wiring FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 49 of 413

02-02-30

Brake System

02-02-30

7.

Disconnect the wire lead at the

parking brake warning light switch

and remove the control assembly.

Installation

1.

Connect the wire lead to the

parking brake warning light switch.

2.

Position the control assembly to

the cowl inner side panel and install

the three attaching screws.

3.

Connect the ball-end of the park-

ing brake front cable assembly to the

control assembly, and install the hair-

pin retainer.

4.

Position the cable ball in the

notch in the brake clevis.

5.

Position the left air vent assem-

bly to the dash and instrument panels.

Install the four bolts and one nut re-

taining the air vent to the panels.

6. Check the operation of the park-

ing brake. Adjust the parking brake.

MUSTANG AND COUGAR

Removal

Refer to Fig. 36.

1.

Make sure the parking brake is

completely released,

2.

Remove all tension from the rear

cables by backing off the jam nut and

adjusting nut from the equalizer.

3.

Disconnect the wire lead at the

parking brake warning light switch (if

so equipped).

4.

Remove the parking brake front

cable ball retaining clip from the clev-

is.

5.

Remove the parking brake warn-

ing light switch and attaching screw (if

so equipped).

6. Disconnect the cable ball from

the notch in the brake clevis.

7.

Remove the three screws that at-

tach the control assembly to the left

cowl inner side panel.

8. Pull the control away from the

cowl, panel. Remove the hair-pin re-

tainer securing the front cable assem-

bly to the control assembly. Remove

the control assembly

Installation

1.

Connect the ball-end of the park-

ing brake front cable assembly to the

control assembly, and install the hair-

pin retainer.

2.

Position the control assembly to

the cowl inner side panel and install

the three attaching screws.

3.

Position the parking brake warn-

ing light switch and install the attach-

ing screw. Connect the parking brake

warning light switch wire lead (if vehi-

cle is so equipped).

4.

Position the cable ball in the

notch in the brake clevis.

5.

Check the operation of the park

ing brake. Adjust the parking brake.

THUNDERBIRD AND

CONTINENTAL MARK III

Removal

Refer to Fig. 37.

1.

Remove the two nuts retaining

the control to the dash panel.

2.

Remove two screws from the left

scuff plate.

3.

Remove one screw retaining the

left cowl trim panel and remove the

panel.

4.

Remove the two screws retaining

the left air duct and remove the air

duct.

5.

Remove the two screws retaining

the dimmer switch and position the

switch out of the way.

6. Remove the clip retaining the

cable assembly to the control.

7.

Disconnect the cable ball from

the control clevis.

8. Disconnect the vacuum hose at

the brake release.

9. Remove the bolt retaining the

control to the cowl side bracket and

remove the control.

Installation

1.

Position the parking brake con-

trol in the vehicle.

2.

Install the cable assembly in the

control and connect the cable ball to

the control clevis.

3.

Install the clip retaining the

cable to the control.

4.

Install the bolt retaining the con-

trol to the cowl side bracket.

5.

Connect the vacuum hose to the

parking brake release vacuum motor.

6. Position the dimmer switch and

install the retaining screws.

7.

Position the air duct and install

the retaining screws.

8. Position the cowl trim panel and

install the retaining screw.

9. Install the two scuff plate screws.

10.

Install the two nuts retaining

the control to the dash panel.

11.

