warning lights FORD MONDEO 1993 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 5 of 279

Working on your car can be dangerous.

This page shows just some of the potential

risks and hazards, with the aim of creating a

safety-conscious attitude.

General hazards

Scalding

• Don’t remove the radiator or expansion

tank cap while the engine is hot.

• Engine oil, automatic transmission fluid or

power steering fluid may also be dangerously

hot if the engine has recently been running.

Burning

• Beware of burns from the exhaust system

and from any part of the engine. Brake discs

and drums can also be extremely hot

immediately after use.

Crushing

• When working under or near

a raised vehicle, always

supplement the

jack with axle

stands, or use

drive-on ramps.

Never venture

under a car

which is only

supported by

a jack.

• Take care if loosening or tightening high-

torque nuts when the vehicle is on stands.

Initial loosening and final tightening should

be done with the wheels on the ground.

Fire

• Fuel is highly flammable; fuel vapour is

explosive.

• Don’t let fuel spill onto a hot engine.

• Do not smoke or allow naked lights

(including pilot lights) anywhere near a

vehicle being worked on. Also beware of

creating sparks

(electrically or by use of tools).

• Fuel vapour is heavier than air, so don’t

work on the fuel system with the vehicle over

an inspection pit.

• Another cause of fire is an electrical

overload or short-circuit. Take care when

repairing or modifying the vehicle wiring.

• Keep a fire extinguisher handy, of a type

suitable for use on fuel and electrical fires.

Electric shock

• Ignition HT

voltage can be

dangerous,

especially to

people with

heart problems

or a pacemaker.

Don’t work on or

near the ignition

system with the

engine running or the

ignition switched on.• Mains voltage is also dangerous. Make

sure that any mains-operated equipment is

correctly earthed. Mains power points should

be protected by a residual current device

(RCD) circuit breaker.

Fume or gas intoxication

• Exhaust fumes are

poisonous; they often

contain carbon

monoxide, which is

rapidly fatal if inhaled.

Never run the

engine in a

confined space

such as a garage

with the doors shut.

• Fuel vapour is also

poisonous, as are the vapours from some

cleaning solvents and paint thinners.

Poisonous or irritant substances

• Avoid skin contact with battery acid and

with any fuel, fluid or lubricant, especially

antifreeze, brake hydraulic fluid and Diesel

fuel. Don’t syphon them by mouth. If such a

substance is swallowed or gets into the eyes,

seek medical advice.

• Prolonged contact with used engine oil can

cause skin cancer. Wear gloves or use a

barrier cream if necessary. Change out of oil-

soaked clothes and do not keep oily rags in

your pocket.

• Air conditioning refrigerant forms a

poisonous gas if exposed to a naked flame

(including a cigarette). It can also cause skin

burns on contact.

Asbestos

• Asbestos dust can cause cancer if inhaled

or swallowed. Asbestos may be found in

gaskets and in brake and clutch linings.

When dealing with such components it is

safest to assume that they contain asbestos.

Special hazards

Hydrofluoric acid

• This extremely corrosive acid is formed

when certain types of synthetic rubber, found

in some O-rings, oil seals, fuel hoses etc, are

exposed to temperatures above 400

0C. The

rubber changes into a charred or sticky

substance containing the acid. Once formed,

the acid remains dangerous for years. If it

gets onto the skin, it may be necessary to

amputate the limb concerned.

• When dealing with a vehicle which has

suffered a fire, or with components salvaged

from such a vehicle, wear protective gloves

and discard them after use.

The battery

• Batteries contain sulphuric acid, which

attacks clothing, eyes and skin. Take care

when topping-up or carrying the battery.

• The hydrogen gas given off by the battery

is highly explosive. Never cause a spark or

allow a naked light nearby. Be careful when

connecting and disconnecting battery

chargers or jump leads.

Air bags

• Air bags can cause injury if they go off

accidentally. Take care when removing the

steering wheel and/or facia. Special storage

instructions may apply.

Diesel injection equipment

• Diesel injection pumps supply fuel at very

high pressure. Take care when working on

the fuel injectors and fuel pipes.

Warning: Never expose the

hands, face or any other part of

the body to injector spray; the

fuel can penetrate the skin with

potentially fatal results.

Remember...

DO

• Do use eye protection when using power

tools, and when working under the vehicle.

• Do wear gloves or use barrier cream to

protect your hands when necessary.

• Do get someone to check periodically

that all is well when working alone on the

vehicle.

• Do keep loose clothing and long hair well

out of the way of moving mechanical parts.

• Do remove rings, wristwatch etc, before

working on the vehicle – especially the

electrical system.

• Do ensure that any lifting or jacking

equipment has a safe working load rating

adequate for the job.

A few tips

DON’T

• Don’t attempt to lift a heavy component

which may be beyond your capability – get

assistance.

• Don’t rush to finish a job, or take

unverified short cuts.

• Don’t use ill-fitting tools which may slip

and cause injury.

• Don’t leave tools or parts lying around

where someone can trip over them. Mop

up oil and fuel spills at once.

• Don’t allow children or pets to play in or

near a vehicle being worked on.

0•5Safety First!

procarmanuals.com

Page 8 of 279

Seat belts and seats

Note: The following checks are applicable to

all seat belts, front and rear.

MExamine the webbing of all the belts

(including rear belts if fitted) for cuts, serious

fraying or deterioration. Fasten and unfasten

each belt to check the buckles. If applicable,

check the retracting mechanism. Check the

security of all seat belt mountings accessible

from inside the vehicle.

MThe front seats themselves must be

securely attached and the backrests must

lock in the upright position.

Doors

MBoth front doors must be able to be opened

and closed from outside and inside, and must

latch securely when closed.

Vehicle identification

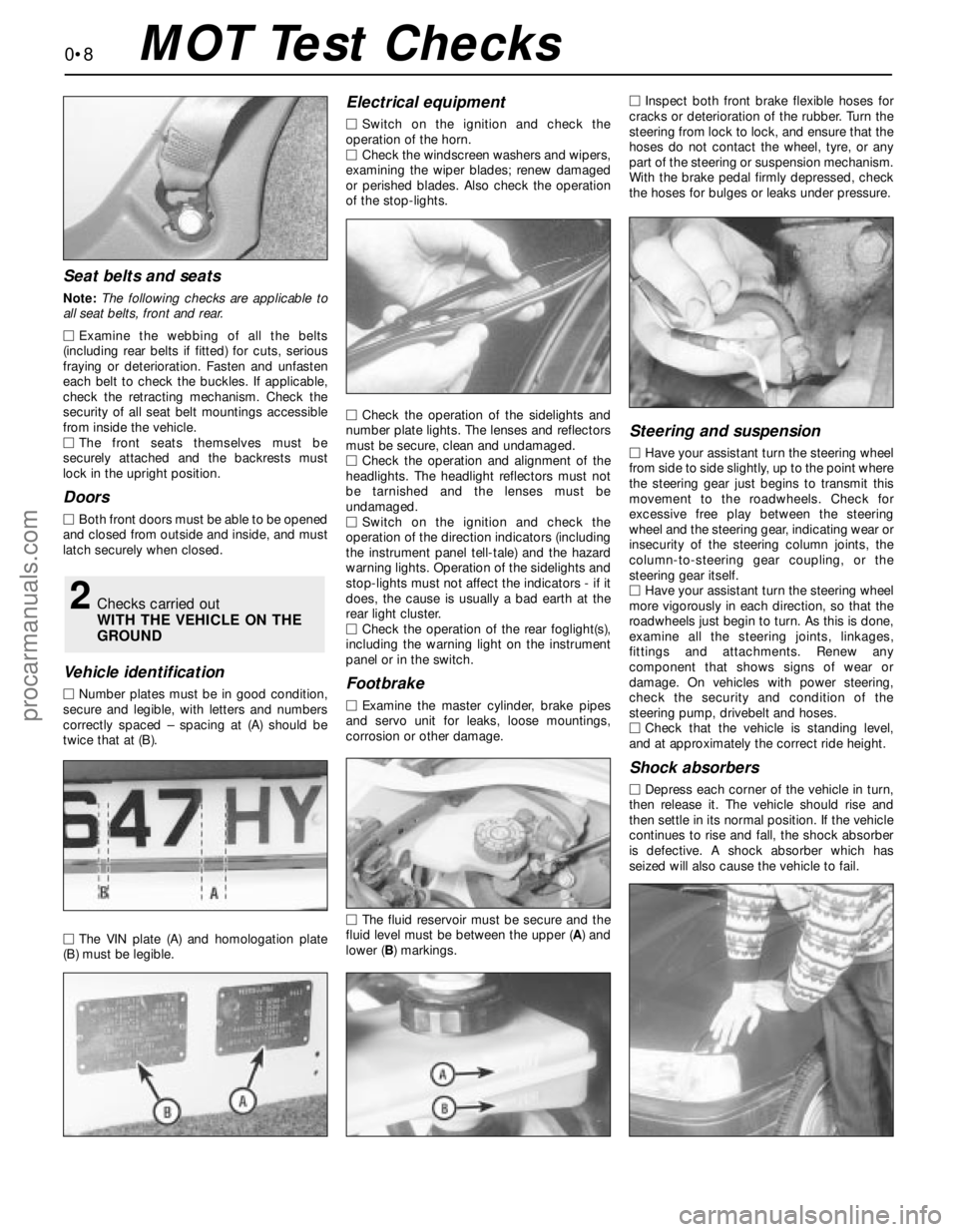

MNumber plates must be in good condition,

secure and legible, with letters and numbers

correctly spaced – spacing at (A) should be

twice that at (B).

