octane FORD MONDEO 1993 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 114 of 279

3Using an ohmmeter, measure the

resistance of the coil’s primary windings,

connecting the meter between the coil’s

terminal pins as follows. Measure first from

one outer pin to the centre pin, then from the

other outer pin to the centre. Compare your

readings with the coil primary resistance listed

in the Specifications Section at the beginning

of this Chapter.

4Disconnect the spark plug (HT) leads - note

their connections or label them carefully, as

described in Chapter 1. Use the meter to

check that there is continuity (ie, a resistance

corresponding to that of the coil secondary

winding) between each pair of (HT) lead

terminals; Nos 1 and 4 terminals are

connected by their secondary winding, as are

Nos 2 and 3. Now switch to the highest

resistance scale, and check that there is no

continuity between either pair of terminals and

the other - ie, there should be infinite

resistance between terminals 1 and 2, or 4

and 3 - and between any terminal and earth.

5If either of the above tests yield resistance

values outside the specified amount, or

results other than those described, renew the

coil. Any further testing should be left to a

dealer service department or other qualified

repair facility.

Removal and refitting

6Disconnect the battery negative (earth) lead

- see Section 1.

7Remove the air mass meter and resonator -

refer to Chapter 4.

8Unplug the electrical connector from each

side of the coil, then disconnect the spark

plug (HT) leads - note their connections or

label them carefully, as described in Chapter

1.

9Undo the two screws securing the EGR

pipe to the coil bracket, then remove the coil

mounting (Torx-type) screws. Withdraw the

coil assembly from the cylinder head (see

illustration).

10The suppressor can be unbolted from the

mounting bracket, if required; note that the

coil and bracket are only available as a single

unit.

11Refitting is the reverse of the removalprocedure. Ensure that the spark plug (HT)

leads are correctly reconnected, and tighten

the coil screws securely.

Note:See Chapter 6 for component location

illustrations.

1Disconnect the battery negative (earth) lead

- see Section 1.

2If better access is required, remove the

resonator (see Chapter 4).

3Unplug the electrical connector from the

module (see illustration).

4Remove the retaining screws, and detach

the module from the bulkhead mounting

bracket.

5Refitting is the reverse of the removal

procedure.

As noted in Section 4, the ignition timing is

controlled entirely by the ECU (acting with the

ignition module, on models with automatic

transmission), and cannot be adjusted. The

value quoted in the Specifications Section of

this Chapter is for reference only, and mayvary significantly if “checked” by simply

connecting a timing light to the system and

running the engine at idle speed.

Not only can the ignition timing not be

adjusted, it cannot be checked either, except

with the use of special diagnostic equipment

(see Chapter 6) - this makes it a task for a

Ford dealer service department.

Owners who are taking their vehicles

abroad should note that the ignition system is

set for the engine to use petrol of 95 RON

octane rating by fitting a “plug-in bridge” to

the service connector on the engine

compartment bulkhead (see illustration).

Removing the “plug-in bridge” retards the

ignition timing - by an unspecified value - to

allow the engine to run on 91 RON fuel. This

grade of fuel is the “Regular” or “Normal”

widely used abroad, but not at present

available in the UK. If you are taking the

vehicle abroad, seek the advice of a Ford

dealer (or of one of the motoring

organisations). This will ensure that you are

familiar with the grades of fuel you are likely to

find (and the sometimes confusing names for

those grades), and that the vehicle is set

correctly at all times for the fuel used. Note:

The octane ratings mentioned above are both,

of course, for unleadedpetrol. Do not use

leaded petrol at any time in a vehicle equipped

with a catalytic converter.

Checking

1See Section 4 of Chapter 6.

Removal and refitting

2Disconnect the battery negative (earth) lead

- see Section 1.

3Raise the front of the vehicle, and support it

securely on axle stands.

Warning: Do not place any part of

your body under a vehicle when

it’s supported only by a jack!

4Unplug the sensor’s electrical connector

(see illustration).

