wheel alignment FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 257 of 413

05-02-03

General Clutch Service

05-02-03

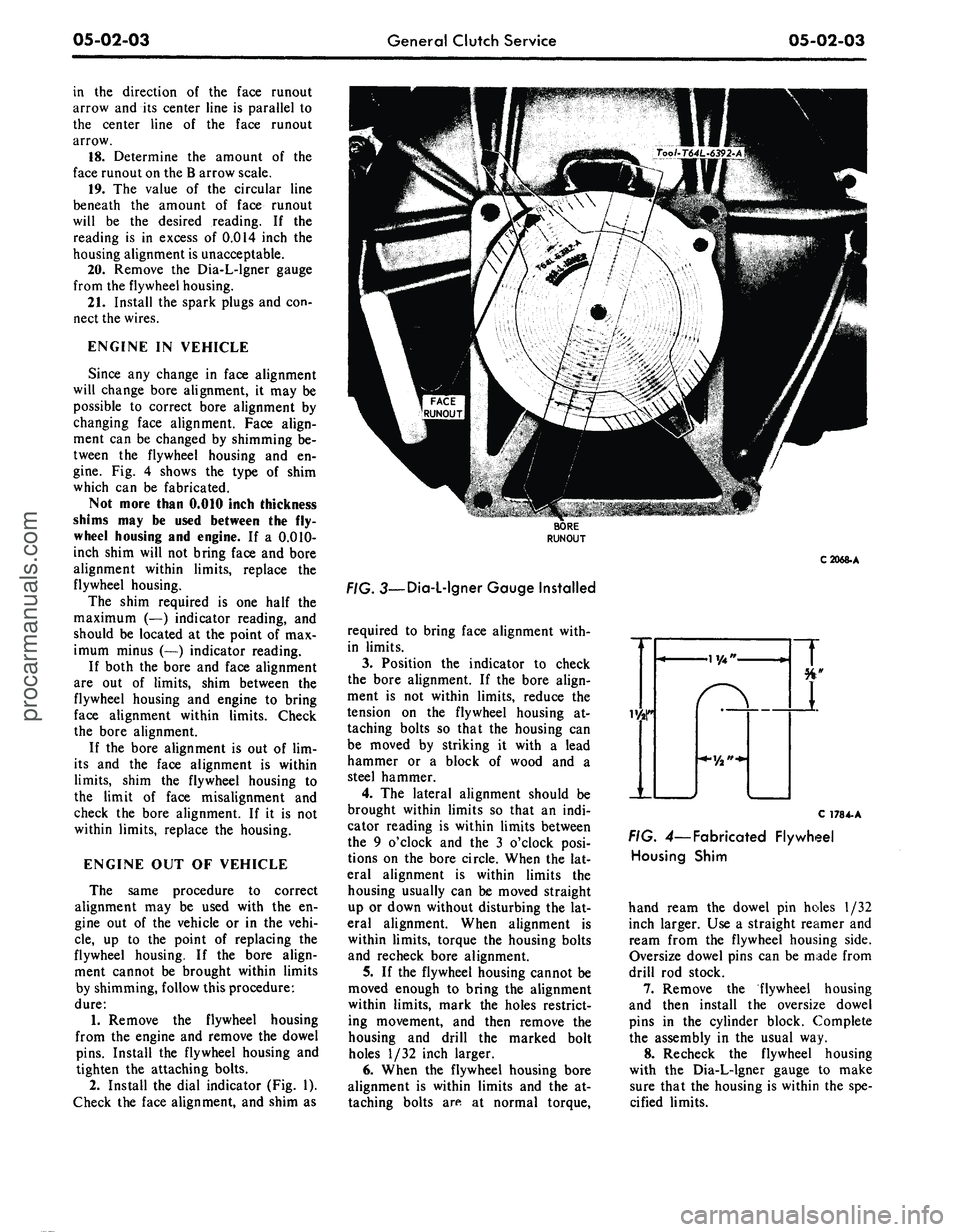

in the direction of the face runout

arrow and its center line is parallel to

the center line of the face runout

arrow.

18.

Determine the amount of the

face runout on the B arrow scale.

19.

The value of the circular line

beneath the amount of face runout

will be the desired reading. If the

reading is in excess of 0.014 inch the

housing alignment is unacceptable.

20.

Remove the Dia-L-lgner gauge

from the flywheel housing.

21.

Install the spark plugs and con-

nect the wires.

ENGINE IN VEHICLE

Since any change in face alignment

will change bore alignment, it may be

possible to correct bore alignment by

changing face alignment. Face align-

ment can be changed by shimming be-

tween the flywheel housing and en-

gine.

Fig. 4 shows the type of shim

which can be fabricated.

Not more than 0.010 inch thickness

shims may be used between the fly-

wheel housing and engine. If a 0.010-

inch shim will not bring face and bore

alignment within limits, replace the

flywheel housing.

The shim required is one half the

maximum (—) indicator reading, and

should be located at the point of max-

imum minus (—) indicator reading.

If both the bore and face alignment

are out of limits, shim between the

flywheel housing and engine to bring

face alignment within limits. Check

the bore alignment.

If the bore alignment is out of lim-

its and the face alignment is within

limits,

shim the flywheel housing to

the limit of face misalignment and

check the bore alignment. If it is not

within limits, replace the housing.

ENGINE OUT OF VEHICLE

The same procedure to correct

alignment may be used with the en-

gine out of the vehicle or in the vehi-

cle,

up to the point of replacing the

flywheel housing. If the bore align-

ment cannot be brought within limits

by shimming, follow this procedure:

dure:

1.

Remove the flywheel housing

from the engine and remove the dowel

pins.

Install the flywheel housing and

tighten the attaching bolts.

2.

Install the dial indicator (Fig. 1).

Check the face alignment, and shim as

C2068-A

. 3—Dia-L-lgner Gauge Installed

required to bring face alignment with-

in limits.

3.

Position the indicator to check

the bore alignment. If the bore align-

ment is not within limits, reduce the

tension on the flywheel housing at-

taching bolts so that the housing can

be moved by striking it with a lead

hammer or a block of wood and a

steel hammer.

4.

The lateral alignment should be

brought within limits so that an indi-

cator reading is within limits between

the 9 o'clock and the 3 o'clock posi-

tions on the bore circle. When the lat-

eral alignment is within limits the

housing usually can be moved straight

up or down without disturbing the lat-

eral alignment. When alignment is

within limits, torque the housing bolts

and recheck bore alignment.

5.

If the flywheel housing cannot be

moved enough to bring the alignment

within limits, mark the holes restrict-

ing movement, and then remove the

housing and drill the marked bolt

holes 1/32 inch larger.

6. When the flywheel housing bore

alignment is within limits and the at-

taching bolts are at normal torque,

C 178 4-A

FIG. 4— Fabricated Flywheel

Housing Shim

hand ream the dowel pin holes 1/32

inch larger. Use a straight reamer and

ream from the flywheel housing side.

Oversize dowel pins can be made from

drill rod stock.

