compression ratio FORD SIERRA 1983 1.G CVH Engines Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1983, Model line: SIERRA, Model: FORD SIERRA 1983 1.GPages: 24, PDF Size: 1.09 MB

Page 1 of 24

1.6 litre engine

Note: Unless otherwise stated, the Specifications for the 1.6 litre CVH engine are as given for the 1.8 litre (R2A type) which follow.

General

Engine code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . L6B

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.960 mm

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.520 mm

Cubic capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1596 cc

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 :1

Compression pressure at starter motor speed . . . . . . . . . . . . . . . . . . . . 12.2 to 14.3 bars

Maximum continuous engine speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6000 rpm

Maximum engine power (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 kW at 5500 rpm

Maximum engine torque (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 Nm at 3500 rpm

Cylinder bore diameter

Standard class 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.940 to 79.950 mm

Standard class 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.950 to 79.960 mm

Standard class 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.960 to 79.970 mm

Standard class 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.970 to 79.980 mm

Oversize class A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80.230 to 80.240 mm

Oversize class B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80.240 to 80.250 mm

Oversize class C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80.250 to 80.260 mm

Chapter 2 Part C:

CVH engines

Camshaft and cam followers - removal, inspection and refitting . . . .23

Compression test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Crankcase ventilation system - inspection and maintenance . . . . . . .3

Crankshaft and bearings - examination and renovation . . . . . . . . . .33

Crankshaft and main bearings - removal and refitting . . . . . . . . . . . .32

Crankshaft front oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Cylinder block and bores - examination and renovation . . . . . . . . . .34

Cylinder head - dismantling and reassembly . . . . . . . . . . . . . . . . . . .21

Cylinder head - inspection and renovation . . . . . . . . . . . . . . . . . . . . .22

Cylinder head - removal and refitting (engine in vehicle) . . . . . . . . . .19

Cylinder head - removal and refitting (engine removed) . . . . . . . . . . .20

Engine - refitting (automatic transmission in vehicle) . . . . . . . . . . . . .13

Engine - refitting (manual gearbox in vehicle) . . . . . . . . . . . . . . . . . . .12

Engine - removal leaving automatic transmission in vehicle . . . . . . . .9

Engine - removal leaving manual gearbox in vehicle . . . . . . . . . . . . . .8

Engine/automatic transmission assembly - reconnection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Engine/automatic transmission assembly - removal and separation .11Engine dismantling, examination, renovation and reassembly - general

information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Engine/manual gearbox assembly - reconnection and refitting . . . . .14

Engine/manual gearbox assembly - removal and separation . . . . . .10

Engine mountings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Engine oil and filter - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Flywheel/driveplate - removal, inspection and refitting . . . . . . . . . . .24

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Initial start-up after overhaul or major repair . . . . . . . . . . . . . . . . . . .35

Major operations possible with the engine in the vehicle . . . . . . . . . . .5

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . . .6

Method of engine removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Oil pump - dismantling, inspection and reassembly . . . . . . . . . . . . .29

Oil pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Pistons and connecting rods - examination and renovation . . . . . . .31

Pistons and connecting rods - removal and refitting . . . . . . . . . . . . .30

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Timing belt and sprockets - removal and refitting . . . . . . . . . . . . . . .18

2C•1

Specifications Contents

2C

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Page 3 of 24

Torque wrench settingsNmlbf ft

Main bearing cap bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 to 10066 to 74

Connecting rod (big-end bearing cap) bolts . . . . . . . . . . . . . . . . . . . . . .30 to 3622 to 27

Crankshaft pulley bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 to 11574 to 85

Camshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54 to 5940 to 44

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82 to 9261 to 68

Oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Oil pump cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 126 to 9

Sump bolts (in two stages) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 to 84 to 6

Rocker arm nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 to 2918 to 21

Cylinder head bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 4015 to 30

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 6030 to 44

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle-tighten a further 90º

Stage 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle-tighten a further 90º

Camshaft cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Timing cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 117 to 8

Timing belt tensioner bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 2012 to 15

Oil pick-up tube/strainer-to-oil pump bolts . . . . . . . . . . . . . . . . . . . . . .8 to 126 to 9

Oil pick-up tube/strainer-to-cylinder block bolt . . . . . . . . . . . . . . . . . . .17 to 2313 to 17

Camshaft thrustplate bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Crankshaft rear oil seal housing bolts . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

1.8 litre (R2A type) engine

General

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Four-cylinder, in-line, single overhead camshaft