Adjust the parking brakf

LINCOLN CONTINENTAL

Removal

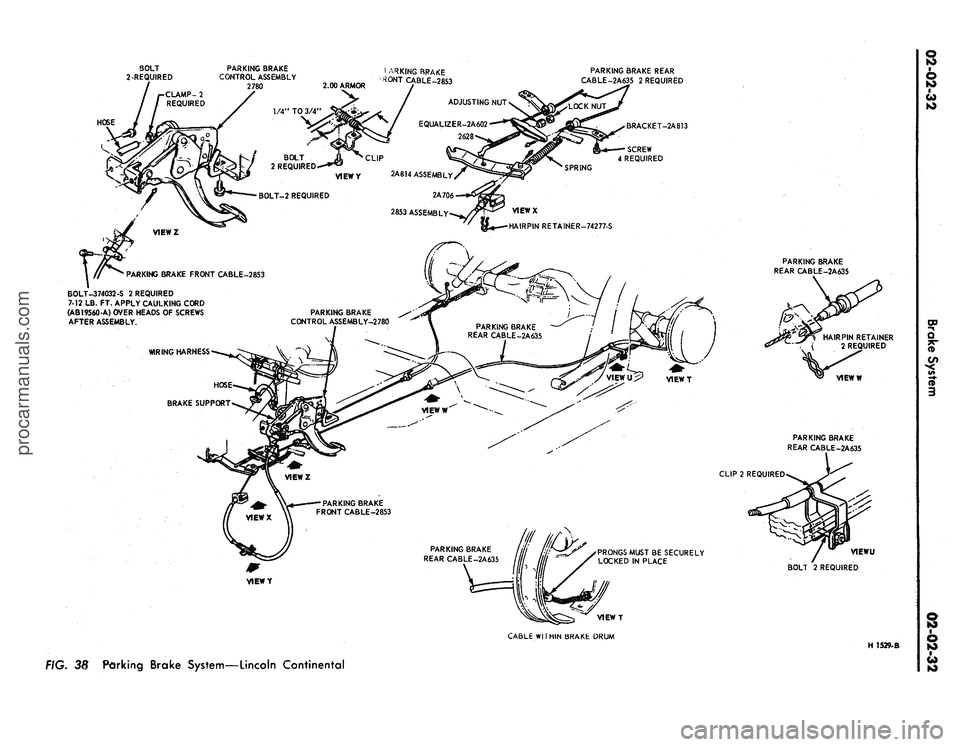

Refer to Fig. 38.

1.

Raise the vehicle on a hoist.

2.

Loosen the parking brake cable

adjusting nut, remove the return

spring and remove the cable ball end

from the equalizer.

3.

Lower the vehicle.

4.

Disconnect the battery.

5.

Disconnect the wire harness con-

nector and two vacuum hoses at the

Automatic Temperature Control box.

6. Working inside the vehicle, re-

move the windshield wiper control

knob and bezel from the lower control

panel.

7.

Remove the screws retaining the

lower control panel. Lower the control

panel and disconnect wire harnesses

and vacuum hoses. Position the con-

trol panel aside.

8. Remove the screw retaining the

plastic wire cover and place 'the cover

aside.

9. Disconnect three vacuum hoses

and the wiring harness at the Auto-

matic Temperature Control box.

10.

Remove the two screws retain-

ing the Automatic Temperature Con-

trol box to the dash panel and remove

the box for clearance.

11.

Disconnect the ball end of the

cable from the control clevis.

12.

Remove the four bolts retaining

the control to the dash panel and

lower instrument panel flange.

13.

Disconnect the vacuum release

hose from the control and remove the

control assembly from the vehicle.

Installation

1.

Position the control assembly to

the dash panel and instrument panel

flange and install the four retaining

screws.

2.

Connect the vacuum release hose

to the control assembly.

3.

Connect the cable ball to the

control clevis.

4.

Position the Automatic Temper-

ature Control box to the dash panel

and install the retaining screws.

5.

Connect the wiring harness and

vacuum hoses to the Automatic Tem-

perature Control box.

6. Position the plastic wire covei

and install the retaining screw.

7.

Connect the wire harnesses and

vacuum lines to the lower control

panel and position the panel to the inprocarmanuals.com

Page 51 of 413

BOLT

2-REQUIRED

PARKING BRAKE

CONTROL ASSEMBLY

2780

2.00 ARMOR

I

A RKING

RRAKE

HONT CABLE-2853

ADJUSTING NUT

EQUALIZER-2A602

2628

CLIP

VIEWY 2A814 ASSEMBLY

BOLT-2 REQUIRED 2A706

2853 ASSEMBLY

PARKING BRAKE REAR

CABLE-2A635 2 REQUIRED

BRACKET-2A813

SCREW

4 REQUIRED

VIEWZ

8~-

VIEWX

HAIRPIN RETAINER-74277-S

PARKING BRAKE FRONT CABLE-2853

BOLT-374032-S 2 REQUIRED

7-12 LB. FT. APPLY CAULKING CORD

(AB19560-A) OVER HEADS OF SCREWS

AFTER ASSEMBLY.