7.

Remove the flywheel housing

and then install the oversize dowel

pins in the cylinder block. Complete

the assembly in the usual way.

8. Recheck the flywheel housing

with the Dia-L-lgner gauge to make

sure that the housing is within the spe-

cified limits.procarmanuals.com

Page 258 of 413

05-02-04

General Clutch Service

05-02-04

CLEANING AND INSPECTION

RELEASE BEARING

Wipe all oil and dirt off the release

bearing. The bearing is prelubricated

and should not be cleaned with sol-

vent.

Inspect the bearing retainer for

loose spring clips and rivets.

Inspect the release bearing assembly

for burrs which may cause the assem-

bly to drag on the transmission bear-

ing retainer. Any such burrs should be

cleaned up with fine crocus cloth. If

burrs are found, inspect the transmis-

sion input shaft bearing retainer for

evidence of scoring. Any scoring

should be polished out with crocus

cloth. Coat the bearing retainer with a

thin film of lithium-base grease

(C3VY-19586-A). Prior to release

bearing installation, apply a light film

of lithium base grease (C3VY-

19586-A) on both sides of the release

lever fork where it contacts the release

bearing hub and retaining springs.

Apply a light film of lithium base

grease (C3VY-19586-A) plate to the

release bearing surface that contacts

the pressure plate fingers. Carefully

fill the grease groove inside the bear-

ing hub with lithium base grease (no

polyethylene). Clean all excess grease

from the bore of the bearing hub. Ex-

cess grease will be forced onto the

spline by the transmission input shaft

bearing retainer and will contaminate

the clutch disc. Also, care must be

exercised when applying lubricants to

the release bearing, release bearing

hub and the release lever fork to avoid

excessive grease from contaminating

the clutch disc.

Hold the bearing inner race and ro-

tate the outer race while applying

pressure to it. If the bearing rotation

is rough or noisy, replace the bearing.

Most release bearing failures are

caused by improper clutch pedal ad-

justments. If the clutch linkage does

not have enough free travel, the re-

lease bearing will constantly touch the

release fingers and will spin whenever

the engine is running.

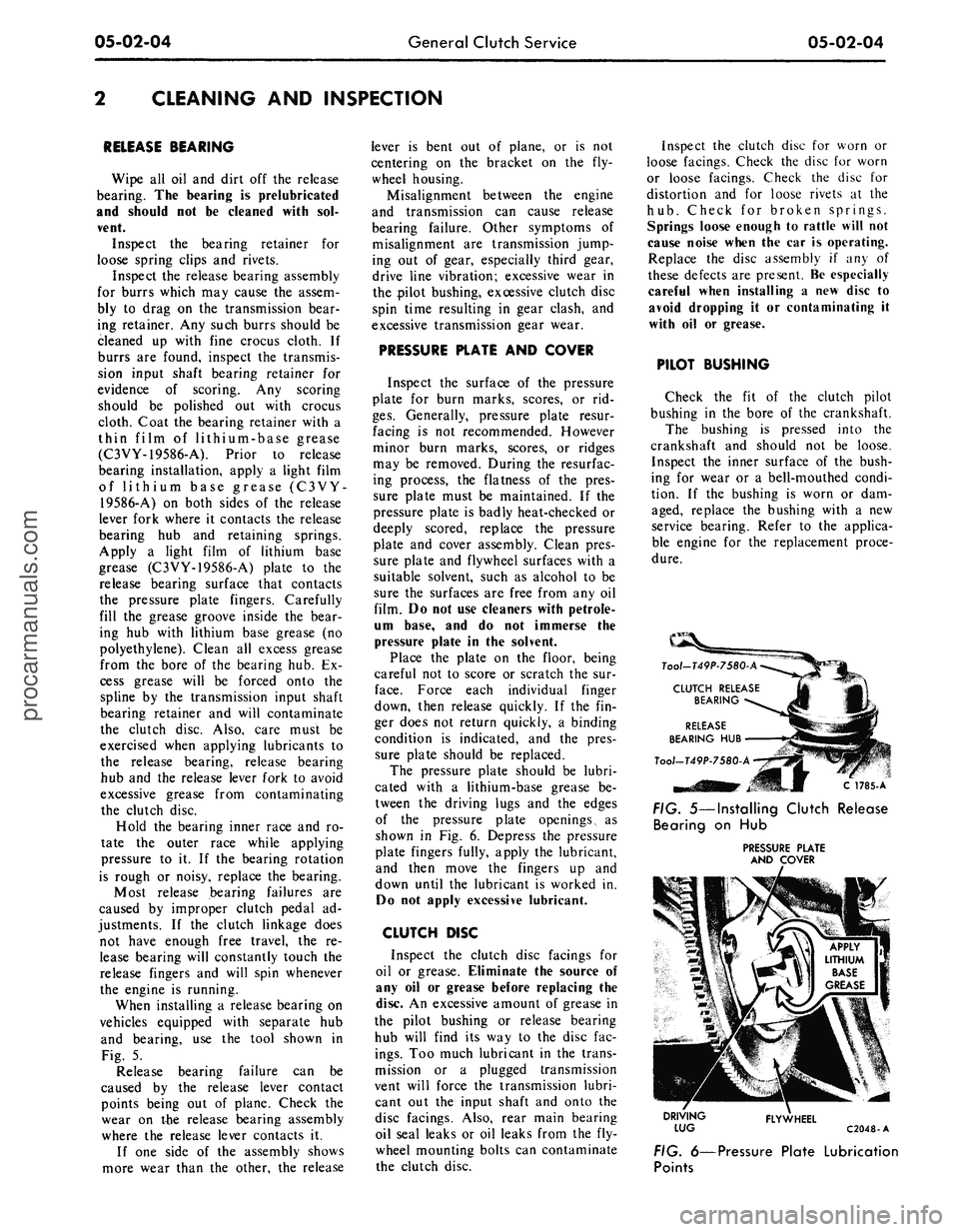

When installing a release bearing on

vehicles equipped with separate hub

and bearing, use the tool shown in

Fig. 5.

Release bearing failure can be

caused by the release lever contact

points being out of plane. Check the

wear on the release bearing assembly

where the release lever contacts it.

If one side of the assembly shows

more wear than the other, the release

lever is bent out of plane, or is not

centering on the bracket on the fly-

wheel housing.

Misalignment between the engine

and transmission can cause release

bearing failure. Other symptoms of

misalignment are transmission jump-

ing out of gear, especially third gear,

drive line vibration; excessive wear in

the pilot bushing, excessive clutch disc

spin time resulting in gear clash, and

excessive transmission gear wear.

PRESSURE PLATE AND COVER

Inspect the surface of the pressure

plate for burn marks, scores, or rid-

ges.

Generally, pressure plate resur-

facing is not recommended. However

minor burn marks, scores, or ridges

may be removed. During the resurfac-

ing process, the flatness of the pres-

sure plate must be maintained. If the

pressure plate is badly heat-checked or

deeply scored, replace the pressure

plate and cover assembly. Clean pres-

sure plate and flywheel surfaces with a

suitable solvent, such as alcohol to be

sure the surfaces are free from any oil

film. Do not use cleaners with petrole-

um base, and do not immerse the

pressure plate in the solvent.