MThe VIN plate (A) and homologation plate

(B) must be legible.

Electrical equipment

MSwitch on the ignition and check the

operation of the horn.

MCheck the windscreen washers and wipers,

examining the wiper blades; renew damaged

or perished blades. Also check the operation

of the stop-lights.

MCheck the operation of the sidelights and

number plate lights. The lenses and reflectors

must be secure, clean and undamaged.

MCheck the operation and alignment of the

headlights. The headlight reflectors must not

be tarnished and the lenses must be

undamaged.

MSwitch on the ignition and check the

operation of the direction indicators (including

the instrument panel tell-tale) and the hazard

warning lights. Operation of the sidelights and

stop-lights must not affect the indicators - if it

does, the cause is usually a bad earth at the

rear light cluster.

MCheck the operation of the rear foglight(s),

including the warning light on the instrument

panel or in the switch.

Footbrake

MExamine the master cylinder, brake pipes

and servo unit for leaks, loose mountings,

corrosion or other damage.

MThe fluid reservoir must be secure and the

fluid level must be between the upper (A) and

lower (B) markings.MInspect both front brake flexible hoses for

cracks or deterioration of the rubber. Turn the

steering from lock to lock, and ensure that the

hoses do not contact the wheel, tyre, or any

part of the steering or suspension mechanism.

With the brake pedal firmly depressed, check

the hoses for bulges or leaks under pressure.

Steering and suspension

MHave your assistant turn the steering wheel

from side to side slightly, up to the point where

the steering gear just begins to transmit this

movement to the roadwheels. Check for

excessive free play between the steering

wheel and the steering gear, indicating wear or

insecurity of the steering column joints, the

column-to-steering gear coupling, or the

steering gear itself.

MHave your assistant turn the steering wheel

more vigorously in each direction, so that the

roadwheels just begin to turn. As this is done,

examine all the steering joints, linkages,

fittings and attachments. Renew any

component that shows signs of wear or

damage. On vehicles with power steering,

check the security and condition of the

steering pump, drivebelt and hoses.

MCheck that the vehicle is standing level,

and at approximately the correct ride height.

Shock absorbers

MDepress each corner of the vehicle in turn,

then release it. The vehicle should rise and

then settle in its normal position. If the vehicle

continues to rise and fall, the shock absorber

is defective. A shock absorber which has

seized will also cause the vehicle to fail.

2Checks carried out

WITH THE VEHICLE ON THE

GROUND

0•8MOT Test Checks

procarmanuals.com

Page 25 of 279

Every 10 000 miles or 12 months

1•11

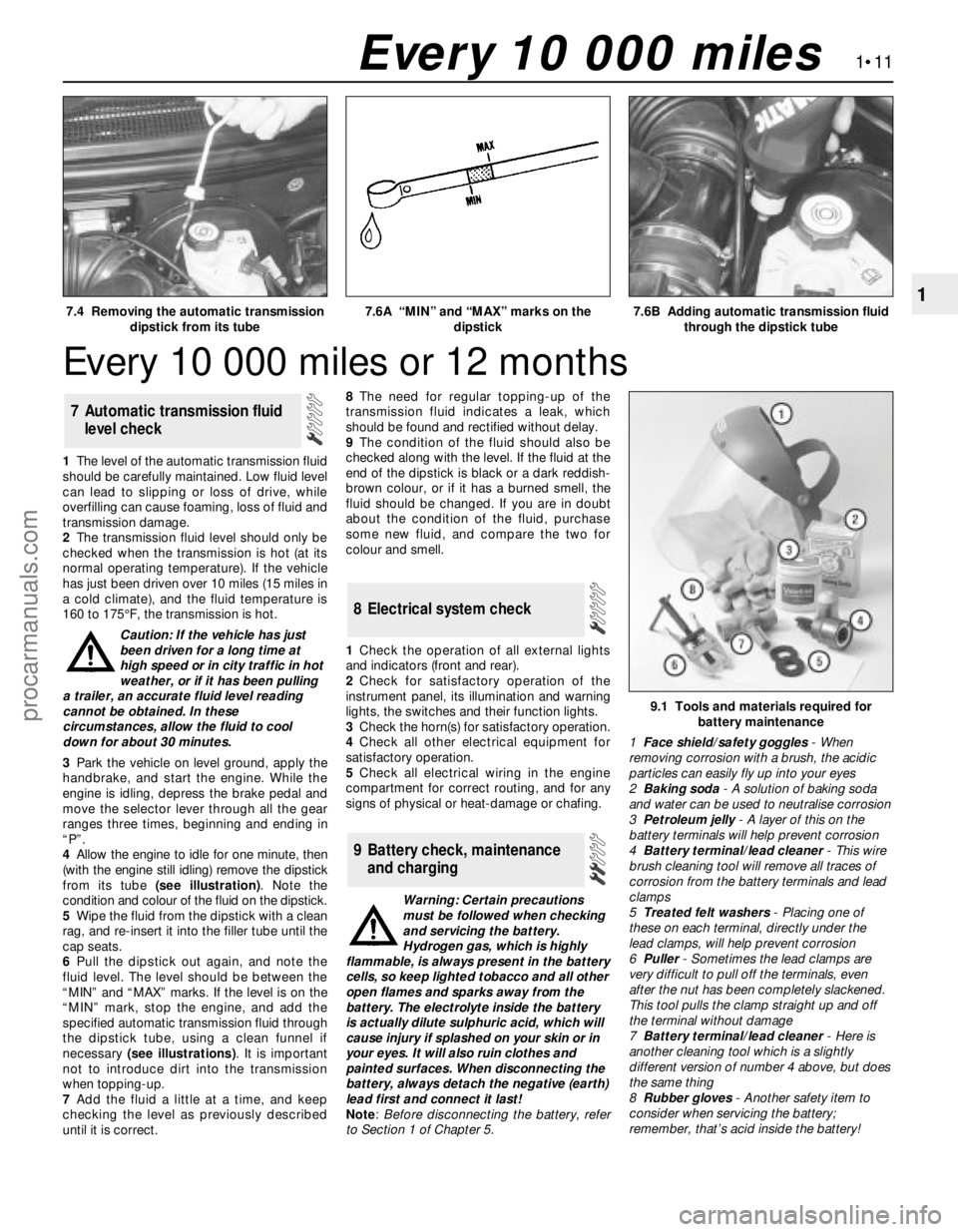

17.4 Removing the automatic transmission

dipstick from its tube7.6A “MIN” and “MAX” marks on the

dipstick7.6B Adding automatic transmission fluid

through the dipstick tube

Every 10 000 miles

1The level of the automatic transmission fluid

should be carefully maintained. Low fluid level

can lead to slipping or loss of drive, while

overfilling can cause foaming, loss of fluid and

transmission damage.

2The transmission fluid level should only be

checked when the transmission is hot (at its

normal operating temperature). If the vehicle

has just been driven over 10 miles (15 miles in

a cold climate), and the fluid temperature is

160 to 175°F, the transmission is hot.

Caution: If the vehicle has just

been driven for a long time at

high speed or in city traffic in hot

weather, or if it has been pulling

a trailer, an accurate fluid level reading

cannot be obtained. In these

circumstances, allow the fluid to cool

down for about 30 minutes.

3Park the vehicle on level ground, apply the

handbrake, and start the engine. While the

engine is idling, depress the brake pedal and

move the selector lever through all the gear

ranges three times, beginning and ending in

“P”.

4Allow the engine to idle for one minute, then

(with the engine still idling) remove the dipstick

from its tube (see illustration). Note the

condition and colour of the fluid on the dipstick.

