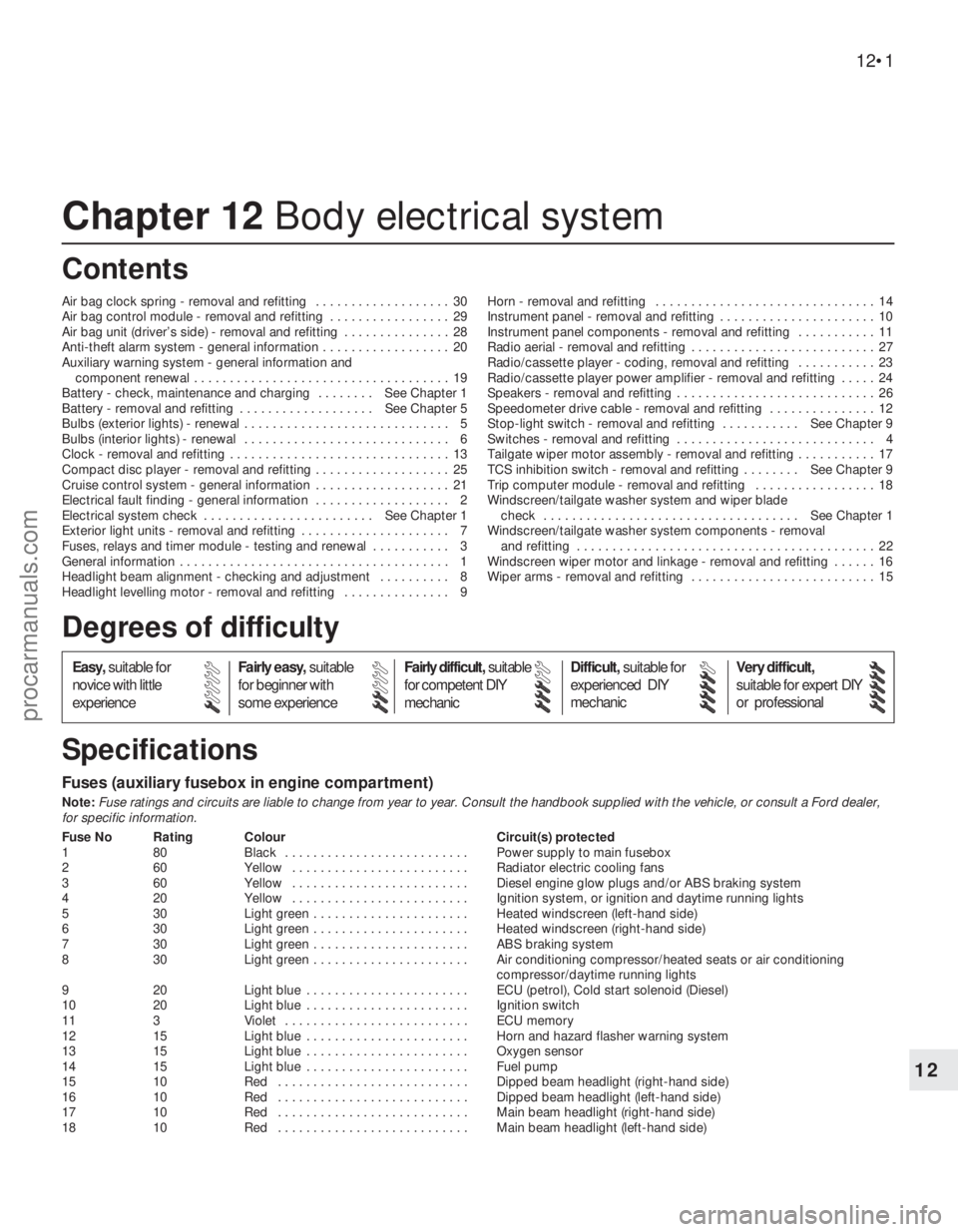

Chapter 12 Body electrical system

Air bag clock spring - removal and refitting . . . . . . . . . . . . . . . . . . . 30

Air bag control module - removal and refitting . . . . . . . . . . . . . . . . . 29

Air bag unit (driver’s side) - removal and refitting . . . . . . . . . . . . . . . 28