Place the plate on the floor, being

careful not to score or scratch the sur-

face.

Force each individual finger

down, then release quickly. If the fin-

ger does not return quickly, a binding

condition is indicated, and the pres-

sure plate should be replaced.

The pressure plate should be lubri-

cated with a lithium-base grease be-

tween the driving lugs and the edges

of the pressure plate openings, as

shown in Fig. 6. Depress the pressure

plate fingers fully, apply the lubricant,

and then move the fingers up and

down until the lubricant is worked in.

Do not apply excessive lubricant.

CLUTCH DISC

Inspect the clutch disc facings for

oil or grease. Eliminate the source of

any oil or grease before replacing the

disc. An excessive amount of grease in

the pilot bushing or release bearing

hub will find its way to the disc fac-

ings.

Too much lubricant in the trans-

mission or a plugged transmission

vent will force the transmission lubri-

cant out the input shaft and onto the

disc facings. Also, rear main bearing

oil seal leaks or oil leaks from the fly-

wheel mounting bolts can contaminate

the clutch disc.

Inspect the clutch disc for worn or

loose facings. Check the disc for worn

or loose facings. Check the disc for

distortion and for loose rivets at the

hub.

Check for broken springs.

Springs loose enough to rattle will not

cause noise when the car is operating.

Replace the disc assembly if any of

these defects are present. Be especially

careful when installing a new disc to

avoid dropping it or contaminating it

with oil or grease.

PILOT BUSHING

Check the fit of the clutch pilot

bushing in the bore of the crankshaft.

The bushing is pressed into the

crankshaft and should not be loose.

Inspect the inner surface of the bush-

ing for wear or a bell-mouthed condi-

tion. If the bushing is worn or dam-

aged, replace the bushing with a new

service bearing. Refer to the applica-

ble engine for the replacement proce-

dure.

C 1785-A

FIG. 5—Installing Clutch Release

Bearing on Hub

PRESSURE PLATE

AND COVER

DRIVING

LUG

FLYWHEEL

C2048-A

FIG. 6—Pressure Plate Lubrication

Pointsprocarmanuals.com

Page 268 of 413

06-01-02

General Transmission Service

06-01-02

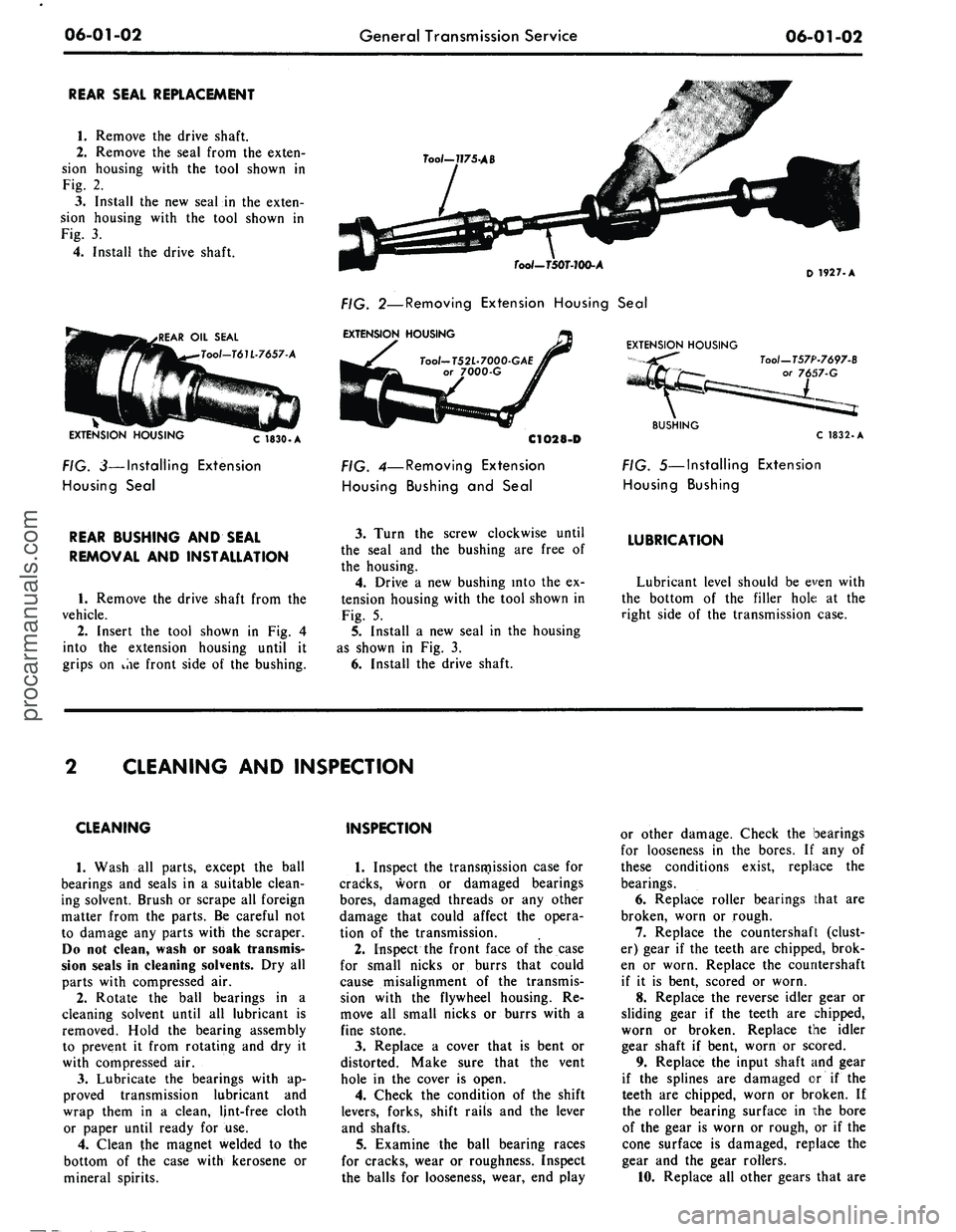

REAR SEAL REPLACEMENT

1.

Remove the drive shaft.

2.

Remove the seal from the exten-

sion housing with the tool shown in

Fig. 2.

3.

Install the new seal in the exten-

sion housing with the tool shown in

Fig. 3.

4.

Install the drive shaft.

.REAR OIL SEAL

Tool-T61L-7657-A

EXTENSION HOUSING

C 1830.A

FIG. 3—Installing Extension

Housing Seal

Too/-7J75-AB

Tool-TSOT-lOO-A

FIG. 2—Removing Extension Housing Seal

EXTENSION HOUSING

Tool-T52L-7000-GAE

or 7000-G

C1O28-D

FIG. 4—Removing Extension

Housing Bushing and Seal

EXTENSION HOUSING

D

1927. A

Tool—T57P-7697-B

57-G

BUSHING

C 1832.A

FIG. 5—Installing Extension

Housing Bushing

REAR BUSHING AND SEAL

REMOVAL AND INSTALLATION

1.