WIRING HARNESS

HOSE

BRAKE SUPPORT

PARKING BRAKE

REAR CABLE-2A635

PARKING BRAKE

REAR CABLE-2A635

PARKING BRAKE

REAR CABLE-2A635

HAIRPIN RETAINER

( 2 REQUIRED

V1EWW

PARKING BRAKE

REAR CABLE-2A635

CLIP 2 REQUIRED

PRONGS MUST BE SECURELY

LOCKED IN PLACE

VtEWU

BOLT 2 REQUIRED

VIEWY

VIEWT

CABLE WllHIN BRAKE DRUM

H 1529-B

FIG. 38

Parking Brake System—Lincoln Continentalprocarmanuals.com

Page 57 of 413

02-02-38

Brake System

02-02-38

2.

Disconnect the actuator solenoid

and warning switch harness connectors

from the control module.

3.

Remove the two wiring harness

grommets from the dash panel and

push the wiring harness and connec-

tors through the openings in the dash

panel.

4.

Working in the engine compart-

ment loosen the hose clamp and re-

move the air hose from the air filter.

5.

Remove the engine air cleaner-

Loosen the hose clamp and remove

the vacuum hose from the vacuum

manifold fitting.

6. Raise the vehicle on a hoist.

7.

Disconnect the exhaust pipes

from the exhaust manifold and sup-

port with wire to provide access to the

actuator assembly.

8. Remove the bolt retaining the

actuator ground wire to the rear outer

corner of the engine right bank.

9. Loosen the tube nuts and discon-

nect the brake system hydraulic tubes

from the hydraulic valve housing.

10.

Remove the three nuts retaining

the actuator assembly to the actuator

support bracket.

11.

Remove the three bolts that re-

tain the actuator mounting bracket to

the side rail and remove the mounting

bracket.

12.

Remove the actuator assembly

from the vehicle and place it on a

bench.

13.

Remove the air and vacuum

hoses from the actuator.

INSTALLATION

1.

Install the air and vacuum hoses

on the new actuator.

2.

Place the actuator assembly into

position under the vehicle, routing the

air and vacuum hoses up between the

engine and fender apron and inserting

the solenoid leads through the holes in

the firewall.

3.

Position the ground wire to the

rear of the engine block and install re-

taining bolt.

4.

Position the actuator mounting

bracket to the frame side rail and in-

stall the three retaining bolts.

5.

Position the actuator assembly

to the mounting bracket and install

the three retaining nuts.

6. Connect the hydraulic tubes to

the hydraulic valve assembly and

tighten the tube nuts to specifications.

7.

Connect the exhaust pipes to the

exhaust manifolds.

8. Lower the vehicle.

9. Pull the actuator solenoid and

brake warning switch wiring harness

through the two holes in the dash

panel from inside the car. Seat the

wiring harness grommets in the dash

panel.

10.

Connect the actuator solenoid

and brake warning switch wiring har-

ness connectors to the control mo-

dules.

'

11.

Position the control module in

the bracket under the glove box and

install the retaining screw.

12.

In the engine compartment con-

nect the air hose to the air filter and

position the hose clamp.

13.

Connect the vacuum hose to the

engine vacuum manifold fitting. In-

stall the engine air cleaner.

14.

Bleed the rear brake system and

centralize the pressure differential

valve.

15.

Raise the rear wheels. Apply

the brakes with the rear wheels turn-

ing to verify proper operation of the

anti-skid control system.

ANTI-SKID CONTROL MODULE

REMOVAL

Refer to Fig. 39.

1.

Remove the retaining strap hold-

ing the harnesses.

2.

Remove the screw that attaches

the forward end of the control module

retainer to the support assembly.

3.

Lower the forward end of the

control module and retainer from the

support assembly; move the module

and retainer forward slightly until the

flange clears the slot in the support

assembly.

4.

Disconnect the five wiring har-

ness plugs from the control module.

5.

Remove the control module from

the vehicle.

INSTALLATION

1.

Connect the five wiring harness

plugs to the control module. Only one

arrangement is possible.

2.

Position the control module in

the retainer, orienting the module per

the markings on it, and insert the re-

tainer flange into the slot at the rear

of the support assembly.

3.

Pivot the retainer and control

module upward and align the screw

hole in the forward end of the retainer

with the hole in the support bracket

assembly. Install the retaining screw.

4.

Test the vehicle on the hoist to

verify correct operation of the skid

control system.

5.-

Secure the wiring to the module

support extension with the retaining

strap.

ANTI-SKID CONTROL SENSOR

REMOVAL

Refer to Fig. 39.

1.

Raise the vehicle on a hoist.

2.

Remove the rear wheel and tire

assembly.

3.

Remove the three Tinnerman

nuts (3) and remove the brake drum.