5Wipe the fluid from the dipstick with a clean

rag, and re-insert it into the filler tube until the

cap seats.

6Pull the dipstick out again, and note the

fluid level. The level should be between the

“MIN” and “MAX” marks. If the level is on the

“MIN” mark, stop the engine, and add the

specified automatic transmission fluid through

the dipstick tube, using a clean funnel if

necessary (see illustrations). It is important

not to introduce dirt into the transmission

when topping-up.

7Add the fluid a little at a time, and keep

checking the level as previously described

until it is correct.8The need for regular topping-up of the

transmission fluid indicates a leak, which

should be found and rectified without delay.

9The condition of the fluid should also be

checked along with the level. If the fluid at the

end of the dipstick is black or a dark reddish-

brown colour, or if it has a burned smell, the

fluid should be changed. If you are in doubt

about the condition of the fluid, purchase

some new fluid, and compare the two for

colour and smell.

1Check the operation of all external lights

and indicators (front and rear).

2Check for satisfactory operation of the

instrument panel, its illumination and warning

lights, the switches and their function lights.

3Check the horn(s) for satisfactory operation.

4Check all other electrical equipment for

satisfactory operation.

5Check all electrical wiring in the engine

compartment for correct routing, and for any

signs of physical or heat-damage or chafing.

Warning: Certain precautions

must be followed when checking

and servicing the battery.

Hydrogen gas, which is highly

flammable, is always present in the battery

cells, so keep lighted tobacco and all other

open flames and sparks away from the

battery. The electrolyte inside the battery

is actually dilute sulphuric acid, which will

cause injury if splashed on your skin or in

your eyes. It will also ruin clothes and

painted surfaces. When disconnecting the

battery, always detach the negative (earth)

lead first and connect it last!

Note: Before disconnecting the battery, refer

to Section 1 of Chapter 5.

9 Battery check, maintenance

and charging

8 Electrical system check

7 Automatic transmission fluid

level check

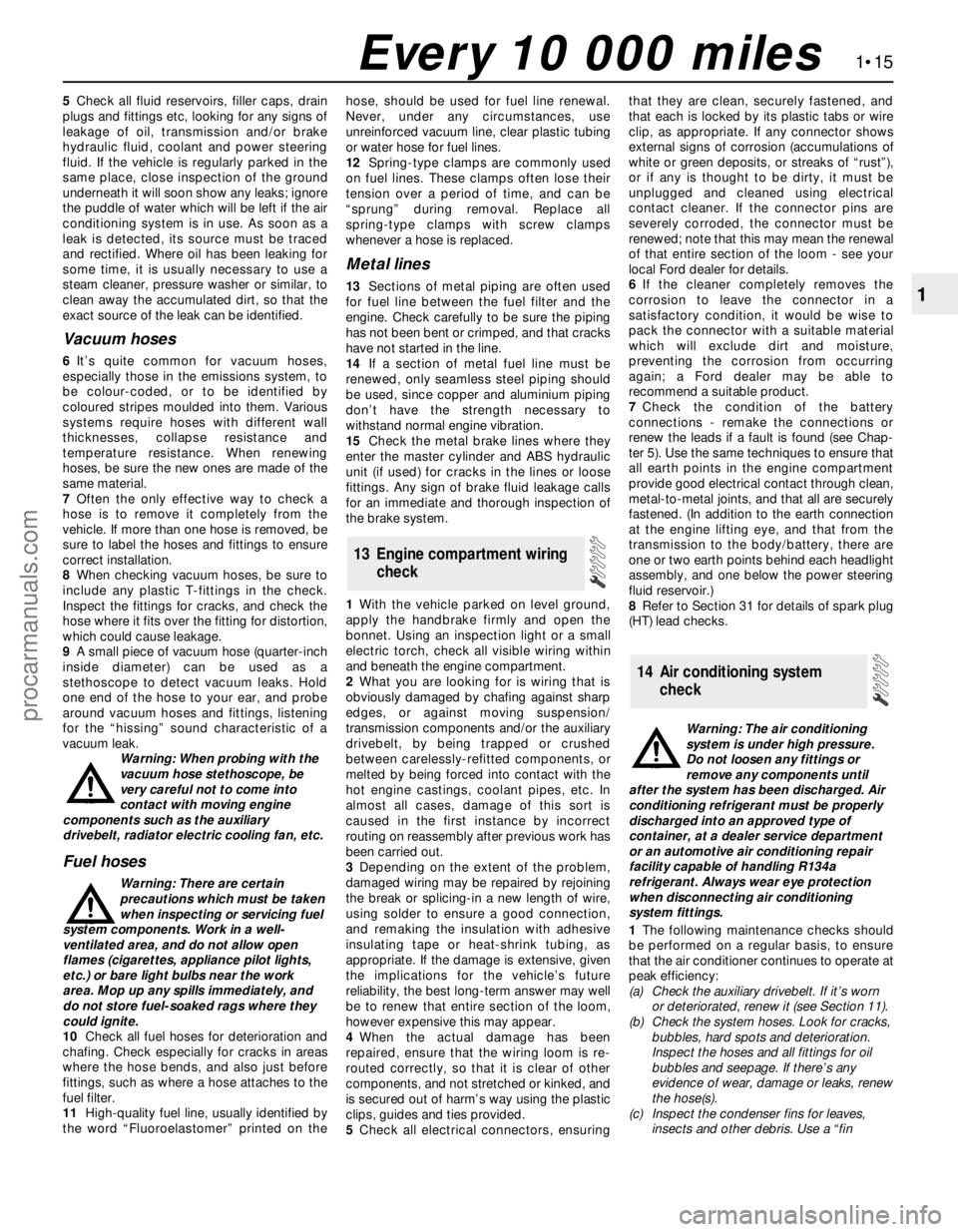

9.1 Tools and materials required for

battery maintenance

1Face shield/safety goggles- When

removing corrosion with a brush, the acidic

particles can easily fly up into your eyes

2Baking soda- A solution of baking soda

and water can be used to neutralise corrosion

3Petroleum jelly- A layer of this on the

battery terminals will help prevent corrosion

4Battery terminal/lead cleaner- This wire

brush cleaning tool will remove all traces of

corrosion from the battery terminals and lead

clamps

5Treated felt washers- Placing one of

these on each terminal, directly under the

lead clamps, will help prevent corrosion

6Puller- Sometimes the lead clamps are

very difficult to pull off the terminals, even

after the nut has been completely slackened.

This tool pulls the clamp straight up and off

the terminal without damage

7Battery terminal/lead cleaner- Here is

another cleaning tool which is a slightly

different version of number 4 above, but does

the same thing

8Rubber gloves- Another safety item to

consider when servicing the battery;

remember, that’s acid inside the battery!

procarmanuals.com

Page 29 of 279

5Check all fluid reservoirs, filler caps, drain

plugs and fittings etc, looking for any signs of

leakage of oil, transmission and/or brake

hydraulic fluid, coolant and power steering

fluid. If the vehicle is regularly parked in the

same place, close inspection of the ground

underneath it will soon show any leaks; ignore

the puddle of water which will be left if the air

conditioning system is in use. As soon as a

leak is detected, its source must be traced

and rectified. Where oil has been leaking for

some time, it is usually necessary to use a

steam cleaner, pressure washer or similar, to

clean away the accumulated dirt, so that the

exact source of the leak can be identified.

Vacuum hoses

6It’s quite common for vacuum hoses,

especially those in the emissions system, to

be colour-coded, or to be identified by

coloured stripes moulded into them. Various

systems require hoses with different wall

thicknesses, collapse resistance and

temperature resistance. When renewing

hoses, be sure the new ones are made of the

same material.

7Often the only effective way to check a

hose is to remove it completely from the

vehicle. If more than one hose is removed, be

sure to label the hoses and fittings to ensure

correct installation.

8When checking vacuum hoses, be sure to

include any plastic T-fittings in the check.

Inspect the fittings for cracks, and check the

hose where it fits over the fitting for distortion,

which could cause leakage.

9A small piece of vacuum hose (quarter-inch

inside diameter) can be used as a

stethoscope to detect vacuum leaks. Hold

one end of the hose to your ear, and probe

around vacuum hoses and fittings, listening

for the “hissing” sound characteristic of a

vacuum leak.

Warning: When probing with the

vacuum hose stethoscope, be

very careful not to come into

contact with moving engine

components such as the auxiliary

drivebelt, radiator electric cooling fan, etc.

Fuel hoses

Warning: There are certain

precautions which must be taken

when inspecting or servicing fuel

system components. Work in a well-

ventilated area, and do not allow open

flames (cigarettes, appliance pilot lights,

etc.) or bare light bulbs near the work

area. Mop up any spills immediately, and

do not store fuel-soaked rags where they

could ignite.