Remove the drive shaft from the

vehicle.

2.

Insert the tool shown in Fig. 4

into the extension housing until it

grips on ihe front side of the bushing.

3.

Turn the screw clockwise until

the seal and the bushing are free of

the housing.

4.

Drive a new bushing into the ex-

tension housing with the tool shown in

Fig. 5.

5.

Install a new seal in the housing

as shown in Fig. 3.

6. Install the drive shaft.

LUBRICATION

Lubricant level should be even with

the bottom of the filler hole at the

right side of the transmission case.

CLEANING AND INSPECTION

CLEANING

1.

Wash all parts, except the ball

bearings and seals in a suitable clean-

ing solvent. Brush or scrape all foreign

matter from the parts. Be careful not

to damage any parts with the scraper.

Do not clean, wash or soak transmis-

sion seals in cleaning solvents. Dry all

parts with compressed air.

2.

Rotate the ball bearings in a

cleaning solvent until all lubricant is

removed. Hold the bearing assembly

to prevent it from rotating and dry it

with compressed air.

3.

Lubricate the bearings with ap-

proved transmission lubricant and

wrap them in a clean, lint-free cloth

or paper until ready for use.

4.

Clean the magnet welded to the

bottom of the case with kerosene or

mineral spirits.

INSPECTION

1.

Inspect the transmission case for

cracks, worn or damaged bearings

bores,

damaged threads or any other

damage that could affect the opera-

tion of the transmission.

2.

Inspect the front face of the case

for small nicks or burrs that could

cause misalignment of the transmis-

sion with the flywheel housing. Re-

move all small nicks or burrs with a

fine stone.

3.

Replace a cover that is bent or

distorted. Make sure that the vent

hole in the cover is open.

4.

Check the condition of the shift

levers, forks, shift rails and the lever

and shafts.

5.

Examine the ball bearing races

for cracks, wear or roughness. Inspect

the balls for looseness, wear, end play

or other damage. Check the bearings

for looseness in the bores. If any of

these conditions exist, replace the

bearings.

6. Replace roller bearings that are

broken, worn or rough.

7.

Replace the countershaft (clust-

er) gear if the teeth are chipped, brok-

en or worn. Replace the countershaft

if it is bent, scored or worn.

8. Replace the reverse idler gear or

sliding gear if the teeth are chipped,

worn or broken. Replace the idler

gear shaft if bent, worn or scored.

9. Replace the input shaft and gear

if the splines are damaged or if the

teeth are chipped, worn or broken. If

the roller bearing surface in the bore

of the gear is worn or rough, or if the

cone surface is damaged, replace the

gear and the gear rollers.

10.

Replace all other gears that areprocarmanuals.com

Page 282 of 413

06-03-03

Ford Design Four-Speed Transmission

06-03-03

cable from the equalizer lever and sep-

arate the lever from the crossmember.

5.

Remove the hairpin retainer se-

curing the cable to the transmission

rear support crossmember, and then

pull the cable assembly forward and

out of the crossmember.

6. Remove the retaining clip, flat

washer, and spring washer that se-

cures the shift rods to the shift levers.

7.

Remove the bolts that attach the

shift linkage control bracket to the ex-

tension housing and position the as-

sembly out of the way.

8. Support the engine with a trans-

mission jack and remove the extension

housing-to-engine rear support attach-

ing bolts.

9. Raise the rear of the engine high

enough to remove the weight from the

crossmember. Remove the bolts re-

taining the crossmember to the frame

side supports and remove the

crossmember.

10.

Support the transmission on a

jack and remove the bolts that attach

the transmission to the flywheel hous-

ing.

11.

Move the transmission and jack

rearward until the transmission input

shaft clears the flywheel housing. If

necessary, lower the engine enough to

obtain clearance for transmission re-

moval.

Do not depress the clutch pedal

while the transmission is removed.

INSTALLATION

1.

Make sure that the mounting

surface of the transmission and the

flywheel housing are free of dirt,

paint, and burrs. Install two guide

pins in the flywheel housing lower

mounting bolt holes. Move the trans-

mission forward on the guide pins

until the input shaft splines enter the

clutch hub splines and the case is posi-

tioned against the flywheel housing.

2.

Install the two upper transmis-

sion to flywheel housing, mounting

bolts snug, and then remove the two

guide pins. Install the two lower

mounting bolts. Torque all mounting

bolts to specifications.

3.

Raise the rear of the engine and

install the crossmember. Install and

torque the crossmember attaching

bolts to specifications, then lower the

engine.

4.

With the transmission extension

housing resting on the engine rear

support, install the transmission ex-

tension housing attaching bolts. Tor-

que the bolts to specifications.

5.

Position the shift linkage control

bracket to the extension housing and

install the attaching bolts.

6. Secure each shift rod to its re-

spective lever with the spring washer,

flat washer, and retaining pin.

7.

Guide the parking brake cable

assembly through the hole in the

transmission rear support crossmemb-

er. Secure the cable assembly to the

crossmember with the hair pin retain-

er.

8. Insert the parking brake front

cable in the equalizer and install the

equalizer in the bracket on the

crossmember. Secure the parking

brake rear cable to the equalizer.

9. Connect the speedometer cable

to the extension housing.

10.

Remove the extension housing

installation tool and slide the forward

end of the drive shaft over the trans-

mission output shaft. Connect the

drive shaft to the rear U-joint flange.

11.

Place both forward gear shift

levers and the reverse shift lever in the

neutral position and insert a 1/4 inch

diameter alignment tool in the shift

linkage alignment hole (Fig. 17). It

may be necessary to loosen the adjust-

ment nuts to install the alignment

tool. Adjust the linkage as necessary

and tighten the adjustment nuts to

specifications. Remove the alignment

tool.

12.

Fill the transmission to the

proper level with the specified lubri-

cant.

13.

Lower the car. Check tne shift

and crossover motion for full shift en-

gagement and smooth crossover oper-

ation.