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3-4-2

Engine code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .R2A

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80.00 mm

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88.00 mm

Cubic capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1769 cc

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.3:1

Compression pressure at starter motor speed . . . . . . . . . . . . . . . . . . . .11 to 13 bar

Maximum continuous engine speed . . . . . . . . . . . . . . . . . . . . . . . . . . . .5850 rpm

Maximum engine power (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66 kW at 5250 rpm

Maximum engine torque (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147 Nm at 3000 rpm

Cylinder bore diameter

Standard class 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.940 to 79.950 mm

Standard class 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.950 to 79.960 mm

Standard class 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.960 to 79.970 mm

Standard class 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.970 to 79.980 mm

Standard class 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.980 to 79.990 mm

Standard class 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.990 to 80.000 mm

Oversize class A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80.000 to 80.010 mm

Oversize class B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80.010 to 80.020 mm

Oversize class C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80.020 to 80.030 mm

Crankshaft

Endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.10 to 0.20 mm (0.004 to 0.008 in)

Main bearing running clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.028 to 0.067 mm

Main bearing journal diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.980 to 54.000 mm

Undersize 0.25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.730 to 54.750 mm

Undersize 0.50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.480 to 53.500 mm

Undersize 0.75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.230 to 53.250 mm

Centre main thrust bearing shell width:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28.825 to 28.875 mm

Undersize 0.15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28.675 to 28.725 mm

Big-end bearing running clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.020 to 0.065 mm

Big-end bearing journal diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.890 to 43.910 mm

Undersize 0.25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.640 to 43.660 mm

Undersize 0.50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.390 to 43.410 mm

Undersize 0.75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.140 to 43.160 mm

Undersize 1.00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42.890 to 42.910 mm

CVH engines 2C•3

2C

Page 23 of 24

the tapered lower compression ring with the

“TOP” mark towards the top of the piston and

the gap 150º from the spreader gap, then fit

the upper compression ring with the gap 150º

on the other side of the spreader gap. Note

that the compression rings are coated with a

molybdenum skin which must not be

damaged.

1.6 and 1.8 litre (R6A type)

6Proceed as described in paragraphs 1 to 5

inclusive, but note the following differences

for the 1.6 litre engine.

7Before fitting the new rings to the pistons,

insert them into the relevant cylinder bore and

use a feeler blade to check that the end gaps

are within the limits given in the Specifications

at the beginning of this Chapter. Check the

end gaps with the ring at the top and the

bottom of the cylinder bore.8Fit the oil control ring sections with the

spreader ends abutted opposite the front of

the piston, making sure that the ends do not

overlap. The side ring gaps should be offset

120º either side of the spreader gap. Fit the

tapered lower compression ring with the

“TOP” mark uppermost and the gap 120º

from the spreader gap, then fit the upper

compression ring with the gap 120º on the

other side of the spreader gap. Note that the

compression rings are coated with a

molybdenum disulphide skin, which must not

be damaged.

1.8 litre (R2A type)

Removal

1With the engine removed from the vehicle,

remove the timing belt, crankshaft sprocket

and thrustwasher.

2Remove the pistons and connecting rods. If

no work is to be done on the pistons and

connecting rods, there is no need to push the

pistons out of the cylinder bores.

3Remove the oil pump and pick-up tube.

4Unscrew the four securing bolts and

remove the crankshaft rear oil seal housing.

5Check the main bearing caps for

identification marks and if necessary use a

centre-punch to identify them.