4.

Disconnect the sensor lead from

the rear wiring harness.

5.

Unseat the sensor lead grommet

pushing it to the inside of the brake

assembly.

6. Remove the four nuts that retain

the sensor to the backing plate and

pull the axle shaft, sensor assembly

and wheel bearing assembly from the

axle housing.

7.

Press the wheel bearing retainer

and wheel bearing off the axle shaft

(Refer to Part 4-2).

8. Remove the sensor assembly and

press the rotor off the shaft with tool

T69P-2B384-A Detail 2 and TOOL

1225-DA.

INSTALLATION

1.

Press a new rotor onto the axle

shaft. Install a new sensor assembly

on the shaft with tool T69P-

2B384-ADetail 1 and TOOL 1225-

DA, and press the bearing and bear-

ing retainer onto the shaft (Refer to

Part 4-2).

2.

Insert the axle shaft assembly in

the rear axle housing onto the four

backing plate retaining bolts, feeding

the sensor lead through the hole in the

backing plate.

3.

Seat the sensor lead grommet in

the backing plate.

4.

Install the four nuts on the re-

taining bolts and tighten to specifica-

tions.

5.

Connect the sensor lead to the

rear wiring harness and install two re-

taining straps.

6. Install the rear brake drum and

retain with the Tinnerrhan drum re-

taining nuts.

7.

Install the rear wheel and tire as-

sembly and tighten the wheel nuts to

specifications.

8. Test the vehicle on the hoist to

verify proper operation of the skid

control system.procarmanuals.com

Page 118 of 413

03-05-05

Steering Columns And Linkage

03-05-05

TILT-AWAY STEERING

COLUMN REPAIRS

VACUUM RELEASE VALVE-

COUGAR AND MUSTANG

Removal

1.

Working from the underside of

the instrument panel disconnect the

hose from the valve.

2.

Disconnect the wire from the

connector on the valve and the con-

nector from the relay.

3.

Remove the bracket-

to-instrument panel attaching bolt and

let the bracket swing down.

4.

Remove the two screws that se-

cure the valve to the mounting bracket

and remove the valve.

Installation

1.

Secure the valve to the mounting

bracket with the two attaching screws.

2.

Position the bracket to the in-

strument panel and install the attach-

ing bolt.

3.

Connect the wire to the terminal

on the valve.

4.

Connect the hose from the vacu-

um motor to the horizontal connector

on the valve and the hose from the

reservoir to the vertical connector.

VACUUM RELEASE VALVE—

THUNDERBIRD

Removal

1.

Remove the lower finish panel.

2.

Disconnect the vacuum hose

from the vacuum release valve.

3.

Disconnect the vacuum release

valve electrical leads at the connector.

4.

Loosen the two attaching screws

holding the bracket to the dash. Lift

up the bracket to clear the screws and

swing it down below the panel.

5.

Remove the screws attaching the

valve to the panel and remove the

valve.

Installation

1.

Position the vacuum release

valve on the bracket.

2.

Install the two attaching screws

and swing the bracket up and over the

screws. Tighten the screws.

3.

Connect the electrical leads to

the wiring harness.

4.

Connect the hose from the vacu-

um dash panel junction block to the

connector on the vacuum release valve

that points downward and forward.

Connect the hose from the vacuum

motor to the other connector on the

release valve.

5.

Install the lower finish panel.

VACUUM MOTOR-

COUGAR AND MUSTANG

Removal

1.

Working from the underside of

the instrument panel, disconnect the

hose to the valve and the wires to the

relay and valve.

2.

Remove the bracket-

to-instrument panel attaching bolt and

swing the bracket downward.

3.

Remove the clevis pin that se-

cures the cable to the vacuum motor

rod.

4.

Disconnect the starter safety

switch wire at the connector.

5.

Remove the two motor-

to-bracket attaching screws and re-

move the motor, disconnecting the

hose to the solenoid.

Installation

1.

Position the motor on the

mounting bracket and the attaching

screws.

2.

Connect the control cable to the

vacuum motor rod with the clevis pin.

3.

Position the bracket to the in-

strument panel and install the attach-

ing bolt. Make all electrical and vacu-

um connections.

4.

Readjust the cable bracket to as-

sure full engagement of the locking

pawl when in driving position.

5.

Connect the hose to the vacuum

motor.

VACUUM MOTOR—

THUNDERBIRD

Removal

1.