9 Crankshaft speed/position

sensor-

checking, removal and refitting

8 Ignition timing - checking

7 Ignition module (automatic

transmission models only) -

removal and refitting

5•4 Engine electrical systems

6.9 Unplug coil electrical connector (A),

suppressor connector (B), and spark

plug/HT leads (C), remove screws (D), then

undo Torx-type screws (E) to release

ignition coil assembly7.3 Separate ignition module is fitted to

automatic transmission models only - note

electrical connector (A) and retaining

screws (B)

8.3 Service connector (A) mounted on

engine compartment bulkhead is fitted with

“plug-in bridge” (B) to set engine to use

(unleaded) petrol of 95 RON octane rating9.4 Location of crankshaft speed/position

sensor - connector arrowed - in front of

cylinder block/crankcase

procarmanuals.com

Page 137 of 279

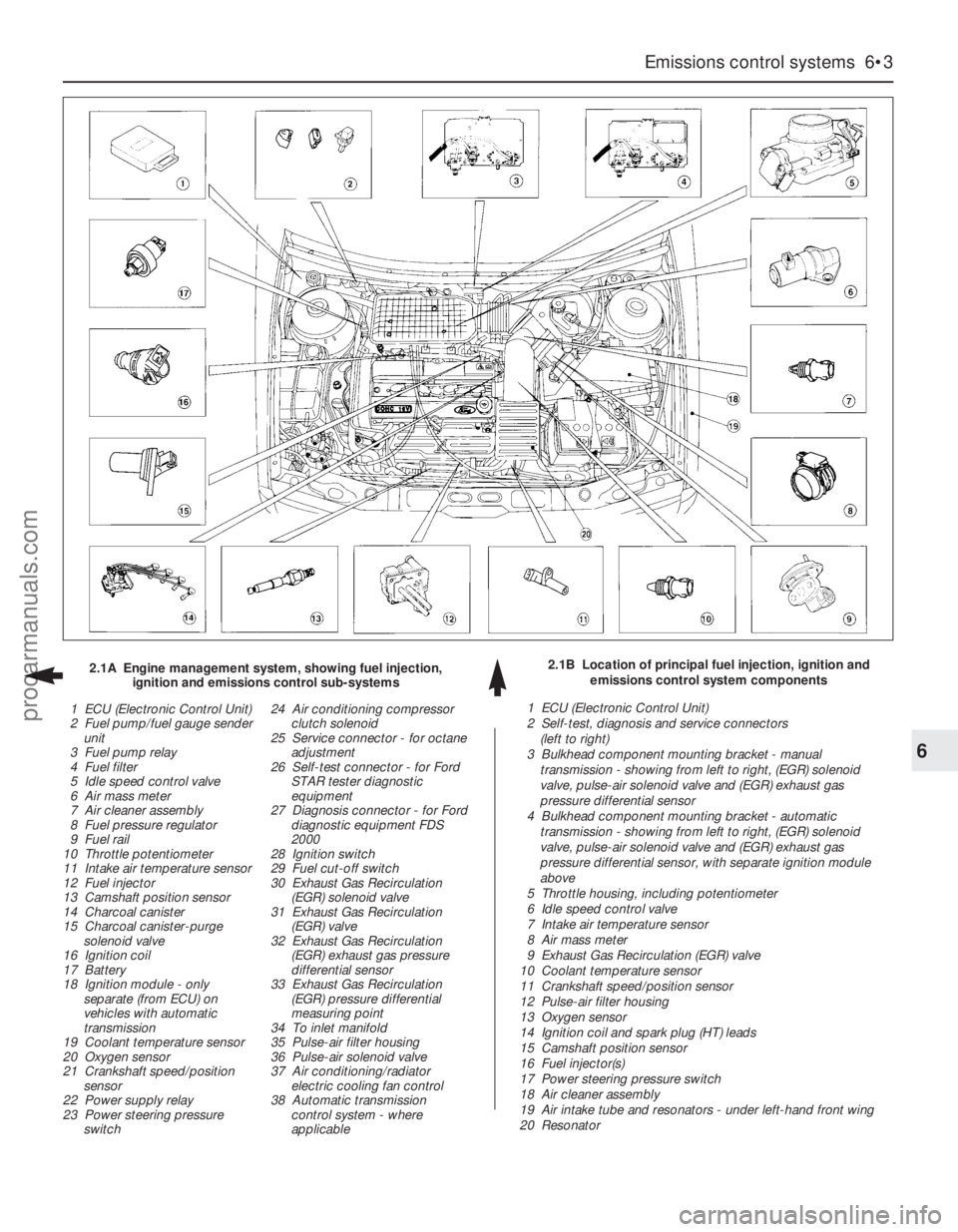

Emissions control systems 6•3

6

2.1B Location of principal fuel injection, ignition and

emissions control system components 2.1A Engine management system, showing fuel injection,

ignition and emissions control sub-systems

1 ECU (Electronic Control Unit)

2 Fuel pump/fuel gauge sender

unit

3 Fuel pump relay

4 Fuel filter

5 Idle speed control valve

6 Air mass meter

7 Air cleaner assembly

8 Fuel pressure regulator

9 Fuel rail

10 Throttle potentiometer

11 Intake air temperature sensor

12 Fuel injector

13 Camshaft position sensor

14 Charcoal canister

15 Charcoal canister-purge

solenoid valve

16 Ignition coil

17 Battery

18 Ignition module - only

separate (from ECU) on

vehicles with automatic

transmission

19 Coolant temperature sensor

20 Oxygen sensor

21 Crankshaft speed/position

sensor

22 Power supply relay

23 Power steering pressure

switch24 Air conditioning compressor

clutch solenoid

25 Service connector - for octane

adjustment

26 Self-test connector - for Ford

STAR tester diagnostic

equipment

27 Diagnosis connector - for Ford

diagnostic equipment FDS

2000