Anti-theft alarm system - general information . . . . . . . . . . . . . . . . . . 20

Auxiliary warning system - general information and

component renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Battery - check, maintenance and charging . . . . . . . . See Chapter 1

Battery - removal and refitting . . . . . . . . . . . . . . . . . . . See Chapter 5

Bulbs (exterior lights) - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bulbs (interior lights) - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Clock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Compact disc player - removal and refitting . . . . . . . . . . . . . . . . . . . 25

Cruise control system - general information . . . . . . . . . . . . . . . . . . . 21

Electrical fault finding - general information . . . . . . . . . . . . . . . . . . . 2

Electrical system check . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Exterior light units - removal and refitting . . . . . . . . . . . . . . . . . . . . . 7

Fuses, relays and timer module - testing and renewal . . . . . . . . . . . 3

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Headlight beam alignment - checking and adjustment . . . . . . . . . . 8

Headlight levelling motor - removal and refitting . . . . . . . . . . . . . . . 9Horn - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Instrument panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . 10

Instrument panel components - removal and refitting . . . . . . . . . . . 11

Radio aerial - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Radio/cassette player - coding, removal and refitting . . . . . . . . . . . 23

Radio/cassette player power amplifier - removal and refitting . . . . . 24

Speakers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Speedometer drive cable - removal and refitting . . . . . . . . . . . . . . . 12

Stop-light switch - removal and refitting . . . . . . . . . . . See Chapter 9

Switches - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Tailgate wiper motor assembly - removal and refitting . . . . . . . . . . . 17

TCS inhibition switch - removal and refitting . . . . . . . . See Chapter 9

Trip computer module - removal and refitting . . . . . . . . . . . . . . . . . 18

Windscreen/tailgate washer system and wiper blade

check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Windscreen/tailgate washer system components - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Windscreen wiper motor and linkage - removal and refitting . . . . . . 16

Wiper arms - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fuses (auxiliary fusebox in engine compartment)

Note:Fuse ratings and circuits are liable to change from year to year. Consult the handbook supplied with the vehicle, or consult a Ford dealer,

for specific information.

Fuse No Rating Colour Circuit(s) protected

1 80 Black . . . . . . . . . . . . . . . . . . . . . . . . . . Power supply to main fusebox

2 60 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . Radiator electric cooling fans

3 60 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . Diesel engine glow plugs and/or ABS braking system

4 20 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . Ignition system, or ignition and daytime running lights

5 30 Light green . . . . . . . . . . . . . . . . . . . . . . Heated windscreen (left-hand side)

6 30 Light green . . . . . . . . . . . . . . . . . . . . . . Heated windscreen (right-hand side)

7 30 Light green . . . . . . . . . . . . . . . . . . . . . . ABS braking system

8 30 Light green . . . . . . . . . . . . . . . . . . . . . . Air conditioning compressor/heated seats or air conditioning

compressor/daytime running lights

9 20 Light blue . . . . . . . . . . . . . . . . . . . . . . . ECU (petrol), Cold start solenoid (Diesel)

10 20 Light blue . . . . . . . . . . . . . . . . . . . . . . . Ignition switch

11 3 Violet . . . . . . . . . . . . . . . . . . . . . . . . . . ECU memory

12 15 Light blue . . . . . . . . . . . . . . . . . . . . . . . Horn and hazard flasher warning system

13 15 Light blue . . . . . . . . . . . . . . . . . . . . . . . Oxygen sensor

14 15 Light blue . . . . . . . . . . . . . . . . . . . . . . . Fuel pump

15 10 Red . . . . . . . . . . . . . . . . . . . . . . . . . . . Dipped beam headlight (right-hand side)

16 10 Red . . . . . . . . . . . . . . . . . . . . . . . . . . . Dipped beam headlight (left-hand side)

17 10 Red . . . . . . . . . . . . . . . . . . . . . . . . . . . Main beam headlight (right-hand side)

18 10 Red . . . . . . . . . . . . . . . . . . . . . . . . . . . Main beam headlight (left-hand side)

12•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,suitable

for competent DIY

mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Specifications Contents

12

procarmanuals.com