10Check all fuel hoses for deterioration and

chafing. Check especially for cracks in areas

where the hose bends, and also just before

fittings, such as where a hose attaches to the

fuel filter.

11High-quality fuel line, usually identified by

the word “Fluoroelastomer” printed on thehose, should be used for fuel line renewal.

Never, under any circumstances, use

unreinforced vacuum line, clear plastic tubing

or water hose for fuel lines.

12Spring-type clamps are commonly used

on fuel lines. These clamps often lose their

tension over a period of time, and can be

“sprung” during removal. Replace all

spring-type clamps with screw clamps

whenever a hose is replaced.

Metal lines

13Sections of metal piping are often used

for fuel line between the fuel filter and the

engine. Check carefully to be sure the piping

has not been bent or crimped, and that cracks

have not started in the line.

14If a section of metal fuel line must be

renewed, only seamless steel piping should

be used, since copper and aluminium piping

don’t have the strength necessary to

withstand normal engine vibration.

15Check the metal brake lines where they

enter the master cylinder and ABS hydraulic

unit (if used) for cracks in the lines or loose

fittings. Any sign of brake fluid leakage calls

for an immediate and thorough inspection of

the brake system.

1With the vehicle parked on level ground,

apply the handbrake firmly and open the

bonnet. Using an inspection light or a small

electric torch, check all visible wiring within

and beneath the engine compartment.

2What you are looking for is wiring that is

obviously damaged by chafing against sharp

edges, or against moving suspension/

transmission components and/or the auxiliary

drivebelt, by being trapped or crushed

between carelessly-refitted components, or

melted by being forced into contact with the

hot engine castings, coolant pipes, etc. In

almost all cases, damage of this sort is

caused in the first instance by incorrect

routing on reassembly after previous work has

been carried out.

3Depending on the extent of the problem,

damaged wiring may be repaired by rejoining

the break or splicing-in a new length of wire,

using solder to ensure a good connection,

and remaking the insulation with adhesive

insulating tape or heat-shrink tubing, as

appropriate. If the damage is extensive, given

the implications for the vehicle’s future

reliability, the best long-term answer may well

be to renew that entire section of the loom,

however expensive this may appear.

4When the actual damage has been

repaired, ensure that the wiring loom is re-

routed correctly, so that it is clear of other

components, and not stretched or kinked, and

is secured out of harm’s way using the plastic

clips, guides and ties provided.

5Check all electrical connectors, ensuringthat they are clean, securely fastened, and

that each is locked by its plastic tabs or wire

clip, as appropriate. If any connector shows

external signs of corrosion (accumulations of

white or green deposits, or streaks of “rust”),

or if any is thought to be dirty, it must be

unplugged and cleaned using electrical

contact cleaner. If the connector pins are

severely corroded, the connector must be

renewed; note that this may mean the renewal

of that entire section of the loom - see your

local Ford dealer for details.

6If the cleaner completely removes the

corrosion to leave the connector in a

satisfactory condition, it would be wise to

pack the connector with a suitable material

which will exclude dirt and moisture,

preventing the corrosion from occurring

again; a Ford dealer may be able to

recommend a suitable product.

7Check the condition of the battery

connections - remake the connections or

renew the leads if a fault is found (see Chap-

ter 5). Use the same techniques to ensure that

all earth points in the engine compartment

provide good electrical contact through clean,

metal-to-metal joints, and that all are securely

fastened. (In addition to the earth connection

at the engine lifting eye, and that from the

transmission to the body/battery, there are

one or two earth points behind each headlight

assembly, and one below the power steering

fluid reservoir.)

8Refer to Section 31 for details of spark plug

(HT) lead checks.

Warning: The air conditioning

system is under high pressure.

Do not loosen any fittings or

remove any components until

after the system has been discharged. Air

conditioning refrigerant must be properly

discharged into an approved type of

container, at a dealer service department

or an automotive air conditioning repair

facility capable of handling R134a

refrigerant. Always wear eye protection

when disconnecting air conditioning

system fittings.

1The following maintenance checks should

be performed on a regular basis, to ensure

that the air conditioner continues to operate at

peak efficiency:

(a) Check the auxiliary drivebelt. If it’s worn

or deteriorated, renew it (see Section 11).

(b) Check the system hoses. Look for cracks,

bubbles, hard spots and deterioration.

Inspect the hoses and all fittings for oil

bubbles and seepage. If there’s any

evidence of wear, damage or leaks, renew

the hose(s).

(c) Inspect the condenser fins for leaves,

insects and other debris. Use a “fin

14 Air conditioning system

check

13 Engine compartment wiring

check

1•15

1

Every 10 000 miles

procarmanuals.com

Page 93 of 279

sender’s electrical connector, and use a

jumper wire to connect the white/red wire to a

clean earth point (bare metal) on the engine.

Switch on the ignition without starting the

engine. If the gauge now indicates Hot, renew

the sender.

5If the gauge still does not work, the circuit

may be open, or the gauge may be faulty. See

Chapter 12 for additional information.

Removal

6Unbolt the resonator support bracket from

the engine compartment front crossmember.

Slacken the two clamp screws securing the

resonator to the air mass meter and plenum

chamber hoses, then swing the resonator up

clear of the thermostat housing (see Chap-

ter 4).

7Drain the cooling system (see Chapter 1).

8Disconnect the expansion tank coolant

hose and the radiator top hose from the

thermostat housing’s water outlet, then

disconnect the metal coolant pipe/hose from

the thermostat.

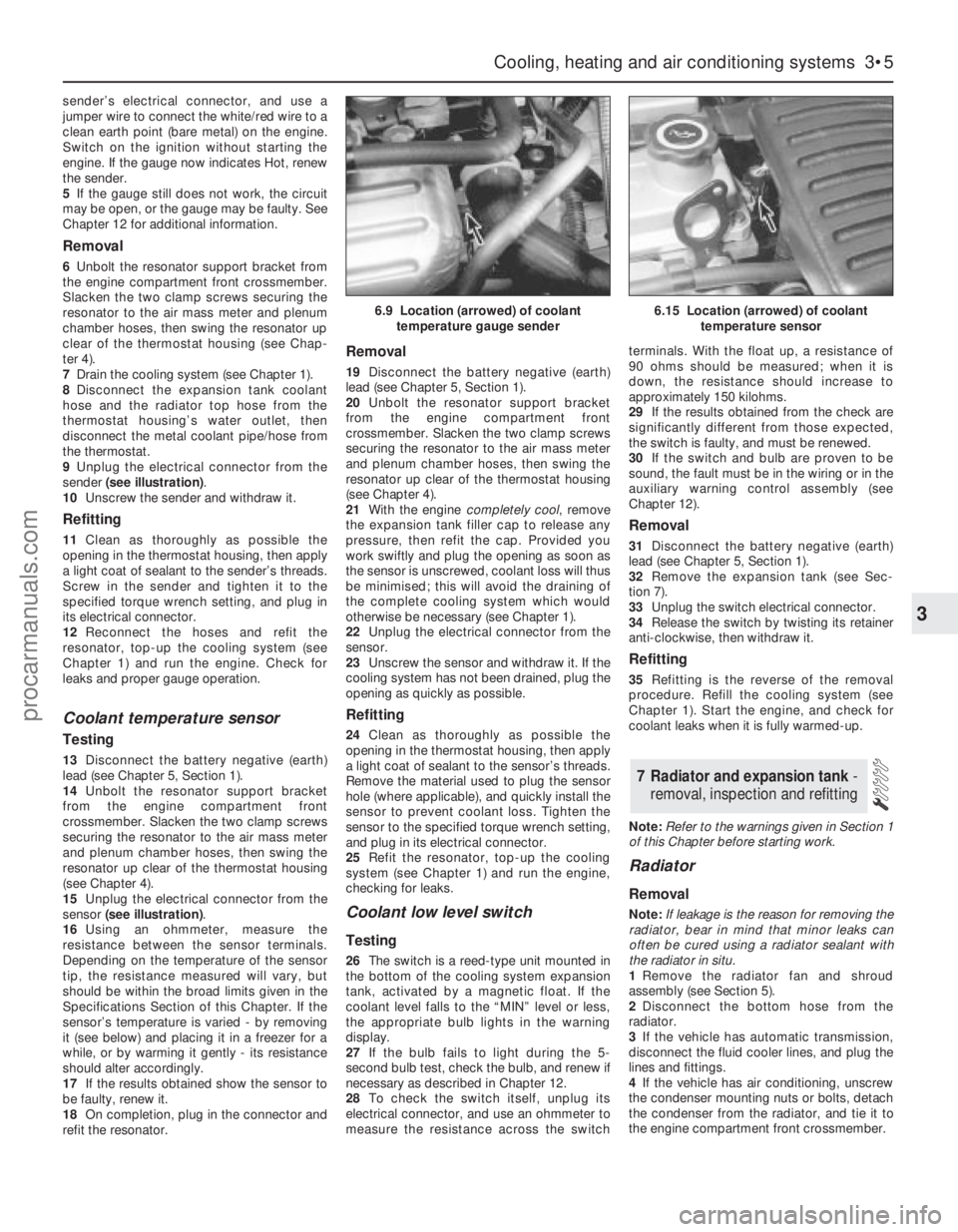

9Unplug the electrical connector from the

sender (see illustration).