28 Ignition switch

29 Fuel cut-off switch

30 Exhaust Gas Recirculation

(EGR) solenoid valve

31 Exhaust Gas Recirculation

(EGR) valve

32 Exhaust Gas Recirculation

(EGR) exhaust gas pressure

differential sensor

33 Exhaust Gas Recirculation

(EGR) pressure differential

measuring point

34 To inlet manifold

35 Pulse-air filter housing

36 Pulse-air solenoid valve

37 Air conditioning/radiator

electric cooling fan control

38 Automatic transmission

control system - where

applicable1 ECU (Electronic Control Unit)

2 Self-test, diagnosis and service connectors

(left to right)

3 Bulkhead component mounting bracket - manual

transmission - showing from left to right, (EGR) solenoid

valve, pulse-air solenoid valve and (EGR) exhaust gas

pressure differential sensor

4 Bulkhead component mounting bracket - automatic

transmission - showing from left to right, (EGR) solenoid

valve, pulse-air solenoid valve and (EGR) exhaust gas

pressure differential sensor, with separate ignition module

above

5 Throttle housing, including potentiometer

6 Idle speed control valve

7 Intake air temperature sensor

8 Air mass meter

9 Exhaust Gas Recirculation (EGR) valve

10 Coolant temperature sensor

11 Crankshaft speed/position sensor

12 Pulse-air filter housing

13 Oxygen sensor

14 Ignition coil and spark plug (HT) leads

15 Camshaft position sensor

16 Fuel injector(s)

17 Power steering pressure switch

18 Air cleaner assembly

19 Air intake tube and resonators - under left-hand front wing

20 Resonator

procarmanuals.com

Page 140 of 279

back again, as an assistant depresses the

accelerator pedal. If the valve shows any sign

of stiffness, sticking or otherwise-inhibited

movement (and the accelerator cable is

known from the previous check to be in good

condition), spray the throttle linkage with

penetrating lubricant, allow time for it to work,

and repeat the check; if no improvement is

obtained, the complete throttle housing must

be renewed (Chapter 4).