Remove the lower finish panel.

2.

Disconnect the vacuum hose

from the solenoid valve. Disconnect

the electrical lead.

3.

Loosen the screws that attach

the bracket to the dash and lift the

bracket up; then, swing it down.

4.

Remove the clevis pin holding

the motor to the cable.

5.

Remove the two attaching

screws, then lift the motor from the

bracket.

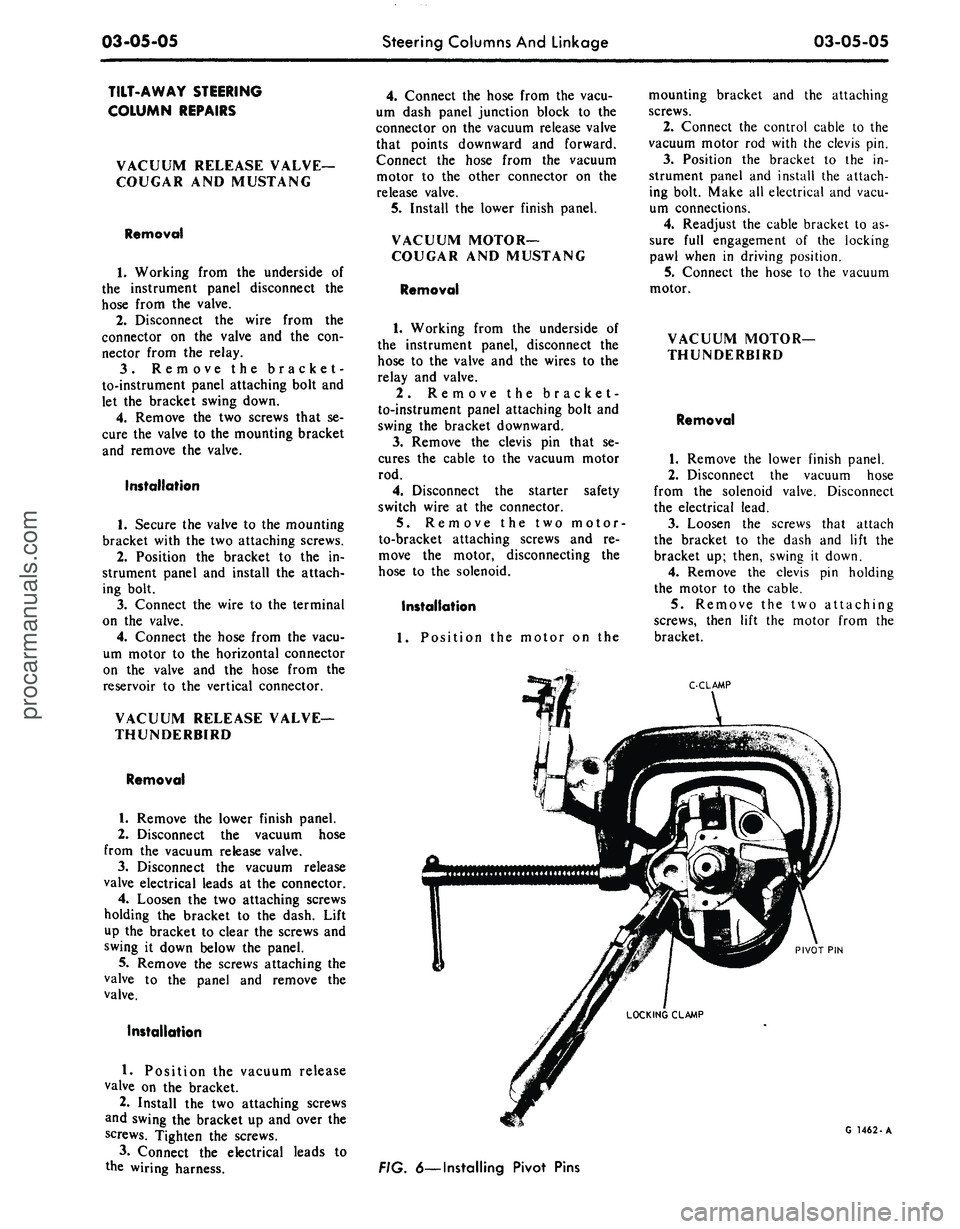

C-CLAMP

PIVOT PIN

G 1462-A

FIG. 6—Installing Pivot Pinsprocarmanuals.com