10Unscrew the sender and withdraw it.

Refitting

11Clean as thoroughly as possible the

opening in the thermostat housing, then apply

a light coat of sealant to the sender’s threads.

Screw in the sender and tighten it to the

specified torque wrench setting, and plug in

its electrical connector.

12Reconnect the hoses and refit the

resonator, top-up the cooling system (see

Chapter 1) and run the engine. Check for

leaks and proper gauge operation.

Coolant temperature sensor

Testing

13Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

14Unbolt the resonator support bracket

from the engine compartment front

crossmember. Slacken the two clamp screws

securing the resonator to the air mass meter

and plenum chamber hoses, then swing the

resonator up clear of the thermostat housing

(see Chapter 4).

15Unplug the electrical connector from the

sensor (see illustration).

16Using an ohmmeter, measure the

resistance between the sensor terminals.

Depending on the temperature of the sensor

tip, the resistance measured will vary, but

should be within the broad limits given in the

Specifications Section of this Chapter. If the

sensor’s temperature is varied - by removing

it (see below) and placing it in a freezer for a

while, or by warming it gently - its resistance

should alter accordingly.

17If the results obtained show the sensor to

be faulty, renew it.

18On completion, plug in the connector and

refit the resonator.

Removal

19Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

20Unbolt the resonator support bracket

from the engine compartment front

crossmember. Slacken the two clamp screws

securing the resonator to the air mass meter

and plenum chamber hoses, then swing the

resonator up clear of the thermostat housing

(see Chapter 4).

21With the engine completely cool, remove

the expansion tank filler cap to release any

pressure, then refit the cap. Provided you

work swiftly and plug the opening as soon as

the sensor is unscrewed, coolant loss will thus

be minimised; this will avoid the draining of

the complete cooling system which would

otherwise be necessary (see Chapter 1).

22Unplug the electrical connector from the

sensor.

23Unscrew the sensor and withdraw it. If the

cooling system has not been drained, plug the

opening as quickly as possible.

Refitting

24Clean as thoroughly as possible the

opening in the thermostat housing, then apply

a light coat of sealant to the sensor’s threads.

Remove the material used to plug the sensor

hole (where applicable), and quickly install the

sensor to prevent coolant loss. Tighten the

sensor to the specified torque wrench setting,

and plug in its electrical connector.

25Refit the resonator, top-up the cooling

system (see Chapter 1) and run the engine,

checking for leaks.

Coolant low level switch

Testing

26The switch is a reed-type unit mounted in

the bottom of the cooling system expansion

tank, activated by a magnetic float. If the

coolant level falls to the “MIN” level or less,

the appropriate bulb lights in the warning

display.

27If the bulb fails to light during the 5-

second bulb test, check the bulb, and renew if

necessary as described in Chapter 12.

28To check the switch itself, unplug its

electrical connector, and use an ohmmeter to

measure the resistance across the switchterminals. With the float up, a resistance of

90 ohms should be measured; when it is

down, the resistance should increase to

approximately 150 kilohms.

29If the results obtained from the check are

significantly different from those expected,

the switch is faulty, and must be renewed.

30If the switch and bulb are proven to be

sound, the fault must be in the wiring or in the

auxiliary warning control assembly (see

Chapter 12).

Removal

31Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

32Remove the expansion tank (see Sec-

tion 7).

33Unplug the switch electrical connector.

34Release the switch by twisting its retainer

anti-clockwise, then withdraw it.

Refitting

35Refitting is the reverse of the removal

procedure. Refill the cooling system (see

Chapter 1). Start the engine, and check for

coolant leaks when it is fully warmed-up.

Note:Refer to the warnings given in Section 1

of this Chapter before starting work.

Radiator

Removal

Note:If leakage is the reason for removing the

radiator, bear in mind that minor leaks can

often be cured using a radiator sealant with

the radiator in situ.

1Remove the radiator fan and shroud

assembly (see Section 5).

2Disconnect the bottom hose from the

radiator.

3If the vehicle has automatic transmission,

disconnect the fluid cooler lines, and plug the

lines and fittings.

4If the vehicle has air conditioning, unscrew

the condenser mounting nuts or bolts, detach

the condenser from the radiator, and tie it to

the engine compartment front crossmember.

7 Radiator and expansion tank -

removal, inspection and refitting

Cooling, heating and air conditioning systems 3•5

3

6.9 Location (arrowed) of coolant

temperature gauge sender6.15 Location (arrowed) of coolant

temperature sensor

procarmanuals.com

Page 109 of 279

rings, and intend to re-use the same injectors,

remove the old nose seal and O-rings, and

discard them.

22Further testing of the injector(s) is beyond

the scope of the home mechanic. If you are in

doubt as to the status of any injector(s), it can

be tested at a dealer service department.

23Refitting is the reverse of the removal

procedure, noting the following points:

(a) Lubricate each nose seal and O-ring with

clean engine oil on installation.

(b) Locate each injector carefully in the fuel

rail recess, ensuring that the locating tab

on the injector head fits into the slot

provided in the rail. Tighten the bolts to

the specified torque.

(c) Fit a new seal to each fuel rail nose, and

ensure the seals are not displaced as the

rail is refitted. Ensure that the fuel rail is

settled fully in the manifold before

tightening the three bolts evenly and to

the torque wrench setting specified.

(d) Fasten the fuel feed and return quick-

release couplings as described in Sec-

tion 3.

(e) Ensure that the breather hose, vacuum

hose and wiring are routed correctly, and

secured on reconnection by any clips or

ties provided.

(f) On completion, switch the ignition on and

off five times, to activate the fuel pump and

pressurise the system, without cranking

the engine. Check for signs of fuel leaks

around all disturbed unions and joints

before attempting to start the engine.

Fuel pressure regulator

Check

24Refer to the fuel pump/fuel pressure

check procedure (see Section 8).

Renewal

25Relieve the residual pressure in the fuel

system (see Section 2), and equalise tank

pressure by removing the fuel filler cap.

Warning: This procedure will

merely relieve the increased

pressure necessary for the engine

to run - remember that fuel will

still be present in the system components,

and take precautions accordingly before

disconnecting any of them.26Disconnect the battery negative (earth)

lead - see Chapter 5, Section 1.

27Remove the plenum chamber (see

Section 4).

28Disconnect the vacuum hose from the

regulator.

29Unscrew the two regulator retaining bolts,

place a wad of clean rag to soak up any spilt

fuel, and withdraw the regulator (see

illustration).

30Refitting is the reverse of the removal

procedure, noting the following points:

(a) Renew the regulator sealing O-ring

whenever the regulator is disturbed.

Lubricate the new O-ring with clean

engine oil on installation.

(b) Locate the regulator carefully in the fuel

rail recess, and tighten the bolts to the

specified torque wrench setting.

(c) On completion, switch the ignition on and

off five times, to activate the fuel pump and

pressurise the system, without cranking

the engine. Check for signs of fuel leaks

around all disturbed unions and joints

before attempting to start the engine.

Idle speed control valve

Check

31Disconnect the battery negative (earth)

lead - see Chapter 5, Section 1.

32Raise the front of the vehicle, and support

it securely on axle stands.

Warning: Do not place any part of

your body under a vehicle when

it’s supported only by a jack!

33Unplug the valve’s electrical connector

(see illustration).

34Connect a 12-volt battery across the

valve’s terminals - positive (+) to terminal 37

(the green/yellow wire) and negative (-) to

terminal 21 (the black/yellow).

Caution: It is essential that the

correct polarity is observed, or

the diode incorporated in the

valve may be damaged.

35A distinct click should be heard each time

contact is made and broken. If not, measure

the resistance between the terminals. If the

resistance is as specified, the valve is okay

(but there may be a problem with the wiring or

the ECU). If the resistance is not as specified,

renew the valve (see below).36Plug in the valve’s electrical connector.