15Unclip the air cleaner cover, and check

that the air filter element and the crankcase

ventilation system filter are not clogged or

soaked. (A clogged air filter will obstruct the

intake air flow, causing a noticeable effect on

engine performance; a clogged crankcase

ventilation system filter will inhibit crankcase

“breathing”). Renew or clean the filter(s) as

appropriate; refer to the relevant Sections of

Chapter 1 for further information, if required.

Before refitting the air cleaner cover, check

that the air intake (located under the front left-

hand wing, opening behind the direction

indicator/headlight assembly) is clear. It

should be possible to blow through the intake,

or to probe it (carefully) as far as the rear of

the direction indicator light.

16Start the engine and allow it to idle.

Note:Working in the engine compartment

while the engine is running requires great care

if the risk of personal injury is to be avoided;

among the dangers are burns from contact

with hot components, or contact with moving

components such as the radiator cooling fan

or the auxiliary drivebelt. Refer to “Safety

first!” at the front of this manual before

starting, and ensure that your hands, and long

hair or loose clothing, are kept well clear of hot

or moving components at all times.

17Working from the air intake junction at the

inner wing panel, via the air cleaner assembly

and air mass meter, to the resonator, plenum

chamber, throttle housing and inlet manifold

(and including the various vacuum hoses and

pipes connected to these), check for air leaks.

Usually, these will be revealed by sucking or

hissing noises, but minor leaks may be traced

by spraying a solution of soapy water on to

the suspect joint; if a leak exists, it will be

shown by the change in engine note and the

accompanying air bubbles (or sucking-in of

the liquid, depending on the pressure

difference at that point). If a leak is found at

any point, tighten the fastening clamp and/or

renew the faulty components, as applicable.

18Similarly, work from the cylinder head, via

the manifold (and not forgetting the related

EGR and pulse-air system components) to the

tailpipe, to check that the exhaust system is

free from leaks. The simplest way of doing

this, if the vehicle can be raised and

supported safely and with complete security

while the check is made, is to temporarily

block the tailpipe while listening for the sound

of escaping exhaust gases; any leak should

be evident. If a leak is found at any point,

tighten the fastening clamp bolts and/or nuts,

renew the gasket, and/or renew the faultysection of the system, as necessary, to seal

the leak.

19It is possible to make a further check of

the electrical connections by wiggling each

electrical connector of the system in turn as

the engine is idling; a faulty connector will be

immediately evident from the engine’s

response as contact is broken and remade. A

faulty connector should be renewed to ensure

the future reliability of the system; note that

this may mean the renewal of that entire

section of the loom - see your local Ford

dealer for details.

20Switch off the engine. If the fault is not yet

identified, the next step is to check the

ignition voltages, using an engine analyser

with an oscilloscope - without such

equipment, the only tests possible are to

remove and check each spark plug in turn, to

check the spark plug (HT) lead connections

and resistances, and to check the

connections and resistances of the ignition

coil. Refer to the relevant Sections of

Chapters 1 and 5.

21The final step in these preliminary checks

would be to use an exhaust gas analyser to

measure the CO level at the exhaust tailpipe.This check cannot be made without special

test equipment - see your local Ford dealer for

details.

Fault code read-out

22As noted in the general comments at the

beginning of this Section, the preliminary

checks outlined above should eliminate the

majority of faults from the engine

management system. If the fault is not yet

identified, the next step is to connect a fault

code reader to the ECU, so that its self-

diagnosis facility can be used to identify the

faulty part of the system; further tests can

then be made to identify the exact cause of

the fault.

23In their basic form, fault code readers are

simply hand-held electronic devices, which

take data stored within an ECU’s memory and

display it when required as two- or three-digit

fault codes. The more sophisticated versions

now available can also control sensors and

actuators, to provide more effective testing;

some can store information, so that a road

test can be carried out, and any faults

encountered during the test can be displayed

afterwards.