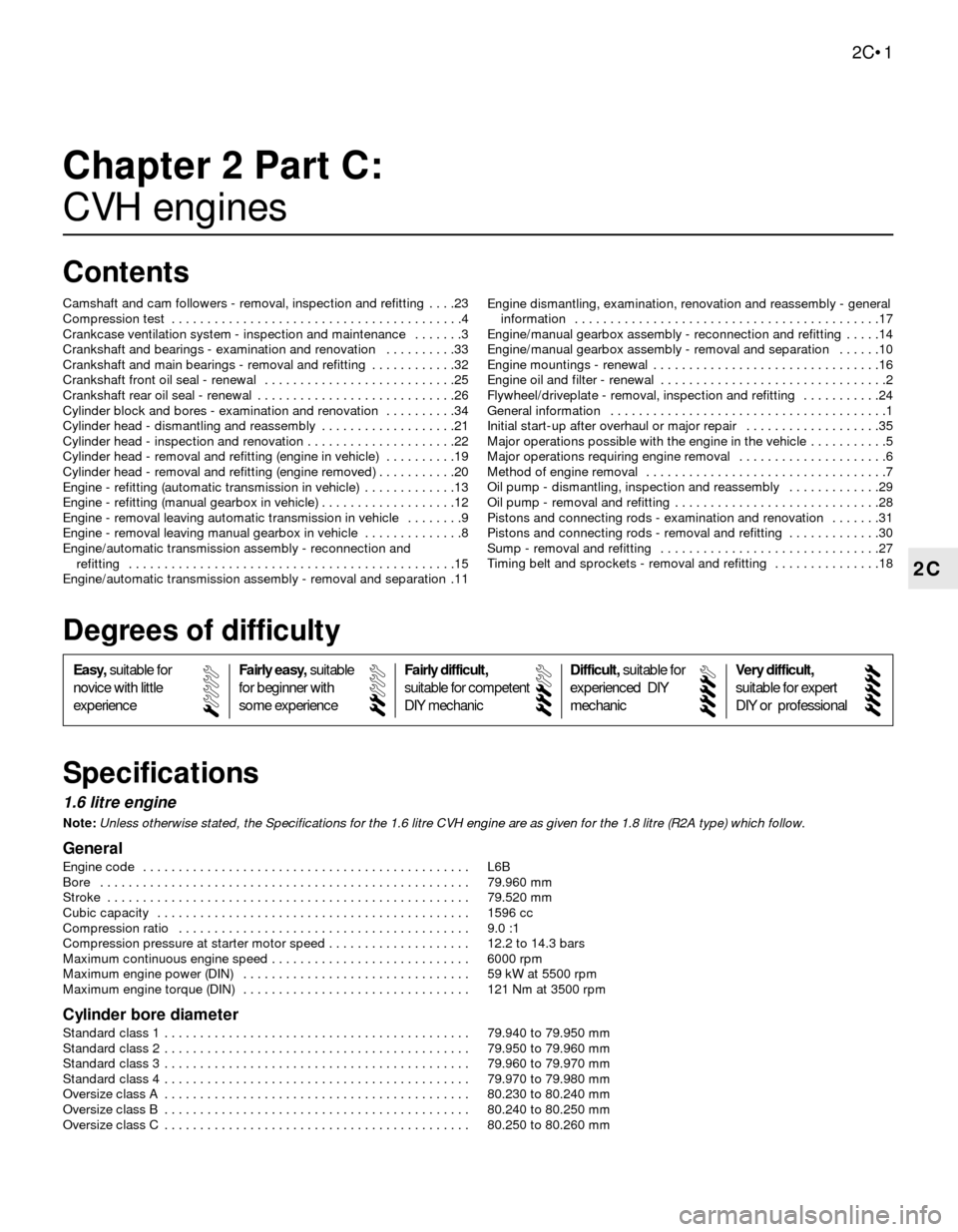

6Before removing the crankshaft, check that

the endfloat is within the specified limits byinserting a feeler blade between the centre

crankshaft web and the thrust bearing shell

(see illustration). This will indicate whether a

new thrust bearing shell is required.

7Unscrew the bolts and tap off the main

bearing caps complete with bearing shells.

8Lift the crankshaft from the crankcase.

9Extract the bearing shells, keeping them

identified for location.

Refitting

10Commence refitting as follows.

11Wipe the bearing shell locations in the

crankcase with a soft, non-fluffy rag.

12Wipe the crankshaft journals with a soft,

non-fluffy rag.