Renewal

37Disconnect the battery negative (earth)

lead - see Chapter 5, Section 1.

38Raise the front of the vehicle, and support

it securely on axle stands.

Warning: Do not place any part of

your body under a vehicle when

it’s supported only by a jack!

39Unplug the valve’s electrical connector.

40Unscrew the two retaining bolts, and

withdraw the valve from the inlet manifold

(see illustration).

41Since the valve’s individual components

are not available separately, and the complete

assembly must be renewed if it is thought to

be faulty, there is nothing to be lost by

attempting to flush out the passages, using

carburettor cleaner or similar solvent. This

won’t take much time or effort, and may well

cure the fault.

42Refitting is the reverse of the removal

procedure, noting the following points:

(a) Clean the mating surfaces carefully, and

always fit a new gasket whenever the

valve is disturbed.

(b) Tighten the bolts evenly and to the

specified torque wrench setting.

(c) Once the wiring and battery are

reconnected, start the engine and allow it

to idle. When it has reached normal

operating temperature, check that the idle

speed is stable, and that no induction (air)

leaks are evident. Switch on all electrical

loads (headlights, heated rear window,

etc), and check that the idle speed is still

correct.

Fuel and exhaust systems 4•11

4

16.43 Location of idle-increase solenoid

valve (A) and diode (B)

16.29 Disconnect vacuum hose, and

unscrew bolts (arrowed) to withdraw fuel

pressure regulator16.33 Access to idle speed control valve is

from underneath vehicle - unplug electrical

connector (arrowed) to check valve16.40 Unscrew bolts (arrowed) to remove

idle speed control valve

procarmanuals.com

Page 112 of 279

General information

The engine electrical systems include all

ignition, charging and starting components.

Because of their engine-related functions,

these components are discussed separately

from body electrical devices such as the

lights, the instruments, etc (which are

included in Chapter 12).

Precautions

Always observe the following precautions

when working on the electrical system:

(a) Be extremely careful when servicing

engine electrical components. They are

easily damaged if checked, connected or

handled improperly.

(b) Never leave the ignition switched on for

long periods of time when the engine is

not running.

(c) Don’t disconnect the battery leads while

the engine is running.

(d) Maintain correct polarity when connecting

a battery lead from another vehicle during

jump starting - see the “Booster battery

(jump) starting” section at the front of this

manual.

(e) Always disconnect the negative lead first,

and reconnect it last, or the battery may

be shorted by the tool being used to

loosen the lead clamps (see illustration).

It’s also a good idea to review the safety-

related information regarding the engine

electrical systems located in the “Safety first!”

section at the front of this manual, before

beginning any operation included in this Chapter.

Battery disconnection

Several systems fitted to the vehicle require

battery power to be available at all times, either

to ensure their continued operation (such as

the clock) or to maintain control unit memories

(such as that in the engine management

system’s ECU) which would be wiped if the

battery were to be disconnected. Whenever thebattery is to be disconnected therefore, first

note the following, to ensure that there are no

unforeseen consequences of this action:

(a) First, on any vehicle with central locking, it

is a wise precaution to remove the key

from the ignition, and to keep it with you,

so that it does not get locked in if the

central locking should engage accidentally

when the battery is reconnected!

(b) The engine management system’s ECU will

lose the information stored in its memory -

referred to by Ford as the “KAM” (Keep-

Alive Memory) - when the battery is

disconnected. This includes idling and

operating values, and any fault codes

detected - in the case of the fault codes, if it

is thought likely that the system has

developed a fault for which the

corresponding code has been logged, the

vehicle must be taken to a Ford dealer for

the codes to be read, using the special

diagnostic equipment necessary for this (see

Chapter 6). Whenever the battery is

disconnected, the information relating to idle

speed control and other operating values will

have to be re-programmed into the unit’s

memory. The ECU does this by itself, but

until then, there may be surging, hesitation,

erratic idle and a generally inferior level of

performance. To allow the ECU to relearn

these values, start the engine and run it as

close to idle speed as possible until it

reaches its normal operating temperature,

then run it for approximately two minutes at

1200 rpm. Next, drive the vehicle as far as

necessary - approximately 5 miles of varied

driving conditions is usually sufficient - to

complete the relearning process.

(c) If the battery is disconnected while the

alarm system is armed or activated, the

alarm will remain in the same state when

the battery is reconnected. The same

applies to the engine immobiliser system

(where fitted).

(d) If a trip computer is in use, any

information stored in memory will be lost.

(e) If a Ford “Keycode” audio unit is fitted,

and the unit and/or the battery is

disconnected, the unit will not function

again on reconnection until the correct

security code is entered. Details of thisprocedure, which varies according to the

unit and model year, are given in the

“Ford Audio Systems Operating Guide”

supplied with the vehicle when new, with

the code itself being given in a “Radio

Passport” and/or a “Keycode Label” at

the same time. Ensure you have the

correct code before you disconnect the

battery. For obvious security reasons, the

procedure is not given in this manual. If

you do not have the code or details of the

correct procedure, but can supply proof

of ownership and a legitimate reason for

wanting this information, the vehicle’s

selling dealer may be able to help.

Devices known as “memory-savers” (or

“code-savers”) can be used to avoid some of

the above problems. Precise details vary

according to the device used. Typically, it is

plugged into the cigarette lighter, and is

connected by its own wires to a spare battery;

the vehicle’s own battery is then disconnected

from the electrical system, leaving the

“memory-saver” to pass sufficient current to

maintain audio unit security codes and ECU

memory values, and also to run permanently-

live circuits such as the clock, all the while

isolating the battery in the event of a short-

circuit occurring while work is carried out.

Warning: Some of these devices

allow a considerable amount of

current to pass, which can mean

that many of the vehicle’s systems are still

operational when the main battery is

disconnected. If a “memory-saver” is used,

ensure that the circuit concerned is

actually “dead” before carrying out any

work on it!

Note:See also the relevant Sections of

Chapter 1.

1Disconnect the battery leads, negative

(earth) lead first - see Section 1.

2Remove the battery hold-down clamp (see

illustrations).

3Lift out the battery. Be careful - it’s heavy.

4While the battery is out, inspect the tray for

corrosion (see Chapter 1).

2 Battery- removal and refitting

1 General information,

precautions and battery

disconnection

5•2 Engine electrical systems

1.2 Always disconnect battery - negative

(earth) lead first - to prevent the possibility

of short-circuits2.2A Unscrew hold-down nuts (one of two

arrowed) . . .2.2B . . . and withdraw hold-down clamp

to release battery

procarmanuals.com

Page 115 of 279

5Undo the sensor’s retaining screw and

withdraw the sensor. The sensor’s bracket

cannot be unbolted from the cylinder

block/crankcase unless the transmission and

flywheel/driveplate have been removed (see

Chapter 2).

6Refitting is the reverse of the removal

procedure.

General information

The charging system includes the

alternator, an internal voltage regulator, a no-

charge (or “ignition”) warning light, the

battery, and the wiring between all the

components. The charging system supplies

electrical power for the ignition system, the

lights, the radio, etc. The alternator is driven

by the auxiliary drivebelt at the front (right-

hand end) of the engine.

The purpose of the voltage regulator is to

limit the alternator’s voltage to a preset value.

This prevents power surges, circuit overloads,

etc., during peak voltage output.

The charging system doesn’t ordinarily

require periodic maintenance. However, the

drivebelt, battery and wires and connections

should be inspected at the intervals outlined

in Chapter 1.

The dashboard warning light should come

on when the ignition key is turned to positions

“II” or “III”, then should go off immediately the

engine starts. If it remains on, or if it comes on

while the engine is running, there is a

malfunction in the charging system (see

Section 11). If the light does not come on

when the ignition key is turned, and the bulb is

sound (see Chapter 12), there is a fault in the

alternator.

Precautions

Be very careful when making electrical

circuit connections to a vehicle equipped with

an alternator, and note the following:

(a) When reconnecting wires to the alternator

from the battery, be sure to note the

polarity.

(b) Before using arc-welding equipment to

repair any part of the vehicle, disconnect

the wires from the alternator and the

battery terminals.

(c) Never start the engine with a battery

charger connected.

(d) Always disconnect both battery leads

before using a battery charger.

(e) The alternator is driven by an engine

drivebelt which could cause serious injury

if your hand, hair or clothes become

entangled in it with the engine running.

(f) Because the alternator is connected

directly to the battery, it could arc or

cause a fire if overloaded or shorted-out.

(g) Wrap a plastic bag over the alternator,

and secure it with rubber bands, beforesteam-cleaning or pressure-washing the

engine.