6•6 Emissions control systems

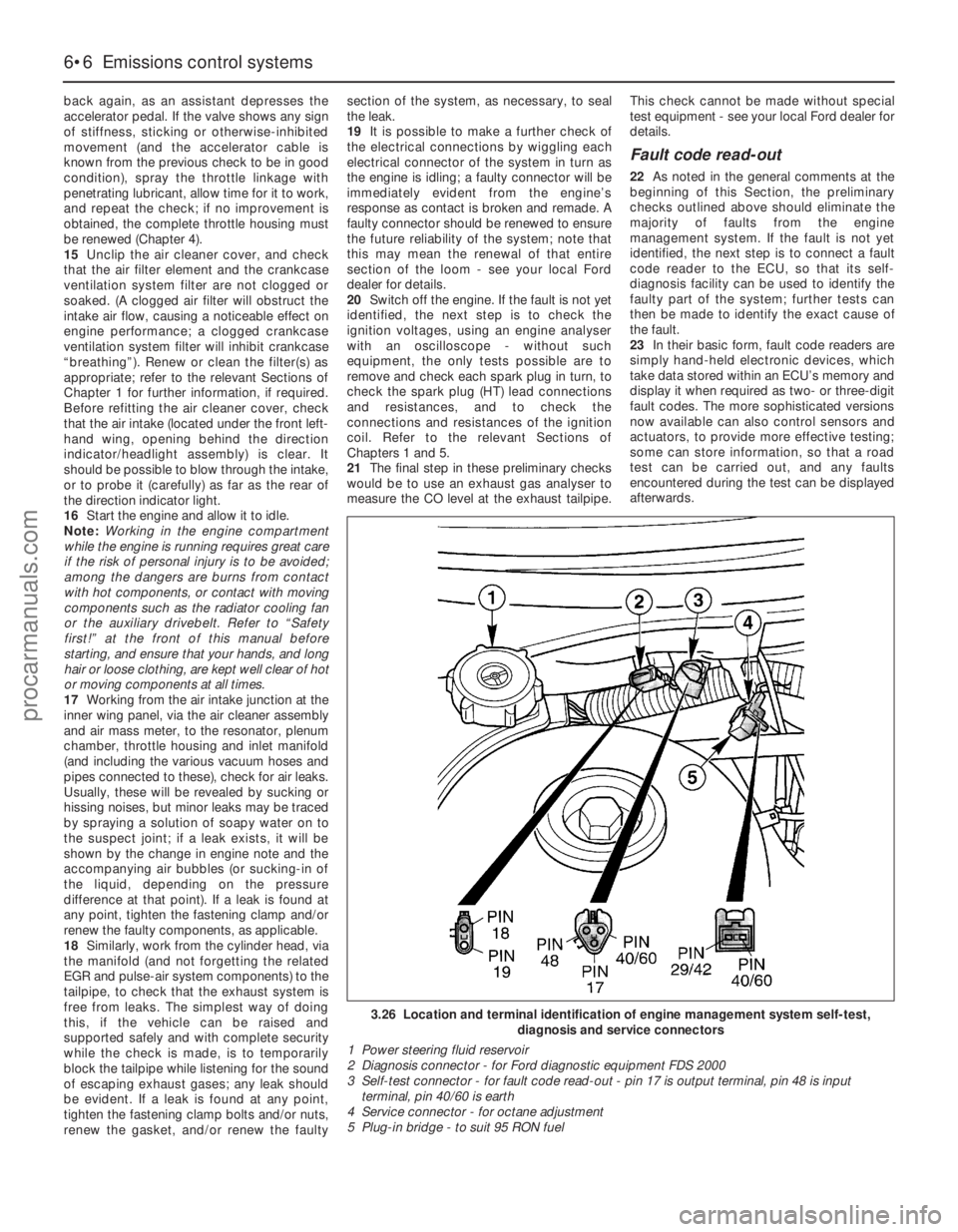

3.26 Location and terminal identification of engine management system self-test,

diagnosis and service connectors

1 Power steering fluid reservoir

2 Diagnosis connector - for Ford diagnostic equipment FDS 2000

3 Self-test connector - for fault code read-out - pin 17 is output terminal, pin 48 is input

terminal, pin 40/60 is earth

4 Service connector - for octane adjustment

5 Plug-in bridge - to suit 95 RON fuel

procarmanuals.com