MAJOR REPAIR OPERATIONS

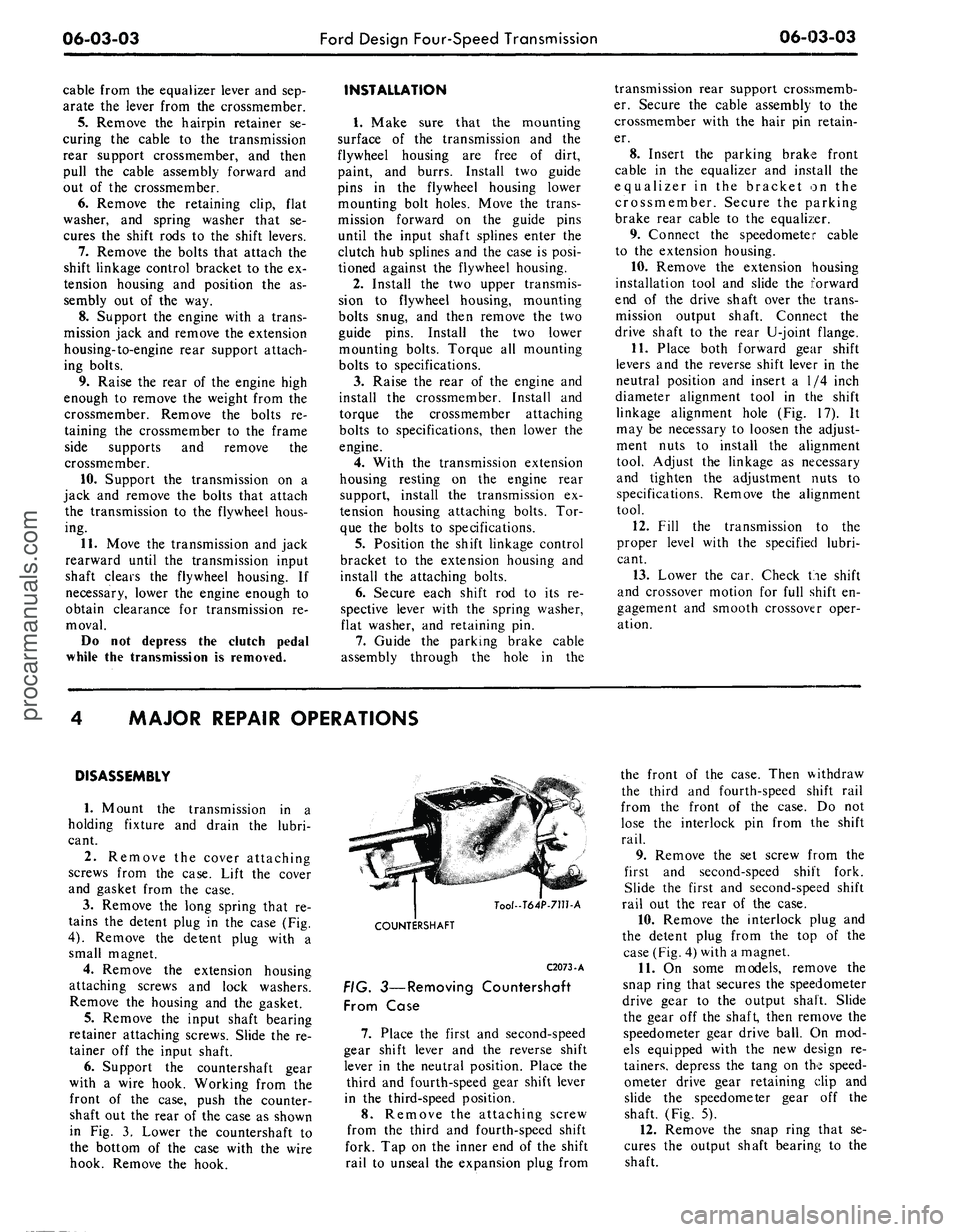

DISASSEMBLY

1.

Mount the transmission in a

holding fixture and drain the lubri-

cant.

2.

Remove the cover attaching

screws from the case. Lift the cover

and gasket from the case.

3.

Remove the long spring that re-

tains the detent plug in the case (Fig.

4).

Remove the detent plug with a

small magnet.

4.

Remove the extension housing

attaching screws and lock washers.

Remove the housing and the gasket.

5.

Remove the input shaft bearing

retainer attaching screws. Slide the re-

tainer off the input shaft.

6. Support the countershaft gear

with a wire hook. Working from the

front of the case, push the counter-

shaft out the rear of the case as shown

in Fig. 3. Lower the countershaft to

the bottom of the case with the wire

hook. Remove the hook.

Tool-T64P-711hA

COUNTERSHAFT

C2073-A

FIG. 3—Removing Countershaft

From Case

7.

Place the first and second-speed

gear shift lever and the reverse shift

lever in the neutral position. Place the

third and fourth-speed gear shift lever

in the third-speed position.

8. Remove the attaching screw

from the third and fourth-speed shift

fork. Tap on the inner end of the shift

rail to unseal the expansion plug from

the front of the case. Then withdraw

the third and fourth-speed shift rail

from the front of the case. Do not

lose the interlock pin from the shift

rail.

9. Remove the set screw from the

first and second-speed shift fork.

Slide the first and second-speed shift

rail out the rear of the case.

10.

Remove the interlock plug and

the detent plug from the top of the

case (Fig. 4) with a magnet.

11.

On some models, remove the

snap ring that secures the speedometer

drive gear to the output shaft. Slide

the gear off the shaft, then remove the

speedometer gear drive ball. On mod-

els equipped with the new design re-

tainers, depress the tang on the speed-

ometer drive gear retaining clip and

slide the speedometer gear off the

shaft. (Fig. 5).

12.

Remove the snap ring that se-

cures the output shaft bearing to the

shaft.procarmanuals.com

Page 383 of 413

07-04-14

C-6 Automatic Transmission

07-04-14

taching bolt to turn the converter to

gain access to the nuts.

5.

Remove the rear mount to

crossmember attaching bolt.

6. Remove the two crossmember-

to-frame attaching bolts.

7.

Remove the two engine rear

support-to-extension housing attaching

bolts.

8. Disconnect the downshift rod

from the transmission downshift lever.

9. Disconnect the manual linkage

rod from the lever at the transmission.

On a column shift, use tool T67P-

7341-A to remove the rod.

10.

Remove the two bolts securing

the bellcrank bracket to the converter

housing.

11.

Raise the transmission with a

transmission jack to provide clearance

to remove the crossmember.

12.

Remove the rear mount from

the crossmember and remove the

crossmember from the side supports.

13.

Lower the transmission to gain

access to the oil cooler lines.

14.

Disconnect each oil line from

the fittings on the transmission.

15.

Disconnect the vacuum line

from the diaphragm located at the

right rear of the transmission. Remove

the metal line from the retaining clip

on the transmission.

16.

Disconnect the speedometer

cable from the extension housing.

17.

Remove the bolt that secures

the transmission fluid filler tube to the

cylinder block. Lift the filler tube and

the dipstick from the transmission.

18.

Secure the transmission to the

jack with the chain.

19.

Remove the converter housing-

to-cylinder block attaching bolts.

20.

Carefully move the transmission

away from the engine and, at the

same time, lower it to clear the und-

erside of the vehicle.

21.

Remove the converter and

mount the transmission in a holding

fixture.

INSTALLATION—FORD

MERCURY AND METEOR

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission to the

jack with the chain.

4.

Rotate the flywheel to place two

converter mounting stud holes that are

adjacent to the drain plug holes in a

vertical position.

5.

Rotate the converter so that the

studs and drain plugs are in alignment

with those in the flywheel.

6. Move the transmission toward

the cylinder block until they are in

contact. Install and torque the attach-

ing bolts to specification making sure

that the vacuum tube retaining clips

are properly positioned.