(h) Never disconnect the alternator terminals

while the engine is running.

1If a malfunction occurs in the charging

circuit, don’t automatically assume that the

alternator is causing the problem. First check

the following items:

(a) Check the tension and condition of the

auxiliary drivebelt - renew it if it is worn or

deteriorated (see Chapter 1).

(b) Ensure the alternator mounting bolts and

nuts are tight.

(c) Inspect the alternator wiring harness and

the electrical connections at the

alternator; they must be in good

condition, and tight.

(d) Check the large main fuses in the engine

compartment (see Chapter 12). If any is

blown, determine the cause, repair the

circuit and renew the fuse (the vehicle

won’t start and/or the accessories won’t

work if the fuse is blown).

(e) Start the engine and check the alternator

for abnormal noises - for example, a

shrieking or squealing sound may indicate

a badly-worn bearing or brush.

(f) Make sure that the battery is fully-charged

- one bad cell in a battery can cause

overcharging by the alternator.

(g) Disconnect the battery leads (negative

first, then positive). Inspect the battery

posts and the lead clamps for corrosion.

Clean them thoroughly if necessary (see

Section 3 and Chapter 1). Reconnect the

lead to the negative terminal.

(h) With the ignition and all accessories

switched off, insert a test light between

the battery negative post and the

disconnected negative lead clamp:

(1) If the test light does not come on, re-

attach the clamp and proceed to the next

step.

(2) If the test light comes on, there is a short

in the electrical system of the vehicle. The

short must be repaired before the

charging system can be checked.

(3) To find the short, disconnect the

alternator wiring harness:

(a) If the light goes out, the alternator is

at fault.

(b) If the light stays on, remove each fuse

until it goes out - this will tell you

which component is short-circuited.

2Using a voltmeter, check the battery

voltage with the engine off. It should be

approximately 12 volts.

3Start the engine and check the battery

voltage again. Increase engine speed until the

voltmeter reading remains steady; it should

now be approximately 13.5 to 14.6 volts.

4Switch on as many electrical accessories

(eg the headlights, heated rear window andheater blower) as possible, and check that the

alternator maintains the regulated voltage at

around 13 to 14 volts. The voltage may drop

and then come back up; it may also be

necessary to increase engine speed slightly,

even if the charging system is working

properly.

5If the voltage reading is greater than the

specified charging voltage, renew the voltage

regulator (see Section 13).

6If the voltmeter reading is less than that

specified, the fault may be due to worn

brushes, weak brush springs, a faulty voltage

regulator, a faulty diode, a severed phase

winding, or worn or damaged slip rings. The

brushes and slip rings may be checked (see

Section 13), but if the fault persists, the

alternator should be renewed or taken to an

auto-electrician for testing and repair.

1Disconnect the battery negative (earth) lead

- see Section 1.

2Remove the plenum chamber (see Chap-

ter 4).

3Unscrew the nuts to disconnect the wiring

from the alternator (see illustration). If

additional working clearance is required, undo

the right-hand of the three screws securing

the wiring “rail” to the rear of the inlet

manifold.

4Jack up and support the front right-hand

corner of the vehicle. Remove the auxiliary

drivebelt and the engine oil filter - place a wad

of rag to soak up the spilled oil (see Chap-

ter 1). Rather than refit a used filter, you are

advised to drain the engine oil, and then to fit

a new filter and refill the engine with clean oil

on reassembly. Where an engine oil cooler is

fitted, it may prove necessary to remove this

as well, to provide the clearance necessary to

remove the alternator (see Chapter 2, Part A).

5Unscrew the two bolts securing the power

steering system pipes to the right-hand side

of the front suspension subframe. With the

front wheels in the straight-ahead position,

disconnect the right-hand track rod end from

the steering knuckle (see Chapter 10).

6Remove the mounting bolts and nuts (one

12 Alternator-

removal and refitting

11 Charging system- testing

10 Charging system - general

information and precautions

Engine electrical systems 5•5

5

12.3 Disconnecting alternator wiring

procarmanuals.com

Page 121 of 279

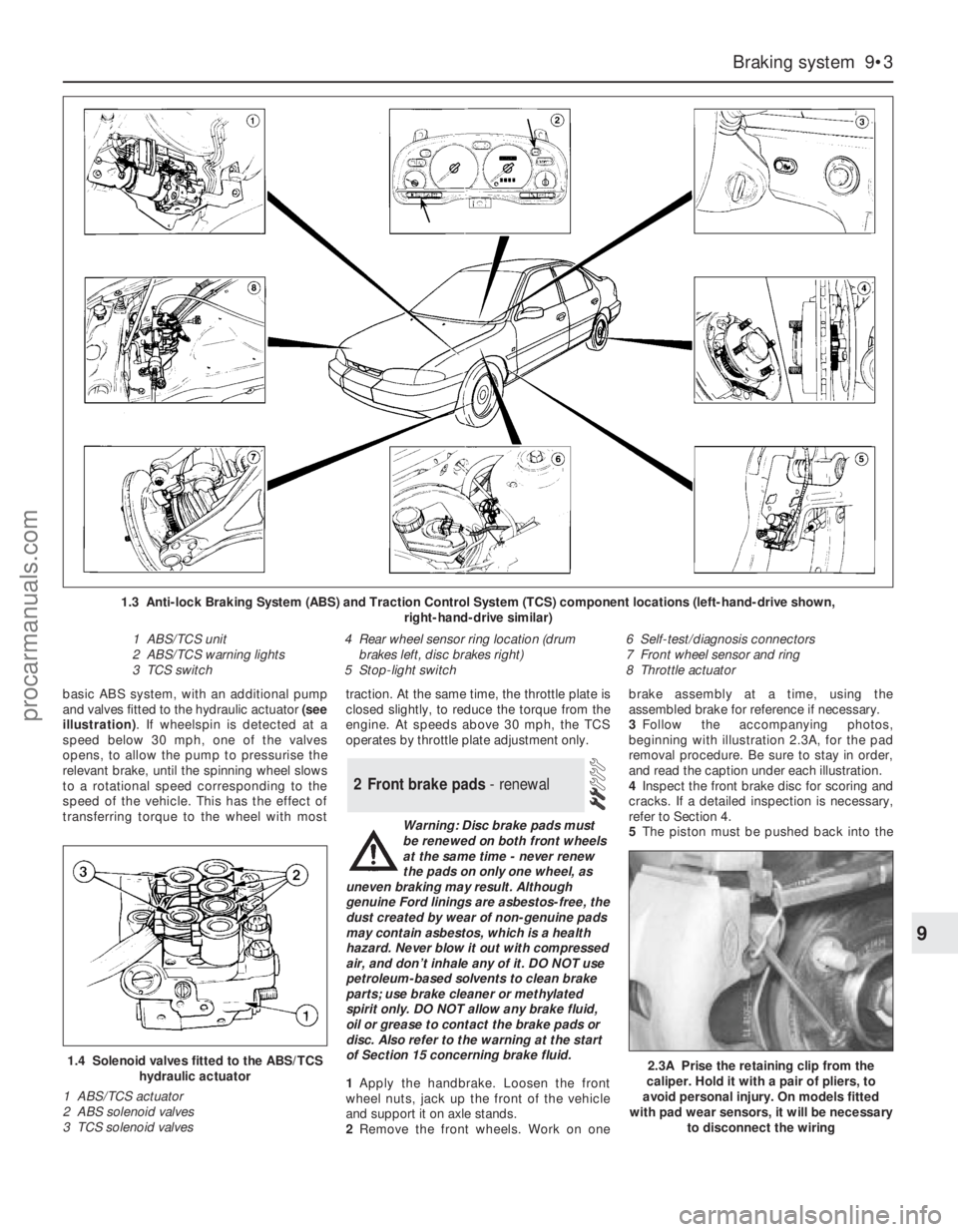

basic ABS system, with an additional pump

and valves fitted to the hydraulic actuator (see

illustration). If wheelspin is detected at a

speed below 30 mph, one of the valves

opens, to allow the pump to pressurise the

relevant brake, until the spinning wheel slows

to a rotational speed corresponding to the

speed of the vehicle. This has the effect of

transferring torque to the wheel with mosttraction. At the same time, the throttle plate is

closed slightly, to reduce the torque from the

engine. At speeds above 30 mph, the TCS

operates by throttle plate adjustment only.