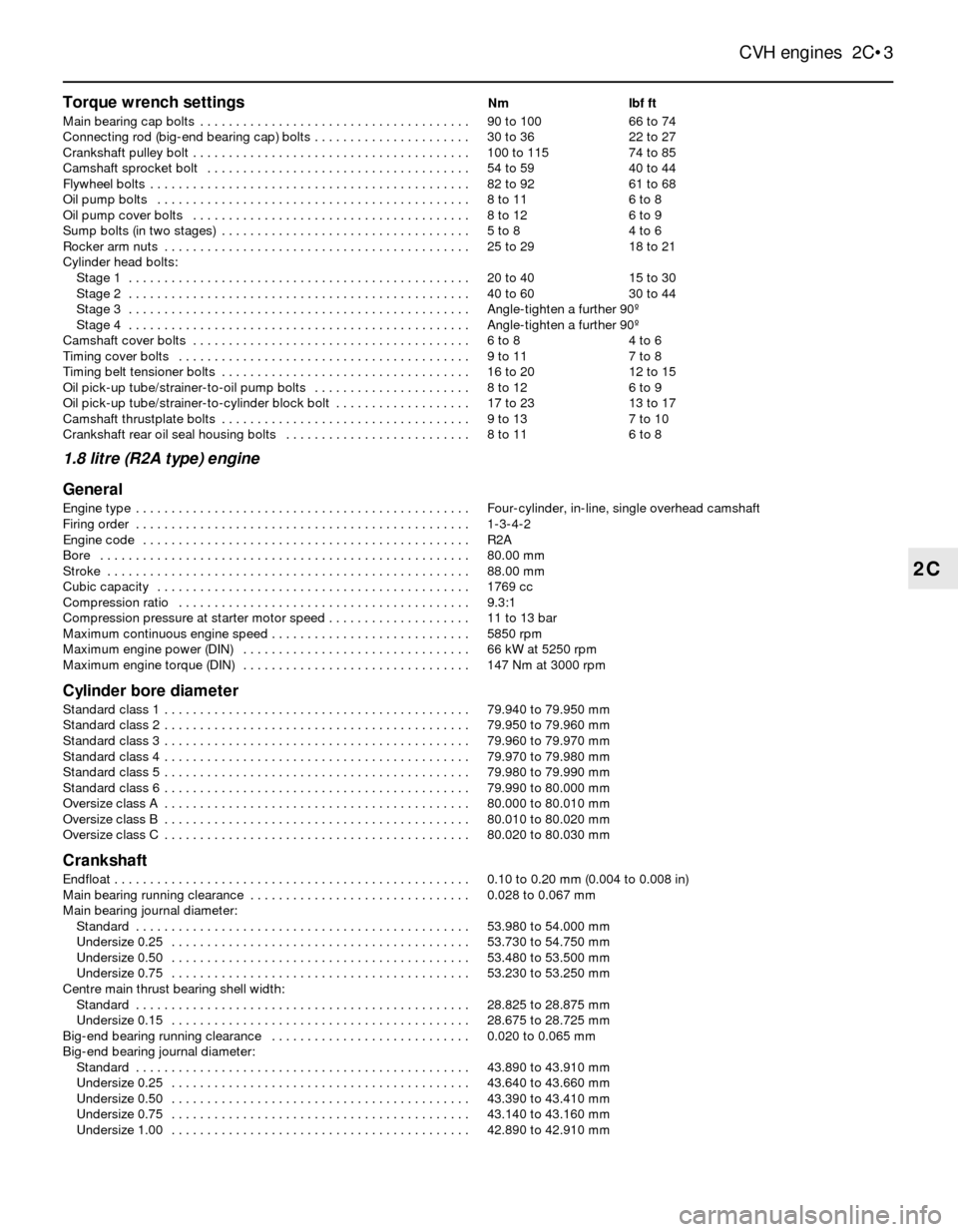

13If the old main bearing shells are to be

renewed (not to do so is a false economy,

unless they are virtually new) fit the five upper

halves of the main bearing shells to their

location in the crankcase. Note the flanged

thrust bearing shell should be fitted to the

centre bearing location (see illustrations).

14Identify each main bearing cap and place

in order. The number is cast on to the cap and

an arrow is also marked which should point

towards the front of the engine.

15Wipe the cap bearing shell location with a

soft non-fluffy rag.

16Fit the bearing half shell onto each main

bearing cap.

17Lubricate the crankshaft journals and the

upper and lower main bearing shells with

clean engine oil.