7.

Remove the transmission jack

chain from around the transmission.

8. Install a new Oring on the lower

end of the transmission filler tube. In-

sert the tube in the transmission case

and secure the tube to the engine with

the attaching bolt.

9. Connect the speedometer cable

to the extension housing.

10.

Connect the oil cooler lines to

the right side of transmission case.

11.

Connect the vacuum line to the

vacuum diaphragm making sure that

the metal tube is secured in the retain-

ing clip.

12.

Position the cross member on

the side supports. Position the rear

mount on the crossmember and install

the attaching bolt and nut.

13.

Secure the engine rear support

to the extension housing and torque

the bolts to specification.

14.

Lower the transmission and re-

move the jack.

15.

Secure the crossmember to the

side supports with the attaching bolts

and torque them to specification.

16.

Position the bellcrank bracket

to the converter housing and install

the two attaching bolts.

17.

Connect the downshift rod to

the transmission downshift lever.

18.

Connect the selector rod to the

manual lever at the transmission. On

a column shift, use tool T67P-7341-A

and install a new grommet in the

manual lever. Then, secure the manual

selector rod to the lever.

19.

Secure the converter-to-flywheel

attaching nuts and torque them to

specification. Use a wrench on the

crankshaft pulley attaching nut to ro-

tate the flywheel. Do not use a wrench

on the converter attaching nuts to ro-

tate it.

20.

Install the converter housing

dust shield and secure it with the at-

taching bolts.

21.

Secure the starter motor in

place with the attaching bolts. Con-

nect the cable to the terminal on the

starter.

22.

Install the driveshaft.

23.

Adjust the shift linkage as de-

tailed in Section 2.

24.

Lower the vehicle.

25.

Fill the transmission to the cor-

rect level with the specified lubricant.

Start the engine and shift the trans-

mission to all ranges, then recheck the

fluid level.

REMOVAL—FAIRLANE,

MONTEGO, MUSTANG

AND COUGAR

1.

On Mustang and Cougar, dis-

connect the neutral switch wires from

the harness connector and the retain-

ing clip on the dash.

2.

Remove the bolt that secures the

filler tube to the rear of the right

cylinder head.

3.

Raise the vehicle on a hoist or

jack stands.

4.

Remove the converter drain plug

access cover from the lower end of the

converter housing.

5.

Place a drain pan under nhe con-

verter housing and remove the two

converter drain plugs. Install the plugs

after the fluid has drained.

6. Place the drain pan under the

transmission fluid pan. Starting at the

rear of the pan and working toward

the front, loosen the attaching bolts

and allow the fluid to drain. Finally

remove all of the pan attaching bolts

except two at the front, to allow the

fluid to further drain. After the fluid

has drained, install two bolts on the

rear side of the pan to temporarily

hold it in place.

7.

Disconnect the drive shaft from

the rear axle flange and remove it

from the transmission. Install tool

T61L-7657-A in the rear of the exten-

sion housing to prevent the fluid from

leaking.

8. Disconnect the downshift rod

from the transmission downshift lever.

9. Disconnect the shift rod from the

manual lever. On a column shift, use

tool T67P-7341-A to remove the rod.

10.

Disconnect the speedometer

cable from the extension housing.

11.

Disconnect the rubber hose

from the vacuum diaphragm at the

rear of the transmission. Remove the

vacuum tube from the retaining clip at

the transmission.

12.

Disconnect the starter cable

from the terminal on the starter. Re-

move the starter attaching bolts and

remove it from the housing.

13.

Lift the fluid filler tube from

the transmission case.

14.

Remove the four converter-

to-flywheel attaching nuts.

15.

On a Mustang or Cougar, dis-

connect the complete exhaust system

and allow it to hang on the rear axle.

16.

Remove the two nuts that at-

tach the engine rear support to the

crossmember.

17.

Raise the transmission with a

jack just enough to remove the weight

from the crossmember.

18.

Remove the cotter pins from

the crossmember-to-frame side sup-procarmanuals.com

Page 384 of 413

07-04-15

C-6

Automatic Transmission

07-04-15

port attaching nuts and remove the

nuts.

Lift the crossmember from the

frame side supports.

19.

Remove the bolts that attach

the engine rear support to the exten-

sion housing and remove the support.

20.

Lower the transmission, then

disconnect the fluid cooler lines from

the transmission case.

21.

Secure the transmission to the

jack with a chain.

22.

Remove the six bolts that at-

tach the converter housing to the cyl-

inder block.

23.

Move the jack rearward until

the transmission clears the engine,

then tip it forward to provide clear-

ance. Lower the transmission and re-

move it from under the vehicle.

24.

Remove the converter from the

transmission. Mount the transmission

in a holding fixture if repairs are nec-

essary.

INSTALLATION—FAIRLANE,

MONTEGO,

MUSTANG

AND COUGAR

1. Mount the transmission in a

transmission jack and secure it with a

safety chain.

2.

Install the converter on the front

pump.

3.

Rotate the flywheel so that the

drain plug holes are in a vertical posi-

tion. Rotate the converter so that the

drain plugs are in the same relative

position as the drain plug holes in the

flywheel.

4.

Roll the transmission into posi-

tion under the vehicle and raise it to

alignment with the engine. Move it

forward until the converter housing

contacts the cylinder block. Install

and torque the converter-to-cylinder

block attaching bolts.

5.

Remove the jack safety chain

from the transmission.

6. Connect the two fluid cooler

lines to the fittings in the transmission

case.

7.

Secure the engine rear support to

the extension housing with the attach-

ing bolts. Torque the bolts to specifi-

cation.

8. Position the crossmember on the

frame side supports and install and

tighten the attaching nuts to specifica-

tion. Install cotter Dins to retain the

nuts.

9. Remove the transmission jack

from under the vehicle. Install and

torque the engine rear support-

to-crossmember attaching nuts.

10.

Install the exhaust system on

Mustang and Cougar.

11.

Install the converter-to-flywheel

attaching nuts and torque them to

specifications. Tighten the drain plugs

to specification.

12.

Secure the converter drain plug

access cover to the lower end of the

converter housing with the attaching

bolts.

13.

Install a new O-ring on the

lower end of the fluid filler tube. Dip

the O-ring in clean automatic trans-

mission fluid and insert the filler tube

in the transmission case.

14.

Secure the starter to the con-

verter housing. Connect the cable to

the terminal on the starter.

15.

Connect the speedometer cable

to the extension housing.

16.

Connect the shift rod to the

manual lever at the transmission. On

a column shift, use tool T67P-7341-A

and install a new grommet in the

manual lever. Then, secure the manual

selector rod to the lever.

17.

Connect the downshift rod to

the lever on the transmission. Adjust

the rod.

18.

Remove the tool from the ex-

tension housing and install the drive

shaft.

19.

Lower the vehicle.

20.

Working from the engine com-

partment, secure the fluid filler tube

to the rear of the right cylinder head

with the attaching bolt.

21.