Warning: Disc brake pads must

be renewed on both front wheels

at the same time - never renew

the pads on only one wheel, as

uneven braking may result. Although

genuine Ford linings are asbestos-free, the

dust created by wear of non-genuine pads

may contain asbestos, which is a health

hazard. Never blow it out with compressed

air, and don’t inhale any of it. DO NOT use

petroleum-based solvents to clean brake

parts; use brake cleaner or methylated

spirit only. DO NOT allow any brake fluid,

oil or grease to contact the brake pads or

disc. Also refer to the warning at the start

of Section 15 concerning brake fluid.

1Apply the handbrake. Loosen the front

wheel nuts, jack up the front of the vehicle

and support it on axle stands.

2Remove the front wheels. Work on onebrake assembly at a time, using the

assembled brake for reference if necessary.

3Follow the accompanying photos,

beginning with illustration 2.3A, for the pad

removal procedure. Be sure to stay in order,

and read the caption under each illustration.

4Inspect the front brake disc for scoring and

cracks. If a detailed inspection is necessary,

refer to Section 4.

5The piston must be pushed back into the

2 Front brake pads - renewal

Braking system 9•3

9

1.4 Solenoid valves fitted to the ABS/TCS

hydraulic actuator

1 ABS/TCS actuator

2 ABS solenoid valves

3 TCS solenoid valves

1.3 Anti-lock Braking System (ABS) and Traction Control System (TCS) component locations (left-hand-drive shown,

right-hand-drive similar)

1 ABS/TCS unit

2 ABS/TCS warning lights

3 TCS switch4 Rear wheel sensor ring location (drum

brakes left, disc brakes right)

5 Stop-light switch6 Self-test/diagnosis connectors

7 Front wheel sensor and ring

8 Throttle actuator

2.3A Prise the retaining clip from the

caliper. Hold it with a pair of pliers, to

avoid personal injury. On models fitted

with pad wear sensors, it will be necessary

to disconnect the wiring

procarmanuals.com

Page 141 of 279

24Ford specify the use of their STAR (Self-

Test Automatic Readout) tester; most Ford

dealers should have such equipment, and the

staff trained to use it effectively. The only

alternatives are as follows:

(a) To obtain one of those proprietary readers

which can interpret EEC-IV three-digit

codes - at present, such readers are too

expensive for the DIY enthusiast, but are

becoming more popular with smaller

specialist garages.

(b) To use an analogue voltmeter, whereby

the stored codes are displayed as sweeps

of the voltmeter needle. This option limits

the operator to a read-out of any codes

stored - ie, there is no control of sensors

and/or actuators - but can still be useful in

pinpointing the faulty part of the engine

management system. The display is

interpreted as follows. Each code

(whether fault code or

command/separator) is marked by a

three-to-four second pause - code “538”

would therefore be shown as long (3 to

4 seconds) pause, five fast sweeps of the

needle, slight (1 second) pause, three fast

sweeps, slight pause, eight fast sweeps,

long pause.

(c) Owners without access to such

equipment must take the vehicle to a Ford

dealer, or to an expert who has similar

equipment and the skill to use it.

25Because of the variations in the design of

fault code readers, it is not possible to give

exact details of the sequence of tests; the

manufacturer’s instructions must be followed,

in conjunction with the codes given below.

The following ten paragraphs outline the

procedure to be followed using a version of

the Ford STAR tester, to illustrate the general

principles, as well as notes to guide the owner

using only a voltmeter.

26The vehicle must be prepared by applying

the handbrake, switching off the air

conditioning (where fitted) and any other

electrical loads (lights, heated rear window,

etc), then selecting neutral (manual

transmission) or the “P” position (automatic

transmission). Where the engine is required to

be running, it must be fully warmed-up to

normal operating temperature before the test

is started. Using any adaptors required,

connect the fault code reader to the system

via the (triangular, three-pin) self-test

connector on the right-hand end of the engine

compartment bulkhead (see illustration). If a

voltmeter is being used, connect its positive

lead to the battery positive terminal, and its

negative lead to the self-test connector’s

output terminal, pin 17. Have a pen and paper

ready to write down the codes displayed.

27Set the tester in operation. For the Ford

STAR tester, a display check will be carried

out and the test mode requirements must be

entered. If a voltmeter is being used, connect

a spare length of wire to earth the self-test

connector’s input terminal, pin 48. Be very

careful to ensure that you earth the correctterminal - the one with the white/green wire.

The first part of the test starts, with the

ignition switched on, but with the engine off.

On pressing the “Mem/test” button, the tester

displays “TEST” and the ready code “000”,

followed by a command code “010” - the

accelerator pedal must be fully depressed

within 10 seconds of the command code

appearing, or fault codes “576” or “577” will

appear when they are called up later. If a

voltmeter is being used, code “000” will not

appear (except perhaps as a flicker of the

needle) and “010” will appear as a single

sweep - to ensure correct interpretation of the

display, watch carefully for the interval

between the end of one code and the

beginning of the next, otherwise you will

become confused and misinterpret the read-

out.

28The tester will then display the codes for

any faults in the system at the time of the test.

Each code is repeated once; if no faults are

present, code “111” will be displayed. If a

voltmeter is being used, the pause between

repetitions will vary according to the

equipment in use and the number of faults in

the system, but was found to be

approximately 3 to 4 seconds - it may be

necessary to start again, and to repeat the

read-out until you are familiar with what you

are seeing.

29Next the tester will display code “010”

(now acting as a separator), followed by the

codes for any faults stored in the ECU’s

memory; if no faults were stored, code “111”

will be displayed.

30When prompted by the tester, the

operator must next depress the accelerator

pedal fully; the tester then checks several

actuators. Further test modes include a

“wiggle test” facility, whereby the operator

can check the various connectors as

described in paragraph 19 above (in this case,

any fault will be logged and the appropriate

code will be displayed), a facility for recalling

codes displayed, and a means for clearing the

ECU’s memory at the end of the test

procedure when any faults have been

rectified.

31The next step when using the Ford STAR

tester is to conduct a test with the engine

running. With the tester set in operation (see

paragraph 26 above) the engine is started and

allowed to idle. On pressing the “Mem/test”

button, the tester displays “TEST”, followed

by one of two codes, as follows.

32If warning code “998” appears, followed

by the appropriate fault code, switch off and

check as indicated the coolant temperature

sensor, the intake air temperature sensor, the

air mass meter, the throttle potentiometer

and/or their related circuits, then restart the

test procedure.

33If command code “020” appears, carry

out the following procedure within ten

seconds:

(a) Depress the brake pedal fully.

(b) Turn the steering to full-lock (either way)and centre it again, to produce a signal

from the power steering pressure switch -

if no signal is sent, fault code “521” will

be displayed.

(c) If automatic transmission is fitted, switch

the overdrive cancel button on and off,

then do the same for the

“Economy/Sport” mode switch.

(d) Wait for separator code “010” to be

displayed, then within 10 seconds,

depress the accelerator pedal fully,

increasing engine speed rapidly above

3000 rpm - release the pedal.

34Any faults found in the system will be

logged and displayed. Each code is repeated

once; if no faults are present, code “111” will

be displayed.

35When the codes have been displayed for

all faults logged, the ECU enters its “Service

Adjustment Programme”, as follows:

(a) The programme lasts for 2 minutes.

(b) The idle speed control valve is

deactivated, and the idle speed is set to

its pre-programmed (unregulated) value. If

the appropriate equipment is connected,

the base idle speed can be checked

(note, however, that it is not adjustable).

(c) The ignition timing can be checked if a

timing light is connected (note, however,

that it is not adjustable).

(d) Pressing the accelerator pedal fully at any

time during this period will execute a

cylinder balance test. Each injector in turn

is switched off, and the corresponding

decrease in engine speed is logged -

code “090” will be displayed if the test is

successful.

(e) At the end of the 2 minutes, the

completion of the programme is shown

by the engine speed briefly rising, then

returning to normal idling speed as

the idle speed control valve is

reactivated.

36As with the engine-off test, further test

modes include a “wiggle test” facility,

whereby the operator can check the various

connectors as described in paragraph 19

above (in this case, any fault will be logged

and the appropriate code will be displayed), a

facility for recalling codes displayed, and a

means for clearing the ECU’s memory at the

end of the test procedure when any faults

have been rectified. If equipment other than

the Ford STAR tester is used, the ECU’s

memory can be cleared by disconnecting the

battery - if this is not done, the code will

reappear with any other codes in the event of

subsequent trouble, but remember that other

systems with memory (such as the clock and

audio equipment) will also be affected. Should

it become necessary to disconnect the

battery during work on any other part of the

vehicle, first check to see if any fault codes

have been logged.

37Given overleaf are the possible codes,

their meanings, and where relevant, the action

to be taken as a result of a code being

displayed.

Emissions control systems 6•7

6

procarmanuals.com