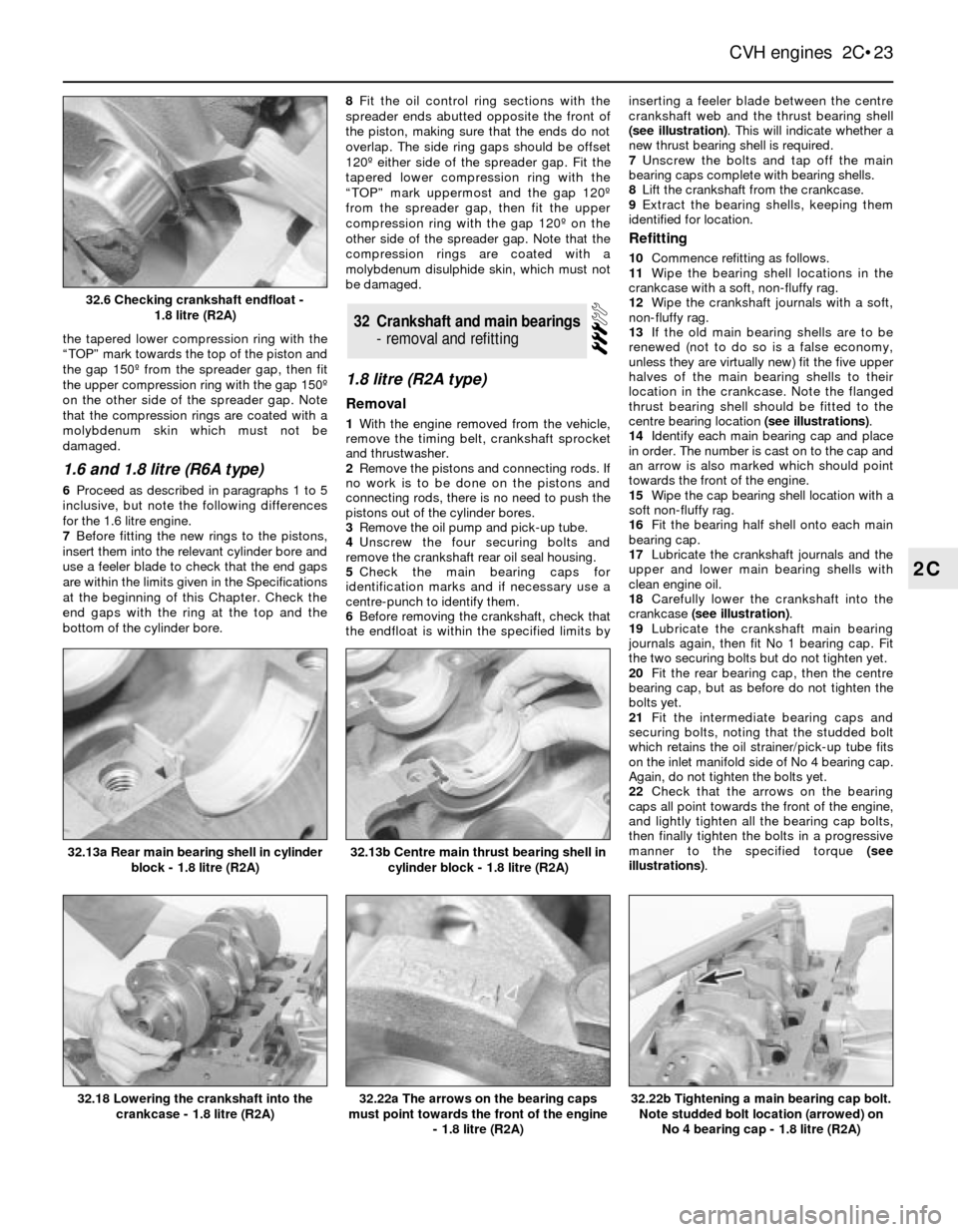

18Carefully lower the crankshaft into the

crankcase (see illustration).

19Lubricate the crankshaft main bearing

journals again, then fit No 1 bearing cap. Fit

the two securing bolts but do not tighten yet.

20Fit the rear bearing cap, then the centre

bearing cap, but as before do not tighten the

bolts yet.

21Fit the intermediate bearing caps and

securing bolts, noting that the studded bolt

which retains the oil strainer/pick-up tube fits

on the inlet manifold side of No 4 bearing cap.

Again, do not tighten the bolts yet.

22Check that the arrows on the bearing

caps all point towards the front of the engine,

and lightly tighten all the bearing cap bolts,

then finally tighten the bolts in a progressive

manner to the specified torque (see

illustrations).

32Crankshaft and main bearings

- removal and refitting

CVH engines 2C•23

2C

32.13b Centre main thrust bearing shell in

cylinder block - 1.8 litre (R2A)

32.22b Tightening a main bearing cap bolt.

Note studded bolt location (arrowed) on

No 4 bearing cap - 1.8 litre (R2A)32.22a The arrows on the bearing caps

must point towards the front of the engine

- 1.8 litre (R2A)32.18 Lowering the crankshaft into the

crankcase - 1.8 litre (R2A)

32.13a Rear main bearing shell in cylinder

block - 1.8 litre (R2A)

32.6 Checking crankshaft endfloat -

1.8 litre (R2A)