On Mustang and Cougar, con-

nect the neutral switch wires to the

harness. Secure the wires to the dash

with the retaining clip.

22.

Fill the transmission with the

specified lubricant as detailed in Part

7-1.

REMOVAL—THUNDERBIRD

1. Working from the engine com-

partment, remove the fluid filler tube

bracket attaching screw that secures it

to the rear of the right cylinder head.

Lift the tube and dipstick from the

transmission.

2.

Remove the starting motor upper

attaching bolt using a long extension.

3.

Remove the two converter hous-

ing upper attaching bolts.

4.

Raise the vehicle on a hoist or

stands.

5.

Remove the dust shield from the

front lower end of the converter hous-

ing.

6. Crank the engine until one of the

converter drain plugs is accessible.

Then, remove the plug.

7.

Crank the engine until the other

plug is at the bottom. Place a drain

pan to catch the fluid, then remove

the pan and allow the fluid to drain.

8. Remove the drive shaft.

9. Remove the frame side rail sup-

port brace attaching bolts and remove

the brace.

10.

After the fluid has been drained

from the converter, install the plug.

11.

Place the drain pan under the

transmission pan and loosen the at-

taching bolts and allow the fluid to

drain. Finally remove all of the pan

attaching bolts except two, to allow

the oil to further drain. After the fluid

has drained, install two bolts on the

opposite side of the pan to temporari-

ly hold it in place.

12.

Remove the converter-

to-flywheel attaching nuts.

13.

Disconnect the downshift link-

age from the transmission downshift

lever.

14.

Using tool T67P-7341-A, re-

move the selector rod from the manu-

al lever.

15.

Remove the two screws that at-

tach the shift rod bellcrank bracket to

the converter housing and remove the

bracket.

16.

Disconnect the vacuum dia-

phragm hose from the upper end of

the vacuum tube.

17.

Disconnect the speedometer

cable from the extension housing and

place it to one side.

18.

Remove the starting motor two

lower attaching bolts and place the

motor to one side.

19.

Disconnect the two oil cooler

lines from the right side of the trans-

mission.

20.

Disconnect the muffler inlet

pipes at the exhaust manifolds and

allow the pipes to hang.

21.

Remove the vibration absorber

from the extension housing.

22.

Remove the two engine rear

support-to-extension housing attaching

bolts.

23.

Place a transmission jack under

the transmission and raise it just

enough to remove the weight from the

support.

24.

Remove the two support attach-

ing bolts and remove the support.

25.

Lower the jack just enough to

remove the weight.

26.

Remove the four remaining

converter housing-to-cylinder block at-

taching bolts and the accelerator link-

age stop from the left side of the

housing.

27.

Carefully lower the transmis-

sion and remove it from under the ve-

hicle.

28.

Remove the converter and

mount the transmission in a holding

fixture.procarmanuals.com

Page 385 of 413

07-04-16

C-6 Automatic Transmission

07-04-16

INSTALLATION—

THUNDERBIRD

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission on a

transmission jack.

4.

Rotate the converter so that the

studs and drain plugs are in alignment

with their holes in the flywheel.

5.

Move the transmission toward

the cylinder block until they contact

each other. Install and torque the at-

taching bolts to specification. Before

tightening the center bolt on the left

side,

make sure that the accelerator

linkage stop bracket is properly posi-

tioned so that the left upper bolt may

be installed later.

6. Connect the fluid cooler lines to

their fittings on the right side of the

transmission.

7.

Raise the transmission and in-

stall the engine rear support and tor-

que the bolts to specification. Make

sure that the hand brake equalizer is

positioned properly.

8. Lower the transmission and re-

move the jack.

9. Install the engine rear support-

to-extension housing attaching bolts.

10.

Install the drive shaft.

11.

Connect the speedometer cable

to the extension housing.

12.

Position the starting motor on

the converter housing and secure it

with the two lower bolts.

13.

Install the torque converter-

to-flywheel attaching nuts and torque

them to specification.

14.

Install the converter housing

dust shield.

15.

Secure the frame side rail sup-

port brace with the attaching bolts

and lock washers. Torque the bolts to

specification.

16.

Connect the downshift rod to

the transmission downshift lever.

17.

Connect the vacuum diaphragm

hose to the upper end of the vacuum

tube.

18.

Using Tool T67P-7341-A, in-

stall a new grommet in the manual

lever. Then, secure the manual selec-

tor rod to the lever.

19.

Position the vibration absorber

to the transmission extension housing

and secure it with the three attaching

bolts.

20.

Connect the muffler inlet pipes

to the exhaust manifolds.

21.

Lower the vehicle and install

the two converter housing upper bolts

and torque them to specification.

22.

Install the starting motor upper

bolt.

23.

Place a new O-ring on the end

of the fluid filler tube and insert it in

the transmission case. Secure the tube

to the rear of the right cylinder head

with the attaching screw and lock

washer.

24.

Fill the transmission to the

proper level with the specified fluids.

25.

Adjust the manual and throttle

linkage as required.

REMOVAL-

CONTINENTAL MARK III

1.

Working from the engine com-

partment, lift the fluid filler tube dio-

stick from the transmission.

2.

Raise the vehicle on a hoist or

stands.

3.

Remove the dust shield from the

front lower end of the converter hous-

ing.

4.

Crank the engine until one of the

converter drain plugs is accessible.

Then, remove the plug.

5.

Crank the engine until the other

plug is at the bottom. Place a drain

pan to catch the fluid, then remove

the pan and allow the fluid to drain.

6. Remove the driveshaft.

7.

Remove the frame side rail sup-

port brace attaching bolts and remove

the brace.

8. After the fluid has been drained

from the converter, install the plug.

9. Place the drain pan under the

transmission pan and loosen the at-

taching bolts and allow the fluid to

drain. Finally remove all of the pan

attaching bolts except two, to allow

the oil to further drain. After the fluid

has drained, install two bolts on the

opposite side of the pan to temporari-

ly hold it in place.

10.

Remove the. converter-

to-flywheel attaching nuts.

11.

Disconnect the downshift link-

age from the transmission downshift

lever.

12.

Using tool T67P-7341-A, re-

move the selector rod from the manu-

al lever.

13.

Remove the two screws that at-

tach the shift rod bellcrank bracket to

the converter housing and remove the

bracket.

14.

Disconnect the vacuum dia-

phragm hose at the transmission.

15.

Disconnect the speedometer

cable from the extension housing and

place it to one side.

16.

Remove the two idler arm

bracket retaining bolts at the frame

side rail and allow the linkage to

hang.

17.

Disconnect the starter cable

from the terminal on the starter. Re-

move the starter attaching bolts and

remove it from the housing.

18.

Remove the clip securing the oil

cooler lines to the support bracket.

19.

Disconnect the two oil cooler

lines from the right side of the trans-

mission.

20.

Disconnect the muffler inlet

pipes at the exhaust manifolds and

allow the pipes to hang.

21.

Remove the vibration absorber

from the extension housing.

22.

Remove the engine rear support

to extension housing attaching bolts.

23.

Place a transmission jack under

the transmission and raise it just

enough to remove the weight from the

support.

24.

Remove the two support attach-

ing bolts and remove the support.

25.

Lower the jack and secure the

transmission to the jack with a safety

chain.

26.

Remove the bolt that secures

the filler tube to the rear of the right

cylinder head and lift the tube from

the transmission case.

27.

Remove the six converter

housing-to-cylinder block attaching

bolts.

28.

Carefully lower the transmis-

sion and remove it from under the ve-

hicle.

29.

Remove the converter and

mount the transmission in a holding

fixture.

INSTALLATION—

CONTINENTAL MARK III

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission on a

transmission jack.

4.

Rotate the converter so that the

studs and drain plugs are in alignment

with their holes in the flywheel.

5.

Move the transmission toward

the cylinder block until they contact

each other. Install and torque the at-

taching bolts to specification

6. Remove the jack safety chain

from the transmission.

7.

Connect the fluid cooler lines to

their fittings on the right side of the

transmission.

8. Install a new O-ring on the lower

end of the fluid filler tube. Dip the

O-ring in clean automatic transmis-

sion fluid and insert the tube in the

transmission case. Install the attach-

ing bolt.procarmanuals.com

Page 386 of 413

07-04-17

C-6 Automatic Transmission

07-04-17

9. Raise the transmission and in-

stall the engine rear support and tor-

que the bolts to specification.

10.

Lower the transmission and re-

move the jack.

11.

Install the engine rear support-

to-extension housing attaching bolts.

12.

Install the drive shaft.

13.

Connect the speedometer cable

to the extension housing.

14.

Connect the muffler inlet pipes

to the exhaust manifolds.

15.

Position the starting motor on

the converter housing and secure it

with the attaching bolts. Connect the

cable to the terminal on the starter.

16.

Position the idler arm bracket

to the frame side rail and install the

attaching bolts.

17.

Install the torque converter-

to-flywheel attaching nuts and torque

them to specification.

18.

Install the converter housing

dust shield.

19.

Secure the frame side rail sup-

port brace with the attaching bolts

and lock washers. Torque the bolts to

specification.

20.

Connect the downshift rod to

the transmission downshift lever.

21.

Using Tool T67P-7341-A, in-

stall a new grommet in the manual

lever. Then, secure the manual selec-

tor rod to the lever.

22.

Connect the vacuum hose to the

vacuum diaphragm.

23.

Install the oil cooler line retain-

ing clip at the transmission support.

24.

Position the vibration absorber

to the transmission extension housing

and secure it with the three attaching

bolts.

25.

Lower the vehicle.

26.

Fill the transmission to the

proper level with the specified fluids.

27.

Adjust the manual and throttle

linkage as required.

REMOVAL-

LINCOLN CONTINENTAL

1.

Raise the hood and remove the

transmission dipstick.

2.

Raise the vehicle on a hoist. Re-

move the bolt that secures the trans-

mission filler tube to the cylinder

head.

3.

Remove the bolts that attach the

reinforcement plate at the rear of the

transmission oil pan and remove the

plate.

4.

Remove the three bolts that at-

tach the manual and downshift control

rod splash shield to the side rail and

remove the shield.

5.

Place a drain pan under the

transmission. Loosen all transmission

pan attaching bolts and allow the fluid

to drain. Remove the bolts from the

rear and both sides of the pan to

allow further drainage; then, finally

remove the pan. After all fluid has

been drained, install the pan using

four attaching bolts.

6. Remove the two bolts that attach

the cover to the lower end of the con-

verter housing.

7.

Remove the two front support

bracket bolts at the converter housing.

8. Remove the two drain plugs

from the converter and allow it to

drain.

9. Remove the four nuts that attach

the converter to the flywheel.

10.

Lift the fluid filler tube from

the transmission case.

11.

Remove the two idler arm

bracket bolts from the frame side rail

and allow the idler arm to hang free.

12.

Disconnect the starter cable

from the starter. Remove the starter

attaching bolts and remove the starter.

13.

Disconnect the oil cooler lines

from the transmission.

14.

Disconnect the vacuum hose

from the diaphragm.

15.

Loosen the parking brake ad-

justing nut at the equalizer and re-

move the retracting spring. Disconnect

the rear brake cables and remove the

equalizer from the bracket.

16.

Disconnect the speedometer

cable from the extension housing.

17.

Disconnect the drive shaft from

the transmission flange and position

the shaft out of the way.

18.

Disconnect the downshift rod

from the transmission downshift lever.

19.

Using tool T67P-7341-A, re-

move the manual selector rod from

the manual lever.

20.

Remove the lower bellcrank at-

taching bolts and remove the bell-

crank.

21.

Pry the upper bellcrank out of

the converter housing and allow it to

hang free.

22.

Remove the cooler lines from

the clip at the cylinder head.

23.

Remove the converter housing-

to-cylinder block lower attaching

bolts.

24.

Remove the two nuts that at-

tach the engine rear mounts to the

crossmember.

25.

Place a transmission jack under

the transmission and raise it just high

enough to remove the weight from the

crossmember.

26.

Remove the engine rear

support-to-extension housing attaching

bolts and remove the supports.

27.

Remove the crossmember-

to-frame attaching nuts and remove

the crossmember.

28.

Secure the transmission to the

jack with the safety chain. Lower the

transmission and remove the upper

converter housing-to-cylinder block at-

taching bolts.

29.

Move the transmission away

from the cylinder block.

30.

Carefully lower the transmis-

sion and remove it from under the ve-

hicle.

31.

Remove the converter and mount

the transmission in a holding fixture.

INSTALLATION-

LINCOLN CONTINENTAL

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission on a

transmission jack.

4.

Rotate the converter so that the

studs and drain plugs are in alignment

with those in the flywheel.

5.

Move the transmission toward the

cylinder block until they contact each

other. Install and torque the attaching

bolts to specification.

6. Secure the converter to the fly-

wheel with the four attaching nuts.

Torque the nuts to specification.

7.

Secure the converter access cover

to the converter housing with the at-

taching bolts.

8. Secure the two front support

brackets to the converter housing with

the attaching bolts.

9. Raise the transmission high en-

ough to position the crossmember. In-

stall the bolts, but do not tighten at

this time.

10.

Secure the engine rear support

to the extension housing and torque

the bolts to specification. At this time,

install and torque the crossmember-

to-frame attaching nuts to specifica-

tion.

11.

Lower the transmission and in-

stall the engine rear support-

to-crossmember attaching nuts and

plates.

Torque the •"its to specifica-

tion. Remove the transmission jack.

12.

Install the upper bellcrank in

the left side of the converter housing.

13.

Position the lower bellcrank to

the transmission and floor pan and se-

cure it with the two attaching bolts.

14.

Connect the downshift rod to

transmission downshift lever.

15.

Using tool T67P-7341-A, install

a new grommet in the manual lever.

Then, secure the manual selector rod

to the lever.procarmanuals.com